Abstract

Frequent disruptions to global supply chains, driven by factors such as trade restrictions and geopolitical conflicts, brought supply chain resilience to the forefront of both academic research and industry practice. Concurrently, the rapid advancement of artificial intelligence (AI) technologies in supply chain management in recent years offers new perspectives for researching resilience. Based on the Organizational Information Processing Theory (OIPT), this study explores the direct and indirect mechanisms through which AI usage impacts supply chain resilience from an information processing perspective. Within the OIPT framework, we develop a theoretical model incorporating AI usage, supply chain resilience, supply chain efficiency, supply chain collaboration, and digital information technology capability. We empirically test the model using survey data collected from 231 Chinese manufacturing senior executives and supply chain managers, employing partial least squares structural equation modeling (PLS-SEM). The findings reveal that AI usage has a significant direct positive effect on supply chain resilience. Additionally, supply chain efficiency and collaboration act as mediators in this relationship. Furthermore, we examined the moderating role of a firm’s digital information technology capability and found that it positively moderates the impact of AI usage on supply chain resilience.

1. Introduction

In recent years, black swan events such as geopolitical conflicts and trade restrictions severely impacted global manufacturing supply chains, causing large-scale disruptions and significant economic losses. In this increasingly volatile and uncertain environment, enhancing supply chain resilience (SCR) has become crucial for firms aiming to maintain business stability and competitiveness [1]. SCR refers to a firm’s ability to swiftly resume operations and maintain efficient performance when facing disruptions and uncertainties [2]. Extensive research has demonstrated that SCR helps firms reduce operational risks, mitigate losses, and quickly capitalize on emerging market opportunities [3]. Therefore, firms should prioritize cultivating and strengthening SCR when building and optimizing supply chains.

Amid the ongoing digital transformation of the manufacturing sector, numerous enterprises have increasingly recognized the importance of digital technologies—particularly artificial intelligence (AI)—in enhancing SCR [4,5]. As a key driver of the new industrial revolution [6], AI is reshaping traditional supply chain management paradigms with its outstanding performance in areas such as rapid response, demand forecasting, and risk management [7]. Given its remarkable effectiveness in strengthening supply chain responsiveness, reliability, and recoverability, artificial intelligence usage (AIU) is considered a key approach to strengthening SCR.

Organizational Information Processing Theory (OIPT) offers a theoretical lens for understanding how AIU influences SCR from an information processing perspective. As part of open systems, firms are exposed to various environmental and market uncertainties, which are considered antecedents to supply chain disruptions [8]. OIPT asserts that firms must maintain a certain level of information processing performance to effectively cope with increasing uncertainties [9]. Regarding how to enhance firm information processing performance, Galbraith [10] proposed two approaches: developing lateral relationships and leveraging vertical information systems. Firms can develop external lateral relationships with customers and suppliers—such as fostering supply chain collaboration (SCC) to improve access to real-time and valuable information [11,12]. On the other hand, firms can leverage vertical information systems to enhance organizational information processing efficiency—such as adopting digital technologies like AI and big data—which directly manifests in improved supply chain efficiency (SCE) [13]. Currently, substantial empirical research supports the maturity and demonstrated performance of AI technology in supply chain management in terms of enhancing SCR. However, the intrinsic mechanisms through which AIU improves SCR remain systematically unexplored. In particular, whether AI enhances SCR by strengthening SCC and SCE is a critical issue requiring in-depth investigation.

Despite the growing interest from non-technical users following the release of generative AI solutions such as ChatGPT, significant challenges persist in implementing AI in supply chain management [14]. Digital information technology capability (DITC) reflects a firm’s level of digital maturity, representing the comprehensive embodiment of critical competencies such as IT infrastructure and data management [15] and is recognized as a critical driver for AIU [16]. Previous research has highlighted the central role of data in AI implementation. Brock and Von Wangenheim [17] and Demlehner et al. [18] contend that data availability, quality, and volume fundamentally determine AI’s effectiveness. Beyond data requirements, effective AI implementation requires substantial organizational resources, including integrated complementary technologies, computational power, and technical talent [19]. These resources are essential both for leveraging AI’s capabilities and ensuring continuous adaptation through timely updates and maintenance in response to volatile market conditions. Although a significant body of research focuses on the interrelationship between AI and SCR, studies that delve into the underlying mechanisms of the interaction between AIU and SCR from the perspective of AI technology characteristics remain insufficient. Given that AI is a key driving force for future global economic development, a thorough investigation into the factors influencing the impact of AIU on SCR will significantly deepen the integration of AI into supply chain management practices. Therefore, this study incorporates DITC into the research model to examine its moderating role in the relationship between AIU and SCR.

Based on the above, this study addresses the following research questions. First, does AIU directly enhance SCR? Second, do SCC and SCE mediate the relationship between AIU and SCR? Third, does DITC moderate this mechanism? We collected survey data from Chinese manufacturing firms to explore these research questions for two reasons. First, under the impact of black swan events, many Chinese manufacturing firms have experienced severe disruptions, underscoring the urgency of enhancing SCR in today’s highly volatile environments. Second, the rapid rise in AI applications such as DeepSeek has drawn unprecedented attention to AI across various sectors in China [20]. This surge in interest, coupled with the implementation of various industrial policies, has accelerated the deep integration of AI into China’s manufacturing sector [21]. Therefore, this study empirically explores the complex interrelationships among AIU, SCR, SCC, SCE, and DITC to establish an integrated theoretical framework that bridges technology and supply chain operations management. This study aims to identify the underlying mechanisms through which AI enhances SCR, expand the theoretical contribution of OIPT in the AI era, and provide critical decision support for supply chain managers to build efficient, collaborative, and resilient supply chains in uncertain environments.

2. Literature Review

2.1. Organizational Information Processing Theory

Rooted in open systems theory, OIPT has been widely adopted in supply chain management research [12], particularly to explain how uncertainty triggers supply chain disruptions [22]. As components of open systems, firms are exposed to significant environmental and market uncertainties, which limit their ability to plan effectively and make informed decisions [23]. When firms struggle to manage these uncertainties, they may escalate into supply chain disruption risks, severely impacting business operations. OIPT conceptualizes firms as information processing systems and posits that effective information processing is critical for mitigating uncertainty [24].

In response to rising uncertainty, Cousins et al. [25] argue that improving firms’ information processing performance can enhance their capacity to manage uncertainty. This can be achieved by strengthening lateral relationships and leveraging vertical information systems [11]. Lateral relationships facilitate information acquisition and coordination, reducing uncertainty arising from information gaps. Vertical information systems effectively enhance information processing efficiency and prevent information overload, helping organizations effectively identify, understand, and respond to uncertainty, such as by adopting digital technologies [26]. AI, as a “datafication” technology, creates value by enabling rapid data integration, processing, and analysis [27]. Unlike traditional digital technologies, the core advantage of AI lies in its superior predictive analytics and intelligent decision support capabilities. Through complex algorithmic models (e.g., machine learning and deep learning), AI can delve deeply into complex patterns and correlations within massive datasets, generate high-precision predictions of future scenarios, and accordingly provide optimized, real-time decision recommendations. This enables supply chain enterprises facing highly dynamic and ambiguous environments to process information flows more efficiently and significantly enhance the proactive, accurate, and agile nature of their decision-making [28]. Consequently, substantial evidence grounded in OIPT indicates that AIU empowers firms to better navigate uncertainties and bolster SCR.

2.2. Supply Chain Resilience

SCR, as a critical aspect of supply chain management, has garnered significant attention from both academic and industrial communities in recent years, particularly in the aftermath of the COVID-19 pandemic [28]. Originally rooted in materials science, the concept of resilience has since been extended to disciplines such as management and ecology. Within the context of supply chain management, resilience refers to a system’s ability to rapidly recover to its original or desired state following disruptions, while simultaneously enhancing its capacity to withstand future risk through structural and strategic optimization [29,30]. Sturm et al. [31] conceptualize SCR as a multidimensional construct, encompassing the supply chain’s capability to adapt, endure, and evolve amid turbulent conditions [4].

Previous research has extensively explored a wide range of factors influencing SCR, identifying multiple corporate capabilities and resources that significantly contribute to its development [32]. These include risk management [33], SCC [34], and social capital [35]. Beyond firm-specific resources and capabilities, recent research has increasingly examined the role of digitalization in enhancing SCR. Leveraging digital technologies to optimize supply chain management is widely recognized as a critical means to ensure adaptability and responsiveness in volatile environments [36,37]. Furthermore, empirical evidence supports the positive impact of digital transformation on SCR [7,38]. However, while the literature acknowledges the role of information technologies in fostering resilience, few studies have examined the specific effects of individual technologies—particularly AI—on SCR [32]. Although AI is commonly presumed to enhance resilience, the underlying mechanisms remain insufficiently understood.

2.3. AI Usage in Supply Chain Management

AI refers to the exploration of machines that simulate human behavior and cognition, leveraging advanced computational capabilities to perform specific tasks [39]. Following decades of research, our utilization of AI has far exceeded its initial theoretical conception [40]. In supply chain management, AI has been extensively applied across various domains, including inventory management [41,42], logistics [43], procurement [44], cost control [45], and predictive decision-making [46,47], significantly driving progress in this field.

Beyond research on the specific application scenarios of AI in supply chain management, an increasing body of research concentrates on AI’s broader impact on supply chain capabilities. For example, Albert and Alijoyo [48] report that AIU in information markets can significantly enhance supply chain operational efficiency and sustainability. Yamin et al. [49] state that AI’s ability to communicate with diverse communication devices and machines, coupled with its capacity for fast analysis and computation, can enhance supply chain agility and significantly strengthen a firm’s ability to maintain operational continuity. They confirm this perspective through an empirical analysis of logistics enterprises. AIU also exhibits unique effectiveness in coordinating inter-organizational relationships. Baryannis et al. [50] and Rodríguez-Espíndola et al. [51] reveal that AI-powered predictive capabilities significantly strengthen collaborative relationships among supply chain partners in multi-tier supply chains, reducing operational costs and mitigating the bullwhip effect. Additionally, Modgil et al. [52] find that AI positively impacts SCR across various industries.

Although some scholars recognize AIU’s potential to enhance SCE and SCC, empirical research on the effects of AIU on SCE, SCC, and SCR remains limited. As a multidimensional concept defined by several supply chain capabilities [53], one can reasonably believe that AIU’s impact will be a multi-faceted and multi-layered process [54]. To generate actionable insights for practitioners seeking to enhance SCR, it is essential to examine the complex mediating and moderating mechanisms underpinning the relationship between AIU and SCR.

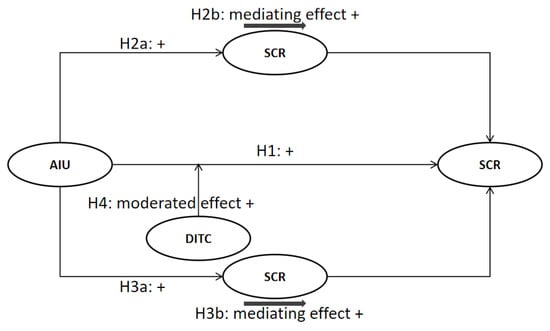

3. Hypothesis Development

Data-driven supply chains generate vast amounts of information during operations. Firms that struggle to effectively access and process this data will have difficulty responding to external uncertainties, which are significant factors creating supply chain disruptions [55]. To better address these uncertainties, OIPT suggests that enhancing a firm’s capabilities in information acquisition, processing, and transmission can improve its ability to make proactive decisions [10]. On the one hand, firms can improve information processing efficiency, and thereby affect their information processing capabilities, by investing in vertical information systems such as computers and information systems. Based on this perspective, we assume that AIU can directly enhance SCR while also being able to achieve this goal by improving SCE. On the other hand, firms can expand lateral relationships to strengthen information acquisition capabilities and enhance overall information processing capacity. Considering AI’s advantages in narrowing information gaps and strengthening supply chain partnerships, we propose that SCC will mediate the relationship between AIU and SCR. Furthermore, given the technological characteristics of AI and its implementation barriers, we examine the moderating role of DITC in the relationship between AIU and SCR.

3.1. The Impact of AIU on SCR

OIPT provides a foundation for understanding how firms maintain operational continuity under uncertainty from an information processing perspective [11], providing insights for our research on SCR. Essentially, SCR refers to an organization’s capacity to effectively navigate environmental uncertainties [56,57]. As a core representative of digital technology, AI is now a key focus area in academia for exploring pathways to enhance SCR. AI has unique capabilities in precise prediction, real-time dynamic responses, and optimization of complex systems—attributes unmatched by any other single digital technology. In emerging market supply chains, Albert and Alijoyo [48] argue that AI has already demonstrated resilience and maturity. Its integration into logistics and supply chain management can significantly improve the sustainability and resilience of supply chain operations. At the application level, AI plays a critical role in systematically enhancing SCR across three phases: predicting and preventing disruptions, responding to and recovering from disruptions when they occur, and post-disruption restructuring and continuous improvement. Aboutorab et al. [58] propose a risk management model based on reinforcement learning, leveraging AI to help supply chain managers proactively identify risks and formulate countermeasures in advance, greatly enhancing enterprises’ ability to cope with various uncertainties in the environment. Following disruption events, Guntuka et al. [59] suggest that AI enables real-time monitoring and dynamic analysis of supplier, customer, and factory data, accelerating response to supply chain disturbances and reducing recovery time. Based on the above reasoning, we propose the following Hypothesis 1:

H1.

AIU is positively associated with SCR.

3.2. The Mediating Effect of SCC and SCE

SCC is the coordinated planning and execution of supply chain operations among multiple independent firms or partners through deep cooperation and information sharing [60]. Current research increasingly examines the relationship between AIU and SCC. By leveraging AI to integrate and predict market information, enterprises can quickly identify customer needs and market trends and automate decision-making, enabling the more efficient and accurate management of relationships with supply chain partners. This AI-driven automated information sharing and reconstruction of trust mechanisms will effectively enhance SCC [61,62]. Furthermore, AI’s inherent technological characteristics can strengthen SCC—an aspect that has received limited scholarly attention. As a “datafication” technology [27], AI’s ability to generate valid outputs fundamentally relies on abundant, high-quality data [63], imposing stringent requirements on enterprise data infrastructure. Consequently, AIU intrinsically motivates firms to enhance SCC, thereby acquiring more valid real-time data to improve AI application performance [64]. Based on these considerations, we propose the following Hypothesis 2:

H2.

AIU is positively associated with SCC.

In supply chain disruption events, the information gap caused by insufficient SCC is widely recognized as one of the antecedents leading to operational failures [28]. This resonates with the OIPT perspective that firms can extend their information processing capacity through lateral relationships to effectively address various uncertainties [65]. Under complex and volatile conditions, strengthening collaborative relationships with supply chain partners can significantly reduce information acquisition costs. Combined with the information integration and processing capabilities provided by AI, this approach effectively enhances supply chains’ response speed and adaptive capacity when confronted with unexpected events [66]. Based on these considerations, we propose the following Hypothesis 3:

H3.

SCC mediates the relationship between AIU and SCR.

AIU can significantly enhance the efficiency of supply chain operations [7]. SCE reflects a firm’s ability to optimize resource allocation, technology application, and process management, with key performance indicators including inventory turnover rate and demand response speed [67]. Cavalcante et al. [44] proposed a supplier selection model based on supervised machine learning. By leveraging AI to comprehensively analyze order information, supplier performance data, and other relevant factors, this model helps supply chain enterprises effectively enhance demand response speed while improving delivery reliability. From the inventory management perspective, AI’s rapid detection of market changes can effectively counteract the “bullwhip effect”, helping firms mitigate the risks of supply–demand imbalances [68]. This capability safeguards and continuously optimizes the overall operational efficiency of the supply chain. Accordingly, we propose the following Hypothesis 4:

H4.

AI usage is positively associated with SCE.

An increasing body of research has highlighted the relationship between SCE and SCR, particularly within the context of digital transformation. Ma et al. [69] argue that digital transformation can significantly promote SCR in manufacturing firms by improving SCE. Similarly, improvements in supply–demand coordination efficiency [70] and supply chain financing efficiency [71] triggered by digital transformation can also positively impact SCR. Compared to other digital technologies, AI particularly excels in data analysis, autonomous decision-making, and prediction, thereby significantly enhancing enterprises’ information processing efficiency. Combined with OIPT, we believe that this enhancement of SCE will ultimately benefit SCR. Therefore, we propose the following Hypothesis 5:

H5.

SCE mediates the relationship between AIU and SCR.

3.3. The Moderating Effect of DITC

DITC refers to a firm’s comprehensive capacity to dynamically support and optimize business processes by acquiring, implementing, integrating, and configuring information technology resources [72]. This capability reflects a firm’s level of digital maturity [15,73]. As a data- and algorithm-driven technology, AI has garnered scholarly attention regarding how its value creation in firms is influenced by firms’ DITC. Particularly in firms with profound technological and contextual expertise in big data and the Internet of Things, AI demonstrates stronger enabling effects on business operations [7,74].

In recent years, AI research has increasingly permeated all aspects of supply chain management, with many firms aiming to leverage AI to enhance business capabilities. However, scholars highlight substantial challenges in AI implementation, many of which stem from DITC-related issues, including technological foundations, IT infrastructure, and information system integration [14]. Crucially, data accessibility, quality, and volume are considered the primary factors impacting AI’s effectiveness [17,18]. This is because AI’s effectiveness depends on model inputs, and high-quality data input is a prerequisite for obtaining valid results from AI. Complementary technologies are also recognized as significant factors that influence the utility of AI. Although AI can function as a standalone technology, its ability to optimize business processes often requires collaboration with other data collection, processing, and automation technologies [14]. While the benefits of AIU for supply chain management are substantial, the realization of these benefits is contingent on DITC.

From the OIPT perspective, integrating AI with DITC enables firms to better understand and manage various uncertainties by leveraging diverse information sources [75]. Firms with strong DITC achieve production and collaboration through various information systems, possessing enhanced capacities for data collection, integration, and cleansing [76], thereby improving the quantity and quality of inputs available for AI applications. Furthermore, such firms are typically better equipped to select appropriate AI models and maintain continuous model updates—both critical prerequisites for ensuring high-quality AI outputs [76]. Bokrantz et al. [19] emphasize that during the preliminary stages of AI implementation in manufacturing, firms must possess the capability to operate and manage AI systems effectively. Although many manufacturing firms typically outsource AI solutions to third-party providers, maintaining high-quality outputs in supply chain management requires ongoing training and regular updates of AI systems [77]. Based on these insights, we propose the following Hypothesis 6:

H6.

DITC positively moderates the relationship between AIU and SCR.

Figure 1 presents the conceptual model.

Figure 1.

The conceptual model. AIU: artificial intelligence usage; DITC: digital information technology capability; SCC: supply chain collaboration; SCE: supply chain efficiency; SCR: supply chain resilience.

4. Research Methodology

4.1. Data Collection

In this study, we investigated the interrelationships among five key constructs. In the proposed model, we designated AIU and SCR as the independent and dependent variables, respectively, and examined their relationship. Furthermore, SCR and SCE were positioned as mediating variables, while DITC was employed as a moderating variable in this relationship. To test the proposed hypotheses, we conducted a random sampling survey of specialized supply chain professionals in Chinese manufacturing firms. Data were collected via a widely adopted professional online survey platform in China, which serves over 3 million enterprises and 90% of Chinese universities. The platform maintains a stable panelist database and has been commissioned by numerous research projects for reliable questionnaire data collection.

Before distributing the survey questionnaires, we established specific criteria to screen suitable respondents. First, given the relatively low adoption rate of AI in China’s manufacturing sector, respondents were required to be currently employed by listed manufacturing companies or their subsidiaries with a documented investment in AI aimed at streamlining firm production over the past 3 years. Second, we targeted senior executives and supply chain managers as primary respondents, due to their in-depth knowledge of overall supply chain operations and AI implementation strategies within their firms [32]. Additionally, to address the research objectives, we screened respondents according to criteria such as industry, position, and years of work experience. After identifying the target survey group, we included attention-check questions, IP address verification, and questionnaire completion time validation using a survey platform to ensure the collection of qualified data.

4.2. Research Design and Measure

The questionnaire comprised two sections. The first section gathered respondents’ basic information, including gender, industry, company size, position, and years of professional experience. The second section contained measurement items related to the five key constructs. Given that the target respondents are senior executives and supply chain managers from Chinese manufacturing firms, particular emphasis was placed on ensuring questionnaire clarity and localization.

The questionnaire design followed a systematic process. First, we collected and reviewed the key literature on OIPT, SCR, and AI to gain a comprehensive understanding of the foundational theories and research advancements in these areas. For the variables in this study, we adopted mature and empirically validated scales from previous research to develop the initial version of the survey questionnaire. Second, the questionnaire was translated into Chinese by a PhD student. To ensure translation equivalence, two master’s students back translated the Chinese version into English. Thirdly, two professors were invited to evaluate and refine the Chinese version. All scholars involved in translation and evaluation specialize in supply chain management research and have previously participated in English-language supply chain management research projects. Finally, several senior supply chain managers were invited to pilot-test the questionnaire, with particular attention paid to their comprehension of the items. Based on their feedback, we optimized the questionnaire items by replacing or explaining certain terms.

To measure the study constructs, we employed well-established, empirically validated scales commonly used in supply chain research [78], ensuring good content validity. AIU was measured using three items adapted from L. Li et al. [21]. To better align the items with the study’s specific objective, we referenced the approach of Yue et al. [32] by replacing “generative artificial intelligence” in the original items with “artificial intelligence”. DITC was assessed using seven items adapted from Proksch et al. [15] and Ueasangkomsate [79]. SCC was measured using three items adopted from Belhadi et al. [28]. To assess SCE, we employed five items based on J. Wang et al. [80], evaluating dimensions such as delivery capability, inventory levels, and labor efficiency. SCR was measured using four items adapted from Brandon-Jones et al. [81]. Respondents were asked to describe their organization’s SCR in terms of material recovery capacity, recovery time, ease of recovery, and response speed. All items for the constructs were measured using a seven-point Likert scale, ranging from 1 (“Strongly Disagree”) to 7 (“Strongly Agree”).

Before the formal launch of the questionnaire survey, a small-scale pilot test was conducted, collecting and analyzing 31 responses. As the surveyed enterprises were not technology or software firms, and based on the pilot test results, we optimized some questionnaire items. Items with inadequate reliability or validity, as well as those with low factor loadings, were removed. Table 1 presents the final questionnaire items used in this study, along with their sources.

Table 1.

Identification of study variables.

5. Results Analysis

5.1. Measurement Validation

After finalizing the survey questionnaire, we commissioned an online research platform to conduct a formal survey of the target population. Within two weeks, 361 questionnaires were distributed. After screening the collected questionnaires based on criteria such as missing data, highly overlapping IP addresses, and failed attention-check questions, we obtained 231 valid responses, yielding a response rate of 64%. Table 2 summarizes the respondents’ demographics and profiles.

Table 2.

Demographic summary.

After performing demographic profiling on the valid samples, we applied structural equation (SEM) modeling to explore whether the theoretical model and research hypotheses hold. SEM integrates factor and path analyses to examine the interrelationships between one or more independent and dependent variables [82]. SEM is particularly suitable when the dependent variable in one regression analysis could become an independent variable in another. Additionally, SEM allows for the simultaneous estimation of measurement error variances in both exogenous and endogenous variables, thus satisfying the study’s methodological requirements [28]. This study primarily explores the intricate relationship between AIU and SCR in China’s manufacturing sector. Given the study’s sample size, Partial Least Squares Structural Equation Modeling (PLS-SEM) was selected as the most appropriate analytical method [83,84]. Subsequent data analysis was conducted using Smart-PLS v4.1.1.1 and IBM SPSS v24.

According to Hair et al. [85], evaluating the measurement model is a prerequisite to assessing structural relationships. This includes examining indicator loadings, internal consistency reliability, convergent validity, and discriminant validity. Table 3 presents the factor loadings, Cronbach’s alpha, composite reliability (CR), and average variance extracted (AVE) for all items and scales. All standardized factor loadings exceeded the 0.7 threshold, indicating item reliability [85]. All constructs exhibited Cronbach’s alpha values above 0.7 and CR values exceeding 0.7, confirming satisfactory internal consistency reliability [86]. Additionally, AVE values surpassed 0.5 for all constructs, establishing adequate convergent validity [85]. Furthermore, as Hair et al. [87] suggest, we evaluated the variance inflation factors (VIFs) before analyzing the structural model to mitigate multicollinearity concerns. As Table 3 shows, all VIFs were below 3.3, which falls within the acceptable limits [88] and confirms the data’s suitability for structural evaluation.

Table 3.

Descriptive analysis of measurement scales.

Additionally, we adopted the Fornell–Larcker criterion to assess discriminant validity among constructs [89]. As Table 4 shows, discriminant validity was verified by comparing the inter-construct correlations with the square roots of the AVE values. The results demonstrate that the square root of each construct’s AVE exceeded its highest correlation with any other construct, indicating adequate discriminant validity [90].

Table 4.

Fornell–Larcker criterion.

The structural model was evaluated using the coefficient of determination (R2) and cross-validated redundancy (Q2) [85]. The coefficient of determination, R2, measures the proportion of variance in endogenous latent variables explained by the model. In this study, the R2 values for SCC, SCE, and SCR were 0.143, 0.120, and 0.280, respectively, indicating moderate explanatory power [91]. Concurrently, cross-validated redundancy, Q2, was employed to assess the model’s predictive relevance. The Q2 values for SCC, SCE, and SCR were 0.117, 0.099, and 0.115, respectively, demonstrating that the model possesses adequate predictive validity [87].

5.2. Common Method Bias

Common method bias (CMB), a frequent source of error in questionnaire-based research, can introduce systematic errors into data. As all variables in this study were measured using a single method and data were obtained from a single respondent, common method variation may affect the data, potentially compromising data quality [92]. To address this issue, we employed two methods to test for CMB. First, Harman’s single-factor test indicated that a single factor accounted for only 29.65% of the variance, which is below the acceptable threshold of 50% [93]. Further, as in Liang et al. [94], a secondary test revealed that the average substantively explained variance of the indicators was 0.651, while the average method-based variance was 0.003. Thus, the ratio of substantive variance to method-based variance was approximately 217 to 1. Given the small and statistically insignificant method variance, we conclude that CMB is not a serious concern in this study.

5.3. Hypothesis Testing

To test our proposed hypotheses, we employed path coefficients (β), T statistics, and p-values for the model variables [95]. Path coefficients, which range from −1 to +1, reflect the strength and direction of relationships (from negative to positive correlation) between variables. A p-Values ≤ 0.05 and a T Statistics > 1.96 are considered indicative of statistically significant relationships [96]. As Table 5 shows, the interactions among the five constructs were analyzed. The results show that AIU has a modest but significant positive effect on SCR (β = 0.230, T Statistics = 3.221, p-Values = 0.001), supporting H1. AIU also has a significant positive effect on SCC (β = 0.378, T Statistics = 4.433, p-Values = 0.000), supporting H2a, and on SCE (β = 0.347, T Statistics = 5.095, p-Values = 0.000), supporting H3a.

Table 5.

Direct effect structural path results.

H2b and H3b propose that SCC and SCE mediate the relationship between AIU and SCR. Accordingly, this study examined the mediating effects within the proposed model (Table 6). The results indicate that the indirect effect of SCC on SCR via AIU is statistically significant (β = 0.072, T Statistics = 2.572, p-Values = 0.010), supporting H2b. Similarly, SCE exhibits a statistically significant indirect effect on SCR through AIU (β = 0.080, T Statistics = 2.238, p-Values = 0.025), supporting H3b.

Table 6.

Mediation relationships.

Finally, H4 proposes that DITC exerts a positive moderating effect on the relationship between AIU and SCR. To test this hypothesis, we conducted a moderation analysis. As Table 7 shows, the results indicate that DITC exerts a moderate positive moderating effect on the relationship between AIU and SCR (β = 0.170, T Statistics = 2.045, p-Values = 0.041), supporting H4.

Table 7.

Moderation analysis.

6. Discussion

To examine the complex and multi-layered relationship between AIU and SCR, this study developed a theoretical model involving AIU, SCR, and five other constructs based on an extensive literature review. Integrating AI application practices in supply chain management with the objectives of supply chain resilience, we employed OIPT to analyze the pathways through which AIU influences SCR. Guided by the OIPT theoretical framework, we incorporated SCC and SCE into the model and hypothesized their mediating roles in the positive impact of AIU on SCR. Furthermore, given the industry’s increasing urgency to leverage AI for production enhancement and the resistance encountered in practice, we introduced OIPT into the model and proposed its moderating effect on the relationship between AIU and SCR. After completing the theoretical model construction, we conducted a questionnaire survey involving 231 senior executives and supply chain managers from China’s manufacturing sector. Empirical analysis of the survey data using PLS-SEM revealed that AIU exerts a strongly positive and significant effect on SCR, with SCC and SCE serving as mediators in this process. Additionally, DITC, a factor receiving limited scholarly attention, was found to have a positive moderating role in this relationship.

With increasing external environmental and market uncertainty, the traditional mechanistic approach to coordinating supply chain activities and resources through rules or procedures has become inadequate [10,11]. This method of reducing reliance on external information to maintain business continuity is no longer viable. Therefore, OIPT posits that in highly uncertain environments, sustaining a certain level of information processing performance is essential for business continuity [28]. This involves two dimensions: information processing requirements and information processing capacity. On the one hand, Tushman et al. [24] define uncertainty as the gap between the information available and the information required to complete a task. To narrow this gap, we argue that AI intervention can optimize SCC, thereby enhancing SCR. Enterprises adopting AI will reinforce this process. Given AI’s technical characteristics, improving its utility will compel firms to strengthen supply chain collaborations to obtain more high-quality data—a perspective overlooked by most scholars. On the other hand, information overload resulting from insufficient processing capacity also impedes a firm’s ability to manage uncertainty. The demand for information processing capacity rises along with uncertainty [24]. AI’s capability to automate and intelligently process multi-source heterogeneous data significantly enhances information processing [97]. Unlike other digital technologies, its abilities to learn, offer predictions, and automate decision-making can drastically reduce data processing delays, further augmenting data handling capabilities. Ultimately, this improves SCE and resilience [98,99].

Additionally, we emphasize the moderating role of DITC, an angle rarely explored in existing research on supply chain operations. Extensive studies in computer science demonstrate that the utility of AI depends on factors such as data availability and IT infrastructure, which are equally crucial for AI applications in supply chain management practices [14]. DITC reflects a company’s level of digitalization, and companies with stronger DITC are generally better equipped to implement and maintain AI systems, thereby enhancing their support for production activities [19,76]. On one hand, such companies can provide higher-quality datasets for AI learning and generate more effective outputs [100]. On the other hand, they can timely adjust AI strategies and optimizations according to market conditions and demand changes, ensuring that AI meets current business needs [101].

6.1. Theoretical Implications

These findings contribute to the existing literature by expanding our understanding of how AI enhances SCR. This study addresses the scarcity of research on the effects of AIU on SCR from an information processing perspective. AI capabilities in data analysis, self-learning, prediction, and automated decision-making can enhance the information processing performance of supply chain enterprises. Using the theoretical framework provided by OIPT, we posit that AIU can effectively improve SCR. Furthermore, we incorporated SCC and SCE as mediating variables into our theoretical model. Our empirical tests validate this proposition, thereby enriching the theoretical understanding of SCR research.

Additionally, this study extends OIPT. Galbraith [10] analyzes the effect of lateral relationships and vertical information system investments as two independent strategies to enhance organizational information processing capability, though they may be complementary. However, in the context of AI technology intervention, we argue that the effective deployment of strong information processing capabilities depends on access to sufficient information. That is, the efficient utilization of AI capabilities requires that the firm acquire adequate, high-quality information as a prerequisite. This need will drive enterprises to proactively strengthen lateral relationships to integrate critical information dispersed across departments, thereby maximizing the utility of AI. This perspective reveals the reframing effect of technological advancement on organizational design motivations, enriching the theoretical implications of OIPT in the digital era.

Within a framework of the relationship between AI and SCR, we systematically introduce and validate DITC as a critical moderating variable, an approach that most supply chain management research overlooks. The results reveal that while AIU could enhance SCR, its effectiveness depends crucially on the maturity of a firm’s existing digital infrastructure, data governance level, and technological integration capabilities (i.e., DITC). This result provides a crucial theoretical explanation for why firms gain varying levels of resilience when applying similar AI technologies, thereby enriching the theoretical foundation for the integration of AI and supply chain management.

6.2. Practical Implications

Our empirical findings offer critical and actionable insights for supply chain managers and senior executives seeking to leverage AI to enhance SCR. First, we contend that advancing the application of AI in production should be a strategic priority for improving SCR. Managers should recognize AI not merely as an efficiency tool, but also as a key driver for building SCR. Leveraging AI capabilities in predictive analytics, autonomous learning, and other domains, managers should strategically deploy AI technologies in risk management, decision analysis, and process optimization. This approach can enhance the supply chain’s capability to withstand disruptions and continuously optimize its operations.

Secondly, managers must prioritize enhancing collaborative relationships with supply chain partners, which significantly contributes to improving the effectiveness of AI systems. The use of AI in production and operations does not imply that AI can independently handle all supply chain forecasting and decision-making tasks. On the contrary, close collaboration with partners is essential to obtain critical and timely information. Improved collaboration not only provides more real-time, actionable data, substantially enhancing the output quality of AI, but also mutually benefits the collaborative process, enabling companies to manage partner relationships more efficiently and precisely.

Additionally, we verified the potential of AI in improving SCC and SCE. Managers can introduce AI into systems such as ERP to monitor, analyze, and forecast multi-source data, including demand, inventory, and risk alerts, which would enable real-time information sharing across the supply chain network. This enhances awareness across all parties, helping companies make faster and more coordinated decisions during normal operations or crises [102]. Simultaneously, AI’s role in boosting SCE is particularly crucial. Higher efficiency provides more flexible resource allocation, faster response times, and lower operational vulnerability, thereby better mitigating disruption risks. This approach can enhance SCR. Managers should focus on applying AI in core efficiency areas, including inventory management [103], logistics [104] and transportation optimization [105], and production optimization. Firms can turn the additional resource buffer and time windows created by efficiency gains into profits or build strategic long-term risk resistance.

Finally, while applying AI to enhance corporate business capabilities will yield significant benefits, enterprises should avoid blindly investing in AI technology. Beyond weighing costs against benefits, companies must also evaluate their own DITC, as this critical factor influences the effectiveness of AI and its ability to improve SCR. Before undertaking extensive AI integration, managers must evaluate the firm’s level of digital maturity. This includes determining whether sufficient accessible data, IT infrastructure, complementary technologies, and relevant talent pools are available to ensure that the model will provide high quality output and that the quality will remain.

6.3. Limitations and Future Research Directions

Despite rigorous design and execution measures to ensure the validity of the experimental results, this study has several limitations that warrant consideration and provide opportunities for future research. First, the study was confined to the manufacturing industry in China, which may limit the generalizability of the findings to other sectors or geographical regions. Future research could expand the scope to include diverse sectors and regions to improve the external validity and broader applicability of the conclusions. Second, the study was grounded solely in OIPT to frame and constrain the model variables. While OIPT offers valuable insights, relying on a single theoretical framework may not fully capture the complex mechanisms through which AIU impacts SCR. Future research should adopt multiple theoretical perspectives and employ mixed-method approaches to develop a more comprehensive understanding of these relationships.

7. Conclusions

As a pillar in China’s economy, the manufacturing sector incurred significant losses due to recent black swan events. These disruptions underscore the critical importance of SCR in sustaining industrial development. Concurrently, rapid advancements in AI prompted growing scholarly and practical interest in understanding the relationship between AIU and SCR. Grounded in OIPT, this study posits that AIU can enhance SCR by improving firms’ information processing efficiency and strengthening inter-organizational collaboration. Accordingly, we develop a theoretical model and test it empirically using data collected from 231 valid questionnaire responses from Chinese manufacturing firms. The results reveal that AIU directly and positively impacts SCR. Furthermore, SCC and SCE are significant mediators in the relationship between AIU and SCR. We also examine the moderating effect of DITC, and find that DITC exerts a significant but modest positive moderating effect on the relationship between AIU and SCR. By exploring the relationships among AIU, SCC, SCE, SCR, and DITC within the OIPT framework, this study improves our understanding of AI applications in supply chain management and provides practical implications for enhancing manufacturing SCR.

Author Contributions

Conceptualization, H.P. and N.Z.; methodology, N.Z.; software, N.Z.; validation, N.Z. and R.W.; formal analysis, N.Z.; investigation, N.Z. and R.W.; resources, H.P.; data curation, N.Z. and R.W.; writing—original draft preparation, N.Z.; writing—review and editing, N.Z. and J.M.; visualization, D.L.; supervision, H.P. and N.Z.; project administration, H.P.; funding acquisition, H.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The datasets presented in this article are not readily available because the data are part of an ongoing study. Requests to access the datasets should be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AI | Artificial Intelligence |

| AIU | Artificial Intelligence Usage |

| AVE | Average Variance Extracted |

| CR | Composite Reliability |

| DITC | Digital Information Technology Capabilities |

| OIPT | Organizational Information Processing Theory |

| PLS-SEM | Partial Least Squares Structural Equation Modeling |

| SCR | Supply Chain Resilience |

| SCC | Supply Chain Collaboration |

| SCE | Supply Chain Efficiency |

| SEM | Structural Equation Modeling |

| SPSS | Statistical Package for the Social Sciences |

| VIF | Variance Inflation Factor |

References

- Rashid, A.; Rasheed, R.; Ngah, A.H.; Amirah, N.A. Unleashing the Power of Cloud Adoption and Artificial Intelligence in Optimizing Resilience and Sustainable Manufacturing Supply Chain in the USA. J. Manuf. Technol. Manag. 2024, 35, 1329–1353. [Google Scholar] [CrossRef]

- Qi, Y.; Wang, X.; Zhang, M.; Wang, Q. Developing Supply Chain Resilience through Integration: An Empirical Study on an E-commerce Platform. J. Oper. Manag. 2023, 69, 477–496. [Google Scholar] [CrossRef]

- Lin, J.; Lin, S.; Benitez, J.; Luo, X.R.; Ajamieh, A. How to Build Supply Chain Resilience: The Role of Fit Mechanisms between Digitally-Driven Business Capability and Supply Chain Governance. Inf. Manag. 2023, 60, 103747. [Google Scholar] [CrossRef]

- Alkhatib, S.F.; Momani, R.A. Supply Chain Resilience and Operational Performance: The Role of Digital Technologies in Jordanian Manufacturing Firms. Adm. Sci. 2023, 13, 40. [Google Scholar] [CrossRef]

- Reischauer, G. Industry 4.0 as Policy-Driven Discourse to Institutionalize Innovation Systems in Manufacturing. Technol. Forecast. Soc. Chang. 2018, 132, 26–33. [Google Scholar] [CrossRef]

- Mannuru, N.R.; Shahriar, S.; Teel, Z.A.; Wang, T.; Lund, B.D.; Tijani, S.; Pohboon, C.O.; Agbaji, D.; Alhassan, J.; Galley, J.; et al. Artificial Intelligence in Developing Countries: The Impact of Generative Artificial Intelligence (AI) Technologies for Development. Inf. Dev. 2023, 41, 1036–1054. [Google Scholar] [CrossRef]

- Zamani, E.D.; Smyth, C.; Gupta, S.; Dennehy, D. Artificial Intelligence and Big Data Analytics for Supply Chain Resilience: A Systematic Literature Review. Ann. Oper. Res. 2023, 327, 605–632. [Google Scholar] [CrossRef]

- Wong, C.Y.; Boon-itt, S.; Wong, C.W.Y. The Contingency Effects of Environmental Uncertainty on the Relationship between Supply Chain Integration and Operational Performance. J. Oper. Manag. 2011, 29, 604–615. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Fosso Wamba, S.; Roubaud, D.; Foropon, C. Empirical Investigation of Data Analytics Capability and Organizational Flexibility as Complements to Supply Chain Resilience. Int. J. Prod. Res. 2021, 59, 110–128. [Google Scholar] [CrossRef]

- Galbraith, J.R. Organization Design: An Information Processing View. Interfaces 1974, 4, 28–36. [Google Scholar] [CrossRef]

- Srinivasan, R.; Swink, M. An Investigation of Visibility and Flexibility as Complements to Supply Chain Analytics: An Organizational Information Processing Theory Perspective. Prod. Oper. Manag. 2018, 27, 1849–1867. [Google Scholar] [CrossRef]

- Benzidia, S.; Makaoui, N.; Bentahar, O. The Impact of Big Data Analytics and Artificial Intelligence on Green Supply Chain Process Integration and Hospital Environmental Performance. Technol. Forecast. Soc. Chang. 2021, 165, 120557. [Google Scholar] [CrossRef]

- Xie, X.; Wu, Y.; Palacios-Marqués, D.; Ribeiro-Navarrete, S. Business Networks and Organizational Resilience Capacity in the Digital Age during COVID-19: A Perspective Utilizing Organizational Information Processing Theory. Technol. Forecast. Soc. Chang. 2022, 177, 121548. [Google Scholar] [CrossRef]

- Culot, G.; Podrecca, M.; Nassimbeni, G. Artificial Intelligence in Supply Chain Management: A Systematic Literature Review of Empirical Studies and Research Directions. Comput. Ind. 2024, 162, 104132. [Google Scholar] [CrossRef]

- Proksch, D.; Rosin, A.F.; Stubner, S.; Pinkwart, A. The Influence of a Digital Strategy on the Digitalization of New Ventures: The Mediating Effect of Digital Capabilities and a Digital Culture. J. Small Bus. Manag. 2024, 62, 1–29. [Google Scholar] [CrossRef]

- Arroyabe, M.F.; Arranz, C.F.A.; Fernandez De Arroyabe, I.; Fernandez De Arroyabe, J.C. Analyzing AI Adoption in European SMEs: A Study of Digital Capabilities, Innovation, and External Environment. Technol. Soc. 2024, 79, 102733. [Google Scholar] [CrossRef]

- Brock, J.K.-U.; Von Wangenheim, F. Demystifying AI: What Digital Transformation Leaders Can Teach You about Realistic Artificial Intelligence. Calif. Manag. Rev. 2019, 61, 110–134. [Google Scholar] [CrossRef]

- Demlehner, Q.; Schoemer, D.; Laumer, S. How Can Artificial Intelligence Enhance Car Manufacturing? A Delphi Study-Based Identification and Assessment of General Use Cases. Int. J. Inf. Manag. 2021, 58, 102317. [Google Scholar] [CrossRef]

- Bokrantz, J.; Subramaniyan, M.; Skoogh, A. Realising the Promises of Artificial Intelligence in Manufacturing by Enhancing CRISP-DM. Prod. Plan. Control 2024, 35, 2234–2254. [Google Scholar] [CrossRef]

- Qiao-Franco, G.; Zhu, R. China’s Artificial Intelligence Ethics: Policy Development in an Emergent Community of Practice. J. Contemp. 2024, 33, 189–205. [Google Scholar] [CrossRef]

- Li, L.; Zhu, W.; Chen, L.; Liu, Y. Generative AI Usage and Sustainable Supply Chain Performance: A Practice-Based View. Transp. Res. Part E Logist. Transp. Rev. 2024, 192, 103761. [Google Scholar] [CrossRef]

- Zhu, S.; Song, J.; Hazen, B.T.; Lee, K.; Cegielski, C. How Supply Chain Analytics Enables Operational Supply Chain Transparency: An Organizational Information Processing Theory Perspective. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 47–68. [Google Scholar] [CrossRef]

- Wong, C.W.Y.; Lirn, T.-C.; Yang, C.-C.; Shang, K.-C. Supply Chain and External Conditions under Which Supply Chain Resilience Pays: An Organizational Information Processing Theorization. Int. J. Prod. Econ. 2020, 226, 107610. [Google Scholar] [CrossRef]

- Tushman, M.L.; Nadler, D.A. Information Processing as an Integrating Concept in Organizational Design. Acad. Manag. Rev. 1978, 3, 613. [Google Scholar] [CrossRef]

- Cousins, P.D.; Lawson, B.; Petersen, K.J.; Handfield, R.B. Breakthrough Scanning, Supplier Knowledge Exchange, and New Product Development Performance. J. Prod. Innov. Manag. 2011, 28, 930–942. [Google Scholar] [CrossRef]

- Han, Y. Navigating Supply Chain Resilience in the Knowledge Economy: Insights from Digital Technologies and Organizational Information Processing. J. Knowl. Econ. 2024, 16, 9898–9931. [Google Scholar] [CrossRef]

- Tian, S.; Wu, L.; Ciano, M.P.; Ardolino, M.; Pawar, K.S. Enhancing Innovativeness and Performance of the Manufacturing Supply Chain through Datafication: The Role of Resilience. Comput. Ind. Eng. 2024, 188, 109841. [Google Scholar] [CrossRef]

- Belhadi, A.; Mani, V.; Kamble, S.S.; Khan, S.A.R.; Verma, S. Artificial Intelligence-Driven Innovation for Enhancing Supply Chain Resilience and Performance under the Effect of Supply Chain Dynamism: An Empirical Investigation. Ann. Oper. Res. 2024, 333, 627–652. [Google Scholar] [CrossRef]

- Hohenstein, N.-O.; Feisel, E.; Hartmann, E.; Giunipero, L. Research on the Phenomenon of Supply Chain Resilience: A Systematic Review and Paths for Further Investigation. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 90–117. [Google Scholar] [CrossRef]

- Tukamuhabwa, B.R.; Stevenson, M.; Busby, J.; Zorzini, M. Supply Chain Resilience: Definition, Review and Theoretical Foundations for Further Study. Int. J. Prod. Res. 2015, 53, 5592–5623. [Google Scholar] [CrossRef]

- Sturm, S.; Hohenstein, N.-O.; Hartmann, E. Linking Entrepreneurial Orientation and Supply Chain Resilience to Strengthen Business Performance: An Empirical Analysis. Int. J. Oper. Prod. Manag. 2023, 43, 1357–1386. [Google Scholar] [CrossRef]

- Yue, X.; Kang, M.; Zhang, Y. The Impact of Artificial Intelligence Usage on Supply Chain Resilience in Manufacturing Firms: A Moderated Mediation Model. J. Manuf. Technol. Manag. 2025, 36, 759–776. [Google Scholar] [CrossRef]

- El Baz, J.; Ruel, S. Can Supply Chain Risk Management Practices Mitigate the Disruption Impacts on Supply Chains’ Resilience and Robustness? Evidence from an Empirical Survey in a COVID-19 Outbreak Era. Int. J. Prod. Econ. 2021, 233, 107972. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Wang, J.; He, C.; Jiang, X.; An, Q. Sewage Treatment Equipment Supply Chain Collaboration and Resilience Improvement Path Analysis: Collaborative Decision-Making, Information Sharing, Risk Management. Sustainability 2024, 16, 9031. [Google Scholar] [CrossRef]

- Chowdhury, M.M.H.; Islam, M.T.; Ali, I.; Quaddus, M. The Role of Social Capital, Resilience, and Network Complexity in Attaining Supply Chain Sustainability. Bus. Strategy Environ. 2024, 33, 2621–2639. [Google Scholar] [CrossRef]

- Eller, R.; Alford, P.; Kallmünzer, A.; Peters, M. Antecedents, Consequences, and Challenges of Small and Medium-Sized Enterprise Digitalization. J. Bus. Res. 2020, 112, 119–127. [Google Scholar] [CrossRef]

- Kamble, S.; Gunasekaran, A.; Dhone, N.C. Industry 4.0 and Lean Manufacturing Practices for Sustainable Organisational Performance in Indian Manufacturing Companies. Int. J. Prod. Res. 2020, 58, 1319–1337. [Google Scholar] [CrossRef]

- Li, Y.; Li, D.; Liu, Y.; Shou, Y. Digitalization for Supply Chain Resilience and Robustness: The Roles of Collaboration and Formal Contracts. Front. Eng. Manag. 2023, 10, 5–19. [Google Scholar] [CrossRef]

- Simon, H.A. Artificial Intelligence: An Empirical Science. Artif. Intell. 1995, 77, 95–127. [Google Scholar] [CrossRef]

- Alfawaz, K.M.; Alshehri, A.A. Applying Artificial Intelligence in Supply Chain Management. Commun. Math. Appl. 2022, 13, 367–377. [Google Scholar] [CrossRef]

- Perez, H.D.; Hubbs, C.D.; Li, C.; Grossmann, I.E. Algorithmic Approaches to Inventory Management Optimization. Processes 2021, 9, 102. [Google Scholar] [CrossRef]

- Wang, F.; Lin, L. Spare Parts Supply Chain Network Modeling Based on a Novel Scale-Free Network and Replenishment Path Optimization with Q Learning. Comput. Ind. Eng. 2021, 157, 107312. [Google Scholar] [CrossRef]

- Puskás, E.; Budai, Á.; Bohács, G. Optimization of a Physical Internet Based Supply Chain Using Reinforcement Learning. Eur. Transp. Res. Rev. 2020, 12, 47. [Google Scholar] [CrossRef]

- Cavalcante, I.M.; Frazzon, E.M.; Forcellini, F.A.; Ivanov, D. A Supervised Machine Learning Approach to Data-Driven Simulation of Resilient Supplier Selection in Digital Manufacturing. Int. J. Inf. Manag. 2019, 49, 86–97. [Google Scholar] [CrossRef]

- Vanvuchelen, N.; Gijsbrechts, J.; Boute, R. Use of Proximal Policy Optimization for the Joint Replenishment Problem. Comput. Ind. 2020, 119, 103239. [Google Scholar] [CrossRef]

- Carbonneau, R.; Laframboise, K.; Vahidov, R. Application of Machine Learning Techniques for Supply Chain Demand Forecasting. Eur. J. Oper. Res. 2008, 184, 1140–1154. [Google Scholar] [CrossRef]

- Castañé, G.; Dolgui, A.; Kousi, N.; Meyers, B.; Thevenin, S.; Vyhmeister, E.; Östberg, P.-O. The ASSISTANT Project: AI for High Level Decisions in Manufacturing. Int. J. Prod. Res. 2023, 61, 2288–2306. [Google Scholar] [CrossRef]

- Albert, Y.; Alijoyo, A. Systematical Review: How Artificial Intelligence Impact Supply Chain Capability and Capacity in Emerging Markets. INOBIS J. Inov. Bisnis Dan Manaj. 2024, 7, 429–441. [Google Scholar] [CrossRef]

- Yamin, M.A.; Almuteri, S.D.; Bogari, K.J.; Ashi, A.K. The Influence of Strategic Human Resource Management and Artificial Intelligence in Determining Supply Chain Agility and Supply Chain Resilience. Sustainability 2024, 16, 2688. [Google Scholar] [CrossRef]

- Baryannis, G.; Validi, S.; Dani, S.; Antoniou, G. Supply Chain Risk Management and Artificial Intelligence: State of the Art and Future Research Directions. Int. J. Prod. Res. 2019, 57, 2179–2202. [Google Scholar] [CrossRef]

- Rodríguez-Espíndola, O.; Chowdhury, S.; Beltagui, A.; Albores, P. The Potential of Emergent Disruptive Technologies for Humanitarian Supply Chains: The Integration of Blockchain, Artificial Intelligence and 3D Printing. Int. J. Prod. Res. 2020, 58, 4610–4630. [Google Scholar] [CrossRef]

- Modgil, S.; Gupta, S.; Stekelorum, R.; Laguir, I. AI Technologies and Their Impact on Supply Chain Resilience during COVID-19. Int. J. Phys. Distrib. Logist. Manag. 2022, 52, 130–149. [Google Scholar] [CrossRef]

- Pires Ribeiro, J.; Barbosa-Povoa, A. Supply Chain Resilience: Definitions and Quantitative Modelling Approaches – A Literature Review. Comput. Ind. Eng. 2018, 115, 109–122. [Google Scholar] [CrossRef]

- Smyth, C.; Dennehy, D.; Fosso Wamba, S.; Scott, M.; Harfouche, A. Artificial Intelligence and Prescriptive Analytics for Supply Chain Resilience: A Systematic Literature Review and Research Agenda. Int. J. Prod. Res. 2024, 62, 8537–8561. [Google Scholar] [CrossRef]

- Daft, R.L.; Lengel, R.H. Organizational Information Requirements, Media Richness and Structural Design. Manag. Sci. 1986, 32, 554–571. [Google Scholar] [CrossRef]

- Van Der Vorst, J.G.A.J.; Beulens, A.J.M. Identifying Sources of Uncertainty to Generate Supply Chain Redesign Strategies. Int. J. Phys. Distrib. Logist. Manag. 2002, 32, 409–430. [Google Scholar] [CrossRef]

- Ponomarov, S.Y.; Holcomb, M.C. Understanding the Concept of Supply Chain Resilience. Int. J. Logist. Manag. 2009, 20, 124–143. [Google Scholar] [CrossRef]

- Aboutorab, H.; Hussain, O.K.; Saberi, M.; Hussain, F.K. A Reinforcement Learning-Based Framework for Disruption Risk Identification in Supply Chains. Future Gener. Comput. Syst. 2022, 126, 110–122. [Google Scholar] [CrossRef]

- Guntuka, L.; Corsi, T.M.; Cantor, D.E. Recovery from Plant-Level Supply Chain Disruptions: Supply Chain Complexity and Business Continuity Management. Int. J. Oper. Prod. Manag. 2024, 44, 1–31. [Google Scholar] [CrossRef]

- Jain, V.; Kumar, S.; Soni, U.; Chandra, C. Supply Chain Resilience: Model Development and Empirical Analysis. Int. J. Prod. Res. 2017, 55, 6779–6800. [Google Scholar] [CrossRef]

- Mosch, P.; Schweikl, S.; Obermaier, R. Trapped in the Supply Chain? Digital Servitization Strategies and Power Relations in the Case of an Industrial Technology Supplier. Int. J. Prod. Econ. 2021, 236, 108141. [Google Scholar] [CrossRef]

- Weisz, E.; Herold, D.M.; Ostern, N.K.; Payne, R.; Kummer, S. Artificial Intelligence (AI) for Supply Chain Collaboration: Implications on Information Sharing and Trust. Online Inf. Rev. 2025, 49, 164–181. [Google Scholar] [CrossRef]

- Qi, M.; Mak, H.; Shen, Z.M. Data-driven Research in Retail Operations—A Review. Nav. Res. Logist. NRL 2020, 67, 595–616. [Google Scholar] [CrossRef]

- Baah, C.; Opoku Agyeman, D.; Acquah, I.S.K.; Agyabeng-Mensah, Y.; Afum, E.; Issau, K.; Ofori, D.; Faibil, D. Effect of Information Sharing in Supply Chains: Understanding the Roles of Supply Chain Visibility, Agility, Collaboration on Supply Chain Performance. Benchmarking Int. J. 2022, 29, 434–455. [Google Scholar] [CrossRef]

- Hult, G.T.M.; Ketchen, D.J.; Slater, S.F. Information processing, knowledge development, and strategic supply chain performance. Acad. Manag. J. 2004, 47, 241–253. [Google Scholar] [CrossRef]

- Pereira, E.T.; Shafique, M.N. The Role of Artificial Intelligence in Supply Chain Agility: A Perspective of Humanitarian Supply Chain. Eng. Econ. 2024, 35, 77–89. [Google Scholar] [CrossRef]

- Hendricks, K.B.; Singhal, V.R. Association Between Supply Chain Glitches and Operating Performance. Manag. Sci. 2005, 51, 695–711. [Google Scholar] [CrossRef]

- Preil, D.; Krapp, M. Artificial Intelligence-Based Inventory Management: A Monte Carlo Tree Search Approach. Ann. Oper. Res. 2022, 308, 415–439. [Google Scholar] [CrossRef]

- Ma, L.; Wang, H.; He, C.; Sui, X. Can Intelligent Development Improve Manufacturing Firms’ Supply Chain Resilience? Int. Rev. Econ. Finance 2025, 97, 103753. [Google Scholar] [CrossRef]

- Jiang, G.; Chen, F.; Gu, M. Supply Chain Digitization and Energy Resilience: Evidence from China. Energy Econ. 2025, 144, 108420. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, H.; Zhang, M. The Impact of Supply Chain Digitalization on Financing Efficiency of Small and Medium Enterprises: A Perspective of Supply Chain Resilience. Procedia Comput. Sci. 2024, 242, 35–42. [Google Scholar] [CrossRef]

- Tippins, M.J.; Sohi, R.S. IT Competency and Firm Performance: Is Organizational Learning a Missing Link? Strateg. Manag. J. 2003, 24, 745–761. [Google Scholar] [CrossRef]

- BarNir, A.; Gallaugher, J.M.; Auger, P. Business Process Digitization, Strategy, and the Impact of Firm Age and Size: The Case of the Magazine Publishing Industry. J. Bus. Ventur. 2003, 18, 789–814. [Google Scholar] [CrossRef]

- Zhang, H.; Song, M.; Wang, Y. Does AI-Infused Operations Capability Enhance or Impede the Relationship between Information Technology Capability and Firm Performance? Technol. Forecast. Soc. Chang. 2023, 191, 122517. [Google Scholar] [CrossRef]

- Awamleh, F.T.; Bustami, A.N. Examine the Mediating Role of the Information Technology Capabilities on the Relationship Between Artificial Intelligence and Competitive Advantage During the COVID-19 Pandemic. Sage Open 2022, 12, 21582440221119478. [Google Scholar] [CrossRef]

- Chu, Y.; Chi, M.; Wang, W.; Luo, B. The Impact of Information Technology Capabilities of Manufacturing Enterprises on Innovation Performance: Evidences from SEM and fsQCA. Sustainability 2019, 11, 5946. [Google Scholar] [CrossRef]

- Helo, P.; Hao, Y. Artificial Intelligence in Operations Management and Supply Chain Management: An Exploratory Case Study. Prod. Plan. Control 2022, 33, 1573–1590. [Google Scholar] [CrossRef]

- Zhang, Y.; Huo, B.; Haney, M.H.; Kang, M. The Effect of Buyer Digital Capability Advantage on Supplier Unethical Behavior: A Moderated Mediation Model of Relationship Transparency and Relational Capital. Int. J. Prod. Econ. 2022, 253, 108603. [Google Scholar] [CrossRef]

- Ueasangkomsate, P. Empowering Thai SMEs through IT Competency, Digitalization and Digital Transformation for New Product Development. Cogent Bus. Manag. 2025, 12, 2458758. [Google Scholar] [CrossRef]

- Wang, J.; Cui, L.; Xu, M. Impact of Digital Transformation on Supply Chain Efficiency: A Parallel Mediation Model. J. Organ. Chang. Manag. 2024, 37, 945–964. [Google Scholar] [CrossRef]

- Brandon-Jones, E.; Squire, B.; Autry, C.W.; Petersen, K.J. A Contingent Resource-Based Perspective of Supply Chain Resilience and Robustness. J. Supply Chain Manag. 2014, 50, 55–73. [Google Scholar] [CrossRef]

- Jin, S.; Vegelius, J.; Yang-Wallentin, F. A Marginal Maximum Likelihood Approach for Extended Quadratic Structural Equation Modeling with Ordinal Data. Struct. Equ. Model. Multidiscip. J. 2020, 27, 864–873. [Google Scholar] [CrossRef]

- Zeng, N.; Liu, Y.; Gong, P.; Hertogh, M.; König, M. Do Right PLS and Do PLS Right: A Critical Review of the Application of PLS-SEM in Construction Management Research. Front. Eng. Manag. 2021, 8, 356–369. [Google Scholar] [CrossRef]

- Huang, Y.-F.; Phan, V.-D.-V.; Do, M.-H. The Impacts of Supply Chain Capabilities, Visibility, Resilience on Supply Chain Performance and Firm Performance. Adm. Sci. 2023, 13, 225. [Google Scholar] [CrossRef]

- Hair, J.F.; Risher, J.J.; Sarstedt, M.; Ringle, C.M. When to Use and How to Report the Results of PLS-SEM. Eur. Bus. Rev. 2019, 31, 2–24. [Google Scholar] [CrossRef]

- Taber, K.S. The Use of Cronbach’s Alpha When Developing and Reporting Research Instruments in Science Education. Res. Sci. Educ. 2018, 48, 1273–1296. [Google Scholar] [CrossRef]

- Hair, J.F.; Ringle, C.M.; Sarstedt, M. Partial Least Squares Structural Equation Modeling: Rigorous Applications, Better Results and Higher Acceptance. Long Range Plann. 2013, 46, 1–12. [Google Scholar] [CrossRef]

- Diamantopoulos, A.; Siguaw, J.A. Formative Versus Reflective Indicators in Organizational Measure Development: A Comparison and Empirical Illustration. Br. J. Manag. 2006, 17, 263–282. [Google Scholar] [CrossRef]

- Sarstedt, M.; Ringle, C.M.; Smith, D.; Reams, R.; Hair, J.F. Partial Least Squares Structural Equation Modeling (PLS-SEM): A Useful Tool for Family Business Researchers. J. Fam. Bus. Strategy 2014, 5, 105–115. [Google Scholar] [CrossRef]

- Fornell, C.; Larcker, D.F. Evaluating Structural Equation Models with Unobservable Variables and Measurement Error. J. Mark. Res. 1981, 18, 39–50. [Google Scholar] [CrossRef]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences, 2nd ed.; Lawrence Erlbaum Associates: New York, NY, USA, 1988. [Google Scholar]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Bryde, D.J.; Giannakis, M.; Foropon, C.; Roubaud, D.; Hazen, B.T. Big Data Analytics and Artificial Intelligence Pathway to Operational Performance under the Effects of Entrepreneurial Orientation and Environmental Dynamism: A Study of Manufacturing Organisations. Int. J. Prod. Econ. 2020, 226, 107599. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.-Y.; Podsakoff, N.P. Common Method Biases in Behavioral Research: A Critical Review of the Literature and Recommended Remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef]

- Liang, H.; Saraf, N.; Hu, Q.; Xue, Y. Assimilation of Enterprise Systems: The Effect of Institutional Pressures and the Mediating Role of Top Management. MIS Q. 2007, 31, 59. [Google Scholar] [CrossRef]

- Islam, S.; Hassan, S.; Hossain, S.; Ahmed, T.; Karmaker, C.L.; Bari, A.B.M.M. Exploring the Influence of Circular Economy on Big Data Analytics and Supply Chain Resilience Nexus: A Structural Equation Modeling Approach. Green Technol. Sustain. 2025, 3, 100219. [Google Scholar] [CrossRef]

- Kock, N. Hypothesis Testing with Confidence Intervals and P Values in PLS-SEM. Int. J. E-Collab. 2016, 12, 1–6. [Google Scholar] [CrossRef]

- Zaman, J.; Shoomal, A.; Jahanbakht, M.; Ozay, D. Driving Supply Chain Transformation with IoT and AI Integration: A Dual Approach Using Bibliometric Analysis and Topic Modeling. IoT 2025, 6, 21. [Google Scholar] [CrossRef]

- Zheng, D.; Wang, T. Supply Chain Resilience, Logistics Efficiency, and Enterprise Competitiveness. Finance Res. Lett. 2025, 79, 107335. [Google Scholar] [CrossRef]

- Ke, J.; Cho, W.; Su, H. Flying through Uncertainty: Air Transportation’s Impact on Supply Chain Resilience and Inventory Efficiency. Transp. Res. Part E Logist. Transp. Rev. 2025, 197, 104042. [Google Scholar] [CrossRef]

- Galbusera, F.; Cina, A. Image Annotation and Curation in Radiology: An Overview for Machine Learning Practitioners. Eur. Radiol. Exp. 2024, 8, 11. [Google Scholar] [CrossRef]

- Teixeira, A.R.; Ferreira, J.V.; Ramos, A.L. Intelligent Supply Chain Management: A Systematic Literature Review on Artificial Intelligence Contributions. Information 2025, 16, 399. [Google Scholar] [CrossRef]

- Delgado, F.; Garrido, S.; Bezerra, B.S. Barriers to Visibility in Supply Chains: Challenges and Opportunities of Artificial Intelligence Driven by Industry 4.0 Technologies. Sustainability 2025, 17, 2998. [Google Scholar] [CrossRef]

- Shen, J.; Bu, F.; Ye, Z.; Zhang, M.; Ma, Q.; Yan, J.; Huang, T. Management of Drug Supply Chain Information Based on “Artificial Intelligence + Vendor Managed Inventory” in China: Perspective Based on a Case Study. Front. Pharmacol. 2024, 15, 1373642. [Google Scholar] [CrossRef]

- Shatat, A.S.; Shatat, A.S. Artificial Intelligence Competencies in Logistics Management: An Empirical Insight from Bahrain. J. Inf. Knowl. Manag. 2024, 23, 2350059. [Google Scholar] [CrossRef]

- Ciccone, F.; Bacciaglia, A.; Ceruti, A. Optimization with Artificial Intelligence in Additive Manufacturing: A Systematic Review. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 303. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).