The Impact of Metal Mining on Global Water Stress and Regional Carrying Capacities—A GIS-Based Water Impact Assessment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Water Footprint Assessment

2.2. Water Stress and Water Scarcity Determination

- 0–1: ‘low’ water stress (<10%). The overall water consumption within a given area is lower than 10% of natural runoff. If taking into account EWR, runoff is defined as WA minus EWR, which is not or is slightly affected by water consumption.

- 1–2: ‘low–medium’ water stress (10–20%). Total water consumption is rated between 10 and 20% of natural runoff minus EWR, which is affected moderately.

- 2–3: ‘medium–high’ water stress (20–40%). Total water consumption is rated between 20 and 40% of natural runoff minus EWR, which is expected to be modified significantly.

- 3–4: ‘high’ water stress (40–80%). Total water consumption is rated between 40 and 80% of natural runoff minus EWR, which is seriously affected and modified.

- 4–5: ‘extremely high’ water stress (>80%). The basin’s overall water consumption exceeds 80% of natural runoff minus EWR, violating the environmental water needs in case of exceeding water availability by 100% (= EWR-related threshold). As many mining operations are located in remote areas which are arid but simultaneously characterized by low water use, thus having less competition amongst water users, these areas are not comparable to the regular definition of WSI. Nevertheless, mining operations have to be aware of localized impacts, particularly with respect to environmental water needs [71]. As a consequence, this category includes ‘arid and low water use’, differing from the established water stress definition but assuming that environmental water needs are violated regardless of the amount of water used.

2.3. Mining Data and System Boundaries Applied for a Water Impact Assessment

- Geographic coordinates and individual mine-site production data of a time period between 2010 and 2018 for 2783 mining operations producing preprocessed ores or concentrates of bauxite, cobalt, copper, iron ore, lead, manganese, molybdenum, silver, U3O8 (uranium concentrate or yellow cake) and zinc as well as the refined metals gold, nickel, palladium and platinum. In addition, 13,817 exploration projects and 11,500 development projects of all 14 commodities were also considered.

- Specific water consumption volumes per t mining commodity based on a comprehensive review of LCA databases as well as recent studies on water footprints in the mining sector (shown in Table 2 and Table 3) and annual water consumption volumes of each individual mining operation according to LCA calculations and mine-site production volumes.

- Water stress index (WSI) at the sub-basin level according to Gassert et al. [69], obtained from the Aqueduct Project, and WSI at the major river basin level as defined by the Global Runoff Data Centre (GRDC) [83]. In total, water stress of approximately 25,000 basin units, representing ~15,000 sub-basins and 405 major river basins according to the GRDC, was implemented.

- Based on calculations by Luck et al. [82], estimated changes in water stress by 2030 and 2040 and projected water stress in 2030 and 2040 at the sub-basin level were implemented in the GIS considering three IPCC climate change scenarios (RCP4.5/SSP2, RCP8.5/SSP2 and RCP8.5/SSP3) to derive estimations of the water stress that mining operations may be confronted with in the next two decades.

2.4. Water Consumption in Mining and Refining of Metal Raw Materials

| Processing Stage of the Mining Commodity | Minimum Range (in m3/t) | Maximum Range (in m3/t) | Averaged Water Consumption (in m3/t Metal Commodity) | Global Water Consumption (in Mm3) | Reviewed Data Sources Providing LCA-Based Inventory Data on Specific Water Consumption Values per t Metal Commodity |

|---|---|---|---|---|---|

| Ore and Metal Concentrate | |||||

| Bauxite | |||||

| Preprocessed ore | 0.320–0.395 [27] | 0.447–0.578 [23,86,87] | 0.447 | 88.9 1 (123.1 2) | International Aluminium Institute [23]; Gunson [27]; Frischknecht et al. (Ecoinvent, bauxite, at mine, GLO #1063) [86]; Buxmann et al. [87] |

| Cobalt | |||||

| Concentrate | 40.72– 170.84 [88]– 258.00 [89] | 364.00–(802.00) [27] | 208.40 (327.12) | 24.5 1 (28.9 2) | Gunson [27]; Dai et al. [88]; Shahjadi et al. [89]; |

| Copper | |||||

| Concentrate | 9.673–10.446 [86,90]; 28.000 [89]; 36.100–37.594 [27,33,86,89,90]; 40.000 [91]–42.403 [86] | 67.081 [86,90]; 70.400–99.550 [27,91] | 43.235 | 859.4 1 (885.9 2) | Gunson [27]; Northey et al. [33]; Frischknecht et al. (copper concentrate at beneficiation) [86]; Shahjadi et al. [89]; Fritsche [90]; Pena and Huijbregts (incl. SX-EW) [91] |

| Iron Ore | |||||

| Fines | 0.210–0.874 [26,27,92,93] | 1.519 [86]– 1.529 [90]; 3.000 [93] | 1.371 | 1382.3 1 (1878.1 2) | Ferreira et al. [26]; Gunson [27]; Frischknecht et al. (Fe at beneficiation, GLO #1100) [86]; Fritsche [90]; Haque and Norgate [92]; Tost et al. [93] |

| Lead | |||||

| Concentrate | (0.528) [90]– 3.995 [27] | 8.222 [89]– 8.485 [27]– 11.754 [86] | 6.597 | 19.9 1 (33.3 2) | Gunson [27]; Frischknecht et al. (lead concentrate at beneficiation, GLO #1104) [86]; Shahjadi et al. [89]; Fritsche [90] |

| Manganese | |||||

| Concentrate | 1.390 [86] | 1.418 [90] | 1.404 | 62.7 1 (85.9 2) | Frischknecht et al. (manganese concentrate at beneficiation, GLO #1110) [86]; Fritsche (2005) (manganese concentrate, GLO 2003–2004) [90] |

| Molybdenum | |||||

| Concentrate | 52.2–209.6 [86] | 382.0 [27]– 490.5 [86]– 797.0 [27] | 240.9 | 55.0 1 (78.5 2) | Gunson [27]; Frischknecht et al. (molybdenum concentrate, GLO #1117, RER #5858, RAS #5859) [86] |

| Ore and Metal Concentrate | |||||

| Silver | |||||

| Concentrate | 1621–1805 [27,89,90] | 3128 [27] | 1713 | 41.1 1 (44.6 2) | Gunson [27]; Shahjadi et al. [89]; Fritsche (Xtra-silver concentrate) [90] |

| Uranium | |||||

| Concentrate (U3O8) | 46.20–100.00 [11,86,94]; 505.00–2478 [11,27,90,94] | 6000–8207 [11,86,94] | 2746 | 17.1 1 (17.1 2) | Mudd [11]; Gunson [27]; Frischknecht et al. (uranium oxide RNA #5988, RNA #5989) [86]; Fritsche (uranium oxide) [90]; Mudd et al. [94] |

| Zinc | |||||

| Concentrate | 11.07 [89]– 13.10 [27]– 13.36 [86] | 24.65 [27] | 11.93 | 114.2 1 (154.5 2) | Gunson [27]; Frischknecht et al. (zinc concentrate at beneficiation, GLO #1157, SE #10099) [86]; Shahjadi et al. [89] |

| Refined Metal | |||||

| Gold | |||||

| Metal | 79,949– 152.630– 174.780– 190,558 [86] | 259,290– 288,140 [95]; 309,110 [27]– 347,910 [86]; 392,686 [93]– 427,696 [90]; 453,305 [27]– 477,000 [96] | 265,861 | 712.79 1 (814.8 2) | Gunson [27]; Frischknecht et al. (gold at refinery #10110-14) [86]; Fritsche [90]; Tost et al. [93]; Norgate and Haque [95]; Mudd [96] |

| Nickel | |||||

| Metal | 80.6 [86]– 107 [13]– 138.0 [27] | 187.36– 193.0 [86]– 240.0 [27]– 258.2 [86] | 193.8 | 355.3 1 (441.4 2) | Mudd [13]; Gunson [27]; Frischknecht et al. (primary nickel, GLO #35, GLO #1121, ZA #1124, RU #1125) [86] |

| Palladium | |||||

| Metal | 56,779–127,172 [27,86,90] | 273,523–327,874 [86,90] | 210,713 | 45.8 1 (46.3 2) | Gunson [27]; Frischknecht et al. (primary at refinery, ZA #1128, RU #1129) [86]; Fritsche (primary at refinery, ZA, RU) [90] |

| Platinum | |||||

| Metal | 169,968–200,000 [27,86,90] | 406,998–487,876 [27,86,90] | 313,496 | 67.3 1 (67.3 2) | Gunson [27]; Frischknecht et al. (primary at refinery, ZA #1134, RU #1135) [86]; Fritsche (primary at refinery, ZA, RU) [90] |

3. Results

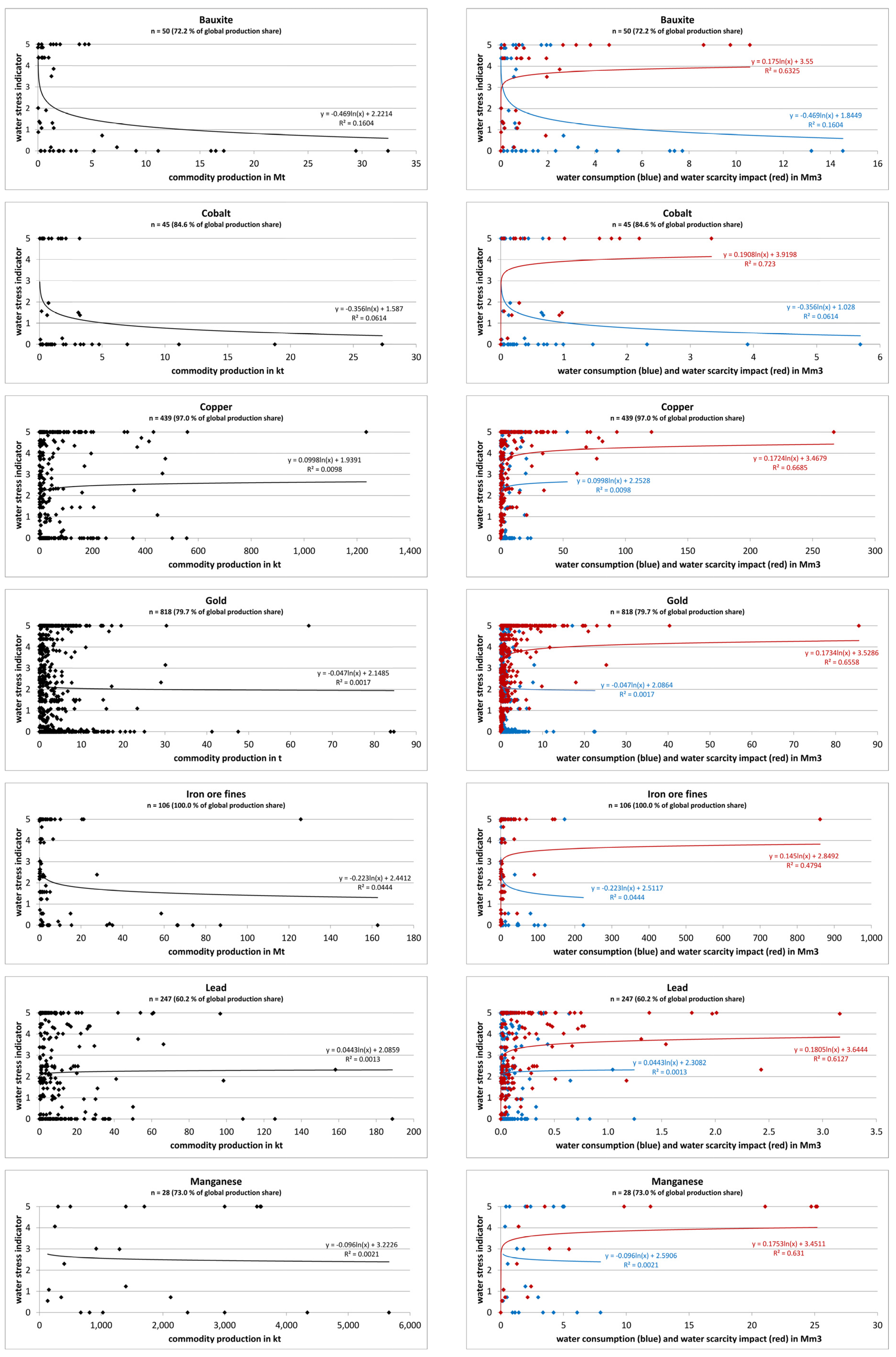

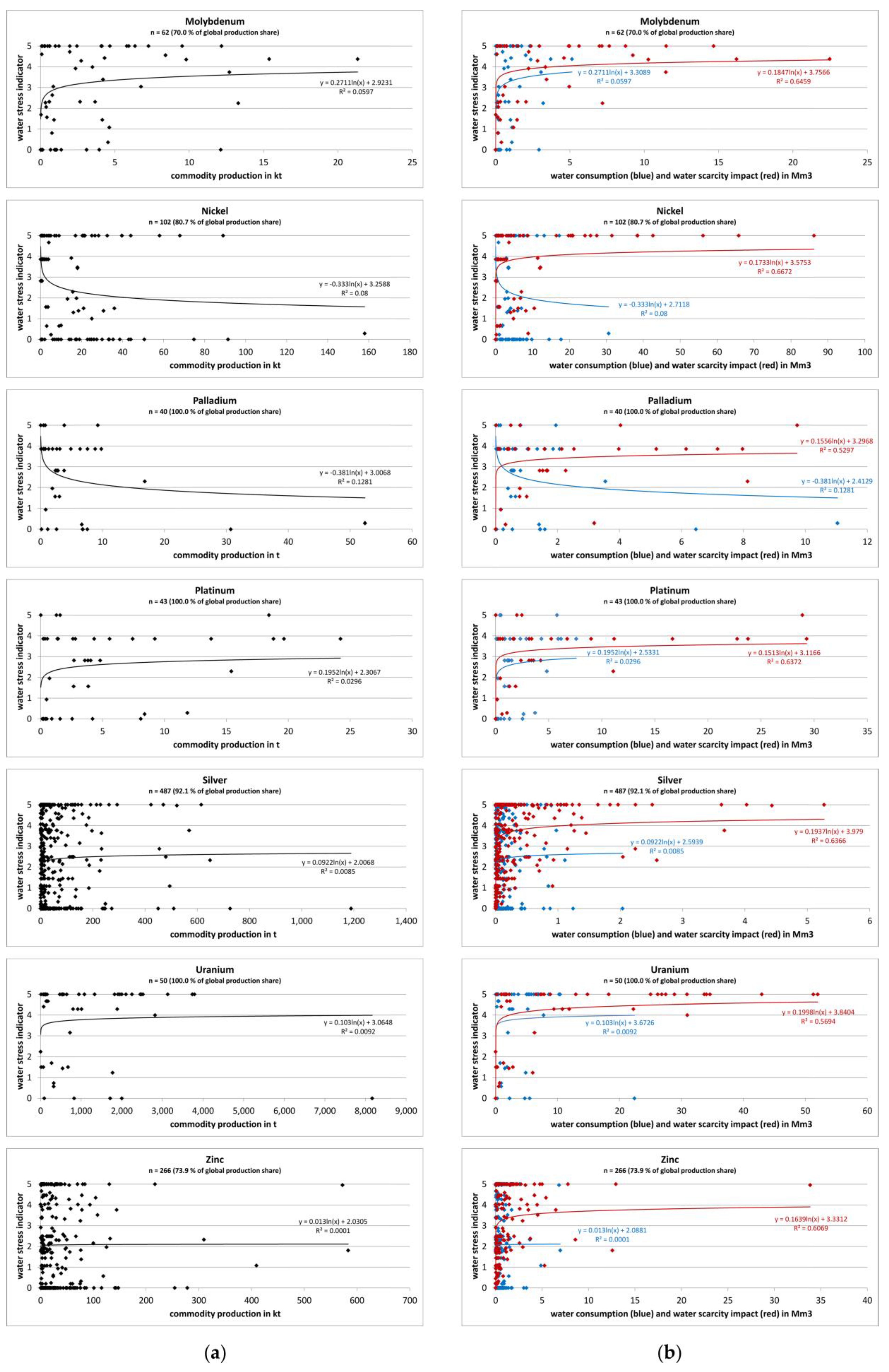

3.1. Mining-Related Water Stress and Global Water Scarcity Impact

| Mining Commodity | Global Production in 2018 (in t) (Except Bauxite in 2016) (Source: SNL [81]) | Global Production Share (in Percent) (According to USGS [103]) | Number of Mining Sites Considered (Source: SNL [81]) | Averaged Water Consumption Factor (in m3/t) | Global Water Consumption in 2018 (in Mm3) | Global WSFP (in Mm3) (=Water Consumption Multiplied with Regional WSI) | Mine-Site ØWSFP (in Mm3) (=Global WSFP Divided by Number of Mining Properties) |

|---|---|---|---|---|---|---|---|

| Preprocessed Ores | |||||||

| Bauxite | 198,374,454 | 72.2 | 50 | 0.447 | 88.94 | 61.18 | 1.25 |

| Iron ore | 1,008,099,678 | 73.6 | 106 | 1.371 | 1382.30 | 1889.52 | 17.83 |

| Concentrates | |||||||

| Cobalt | 117,332 * | 79.3 | 45 | 208.4 | 24.45 | 16.25 | 0.36 |

| Copper | 19,876,739 * | 97.0 | 439 | 43.235 | 859.38 | 2325.35 | 5.30 |

| Lead | 3,020,613 * | 60.2 | 247 | 6.597 | 19.93 | 39.64 | 0.16 |

| Manganese | 44,637,552 * | 73.0 | 28 | 1.404 | 62.67 | 149.88 | 5.92 |

| Molybdenum | 228,207 * | 70.0 | 62 | 240.9 | 54.98 | 192.78 | 3.11 |

| Silver | 23,986.37 * | 92.1 | 487 | 1713 | 41.08 | 97.64 | 0.20 |

| Uranium | 62,236.74 * | 100.0 | 50 | 2746 | 170.91 | 617.02 | 12.34 |

| Zinc | 9,574,839 * | 73.9 | 266 | 11.93 | 114.22 | 233.93 | 0.89 |

| Refined Metals | |||||||

| Gold | 2,681.05 | 79.7 | 818 | 265,861 | 712.79 | 1320.98 | 1.61 |

| Nickel | 1,833,467 | 80.7 | 102 | 193.8 | 355.32 | 720.27 | 7.28 |

| Palladium | 217.51 | 98.9 | 40 | 210,713 | 45.83 | 77.89 | 1.95 |

| Platinum | 214.81 | 100.0 | 43 | 313,496 | 67.34 | 202.56 | 4.94 |

| Summary | |||||||

| Total | 1,285,852,217.48 | 2783 | 4000.14 | 7944.89 | |||

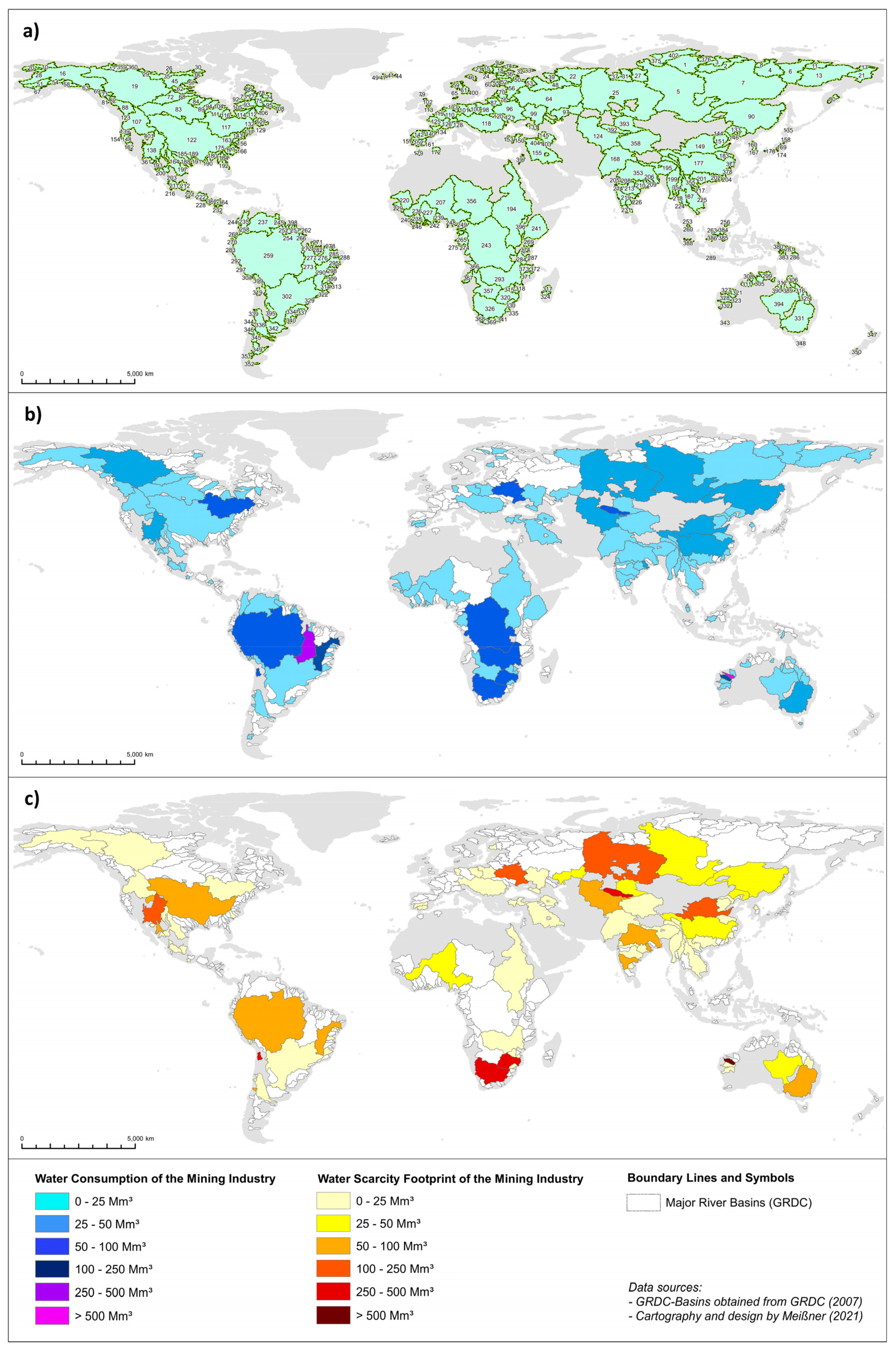

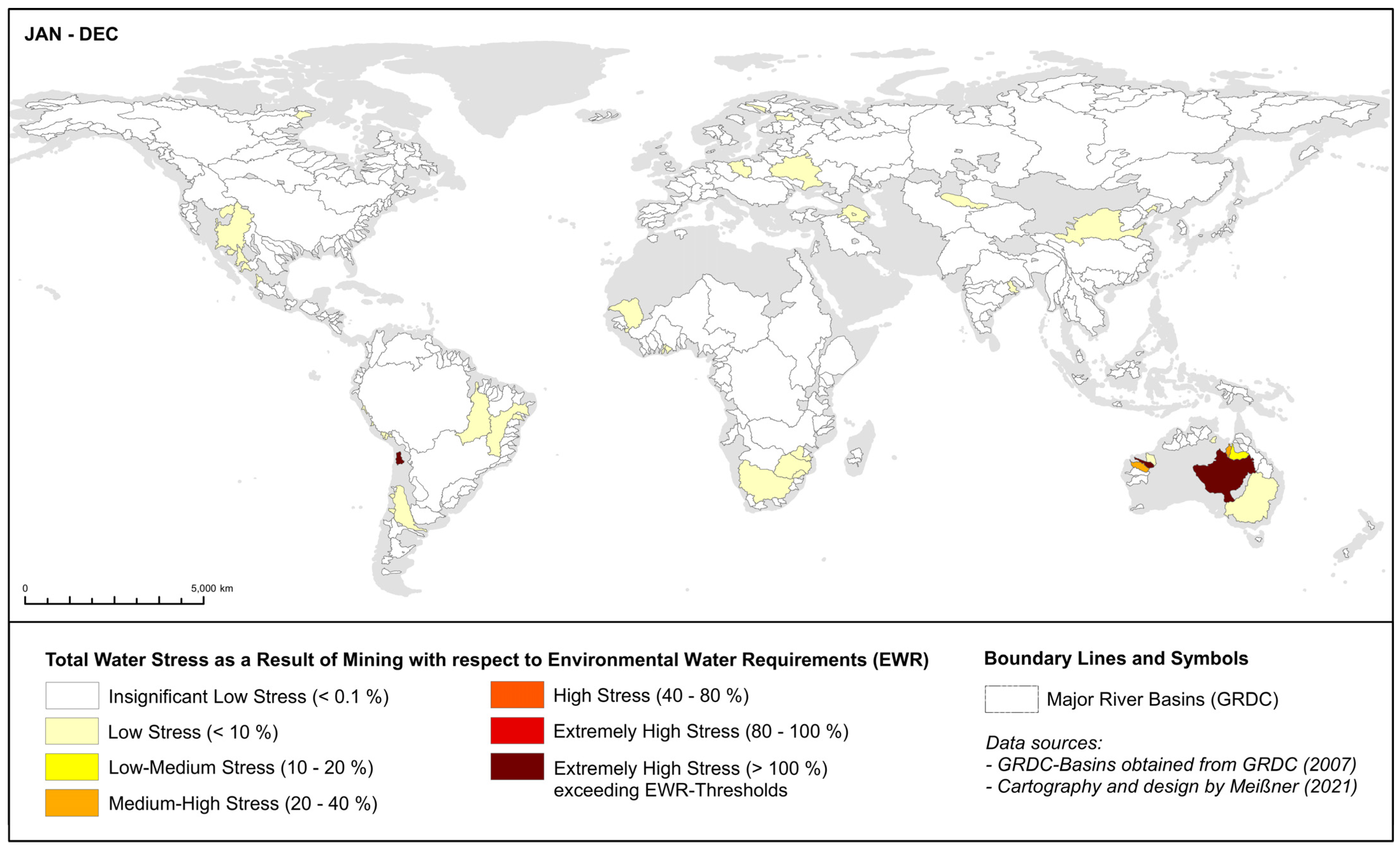

3.2. Mining’s Influence on Regional Water Stress and Carrying Capacities

- Loa Basin (Figure 4a, basin no. 319), located in the northern part of the Antofagasta region in Chile, is one of the world’s leading copper-mining areas, hosting 7.9% of global copper and 8.2% of global molybdenum production (according to production in 2018). Mining alone is the main driving factor causing the ‘extremely high’ water stress due to exceeding the available water limits during the entire year as a result of hyper-arid conditions simultaneously paired with the highest rates of water consumption in the mining sector. Owing to the fact that copper mining is ranked as one of the largest water-consuming sectors in the global mining industry, many large-scale production capacities are primarily located in Chile, therefore resulting in intense water scarcity impacts in the Chilean Loa Basin. As a consequence, the total annual water scarcity impact caused by mining operations in Loa Basin accounts for 368.17 Mm3, of which 338.3 Mm3 is associated with copper mining, which represents 14.5% of the global copper-related water scarcity effect. Another large water scarcity impact of 22.5 Mm3 results from molybdenum mining, which is often jointly performed with copper production.

- Similar to Loa Basin, the Pilbara region in northwestern Australia is also characterized by high water scarcity impacts due to large-scale mining under arid conditions. Pilbara comprises three river basins, namely De Grey River (Figure 4a, basin no. 321), Fortescue (basin no. 323) and Ashburton (basin no. 327), altogether providing 53.3% of the global iron ore fine supply—i.e., the overall results in Pilbara are significantly influenced by iron ore mining. However, the percentage of water consumption for mining in Pilbara varies significantly between the basins. For instance, while mining’s influence on the basin’s water stress in De Grey River is basically low (usually below 10% of the basin’s total water consumption per month), its contribution to the overall water stress in Ashburton is slightly above 10% in the period from January to March but exceeds the EWR limits significantly from September to October, thus causing a range of ‘low–medium’ to ‘extremely high’ water stress throughout the year. By contrast, in Fortescue River Basin, mining alone is responsible for the ‘extremely high’ water stress during most of the year, particularly surpassing EWR thresholds from April to December. Overall, as the production of iron ore fines is responsible for the largest global water consumption amongst all mining commodities observed in this study, Pilbara is, after Loa Basin, the most prominent area affected by high mining-related water stress as well as a water scarcity impact accounting for 1039.91 Mm3 in total. This represents roughly 55% of the global water scarcity effect resulting from iron ore mining, particularly regarding iron ore fines.

- Orange Basin (Figure 4a, basin no. 326) and Limpopo Basin (basin no. 320) are further prominent examples of river catchments affected by high water stress and water scarcity effects caused by the mining industry. Both basins are located in South Africa, covering areas of the Republic of South Africa, Lesotho, Namibia, Botswana, Zimbabwe and Mozambique. While Limpopo Basin supplied 68.3% (146.7 t) of global platinum and 36.9% (80.3 t) of palladium production in 2018, mining operations situated in Orange Basin contributed to 4.3% (114.4 t) of global gold production, which is the largest gold production capacity in the basins observed. However, even relatively low quantities of metal production for gold or platinum group metals, for example, may cause high water stress and water scarcity impacts, particularly due to the relatively high specific water demand per t refined metal. Consequently, both basins are highly influenced by water consumption for the precious metals mining and refining industry. Overall, this mining sector is mostly responsible for ‘low’ water stress in both basins, primarily averaging between 5 and 9% from June and December and peaking at 13.5% in November, which is classified as ‘low–medium’ water stress. Besides gold and PGM production, mining of copper, iron ore and manganese also has a significant influence on the hydrological system of both basins. Manganese production in Orange Basin represents 35.6% of global manganese production, resulting in a global water scarcity footprint (WSFP) of 74.4% for manganese mining. While the total WSFP of mining in Orange Basin is 270 Mm3, the annual mining-related WSFP in Limpopo Basin is estimated to be 256 Mm3, mainly caused by the mining and refining of platinum group metals. For instance, palladium production in Limpopo accounts for 72.6% of the global palladium WSFP and platinum production accounts for approximately 81% of the global platinum WSFP.

4. Discussion and Conclusions

Supplementary Materials

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| BWS | Baseline water stress |

| CTA | Consumption-to-availability ratio |

| EFR | Environmental flow requirement |

| EWR | Environmental water requirement |

| GIS | Geographic information system |

| GRDC | Global Runoff Data Centre |

| ISO | International Organization for Standardization |

| LCA | Life cycle assessment |

| MAR | Mean annual runoff |

| RCP | Representative concentration pathway |

| SDG | Sustainable development goal |

| SSP | Shared socioeconomic pathway |

| WA | Water availability |

| WS | Water stress |

| WSFP | Water scarcity footprint |

| WSI | Water stress index |

| WTA | Withdrawal-to-availability ratio |

| WU | Water use |

References

- Helbig, C.; Bruckler, M.; Thorenz, A.; Tuma, A. An Overview of Indicator Choice and Normalization in Raw Material Supply Risk Assessments. Resources 2021, 10, 79. [Google Scholar] [CrossRef]

- Sonderegger, T.; Berger, M.; Alvarenga, R.; Bach, V.; Cimprich, A.; Dewulf, J.; Frischknecht, R.; Guinée, J.; Helbig, C.; Huppertz, T.; et al. Mineral resources in life cycle impact assessment—Part I: A critical review of existing methods. Int. J. Life Cycle Assess. 2020, 25, 784–797. [Google Scholar] [CrossRef]

- Spitz, K.; Trudinger, J. Mining and the Environment. From Ore to Metal; CRC Press Taylor & Francis Group: London, UK, 2009. [Google Scholar]

- Schrijvers, D.; Hool, A.; Blengini, G.A.; Chen, W.-Q.; Dewulf, J.; Eggert, R.; van Ellen, L.; Gauss, R.; Goddin, J.; Habib, K.; et al. A review of methods and data to determine raw material criticality. Resour. Conserv. Recycl. 2020, 155, 104617. [Google Scholar] [CrossRef]

- Gunson, A.J.; Klein, B.; Veiga, M.; Dunbar, S. Reducing mine water requirements. J. Clean. Prod. 2012, 21, 71–82. [Google Scholar] [CrossRef]

- Brown, E. Water for a sustainable minerals industry—A review. In Proceedings of the Water in Mining 2003, Brisbane, Australia, 13–15 October 2003; The Australasian Institute of Mining and Metallurgy (AusIMM): Brisbane, Australia, 2003. [Google Scholar]

- Bangerter, P.; Dixon, R.; Villegas, M. Improving overall usage of water in mining-A sustainable development approach. In Proceedings of the 2nd International Congress on Water Management in the Mining Industry, Water in Mining, Antofagasta, Chile, 2–4 June 2010; Wiertz, J., Ed.; p. 403. [Google Scholar]

- Nedved, M.; Jansz, J. Waste water pollution control in the Australian mining industry. J. Clean. Prod. 2006, 14, 1118–1120. [Google Scholar] [CrossRef]

- Akcil, A.; Koldas, S. Acid mine drainage (AMD): Causes, treatment and case studies. J. Clean. Prod. 2006, 14, 1139–1145. [Google Scholar] [CrossRef]

- Cohen, R. Use of microbes for cost reduction of metal removal from metals and mining industry waste streams. J. Clean. Prod. 2006, 14, 1146–1157. [Google Scholar] [CrossRef]

- Santana, C.S.; Montalván, D.M.; Vinnícius, O.; Francisco, H.C.S.; Fermin, H.M.L.; Raildo, G.V.; de Jesus, M. Assessment of water resources pollution associated with mining activity in a semi-arid region. J. Environ. Manag. 2020, 273, 111148. [Google Scholar] [CrossRef]

- Ugya, A.; Ajibade, F.; Ajibade, T. Water pollution resulting from mining activity: An overview. In Proceedings of the 2018 Annual Conference of the School of Engineering & Engineering Technology, The Federal University of Technology (FUTA), Akure, Nigeria, 17–19 July 2018; Available online: https://www.researchgate.net/publication/326925600_Water_Pollution_Resulting_From_Mining_Activity_An_Overview (accessed on 6 November 2021).

- Mudd, G.M. Sustainability Reporting and Water Resources: A Preliminary Assessment of Embodied Water and Sustainable Mining. Mine Water Environ. 2008, 27, 136–144. [Google Scholar] [CrossRef]

- Northey, S.A.; Mudd, G.M.; Saarivuori, E.; Wessman-Jääskeläinen, H.; Haque, N. Water footprinting and mining: Where are the limitations and opportunities? J. Clean. Prod. 2016, 135, 1098–1116. [Google Scholar] [CrossRef]

- Meißner, S. Global Metal Mining and Physical Water Stress–Water Impact Assessment of the Mining Industry within the Raw Materials Criticality Methodology. Habilitation-Thesis, University of Augsburg, Augsburg, Germany, 20 June 2021. [Google Scholar]

- Northey, S.A.; Mudd, G.M.; Werner, T.T.; Jowitt, S.M.; Haque, N.; Yellishetty, M.; Weng, Z. The exposure of global base metal resources to water criticality, scarcity and climate change. Glob. Environ. Chang. 2017, 44, 109–124. [Google Scholar] [CrossRef]

- International Council on Mining & Metals (ICMM) (Ed.) Where and How does Mining Take Place? London, UK. 2019. Available online: https://www.icmm.com/en-gb/metals-and-minerals/producing-metals/where-and-how-does-mining-take-place (accessed on 20 December 2019).

- Gilsbach, L.; Schütte, P.; Franken, G. Applying water risk assessment methods in mining: Current challenges and opportunities. Water Resour. Ind. 2019, 22, 100118. [Google Scholar] [CrossRef]

- Kinnunen, P.; Obenaus-Emler, R.; Raatikainen, J.; Guignot, S.; Guimerà, G.; Ciroth, A.; Heiskanen, K. Review of closed water loops with ore sorting and tailings valorisation for a more sustainable mining industry. J. Clean. Prod. 2021, 278, 123237. [Google Scholar] [CrossRef]

- Masood, N.; Hudson-Edwards, K.; Farooqi, A. True cost of coal: Coal mining industry and its associated environmental impacts on water resource development. J. Sustain. Min. 2020, 19, 135–149. [Google Scholar] [CrossRef]

- Miller, K.D.; Bentley, M.J.; Joseph, N.; Linden, R.K.G.; Larison, C.; Kienzle, B.A.; Katz, L.E.; Wilson, A.M.; Cox, J.T.; Kurup, P.; et al. Mine Water Use, Treatment, and Reuse in the United States: A Look at Current Industry Practices and Select Case Studies. ACS ES&T Eng. 2021. [Google Scholar] [CrossRef]

- Le, T.M.K.; Miettinen, H.; Bomberg, M.; Schreithofer, N.; Dahl, O. Challenges in the Assessment of Mining Process Water Quality. Minerals 2020, 10, 940. [Google Scholar] [CrossRef]

- International Aluminium Institute (IAI). Life Cycle Inventory Data and Environmental Metrics for the Primary Aluminium Industry, 2015 Data; International Aluminium Institute: London, UK, 2017. [Google Scholar]

- Cote, C.; Moran, C.; Cummings, J.; Ringwood, K. Developing a water accounting framework for the Australian minerals industry. Min. Technol. 2009, 118, 162–176. [Google Scholar] [CrossRef]

- Cote, C.; Moran, C.; Hedemann, C.; Koch, C. Systems modelling for effective mine water management. Environ. Model. Softw. 2010, 25, 1664–1671. [Google Scholar] [CrossRef]

- Ferreira, H.; Leite, M.G.P. A Life Cycle Assessment study of iron ore mining. J. Clean. Prod. 2015, 108, 1081–1091. [Google Scholar] [CrossRef]

- Gunson, A.J. Quantifying, Reducing and Improving Mine Water Use. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2013. [Google Scholar] [CrossRef]

- Lutter, S.; Giljum, S. Copper Production in Chile Requires 500 Million Cubic Metres of Water. An Assessment of the Water Use by Chile’s Copper Mining Industry; FINEPRINT Brief No. 9; Vienna University of Economics and Business: Vienna, Austria, 2019; Available online: https://www.fineprint.global/publications/briefs/chile-copper-water/ (accessed on 26 October 2020).

- Mudd, G.M. An analysis of historic production trends in Australian base metal mining. Ore Geol. Rev. 2007, 32, 227–261. [Google Scholar] [CrossRef]

- Mudd, G.M. Gold mining in Australia: Linking historical trends and environmental and resource sustainability. Environ. Sci. Policy 2007, 10, 629–644. [Google Scholar] [CrossRef]

- Mudd, G.M. The Sustainability of Mining in Australia: Key Production Trends and Their Environmental Implications for the Future; Research Report No. RR5; Department of Civil Engineering, Monash University and Mineral Policy Institute: Clayton, Australia, 2009. [Google Scholar]

- Norgate, T.; Haque, N. Energy and greenhouse gas impacts of mining and mineral processing operations. J. Clean. Prod. 2010, 18, 266–274. [Google Scholar] [CrossRef]

- Northey, S.A.; Haque, N.; Mudd, G. Using sustainability reporting to assess the environmental footprint of copper mining. J. Clean. Prod. 2013, 40, 118–128. [Google Scholar] [CrossRef]

- Northey, S.A. Assessing Water Risks in the Mining Industry Using Life Cycle Assessment Based Approaches. Ph.D. Thesis, Monash University, Clayton, Australia, 2018. [Google Scholar]

- Northey, S.A.; Mudd, G.M.; Werner, T.T.; Haque, N.; Yellishetty, M. Sustainable water management and improved corporate reporting in mining. Water Resour. Ind. 2019, 21, 100104. [Google Scholar] [CrossRef]

- Suppen, N.; Carranza, M.; Huerta, M.; Hernández, M.A. Environmental management and life cycle approaches in the Mexican mining industry. J. Clean. Prod. 2006, 14, 1101–1115. [Google Scholar] [CrossRef]

- Worrall, R.; Neil, D.; Brereton, D.; Mulligan, D. Towards a sustainability criteria and indicators framework for legacy mine land. J. Clean. Prod. 2009, 17, 1426–1434. [Google Scholar] [CrossRef]

- Damkjaer, S.; Taylor, R. The measurement of water scarcity: Defining a meaningful indicator. Ambio 2017, 46, 513–531. [Google Scholar] [CrossRef] [Green Version]

- International Organization for Standardization (ISO). ISO 14040:2006. Environmental Management-Life Cycle Assessment—Principles and Framework; International Organization for Standardization (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization (ISO). ISO 14046:2014. Environmental Management-Water Footprint-Principles, Requirements and Guidelines; International Organization for Standardization (ISO): Geneva, Switzerland, 2014. [Google Scholar]

- Allan, J.A. Fortunately there are Substitutes for Water Otherwise our Hydro-political Futures would be Impossible, Priorities for Water Resources Allocation and Management. In Priorities for water resources allocation and management; ODA: London, UK, 1993; pp. 13–26. [Google Scholar]

- Allan, J.A. Overall Perspectives on Countries and Regions. In Water in the Arab World: Perspectives and Prognoses; Rogers, P., Lydon, P., Eds.; Harvard University Press: Cambridge, UK, 1994; pp. 65–100. [Google Scholar]

- Hoekstra, A.Y. (Ed.) Virtual Water Trade. In Proceedings of the International Expert Meeting on Virtual Water Trade; Value of Water Research Report Series No. 12; IHE Delft: Delft, The Netherlands, 2003. [Google Scholar]

- Hoekstra, A.Y.; Chapagain, A.K.; Aldaya, M.M.; Mekonnen, M.M. Water Footprint Manual, State of the Art 2009; Water Footprint Network, Earthscan: London, UK, 2009. [Google Scholar]

- Hoekstra, A.Y.; Chapagain, A.K.; Aldaya, M.M.; Mekonnen, M.M. The Water Footprint Assessment Manual: Setting the Global Standard; Water Footprint Network, Earthscan: London, UK, 2011. [Google Scholar]

- Pfister, S. Environmental Evaluation of Freshwater Consumption within the Framework of Life Cycle Assessment. Ph.D. Thesis, Diss. ETH no. 19490. ETH Zurich, Zurich, Switzerland, 2011. [Google Scholar] [CrossRef]

- Kasbohm, J.; Grothe, S.; Steingrube, W.; Lài, L.; Ngân, L.; Hồng, N.T.; Oanh, L.T.K.; Hương, N.Q. Integrated water resources management (iwrm)–An introduction. J. Geol. 2009, 33, 3–14. Available online: https://www.researchgate.net/publication/237062491 (accessed on 26 October 2020).

- Falkenmark, M.; Lundqvist, J.; Widstrand, C. Macro-scale water scarcity requires micro-scale approaches. Natl. Resour. Forum 1989, 13, 258–267. [Google Scholar] [CrossRef] [PubMed]

- Brown, A.; Matlock, M.D. A Review of Water Scarcity Indices and Methodologies; White Paper; Sustainability Consortium: Scottsdale, AZ, USA; Fayetteville, NC, USA; Den Haag, The Netherlands, 2011; Volume 106, Available online: https://www.sustainabilityconsortium.org/tsc-downloads/a-review-of-water-scarcity-indices-and-methodologies/ (accessed on 24 October 2020).

- Liu, J.; Yang, H.; Gosling, S.N.; Kummu, M.; Flörke, M.; Pfister, S.; Hanasaki, N.; Wada, Y.; Zhang, X.; Zheng, C. Water scarcity assessments in the past, present, and future. Earth’s Future 2017, 5, 545–559. [Google Scholar] [CrossRef]

- Rijsberman, F.R. Water scarcity: Fact or fiction? Agric. Water Manag. 2006, 80, 5–22. [Google Scholar] [CrossRef] [Green Version]

- Vanham, D.; Hoekstra, A.Y.; Wada, Y.; Bouraoui, F.; de Roo, A.; Mekonnen, M.; van de Bund, W.; Batelaan, O.; Pavelic, P.; Bastiaanssen, W.; et al. Physical water scarcity metrics for monitoring progress towards SDG target 6.4: An evaluation of indicator 6.4.2 “Level of water stress”. Sci. Total Environ. 2018, 613–614, 218–232. [Google Scholar] [CrossRef]

- Falkenmark, M.; Gunnar, L. How can we cope with the water resources situation by the year 2015? Ambio 1974, 3, 114–122. Available online: https://www.jstor.org/stable/4312063 (accessed on 26 October 2020).

- Raskin, P.; Gleick, P.; Kirshen, P.; Pontius, G.; Strzepek, K. Water Futures: Assessment of long-range patterns and problems. Comprehensive Assessment of the Freshwater Resources of the World; SEI report; Stockholm Environment Institute: Stockholm, Sweden, 1997. [Google Scholar]

- Rockström, J.; Falkenmark, M.; Karlberg, L.; Hoff, H.; Rost, S.; Gerten, D. Future water availability for global food production: The potential of green water for increasing resilience to global change. Water Resour. Res. 2009, 45, W00A12. [Google Scholar] [CrossRef] [Green Version]

- Swain, A.; Wallensteen, P. Comprehensive Assessment of the Freshwater Resources of the World, International Fresh Water Resources: Conflict or Cooperation? Stockholm Environment Institute: Stockholm, Sweden, 1997. [Google Scholar]

- Alcamo, J.; Henrich, T.; Rosch, T. World Water in 2025-Global Modelling and Scenario Analysis for the World Commission on Water for the 21st Century; Report A0002; Centre for Environmental System Research, University of Kassel: Kassel, Germany, 2000. [Google Scholar]

- Arnell, N.W. Climate change and global water resources. Glob. Environ. Chang. 1999, 9 (Suppl. 1), S31–S49. [Google Scholar] [CrossRef]

- Arnell, N.W. Climate change and global water resources: SRES emissions and socioeconomic scenarios. Glob. Environ. Chang. 2004, 14, 31–52. [Google Scholar] [CrossRef]

- Oki, T.; Agata, Y.; Kanae, S.; Saruhashi, T.; Yang, D.; Musiake, K. Global assessment of current water resources using total runoff integrating pathways. Hydrol. Sci. J. 2001, 46, 983–995. [Google Scholar] [CrossRef] [Green Version]

- Seckler, D.; Barker, R.; Amarasinghe, U. Water scarcity in the twenty-first century. Int. J. Water Resour. Dev. 1999, 15, 29–42. [Google Scholar] [CrossRef]

- Vörösmarty, C.J.; Green, P.; Salisbury, J.; Lammers, R.B. Global water resources: Vulnerability from climate change and population growth. Science 2000, 289, 284–288. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- European Commission (EC). Ecological Flows in the Implementation of the Water Framework Directive; CIS Guidance Document n°31; European Commission, DG Environment: Bruxelles, Belgium, 2015. [Google Scholar] [CrossRef]

- European Environmental Agency (EEA). Water Exploitation Index. Available online: https://www.eea.europa.eu/data-and-maps/indicators/use-of-freshwater-resources-3/assessment-4 (accessed on 25 October 2020).

- Pfister, S.; Koehler, A.; Hellweg, S. Assessing the environmental impacts of freshwater consumption in LCA. Environ. Sci. Technol. 2009, 43, 4098–4104. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ridoutt, B.G.; Pfister, S. A revised approach to water footprinting to make transparent the impacts of consumption and production on global freshwater scarcity. Glob. Environ. Chang. 2010, 20, 113–120. [Google Scholar] [CrossRef]

- Hoekstra, A.Y. A critique on the water-scarcity weighted water footprint in LCA. Ecol. Indic. 2016, 66, 564–573. [Google Scholar] [CrossRef] [Green Version]

- Pfister, S.; Boulay, A.-M.; Berger, M.; Hadjikakou, M.; Motoshita, M.; Hess, T.; Ridoutt, B.; Weinzettel, J.; Scherer, L.; Döll, P.; et al. Understanding the LCA and ISO water footprint: A response to Hoekstra (2016) “A critique on the water-scarcity weighted water footprint in LCA”. Ecol. Indic. 2017, 72, 352–359. [Google Scholar] [CrossRef]

- Gassert, F.; Luck, M.; Landis, M.; Reig, P.; Shiao, T. Aqueduct Global Maps 2.1: Constructing Decision-Relevant Global Water Risk Indicators; Working Paper; World Resources Institute: Washington, DC, USA, 2014; Available online: https://www.wri.org/research/aqueduct-global-maps-21-indicators (accessed on 23 September 2021).

- Gassert, F.; Reig, P.; Luo, T.; Maddocks, A. Aqueduct Country and River Basin Rankings: A Weighted Aggregation of Spatially Distinct Hydrological Indicators; Working paper; World Resources Institute: Washington, DC, USA, 2013; Available online: https://www.wri.org/research/aqueduct-country-and-river-basin-rankings (accessed on 23 September 2021).

- Commonwealth of Australia (CoA). Leading Practice Sustainable Development Program for the Mining Industry, Water Stewardship; Australian Government, Department of Industry, Science, Energy and Resources: Canberra, Australia, 2016. Available online: https://www.industry.gov.au/data-and-publications/leading-practice-handbook-water-stewardship (accessed on 23 September 2021).

- Sullivan, C. Calculating a Water Poverty Index. World Dev. 2002, 30, 1195–1210. [Google Scholar] [CrossRef]

- Sood, A.; Smakhtin, V.; Eriyagama, N.; Villholth, K.G.; Liyanage, N.; Wada, Y.; Ebrahim, G.; Dickens, C. Global Environmental Flow Information for the Sustainable Development Goals; IWMI Research Report 168; International Water Management Institute (IWMI): Colombo, Sri Lanka, 2017. [Google Scholar] [CrossRef] [Green Version]

- Zeiringer, B.; Seliger, C.; Greimel, F.; Schmutz, S. River Hydrology, Flow Alteration, and Environmental Flow. In Riverine Ecosysteme Management. Science for Governing towards a Sustainable Future; Aquatic Ecology Series; Schmutz, S., Sendizimir, J., Eds.; Springer: Cham, Germany, 2018; Volume 8, pp. 67–89. [Google Scholar] [CrossRef]

- Hirji, R.; Davis, R. Environmental Flows in Water Resources Policies, Plans, and Projects. Findings and Recommendations; World Bank: Washington, DC, USA, 2009. [Google Scholar] [CrossRef]

- Smakhtin, V.; Revenga, C.; Döll, P. Taking into Account Environmental Water Requirements in Global-Scale Water Resources Assessments; Comprehensive Assessment Research Report 2; Comprehensive Assessment Secretariat: Colombo, Sri Lanka, 2004. [Google Scholar]

- Falkenmark, M.; Berntell, A.; Jägerskog, A.; Lundqvist, J.; Matz, M.; Tropp, H. On the Verge of a New Water Scarcity: A Call for Good Governance and Human Ingenuity; SIWI Policy Brief; Stockholm International Water Institute (SIWI): Stockholm, Sweden, 2007. [Google Scholar]

- Pastor, A.V.; Ludwig, F.; Biemans, H.; Hoff, H.; Kabat, P. Accounting for environmental flow requirements in global water assessments. Hydrol. Earth Syst. Sci. 2014, 18, 5041–5059. [Google Scholar] [CrossRef] [Green Version]

- Richter, B.D.; Davis, M.M.; Apse, C.; Konrad, C. A presumptive standard for environmental flow protection. River Res. Appl. 2012, 28, 1312–1321. [Google Scholar] [CrossRef]

- Tharme, R.E. A global perspective on environmental flow assessment: Emerging trends in the development and application of environmental flow methodologies for rivers. River Res. Appl. 2003, 19, 397–441. [Google Scholar] [CrossRef]

- SNL Metals & Mining Database. Essential Mining Industry Data with Actionable Insights; S&P Global Market Intelligence (S&P): New York, NY, USA, 2019; Available online: https://www.spglobal.com/marketintelligence/en/solutions/metals-and-mining (accessed on 1 June 2019).

- Luck, M.; Landis, M.; Gassert, F. Aqueduct Water Stress Projections: Decadal Projections of Water Supply and Demand Using CMIP5 GCMs; Technical Note; World Resources Institute: Washington, DC, USA, 2015; Available online: https://www.wri.org/research/aqueduct-water-stress-projections-decadal-projections-water-supply-and-demand-using-cmip5 (accessed on 23 September 2021).

- Global Runoff Data Centre (GRDC). Major River Basins of the World/Global Runoff Data Centre; Federal Institute of Hydrology (BfG): Koblenz, Germany, 2007. Available online: https://www.bafg.de/GRDC/EN/02_srvcs/22_gslrs/221_MRB/riverbasins_node.html (accessed on 23 September 2021).

- Hoekstra, A.Y.; Mekonnen, M.M. Global Water Scarcity: Monthly Blue Water Footprint Compared to Blue Water Availability for the World’s Major River Basins; Value of Water Research Report Series No. 53; UNESCO-IHE: Delft, The Netherlands, 2011. [Google Scholar]

- Giurco, D.; Prior, T.; Mudd, G.; Mason, L.; Behrisch, J. Peak Minerals in Australia: A Review of Changing IMPACTS and Benefits; Prepared for CSIRO Minerals Down Under Flagship; Institute for Sustainable Futures (University of Technology, Sydney) and Department of Civil Engineering (Monash University): Sydney/Clayton, Australia, 2010. [Google Scholar]

- Frischknecht, R.; Jungbluth, N.; Althaus, H.-J.; Doka, G.; Dones, R.; Heck, T.; Hellweg, S.; Hischier, R.; Nemecek, T.; Rebitzer, G.; et al. The ecoinvent database: Overview and methodological framework. Int. J. Life Cycle Assess. 2005, 10, 3–9. [Google Scholar] [CrossRef]

- Buxmann, K.; Koehler, A.; Thylmann, D. Water scarcity footprint of primary aluminium. Int. J. Life Cycle Assess. 2016, 21, 1605–1615. [Google Scholar] [CrossRef] [Green Version]

- Dai, Q.; Kelly, J.C.; Elgowainy, A. Cobalt Life Cycle Analysis Update for the GREET Model; Argonne National Laboratory: Argonne, IL, USA, 2018. Available online: https://greet.es.anl.gov/publication-Li_battery_update_2017 (accessed on 25 October 2020).

- Shahjadi, H.F.; Nazmul Huda, M.A.; Parvez, M. Life cycle assessment of cobalt extraction process. J. Sustain. Min. 2019, 18, 150–161. [Google Scholar] [CrossRef]

- Fritsche, U. Process-oriented Basic Data for Environmental Management Instruments-www.probas.umweltbundesamt.de. Int. J. Life Cycle Assess. 2005, 10, 225. [Google Scholar] [CrossRef]

- Pena, C.; Huijbregts, M. The Blue Water Footprint of Primary Copper Production in Northern Chile. J. Ind. Ecol. 2013, 18, 49–58. [Google Scholar] [CrossRef]

- Haque, N.; Norgate, T. Life cycle assessment of iron ore mining and processing. In Iron Ore. Mineralogy, Processing and Environmental Sustainability; Lu, L., Ed.; Woodhead Publishing: Cambridge, UK, 2015; pp. 615–630. [Google Scholar] [CrossRef]

- Tost, M.; Bayer, B.; Hitch, M.; Lutter, S.; Moser, P.; Feiel, S. Metal Mining’s Environmental Pressures: A Review and Updated Estimates on CO2 Emissions, Water Use, and Land Requirements. Sustainability 2018, 10, 2881. [Google Scholar] [CrossRef] [Green Version]

- Mudd, G.M.; Diesendorf, M. Sustainability of Uranium Mining and Milling: Toward Quantifying Resources and Eco-Efficiency. Environ. Sci. Technol. 2008, 42, 2624–2630. [Google Scholar] [CrossRef]

- Norgate, T.; Haque, N. Using life cycle assessment to evaluate some environmental impacts of gold production. J. Clean. Prod. 2012, 29–30, 53–63. [Google Scholar] [CrossRef]

- Mudd, G.M. Resource Consumption Intensity and the Sustainability of Gold Mining. In Proceedings of the 2nd International Conference on Sustainability Engineering & Science, Auckland, New Zealand, 20–23 February 2007. [Google Scholar]

- Talbot, D.; Barbat, G. Water disclosure in the mining sector: An assessment of the credibility of sustainability reports. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 1241–1251. [Google Scholar] [CrossRef]

- World Water Assessment Programme (WWAP). The United Nations World Water Development Report 2019: Leaving No One Behind; UNESCO: Paris, France, 2019. [Google Scholar]

- Mindat.org dba. Hudson Institute of Mineralogy, Ed.: Keswick, USA. 2019. Available online: https://www.mindat.org/ (accessed on 21 September 2021).

- United States Geological Survey (USGS). USGD, Ed.: Reston, USA. 2021. Available online: https://www.usgs.gov/ (accessed on 21 September 2021).

- British Geological Survey (BGS). BGS, Ed.: Nottingham, UK. 2021. Available online: https://www.bgs.ac.uk/ (accessed on 21 September 2021).

- Australian Geoscience Information Network (AUSGIN)-Geoscience Portal. Australian Government’s Department of Industry, Innovation and Science, Ed.: Canberra, Australia. 2021. Available online: https://portal.geoscience.gov.au/ (accessed on 21 September 2021).

- United States Geological Survey (USGS). Mineral Commodity Summaries 2020; U.S. Geological Survey: Reston, VA, USA, 2020. [CrossRef] [Green Version]

- Fekete, B.M.; Vörösmarty, C.J.; Grabs, W. High-resolution fields of global runoff combining observed river discharge and simulated water balances. Glob. Biogeochem. Cycles 2002, 16, 15/1–15/10. [Google Scholar] [CrossRef]

| Continental Region | Annual Flow (km3a−1) and Percentage of Natural Flow (%) to Be Preserved as EWR | Sustainable Groundwater Abstraction (km3a−1) and Percentage of Natural Recharge (%) |

|---|---|---|

| Asia | 10,178.2 (57.0) | 110.3 (3.4) |

| North America | 3656.3 (55.2) | 30.3 (1.9) |

| Europe | 1489.7 (52.8) | 20.0 (1.7) |

| Africa | 5032.1 (70.2) | 14.3 (0.7) |

| South America | 11,242.9 (73.4) | 24.0 (0.6) |

| Oceania | 240.4 (35.1) | 2.6 (1.0) |

| Australia | 251.0 (48.4) | 1.9 (1.3) |

| Global | 32,090.6 (63.0) | 203.3 (1.6) |

| Basin | Basin-ID | Water Consumption (Mm3) | Water Scarcity Impact (Mm3) | Water Consumption/Water Scarcity Ratio | Most Relevant Mining Commodities (in Terms of Production Volumes) |

|---|---|---|---|---|---|

| Fortescue River (Australia) | No. 323 | 522.7 | <1.0 1 | >500:1 | Iron ore |

| Tocantins (Brazil) | No. 273 | 259.9 | <1.0 | ~260:1 | Iron ore |

| Ashburton River (Australia) | No. 327 | 208.0 | 1040.0 | ~1:5 | Iron ore |

| Sao Francisco (Brazil) | No. 290 | 166.0 | 63.2 | 2.6:1 | Iron ore |

| Orange (South Africa) | No. 326 | 87.5 | 270.6 | 1:3.1 | Gold, iron ore, manganese |

| Amazonas (Brazil) | No. 259 | 85.6 | 71.2 | 1:0.8 | Copper, gold, bauxite, zinc, silver |

| Limpopo (South Africa) | No. 320 | 76.8 | 256.0 | 1:3.3 | Platinum, palladium, nickel, gold, copper |

| Loa (Chile) | No. 319 | 73.6 | 270.6 | 1:3.7 | Copper, molybdenum, silver |

| Congo (Central Africa) | No. 243 | 69.1 | <1.0 | ~70:1 | Copper, cobalt, gold |

| St. Lawrence (USA, Canada) | No. 117 | 62.5 | <1.0 | ~100:1 | Nickel, cobalt, copper, gold |

| Zambezi (Central Africa) | No. 293 | 57.5 | 1.4 | ~40:1 | Copper, nickel |

| Dnieper (Ukraine, Belarus, Russia) | No. 96 | 55.3 | 114.8 | 1:2.1 | Iron ore |

| Issyk-Kul (Kazakhstan, Kyrgyzstan) | No. 392 | 51.2 | 255.9 | 1:5 | Uranium |

| Ob (Russia) | No. 25 | 46.2 | 132.0 | 1:2.9 | Gold, copper, zinc, iron ore, bauxite, lead, silver, uranium |

| Colorado River (USA, Mexico) | No. 138 | 43.9 | 192.5 | 1:4.4 | Copper, molybdenum, gold |

| Huang He (Yellow River) (China) | No. 149 | 43.1 | 200.8 | 1:4.7 | Nickel, molybdenum, gold, copper, zinc |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meißner, S. The Impact of Metal Mining on Global Water Stress and Regional Carrying Capacities—A GIS-Based Water Impact Assessment. Resources 2021, 10, 120. https://doi.org/10.3390/resources10120120

Meißner S. The Impact of Metal Mining on Global Water Stress and Regional Carrying Capacities—A GIS-Based Water Impact Assessment. Resources. 2021; 10(12):120. https://doi.org/10.3390/resources10120120

Chicago/Turabian StyleMeißner, Simon. 2021. "The Impact of Metal Mining on Global Water Stress and Regional Carrying Capacities—A GIS-Based Water Impact Assessment" Resources 10, no. 12: 120. https://doi.org/10.3390/resources10120120

APA StyleMeißner, S. (2021). The Impact of Metal Mining on Global Water Stress and Regional Carrying Capacities—A GIS-Based Water Impact Assessment. Resources, 10(12), 120. https://doi.org/10.3390/resources10120120