Abstract

Optimizing warehouse operations is a strategic priority for ensuring the timely and efficient flow of materials in industrial environments. In contexts with limited digital infrastructure, organizations often face persistent challenges such as inefficient picking, poor material traceability, and suboptimal space utilization, ultimately leading to productivity losses and operational delays. This paper introduces a systematic, lean-driven framework for warehouse optimization, structured around a sequential methodology involving Define, Improve, and Control. The approach begins with a comprehensive diagnostic phase to evaluate the current state and identify performance gaps. It then guides the development and implementation of targeted interventions aimed at eliminating waste, standardizing operations, and aligning resources with value-added activities. Finally, the framework supports long-term sustainability through continuous monitoring, process standardization, and performance control. The methodology is validated through its application in a parts warehouse within the glass transformation industry, highlighting its adaptability, practical relevance, and capacity to generate meaningful improvements, even in low-digitalization environments. The framework offers a scalable solution for organizations seeking to enhance warehouse performance through structured lean practices.

1. Introduction

Warehouse management is a critical component of modern supply chains and is increasingly recognized as a strategic function due to globalization, heightened competition, and shorter product life cycles [1]. Efficient warehouse operations directly influence operational performance and customer satisfaction through timely and accurate handling of materials and products [2,3]. Since storage activities incur holding costs without adding direct value, optimizing storage and picking processes is essential for cost control and service quality [1,4].

Storage and picking policies strongly affect space utilization and operational efficiency. Dedicated storage simplifies retrieval but wastes space, whereas random storage maximizes utilization at the cost of complexity. Hybrid methods—such as class-based (A-B-C) and family grouping—offer a balance, while strategies like forwarding, reserving, and replenishing improve material flow between reserve and dispatch areas [4,5]. Picking is typically the most labor-intensive and costly warehouse activity, often accounting for over 50% of total warehouse costs [4], and its efficiency is crucial for timely delivery and customer satisfaction [6]. To cope with increasing product variety and demand for speed, advanced IT-driven systems are often deployed to reduce errors and optimize resources [7].

However, in non-digitalized environments, such as many small- and medium-sized enterprises (SMEs), warehouse operations remain prone to errors, affecting efficiency, production flow, and traceability. SMEs often face constraints in manpower, technology, and management capabilities [8,9,10], underscoring the need for structured, low-complexity frameworks that integrate Lean and quality management tools while providing practical guidance for problem identification, prioritization, and solution design.

Lean methodology, rooted in the Toyota Production System (TPS), is particularly suitable for these contexts. By emphasizing waste elimination, flow improvement, and value creation, Lean promotes continuous improvement, efficient resource utilization, and faster problem resolution [11,12,13,14]. In logistics, it addresses inefficiencies such as unnecessary transport and excess inventory by streamlining material and information flows [6,15,16]. Lean tools—including Ishikawa diagrams, the 5 Whys, visual management, and 5S—are effective in low-digitalization environments, relying on simple records, manual measurements, or operator experience [17,18]. These tools require only modest on-site knowledge, facilitating rapid adoption and integration into daily routines.

Although several studies have explored Lean and quality management in warehouse operations (e.g., [19,20,21,22]) and examined SMEs’ adoption challenges [9,10,23], comprehensive, sequential, stepwise frameworks for SMEs operating under low-digitalization conditions remain scarce.

To address this gap, the present work proposes a structured Lean-based methodology organized into a sequential three-step framework—Define–Improve–Control—where the latter two steps are iterative. The approach consists of three main stages: (i) Diagnosis: Characterize the current (AS-IS) process, quantify inefficiencies, and analyze root causes to prioritize improvement areas; (ii) Improve: Design the desired (TO-BE) state and develop an implementation plan based on issue criticality and cost–benefit considerations, establishing performance indicators and monitoring mechanisms; (iii) Control: Execute the improvement plan and track outcomes to sustain performance gains, embedding improvements within a continuous improvement framework.

The Diagnosis phase integrates problem definition, measurement, and analysis, reflecting their iterative and interdependent nature. In practice, defining the process, measuring key variables, and identifying root causes often occur in parallel or through repeated cycles—particularly in low-digitalization settings. This integrated approach supports adaptive learning and context-sensitive decision-making. The methodology is illustrated through a real-world case study of a glass transformation warehouse, emphasizing practical applicability, simplicity, and operator engagement.

Novelty Statement and Organization

Although several methodologies integrate Lean and quality management tools in warehouse operations (e.g., [19,20,21,22]), practical, low-complexity frameworks for low-digitalization environments remain limited. Specifically, there is a need for approaches that (i) integrate Lean and quality management tools into a coherent, operational workflow; (ii) provide structured guidance for problem identification, prioritization, and solution design; and (iii) demonstrate practical applicability through industrial case studies, particularly in SMEs and low-digitalization contexts. While individual Lean tools are widely applied in warehousing, comprehensive frameworks that operationalize these tools under low-digitalization conditions and provide stepwise guidance for SMEs are scarce.

Our work addresses this gap with three main contributions. First, we propose a systematic workflow that integrates Lean, quality, and project management tools into a stepwise methodology for improving warehouse operations in low-digitalization environments. Second, we demonstrate the workflow’s application through a real-world case study in a glass transformation warehouse. Third, we highlight the workflow’s adaptability to different company contexts, ensuring simplicity, operator-friendliness, and compatibility with daily operational routines. The novelty lies not in the individual tools, but in the structured, SME-oriented, and practically applicable framework tailored for environments with limited digital resources.

The structure of the paper is as follows. Section 2 reviews the Lean tools employed across the different phases of the framework. Section 3 presents the systematic methodology for improving warehouse efficiency, starting with an analysis of the overall process flow and followed by a detailed discussion of the core operational tasks and the Lean tools applied to optimize them. Section 4 illustrates the application of the framework to a real-world industrial case, describing the problem definition, the diagnostic methodologies used during the Diagnosis phase, and the analysis of collected data to identify and prioritize sources of inefficiency. Section 5 continues with the Improvement and Control phases, detailing the actions implemented and the measures adopted to ensure sustainable performance. Section 6 situates the results within the broader literature, highlighting the contributions and limitations of the proposed approach. Finally, Section 7 summarizes the main findings and emphasizes the study’s key contributions to warehouse optimization in low-data environments.

2. Fundamental Tools

This Section presents the Lean tools that form the foundation of the proposed improvement framework. Section 2.1 introduces the techniques applied in the Diagnosis phase, while Section 2.2 describes those employed in the Improvement and Control phases. The selection of tools for each phase follows three guiding criteria: (i) documented applicability in warehouse management and Lean-based improvement initiatives, as reported in prior research; (ii) simplicity and low implementation cost, which facilitate adoption in practice without imposing steep learning curves on operators; and (iii) complementarity, where qualitative techniques (e.g., VSM, 5S, 5W, Fishbone) support problem identification and root-cause analysis, and semi-quantitative or quantitative methods (e.g., FMECA, ABC, A3, Gantt, SOPs) provide structured prioritization, planning, and control, ensuring a coherent progression from diagnosis to implementation. These criteria ensure that the framework balances methodological rigor with practical feasibility, making it accessible to both scholars and practitioners.

2.1. Tools Used in the Diagnosis Phase

The Diagnosis phase focuses on identifying, quantifying, and analyzing inefficiencies in current warehouse operations. The following Lean tools were employed:

- Value Stream Mapping (VSM)—to visualize the end-to-end flow of materials and information, highlighting non-value-adding activities and operational bottlenecks.

- 5S Methodology (Sort, Set in Order, Shine, Standardize, Sustain)—to (i) audit and evaluate the baseline efficiency of processes during the AS-IS analysis, and (ii) create a structured environment to support effective space utilization and process improvement.

- 5W Analysis (Who, What, Where, When, Why)—to explore the root causes of inefficiencies, promoting a transition from superficial observations to deeper understanding.

- Ishikawa (Fishbone) Diagram—to systematically categorize and visualize the potential root causes identified through audits and process analysis.

- Failure Mode, Effects, and Criticality Analysis (FMECA)—to evaluate and prioritize root causes based on severity, frequency, and detectability, ensuring the most critical issues receive attention first.

2.1.1. Value Stream Mapping

Value Stream Mapping (VSM) is a fundamental Lean tool for analyzing and optimizing material and information flows across a value chain. Introduced by Rother and Shook [24], VSM provides a comprehensive view of the processes that deliver value to the customer, facilitating the identification of inefficiencies, waste elimination, and targeted improvements consistent with Lean principles.

Unlike analysis focused solely on isolated value-added activities, VSM offers a holistic perspective by integrating operational tasks and communication flows—both essential for establishing efficient, end-to-end production systems. This broad view uncovers gaps, bottlenecks, and opportunities for improvement, supporting strategic and operational decision-making. The mapping process relies on direct observation and data collection at the gemba (shop floor), ensuring an accurate representation of actual operations [25]. VSM typically proceeds through two main phases: (i) Current state (AS-IS): A detailed depiction of the existing value stream; and (ii) Future state (TO-BE): A design of the improved system emphasizing flow, waste reduction, and responsiveness.

These phases enable a structured evaluation of the value stream and aid in prioritizing targeted improvements [26]. To guide effective implementation, Rother and Shook [24], Ohno [27] recommend core principles that align operations with customer demand and enhance flow. The VSM methodology generally follows four key steps:

- Initial analysis: Identify critical issues with input from multidisciplinary teams;

- Current state characterization: Conduct on-site observation and data gathering;

- Future state design: Propose improvements aimed at continuous flow and waste minimization;

- Implementation and monitoring: Execute changes and assess their impact.

This structured approach closely follows the Plan-Do-Check-Act (PDCA) cycle, reinforcing VSM’s pivotal role in driving continuous improvement and quality management. Its practical benefits for industrial decision-making are well documented [28].

2.1.2. 5S Methodology

The 5S method is a structured approach designed to improve workplace organization, cleanliness, and efficiency. It consists of five sequential steps—Seiri (Sort), Seiton (Set in order), Seiso (Shine), Seiketsu (Standardize), and Shitsuke (Sustain)—with the goal of standardizing work practices and optimizing operational flow [29].

Widely used in Lean environments, 5S enhances continuous improvement by reducing waste and streamlining resource use, which in turn boosts productivity, minimizes accidents, and supports preventive maintenance [30]. Its practical focus makes it suitable for immediate implementation across diverse industrial settings. The five steps are as follows:

- Seiri (Sort): Eliminate unnecessary items from the workspace, keeping only what is essential to improve efficiency and free up space.

- Seiton (Set in order): Arrange tools and materials based on usage frequency, assigning clear and accessible locations for each item.

- Seiso (Shine): Maintain cleanliness through regular inspection and cleaning, which also reinforces the first two steps.

- Seiketsu (Standardize): Establish clear, consistent procedures and visual cues to maintain organization and hygiene.

- Shitsuke (Sustain): Promote adherence to 5S through training, accountability, and a culture of continuous discipline.

The 5S methodology extends beyond workplace organization and serves as a practical auditing tool for evaluating and enhancing operational standards. When applied systematically, it becomes a repeatable and measurable process that promotes accountability, operational discipline, and continuous improvement. Gapp et al. [31] emphasizes both the advantages and the implementation challenges faced in industrial contexts.

2.1.3. 5W Analysis

The “Five Whys” is a structured method for identifying root causes of operational issues, deeply rooted in Lean thinking. Although formally developed by Ohno [27] as part of the Toyota Production System (TPS), the iterative questioning approach traces back to classical philosophy, notably Plato’s dialogues and Aristotle’s Four Causes [32]. By repeatedly asking “why,” this technique moves beyond surface symptoms to reveal underlying structural causes. A typical diagnostic process begins by addressing five core questions: (i) (W)ho is involved?; (ii) (W)hat is the issue?; (iii) (W)hen does it occur?; (iv) (W)here does it manifest?; and (v) (W)hy does it happen?

This approach improves diagnostic accuracy, minimizes subjectivity [33], and supports continuous improvement efforts [34]. In logistics, for instance, it can help trace inventory discrepancies back to process flaws or training deficiencies. As a first step in PDCA cycles, the 5W method facilitates root-cause analysis and complements tools such as Ishikawa diagrams and FMECA [35], reinforcing a culture of operational excellence.

In this context, the “Five Whys” is embedded within the extended 5W2H framework, which adds two additional questions: How? and How much? This expanded structure not only facilitates root cause identification but also defines the actions, methods, and resources required for resolution—bridging diagnosis with execution. Widely adopted in quality management and project follow-up, 5W2H enhances cross-functional communication and accountability, thereby increasing the effectiveness of continuous improvement initiatives [35].

While the 5W component plays a central role during the Diagnosis phase, the 2H elements are typically addressed in the Improve phase. In practice, however, both are closely integrated to form a comprehensive framework for problem-solving and action planning.

2.1.4. Fishbone Diagram

The Ishikawa or Fishbone Diagram is a structured tool for root-cause analysis, designed to systematically trace the origins of specific problems [36]. It organizes potential causes into standard categories—typically “Methods”, “People”, “Machines”, “Materials”, “Environment”, and “Systems”—and allows further breakdown into more specific contributing factors [37]. This visual and collaborative format facilitates structured brainstorming, enhances understanding of complex cause–effect relationships, and supports problem-solving even in resource-constrained environments.

While the “Five Whys” technique is well-suited for linear problems with a single root cause, it can be insufficient when addressing issues driven by multiple, interrelated factors. In such cases, the Fishbone Diagram offers a more robust and holistic framework for diagnosing problems and identifying targeted corrective actions [38].

In our context, the Fishbone Diagram is applied as a graphical representation of causal relationships, structured around classical categories. It supports systematic problem analysis in complex operational settings by visually organizing root causes and their interactions.

2.1.5. Failure Mode, Effects, and Criticality Analysis

Failure Mode and Effects Analysis (FMEA) is a fundamental risk management tool that systematically identifies potential failure modes in systems, products, or processes, assessing their effects and underlying causes [39]. It facilitates early detection and implementation of corrective actions to prevent failures [40], promoting continuous improvement in quality, reliability, and safety. Consequently, its application is strongly recommended during early project phases [41,42]. FMEA structures failure identification by severity, likelihood, and detection capability, enabling risk-based prioritization and timely interventions before failures impact end-users [43]. Typically, failure effects are analyzed first, followed by tracing root causes, highlighting the importance of early and comprehensive failure mode identification.

While FMEA offers qualitative insights, Failure Mode, Effects, and Criticality Analysis (FMECA) adds a crucial quantitative dimension. By extending beyond failure identification and effects assessment, FMECA integrates criticality evaluation, enabling prioritization of failure modes based on quantitative criteria such as likelihood, severity, and their impact on cost, safety, or performance [39,40]. The central distinction is that FMECA quantifies failure effects, often using metrics like the Criticality Index, providing a more precise assessment of risk and guiding informed resource allocation for mitigation.

FMECA is applicable throughout the entire lifecycle of a product or process—from design and development to operation and maintenance. Its early application enables the identification of critical vulnerabilities and helps to mitigate costly redesigns and operational failures [44]. According to IEC 60812:2018, FMECA is conducted using a structured and standardized sequence of methodological steps to ensure consistency and analytical rigor [45].

The FMECA follows a structured, tabular format designed to facilitate systematic risk analysis of products, components, or processes. This standardized form includes several critical fields that must be accurately and thoroughly completed to ensure the reliability and effectiveness of the assessment. Key elements typically captured in the FMECA form include (i) identification of the item or process under analysis; (ii) potential failure modes; (iii) potential effects of each failure; (iv) existing controls for prevention or detection; and (v) quantitative or qualitative risk evaluation. By organizing this information consistently, the FMECA worksheet enables teams to prioritize failure modes, assign corrective actions, and track mitigation efforts across complex systems.

The risk assessment process aims to quantify the risk associated with each failure mode by evaluating three key criteria: Severity (S), Occurrence (O), and Detectability (D).

- Severity reflects the impact of a failure on system functionality, safety, or customer satisfaction. Following the scale adapted from U.S. Department of Defense [46], values range from 10 (critical safety compromise) to 1 (no noticeable effect).

- Occurrence estimates the likelihood of a failure based on historical data and expert judgment. This scale ranges from 10 (very frequent) to 1–2 (extremely rare).

- Detectability measures the likelihood that existing controls will detect the failure before it affects the system or end-user. Scores range from 10 (undetectable failure) to 1 (almost certain detection).

These three criteria are combined into a composite index known as the Risk Priority Number (RPN), which provides a standardized method for prioritizing risks across a system, product, or process. It is defined as

Based on RPN values, risks can be categorized into levels that guide decision-making and action prioritization, as follows [44,47,48]:

- : Very low risk

- : Low risk

- : Moderate risk

- : High risk

This classification facilitates communication across stakeholders and informs the prioritization of corrective and preventive actions. In addition to risk mitigation, RPN analysis supports maintenance planning and reduces the likelihood of critical failures [49]. Numerous studies demonstrate the application of FMECA across industrial sectors. For example, Braaksma et al. [50] explores its role in asset management, while ElKasrawy et al. [51] investigates its use in the process industry.

2.2. Tools Used in Improvement and Control Phases

Here, we present the tools applied during the Improvement and Control phases to enhance warehouse efficiency through structured planning, execution, and monitoring. The following tools supported systematic improvement and operational control:

- A-B-C classification of parts—used to reorganize the warehouse layout by grouping items according to usage frequency and cost. This segmentation enabled strategic placement of parts, improving retrieval and storage efficiency with moderate investment.

- PDCA cycle—applied to guide continuous improvement through iterative Plan–Do–Check–Act stages.

- A3 matrix—served as a structured framework to define problems, analyze root causes, and propose targeted solutions.

- Activity-based costing (ABC)—employed to prioritize actions based on required resources and their impact on risk reduction, as indicated by the risk priority number (RPN), supporting cost-effective decision-making.

- Gantt chart—used for scheduling and tracking the implementation of tasks and corrective actions over time.

- Standard operating procedures (SOPs)—developed to ensure consistency and compliance by formalizing key operational processes.

2.2.1. A-B-C Classification of Parts

A-B-C classification is a fundamental inventory management technique that categorizes stock-keeping units (SKUs) into three groups—A, B, and C—based on their relative importance to key metrics such as annual consumption value, usage frequency, cost, or operational criticality [52]. This segmentation facilitates tailored inventory control strategies, enabling better prioritization of managerial focus, optimized stock investment, and enhanced warehouse performance. The approach is grounded in the Pareto principle, which highlights that a small proportion of items typically accounts for a large share of outcomes (e.g., cost, usage). Although not a rigid 80/20 rule, A-B-C classification functions as a practical heuristic consistent with foundational inventory models such as Economic Order Quantity (EOQ) and service-level optimization frameworks [53].

A typical categorization into classes of parts includes the following:

- Category A: High-value or high-impact items, usually comprising 10–20% of SKUs but contributing 70–80% of total inventory value. These require close monitoring, precise forecasting, and frequent replenishment to minimize holding costs and stockouts.

- Category B: Moderately significant items, representing 20–30% of SKUs and around 15–25% of inventory value. These are managed with routine review and control policies that balance cost-efficiency and availability.

- Category C: Low-value or low-risk items, often 50–70% of SKUs but only 5–10% of inventory value. These can be controlled with simplified policies such as bulk purchasing, longer review cycles, or even two-bin systems.

2.2.2. PDCA Cycle

The PDCA cycle is a widely recognized model in quality management and continuous improvement. It comprises four iterative stages that support structured problem-solving and incremental enhancement of processes [54]:

- (P) Plan—Identify the problem or opportunity for improvement, set clear objectives, and develop a detailed action plan.

- (D) Do—Execute the proposed solution or pilot initiative in accordance with the plan.

- (C) Check—Assess the outcomes, compare actual results to expected targets, and analyze any discrepancies.

- (A) Act—Institutionalize successful changes or revise the plan based on performance gaps, restarting the cycle as needed.

The cyclic repetition of these steps enables organizations to promote continuous learning, build resilience, and drive sustained performance improvements. When applied systematically, PDCA contributes to long-term sustainability and operational excellence [55]. More than just a tool, PDCA embodies a strategic mindset for process innovation and adaptive management. Its straightforward structure allows for broad applicability across sectors, while its success hinges on tailoring actions to specific organizational realities. The cycle is firmly embedded in business practices and is well supported in the academic literature [56,57].

2.2.3. The A3 Problem Solving Methodology

The A3 Problem Solving methodology is a structured approach to problem resolution, extensively used in Lean Manufacturing. Developed by Toyota, it is rooted in the PDCA cycle and facilitates a systematic, visually accessible process for identifying problems, developing solutions, and implementing sustainable improvements [58].

Creating an A3 report involves collecting factual data, integrating stakeholder feedback, and defining responsibilities. This structured approach establishes a clear path to resolution, ensuring consistency throughout the problem-solving process [59]. The A3 report follows a logical progression that guides users from problem identification to solution implementation and standardization. Its main components include the following:

- Theme identification—Precise definition of the problem and its context.

- Problem description—Analysis of the current state (AS-IS) and identification of issues prompting action.

- Objective setting—Specification of the desired future state (TO-BE), including scope and goals.

- Root cause analysis—Investigation of underlying causes using tools like the 5 Whys or Ishikawa diagrams.

- Action plan—Comprehensive plan detailing how to achieve the desired future state.

- Result verification—Evaluation of the implemented actions’ effectiveness and integration into existing processes to ensure sustainability.

More than a technical document, the A3 report serves as a catalyst for organizational development. It fosters a systemic perspective, enhances problem comprehension, and encourages collaborative, data-driven improvement. By transforming problem-solving into a learning process, it empowers organizations to tackle complex challenges. Rossini et al. [60] demonstrate the use of the A3 report as an effective knowledge systematization tool in industrial contexts.

2.2.4. ABC Prioritization Analysis

ABC analysis is a prioritization method used to rank items based on their relative contribution to a defined objective [61]. In this study, it is applied to prioritize corrective actions—rather than the underlying causes—based on their estimated impact, such as risk reduction, cost savings, or process improvement. Unlike traditional ABC analysis grounded in the Pareto principle, this application does not assume a specific distribution of impact. The analysis proceeds as follows:

- Each corrective action is quantified based on its expected effect on risk (measured by RPN), cost reduction, and/or return on investment;

- Actions are ranked in descending order of estimated impact;

- They are then classified into categories A, B, or C according to cumulative impact thresholds.

Category A includes high-priority actions that require prompt implementation and close monitoring. Category B includes actions of moderate importance to be addressed as resources allow. Category C includes low-impact actions that may be implemented with minimal urgency. This structured approach facilitates effective resource allocation by focusing efforts on actions with the greatest potential benefit. To avoid ambiguity, it is noted that this form of ABC analysis is distinct from typical Activity-Based Costing, which refers to a cost accounting methodology used to assign overhead and indirect costs to specific activities.

2.2.5. Gantt Diagram

The Gantt Chart is one of the oldest and most widely used tools in project management. It offers a graphical representation of the tasks that constitute a project, along with their duration and interdependencies over time. In practice, it supports the three fundamental functions of project management: planning, execution, and control [62].

Visually, the Gantt Chart takes the form of a bar chart in which each row corresponds to a specific task. The length of each bar is proportional to the estimated time required to complete the task, while its position on the timeline reflects the task’s start and end dates. Dependencies between tasks are depicted through the sequential alignment of these bars, illustrating which tasks must precede or follow others [63].

The chart’s flexibility and capacity to accommodate project-specific constraints and priorities make it a valuable tool not only for scheduling but also for managing task execution strategies. This adaptability enhances its usefulness in a wide range of project types and scales [64].

2.2.6. Standard Operating Procedure

The Standard Operating Procedure (SOP) is a fundamental tool for promoting efficiency, consistency, and continuous improvement in organizational processes. As noted by George [65], SOPs guide the execution of specific tasks to achieve desired outcomes while minimizing risks and losses. Standardization, according to Liker [66], underpins continuous improvement by reducing variability and increasing workflow transparency, thereby enhancing operational stability.

In production, standardized work refers to predefined task specifications that ensure uniform execution, reduce waste, and improve performance [67]. When effectively implemented, SOPs stabilize processes, facilitate training, enhance safety, and support productivity, quality, cost, and lead time objectives [35]. As a pillar of Lean management, SOPs institutionalize best practices, reduce variability, and foster sustainable process improvement.

3. Proposed Methodology

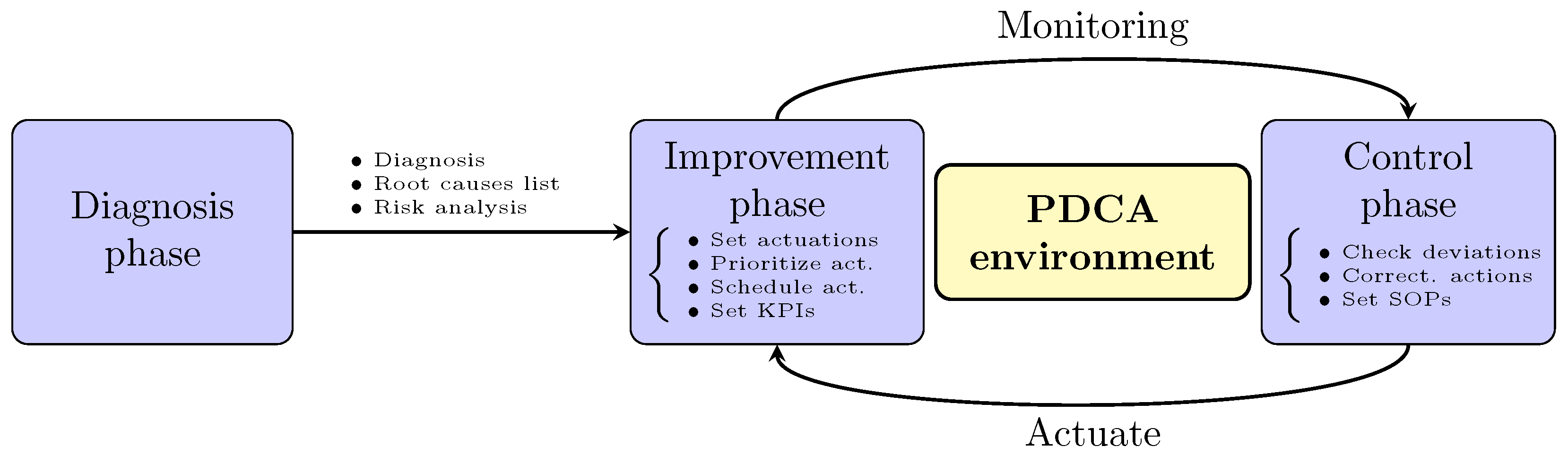

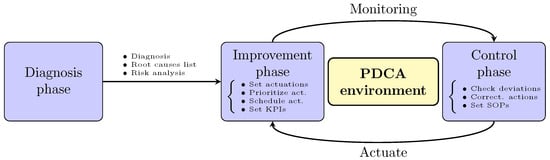

This Section presents the overarching framework developed to address the problem, structured as a three-phase methodology (see Figure 1). The initial Diagnosis phase establishes the foundation for the subsequent Improvement and Control phases, which are iterative and aligned with the PDCA cycle.

Figure 1.

General framework for process improvement, showing the three core phases and their interconnections through monitoring and feedback loops. Blue rectangles represent activities, while yellow rectangles denote adopted practices.

The framework is conceived as an integrated sequence rather than a checklist, as schematically illustrated in Figure 1. Each tool is embedded within one of the three phases—Diagnosis, Improvement, or Control—and generates outputs that serve as inputs for the subsequent stage. Exploratory methods are first applied to capture the current state and identify root causes; these are then complemented by prioritization tools that guide solution design and implementation. Finally, standardization and monitoring mechanisms sustain the achieved improvements. This progression ensures that problem identification, solution development, and long-term control remain logically connected. It should be noted that while Improvement and Control follow Diagnosis sequentially, they are cyclically linked to one another: improvement actions are implemented and subsequently controlled, while control activities in turn reveal new opportunities for improvement. This interplay reflects the continuous improvement environment characteristic of PDCA.

To clarify the rationale behind the proposed methodology, the selected methods are embedded within a structured sequence that ensures continuity across phases. Each tool generates outputs that feed into subsequent stages, reinforcing the coherence and effectiveness of the approach. The integrated use of these tools reflects established practices in Lean management, quality improvement, and operational planning:

- Lean and quality management: Value Stream Mapping (VSM), 5S, and root-cause analysis methods (5W, Fishbone) are combined to explore and diagnose process inefficiencies, with PDCA providing a structured approach for iterative improvement [57,68].

- Risk and reliability management: FMECA prioritizes failure modes to ensure that interventions target areas of greatest impact [69].

- Project and operations management: A3 reports, A-B-C classification, and Gantt charts translate diagnostic insights into actionable plans with clear timelines and responsibilities [70].

- Sustainability and control: SOPs and 5S help institutionalize improvements and maintain performance gains [71,72].

This methodology synthesizes individually validated tools into a unified framework that connects problem identification, solution design, implementation, and ongoing monitoring. Its novelty lies not in introducing new methods, but in combining complementary tools into a coherent pathway that ensures continuity between phases and facilitates knowledge transfer, accountability, and long-term improvement. To make this rationale explicit, the manuscript includes tables that highlight the precedence of each tool and the deliverables generated for the subsequent stage.

The Improvement phase translates diagnostic insights into a coherent strategy, encompassing the design and execution of improvement actions, incorporating prioritization, accountability, and monitoring mechanisms. The Control phase monitors progress and applies corrective measures as needed to ensure sustainability. The methodology comprises the following phases:

- Diagnosis: This phase assesses the current state and identifies opportunities for improvement by

- mapping existing processes to uncover inefficiencies, bottlenecks, and recurring issues;

- identifying and analyzing root causes of performance problems;

- prioritizing causes based on their criticality and potential impact.

- Improvement: This phase involves developing and executing the improvement strategy through the following:

- Designing and implementing warehouse reorganization to enhance operational efficiency;

- Defining targeted corrective actions for prioritized root causes;

- Prioritizing interventions based on expected risk reduction and cost-benefit trade-offs;

- Developing a structured action plan with clear timelines and assigned responsibilities;

- Establishing key performance indicators (KPIs) and applying appropriate tools for ongoing monitoring;

- Initiating the action plan to begin implementation.

- Control: This phase ensures the long-term effectiveness of implemented actions by:

- periodically reviewing performance against KPIs;

- initiating corrective actions when deviations occur;

- institutionalizing successful practices through documentation, such as SOPs, to support continuous improvement.

We now delve into each phase in detail, starting with the diagnostic stage and the tools used to support it.

3.1. Diagnosis Phase

This phase delivers a systematic diagnosis of the current warehouse configuration (AS-IS), aiming to establish a solid empirical and analytical foundation for subsequent improvements. It comprises a series of diagnostic tasks that progressively deepen the understanding of operational challenges and identify opportunities for enhancement. Table 1 outlines the diagnostic workflow, specifying the tools utilized, task dependencies, and corresponding methodological sections. Here, the symbol “§” is used to denote a “section” or a “paragraph”.

Table 1.

Sequential diagnostic tasks, tools employed, and task dependencies.

The diagnostic process begins with an on-site spatial assessment supported by CAD modeling to identify structural and operational constraints. This is followed by Value Stream Mapping, which highlights inefficiencies and recurring errors impacting flow and quality. Based on VSM outcomes, a 5S audit is conducted along the product and information flows to identify waste and suboptimal practices, setting the stage for root cause analysis. The 5 Whys technique is applied to observed issues to uncover underlying root causes, which are then organized using a Fishbone Diagram to provide clear visualization and structure. Finally, a logistics-focused risk assessment through FMECA ranks these root causes according to their criticality and operational impact.

3.2. Improvement Phase

Insights derived from the FMECA analysis (see Section 3.1) inform two complementary courses of action:

- Operational adjustments with minimal capital expenditure: A warehouse reorganization is proposed leveraging A-B-C inventory classification based on item usage frequency and cost (see Section 2.2.1). This aligns storage locations with item value and operational priority, improving layout efficiency by

- Positioning Class A items near dispatch zones for rapid access;

- Locating Class B items in intermediate areas;

- Assigning Class C items to peripheral zones.

Expected benefits include reduced picking times, streamlined restocking, and enhanced inventory control. - Targeted root cause eradication measures: Prioritization and definition of corrective actions are guided by FMECA scores. Actions are ranked based on estimated capital investment and expected risk reduction. An implementation timeline is established, along with key performance indicators (KPIs) to monitor progress. Additional methodological details are provided in Section 3.2. Execution of the improvement plan follows thereafter.

This dual approach drives measurable improvements in logistics performance. Diagnostic findings—including root causes, risk rankings, and corrective measures—are summarized in a dedicated table to facilitate targeted interventions. The Implementation of root cause eradication measures comprises five key steps:

- Setting corrective actions: Solutions are developed through a structured problem-solving approach using the A3 Matrix, formulating targeted responses to diagnosed root causes.

- Prioritization of actions: Corrective measures are ranked by cost estimates derived via Activity-Based Costing (see Section 2.2.4). Two prioritization strategies may be employed:

- A heuristic method, such as applying the Pareto principle to cost–impact data; or

- An optimization-based approach that maximizes the total Risk Priority Number (RPN) of selected causes within a budget constraint.

In the latter case, each cause i is associated with an estimated investment cost , and a total budget B is defined for the intervention period. The selection problem is formulated as a Mixed Integer Linear Program (MILP):Here, is a binary decision variable indicating whether cause i is selected, and is the vector of such variables. Equation (2a) defines the objective to maximize risk reduction, while Equation (2b) enforces the budget constraint. Cost coefficients are estimated from prior data.It should be noted that the optimization model in Equation (2) assumes independence among fault modes, as the RPNs are aggregated linearly. This simplifying assumption is consistent with standard practice in FMECA prioritization and ensures a tractable MILP formulation. Nevertheless, in real warehouse operations certain causes may be coupled, and corrective actions can interact, leading to overlapping or correlated effects. Future improvements could address these dependencies by introducing correlation constraints, incorporating joint probability structures into the objective, or applying sensitivity analysis to evaluate the robustness of prioritization results under alternative dependency scenarios. - Scheduling interventions: Selected actions are organized over the defined time horizon using a Gantt chart to ensure efficient resource coordination and timely execution.

- Definition of KPIs: Performance metrics are established to monitor and evaluate implementation outcomes, enabling objective assessment and continuous feedback.

- Sustaining improvements: A continuous improvement culture is fostered through the PDCA cycle, ensuring long-term adherence and ongoing refinement of optimized processes.

Table 2 summarizes the key decisions within the Improvement phase, outlining dependencies and primary tools or methods applied.

Table 2.

Key decisions in the Improvement phase with associated tools/methods, dependencies, and references.

3.3. Control Phase

The Control phase ensures that the implemented improvements are sustained over time. It focuses on monitoring performance, making necessary adjustments, and institutionalizing successful practices. Key activities in this phase include the following:

- Monitoring the implementation progress using the KPIs established during the Improvement phase.

- Adjusting actions based on performance indicators, if deviations from expected results are observed.

- Promoting a culture of continuous improvement that supports ongoing process optimization by using PDCA cycle.

- Standardizing successful practices by converting them into standard operating procedures (SOPs); see Section 2.2.6.

- Documenting and communicating results to relevant stakeholders to ensure transparency, alignment, and knowledge retention.

Table 3 summarizes the key decisions made during the Control phase, along with the corresponding tools, dependencies, and relevant section references.

Table 3.

Key decisions in the Control phase, associated tools and methods, dependencies, and relevant section references.

The workflow integrates qualitative and quantitative tools in a project-based sequence, where each method’s output informs the next. Qualitative analyses (e.g., VSM, 5S, 5 Whys, Fishbone) reveal inefficiencies and root causes, while quantitative tools (e.g., FMECA, A-B-C classification, Gantt charts) support prioritization, risk assessment, and resource allocation. Monitoring mechanisms (KPIs, SOPs, PDCA cycles) ensure performance tracking and continuous improvement. Table 1, Table 2 and Table 3 summarize activities, tools, dependencies, and section references.

3.4. Rationale for the Integrated Framework

The methodology uses a deliberately sequenced workflow rather than a checklist, ensuring that each tool contributes meaningfully:

- Qualitative tools: identify inefficiencies and structure observational knowledge.

- Quantitative and organizational tools: prioritize interventions and guide implementation decisions.

- Monitoring and sustainability tools: track performance and embed continuous improvement.

The sequence ensures coherence:

- Diagnostic insights inform the design and prioritization of improvements.

- Quantitative assessments guide scheduling and resource allocation.

- Control mechanisms provide feedback for iterative refinement and adaptation.

This integration creates a systematic, actionable methodology tailored for SMEs operating in low-digitalization environments.

4. Application—Diagnosis Phase

This Section demonstrates the application of the proposed framework, as introduced in Section 3, through a real-world case study conducted in the parts warehouse of a glass transformation company. The company’s core activity is the design and production of customized glass structures using CAD-CAM tools, with manufacturing based on cutting individual glass blocks and assembling them either in the factory for smaller projects or on-site for larger installations.

The company processes between 12,000 and 15,000 orders annually, averaging approximately 48 orders per day. Daily operations involve handling about 1000 m2/day of tempered glass and 800 m2/day of double glass. Production is organized into two 8 h shifts, supported by a workforce of around 100 operators. Warehouse activities are substantial, reflecting a high volume of daily material movements and logistical operations.

The warehouse is a mixed-use facility, primarily storing customized glass components and assembly-related materials. Storage is organized in shelving units and floor areas, and items are handled manually for both in-factory and on-site projects. While specific operational performance data cannot be disclosed due to confidentiality, and certain indicators—such as the number of order lines per period, warehouse fill rate, or occupancy—are not systematically recorded, the facility operates in a low-digitalization environment. This limitation reflects the actual operating conditions of the case and underscores the relevance of Lean tools, which leverage qualitative knowledge and semi-quantitative assessments to drive improvements even in environments with limited digital data.

The implementation strictly follows the sequence of activities established for the Diagnosis phase, as detailed in Section 3.1.

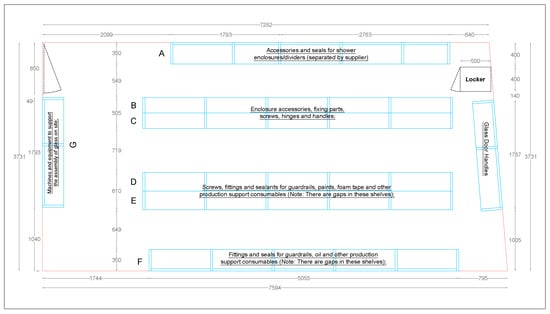

4.1. On-Site Observation

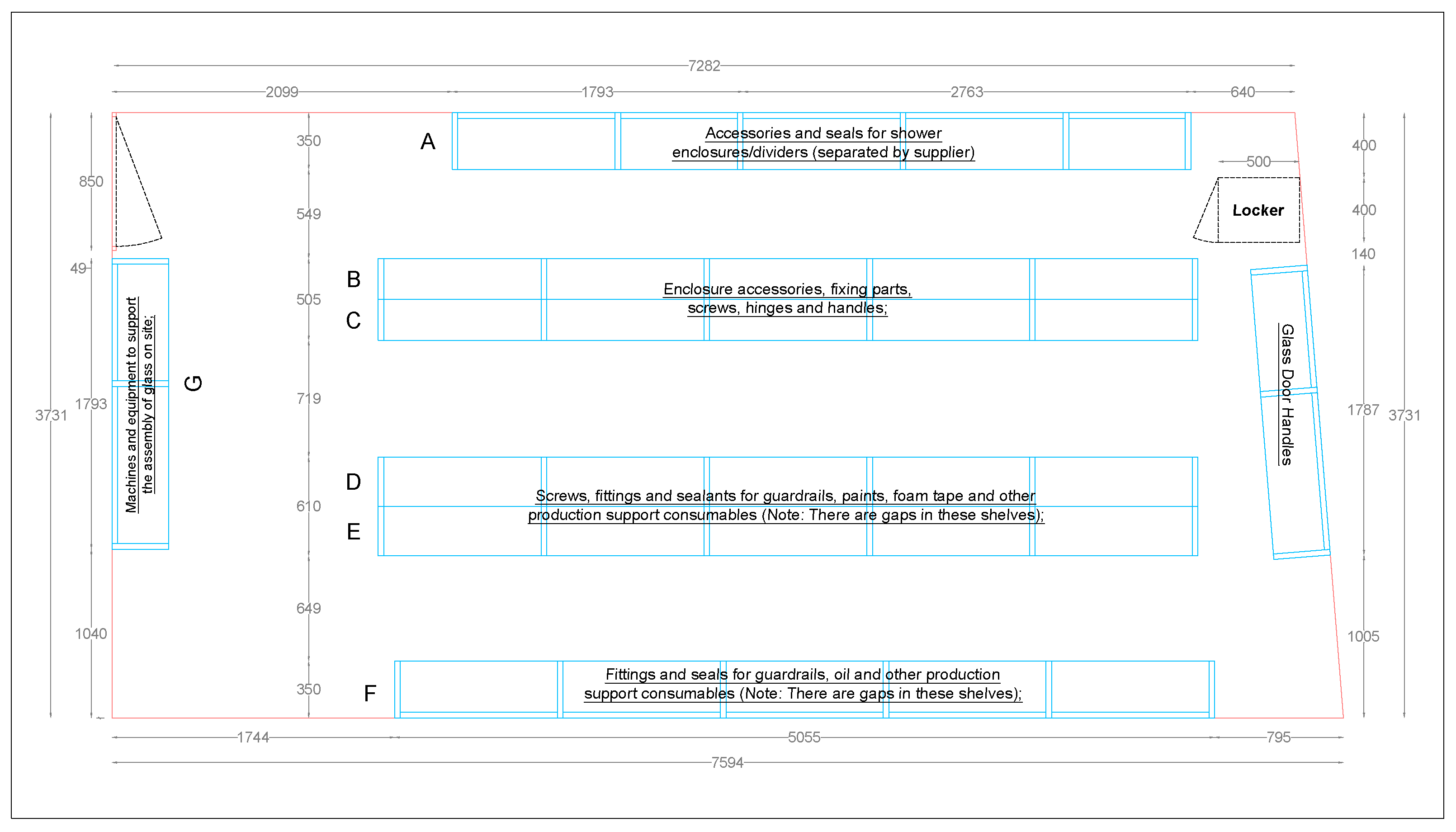

The warehouse layout is depicted in the CAD diagram in Figure 2. It follows a linear configuration composed of six main aisles (A–F), each equipped with shelving that extends the full length of the warehouse. An auxiliary shelf (G) is designated for machinery and equipment used by the Production and Assembly Services.

Figure 2.

Initial warehouse layout with linear aisle configuration (A–F) and auxiliary shelf (G) for production equipment.

The three technicians involved in the audits have long-standing experience within the company and in conducting similar assessments on different production line sections. Their training was not project-specific, but rather acquired through company training programs carried out several years ago, which were designed to prepare them for systematic 5S and FMECA evaluations. Prior to the present audits, the guidelines of both analyses were revisited collectively to ensure a common understanding and consistent application of the criteria.

For the 5S audit, the scoring framework already presented in Table 4 was applied by the team in a collaborative manner. Although no formal inter-rater reliability statistic (e.g., Cohen’s Kappa) was computed, consistency was reinforced through the auditors’ shared experience, prior training, and the consensus-based evaluation process.

Table 4.

5S Internal audit—scoring criteria.

The main findings of the audit are summarized below:

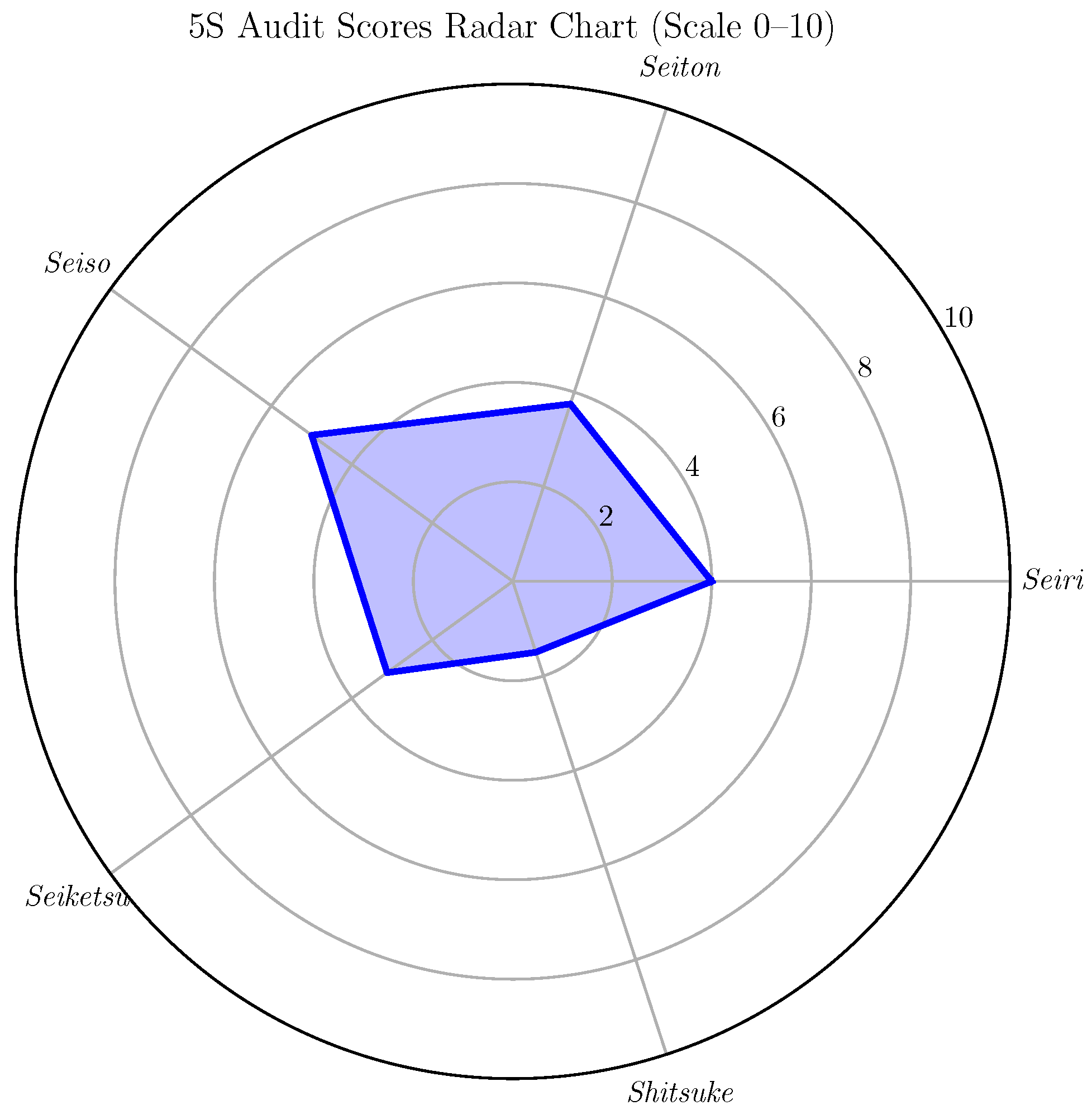

- The audit identified major shortcomings in the application of the Seiri (Sort) principle, particularly regarding material segregation and classification. Conforming parts, obsolete items, and damaged materials were found stored together without appropriate labeling. This compromised inventory accuracy and created discrepancies between physical stock and ERP data, especially since defective items were still marked as available.Although the absence of a formal picking system currently limits operational disruption, the key risk lies in the accidental shipment of non-conforming items to customers, jeopardizing service quality and project timelines. Despite being physically easy to correct, this issue has serious implications for quality control and data integrity.The average score of 4.0 reflects a substandard performance by Lean logistics benchmarks, highlighting the urgent need for structured routines in sorting, discarding, and organizing, supported by visual controls and continuous team engagement.

- The application of the Seiton (Set in Order) principle was inconsistent. While some shelves were labeled alphanumerically, the absence of a coherent location logic and standardized visual guidance hindered rapid identification of stored materials. There were no designated zones for receiving or shipping, no floor markings, and no standard labeling conventions. Critical gaps also included a lack of stock level controls, missing Kanban cards, and unsafe chemical storage.An average score of 3.75 indicates a medium maturity level. Although sporadic efforts were evident, overall storage remains disorganized and must be systematically improved to ensure safety and operational coherence.

- The Seiso (Shine) principle was partially implemented but lacked formalization. Although the warehouse floor was generally clean despite wear, and equipment appeared reasonably maintained, some damaged tools (e.g., grinder, screwdriver) revealed gaps in aligning cleaning with preventive maintenance. Other deficiencies included the absence of hazardous waste segregation, lack of a formal cleaning checklist, and undefined responsibilities—cleaning duties were informally assigned to a single employee.The average score of 5.0 suggests a moderate level of implementation, pointing to the need for standardized and sustainable cleaning routines, with clearly assigned responsibilities.

- The Seiketsu (Standardize) principle exhibited structural weaknesses. No records of internal improvement audits or tracking of corrective actions were available, which hampers structured oversight and continuous improvement. Although certain procedures were included in the management manual, they were neither visible nor readily accessible at the workplace.The average score of 3.125 highlights an early-stage maturity level. The lack of visual controls, routine verification mechanisms, and accountability structures inhibits the consolidation of good practices and exposes the system to backsliding. Strengthening this principle will require visible procedures, standardized routines, and accessible documentation.

- The lowest score was recorded for Shitsuke (Sustain), at just 1.5, indicating a critical lack of discipline and process adherence. Stock control via Kanban was nonexistent, procedures were outdated, and no 5S-related information was displayed, undermining team alignment and execution. Moreover, there were no formal training programs, no clear role definitions, and no visual performance indicators.Significant improvements in Shitsuke will require structured training initiatives, clearly defined responsibilities, and a deeply embedded culture of continuous improvement and accountability.

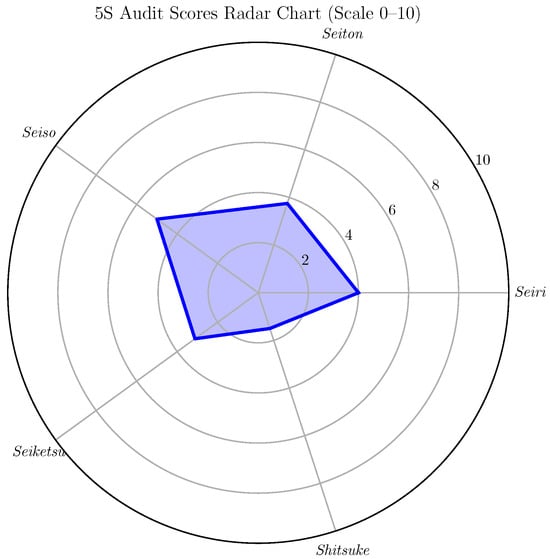

In summary, the 5S audit assessed the warehouse’s organizational maturity across all five principles, revealing highly uneven implementation. Figure 3 presents the audit scores per principle, visually highlighting both strengths and areas requiring substantial improvement. The radar chart illustrates a system still in its infancy, characterized by fragmented and uncoordinated practices. The lowest-scoring principles—Seiketsu and Shitsuke—reflect a lack of formal routines, systematic verification, and employee engagement, all of which are crucial for sustaining improvement and fostering a continuous improvement mindset.

Figure 3.

5S audit results by principle.

4.2. Root Cause Identification

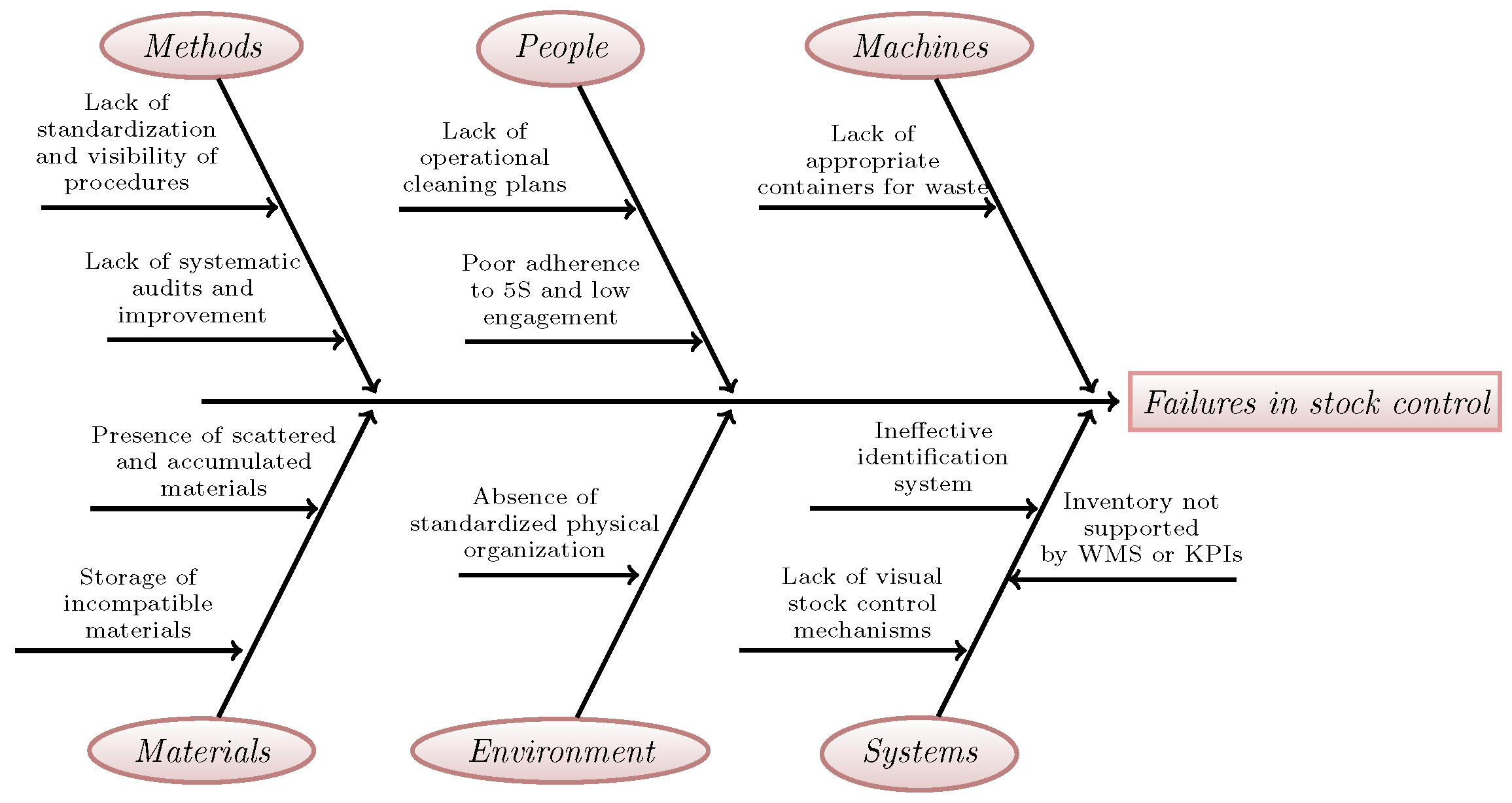

Building on the observations presented in Section 4.1, we structured the list of operational problems and their root causes using a combined 5W analysis and Fishbone Diagram approach to systematize the findings.

The on-site implementation of the 5W component of the extended 5W2H method—carried out through direct observations and operator interviews—enabled the clear identification of recurring, concrete dysfunctions. This approach facilitated the precise mapping of critical failures according to each 5S principle, detailing their root causes, physical locations, frequencies, responsible parties, and logistical impacts.

The analysis revealed that the most significant constraints arise under the Seiton principle, related to physical organization and space utilization, characterized by a lack of arrangement criteria, standardized signage, and visual stock control mechanisms. Notable deficiencies were also found in Seiketsu, where weak standardization and absence of internal audits undermine continuous improvement efforts. Meanwhile, Seiri, Seiso, and Shitsuke displayed inconsistent practices in sorting, cleaning, and discipline, reflecting an underdeveloped organizational culture rooted in lean principles.

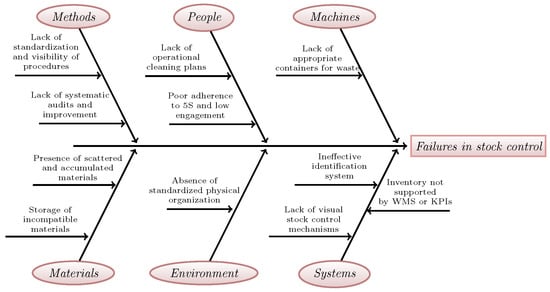

To support a thorough and structured analysis of the root causes behind logistical inefficiencies in the Organization’s warehouse, a Fishbone Diagram was constructed. This tool facilitated the decomposition of the central issue—identified as “Failures in stock control”—into thematic categories, thereby shedding light on the structural sources and interrelated factors contributing to the problem (Figure 4). It is important to emphasize that, in this context, the Fishbone Diagram is not intended to delineate actionable corrective measures. Rather, it serves as a visual aid to organize and aggregate potential causes into classical categories, thus providing a comprehensive overview of the problem landscape.

Figure 4.

Fishbone diagram illustrating the root causes of stock control failures, derived using the 5W methodology.

To complement this qualitative analysis with an objective measure, the metric Stock Accuracy is proposed as a KPI. It quantifies the reliability of digital system records compared to physical stock, directly reflecting stock control quality. Stock Accuracy is defined as the ratio of items with correct records—where physical stock matches digital records exactly in quantity, location, and batch number if applicable—to total items audited:

This metric should be monitored in future internal audits and cycle counts, serving as a key indicator to assess the impact of improvement actions on data reliability, traceability, and overall stock management efficiency.

4.3. Risk Assessment

The FMECA methodology was then applied to characterize the root causes of the identified problems and to rank them according to criticality (or severity), detectability (or observability), and frequency (or occurrence). Before the audits, the FMECA guidelines [45] were reviewed by the auditing team to ensure their proper and uniform application.

Building on the causal relationships established previously (see Section 4.2), specific failure modes were identified for each observed issue. Root causes structured in the Ishikawa diagram, complemented by the 5W analysis, were interpreted as contributing factors that, due to their nature and persistence, lead to recurring failures in warehouse operations. Each problem identified during the 5S audit was thus mapped to a corresponding failure mode, linking qualitative diagnosis with quantitative risk assessment.

Table 5 presents the FMECA matrix, derived from combining the non-conformities identified during the 5S audit with the application of the 5W tool. It highlights failure modes with the greatest impact on logistics performance, organized by predefined criteria. Each entry describes a potential failure—any condition, practice, or lack of control that could adversely affect system performance. Identifying these failures supports a preventive approach, enabling corrective actions before breakdowns occur. Parameters were scored on a 1-to-10 scale, with the RPN calculated accordingly.

Table 5.

Expanded FMECA matrix: failure cause, effect, detection.

The FMECA scoring in this study relied on assessments from three internal technicians. While their expertise ensured context-specific relevance, the limited panel size and the absence of a formal consistency check (e.g., Cohen’s Kappa) introduce a degree of subjectivity into the Severity–Occurrence–Detection ratings. To reduce this bias, fuzzy logic or Bayesian-based FMECA formulations, which explicitly model uncertainty and provide more robust aggregation of expert judgments, can be used.

The matrix details key failure modes, their scores, and the technical rationale behind each assessment, forming the basis for prioritizing actions in the improvement plan. The most critical failure is the joint storage of potentially incompatible materials (RPN = 378), for which preventive segregation, risk signage, and containment aligned with safety and storage best practices are recommended. Other notable issues include inventory management lacking WMS and KPI support (RPN = 336) and ineffective screening of obsolete materials (RPN = 294), revealing digital and procedural gaps that impact traceability, planning, space utilization, and logistics.

In summary, the FMECA matrix prioritizes failures by criticality, exposing structural weaknesses and guiding the strategic allocation of resources in the warehouse action plan.

5. Application—Improvement-Control Phases

This Section presents the structured execution of the improvement plan across two phases: Improvement and Control.

5.1. Improvement Phase

First, we describe the action taken under the Operational adjustment with minimal capital expenditure. Then, in subsequent Sections we address the various tasks in Implementation of root cause eradication measures phase.

5.1.1. Warehouse Reorganization

The A-B-C segmentation analysis was performed considering both the usage frequency and the economic value of each stock item, where value was calculated as quantity multiplied by unit price. Items were ranked in descending order by their total stock value and classified according to their relative contribution to the cumulative inventory value. The segmentation adhered to standard logistics criteria, adapted to this context as follows:

- Class A: Items comprising the top 80% of cumulative value, typically representing about 15–20% of SKUs.

- Class B: Items which, together with Class A, account for 95% of the total value.

- Class C: Items making up the remaining 5% of value, usually numerous but with low individual financial impact.

To enhance operational decision-making, the A-B-C segmentation was further analyzed by product category, as summarized in Table 6. This analysis underscores the strategic importance of A-B-C classification in guiding warehouse priorities. For example, the Fastening Parts category concentrates the majority of Class A items, with a total stock value exceeding EUR 34,000. These high-value items warrant stringent inventory control measures, prime warehouse locations for easy accessibility, enhanced traceability, and stricter replenishment policies to ensure uninterrupted availability.

Table 6.

Value distribution by product category and A-B-C class.

Conversely, categories such as Production Consumables and Accessories are dominated by Class C items, which are low in individual value and overall economic impact. For these, a simplified and aggregated management approach is appropriate, avoiding unnecessary effort in detailed tracking. Operational efficiencies can be gained by grouping items by function, applying flexible reorder points, or consolidating picking zones.

The Hinges and Handles category exhibits a balanced distribution across the A-B-C classes, suggesting the need for hybrid management strategies: rigorous control and monitoring for Class A items, alongside streamlined, less intensive handling for Classes B and C. This nuanced A-B-C-based segmentation supports targeted resource allocation, optimizes warehouse layout, and tailors inventory management policies according to the financial and operational significance of stock items.

5.1.2. Setting Corrective Actions

The A3 Matrix initiates the improvement process by integrating the findings from the FMECA, identifying root causes, defining objectives, and outlining strategic actions. Informed by the results of the 5S audit and the value stream mapping (VSM) of the production line, the matrix emphasizes persistent stock management issues—such as mismatches between physical and digital inventory, unregistered materials, and incorrect stock counts. These issues compromise data reliability, trigger redundant orders, elevate idle inventory levels, and inflate operational costs.

The underlying causes of these dysfunctions include (i) the absence of standardized bin labeling, (ii) a lack of visual inventory control mechanisms, and (iii) a disorganized warehouse layout compounded by informal and inconsistent cleaning practices. These structural weaknesses hinder informed decision-making and disrupt the seamless flow of materials throughout the system.

Identifying the root causes of these issues was a pivotal step in the improvement initiative. A thorough review of logistics flows, combined with on-site observations, revealed a consistent set of structural and operational failures corresponding to the critical failure modes documented in the FMECA matrix. To ensure the validity of the identified causes, a triangulation approach was employed—integrating operator feedback, direct field observations, and cross-referencing with the most critical failure modes. This confirmed the following root causes:

- Lack of integration between physical and digital systems (ERP/WMS);

- Absence of formal policies for sorting, organizing, cleaning, and labeling;

- Inconsistent practices in logistics operations (picking, restocking, storage);

- Weak organizational culture with limited adherence to 5S principles;

- Lack of systematic monitoring, internal audits, and performance indicators.

Based on this critical analysis, the desired future state (TO-BE) for the warehouse is a reliable, standardized, and digitally traceable management model, grounded in sound logistics principles and Lean thinking. The objective is to establish technical, operational, and cultural foundations that enable seamless future WMS–ERP integration, fostering a clean, efficient, and transparent operation. To achieve this objective, the action plan focuses on the following:

- Implementing a bin location system with logical, standardized coding;

- Ensuring clear product identification using alphanumeric or QR codes, from receipt to dispatch;

- Establishing a foundation for WMS–ERP integration through standardized coding, visual sorting, and ERP data configuration;

- Formalizing the picking process with work order checklists and shipment verification controls;

- Supporting stock management via 5S practices—sorting, standardized layout, and structured cleaning;

- Utilizing A-B-C parts segmentation to inform layout design, restocking priorities, and obsolescence control.

5.1.3. Prioritize Corrective Actions

The action plan follows a structured prioritization policy that goes beyond a purely risk-based approach. While Risk Priority Number (RPN) values inform urgency, actions are sequenced based on estimated economic requirements (CAPEX), allowing for the progressive removal of structural constraints and laying the groundwork for sustainable improvements. CAPEX estimates are derived from historical benchmarks. Actions are then ranked accordingly, balancing impact on risk mitigation and feasibility. This approach ensures immediate gains while preparing the organization for future digital transformation—such as traceability systems and decision-support tools. Actions enabling the minimum physical and organizational conditions for such transformation are prioritized, even if their RPN values are moderate.

It is worth noting that the economic evaluation in this study was based on a simplified payback period approach, focusing on the short-term feasibility of the proposed actions. This choice reflects the relatively modest investment requirements and the fact that operational gains may not be sustained uniformly over a long horizon. However, this simplification also implies that key financial aspects such as the time value of money, inventory holding costs, and discounted cash flow indicators (e.g., NPV, IRR) were not explicitly considered. While this limitation does not significantly affect the conclusions for low-CAPEX interventions with rapid returns, we recognize that incorporating these advanced financial methods would be essential in cases involving larger investments or longer-term benefit streams. Future research should therefore extend the model to include such methods, providing a more comprehensive basis for investment decisions.

Table 7 presents the estimated CAPEX and RPN for each corrective action, forming the technical foundation of the action plan. Aligned with the 5W2H framework, column two addresses “How?” by describing the intervention strategy, while column three answers “How much?” with the associated cost. These figures are derived from Task 2—Estimation of intervention costs—in Table 2, and, together with the root causes from Section 4.2, inform Task 3—Prioritize corrective actions, according to a predefined ranking criterion. In total, the plan includes twelve actions, ordered by increasing intervention cost to ensure a gradual and cost-effective implementation.

Table 7.

Estimated CAPEX and RPN per corrective action for identified root causes.

This integrated prioritization underscores the need for a systematic overhaul of the warehouse’s logistical, physical, and informational processes. The diagnosis revealed critical gaps—such as poor traceability, disorganization, unsafe storage, and absent standard procedures—that hinder performance and limit readiness for digital transformation.

Using the heuristic from Section 2.2.4, and sorting actions by descending RPN, an investment of EUR 10,240 suffices to mitigate over 80% of total A-class risks. All but the fourth, fifth, and twelfth actions fall into this high-priority group. Alternatively, solving formulation (2) with EUR 5000 yields an optimal policy that excludes only the tenth action.

5.1.4. Action Plan Implementation

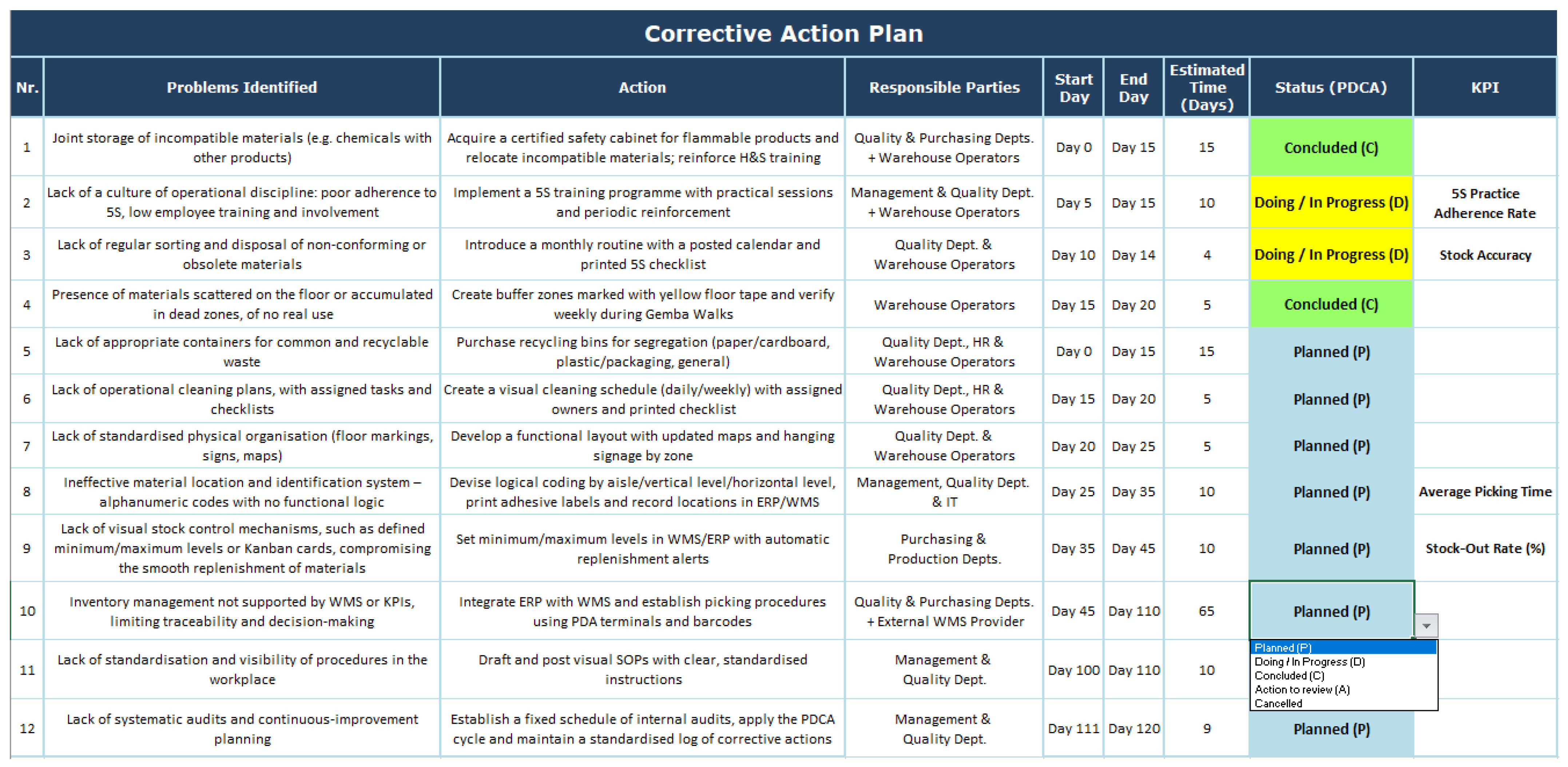

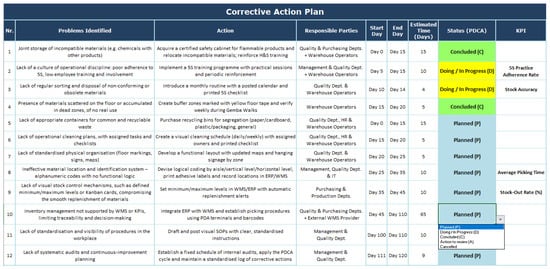

The implementation of the prioritized actions follows a structured and transparent roadmap grounded in the PDCA cycle. Figure 5 presents twelve key actions, outlining their respective deadlines, assigned responsibilities, estimated costs, execution status, and associated KPIs. To ensure effective monitoring, a control tool featuring a status selection box was developed to track the progress of each action across the PDCA stages. This visual management aid promotes agile, responsive, and participatory oversight, in alignment with Lean management principles.

Figure 5.

Corrective Action Plan showing priorities, timelines, responsibilities, estimated costs, execution status, and associated KPIs.

Each action is assigned to one of the following categories, enabling clear and objective status tracking:

- Planned (P)—structured and validated, in preparation or scheduling;

- In progress (D)—operational activities underway;

- Completed (C)—successfully executed and KPI-verified;

- To be reviewed (A)—executed with deviations, requiring adjustment;

- Cancelled—removed from the plan due to operational or strategic reasons.

This classification enables real-time tracking and early detection of issues or re-planning needs. Its integration with the PDCA cycle ensures that corrective actions contribute to continuous learning, process improvement, and the consolidation of best practices.

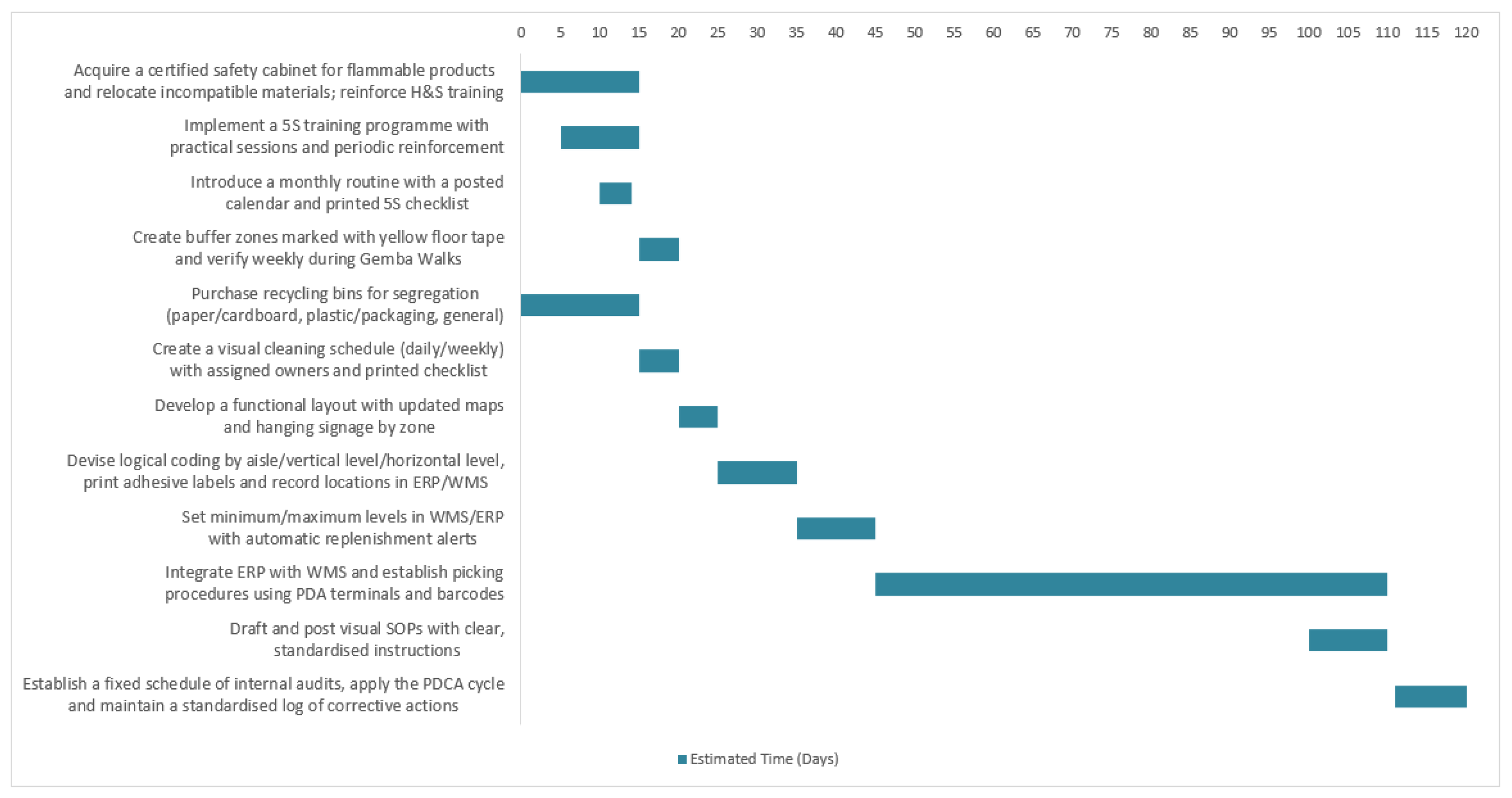

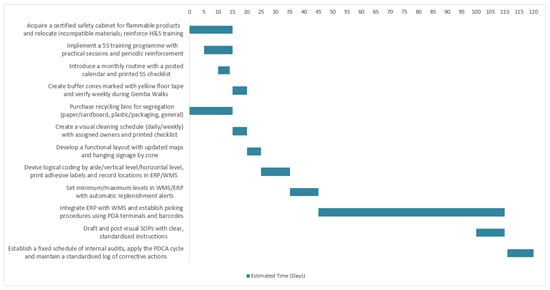

To provide a clear and structured timeline for implementing corrective actions, a Gantt chart was developed (Figure 6). It illustrates the estimated duration, temporal overlap, and logical sequence of actions, as defined in the 5W2H plan. Each horizontal bar represents a specific action, positioned according to the overall project calendar. The sequencing of tasks reflects prioritization based on criticality, practical feasibility, and operational prerequisites for future WMS integration—ensuring that foundational actions are addressed in the early stages.

Figure 6.

Gantt chart outlining the execution timeline of corrective actions, with emphasis on priorities, dependencies, and implementation phases.

The Gantt chart enables a clear overview of progress and interdependencies, supporting effective resource allocation, audit planning, and communication with project stakeholders. Its continuous updates, aligned with the PDCA status of each action, make it a key tool for implementation tracking and continuous improvement. This chart operationalizes Task 4—Scheduling of interventions—from Table 2.

To monitor implementation and ensure sustainability, the following KPIs were established:

- Stock Accuracy (%): measures the percentage of items for which physical stock matches ERP records exactly in quantity, batch number, and location. This KPI is calculated using Equation (3) and updated monthly through cycle counts or representative sampling. Original audit sheets and ERP logs are maintained for verifiability.

- Stockout Rate (%): indicates the proportion of orders experiencing stock shortages in a given period. It is calculated asand updated monthly.

- Average Picking Time: quantifies the efficiency of warehouse operations by measuring the time required to pick orders. It is calculated asusing a representative sample of orders timed weekly or monthly. Original timing records are maintained for verification.

- 5S Compliance Rate (%): reflects adherence to the 5S principles and is calculated asAudits are performed monthly or quarterly, and records are maintained for traceability.

Collectively, these metrics address Task 5—Define KPIs—in Table 2 and provide a quantitative basis for monitoring improvements in stock control, operational efficiency, and organizational practices.

5.1.5. Fostering a Continuous Improvement Environment

To ensure a structured, participative, and sustainable implementation, all actions will follow the PDCA cycle—a foundational Lean methodology that enables execution, monitoring, and adaptive improvement.

- Plan: A detailed action plan will be developed based on the priorities in Table 7, outlining timelines, responsibilities, resources, and KPIs. Alignment sessions with operations and quality teams will ensure clarity and feasibility.

- Do: Actions will be deployed in phases using the 5W2H method. Operational teams will lead implementation, supported by photo records and progress reports. Quick-win actions (e.g., layout adjustments, buffer zones, cleaning plans) will be prioritized, while more complex tasks (e.g., ERP / WMS integration) will require external support and interdepartmental coordination.

- Check: Effectiveness will be evaluated through internal audits and KPI monitoring, focusing on RPN reduction, workflow improvements, spatial organization, and process efficiency.

- Act: Corrective or reinforcing actions will be taken based on results. Best practices will be standardized, SOPs updated, and future plans revised accordingly. High-impact actions will be institutionalized to drive long-term improvement and continuous learning. The standardization of procedures will be discussed in a later section.

We recognize that sustaining the Shitsuke (Sustain) phase of 5S depends on both procedural adherence and organizational culture. Implementation was designed to minimize disruption, focusing on operator training, SOPs, and visual management, while active supervisor involvement and continuous communication help address cultural resistance. Quantitative monitoring relied on KPIs such as 5S compliance, stock accuracy, and average picking time to track adherence. The implementation could incorporate longitudinal assessments and formal cultural metrics to more precisely evaluate and reinforce sustained improvements.

The systematic use of PDCA ensures that improvements are sustained, integrated into daily operations, and aligned with principles of operational excellence, standardization, and total quality management.

5.2. Control Phase

5.2.1. Monitoring and Correcting

This phase involves the continuous monitoring of the activities described in Section 5.1.4. Progress is tracked using the KPIs defined in Equations (3)–(6) and the project timeline shown in Figure 6. Any deviations—whether from baseline performance targets or the established schedule—are promptly identified and addressed through appropriate corrective measures. This ensures alignment with expected outcomes and maintains the project’s momentum.

Effective practices are formalized into SOPs. Based on the issues identified and the improvement actions proposed, a SOP was developed to consolidate, in a structured and cross-functional manner, the essential logistics procedures required for the efficient operation of the parts warehouse. This addresses the need to standardize key operations such as receiving, storage, inventory control, shipping, and the digital tracking of material flows—ensuring consistency, traceability, and safety across all internal logistics processes. An introduction to SOPs in industrial settings is provided in Section 2.2.6.

The SOP applies to all personnel involved in warehouse operations and serves as a reference for training, audits, and performance evaluation. It is reviewed annually or whenever significant changes occur, and it is organized into six main sections:

- Objective–defines the procedure’s purpose;

- Scope–outlines the area of application;

- Responsibilities–assigns roles to stakeholders;

- Definitions and Abbreviations–clarifies technical terminology;

- Procedure–subdivided into the following:

- (a)

- Receiving and Inspection;

- (b)

- Storage;

- (c)

- Inventory Control;

- (d)

- Shipping;

- (e)

- Warehouse Safety;

- (f)

- Record Maintenance.

5.2.2. Financial Feasibility Analysis of the Improvement Project

Following a thorough diagnostic of the warehouse, twelve high-impact operational issues were identified, leading to targeted and quantified improvement proposals. This section evaluates their implementation feasibility based on financial, technical, and strategic criteria.

The proposed actions are classified as short-maturity operational CAPEX, consisting of tangible and structural enhancements directly impacting warehouse performance and compliance. Examples include Warehouse Management System software, barcode scanners, label printers, A-B-C-based layout reorganization, signage, waste segregation bins, and a certified cabinet for hazardous materials. These low-to-moderate cost investments provide immediate benefits in productivity, traceability, and safety, with typical payback periods under 12 months due to reduced errors, waste, and inventory blind spots. Their classification as CAPEX is justified by the durable nature of the assets and the lasting improvements to infrastructure, which enhance both physical and organizational asset value. While some measures (e.g., signage and training) do not yield direct financial returns, they reduce operational risks and support Lean and continuous improvement objectives.

Financial viability was assessed using three complementary criteria:

- Prevention cost:expenses required to avoid future failures, such as obsolescence, picking errors, stockouts, or accidents.

- Asset proportion: total investment (EUR 10,300) relative to inventory value (EUR 62,091.59), representing only 16.6%.

- Average RPN per proposal: based on FMECA, ensuring priority is given to high-risk issues with cost-effective solutions.

Prioritized proposals have an average RPN above 240, highlighting their critical operational relevance. Many low-cost actions target failures with high disruption potential; for example, marking buffer zones—costing under EUR 50—addresses recurring issues in operator flow and material misplacement. Table 8 presents the cost, RPN, and cost-effectiveness ratio (EUR per RPN point) for the twelve identified issues.

Table 8.

Cost, criticality (RPN), and cost-effectiveness of proposed corrective actions.

Over half the actions have a cost-effectiveness ratio below EUR 1 per RPN point, confirming the efficiency of prioritization and supporting FMECA as a decision-making tool.

It should be noted that the cost-effectiveness ratio (EUR per RPN point) is intended as a prioritization metric rather than a direct financial return. While many actions are expected to generate operational savings—such as reduced errors, lower inventory levels, and improved material flow—quantifying actual OPEX reductions and annual cash flows is challenging at this stage, as implementation is ongoing and operational data remain limited. The estimated payback period of approximately 12 months reflects internal company expectations based on prior experience with similar interventions, rather than a formal Net Present Value (NPV) or Internal Rate of Return (IRR) calculation. Future work could complement this technical prioritization with a full financial assessment, including annualized OPEX savings, NPV, or IRR analysis, providing a more rigorous economic justification.

From a strategic standpoint, the proposed plan is feasible and aligned with company objectives. Key features include the following:

- Total investment under 17% of inventory value, providing high potential return.

- Actions based on practical diagnostics (5S, FMECA, A-B-C segmentation) and executable with in-house resources.

- Low CAPEX requirements with immediate impact on organization, traceability, and control.

- Full alignment with Lean and continuous improvement principles.