Abstract

Autonomous production needs to be reliable. Outputs from reliable production systems consistently conform to performance requirements. By contrast, outputs from unreliable production systems often do not conform to performance requirements. Unreliable production can lead to accidents, rework, scrap, loss of good will, etc. In this communication paper, comparative analyses are provided of work characteristics in the manufacturing and construction industries, which affect opportunities for reliable high-level autonomous production systems. Analyses indicate that there are strong opportunities and weak opportunities for reliable high-level autonomous production systems in these industries. In the strongest opportunities, there is repeated work certainty; the composition of work involves few materials/parts that have little variation; and work is carried out in settings that require no additional engineering to facilitate reliable autonomous production. In the weakest opportunities, work settings require extensive additional engineering; the composition of work involves many materials/parts that have lots of variation; the work to be done is not certain until completion and then it is never repeated. It is explained that when seeking to improve weak opportunities for reliable high-level autonomous production systems, industrial engineering methods and situation awareness modelling can be combined within a critical realist framework in order to address challenges in work setting, composition and uncertainty.

1. Introduction

There are levels of autonomous systems: for example, 1–6 [1]. Although high-level autonomous production systems are necessary to enable high-levels of autonomous production, they are not sufficient to enable reliable conformance to production performance requirements. Rather, as with any production system, the deployed system needs to be compatible with work characteristics in order for there to be reliable conformance to production performance requirements in practice [2,3,4].

Autonomous production technologies go beyond conventional automation by having autonomous cognition, which can involve sensing, awareness, deciding, acting, adapting and learning [5]. Autonomous cognition is being introduced by vendors into updates of their established production technologies. Also, autonomous cognition is included in new kinds of production technologies such as mobile robots used in building construction. Overall, different types of production technologies are being combined in autonomous production systems. For example, industrial company Komatsu is working with high-tech firm NVIDIA to introduce autonomous systems for carrying out raw material extraction at mines, and for groundworks at construction sites [6]. However, the potential for reliable implementation of high-level autonomous production systems is affected by work characteristics in the manufacturing and construction industries.

First, in this communication paper, work characteristics affecting potential for reliable implementation of high-level autonomous production systems are explained in terms of work setting, work composition, and work certainty. Next, strong and weak opportunities for reliable high-level autonomous production systems are described for two industries: manufacturing and construction. Then, it is explained how weak opportunities for reliable high-level autonomous production can be improved through the application of industrial engineering methods and situation awareness modelling within a critical realist framework. In conclusion, principal contributions are stated, together with implications for research and for practice.

2. Work Characteristics’ Challenges to Reliable High-Level Autonomous Production

2.1. Work Setting

2.1.1. Overview

Potential for reliable high-level autonomous production systems is affected by the distribution and regularity of work settings. Lots of production work needs to be widely distributed and must take place in settings that have irregular characteristics. For example, much of the world’s agri-food production begins on small holdings at different altitudes where there are different ground and weather conditions [7]. At low altitude on flat ground, autonomous cognition by farming robots is more technically feasible than at high altitude on uneven sloping ground. This is because of difficulties in farming robots maintaining stability and difficulties in taking accurate data from sensors in adverse conditions, such as from computer vision during the mist, rain and wind of higher altitudes. Subsequently, there are risks of incorrect action selection from computation of inaccurate sensor data. Work settings can be engineered to better facilitate the reliable operation of autonomous systems, but this can be very complicated and expensive. For example, it is recognized in Vehicle–Infrastructure Integration initiatives throughout the world that the extent of driverless vehicle autonomy will depend upon the extent of autonomous vehicle integration with new types of smart vehicle infrastructure. Accordingly, public roads are being re-engineered to be smart roads that provide “cooperative infrastructure” for autonomous vehicles. This involves a range of costly engineering activities. For example, the installation of V2X (Vehicle-to-Everything) WiFi enables traffic lights to communicate with nearby cars. Also, sensors are being developed to be integrated into road surfaces. These in-road sensors are intended to detect the passage of traffic in real time. They can be used to inform communication to autonomous vehicles by new types of smart road signage. In addition, there is the need for overhead cameras that send alerts to autonomous vehicles in the event of an emergency that cannot be detected by road sensors, such as an animal straying onto a road. Further smart road developments include engineering power-generating road surfaces that have technologies for recharging autonomous vehicles as they drive along the road surface. Overall, these investments in smart “cooperative infrastructure” do not engineer out all possible irregularities in the operation of autonomous vehicles. Rather, they are intended to engineer out the effects of irregularities in the operation of autonomous vehicles. For example, an animal may stray on to a road but, if the various sensors and signals of smart “cooperative infrastructure” function as intended, that will not cause a vehicle crash. The economic viability of engineering work settings depends on the costs and number of operations over which the costs can be spread. For example, power-generating road surfaces that charge autonomous vehicles cost several million euros per kilometre/dollars per mile. Such costs can perhaps be absorbed over main roads with a high frequency of autonomous vehicles, but can be prohibitively expensive for low-frequency roads and for off-road locations [8,9,10,11].

2.1.2. Manufacturing Industry

Physical production in the manufacturing industry can be considered in terms of the following phases: raw materials extraction/harvesting, converting raw materials into processed materials, manufacturing parts, and assembling goods. In terms of work settings, sites of raw materials extraction/harvesting can be highly distributed and have irregular conditions. Hence, the prospects for reliable autonomous production can depend upon the economic viability of engineering the effects of irregularities out of work settings to facilitate accurate autonomous sensing, which provides the basis for effective autonomous deciding and acting. The cost of engineering work settings for autonomous materials extraction is illustrated by the mining corporation Rio Tinto’s plan to spend more than two billion U.S. dollars to develop an “intelligent” iron ore mine, which will incorporate driverless vehicles and robotics [12]. By contrast, much of converting raw materials, manufacturing parts, and assembling goods is already concentrated in factories, where work settings are conducive to sensing and awareness by autonomous robots and vehicles. For example, automated guided vehicle systems (AGVS) are used extensively inside factories to move materials, components, and goods. Factories are well suited to providing “cooperative infrastructure” for automated guided vehicles (AGV) to operate in. In particular, factories have controlled internal environments where markers, wires, etc., can be easily set up and maintained for AGVs to follow predetermined routes. Also, factories have controlled internal environments that are well suited to more sophisticated AGV navigation methods. For example, AGVS laser navigation involves mounting reflective tape on factory fixtures. The AGV carries a laser transmitter and receiver via which laser information is compared to the map of the reflector layout stored in the AGV’s memory. This allows the AGVS to triangulate the current position of the AGV and guide travel to its destination by constantly updating the position. Thus, “vehicle–infrastructure integration” is commonplace in factories where the positions of loading bays, storage spaces, work stations, etc., are fixed for long durations and are always protected from adverse weather conditions that could be detrimental to AGVS operations [13].

2.1.3. Construction Industry

Physical production in construction industry can be considered in terms of the following phases: raw materials extraction; site works; continuous processes, such as concrete pouring, slip forming and large-scale 3D printing; and combining discrete materials/parts/goods produced by companies in the manufacturing industry as components for building construction, such as paints, concrete blocks, screws, door sets, and bathroom modules. Issues involved in raw materials extraction are similar to those in the manufacturing industry, and issues involved in site works are much the same as for raw materials extraction. Specifically, if it is economically viable to engineer the effects of irregularities out of work settings for autonomous operation, then autonomous vehicles and robots can be used. This can be difficult at any small construction site, and particularly difficult for building renovation work settings where many existing features have to be worked around and existing surfaces have to be protected for preservation: rather than engineered to suit the temporary needs of autonomous construction activities [14]. More generally, when compared to factories, construction sites do not have loading bays, storage spaces, work stations, etc., that are in fixed positions for long durations. Rather, the positions of loading bays, storage spaces, work stations, etc., change as work progresses from site works to combining materials in substructures to combining parts in superstructures to combining goods in internal fit-outs. Furthermore, it is often only in the later stages of construction projects when there can be controlled internal environments that could facilitate AGV navigation, which could cope with frequently changing layouts of workspaces. Moreover, when compared to public roads, construction sites do not provide the high volume of traffic needed to recover the costs of investment in vehicle–infrastructure integration technologies. Hence, when compared to factories and to public roads, construction sites are much more challenging locations for economically viable engineering of “cooperative infrastructures” for autonomous production systems. Thus, human operated moveable cranes, rough terrain forklift trucks, pallet jacks, etc., continue to be widely used on construction sites as economically viable robust solutions for irregular work settings.

2.2. Work Composition

2.2.1. Overview

Work composition includes the number and variability of materials/parts. If materials/parts are always the same, reliable autonomous production is technically feasible. If there are many materials/parts that are always the same, then investment in autonomous production is economically viable. Here, always the same means conformance to production process parameters. For example, materials extracted from mines may have many different geometries, but they are effectively all the same if they can be handled by the same designated equipment. More difficult to handle variability can be natural, such as in foodstuffs, and/or can take place through production such as the deforming of textiles during apparel production. The more variability there is, the more sophisticated the computer vision, image processing, and handling manipulators, etc. that are needed in autonomous sensing and acting [15].

2.2.2. Manufacturing Industry

In terms of work composition, the number and variability of material types can be low in raw materials extraction/harvesting, converting raw materials, and manufacturing parts. The number of parts in the assembly of goods depends on the type of good and can range from less than 10 (e.g., in a simple toy) to more than 10 thousand (e.g., in an aeroplane). The variability of parts will typically be within agreed parameters, which are stable other than for parts in soft products such as apparel [15]. Hence, accurate autonomous sensing of work composition is technically feasible in most of the manufacturing industry.

2.2.3. Construction Industry

Work composition involves formless materials (e.g., paint), formed materials (e.g., concrete blocks), loose parts (e.g., screws), sub-assemblies (e.g., door sets), assemblies (e.g., bathroom modules). There can be on-site deformation of components, such as twisting of door set frames due to damp air. In addition, there can be unpredictable variation at interfaces, such as between door openings in walls built with concrete blocks and wooden door sets. Consequently, much more computational effort is required for accurate autonomous combining materials/parts/goods in building construction than in manufacturing industry assembly of parts that have all been designed specifically to fit together for one particular product.

2.3. Work Certainty

2.3.1. Overview

The timing, extent and repetition of work certainty affect the potential for reliable autonomous production. If all the work to be undertaken is always certain from the outset, then reliable autonomous production can be technically feasible and economically viable—for example, in so called “lights-out” factories where no lighting is needed because no human workers are involved [16]. By contrast, if work to be done is not certain until its completion and subsequently there is no repetition of that certainty, such as in building renovations, then autonomous production is less likely to be technically feasible and economically viable. In particular, continual work uncertainty increases the difficulty of achieving accuracy in autonomous learning and adapting.

2.3.2. Manufacturing Industry

In terms of work certainty, production operations in raw materials extraction/harvesting and converting raw materials typically involve high repetition of certainty that is defined before work begins. Work certainty in assembling goods depends upon how much authority is given to individual customers. Make-to-stock (MTS) production is characterized by work certainty. By contrast, engineer-to-order production (ETO) is based on eliciting requirements from individual customers. Hence, there is little or no repetition of work certainty because individual customers have diverse requirements. The more uncertainty there is, the more challenging is autonomous transfer learning, which enables accurate autonomous adaptation. This is case even for assemble-to-order (ATO) production that offers individual customers more choice than MTS, but less authority than ETO [14]. For example, Mercedes has replaced robots with human workers in the assembly of its S-Class sedan car, because of the number of vehicle options and the frequency with which it changes the kinds of options being offered [17].

2.3.3. Construction Industry

To meet customer-specific and location-specific requirements, many buildings are engineered to order. Even where more building standardization is possible, such as petrol stations and drive-through restaurants, site works will be location-specific and characterized by work uncertainty. In addition, building standardization does not necessarily bring work certainty to continuous process, such as concrete pouring at an inner city construction site. While driving the concrete pump through inner city traffic can eventually be within the scope of autonomous vehicles, repeatedly positioning and repositioning the hose of a concrete pump when pouring concrete is a far more dynamic operation. This is because of the uncertainty about where each hose position will be, uncertainty about the amount of force needed to hold the hose in each position, and uncertainty about deformation of the hose. Moreover, there is often little work certainty to facilitate autonomous combining parts/goods. For example, what is to be picked and placed at construction sites, and where it is to be picked from and placed to, can be uncertain from one day to the next as work progresses. Hence, the opportunities for autonomous learning and adaptation can be limited.

2.4. Strong and Weak Opportunities for Reliable High-Level Autonomous Production

A summary of the relative strength of opportunities for reliable high-level autonomous production is provided in Table 1.

Table 1.

Strong and weak opportunities for reliable high-level autonomous production.

In particular, the opportunities for reliable high-level autonomous production are strongest in the manufacturing industry during make-to-stock (MTS) production inside factories. They are weaker in the manufacturing industry when there is work uncertainty, such as in engineer-to-order, and/or work settings have irregular conditions. Work certainty can be increased through increased standardization, but this can be contrary to the demand for increased personalization [17]. Work settings can be engineered to better facilitate autonomous production, but this can be extremely costly [12].

Opportunities for reliable high-level autonomous production in the construction industry are often weaker than in the manufacturing industry. This is because of the comparative difficulty of engineering irregularity effects out of work settings to facilitate autonomous production, the wider variation in work composition, and less frequent work certainty. Together, these factors combine to increase the difficulty of implementing autonomous cognition during production operations.

Furthermore, in the manufacturing industry, any additional costs incurred to better enable operation of autonomous production technologies can be recovered from many sales of the same good. By contrast, in the construction industry, costs incurred to facilitate implementation of autonomous production often need to be recovered from one project.

3. Critical Realist Framework for Improving Autonomous Production Reliability

3.1. Critical Realism

Critical realism is a philosophy of science that can provide a unifying framework for application of industrial engineering methods and situation awareness modelling. This is because it is recognized within critical realism that reality is an open system in which the effectiveness of causal mechanisms (e.g., autonomous production technologies) is dependent upon them acting with appropriate causal contexts (e.g., work setting, work composition, work certainty). Moreover, critical realism is a philosophy of science that is open to practical application through reference to any individual methods that can be combined in order to address causal mechanisms and causal contexts. Thus, critical realism is not in competition with existing methods. Rather, it is a philosophy of science that can provide a unifying direction for the combination of diverse methods. Overall, the critical realist perspective is that the exact details of appropriate causal context (e.g., work characteristics) to enable effective operation of a causal mechanism (e.g., autonomous production technology) cannot be known at the outset. Rather, initial proposals as to what might be the appropriate causal context evolve as understanding increases through investigation. This is because causation in the real world is open to a huge range of codetermining factors [18,19].

3.2. Industrial Engineering Methods

Industrial engineering seeks to optimize complex production processes. Industrial engineering methods can be used to develop and control production processes that are designed to generate most value for lowest resource consumption. Methods to develop production processes include task analysis, design for manufacture and assembly (DFMA), failure modes and effects analysis (FMEA), and job design [20,21,22]. Methods to control production processes include statistical process control (SPC), which is often implemented with the slogan, Six Sigma [23,24]. Thus far, these methods have been applied mostly to make-to-stock (MTS) and assemble-to-order (ATO) production inside factories: rather than to engineer-to-order (ETO) production outside of factories.

One reason has been that industrial engineering methods depend upon the extensive sampling and processing of production data to inform iterations of assessment–improvement–reassessment during the development of production processes [25]. Beyond MTS and ATO inside factories, it has been much more difficult to sample and process production data. Now, however, data sampling and processing for the development of production processes is becoming more possible. This is because of the introduction of Big Data Analytics technologies into ETO production [26,27]. For example, video recordings of construction processes can be analysed to reveal common features across different operations [28]. Also, video recordings can be analysed to identify safety issues during construction work [29]. In addition, databases linked to digital building models can be analysed to assign work optimally within time constraints [30]; and to reveal causes of delays in construction work [31]. Furthermore, there is now increased potential for assessment–improvement–reassessment during production processes through rapid iterations with digital simulation models, which are being introduced into ETO production [32,33]. For example, the alternative pathways for the movement of construction resources on congested construction sites can be simulated [34]. Also, productivity can be simulated as an emergent property of interactions between individual workers and groups of workers [35]. In addition, digital simulation models can be applied to assess and improve strategies for dealing with unexpected circumstances during construction operations [36]. Importantly, there are some advances in automated collection by on-site sensors of direct inputs into digital simulation models [37]. Such analyses and simulations are mostly at the stage of proof-of-concept demonstrations, but indicate that there is increasing potential for production data sampling and processing beyond MTS and ATO factory production.

Task analysis, DFMA, FMEA, and job design can be applied to basic motions. For example, the basic motions of laying bricks, such as picking, orientating and placing, can be analysed and designed for maximum efficiency. Indeed, organizations that are developing autonomous construction equipment, such as bricklaying robots, undertake thorough task analysis, job design, and DFMA in order to enable high speed picking, orientating, and placing of bricks by robots arms. For example, DFMA design rules and strategies can be applied to develop bricks with shapes that are easy to robots to handle [38]. The introduction of Big Data Analytics and simulation modelling into ETO can enable assessment–improvement–reassessment of basic motions such as picking, orientating and placing. However, the process of entire ETO operations, such as building entire walls, can have too little work certainty, too varying work compositions, and too irregular work settings to be generalized as a standardized job design, which can be assessed, improved, and reassessed in process. Nonetheless, the well-established industrial engineering method of statistical process control (SPC) can be applied to control specific outcomes of many ETO operations, such as building entire walls.

In particular, upper and lower specification limits can be set for main process variables using process capability indices. These indices provide statistical measures of the capability of a process to produce output within production specification limits. Process capability indices have a specified mean value together with upper specification limits (USL) and lower specification limits (LSL). The reason SPC is often implemented with the slogan Six Sigma is that sigma or σ is the symbol for standard deviation, which is term used for the spread around the mean value. The drift of production processes away from the mean value towards either of these limits should lead to production processes being slowed or being stopped and corrected. Typically, if a process operates within six standard deviations (i.e., six sigma) between USL and LSL, it is a reliable process that conforms efficiently to production performance requirements [23,24].

The ranges between specification limits (SL) in ETO work can be far higher than the miniscule ranges of hundredths of millimetres that are common in precision engineering applied in MTS. For example, in brick construction work, a range of 10 millimetres (mm) in straightness between USL and LSL is permissible for walls of any length up to five meters (m). In other words, a building inspector will approve brickwork if it bends in its length up to 10 mm in 5 m, but will not approve the brickwork if it bend 11 mm or more in 5 m of length. If the wall is over 5 m long the maximum range should be no more than 15 mm. Thus, specification ranges that would be impossibly large in MTS production are common in ETO [39].

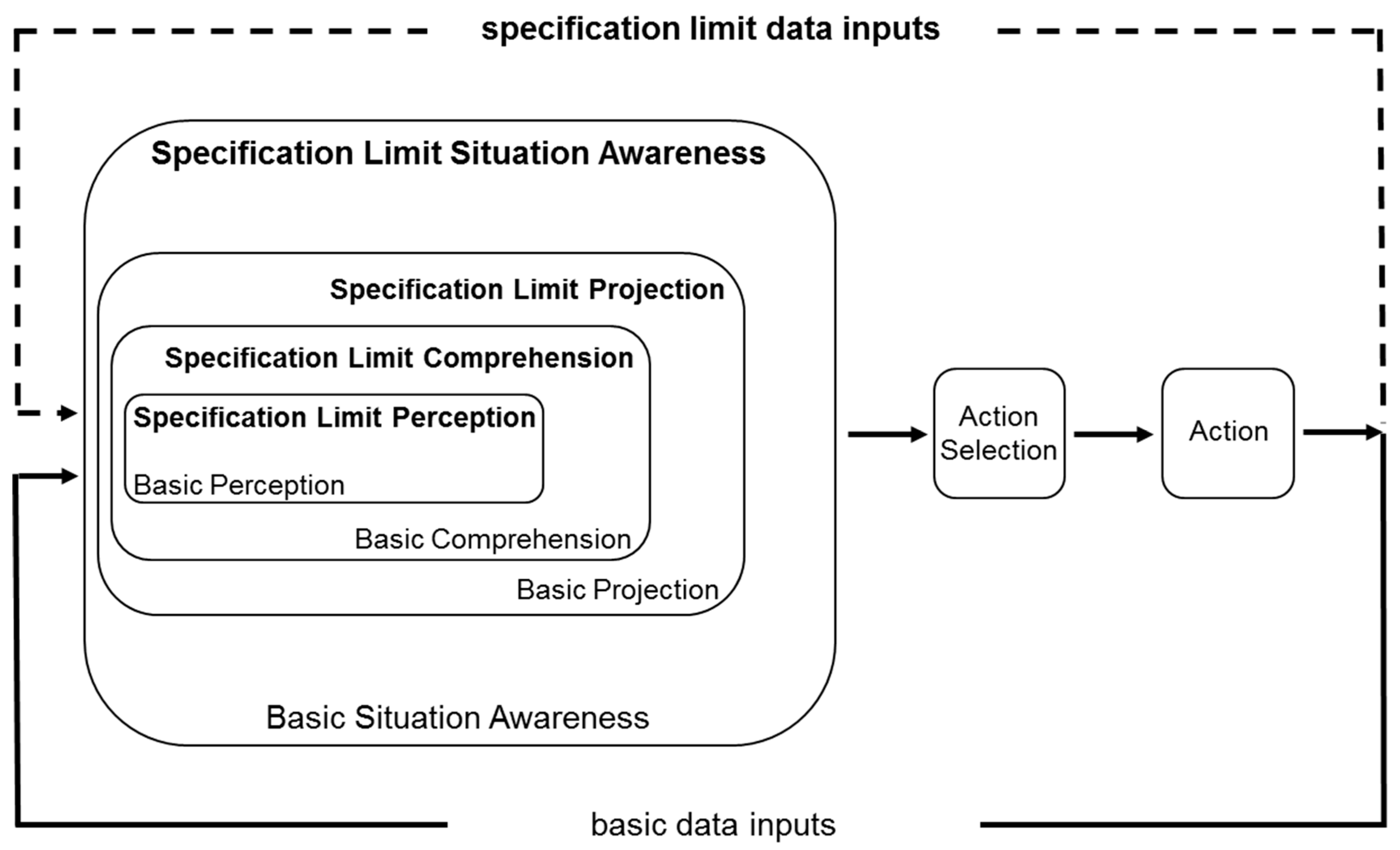

3.3. Situation Awareness Modelling

Situation awareness involves perception, comprehension and projection [40,41]. Typically, the higher the level of autonomous production, the higher the level of autonomous situation awareness that is needed by autonomous technologies [42]. Enabling production technologies with autonomous situation awareness is a formidable challenge for computer science [43,44]. However, computational complexity can be reduced if modelling of situation awareness includes definition of consistent parameters and design of clear parameter markers. In order to better enable accurate situation awareness when there are challenging work settings, visual controls and other types of clear markers can be related to SPC specification limits (SL). Where there are insufficient financial resources to engineer irregularity effects out of work settings fully, this can be a low cost means of making at least some progress towards work settings being compatible with reliable high-level autonomous production. Also, recognition of parts within work composition can involve defining appropriate USL and LSL for different types of components. If SL markers are very clear and very durable, they can increase potential for consistent conformance to production requirements by making USL and LSL explicit in production beyond MTO and ATO inside factories. A model of situation awareness that incorporates the addition of SL data inputs is shown in Figure 1.

Figure 1.

Specification limit situation awareness.

This model is based on the widely applied three-level situation awareness construct that integrates perception, comprehension and projection [40,45]. Perception involves the processing of data inputs for multiple situational variables. It can be expected that robots, such as bricklaying robots, will be preprogrammed to process data inputs for basic motions such as picking, orientating, and placing bricks. For example, the robot will be equipped with sensors that provide data inputs about what basic motion in currently in progress. Also, robots will be preprogrammed for situation comprehension through synthesis and evaluation of basic inputs. In addition, robots will be preprogrammed to project multiple situational variables into action selections, such as picking the next brick to be orientated and placed. SL situation awareness can be added to basic perception, comprehension and projection through relatively simple means. For example, a laser transmitter/receiver can be attached to a robot for the purpose of determining the distance between the vertical surface of a brick wall as it is constructed and SLs. The USL and LSL can be marked, for example, with reflective tape mounted onto moveable stands, which are positioned the appropriate distance from the location of wall surfaces. As with laser transmitter/receivers on AGVs, distances can be calculated automatically. Then, the robot can be automatically stopped if the distance between USL or LSL and the wall surface is close to the SL maximum. Thus, the robot is not integrated into the working environment as with Vehicle—Infrastructure Integration for public main roads. Rather, some targeted simple temporary works can be carried out in the work environment to make it a more “cooperative infrastructure” for important tasks as they arise amidst the changing work layouts of ETO production. However, it is essential that such situation awareness modelling should encompass the extremes of work characteristics, such as high winds and heavy rain at locations of changeable ground conditions. This is necessary to ensure that situation awareness can be accurate enough in practice to enable appropriate autonomous action selection [46].

3.4. Combination of Methods and Modelling within a Critical Realist Framework

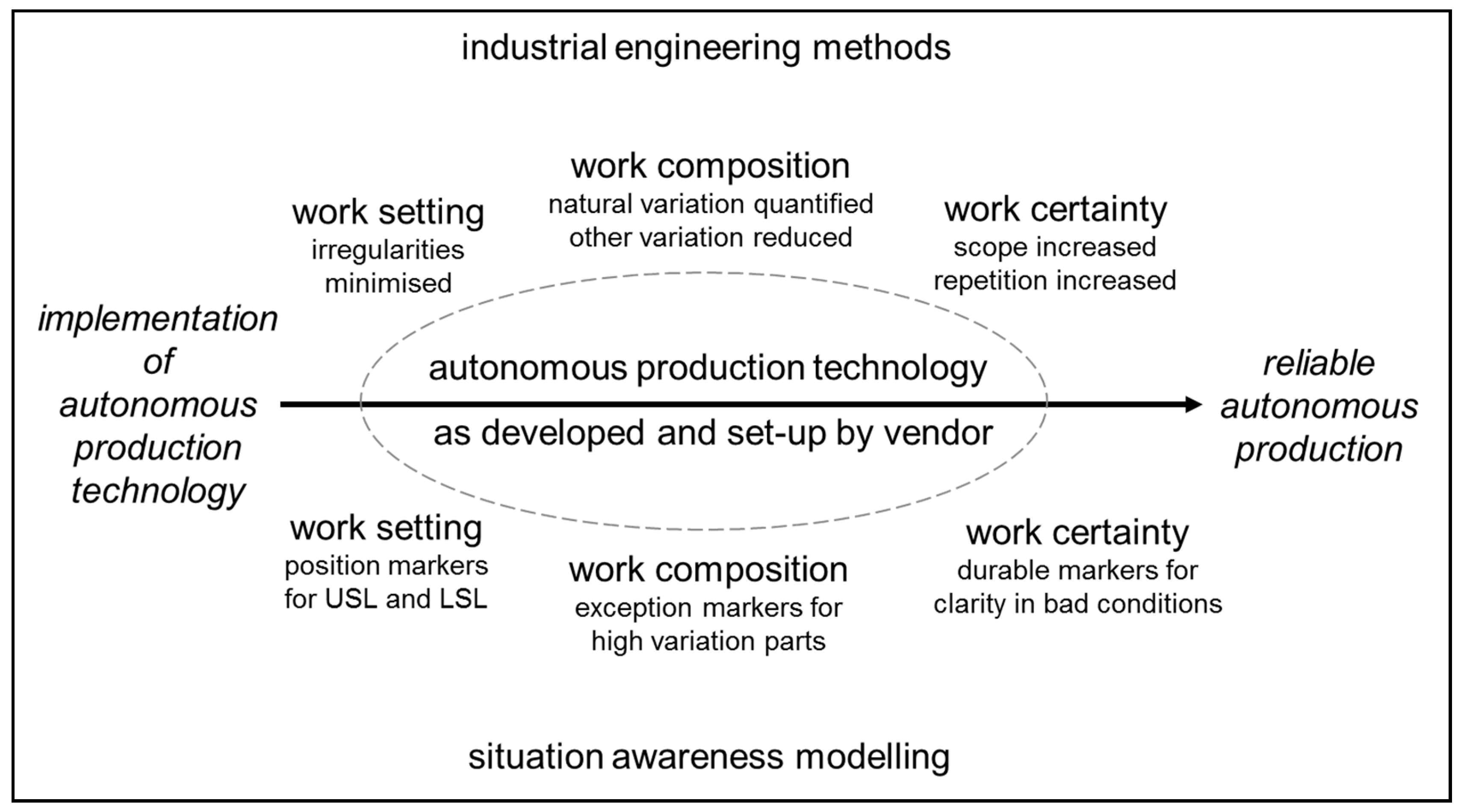

A critical realist diagram is shown in Figure 2. This illustrates that the achievement of a desired outcome from a planned action depends on both the causal mechanism and the causal context. As indicated in Figure 2, many of the small- to medium-sized enterprises working in the manufacturing and construction industries can apply industrial engineering methods and non-computational situation awareness modelling to improve the compatibility of work characteristics with autonomous production technologies.

Figure 2.

Combining industrial engineering methods and situation awareness modelling in critical realist design of reliable autonomous production systems.

As summarized in Figure 2, industrial engineering methods can be applied to minimize irregularity effects at work settings in so far as is possible within financial constraints; to reduce non-value adding variations in work composition, and to increase work certainty wherever it is possible without reducing sales by limiting customer choice. Situation awareness modelling can include identifying where position markers for USL and LSL should be located at work settings; identifying which parts in the composition of work should be marked as being prone to variation; and designing durable markers in order to maintain work certainty in all conditions.

4. Conclusions

4.1. Implications for Theory Building

Within critical realism, causal mechanisms in real-world activities may be generalizable, but will only enable intended outcomes if those causal mechanisms operate within appropriate causal contexts. Thus, critical realism is different to other philosophies of science. For example, positivism seeks to define causation in terms of generalizable laws that will operate irrespective of context, while interpretivism eschews generalizable causation in favour of the notion that reality is always a subjective construction. Also, critical realism differs from design science that often overlooks underlying causation in technology-orientated cycles of build-and-evaluate [47,48]. This communication paper provides a starting point for critical realist theory building for autonomous production systems. In particular, research that seeks to determine how and where causation can be generalized across the diversity of many real-world implementations in the manufacturing and construction industries.

For example, extant research into autonomous systems involves theoretical formulations such as the Paperclip Maximizer and the Trolley Problem. The widely debated Paperclip Maximizer though experiment involves an autonomous production system being programmed to turn all matter, including human beings, into paperclips or machines that manufacture paperclips. This speculative formulation is intended to illustrate that autonomous systems pose existential threats to humanity even when robots are programmed to pursue seemingly harmless goals [49,50]. However, thought about this thought experiment has hitherto failed to recognize the work characteristic challenges involved in raw materials extraction/harvesting. Moreover, it has failed to recognise that challenges could be greatly exacerbated by human beings deliberately increasing work setting irregularities, increasing work composition variations, and reducing work certainty. This is possible through applying industrial engineering methods and situation awareness modelling to prevent, rather than facilitate, the reliable operation of autonomous production systems intent on paperclip maximizing at the cost of humanity. Another well-known speculative formulation is the Trolley Problem thought experiment, which is widely applied in debate about driverless cars [51,52]. This involves a runaway trolley being about to hit and kill five people who are tied up and unable to move. The trolley can be diverted but only to an alternative track where there is one other person tied up and unable to move. There are only two options within the conventional thought of the Trolley Problem thought experiment: do nothing and the trolley kills the five people on the main track or divert the trolley onto the side track where it will kill one person. However, from the critical realist perspective, there is certainly another option: apply industrial engineering methods and situation awareness modelling to work characteristics so that it is not possible to tie people up onto the paths of moving trolleys and/or for the presence of stationary loads on the track to reduce the trolley to a harmless speed.

These examples illustrate the need for critical realism to be applied to bring speculative theorizing about autonomous production systems into the scope of critical realist framing of challenging work characteristics and the different opportunities for these to be addressed through industrial engineering methods and situation awareness modelling.

4.2. Implications for Applied Research

In addition to providing a philosophy of science for theory building, critical realism can also provide a framework for applied research. Importantly, critical realism is a philosophy of science that is open to practical application through reference to any individual scientific theories and use of any individual research methods. Most relevant to application of critical realism to improving the reliability of autonomous production systems is action research. In addition to the traditional research objectives of improving explanation and prediction of complex phenomena, action research aims to influence or to change some aspect of whatever is the focus of the research [53,54]. For this topic, the purpose of future action research would be to change the reliability of autonomous systems from dependence upon massive capital investment in engineering entire infrastructures. In particular, we can enable reliable autonomous production systems through targeted applications of industrial engineering and situation awareness modelling. Action research evolves in stages that are not fully defined at the outset. Rather, the findings of each stage lead to the development of the next stage [55,56]. This is entirely compatible with the critical realist perspective that causal mechanism and causal context cannot be known at the outset. Rather, initial proposals as to what might be causal mechanism and causal context evolve as understanding increases through research [18,19]. Furthermore, both critical realism and action research involve abductive reasoning. This involves inferring causal mechanism and context for a particular situation through iterative cycles of reference to theories and observations. By contrast, inductive reasoning involves moving from observation to theory; and deductive reasoning involves moving from theory to observation [57].

A first stage of critical realist action research could be to define the state of the art for autonomous production technologies through multi-vocal literature review and vendor demonstrations. Multi-vocal literature reviews extend beyond scientific literature to online reports. Multi-vocal literature review is appropriate when the topic of a study is developing quickly and/or there few scientific papers on the topic [58]. A second stage could be to trial operation of the autonomous production in mock-ups of work characteristics in order to inform task analysis and failure modes and effects analysis (FMEA). A third stage could also be trails carried out in mock-ups. This could involve preliminary application of design for manufacture and assembly (DFMA) and job design, together with application of situation awareness modelling. Initial trails in mock-ups can be framed as pre-tests and follow-up trials could be framed as post-tests in quasi-experimental testing of the efficacy of industrial engineering methods and situation awareness modelling. However, the purpose of action research is to bring about change. Accordingly, post-test findings should be used straightaway in the next stages of critical realist action research to improve the match of work characteristics to the autonomous production technology. After mock-up stages, action research can progress to the actual work stages. Particularly in ETO work, this should involve seeking to implement new opportunities to apply Big Data Analytics and simulation modelling in iterations of assessment–improvement–reassessment. In this way, critical realist action research can be embedded into practice as a continual endeavour to bring about improvements to the reliability of autonomous production as soon as possible.

4.3. Implications for Practice

The development of autonomous production technologies supplied by vendors will involve task analysis, DFMA, etc., to enable robots to carry out basic motions efficiently. Also, autonomous production technologies supplied by vendors will have situation awareness at least for the status of basic motions such as picking, orientating and placing. Outside of fully autonomous production systems in MTS factories, there are an increasing number of production technologies with some autonomous functionalities. For example, several companies now produce robotic glazing machines, which are used for installing glass panels and glass windows at construction sites. These robots grip the glass with multiple suction pads. They can have handling capacities that exceed 1000 kilograms (kg) and robotic arms that can extend more than 2 m with potential for 360 degrees rotation. However, much of their operation is still controlled remotely by human operators [38].

As summarized in Figure 2, human remote control and on-site safety risks can be reduced by targeted application of selected industrial engineering methods and situation awareness modelling within the cost constraints of individual ETO projects and company resources. Here, it is significant that production in the manufacturing and construction industries involves many small- to medium-sized companies, which do not have sufficient in-house expertise to undertake the computer science involved in developing their own autonomous production technologies or to modify substantially those offered by vendors. By contrast, the application of industrial engineering methods can be quite straightforward when summarized in simple rules such as “Ensure adequate access and unrestricted vision”; “minimize the need for reorientation during assembly”; and “mark parts with correct orientation” [22]. Similarly, the development of visual controls in situation awareness modelling can follow simple principles for avoiding conceptual, presentational and linguistic ambiguity [53]. Progress towards implementation of statistical process control can be made by drawing upon the expert knowledge of relevant practitioners such as working foreman and production supervisors. In particular, through asking and answering simple questions such as “if this work were to be constructed with this autonomous production system five times, how many times would it be constructed right first time within the agreed time and for the agreed cost in accordance with relevant safety regulations?” If the response for relevant expert practitioners is less than five times out of five, then more effort should be made to improve work characteristics [23,24].

Subsequently, the introduction of big data analytics and simulation modelling into ETO bring possibilities for digital capture and analysis of the performance of production systems that are made more autonomous through combination of autonomous production technologies with work characteristic improved by application of industrial engineering methods and situation awareness modelling [26,27,28,29,30,31,32,33,34,35,36,37]. A relevant technical measurement that can be used in computer-aided analysis of the fit of autonomous production systems to challenging work characteristics is entropy and the associated Information Gain needed to increase the reliability of autonomous production systems. The more different ways there are of undertaking the same work, the more entropy is involved and the more additional information is needed for either a human being or an autonomous machine to know how to do the work correctly. If the application of industrial engineering methods and situation awareness modelling is successful, there will be only one way to carry out a work process—the way that achieves most value with the least waste. In such cases, the entropy is 0.00. By contrast, if there are five different ways to carry out a work process, each of which involves different set-up arrangements etc., then entropy is 2.32 and so the required Information gain is 2.32. If there are five ways to carry out a work process but one of those ways is followed four times in five, then the entropy is 1.12. Thus, entropy and Information Gain can provide a practical bridge between practitioner expertise and computer-aided analyses of the fit of autonomous production systems to work with challenging characteristics [59,60,61].

4.4. Principal Contributions

Three contributions to knowledge are provided in this communication paper. First, challenges arising from work characteristics to reliable implementation of high-level autonomous production technologies are explained in terms of work setting, work composition, and work certainty. This contribution goes beyond previous implementation-specific descriptions, such as those for driverless cars on public roads. Furthermore, it goes beyond implementation-specific descriptions that emphasize one particular technology, such as driverless cars: rather than the fundamental importance of engineering work characteristics to enable realization of reliable autonomous operation. For example, there needs to be Vehicle–Infrastructure Integration involving smart roads, smart signage, etc., in order for driverless cars to operate reliably [8,9,10,11]. Yet, the fundamental importance of engineering work characteristics to enable autonomous operation is not communicated in the hype about driverless cars or more generally in the hype about autonomous systems [62,63]. The second contribution provided is a definition of strong and weak opportunities for high-level autonomous production in two industries: manufacturing and construction. The third contribution is an explanation of how industrial engineering methods and situation awareness modelling can be combined in a critical realist framework to improve otherwise weak opportunities for reliable high-level autonomous production systems. In particular, it is explained how weak opportunities can be improved within the practical constraints of ETO where there are challenges in work characteristics that cannot be addressed through massive capital investment in enabling engineering for autonomous production. Massive capital investment in enabling engineering is often not economically viable because all costs need to be recovered within each individual ETO project. This is very different to the economic viability of massive financial investment in Vehicle–Infrastructure Integration on main public roads, which can have millions of users every year for many decades.

Funding

This research was funded by VTT X-BA FASAN.

Conflicts of Interest

The author declares no conflict of interest.

References

- NFA. Autonomous Systems: Opportunities and Challenges for the Oil & Gas Industry; Norwegian Society of Automatic Control (NFA): Kristiansand, Norway, 2012. [Google Scholar]

- Goodhue, D.L.; Thompson, R.L. Task-technology fit and individual performance. MIS Q. 1995, 19, 213–236. [Google Scholar] [CrossRef]

- Oakland, J.S. Total Quality Management and Operational Excellence, 4th ed.; Routledge: New York, NY, USA, 2014. [Google Scholar]

- Oyebisi, T.O. On reliability and maintenance management of electronic equipment in the tropics. Technovation 2000, 20, 517–522. [Google Scholar] [CrossRef]

- Bayat, B.; Bermejo-Alonso, J.; Carbonera, J.; Facchinetti, T.; Fiorini, S.; Goncalves, P.; Jorge, V.A.; Habib, M.; Khamis, A.; Melo, K.; et al. Requirements for building an ontology for autonomous robots. Ind. Robot 2016, 43, 469–480. [Google Scholar] [CrossRef]

- Grayson, W. Komatsu brings artificial intelligence to heavy equipment with NVIDIA-powered cameras. Equipment World, 13 December 2017. [Google Scholar]

- Shah, Z.A.; Singh, R.; Dar, M.A.; Matoo, J.M.; Mir, R. An analysis of socio-personal characteristics of apple growers and their attitude towards apple cultivation in District Shopian of J&K. Adv. Res. 2017, 12, 1–11. [Google Scholar]

- Edwards, C. Every road tells a story: Communication smart roads. Eng. Technol. 2017, 12, 64–67. [Google Scholar] [CrossRef]

- Mi, C.C.; Buja, G.; Choi, S.Y.; Rim, C.T. Modern advances in wireless power transfer systems for roadway powered electric vehicles. IEEE Trans. Ind. Electron. 2016, 63, 6533–6545. [Google Scholar] [CrossRef]

- Johnson, C. Readiness of the Road Network for Connected and Autonomous Vehicles; RAC Foundation: London, UK, 2017. [Google Scholar]

- Wang, M.; Daamen, W.; Hoogendoorn, S.P.; Van Arem, B. Connected variable speed limits control and car-following control with vehicle-infrastructure communication to resolve stop-and-go waves. J. Intell. Transp. Syst. 2016, 20, 559–572. [Google Scholar] [CrossRef]

- Regan, J. Rio Tinto aims for “intelligent” Australian iron ore mine. Reuters, 4 December 2017. [Google Scholar]

- Schulze, L.; Zhao, L. Worldwide development and application of automated guided vehicle systems. Int. J. Serv. Oper. Inf. 2007, 2, 164–176. [Google Scholar] [CrossRef]

- Fox, S. Potential of virtual-social-physical convergence for project manufacturing. J. Manuf. Technol. Manag. 2014, 25, 1209–1223. [Google Scholar] [CrossRef]

- Guizzo, E. Your next t-shirt will be made by a robot. IEEE Spec. 2018, 55, 50–57. [Google Scholar] [CrossRef]

- Schweder, J. Turning out lights on the factory floor. Automation World, 22 February 2017. [Google Scholar]

- Behrmann, E.; Rauwald, C. Mercedes boots robots from the production line. Bloomberg Businessweek, 25 February 2016. [Google Scholar]

- Bhaskar, R.A. Realistic Theory of Science; Harvester Press: Brighton, UK, 1978. [Google Scholar]

- Mingers, J. Systems Thinking, Critical Realism and Philosophy: A Confluence of Ideas; Routledge: Abingdon, UK, 2014. [Google Scholar]

- Doray, B. From Taylorism to Fordism; Free Association Books: London, UK, 1988. [Google Scholar]

- Parker, S.; Wall, T.D. Job and Work Design: Organizing Work to Promote Well-Being and Effectiveness; Sage: Thousand Oaks, CA, USA, 1998. [Google Scholar]

- Boothroyd, G.; Dewhurst, P.; Knight, W.A. Product Design for Manufacture and Assembly; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Oakland, J.S. Statistical Process Control, 5th ed.; Routledge: New York, NY, USA, 2007. [Google Scholar]

- Pande, P.S.; Neuman, R.P.; Cavanagh, R.R. The Six Sigma Way: How GE, Motorola, and Other Top Companies Are Honing Their Performance; McGraw-Hill: New York, NY, USA, 2000. [Google Scholar]

- Sommerville, I.; Ransom, J. An empirical study of industrial requirements engineering process assessment and improvement. ACM Trans. Softw. Eng. Methodol. (TOSEM) 2005, 14, 85–117. [Google Scholar] [CrossRef]

- Bao, J.; Zheng, X.; Zhang, J.; Ji, X.; Zhang, J. Data-driven process planning for shipbuilding. AI EDAM 2018, 32, 122–130. [Google Scholar] [CrossRef]

- Bilal, M.; Oyedele, L.O.; Qadir, J.; Munir, K.; Ajayi, S.O.; Akinade, O.O.; Owolabi, H.A.; Alaka, H.A.; Pasha, M. Big Data in the construction industry: A review of present status, opportunities, and future trends. Adv. Eng. Inf. 2016, 30, 500–521. [Google Scholar] [CrossRef]

- Gong, J.; Caldas, C.H.; Gordon, C. Learning and classifying actions of construction workers and equipment using bag-of-video-feature-words and Bayesian network models. Adv. Eng. Inf. 2011, 25, 771–782. [Google Scholar] [CrossRef]

- Han, S.; Lee, S.; Peña-Mora, F. A machine-learning classification approach to automatic detection of workers actions for behavior-based safety analysis. In Proceedings of the ASCE International Workshop on Computing in Civil Engineering, Clearwater Beach, FL, USA, 17–20 June 2012; pp. 65–72. [Google Scholar]

- Chen, Y.-J.; Feng, C.-W.; Wang, Y.-R.; Wu, H.-M. Using BIM model and genetic algorithms to optimize the crew assignment for construction project planning. Int. J. Technol. 2011, 3, 179–187. [Google Scholar]

- Kim, H.; Soibelman, L.; Grobler, F. Factor selection for delay analysis using knowledge discovery in databases. Autom. Construct. 2008, 17, 550–560. [Google Scholar] [CrossRef]

- Steinhauer, D.; Sikorra, J.N.; Haux, M.A.; Friedewald, A.; Lödding, H. Processing incomplete data for simulation-based production planning in shipbuilding. J. Simul. 2017, 11, 30–37. [Google Scholar] [CrossRef]

- Ben-Alon, L.; Sacks, R. Simulating the behavior of trade crews in construction using agents and building information modeling. Autom. Construct. 2017, 74, 12–27. [Google Scholar] [CrossRef]

- Kim, K.; Kim, K.J. Multi-agent-based simulation system for construction operations with congested flows. Autom. Construct. 2010, 19, 867–874. [Google Scholar] [CrossRef]

- Watkins, M.; Mukherjee, A.; Onder, N.; Mattila, K. Using agent-based modeling to study construction labor productivity as emergent property of individual and crew interaction. J. Construct. Eng. Manag. 2009, 135, 657–667. [Google Scholar] [CrossRef]

- Tang, P.; Mukherjee, A.; Onder, N. Using an interactive schedule simulation platform to assess and improve contingency management strategies. Autom. Construct. 2013, 35, 551–560. [Google Scholar] [CrossRef]

- Akhavian, R.; Behzadan, A.H. Construction equipment activity recognition for simulation input modeling using mobile sensors and machine learning classifiers. Adv. Eng. Inf. 2015, 29, 867–877. [Google Scholar] [CrossRef]

- Bogue, R. What are the prospects for robots in the construction industry? Ind. Robot 2018, 45, 1–6. [Google Scholar] [CrossRef]

- Local Authority Building Control. LABC Warranty Technical Manual, version 8; Local Authority Building Control: Birkenhead, UK, 2017. [Google Scholar]

- Endsley, M.R. Toward a theory of situation awareness in dynamic systems. Hum. Factors 1995, 37, 32–64. [Google Scholar] [CrossRef]

- Endsley, M.R. Situation awareness misconceptions and misunderstandings. J. Cognit. Eng. Decis. Mak. 2015, 9, 4–32. [Google Scholar] [CrossRef]

- Miller, D.; Sun, A.; Ju, W. Situation awareness with different levels of automation. In Proceedings of the IEEE International Conference on Systems, Man and Cybernetics (SMC), San Diego, CA, USA, 5–8 October 2014; pp. 688–693. [Google Scholar]

- Barona López, L.I.; Valdivieso Caraguay, Á.L.; Maestre Vidal, J.; Sotelo Monge, M.A.; García Villalba, L.J. Towards incidence management in 5G based on situational awareness. Future Internet 2017, 9, 3. [Google Scholar] [CrossRef]

- Moradi-Pari, E.; Tahmasbi-Sarvestani, A.; Fallah, Y.P. A hybrid systems approach to modeling real-time situation-awareness component of networked crash avoidance systems. IEEE Syst. J. 2016, 10, 169–178. [Google Scholar] [CrossRef]

- Ghezala, M.W.B.; Bouzeghoub, A.; Leroux, C. RSAW: A situation awareness system for autonomous robots. In Proceedings of the 13th IEEE International Conference on Control Automation Robotics & Vision (ICARCV), Marina Bay Sands, Singapore, 10–12 December 2014; pp. 450–455. [Google Scholar]

- Feng, Y.H.; Teng, T.H.; Tan, A.H. Modelling situation awareness for Context-aware Decision Support. Expert Syst. Appl. 2009, 36, 455–463. [Google Scholar] [CrossRef]

- Fox, S. Getting real about ICT: Applying critical realism to the framing of information and communication technologies. Manag. Res. Rev. 2013, 36, 296–319. [Google Scholar] [CrossRef]

- Wynn, D.; Williams, C.K. Principles for conducting critical realist case study research in information systems. MIS Q. 2012, 36, 787–810. [Google Scholar]

- Bostrom, N. Ethical issues in advanced artificial intelligence. In Cognitive, Emotive and Ethical Aspects of Decision Making in Humans and in Artificial Intelligence; Smit, I., Lasker, G.E., Eds.; International Institute for Advanced Studies in Systems Research and Cybernetics: Windsor, ON, Canada, 2003; Volume 2, pp. 12–17. [Google Scholar]

- Ford, P. Our fear of artificial intelligence. MIT Technology Review, 11 February 2015. [Google Scholar]

- Nyholm, S.; Smids, J. The ethics of accident-algorithms for self-driving cars: An applied trolley problem? Ethical Theory Moral Pract. 2016, 19, 1275–1289. [Google Scholar] [CrossRef]

- Bogost, I. Enough with the Trolley Problem. The Atlantic, 30 March 2018. [Google Scholar]

- Lewin, K. Action research and minority problems. J. Soc. Issues 1946, 2, 34–36. [Google Scholar] [CrossRef]

- Alana, J.E.; Slater, T.; Bucknam, A. Action Research for Business, Nonprofit, and Public Administration—A Tool for Complex Times; Sage: Thousand Oaks, CA, USA, 2011. [Google Scholar]

- Bassey, M. Action research for improving education in practice. In Teacher Research and School Improvement: Opening the Doors from the Inside; Halsall, R., Ed.; Open University Press: Buckingham, UK, 1998. [Google Scholar]

- Kemmis, S.; Wilkinson, M. Participatory action research and study of practice. In Action Research in Practice: Partnership for Social Justice in Education; Atweh, B., Kemmis, S., Weeks, P., Eds.; Routledge: London, UK, 1998. [Google Scholar]

- Proctor, R.W.; Capaldi, E.J. Why Science Matters: Understanding the Methods of Psychological Research; Blackwell: Oxford, UK, 2006. [Google Scholar]

- Garousi, V.; Felderer, M.; Mäntylä, M.V. The need for multivocal literature reviews in software engineering: Complementing systematic literature reviews with grey literature. In Proceedings of the 20th International Conference on Evaluation and Assessment in Software Engineering, Limerick, Ireland, 1–3 June 2016; pp. 1–6. [Google Scholar]

- Fox, S. The importance of information and communication design for manual skill instruction with augmented reality. J. Manuf. Technol. Manag. 2010, 21, 188–205. [Google Scholar] [CrossRef]

- Shannon, C.E. A Mathematical Theory of Communication. Bell Syst. Tech. J. 1948, 27, 379–423. [Google Scholar] [CrossRef]

- Zurek, W.H. Complexity, Entropy and the Physics of Information; Westview Press: Boulder, CO, USA, 2018. [Google Scholar]

- Feenberg, A. Beyond the hype. Found. Sci. 2017, 22, 381–383. [Google Scholar] [CrossRef]

- Gomes, L. Self-Driving Cars, Fueled by Hype. The New York Times, 9 July 2016. [Google Scholar]

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).