Does the Optimal Update Strategy Effectively Promote the Low-Carbon Technology Diffusion Among Manufacturers? An Evolutionary Game of Small-World Network Analysis

Abstract

1. Introduction

- For those manufacturers who produce products lack of low-carbon characteristics, what impacts do carbon reduction costs, carbon taxes and subsidies have on the adoption of low-carbon technology?

- How does the topological structure of small-world networks influence the low-carbon technology diffusion among manufacturers?

- Which primary strategy—that is, random or preferential selection—is best aligned with the mechanisms driving strategic adjustments in manufacturers?

2. Literature Review

2.1. Carbon Taxes and Subsidies

2.2. Low-Carbon Technology

2.3. Incremental Contributions

3. Network Game Model

3.1. Network Structure

3.2. Game Model

3.3. Update Strategy

4. Parameters and Simulation

4.1. Parameters Setting

4.2. Simulation Design

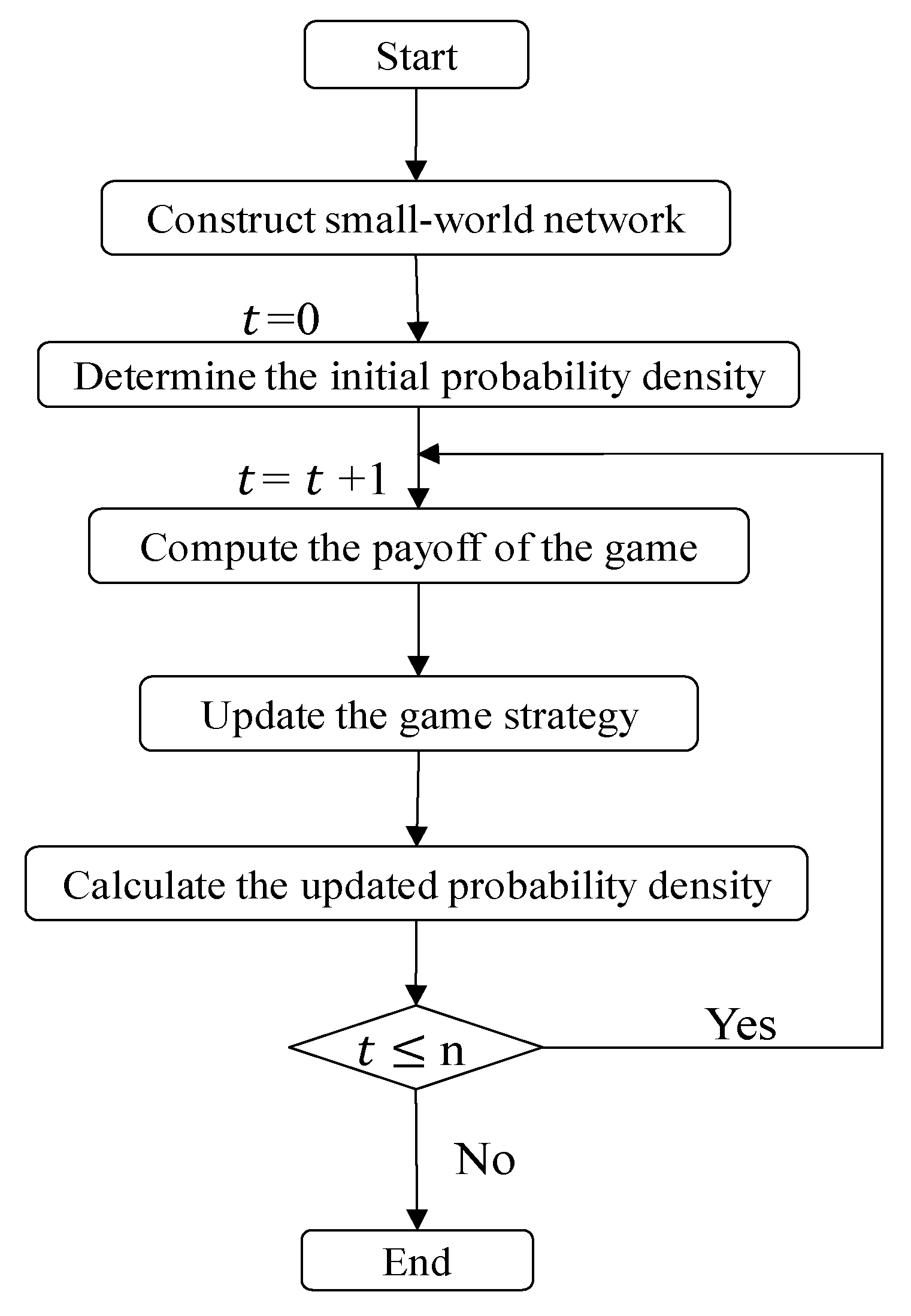

- (1)

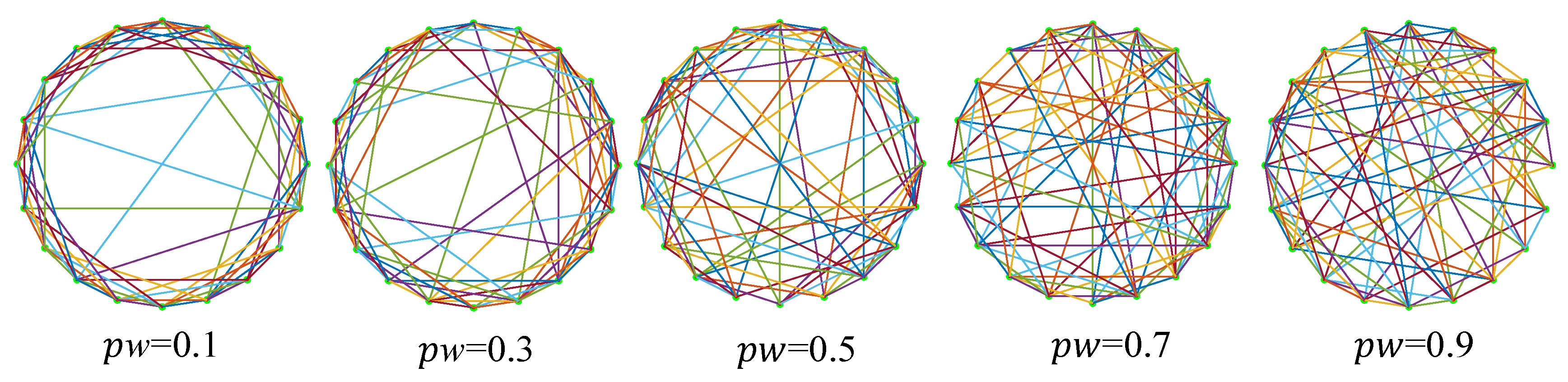

- Small-world networks construction: Based on the WS small-world construction algorithm described in Section 3.1 and following the parameter settings of Liu et al. [35], WS small-world network models with N = 100 (10 × 10) and N = 400 (20 × 20) are constructed using node-networked degree K = 4 and edge reconnection probability .

- (2)

- Determination of the initial probability density: The time horizon for the network evolutionary game is defined from to . At (i.e., in the first round of the game), the initial probability density of manufacturers adopting low-carbon technology is set to , and initial strategy for each manufacturer Vi in the small-world network is then randomly assigned based on this initial probability density. It is important to note that the initial probability density only determines the starting point of the evolutionary process and has no influence on the subsequent trajectory or outcome.

- (3)

- Calculation of game payoffs: For each time step , the payoffs for each manufacturer Vi in the small-world network are figured using the payoff matrix established in the network game model in Section 3.2.

- (4)

- Game strategies update: Based on the update rule outlined in Section 3.3, each manufacturer Vi in the small-world network compares its payoff with that of a neighboring enterprise Vj with a higher degree and then updates its strategies simultaneously based on the comparison results.

- (5)

- Recalculation of the probability density after the update: After one round of the game, the updated strategies of each manufacturer Vi are recorded, and the probability density of manufacturers choosing low-carbon technology at time t is recalculated.

- (6)

- Iterative process: Steps 3–5 are repeated until the predefined game evolution time stepis reached, at which point the simulation experiment ends.The simulation design process is shown in Figure 2.

5. Results and Discussion

5.1. Variations in Critical Coefficients

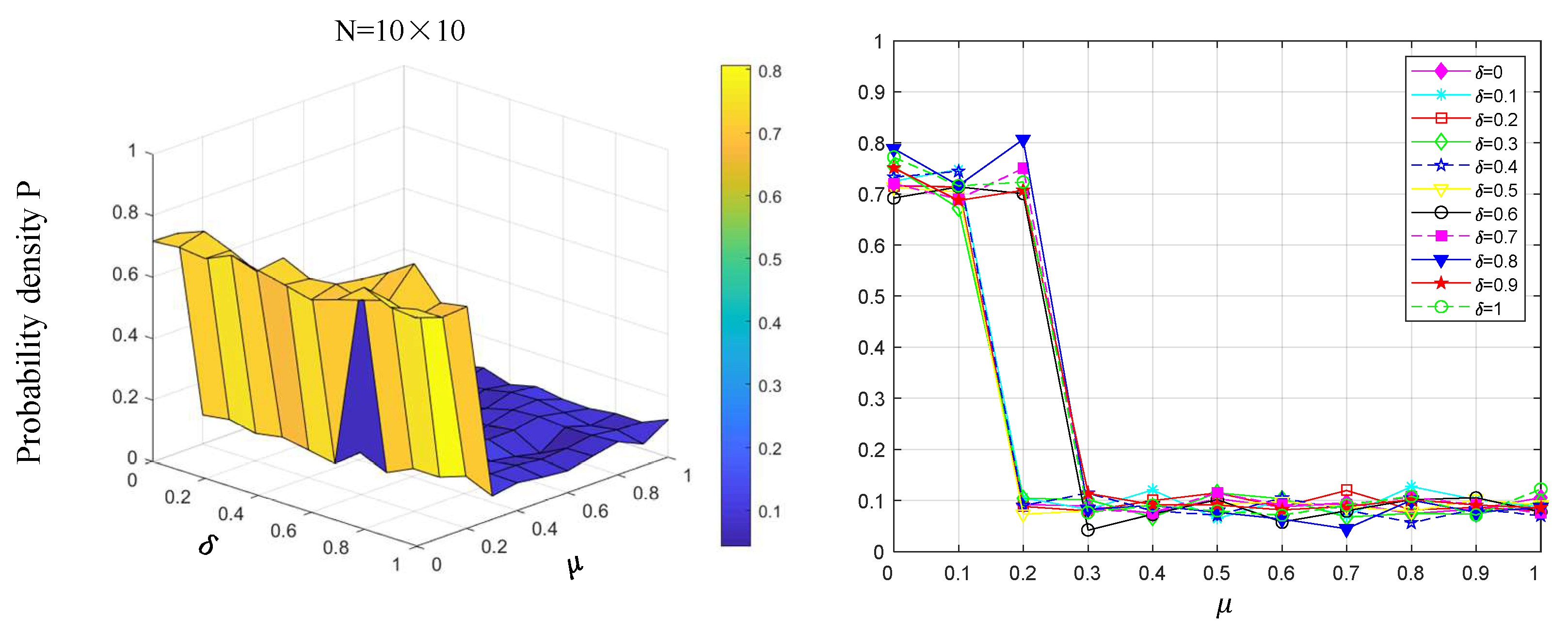

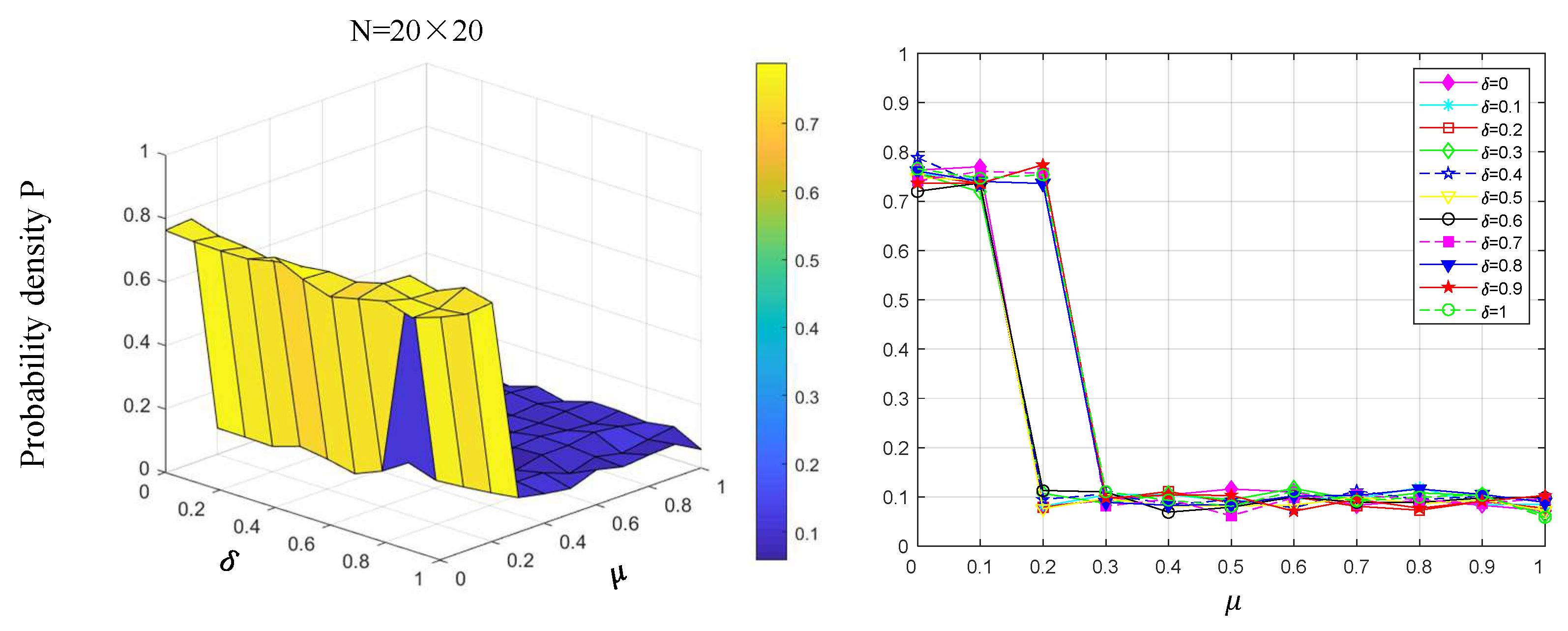

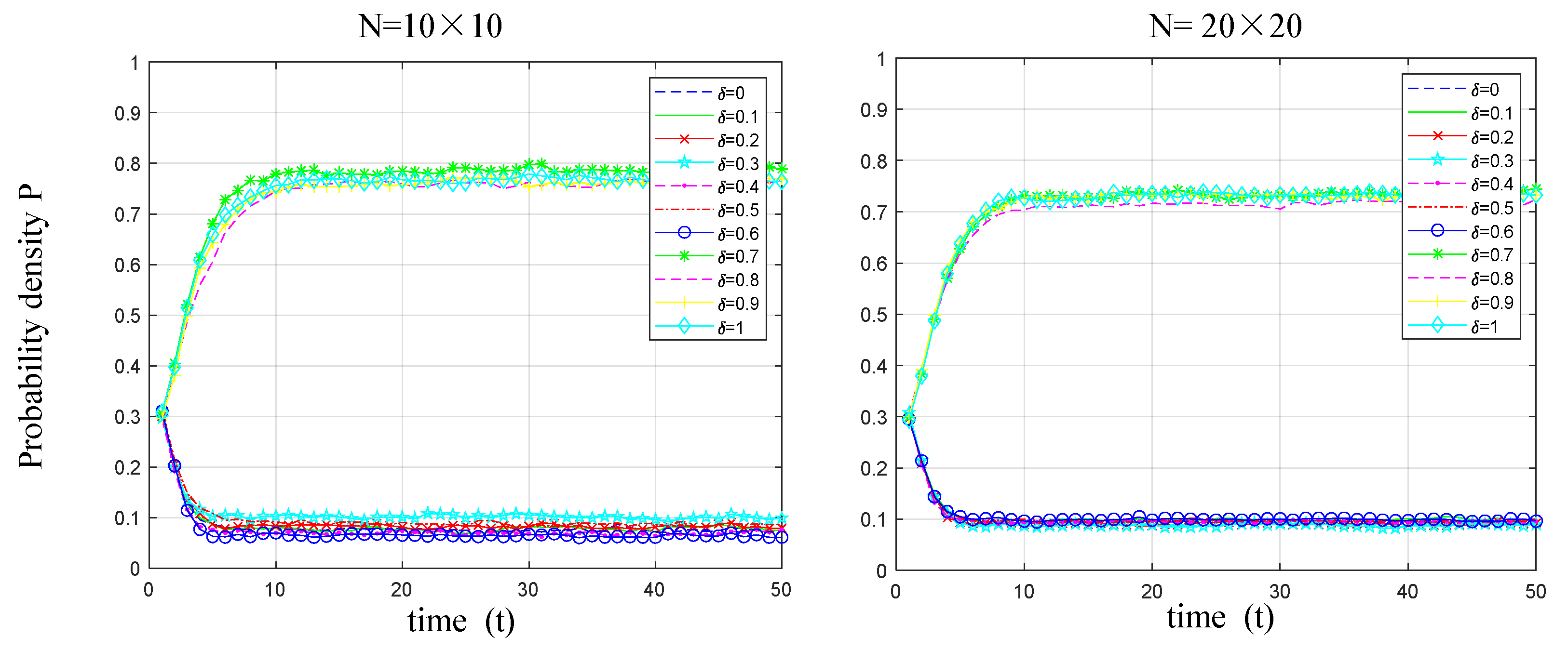

5.1.1. Variations in Low-Carbon Correlation Coefficient

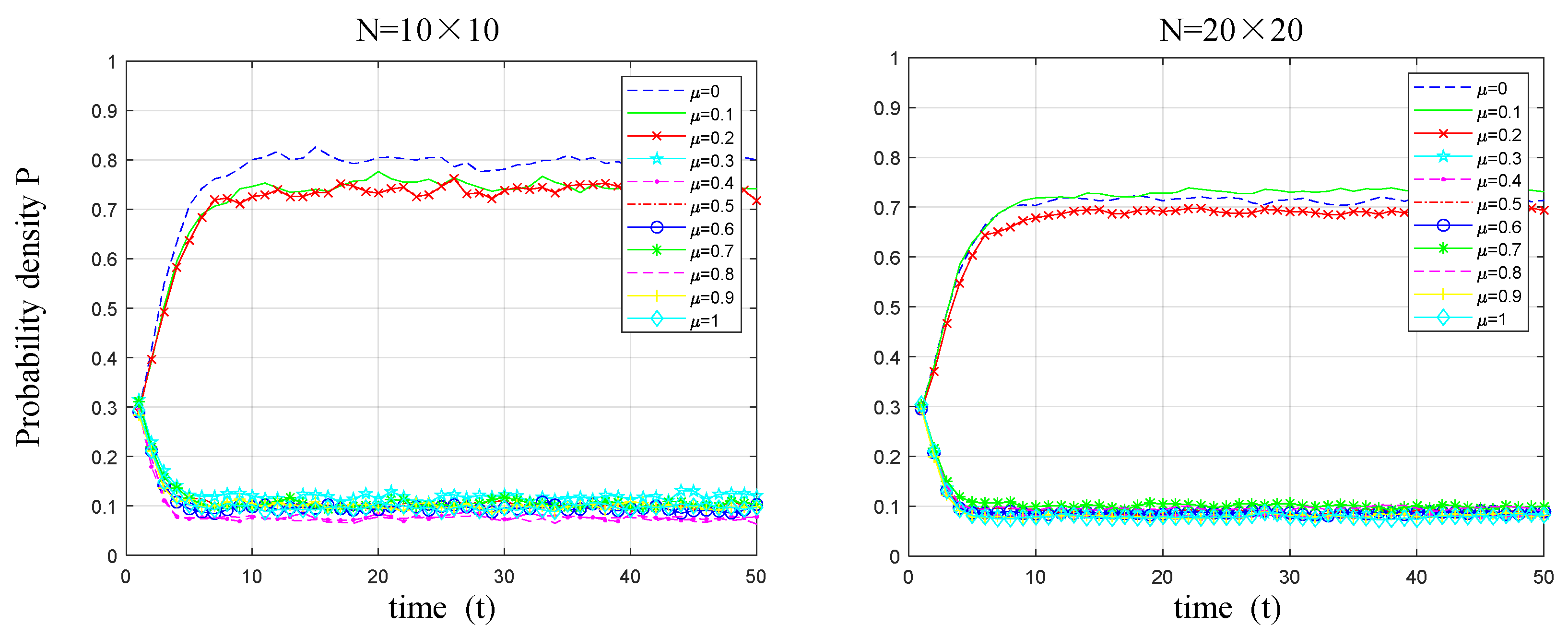

5.1.2. Variations in Government Subsidy Coefficient

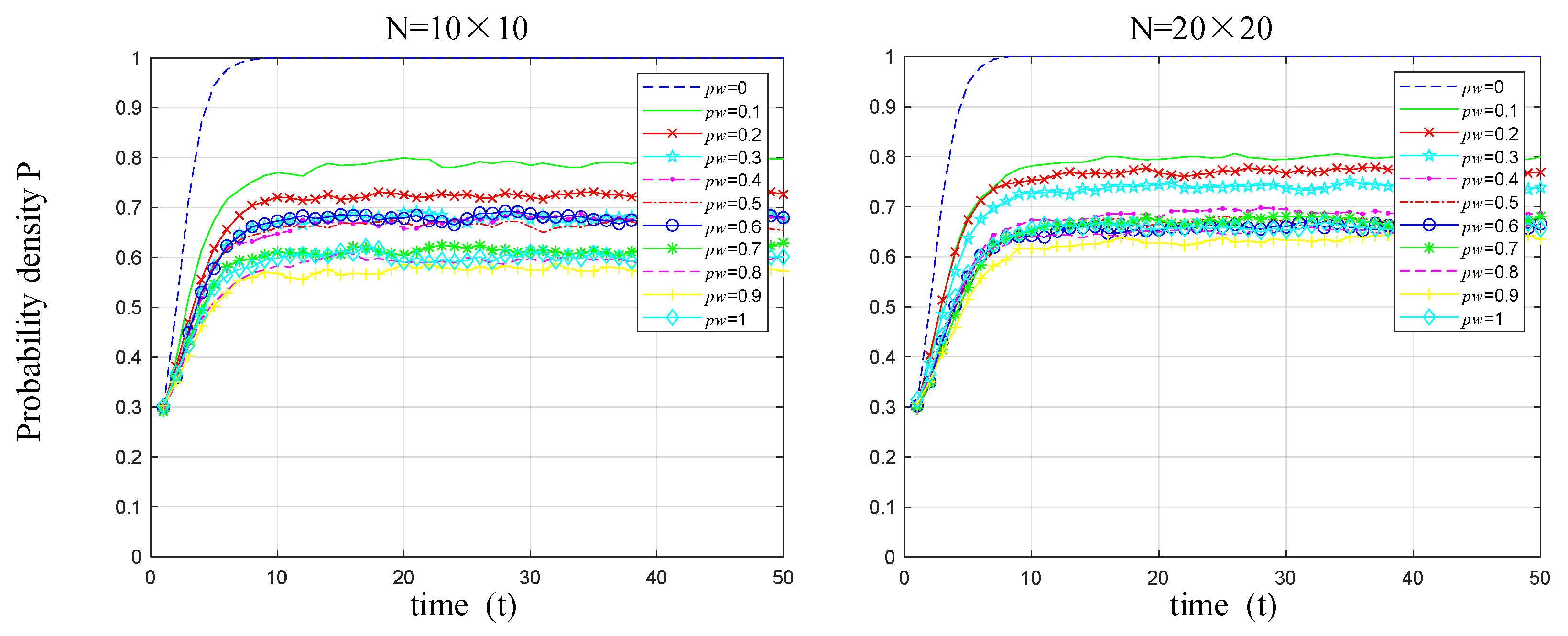

5.1.3. Variations in Carbon Reduction Cost Coefficient

5.2. Variations in Network Structure

5.2.1. Variations in Reconnecting Edges Probability

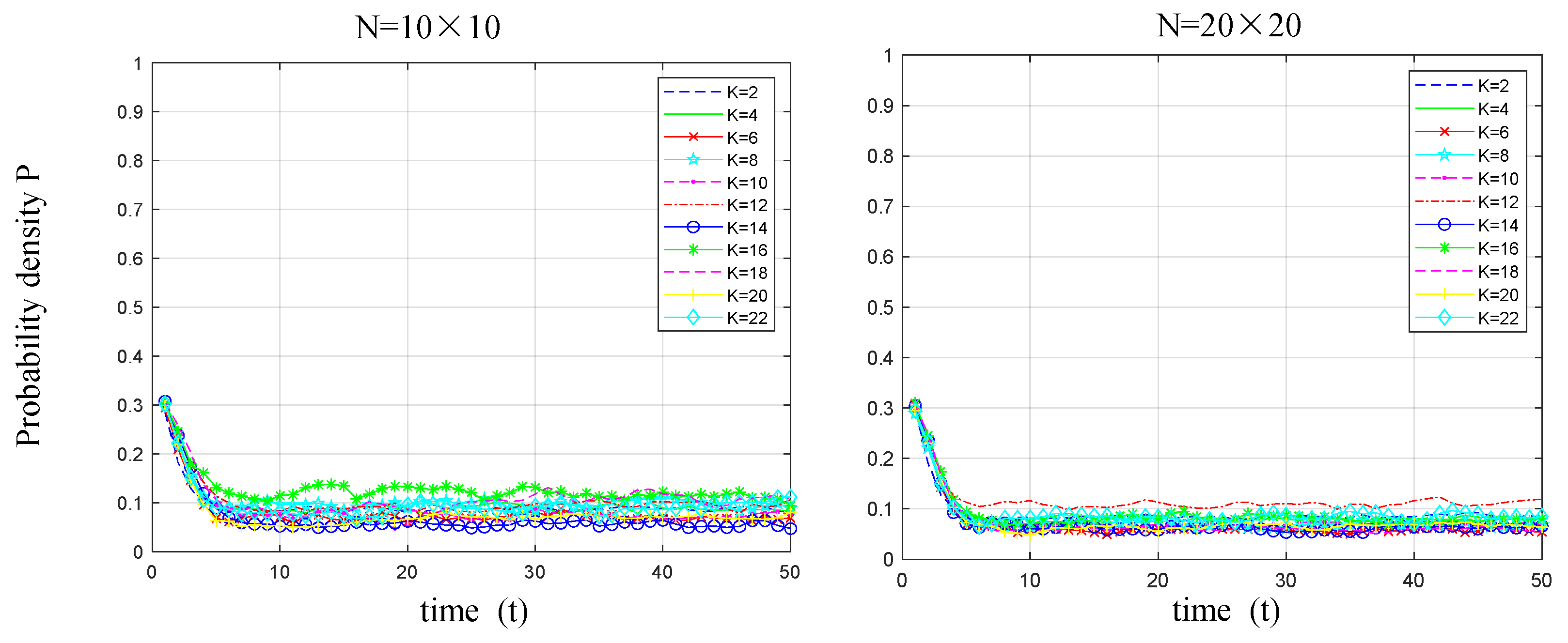

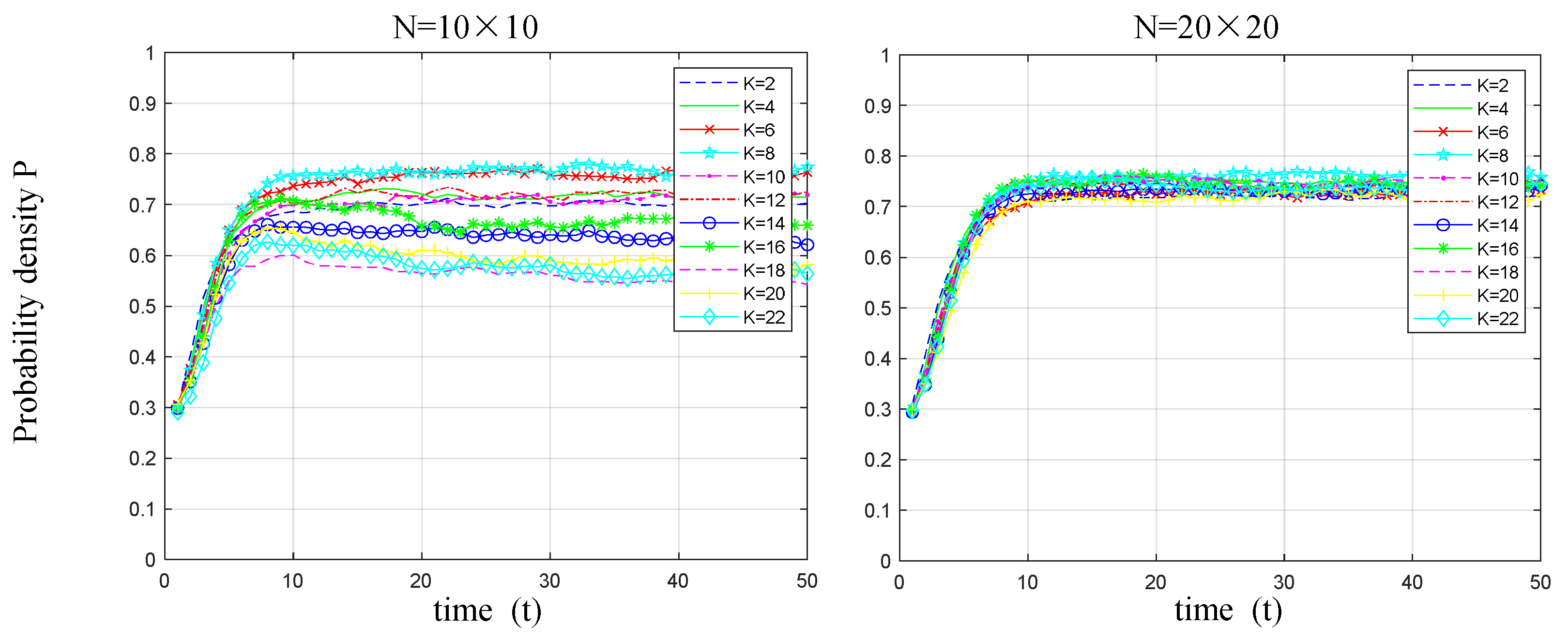

5.2.2. Variations in Node Degree

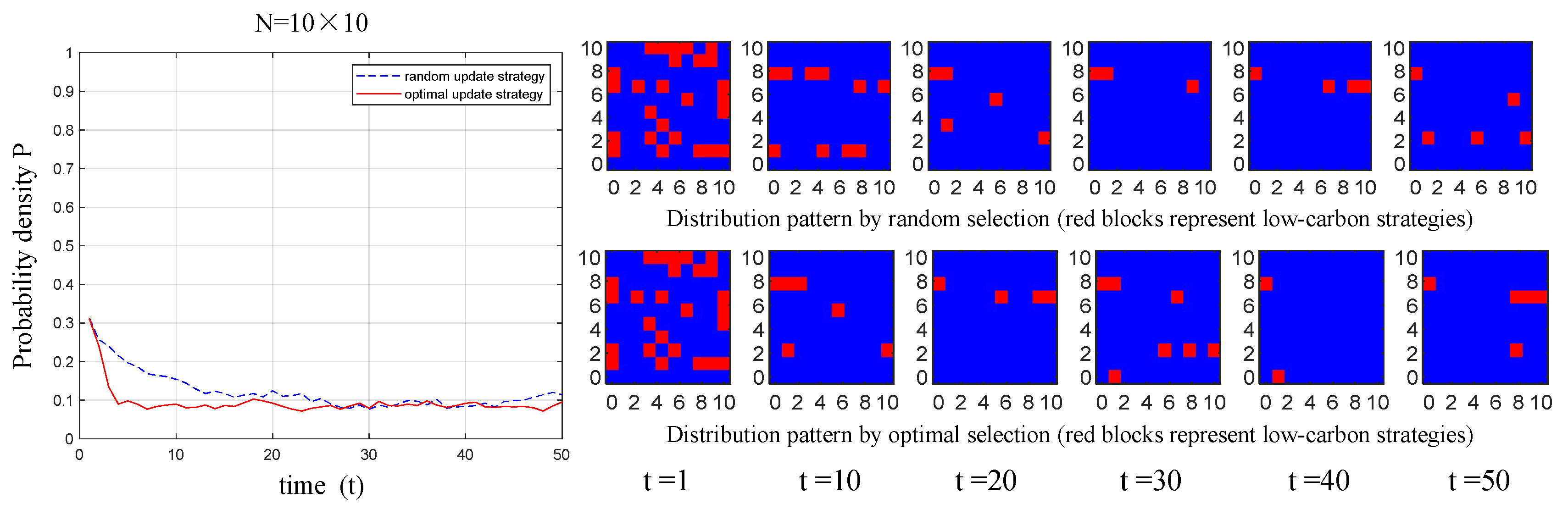

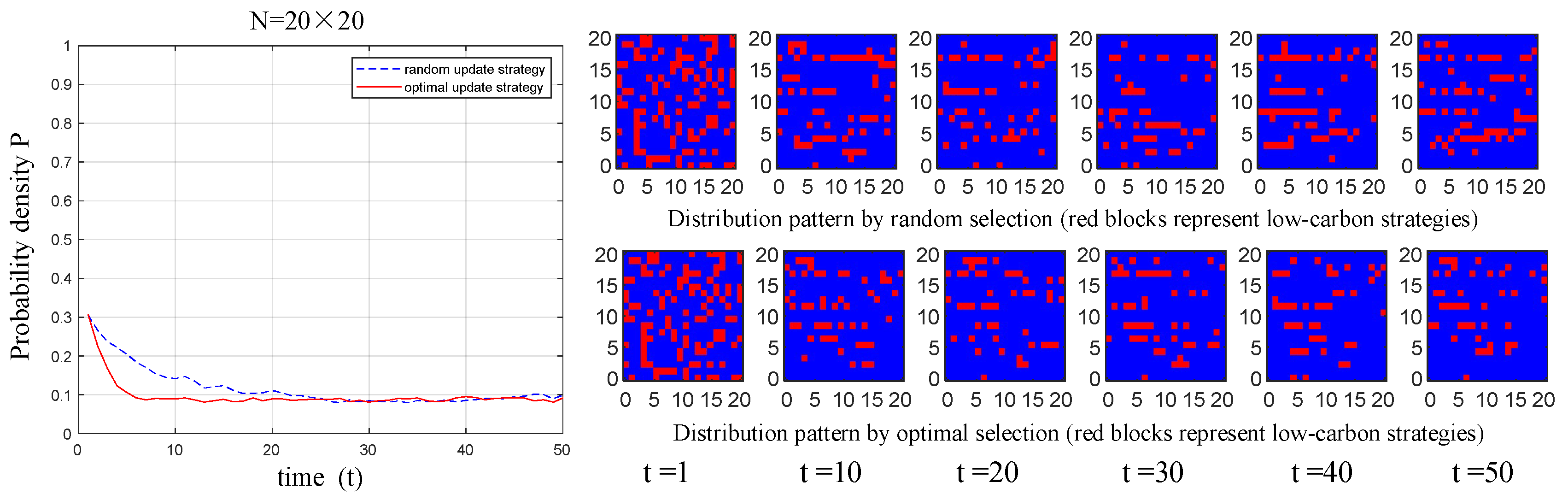

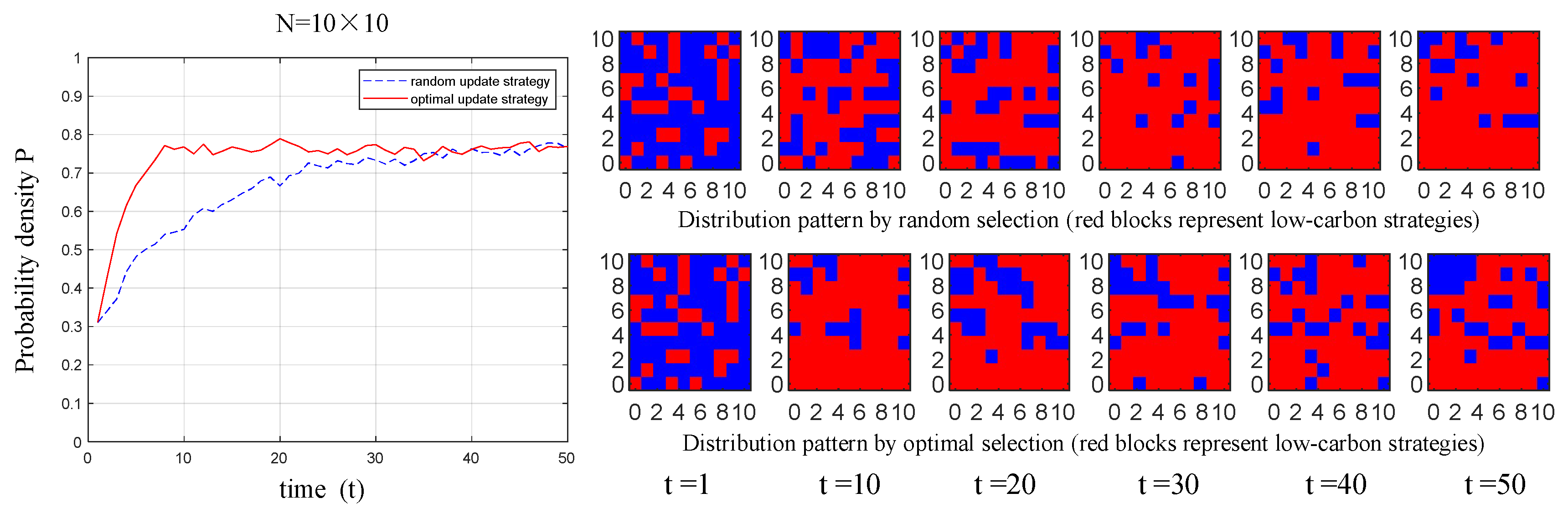

5.3. Variations in Update Strategy

6. Conclusions and Policy Implications

- Based on government-imposed carbon taxes, appropriately increasing subsidies can increase low-carbon technology diffusion among manufacturers. However, once subsidies reach a certain threshold, further increases have no added effect on low-carbon technology diffusion. Thus, reducing carbon-emission reduction costs for manufacturers can encourage low-carbon technology diffusion in small-world networks. Nonetheless, the initial investment required for low-carbon technologies and the uncertainty of future returns are key factors hindering independent adoption by manufacturers. However, as the scale of manufacturing enterprise small-world networks increases, firms’ low-carbon behavioral decisions become more consistent, reducing the likelihood of random variations.

- Whether through continued increases in government subsidies or reductions in emission-reduction costs, manufacturers’ low-carbon technology selection and diffusion will tend toward stable equilibrium after reaching a certain threshold, beyond which no further enhancement of low-carbon technology diffusion is possible. The key to low-carbon technology diffusion lies in the structural composition of manufacturers’ small-world networks, which heavily influences the evolution of low-carbon technology adoption and diffusion. Under favorable conditions, when the small-world network approaches a regular network structure, the extent of low-carbon technology diffusion reaches its maximum. Conversely, in unfavorable conditions, the extent of low-carbon technology diffusion is minimized.

- When manufacturers select objects to imitate and learn from, the strategy of preferentially selecting neighbors for updates aligns more closely with their current considerations in choosing competitors. Compared with the traditional random selection update strategy, the preferential selection update strategy can increase the probability density of low-carbon technology diffusion among manufacturers and rapidly achieve a balanced, stable state among them. Although the probability density of low-carbon technology diffusion may decline as the scale of manufacturers’ small-world networks increases, this trend does not diminish the overall effectiveness of the preferential selection strategy.

- China has implemented carbon trading mechanisms in only a limited number of industries, but these mechanisms have yet to impose binding constraints on the majority of manufacturing enterprises, particularly those operating in sectors that are difficult to integrate into the carbon trading market. In this context, carbon taxes offer distinct advantages in terms of implementation ease, regulatory oversight, and broader applicability. As Wang et al. [19] pointed out, carbon taxes can serve as a complementary policy instrument to carbon trading, ensuring more comprehensive coverage of carbon emissions across the manufacturing sector in the future. Furthermore, the allocation and withdrawal of government subsidies should be aligned with carbon tax policies to strengthen the effectiveness of subsidy supervision and incentivization.

- With global industrialization, the manufacturing sector has transitioned from an initial phase of free-market equilibrium to a more structured phase marked by industrial clustering and the emergence of networked hubs. The impact of network structure on the adoption and diffusion of low-carbon technologies by manufacturers has become increasingly significant. Governments must also consider how the networks formed by competition and collaboration among manufacturers affect their decision-making processes when designing policies. Importantly, governments can shape these networks by adjusting market access regulations to encourage the concentration and growth of manufacturing firms. Such interventions could help regulate industry competition and in turn facilitate the low-carbon technologies diffusion.

- Establishing benchmark enterprises for low-carbon transition and disseminating their successful practices can serve as a model for broader industry adoption. Accordingly, the government should prioritize supporting large manufacturing enterprises in their low-carbon transformation processes. In 2023, multiple departments of China jointly issued the “Opinions on Accelerating the Establishment of a Product Carbon Footprint Management System”, which highlighted the critical role of leading enterprises in setting industry benchmarks, further supporting the arguments of this paper. In addition, fostering interaction and communication among enterprises facilitates knowledge transfer and learning, thereby facilitating the low-carbon technologies diffusion across industries.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xinhua Net. 2024 Was the Hottest Year in History, and the Global Average Temperature Exceeded the 1.5 °C Temperature Control Target for the First Time. Available online: https://www.xinhuanet.com/tech/20250114/2048ca22d7e74da4a5b1efa251d85c74/c.html (accessed on 20 January 2025). (In Chinese).

- Dengjie, T. Vigorously Promote Energy Conservation Work to Assist in Achieving Carbon Peak and Carbon Neutrality People’s Daily. 2021-08-25(013). Available online: https://www.ndrc.gov.cn/fzggw/wld/tdj/zyhd/202108/t20210825_1294578.html (accessed on 20 January 2025). (In Chinese)

- Ministry of Industry and Information Technology of the People’s Republic of China. Guiding Opinions on Accelerating the Green Development of Manufacturing Industry. 2024. Available online: https://www.gov.cn/zhengce/zhengceku/202403/content_6935684.htm (accessed on 20 January 2025). (In Chinese)

- China Development Network. Fully Recognizing the Necessity and Difficulty of Achieving the “Double Carbon” Goal. Available online: http://www.chinadevelopment.com.cn/news/zj/2022/03/1771088.shtml (accessed on 20 January 2025). (In Chinese).

- Onozaka, Y.; McFadden, D.T. Does Local Labeling Complement or Compete with Other Sustainable Labels? A Conjoint Analysis of Direct and Joint Values for Fresh Produce Claim. Am. J. Agric. Econ. 2011, 93, 689–702. [Google Scholar] [CrossRef]

- Wang, L.; Zheng, J.J. Research on low-carbon diffusion considering the game among enterprises in the complex network context. J. Clean. Prod. 2019, 210, 1–11. [Google Scholar] [CrossRef]

- Shi, Y.; Wei, Z.; Shahbaz, M.; Zeng, Y. Exploring the dynamics of low-carbon technology diffusion among enterprises: An evolutionary game model on a two-level heterogeneous social network. Energy Econ. 2021, 101, 105399. [Google Scholar] [CrossRef]

- Wu, B.; Liu, P.; Xu, X. An evolutionary analysis of low-carbon strategies based on the government–enterprise game in the complex network context. J. Clean. Prod. 2017, 141, 168–179. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, W.; He, P.; Xu, X. Production and pricing problems in make-to-order supply chain with cap-and-trade regulation. Omega 2017, 66, 248–257. [Google Scholar] [CrossRef]

- Hu, X.; Yang, Z.; Sun, J.; Zhang, Y. Carbon tax or cap-and-trade: Which is more viable for Chinese remanufacturing industry? J. Clean. Prod. 2020, 243, 118606. [Google Scholar] [CrossRef]

- Wittneben, B.B.F. Exxon is right: Let us re-examine our choice for a cap-and-trade system over a carbon tax. Energy Policy 2009, 37, 2462–2464. [Google Scholar] [CrossRef]

- Krass, D.; Nedorezov, T.; Ovchinnikov, A. Environmental Taxes and the Choice of Green Technology. Prod. Oper. Manag. 2013, 22, 1035–1055. [Google Scholar] [CrossRef]

- Xu, X.; Xu, X.; He, P. Joint production and pricing decisions for multiple products with cap-and-trade and carbon tax regulations. J. Clean. Prod. 2016, 112, 4093–4106. [Google Scholar] [CrossRef]

- Zhou, D.; An, Y.; Zha, D.; Wu, F.; Wang, Q. Would an increasing block carbon tax be better? A comparative study within the Stackelberg Game framework. J. Environ. Manag. 2019, 235, 328–341. [Google Scholar] [CrossRef] [PubMed]

- Ahmadi, Y.; Yamazaki, A.; Kabore, P. How Do Carbon Taxes Affect Emissions? Plant-Level Evidence from Manufacturing. Environ. Resour. Econ. 2022, 82, 285–325. [Google Scholar] [CrossRef] [PubMed]

- Xia, X.; Chen, J.; Wang, W.; Wang, H. Impact of differentiated carbon taxes on remanufacturing mode selection. Energy Econ. 2024, 140, 107955. [Google Scholar] [CrossRef]

- www.gov.cn. First Expansion! The National Carbon Emission Trading Market has Added the Steel, Cement and Aluminum Smelting Industries. Available online: https://www.gov.cn/lianbo/bumen/202503/content_7015718.htm (accessed on 20 May 2025).

- Yu, Q.; Rui, Z.; Yankun, X. Establish a collaborative mechanism for the new carbon tax and carbon emission rights trading market in our country. Jianghuai Forum 2024, 4, 97–105. (In Chinese) [Google Scholar] [CrossRef]

- Wang, J.; Cheng, S.; Guo, X.; Xu, X.; Wang, Z. An evolutionary analysis of the diffusion of low-carbon technology innovation in supply networks. Res. Int. Bus. Financ. 2024, 70, 102400. [Google Scholar] [CrossRef]

- Huang, Y.; He, P.; Cheng, T.C.E.; Xu, S.; Pang, C.; Tang, H. Optimal strategies for carbon emissions policies in competitive closed-loop supply chains: A comparative analysis of carbon tax and cap-and-trade policies. Comput. Ind. Eng. 2024, 195, 110423. [Google Scholar] [CrossRef]

- Xu, C.; Wang, C.; Huang, R. Impacts of horizontal integration on social welfare under the interaction of carbon tax and green subsidies. Int. J. Prod. Econ. 2020, 222, 107506. [Google Scholar] [CrossRef]

- Wu, H.; Sun, Y.; Su, Y.; Chen, M.; Zhao, H.; Li, Q. Which Is the Best Supply Chain Policy: Carbon Tax, or a Low-Carbon Subsidy? Sustainability 2022, 14, 6312. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhao, Q.; Zhao, X.; Tang, L. On the introduction of green product to a market with environmentally conscious consumers. Comput. Ind. Eng. 2020, 139, 106190. [Google Scholar] [CrossRef]

- Zhou, Z.; Hu, F.; Xiao, D. Optimal pricing strategy of competing manufacturers under carbon policy and consumer environmental awareness. Comput. Ind. Eng. 2020, 150, 106918. [Google Scholar] [CrossRef]

- He, P.; Sun, Y. The impacts of retailer’s carbon tax on the price and carbon reduction decisions in supply chain. Comput. Ind. Eng. 2024, 190, 110034. [Google Scholar] [CrossRef]

- Liao, D.; Tan, B. An evolutionary game analysis of new energy vehicles promotion considering carbon tax in post-subsidy era. Energy 2023, 264, 126156. [Google Scholar] [CrossRef]

- Hu, Z.H.; Wang, S.W. An Evolutionary Game Model Between Governments and Manufacturers Considering Carbon Taxes, Subsidies, and Consumers’ Low-Carbon Preference. Dyn. Games Appl. 2022, 12, 513–551. [Google Scholar] [CrossRef]

- Zheng, P.; Pei, W.; Pan, W. Impact of different carbon tax conditions on the behavioral strategies of new energy vehicle manufacturers and governments—A dynamic analysis and simulation based on prospect theory. J. Clean. Prod. 2023, 407, 137132. [Google Scholar] [CrossRef]

- Wang, Y.; Luo, H.; Zhang, X.; Li, Y.; Yang, S.; Lu, Q.; Wang, L. Research on evolutionary game of low-carbon logistics in two-level supply chain under carbon tax policy. Sustain. Futures 2024, 8, 100387. [Google Scholar] [CrossRef]

- Liu, D.; Feng, M.; Liu, Y.; Wang, L.; Hu, J.; Wang, G.; Zhang, J. A tripartite evolutionary game study of low-carbon innovation system from the perspective of dynamic subsidies and taxes. J. Environ. Manag. 2024, 356, 120651. [Google Scholar] [CrossRef]

- Xu, Y.D.; Han, L.; Li, X.; Zhu, W.X.; Ren, H.P. Evolutionary Game-Based New Energy Vehicle Supply Chain Strategies That Consider Carbon Reduction and Consumers’ Low-Carbon Preferences. Systems 2024, 12, 328. [Google Scholar] [CrossRef]

- Fan, R.; Dong, L.; Yang, W.; Sun, J. Study on the optimal supervision strategy of government low-carbon subsidy and the corresponding efficiency and stability in the small-world network context. J. Clean. Prod. 2017, 168, 536–550. [Google Scholar] [CrossRef]

- Liu, P.; Li, X.; Li, J. Competitive firms’ low-carbon technology diffusion under pollution regulations: A network-based evolutionary analysis. Energy 2023, 282, 128836. [Google Scholar] [CrossRef]

- Lu, Q.; Fang, H.; Hou, J. The impact of energy supply side on the diffusion of low-carbon transformation on energy demand side under low-carbon policies in China. Energy 2024, 307, 132817. [Google Scholar] [CrossRef]

- Liu, J.; Sun, J.; Bao, H.; Lu, Y. Research on value co-creation of green hydrogen value chain considering carbon emission trading: A multi-layer complex network evolutionary game perspective. Renew. Energy 2025, 242, 122423. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, Z.; Li, X. Impact of policies on electric vehicle diffusion: An evolutionary game of small world network analysis. J. Clean. Prod. 2020, 265, 121703. [Google Scholar] [CrossRef]

- Fan, R.; Bao, X.; Du, K.; Wang, Y.; Wang, Y. The effect of government policies and consumer green preferences on the R&D diffusion of new energy vehicles: A perspective of complex network games. Energy 2022, 254, 124316. [Google Scholar] [CrossRef]

- Yang, M.; Chen, H.; Long, R.; Sun, Q.; Yang, J. How does government regulation promote green product diffusion in complex network? An evolutionary analysis considering supply side and demand side. J. Environ. Manag. 2022, 318, 115642. [Google Scholar] [CrossRef]

- Watts, D.; Strogatz, S. Collective Dynamics of Small World Networks. Nature 1998, 393, 440–442. [Google Scholar] [CrossRef]

- Qin, Q.; Liu, Y.; Huang, J.-P. A cooperative game analysis for the allocation of carbon emissions reduction responsibility in China’s power industry. Energy Econ. 2020, 92, 104960. [Google Scholar] [CrossRef]

- Chen, W.; Hu, Z.-H. Using evolutionary game theory to study governments and manufacturers’ behavioral strategies under various carbon taxes and subsidies. J. Clean. Prod. 2018, 201, 123–141. [Google Scholar] [CrossRef]

- GB/T 4754-2017; Industrial Classification for National Economic Activities. China Standard Publishing House: Beijing, China, 2017.

- Lin, B.; Lei, X. Carbon emissions reduction in China’s food industry. Energy Policy 2015, 86, 483–492. [Google Scholar] [CrossRef]

- Bossek, D.; Bach, V.; Finkbeiner, M. Lifestyle-LCA: Challenges and Perspectives. Sustainability 2023, 15, 11313. [Google Scholar] [CrossRef]

- CO2 Everythinge. Carbon Footprint of Drinks. Available online: https://www.co2everything.com/co2e-of/beer (accessed on 25 August 2025).

- GB/T 32151.25-2024; Requirements of the Greenhouse Gas Emissions Accounting and Reporting—Part 25: Food, Tobacco, Alcohol, Beverage and Refined Tea Enterprise. China Standard Publishing House: Beijing, China, 2024.

- Wang, H.; Wang, F. Study on purification of food grade carbon dioxide impurities by adsorption technology. Chin. Foreign Wine Ind. Beer Sci. Technol. 2017, 11, 20–25. (In Chinese) [Google Scholar]

- Yang, J.; Zhong, J.; Zhang, K. Beer Carbon Footprint and Calculation Case. Beer Sci. Technol. 2013, 08, 6–14. (In Chinese) [Google Scholar]

- Carbon Trading Network. Industry Carbon Intensity Advanced Value Data Query List. Available online: www.tanpaifang.com/tanjiliang/2014/0504/31846.html (accessed on 20 January 2025). (In Chinese).

- Guo, L.; Cui, M.; Qu, Y.; He, P. An integrated approach to modeling the influence of critical factors in low-carbon technology adoption by chemical enterprises in China. J. Environ. Manag. 2025, 373, 123834. [Google Scholar] [CrossRef] [PubMed]

- China Finance. The Total Trading Volume of the National Carbon Market Exceeded 180 Million Tons in 2024. Available online: https://finance.china.com.cn/esg/20250101/6202067.shtml (accessed on 20 January 2025). (In Chinese).

- Wang, J.; Yin, L.; Yin, X.; He, W.; Cheng, Z.; Zeng, P. Fully distributed expansion planning for cross-border energy systems using hierarchical dynamic game embedded with carbon emissions. Energy 2025, 314, 134211. [Google Scholar] [CrossRef]

| Parameters | Definitions |

|---|---|

| N | Number of manufacturers |

| Unit sales price of the product | |

| Unit production cost for low-carbon products | |

| Unit production cost for original products | |

| Carbon-reduction cost coefficient per unit of product | |

| Average market capacity per unit of product | |

| Profit function for producing ordinary products | |

| Profit function for producing low-carbon products | |

| Carbon tax levied on ordinary products | |

| Carbon tax rate per unit of ordinary product | |

| Government subsidies for low-carbon products | |

| Government subsidy coefficient for low-carbon products |

| Manufacturers (Vj) | |||

|---|---|---|---|

| Low-Carbon Technology | Original Technology | ||

| Manufacturers (Vi) | Low-carbon technology | ||

| Original technology | |||

| Products | Capacity | Carbon Emissions (kg CO2e) |

|---|---|---|

| Milk (Cow) | 250 mL | 0.8 |

| Coffee | 15 g | 0.4 |

| Rice Milk | 250 mL | 0.3 |

| Beer | 335 mL | 0.25 |

| Soy Milk | 250 mL | 0.25 |

| Oat Milk | 250 mL | 0.22 |

| Almond Milk | 250 mL | 0.18 |

| Coke | 330 mL | 0.17 |

| Wine | 150 mL | 0.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, W.; Hu, Z.-H. Does the Optimal Update Strategy Effectively Promote the Low-Carbon Technology Diffusion Among Manufacturers? An Evolutionary Game of Small-World Network Analysis. Systems 2025, 13, 792. https://doi.org/10.3390/systems13090792

Chen W, Hu Z-H. Does the Optimal Update Strategy Effectively Promote the Low-Carbon Technology Diffusion Among Manufacturers? An Evolutionary Game of Small-World Network Analysis. Systems. 2025; 13(9):792. https://doi.org/10.3390/systems13090792

Chicago/Turabian StyleChen, Wanting, and Zhi-Hua Hu. 2025. "Does the Optimal Update Strategy Effectively Promote the Low-Carbon Technology Diffusion Among Manufacturers? An Evolutionary Game of Small-World Network Analysis" Systems 13, no. 9: 792. https://doi.org/10.3390/systems13090792

APA StyleChen, W., & Hu, Z.-H. (2025). Does the Optimal Update Strategy Effectively Promote the Low-Carbon Technology Diffusion Among Manufacturers? An Evolutionary Game of Small-World Network Analysis. Systems, 13(9), 792. https://doi.org/10.3390/systems13090792