Three Generic Policies for Sustained Market Growth Based on Two Interdependent Organizational Resources—A Simulation Study and Implications

Abstract

1. Introduction

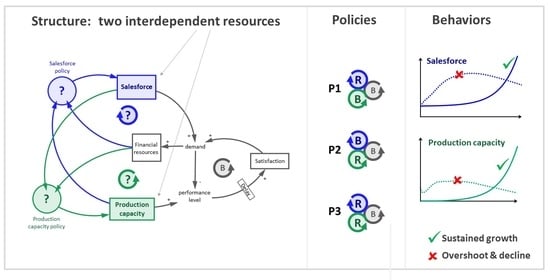

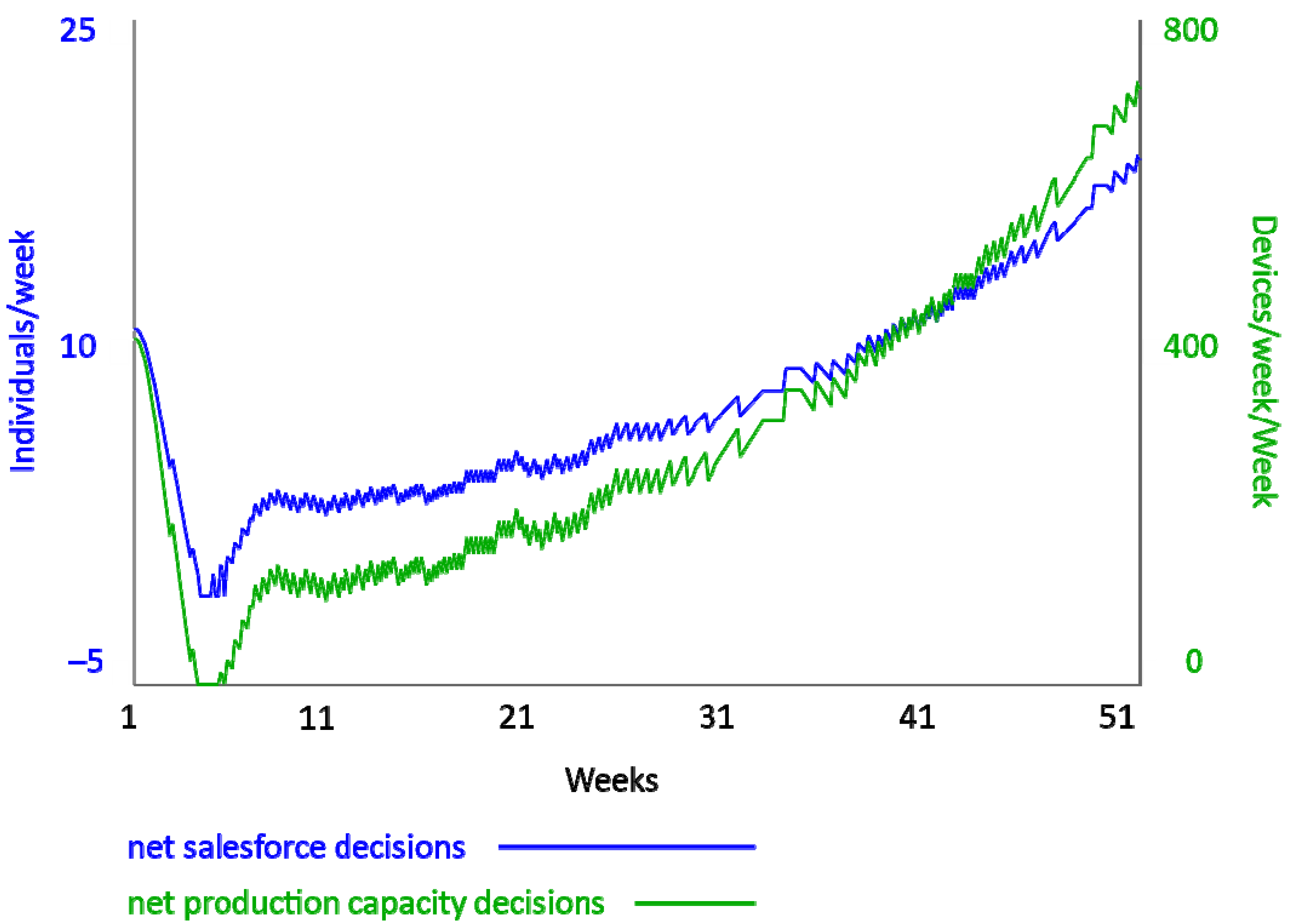

- Generic policy GP1: Drive growth through increases of the salesforce and adjust production capacity as needed.

- Generic policy GP2: Drive growth by investing in production capacity and adjust salesforce as needed.

- Generic policy GP3: Drive growth through simultaneous and harmonic increases of both salesforce and production capacity.

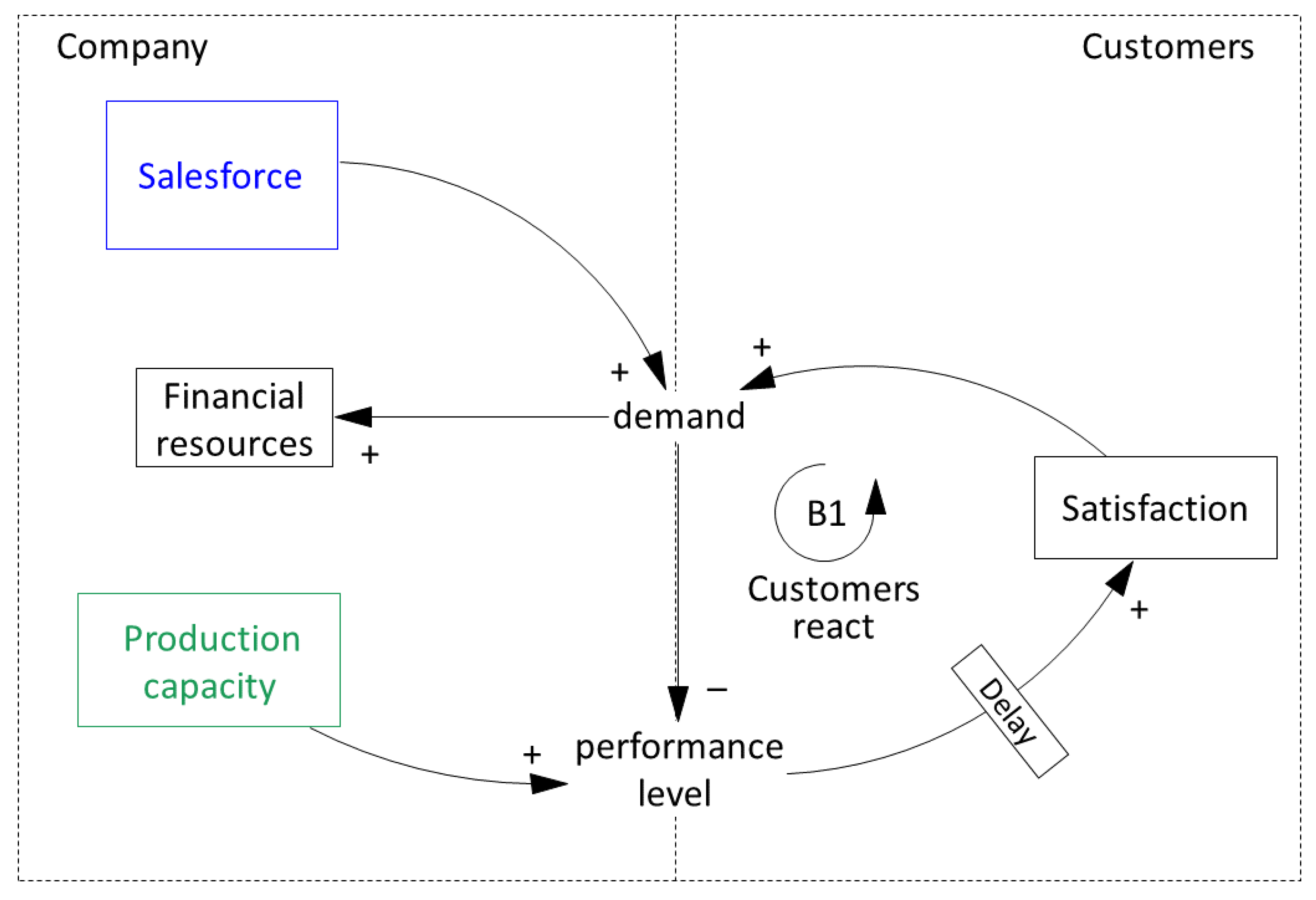

2. Theory: A Three-Loop System

2.1. The Structure and Dynamics of a Three-Resource System

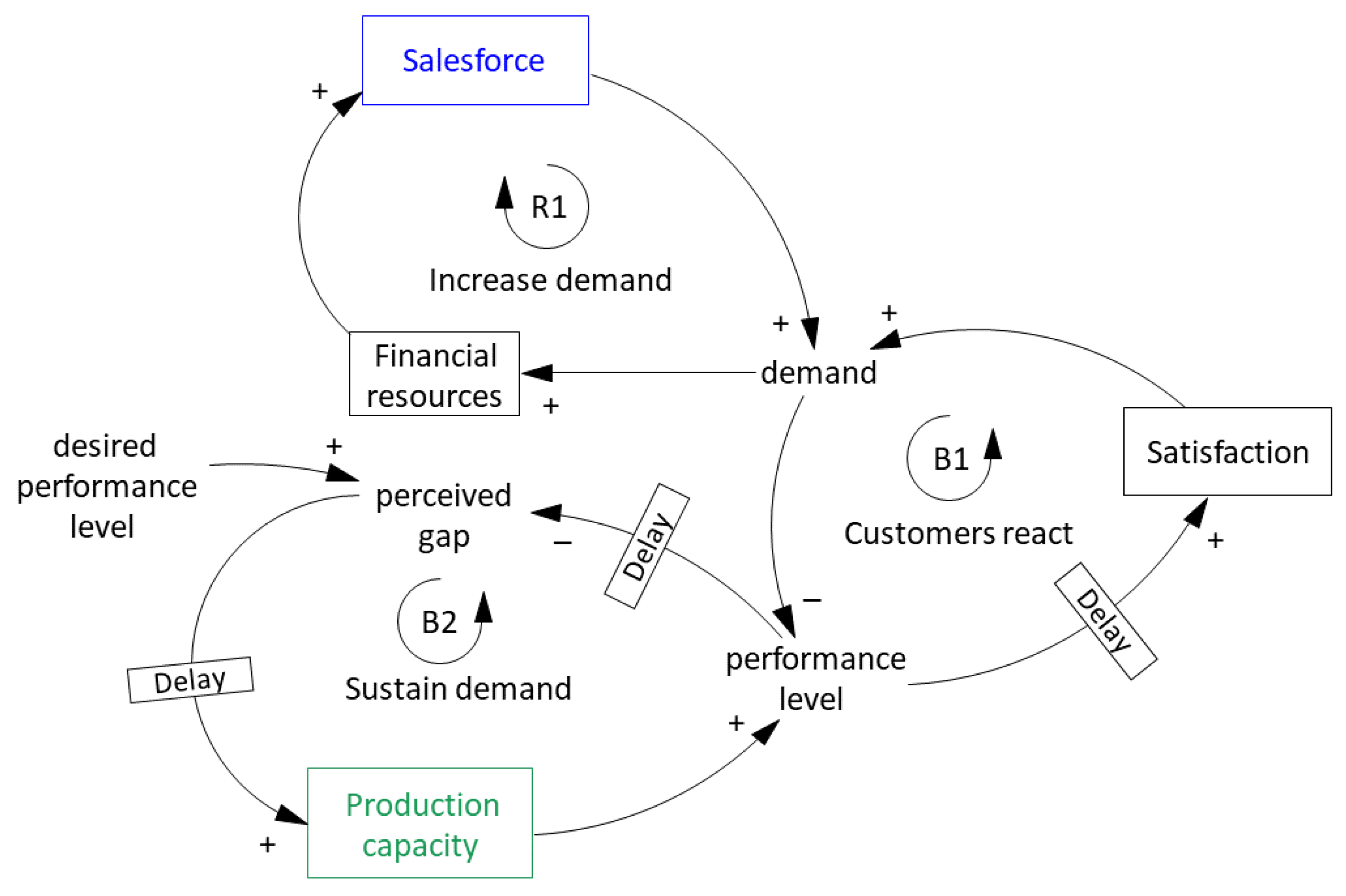

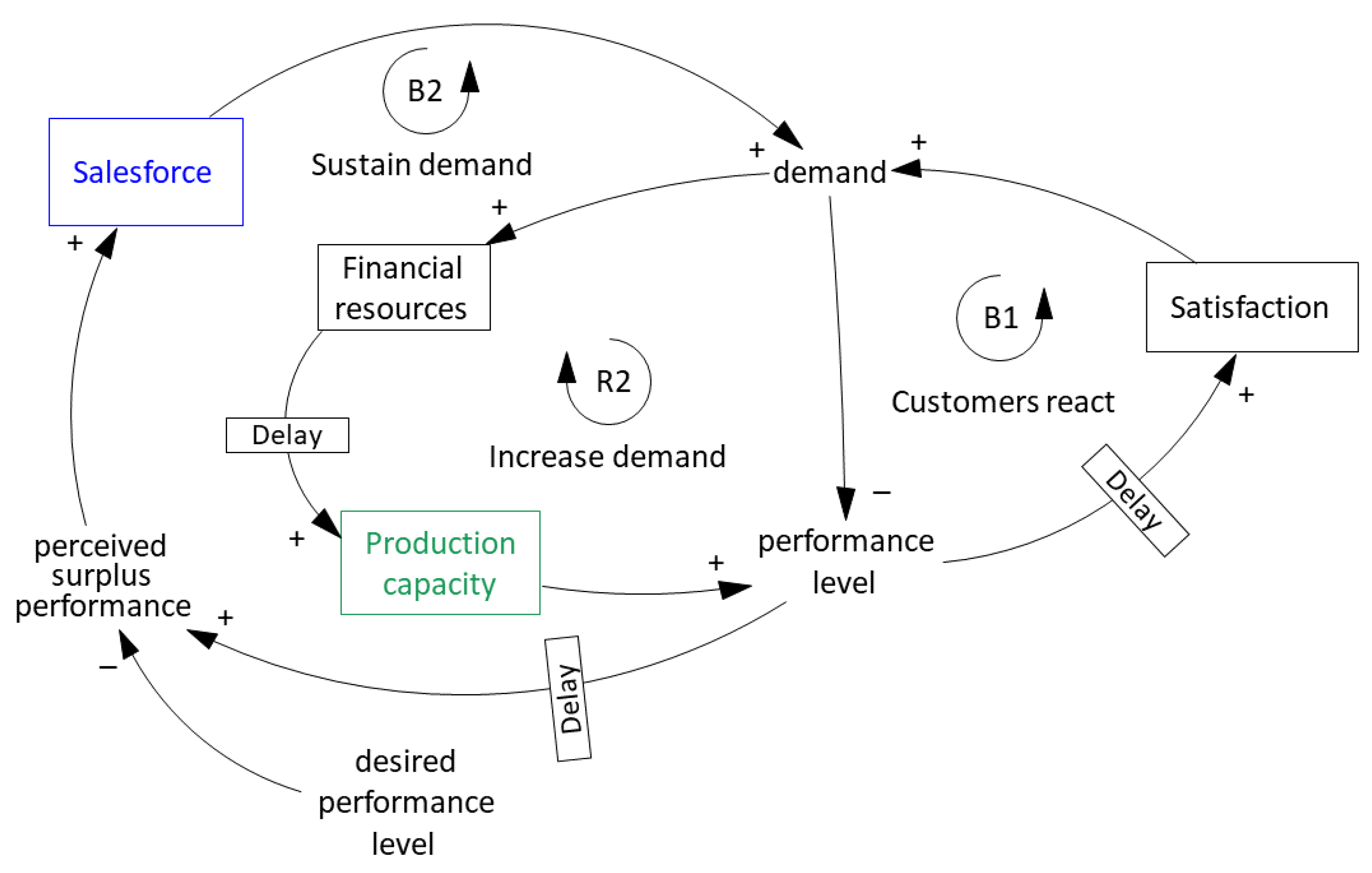

2.2. Different Generic Policies to Develop Resources in This Context

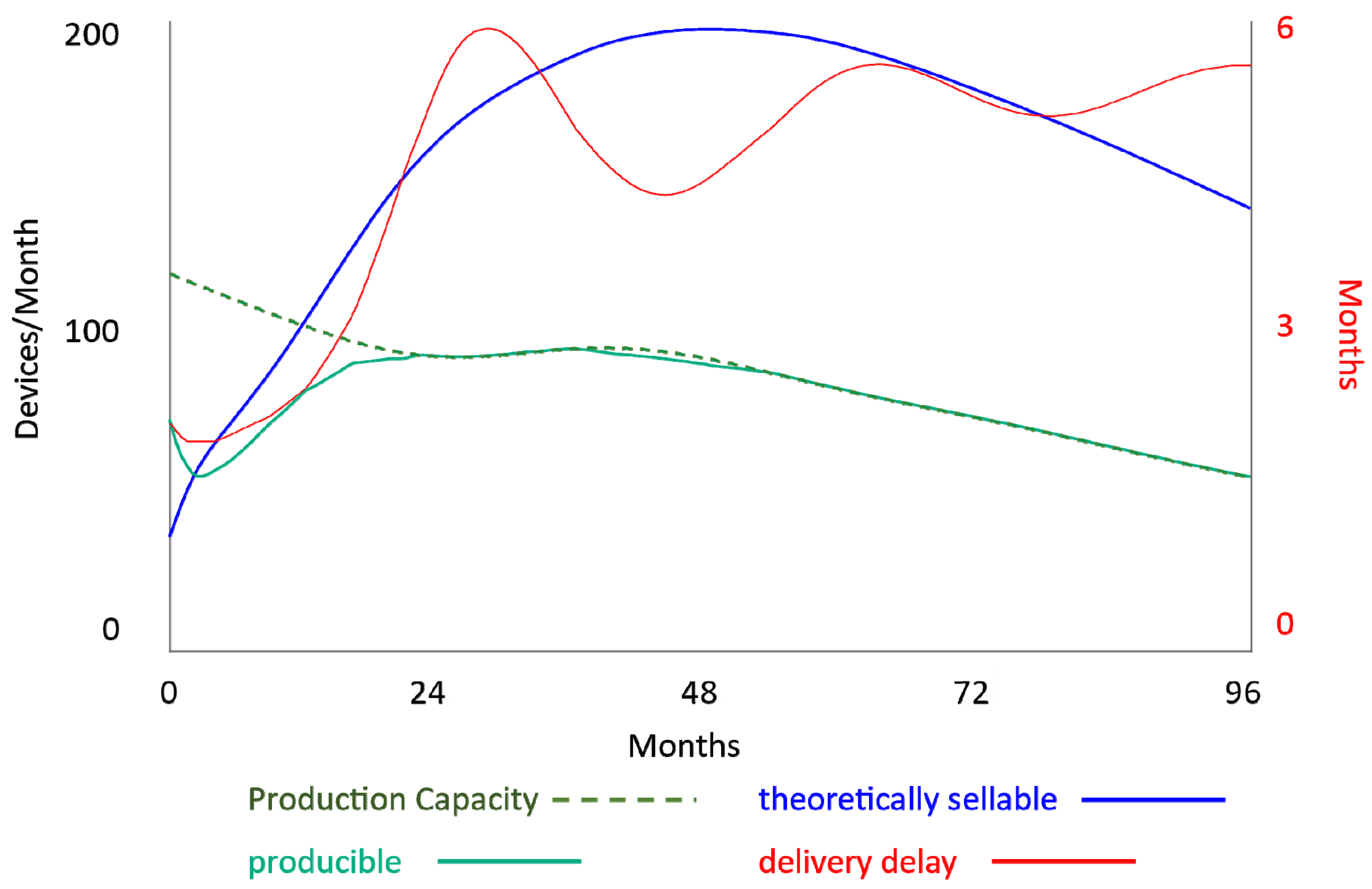

2.2.1. Generic Policy GP1: Drive Demand Growth with the Salesforce and Adjust Production Capacity When Needed

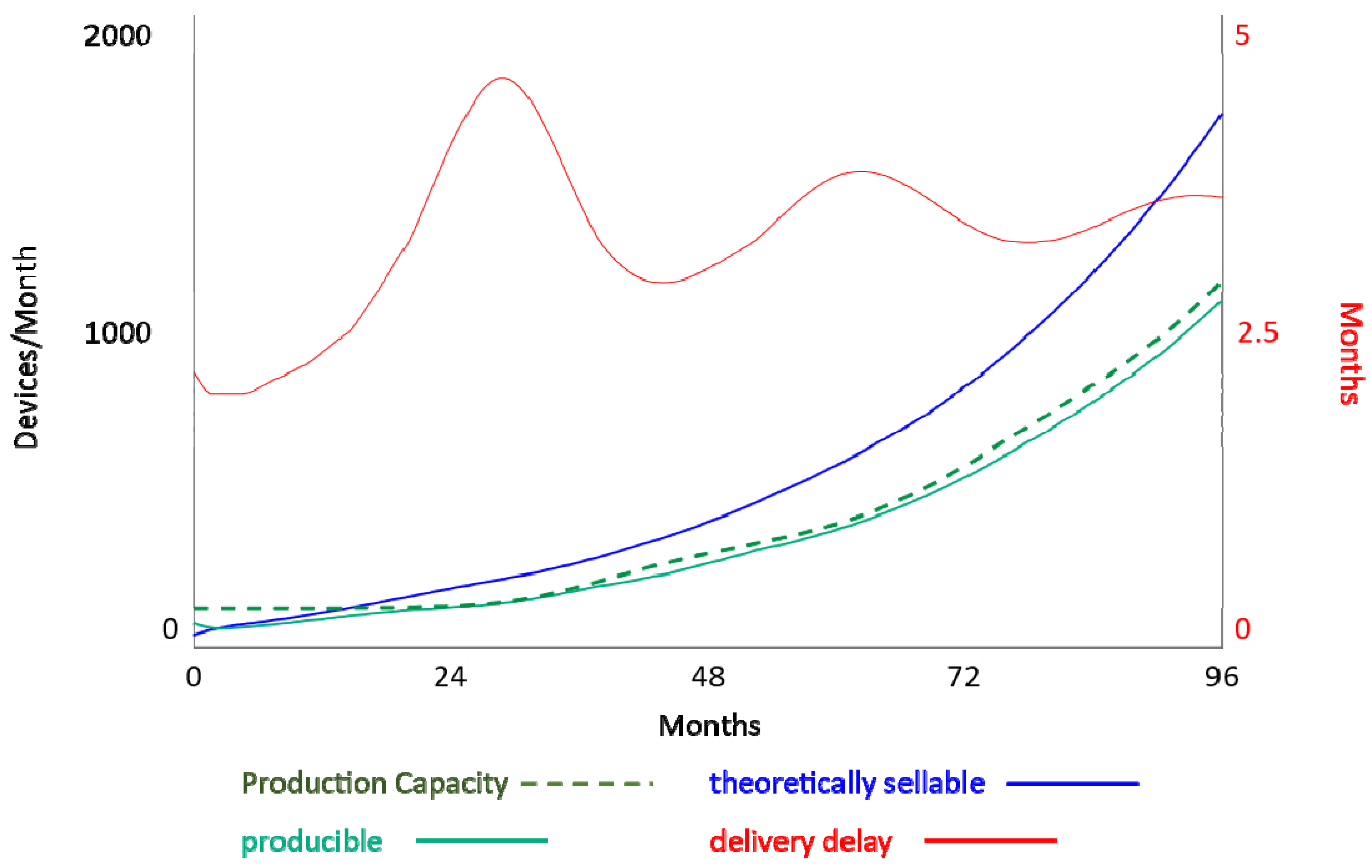

2.2.2. Generic Policy GP2: Enable Demand Growth through Production Capacity and Adjust the Salesforce When Possible

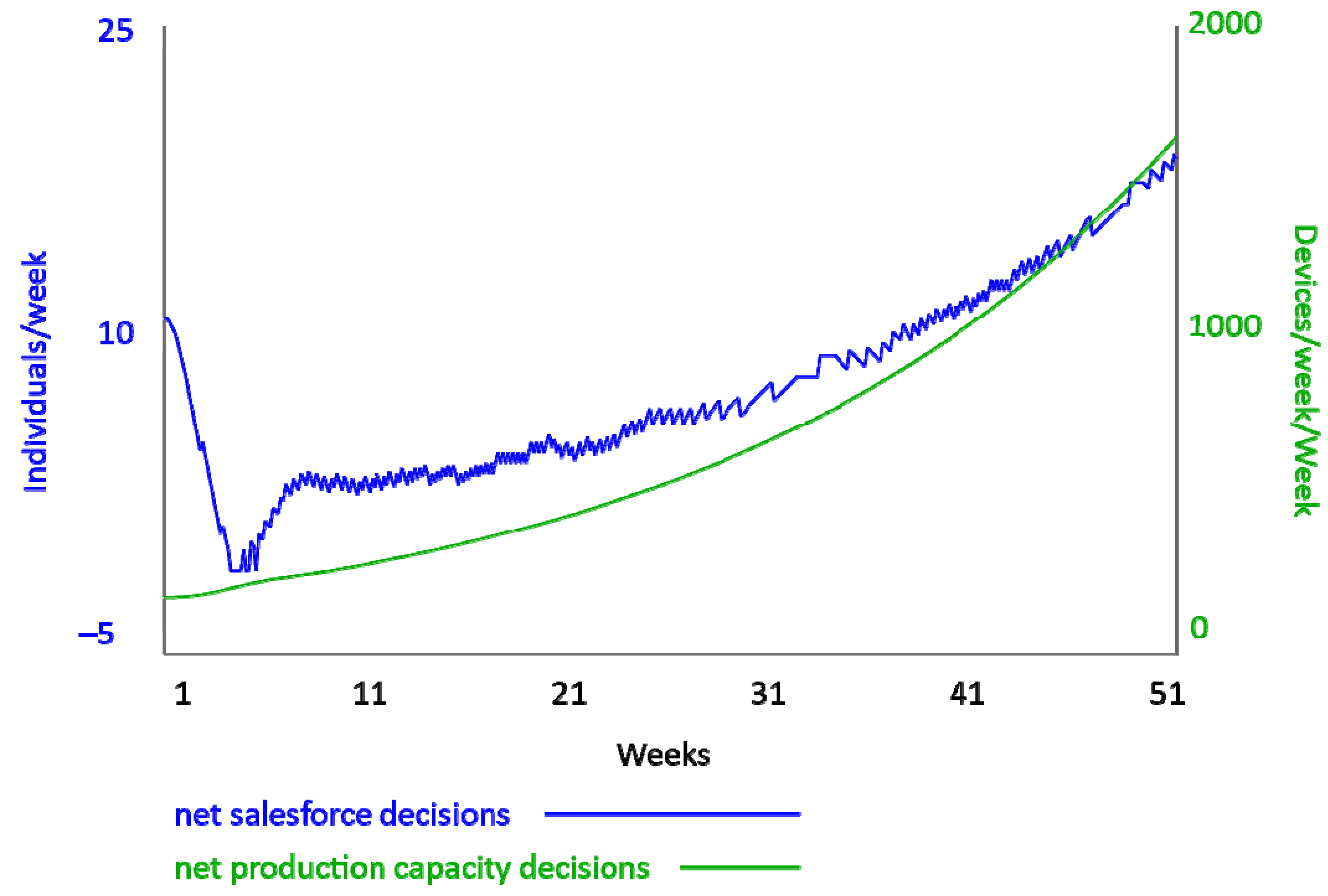

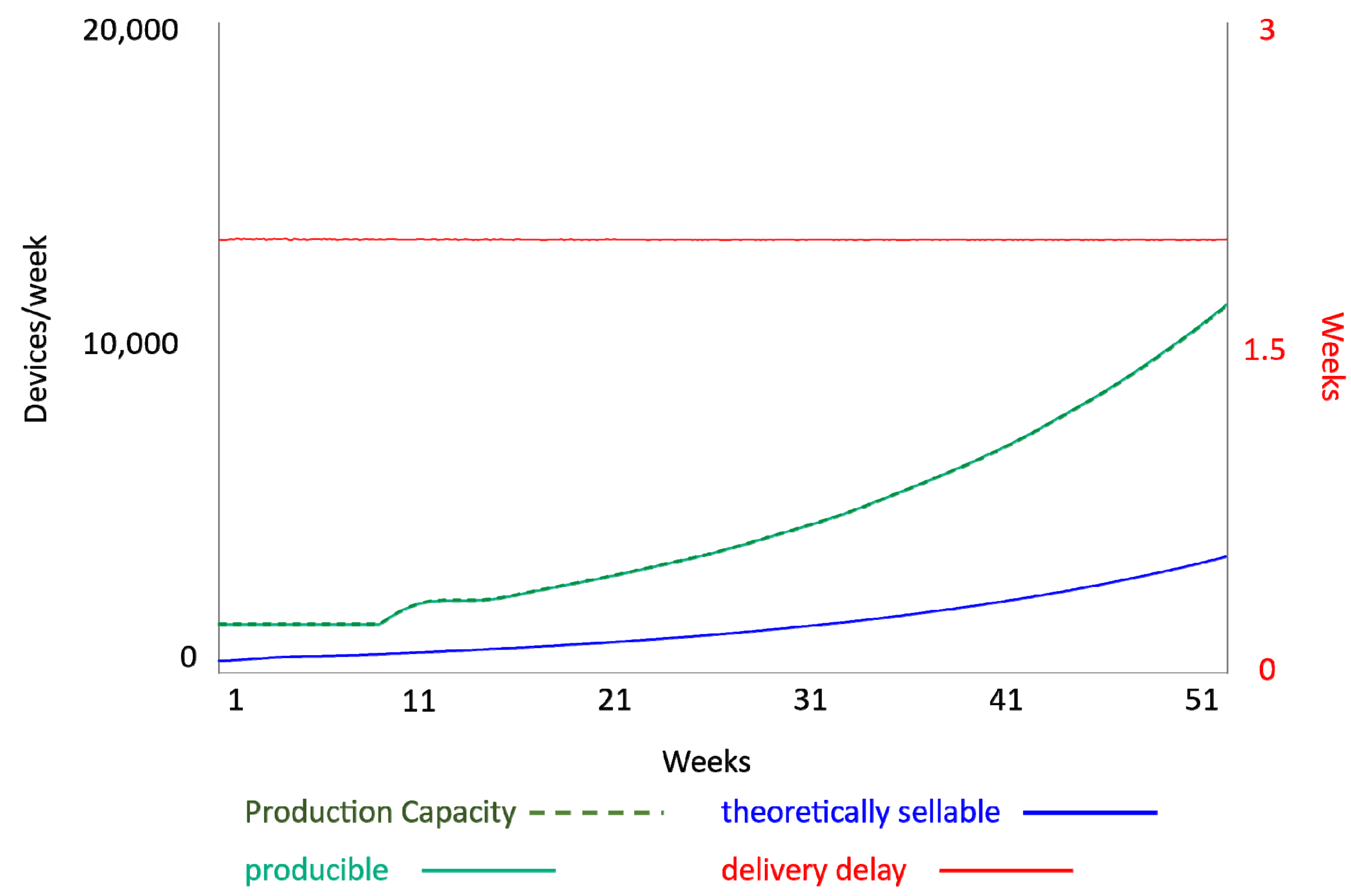

2.2.3. Generic Policy GP3: Drive and Enable Growth Simultaneously

3. Method

3.1. Description of the Specific Decision Situation Used in the Simulation

3.2. Benchmarks for Comparing Possible Policies

3.2.1. The Classical Example of Market Growth and Underinvestment in Capacity

3.2.2. How to Include the Interdependency between Salesforce and Production Capacity in Specific Policies

3.2.3. Specific Policy P1

3.2.4. Specific Policy P2

3.2.5. Specific Policy P3

4. Discussion

- An increased salesforce generates an augmented stress on production capacity and calls for a more-than-proportional effort to increase production capacity: even small increases of the salesforce would require an important (financial) effort to adjust production capacity sufficiently and timely.

- An increased production capacity generates stress on the salesforce (because the current salesforce cannot sell enough, which leads to increased salesforce salary costs per unit sold). The comparatively short recruitment delay implies that the effort needed to adjust the salesforce is smaller than the efforts which have gone into the production capacity increase. An alternative interpretation would be: the more one increases the production capacity per period of time, the easier it becomes that an adequately adjusted salesforce can generate the new orders needed for the sales revenue to lead to a sufficient salesforce salary budget to sustain this increased salesforce.

- Does the set of three generic policies discussed here cover the possibilities of how to think about steering two (groups of) interdependent resources? The argument made in this article is that if any steering logic can be mapped to a feedback loop, and there are only two types of feedback loop, then there are only four possibilities: two of them are the combinations of one reinforcing and one balancing loop, one comprises two reinforcing loops, and the fourth possibility would be two balancing loops. If the decision-makers goals include growth, one must then decide if balancing loops alone can drive growth, or if this would mean that the driver is a third, balancing, loop passing through entities outside the organization. Another potential extension follows from the fact that the current generic policies are “single-loop” architectures. One might also consider the design of double-loop architectures, where the values of some parameters like the revenue fraction for salesforce salaries could be corrected depending on the tendency of an indicator over time, for instance an excessive production capacity. This might enable decision-makers to improve their policies over time. Certainly, deciding this question exclusively on theoretical grounds is a limitation of the current discussion, and if this line of inquiry is furthered, a reference taxonomy similar to the system archetypes discussed decades ago in the intersection between organizational learning and systems thinking [59].

- Can all operationally formulated policies be directly assigned to one of the generic policies—resulting in a two-level hierarchy of policies—or should there be an intermediate level? Possibly the current two levels are too limited, especially when several operational policies have shared traits. This is already a question to ask regarding the possibility to have a version of GP1 where each resource is steered by a double-loop architecture. But consider also the following example. Regarding adjustments driven by balancing loops, the adjustments to a resource might include a supercompensation—not only adjusting to the level indicated at the time of adjustment, but a little more. This is a kind of homeostatic response to an imbalance. The process of homeostasis can be found in many areas of natural and social systems [60,61]. Since supercompensation adjusts more than needed to close a gap, it can be thought of as anticipating future adjustment needs before they can be detected in the real situation, which is not only well-known in sports science [62], but also a kind of predictive homeostasis, sometimes referred to as allostasis [63]. Such additional formulations may be additional generic policies or additional instances of already identified generic policies.

- Which decision rules operationalize individuals’ policies? what is the reasoning leading them to their respective policies and which features of the decision situation (including the interdependencies and the different delays) play a role in their reasoning? The chain recognized features → reasoning → policy is relevant because flaws in a policy will usually be the consequence of reasoning errors, which may be the consequence of not accounting for relevant features of the decision situation [37], in particular interdependencies and delays.

- Do the policies of real individuals always match with one of the three generic policies or does the set of generic policies need to be extended?

- With which relative frequency is each generic policy chosen?

- How successful are the policies?

- Do individuals change some aspects of how to carry out their policy or even switch to an entirely different policy over the iterations of perceiving the situation, interpreting it, and taking a decision?

5. Conclusions

- Use the quick-to-react resource to drive growth (reinforcing loop) and adjust the slow-to-react resource as needed (balancing loop).

- Use the slow-to-react resource to drive growth (reinforcing loop) and adjust the quick-to-react resource as needed (balancing loop).

- Use both resources simultaneously to drive growth (two reinforcing loops).

Supplementary Materials

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Simulation Model on the INTERNET

- Policy implementation fraction: The computed value for the decisions can be used as suggested by the model or at a fraction between 0.1 and 0.9. The main text of the article discusses the behavior assuming one specific policy implementation fraction, but model users can explore how behavior and performance change when a different value is used.

- For policies P1 and P3, the revenue fraction for salesforce salaries can be changed to values smaller than or greater than the default value of 25%. Around 30%, oscillations appear. This is not addressed in the article, but readers may be interested in this aspect.

- For policy P2, one can use the revenue fraction for salesforce salaries to impose an upper limit on recruitments. Table 2 in the article reports on this under the title “P2 limited,” but one can explore the range of effects by varying the control for revenue fraction for salesforce salaries.

- Capacity construction delay accounted for: By default, the computations are based on the total capacity, including the capacity under construction, to avoid the oscillations typical for second order negative feedback loops. This can be deactivated to explore how behaviors change.

- Proactive capacity reasoning: by default, the computations assuming that the degree of change of production capacity is determined proactively. This can be deactivated to explore how behaviors change.

Appendix B. Summary Results from All Simulated Policies

| Indicator | Specific Policy | |||||||

|---|---|---|---|---|---|---|---|---|

| P1 Default | P1 50% | P1 75% | P2 Default | P2 Limited | P3 Default | P3 50% | P3 75% | |

| Parameters | ||||||||

| policy implementation fraction | 0.2 | 0.7 | 0.6 | |||||

| revenue fraction for salesforce salaries | 25% | 50% | 75% | na | 25% | 25% | 50% | 75% |

| Model Variables | ||||||||

| Sales Force | 398 | 11,402 | 29,698 | 12,656 | 398 | 398 | 9435 | 28,200 |

| Theoretically sellable | 3585 | 103,000 | 267,000 | 113,907 | 3585 | 3585 | 84,914 | 253,801 |

| Production Capacity | 5930 | 56,539 | 93,209 | 118,860 | 16,974 | 6200 | 35,744 | 70,105 |

| Production capacity surplus or lack absolute | 2344 | −46,461 | −173,791 | 4952 | 13,388 | 2615 | −49,169 | −183,696 |

| Production capacity surplus or lack relative | 65% | −45% | −65% | 4% | 373% | 73% | −58% | −72% |

| Accumulated deliveries | 66,284 | 585,194 | 921,889 | 823,596 | 66,284 | 66,284 | 724,657 | 1,435,274 |

| Accumulated excess production capacity | 68,859 | 4487 | 3962 | 65,959 | 232,489 | 68,723 | 6164 | 3962 |

| Accumulated excess salesforce | 0 | 469,547 | 1,487,410 | 0 | 0 | 0 | 799,017 | 3,102,219 |

| Delivery delay real | 2.0 | 3.5 | 5.3 | 2.0 | 2.0 | 2.0 | 5.2 | 6.7 |

| Accumulated profits | −126,630,840 | −2,106,130,554 | −4,043,396,613 | −5,700,338,232 | −458,165,449 | −89,220,517 | −798,131,201 | −1,732,646,384 |

| Additional Indicators | ||||||||

| Additional deliveries | 49,004 | 567,914 | 904,609 | 806,316 | 49,004 | 49,004 | 707,377 | 1,417,994 |

| Total growth in % | 284% | 3287% | 5235% | 4666% | 284% | 284% | 4094% | 8206% |

| Monthy growth rate | 9% | 34% | 39% | 38% | 9% | 9% | 36% | 44% |

| Steady state deliveries at end of year | 49,004 | 567,914 | 904,609 | 806,316 | 49,004 | 49,004 | 707,377 | 1,417,994 |

| Accelerating growth | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Behavior smoothness of resources | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous | Continuous |

| Strength of growth | Moderate | Extreme | Extreme | Extreme | Moderate | Moderate | Extreme | Extreme |

| Sustainable | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| Delivery delay behavior | Steady | Increase | Increase | Steady | Steady | Steady | Increase | Increase |

| Delivery delay values | Constant | Oscillation | Oscillation | Constant | Constant | Constant | Oscillation | Oscillation |

| Likely to be followed | Yes | No | No | Tes | No | Yes | No | No |

Appendix C. Model Documentation

Appendix C.1. Main Model

Appendix C.1.1. Salesforce

Appendix C.1.2. Production Capacity

Appendix C.1.3. Orders

Appendix C.1.4. Intermediate Variables

| Input | Output |

| 0 | 1.000 |

| 1 | 0.970 |

| 2 | 0.900 |

| 3 | 0.730 |

| 4 | 0.530 |

| 5 | 0.380 |

| 6 | 0.250 |

| 7 | 0.150 |

| 8 | 0.080 |

| 9 | 0.030 |

| 10 | 0.020 |

Appendix C.2. Policy GP1

Appendix C.3. Policy GP2

Appendix C.4. Policy GP3

Appendix C.5. Stress_on_Salesforce

Appendix C.6. Auxiliary_Calculations

Appendix C.7. Accounting Module

| Input | Output |

| 0 | 0.0000 |

| 1 | 0.0000 |

| 2 | 0.0000 |

| 3 | 0.0000 |

| 4 | 0.0000 |

| 5 | 1.0000 |

| 6 | 1.041666667 |

| 7 | 1.107142857 |

| 8 | 0.0000 |

| 9 | 0.0000 |

| 10 | 1.1250 |

| 11 | 0.0000 |

| 12 | 1.1666666667 |

| 13 | 0.0000 |

| 14 | 1.232142857 |

| 15 | 1.2500 |

| 16 | 0.0000 |

| 17 | 0.0000 |

| 18 | 1.291666667 |

| 19 | 0.0000 |

| 20 | 0.0000 |

| 21 | 1.357142857 |

References

- Barney, J. Firm Resources and Sustained Competitive Advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Crook, T.R.; Ketchen, D.J.; Combs, J.G.; Todd, S.Y. Strategic resources and performance: A meta-analysis. Strateg. Manag. J. 2008, 29, 1141–1154. [Google Scholar] [CrossRef]

- Kor, Y.Y.; Mahoney, J.T. Edith Penrose’s (1959) Contributions to the Resource-based View of Strategic Management. J. Manag. Stud. 2004, 41, 11. [Google Scholar] [CrossRef]

- Penrose, E.T. The Theory of the Growth of the Firm; John Wiley: New York, NY, USA, 1959. [Google Scholar]

- Peteralf, M.A. The Cornerstones of Competitive Advantage: A Resource-Based View. Strateg. Manag. J. 1993, 14, 12. [Google Scholar]

- Wernerfelt, B. A Resource-Based view of the Firm. Strateg. Manag. J. 1984, 5, 10. [Google Scholar] [CrossRef]

- Warren, K. Improving strategic management with the fundamental principles of system dynamics. Syst. Dyn. Rev. 2005, 21, 329–350. [Google Scholar] [CrossRef]

- Barney, J. Is the Resource-Based “View” a Useful Perspective for Strategic Management Research? Yes. Acad. Manag. Rev. 2001, 26, 41–56. [Google Scholar]

- Kunc, M.H.; Morecroft, J.D.W. Managerial decision making and firm performance under a resource-based paradigm. Strateg. Manag. J. 2010, 31, 1164–1182. [Google Scholar] [CrossRef]

- Priem, R.L.; Butler, J.E. Is the Resource-Based “View” a Useful Perspective for Strategic Management Research? Acad. Manag. Rev. 2001, 26, 19. [Google Scholar]

- Ozgun, O.; Barlas, Y. Effects of systemic complexity factors on task difficulty in a stock management game. Syst. Dyn. Rev. 2015, 31, 115–146. [Google Scholar] [CrossRef]

- Moxnes, E. Not only the tragedy of the commons: Misperceptions of feedback and policies for sustainable development. Syst. Dyn. Rev. 2000, 16, 325–348. [Google Scholar] [CrossRef]

- Moxnes, E. Misperceptions of basic dynamics: The case of renewable resource management. Syst. Dyn. Rev. 2004, 20, 139–162. [Google Scholar] [CrossRef]

- Sterman, J. Misperceptions of Feedback in Dynamic Decision Making. Organ. Behav. Hum. Decis. Process. 1989, 43, 301–335. [Google Scholar] [CrossRef]

- Sterman, J. Modeling managerial behavior—Misperceptions of feedback in a dynamic decision-making experiment. Manag. Sci. 1989, 35, 18. [Google Scholar] [CrossRef]

- Baghaei Lakeh, A.; Ghaffarzadegan, N. Does analytical thinking improve understanding of accumulation? Syst. Dyn. Rev. 2015, 31, 46–65. [Google Scholar] [CrossRef]

- Cronin, M.A.; Gonzalez, C. Understanding the building blocks of dynamic systems. Syst. Dyn. Rev. 2007, 23, 1–17. [Google Scholar] [CrossRef]

- Cronin, M.A.; Gonzalez, C.; Sterman, J.D. Why don’t well-educated adults understand accumulation? A challenge to researchers, educators, and citizens. Organ. Behav. Hum. Decis. Process. 2009, 108, 116–130. [Google Scholar] [CrossRef]

- Gonzalez, C.; Wong, H.-y. Understanding stocks and flows through analogy. Syst. Dyn. Rev. 2012, 28, 3–27. [Google Scholar] [CrossRef]

- Sterman, J. Does formal system dynamics training improve people’s understanding of accumulation? Syst. Dyn. Rev. 2010, 26, 316–334. [Google Scholar] [CrossRef]

- Stouten, H.; Grosler, A. Task Complexity in Individual Stock Control Tasks for Laboratory Experiments on Human Understanding of Dynamic Systems. Syst. Res. Behav. Sci. 2017, 34, 62–77. [Google Scholar] [CrossRef]

- Sweeney, L.B.; Sterman, J. Bathtub dynamics: Initial results of a systems thinking inventory. Syst. Dyn. Rev. 2000, 16, 249–286. [Google Scholar] [CrossRef]

- Paich, M.; Sterman, J. Boom, Bust, and Failures to Learn in Experimental Markets. Manag. Sci. 1993, 39, 1439–1458. [Google Scholar] [CrossRef]

- Arquitt, S.; Honggang, X.; Johnstone, R. A system dynamics analysis of boom and bust in the shrimp aquaculture industry. Syst. Dyn. Rev. 2005, 21, 305–324. [Google Scholar] [CrossRef]

- Ford, A. Boom & Bust in Power Plant Construction: Lessons from the California Electricity Crisis. J. Ind. Compet. Trade 2002, 2, 59–74. [Google Scholar]

- Gary, M.S.; Dosi, G.; Lovallo, D. Boom and Bust Behavior: On the Persistence of Strategic Decision Biases. In The Oxford Handbook of Organizational Decision Making; Hodgkinson, G., Starbuck, W., Eds.; Oxford University Press: Oxford, UK, 2008; pp. 33–55. [Google Scholar]

- Morecroft, J.D.W. System Dynamics, RBV and Behavioural Theories of Firm Performance: Lessons from People Express. In Proceedings of the 28th International Conference of the System Dynamics Society, Athens, Greece, 20–24 July 2008; System Dynamics Society: Albany, NY, USA. [Google Scholar]

- Ghaffarzadegan, N.; Lyneis, J.; Richardson, G.P. How small system dynamics models can help the public policy process. Syst. Dyn. Rev. 2011, 27, 22–44. [Google Scholar] [CrossRef]

- Saysel, A.K.; Barlas, Y. Model simplification and validation with indirect structure validity tests. Syst. Dyn. Rev. 2006, 22, 241–262. [Google Scholar] [CrossRef]

- Schoenenberger, L.; Schmid, A.; Ansah, J.; Schwaninger, M. The challenge of model complexity: Improving the interpretation of large causal models through variety filters. Syst. Dyn. Rev. 2017, 33, 112–137. [Google Scholar] [CrossRef]

- Sian Morgan, J.; Graber-Naidich, A. Small system dynamics model for alleviating the general practitioners rural care gap in Ontario, Canada. Socio Econ. Plan. Sci. 2019, 66, 10–23. [Google Scholar] [CrossRef]

- Gonzalez, C.; Fakhari, P.; Busemeyer, J. Dynamic Decision Making: Learning Processes and New Research Directions. Hum. Factors 2017, 59, 713–721. [Google Scholar] [CrossRef]

- Beckmann, J.F.; Birney, D.P.; Goode, N. Beyond Psychometrics: The Difference between Difficult Problem Solving and Complex Problem Solving. Front. Psychol. 2017, 8, 1739. [Google Scholar] [CrossRef]

- Dorner, D.; Funke, J. Complex Problem Solving: What It Is and What It Is Not. Front Psychol. 2017, 8, 1153. [Google Scholar] [CrossRef] [PubMed]

- Qi, L.; Gonzalez, C. Mathematical knowledge is related to understanding stocks and flows: Results from two nations. Syst. Dyn. Rev. 2015, 31, 97–114. [Google Scholar] [CrossRef]

- Sweeny, L.B.; Sterman, J. Cloudy skies: Assessing public understanding of global warming. Syst. Dyn. Rev. 2005, 18, 207–240. [Google Scholar]

- Gary, M.S.; Wood, R.E. Unpacking mental models through laboratory experiments. Syst. Dyn. Rev. 2016, 32, 101–129. [Google Scholar] [CrossRef]

- Warren, K. Competitive Strategy Dynamics; John Wiley & Sons: Chichester, UK, 2008. [Google Scholar]

- Forrester, J.W. Market Growth as Influenced by Capital Investment. Ind. Manag. Rev. 1975, 9, 23. [Google Scholar]

- Morecroft, J.D. Strategic Modelling and Business Dynamics; John Wiley & Sons: Chichester, UK, 2015. [Google Scholar]

- Oliva, R.; Sterman, J.D.; Giese, M. Limits to growth in the new economy: Exploring the “Get Big Fast” strategy in e-commerce. Syst. Dyn. Rev. 2003, 19, 83–117. [Google Scholar] [CrossRef]

- Sterman, J.D.; Henderson, R.; Beinhocker, E.D.; Newman, L.I. Getting Big Too Fast: Strategic Dynamics with Increasing Returns and Bounded Rationality. Manag. Sci. 2007, 53, 683–696. [Google Scholar] [CrossRef]

- Arango, S.; Larsen, E. Cycles in deregulated electricity markets: Empirical evidence from two decades. Energy Policy 2011, 39, 9. [Google Scholar] [CrossRef]

- Schaffernicht, M.F. Causal loop diagrams as means to improve the understanding of dynamic problems: A critical analysis. Syst. Res. Behav. Sci. 2010, 27, 13. [Google Scholar]

- Sterman, J. Business Dynamics—Systems Thinking and Modelling for a Complex World; McGraw Hill: New York, NY, USA, 2000. [Google Scholar]

- Groesser, S.N.; Schaffernicht, M.F. Mental models of dynamic systems: Taking stock and looking ahead. Syst. Dyn. Rev. 2012, 28, 22. [Google Scholar] [CrossRef]

- Sweeney, L.B.; Sterman, J. Thinking about systems: Student and teacher conceptions of natural and social systems. Syst. Dyn. Rev. 2007, 23, 285–312. [Google Scholar] [CrossRef]

- Rahmandad, H.; Repenning, N.; Sterman, J. Effects of feedback delay on learning. Syst. Dyn. Rev. 2009, 25, 309–338. [Google Scholar] [CrossRef]

- Arango, A.S.; Castañeda, A.J.A.; Olaya, M.Y. Laboratory experiments in the system dynamics field. Syst. Dyn. Rev. 2012, 28, 94–106. [Google Scholar] [CrossRef]

- Byrne, R.M.J.; Johnson-Laird, P.N. If and or: Real and counterfactual possibilities in their truth and probability. J. Exp. Psychol. Learn. Mem. Cogn. 2020, 46, 760–780. [Google Scholar] [CrossRef]

- Johnson-Laird, P.N. Mental Models Towards a Cognitive Science of Language; Cambridge University Press: Cambridge, UK, 1983. [Google Scholar]

- Johnson-Laird, P.N.; Byrne, R.M.J. Conditionals: A theory of meaning, pragmatics, and inference. Psychol. Rev. 2002, 109, 646–678. [Google Scholar] [CrossRef] [PubMed]

- Ragni, M.; Johnson-Laird, P. Reasoning about epistemic possibilities. Acta Psychol. 2020, 208. [Google Scholar] [CrossRef]

- Langan-Fox, J.; Anglim, J.; Wilson, J.R. Mental Models, Team Mental Models, and Performance: Process, Development, and Future Directions. Hum. Factors Ergon. Manuf. 2004, 14, 21. [Google Scholar] [CrossRef]

- Mohammed, S.; Klimoski, R.; Rentsch, J.R. The Measurement of Team Mental Models: We Have No Shared Schema. Organ. Res. Methods 2000, 3, 123–165. [Google Scholar] [CrossRef]

- Schaffernicht, M.F. Causal attributions of vineyard executives—A mental model study of vineyard management. Wine Econ. Policy 2017, 6, 107–135. [Google Scholar] [CrossRef]

- Schaffernicht, M.F. Unrecognized interdependencies in mental models—The case for taking feedback loops into account. Syst. Res. Behav. Sci. 2019, 36, 580–603. [Google Scholar] [CrossRef]

- Johnson-Laird, P.N. Mental models and human reasoning. Proc. Natl. Acad. Sci. USA 2010, 107, 18243–18250. [Google Scholar] [CrossRef] [PubMed]

- Wolstenholme, E. Using generic system archetypes to support thinking and modelling. Syst. Dyn. Rev. 2004, 20, 341–356. [Google Scholar] [CrossRef]

- Damasio, A. The Strange Order of Things; Vintage Books: New York, NY, USA, 2018. [Google Scholar]

- Richardson, G.P. Feedback Thought in Social Science and Systems Theory; University of Pennsylvania Press: Philadelphia, PA, USA, 1991. [Google Scholar]

- Viru, A. Early contributions of Russian stress sand exercise physiologists. J. Appl. Physiol. 2002, 92, 1378–1382. [Google Scholar] [CrossRef] [PubMed]

- McEwen, B.S. Central Role of the Brain in Stress and Adaptation: Allostasis, Biological Embedding, and Cumulative Change. In Stress: Concepts, Cognition, Emotion, and Behavior; Fink, G., Ed.; Academic Press: Cambridge, MA, USA, 2016; pp. 39–55. [Google Scholar]

| Generic Policy | Resource | |

|---|---|---|

| Salesforce | Production Capacity | |

| GP1 | Reinforcing | Balancing |

| GP2 | Balancing | Reinforcing |

| GP3 | Reinforcing | Reinforcing |

| Week | P1 | P2 | P1 50% | P1 75% | P2 Limited |

|---|---|---|---|---|---|

| 1 | 30,000 | 30,000 | 30,000 | 30,000 | 30,000 |

| 2 | 31,875 | 37,031 | 35,531 | 36,844 | 31,875 |

| 3 | 35,625 | 45,938 | 45,750 | 48,844 | 35,625 |

| 4 | 39,375 | 52,125 | 59,344 | 65,156 | 39,375 |

| Indicator | Specific Policy | ||

|---|---|---|---|

| P1 Default | P2 Default | P3 Default | |

| Parameters | |||

| policy implementation fraction | 0.2 | 0.7 | 0.6 |

| revenue fraction for salesforce salaries | 25% | n.a. | 25% |

| Model Variables | |||

| Sales Force | 398 | 12,656 | 398 |

| Theoretically sellable | 3585 | 113,907 | 3585 |

| Production Capacity | 5930 | 118,860 | 6200 |

| Production capacity surplus or lack absolute | 2344 | 4952 | 2615 |

| Production capacity surplus or lack relative | 65% | 4% | 73% |

| Accumulated deliveries | 66,284 | 823,596 | 66,284 |

| Accumulated excess production capacity | 68,859 | 65,959 | 68,723 |

| Accumulated excess salesforce | 0 | 0 | 0 |

| Delivery delay real | 2.0 | 2.0 | 2.0 |

| Accumulated profits | −126,630,840 | −5,700,338,232 | −89,220,517 |

| Additional Indicators | |||

| Additional deliveries | 49,004 | 806,316 | 49,004 |

| Total growth in % | 284% | 4666% | 284% |

| Monthly growth rate | 9% | 38% | 9% |

| Steady state deliveries at end of year | 49,004 | 806,316 | 49,004 |

| Accelerating growth | Yes | Yes | Yes |

| Behavior smoothness of resources | Continuous | Continuous | Continuous |

| Strength of growth | Moderate | Extreme | Moderate |

| Sustainable | Yes | Yes | Yes |

| Delivery delay behavior | Steady | Steady | Steady |

| Delivery delay values | Constant | Constant | Constant |

| Likely to be followed | Yes | Tes | Yes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schaffernicht, M.F.G. Three Generic Policies for Sustained Market Growth Based on Two Interdependent Organizational Resources—A Simulation Study and Implications. Systems 2021, 9, 43. https://doi.org/10.3390/systems9020043

Schaffernicht MFG. Three Generic Policies for Sustained Market Growth Based on Two Interdependent Organizational Resources—A Simulation Study and Implications. Systems. 2021; 9(2):43. https://doi.org/10.3390/systems9020043

Chicago/Turabian StyleSchaffernicht, Martin F. G. 2021. "Three Generic Policies for Sustained Market Growth Based on Two Interdependent Organizational Resources—A Simulation Study and Implications" Systems 9, no. 2: 43. https://doi.org/10.3390/systems9020043

APA StyleSchaffernicht, M. F. G. (2021). Three Generic Policies for Sustained Market Growth Based on Two Interdependent Organizational Resources—A Simulation Study and Implications. Systems, 9(2), 43. https://doi.org/10.3390/systems9020043