Based on the above theoretical framework, the research methodology of this paper includes two parts: carbon emission accounting and impact factor analysis, corresponding to the LCA method and the STIRPAT model regression analysis method, respectively. In terms of method selection, it is necessary to ensure both the comprehensiveness and accuracy of carbon emission measurement and the scientific and effective analysis of driving factors. In view of this, this paper adopts the process analysis idea in the LCA method in carbon emission accounting, and calculates the carbon emission of the residential building construction stage by the emission coefficient method; and adopts the STIRPAT model extension regression method in the analysis of the influencing factors, and demonstrates its applicability by comparing with other models. The specific contents of these two parts of the method are introduced separately below.

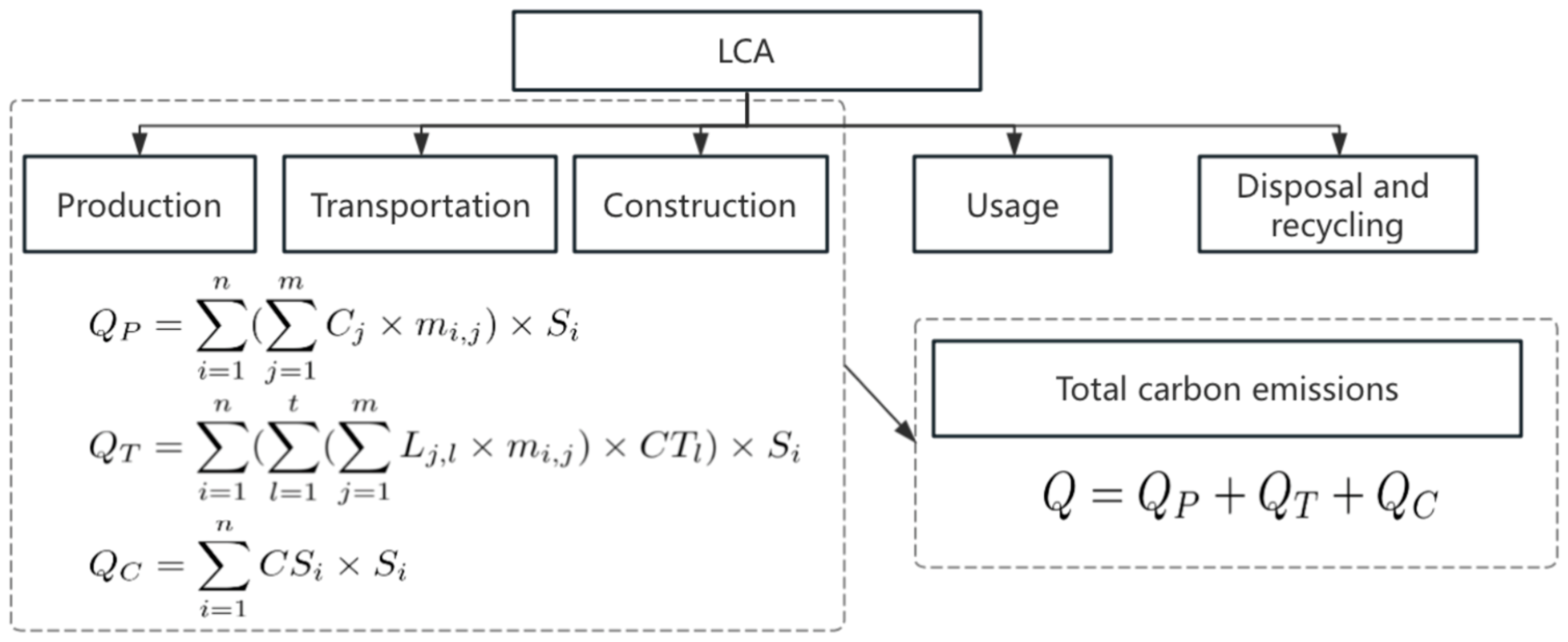

3.2.1. LCA Approach to Accounting for Carbon Emissions

System boundaries and functional units: The first step in LCA is to define the system boundaries and functional units of the study. The system boundary refers to the delineation of the scope of processes included in carbon accounting. The whole life cycle of a residential building consists of five phases: production of building materials, transport, construction, use and operation, and dismantling and recycling. This study focuses on carbon emissions from the physical phase, so the system boundary is limited to the three upstream processes of building materials production, building materials transport and construction, excluding emissions from residential use and dismantling and recycling phases. This choice of boundary is equivalent to the “cradle to construction end” in the LCA category, which covers all the carbon-containing activities that occur before the house is put into use. Within this scope, the carbon emissions from the production of building materials mainly come from the energy consumption and process emissions of raw material extraction, processing and manufacturing of building materials; the emissions from the transport of building materials come from the fuel consumption of transport vehicles and losses in the transport process; and the emissions from the construction process come from the operation of construction machinery and equipment and the energy consumption at the construction site. In terms of functional units, in order to facilitate the horizontal comparison of carbon emissions under different scenarios, it is necessary to select a unified reference benchmark. In view of the large differences in the scale of residential buildings in different regions and the lack of comparability in directly comparing the total carbon emissions, this paper adopts the carbon dioxide equivalent emissions per unit of building area (kg CO2e/m2) as the functional unit. This functional unit is commonly used in the study of building carbon emissions, which can effectively improve the comparability of carbon emission indicators of different regions and different types of buildings.

Accounting method and selection of emission coefficients: This paper adopts the process analysis method of life cycle assessment to account for carbon emissions in the materialisation phase of urban and rural housing. Specifically, the emission factor method is used to establish a carbon emission calculation model, i.e., multiplying the activity level data with the corresponding carbon emission factor and adding them up. This method is equivalent to combining the “activity factor” and “emission factor” of construction activities, which can be detailed to different materials and processes, and has a higher accuracy for carbon accounting of complex systems. In contrast, macro-accounting methods such as the input–output method have relatively rough results because they are based on input–output tables or energy balance tables, while the traditional process method uses fine data but the system boundary is not easy to be clarified, and it is prone to truncation errors, which affects the accuracy of the results. Therefore, this paper draws on the research ideas of Huang Zhijia et al. (2014) [

20] to improve the life cycle carbon accounting of residential buildings by multiplying the activity level by the emission factor. The accounting model is constructed according to the three sub-processes of the materialisation stage, respectively:

At the building material production stage, carbon emissions are calculated using the energy consumed in the production of various types of building materials and emission factors. The calculation formula is as follows:

QP is the carbon emissions from the production process of building materials; Si is the floor area of the ith residential structure; Cj is the carbon emission factor of the jth building material in the production process of building materials; mi,j is the consumption of the jth building material per unit floor area of the ith residential structure.

In the building material transport stage, the transport emissions are calculated using the transport distance of building materials and the emission factor of transport means. The calculation formula is as follows:

QT is the carbon emissions from the transport of building materials; Si is the floor area of the ith residential structure; Lj,l is the distance of the jth building material transported by the lth mode; mi,j is the consumption of the jth building material per unit of floor area of the ith residential structure; and CTl is the carbon emission factor of the lth mode of transport.

In the building construction stage, construction emissions are calculated using construction energy consumption and construction equipment emission factors. The calculation formula is as follows:

QC is the carbon emission of the building construction process; Si is the floor area of the ith residential structure; CSi is the unit carbon emission corresponding to the construction stage of the ith residential structure.

The total carbon emissions of the residential building construction stage can be obtained by adding the results of the above three parts. The calculation formula is as follows:

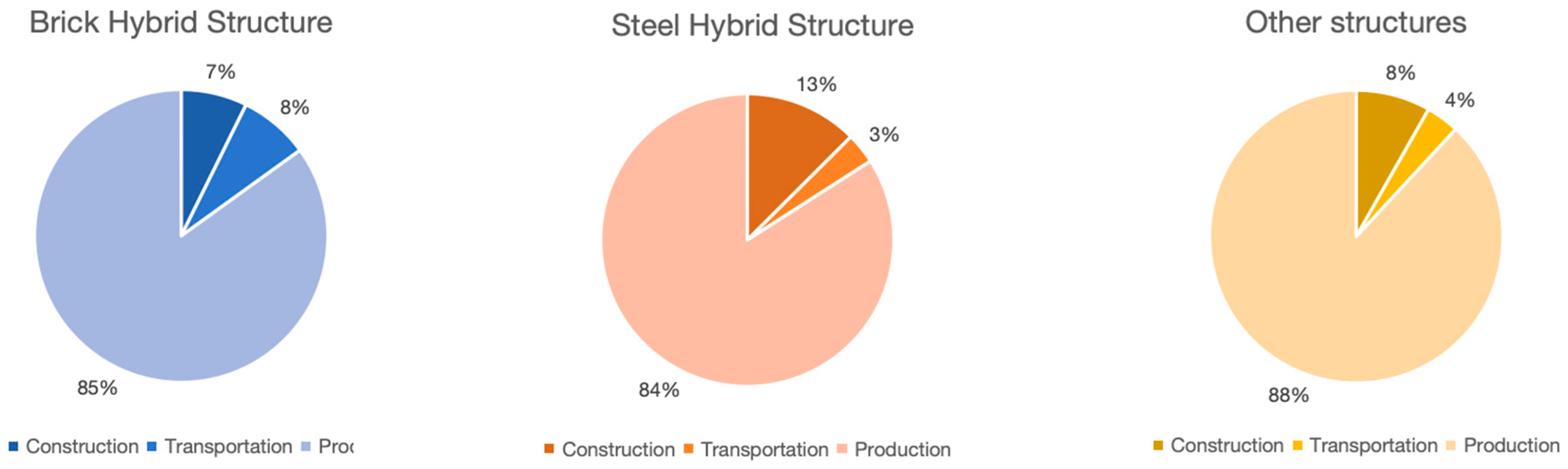

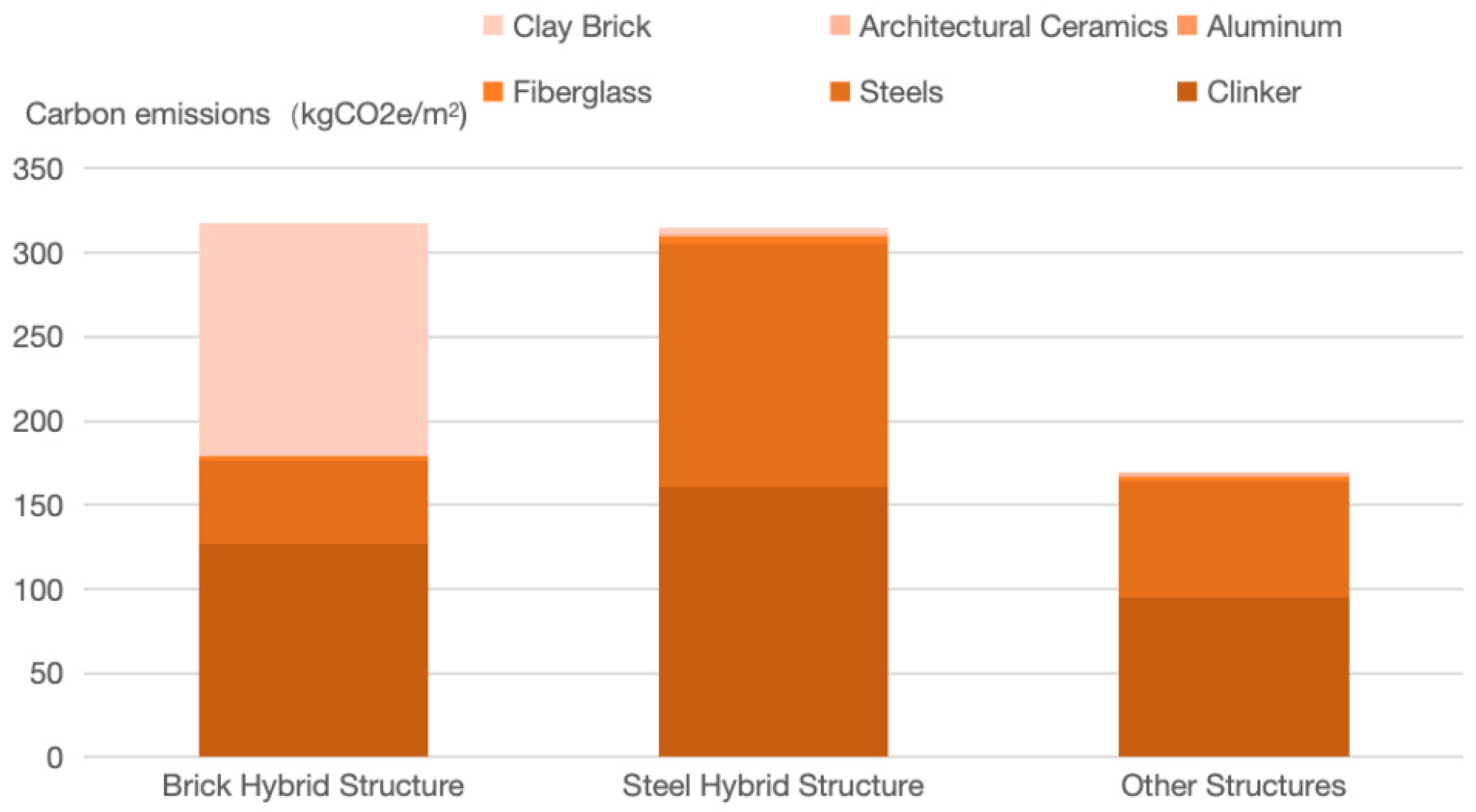

In order to improve the accuracy of accounting, this paper calculates carbon emissions separately according to the differences in residential building structure types. The study shows that the significant difference in the amount of building materials used and the level of energy consumption per unit area of residential buildings of different structural types is a key factor affecting the intensity of physical and chemical carbon emissions [

28,

29]. Accordingly, this paper further subdivided urban and rural dwellings into major structural types, and estimated the carbon emissions per unit area of different structural dwellings, such as reinforced concrete and brick and wood concrete, during the materialisation stage, and then combined the value with the completed area of dwellings in each province and city to obtain the total regional emissions. The calculation framework is shown in

Figure 1.

In terms of data acquisition, the construction area of residential buildings by structural type is obtained from authoritative statistics such as the China Construction Industry Statistical Yearbook, and the unit consumption of building materials refers to the relevant engineering quotas and literature [

28,

29]. Carbon emission factors are preferred to values provided by authoritative studies and databases at home and abroad, such as the IPCC Greenhouse Gas Inventory Guidelines and the China Life Cycle Database [

54]. The selection of emission coefficients follows the principle of higher rather than lower, i.e., taking the higher value when data from multiple sources are available to avoid underestimating carbon emissions. Through the above methodology and boundary setting, the comprehensiveness and comparability of carbon emission accounting in the urban and rural residential building construction stage are ensured.

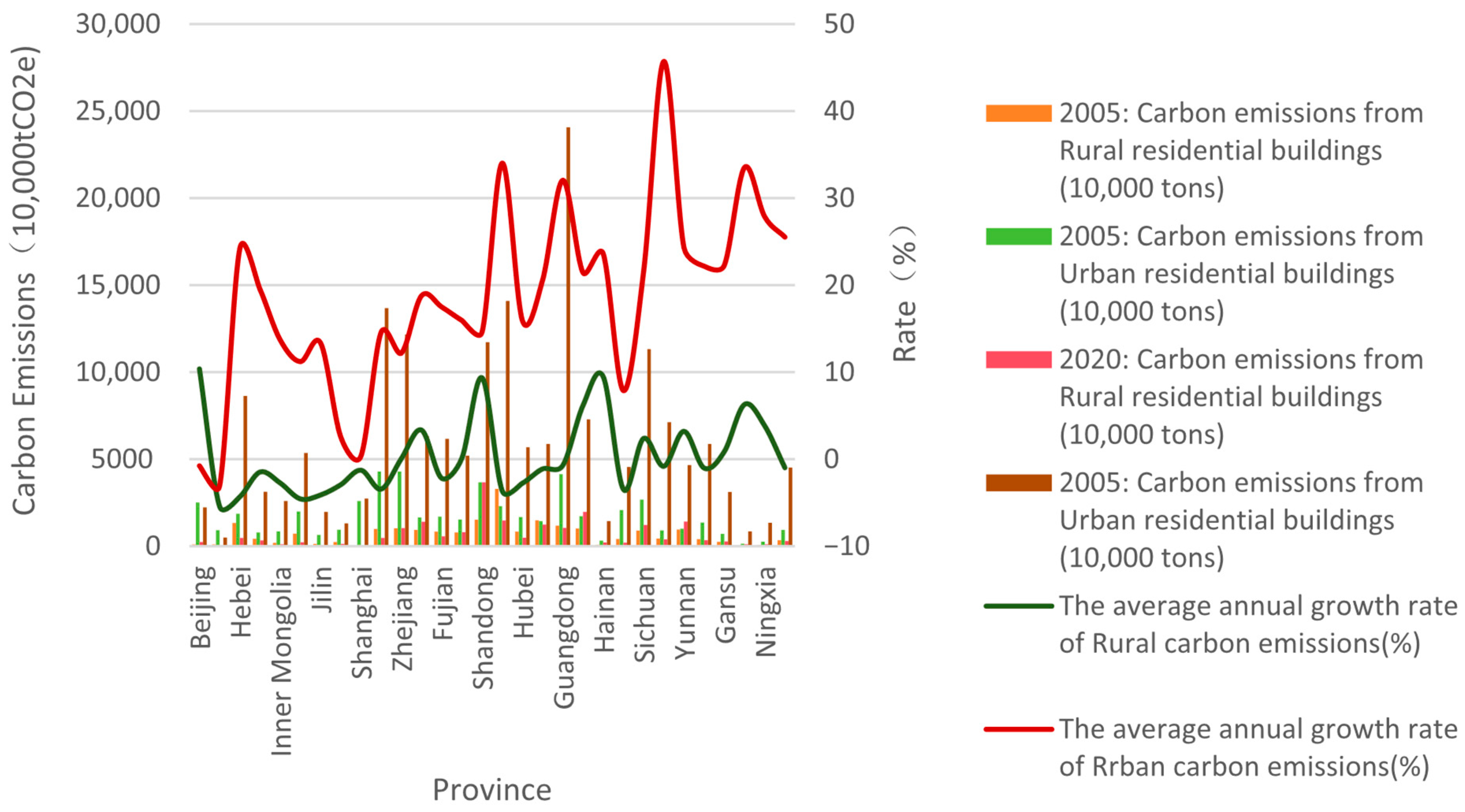

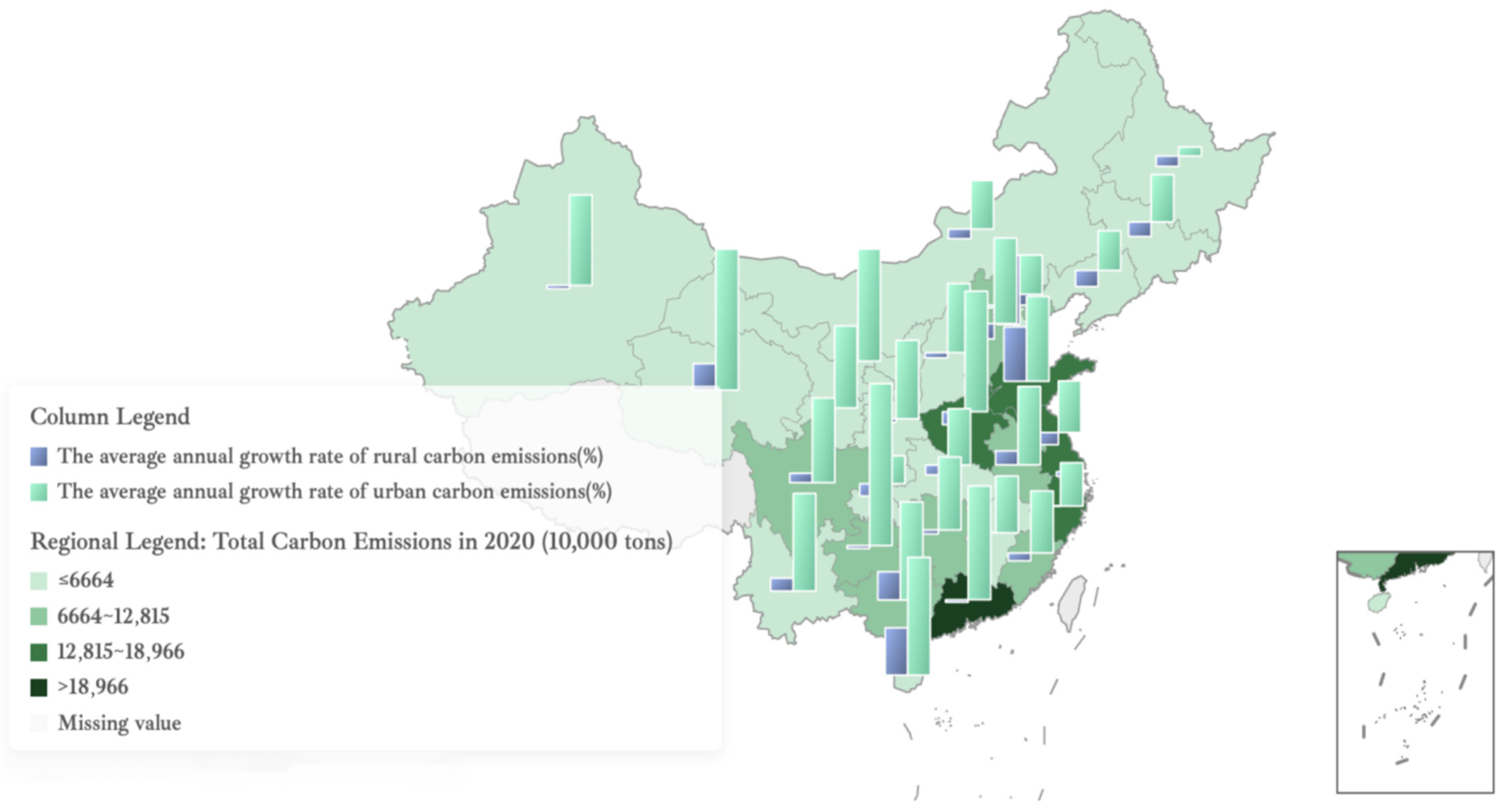

Specifically, in order to quantitatively evaluate the impact of physical carbon emissions due to the development and spatial differences between urban and rural residential buildings, this paper selects urban and rural residential buildings constructed in 2005 and 2020 in 30 provinces and cities in China (except Tibet, Hong Kong, Macao, and Taiwan), which are capable of reflecting the carbon emissions brought by the phase of residential building construction in those years. The data on the construction area of urban and rural residential buildings in each province and city are taken from the China Statistical Yearbook, China Rural Statistical Yearbook, and China Construction Industry Yearbook, and are quantified by the annual construction area of urban and rural residential buildings. The annual residential construction area includes all the buildings constructed in that year, including those that had been started or stopped before and then started again in that year, as well as the construction area of new buildings started in that year.

At present, China has not made public detailed and specific statistics on residential building structures in urban and rural areas. This paper is based on a case study on the distribution of building structures in China from 2003 to 2005 [

55]. The main data from the 2005 National 1% Population Sample Survey and the relevant data from the Seventh National Population Census in 2020 were used to study China’s main residential structures and their share of the total, which, in keeping with the calibre of the Population Census, can be divided into three specific categories, namely, steel–concrete, brick–concrete and other structures. Accordingly, the proportion of urban and rural residential structures of various types in China’s provinces and cities in 2005 and 2020 was calculated, totalling 120 sets of weighted data for 30 provinces and cities, divided into urban and rural areas for each year.

Corresponding to the various types of residential structures, six types of building materials, including cement, steel, glass, aluminium, building ceramics and clay bricks, which mainly affect carbon emissions in the physical and chemical stages, were identified, and the consumption of the corresponding building materials was analysed in conjunction with the relevant literature (e.g.,

Table 1) [

18,

56].

Carbon emission factors for the production and transportation of various building materials (as shown in

Table 2) are derived from the ‘Building Carbon Emission Calculation Standard’ issued by the Ministry of Housing and Urban-Rural Development of China and relevant literature [

57,

58,

59], with the average values used. Carbon emissions from the production and transportation of building materials are primarily calculated from the consumption end. The default transportation distance is 500 km (in accordance with the relevant provisions of the ‘Building Carbon Emission Calculation Standard’ GB/T51366-2019) and transportation is assumed to be by diesel trucks [

58]. The unit carbon emissions during the construction process of various residential building structures (as shown in

Table 3) are derived from the research results of Bai Jing et al. [

56,

60,

61], with the average values taken.

3.2.2. Comparative Analysis of the STIRPAT Model and Model Selection

Model applicability and comparative analysis: Before selecting the STIRPAT model, it is necessary to compare and evaluate it with other commonly used models. Common methods for analysing macro-level carbon emission factors include the Kaya identity and its extended LMDI decomposition method, the IPAT/STIRPAT model, and econometric regression models. The Kaya identity equation, derived from the IPAT concept, expresses carbon emissions as a constant relationship between population, economic output, energy intensity, and carbon intensity. It can be used to decompose the sources of carbon emission changes. Its improved LMDI (logarithmic mean Dice index) decomposition method fully decomposes emission increases and decreases across different time periods based on the identity equation, quantitatively assessing the contributions of various factors. Previous studies have used the Kaya/LMDI method to identify the primary drivers of building carbon emissions, such as economic growth and population expansion, which have been proven to be the main factors driving carbon emissions, while reductions in energy intensity help mitigate carbon emissions [

35,

36]. The advantage of this method lies in its intuitive decomposition results, where factor contributions can be summed to represent the total change in emissions. However, the Kaya identity predefines fixed decomposition factor categories, making it difficult to incorporate additional potential factors. Additionally, the decomposition analysis is a post hoc attribution approach, unable to test the statistical significance or causal relationships between factors. In contrast, the STIRPAT model, as an extension of IPAT, offers greater flexibility and applicability. First, the STIRPAT model appears in the form of a regression model, allowing the introduction of any number of independent variables, not limited to the four factors of population, GDP, energy consumption, and emissions in the Kaya identity. When the focus of the study changes (e.g., considering urbanisation rates, industrial structure, or climate factors), the model can be expanded accordingly to avoid omitting important influencing variables. Second, the STIRPAT model allows factors to influence the dependent variable through elasticity coefficients, breaking the assumption of proportional changes in factors and reflecting nonlinear effects and inconsistent returns to scale. Third, since STIRPAT is based on regression analysis, it can provide statistical measures such as significance tests and goodness-of-fit, which are more helpful for assessing the reliability of factor effects and the explanatory power of the model. These advantages have led to the widespread application of STIRPAT in the environmental field. For example, Yu et al. employed an extended STIRPAT model to incorporate climate factors into carbon emissions driver analysis, demonstrating the significant impact of temperature changes on regional carbon emissions, thereby showcasing the STIRPAT model’s applicability in complex scenario [

54]. Overall, compared to methods such as the Kaya identity/LMDI decomposition, the STIRPAT model can integrate more diverse influencing factors and reveal their elasticity mechanisms, making it suitable for investigating issues such as carbon emissions from urban and rural residential buildings, which are driven by multiple socio-economic factors. For the aforementioned reasons, this study selects the STIRPAT model as the primary econometric analysis tool. During model construction and empirical analysis, we strictly adhere to econometric norms, conducting tests and controls for variable selection, data stationarity, and multicollinearity, and referencing relevant representative research results to validate the model’s rationality, ensuring the scientific validity of the conclusions. By integrating LCA results with STIRPAT regression analysis, this study comprehensively characterises the carbon emissions characteristics and underlying causes of urban and rural residential buildings across Chinese provinces and municipalities during the building phase from both quantitative and causal perspectives, providing a robust foundation for developing differentiated building emissions reduction strategies.

Model Construction and Variable Selection: After clarifying the carbon emission calculation results, this study employs the STIRPAT model to conduct a quantitative analysis of the influencing factors of carbon emissions during the materialisation phase of urban and rural residential buildings. The rationality of variable selection is determined based on existing literature findings: on the one hand, population size and economic level are widely recognised as drivers of carbon emissions [

35,

36]. As population urbanisation accelerates and residents’ income increases, this often leads to an expansion in residential construction scale and carbon emissions [

40]. On the other hand, technical factors such as industrial structure and energy intensity influence carbon emissions per unit of output and are important sources of carbon emission differences [

37]. For example, Yang et al. found through STIRPAT model analysis that Beijing’s building carbon emissions are significantly positively correlated with urbanisation rate and per capita income [

40]; Cong et al.’s research indicates that building carbon emissions are positively correlated with per capita living area and household consumption levels across different climate zones [

41]; Liu Xinghua et al.’s study on Guangzhou’s residential buildings also noted that residential area and population size are the drivers with the highest carbon emission elasticity coefficients [

42]. Drawing on these studies, this paper adopts an extended STIRPAT framework, incorporating population size (P), per capita income (A), industrial structure (S), and energy intensity per unit of GDP (T) as the core explanatory variables, and conducts separate estimations for the overall, urban, and rural samples to identify urban–rural heterogeneity. This specification is consistent with the latest national- and provincial-scale studies on embodied carbon, which generally find that P and A exhibit robust positive elasticities, whereas the sign and magnitude of S and T vary according to regional structural characteristics and stage-specific conditions [

5,

11]. Moreover, the integration of process-based LCA with econometric modelling (including spatial econometrics) has been demonstrated in recent reviews and guidelines to provide a closed-loop evidence chain linking measurement, interpretation, and policy formulation [

47]. It should be noted that, given the differences in structural forms and energy use between urban and rural residential buildings, this study will establish separate regression models for the overall, urban, and rural residential sectors in the analysis to compare the differences in the effects of various factors under different residential forms. Model parameters are estimated using panel data fixed-effects regression, employing parallel data from 30 provinces and municipalities in mainland China from 2005 to 2020 (time dimension: year; spatial dimension: provincial-level regions) for fitting. The reliability of the regression results is ensured through VIF value tests and significance tests on the variables [

54]. The fixed effects model controls for the influence of unobservable regional characteristics across provinces and municipalities on carbon emissions, making the estimated coefficients more meaningful in practical terms. After regression, the direction and strength of the effects of each influencing factor are determined based on the magnitude and significance of the elasticity coefficients, thereby providing a basis for subsequent discussions on the mechanisms through which these factors influence carbon emissions.

Considering that the impact of the differences in economic structure among Chinese regions on carbon emissions cannot be ignored, this paper adds structural factors to the classical STIRPAT framework to construct an extended STIRPAT model. Specifically, the physical carbon emission I of urban and rural dwellings is set as the dependent variable, the number of permanent residents (

P) is selected as the demographic factor, the disposable income per capita (

A) as the affluence factor, the proportion of the secondary industry or the urbanisation rate, etc., as a proxy for the structural factor (

S), and the energy consumption per unit of GDP (energy intensity) as a proxy for the technological progress factor (

T). The exponential form of the model is as follows:

I is the environmental pressure; P is a demographic factor; A is a wealth factor; S is a structural factor; and T is a technological factor. From the influencing factor identification section above, P, A, S, and T are characterised using resident population, disposable income per capita, industrial structure, and energy consumption intensity, respectively.

A is the model coefficient, the constant term; b, c, d, and e are the elasticity coefficients corresponding to the demographic, wealth, structural, and technological factors, respectively; and u is the error term.

The STIRPAT extended model is transformed into a linear equation with logarithms on each side, with the following structure:

Among them, b, c, d and e represent the elasticity coefficients of population, affluence, structure and technology factors, respectively, reflecting the degree of elasticity influence of the changes of each factor on carbon emissions.

For the identified key factors, this paper collects the relevant data of 30 provinces and cities in 2005 and 2020 from China Statistical Yearbook and China Energy Statistical Yearbook, among which the industrial structure and energy consumption intensity are calculated based on the original data. The variables and their data sources are summarised in

Table 4, and the factors are treated as disinflation at constant 2005 prices, totalling 120 sets of weights for the 30 provinces and municipalities, divided into urban and rural areas for each year.