Assessing Critical Success Factors for Supply Chain 4.0 Implementation Using a Hybrid MCDM Framework

Abstract

1. Introduction

2. Review of the Literature

2.1. The Necessity of SC4.0

2.2. Essential Success Factors and Strategies for SC4.0

3. Methodology

3.1. Intuitionistic Fuzzy Set

3.2. Integration of Analytic Network Process with Fuzzy Systems

- Step 1

- Construct the Pairwise Comparison Matrix (D):

- Step 2

- Verify that the matrix is consistent:

- Step 3

- Determine the comparative weights of the CSFs:

3.3. Structural Equation Modeling (SEM)

- Step 1

- Develop a Direct-Relation Matrix (D)

- Step 2

- Normalize the Direct-Relation Matrix (D)

- Step 3

- Construct the Total-Relation Matrix (n)

- Step 4

- Categorize Factors into Cause-and-Effect Groups

3.4. Integrated Compromise Approach

- Step 1

- Create the Initial Decision-Making Matrix (E):

- Step 2

- Normalize the Initial Decision-Making Matrix:

- Step 3

- Calculate the Weighted Sum for Alternatives:

- Step 4

- Compute the Relative Weights of the Alternatives:

- Step 5

- Rank the Alternatives:

4. A Contemporary Case Analysis

4.1. Selection and Profiling of Experts

4.2. Determining and Finalizing Key Success Factors and Strategies in SC4.0

4.3. Evaluation of CSFs and Strategy Prioritization Using Advanced Analytical Methods

5. Findings and Analysis

6. Implications of the Study

6.1. Theoretical Implications

6.2. Implications for Management and Society

- Engage stakeholders in SC digitalization and ensure alignment: In an SC network, the involvement of all stakeholders is crucial. For successful digitalization, every part of the network must undergo this transformation. However, many stakeholders are hesitant due to the high investment costs associated with SC digitalization. The proposed strategies in this work rely heavily on stakeholder agreement. Full digitalization is essential for seamless data transmission through an integrated platform, as well as for data optimization and enhancing analytical capabilities. Raising awareness among stakeholders about the importance of SC4.0 is therefore necessary.

- Develop organizational policies focused on SC digitalization: To remain competitive, companies must regularly update their policies to reflect ongoing technological advancements. Keeping pace with global trends is critical for the long-term success of the industrial sector. Governments should recognize the positive impact digital technologies can have on industry and economic growth, providing both financial and technical support to help organizations implement SC4.0. Consequently, the industrial community should adopt SC4.0 and expedite the digital transformation with support from governmental agencies.

7. Conclusions, Limitations, and Directions for Future Research

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qureshi, K.M.; Mewada, B.G.; Alghamdi, S.Y.; Almakayeel, N.; Qureshi, M.R.N.; Mansour, M. Accomplishing Sustainability in Manufacturing System for Small and Medium-Sized Enterprises (SMEs) through Lean Implementation. Sustainability 2022, 14, 9732. [Google Scholar] [CrossRef]

- Debnath, B.; Shakur, M.S.; Bari, A.B.M.M.; Karmaker, C.L. A Bayesian Best–Worst Approach for Assessing the Critical Success Factors in Sustainable Lean Manufacturing. Decis. Anal. J. 2023, 6, 100157. [Google Scholar] [CrossRef]

- Rehman, S.U. SMEs Internationalization! Market Intelligence and Entrepreneurial Orientation Influence on International Performance: A Moderation Model. Bus. Process Manag. J. 2024, 31, 54–73. [Google Scholar] [CrossRef]

- Li, N.; Yao, Q.; Tang, H.; Lu, Y. Is Digitalization Necessary? Configuration of Supply Chain Capabilities for Improving Enterprise Competitive Performance. J. Bus. Res. 2025, 186, 114972. [Google Scholar] [CrossRef]

- Culotta, C.; Blome, C.; Henke, M. Theories of Digital Platforms for Supply Chain Management: A Systematic Literature Review. Int. J. Phys. Distrib. Logist. Manag. 2024, 54, 449–475. [Google Scholar] [CrossRef]

- Agarwal, A.; Srivastava, S.; Gupta, A.; Singh, G. Food Wastage and Consumerism in Circular Economy: A Review and Research Directions. Br. Food J. 2024, 126, 2561–2587. [Google Scholar] [CrossRef]

- Zanon, L.G.; Bertassini, A.C.; Sigahi, T.F.A.C.; Anholon, R.; Carpinetti, L.C.R. Relations between Supply Chain Performance and Circular Economy Implementation: A Fuzzy Cognitive Map-based Analysis for Sustainable Development. Bus. Strategy Dev. 2024, 7, e373. [Google Scholar] [CrossRef]

- Akbari, M.; Kok, S.K.; Hopkins, J.; Frederico, G.F.; Nguyen, H.; Alonso, A.D. The Changing Landscape of Digital Transformation in Supply Chains: Impacts of Industry 4.0 in Vietnam. Int. J. Logist. Manag. 2024, 35, 1040–1072. [Google Scholar] [CrossRef]

- Al-Banna, A.; Rana, Z.A.; Yaqot, M.; Menezes, B. Interconnectedness between Supply Chain Resilience, Industry 4.0, and Investment. Logistics 2023, 7, 50. [Google Scholar] [CrossRef]

- Abdelwahed, N.A.A.; Al Doghan, M.A.; Shah, N.; Soomro, B.A. Entrepreneurial Orientation and Product Innovation Performance: Developing the Linkages through Strategic Human Resource Management and Technology Capability. J. Sci. Technol. Policy Manag. 2024; ahead-of-print. [Google Scholar] [CrossRef]

- Jetty, S.; Afshan, N. A Bibliometric Analysis and Systematic Literature Review of Industry 4.0 Implementation in Supply Chain. J. Sci. Technol. Policy Manag. 2024; ahead-of-print. [Google Scholar] [CrossRef]

- Kabir, M.A.; Khan, S.A.; Kabir, G. A Hierarchical Structure Modeling and Relationships Exploration of Supply Chain 5.0 Capabilities. IEEE Trans. Eng. Manag. 2024, 71, 11253–11268. [Google Scholar] [CrossRef]

- Alkatheeri, H.; Ahmad, S.Z. Examining Blockchain Adoption Determinants and Supply Chain Performance: An Empirical Study in the Logistics and Supply Chain Management Industry. J. Model. Manag. 2024, 19, 1566–1591. [Google Scholar] [CrossRef]

- Chatterjee, R.; Kumar, B.; Singh, A.K.; Pandey, S. Investigating Organizational Transformations on the Path to Sustainable Supply Chain 4.0 Implementation. Circ. Econ. Sustain. 2025, 5, 277–320. [Google Scholar] [CrossRef]

- Suzianti, A.; Kaniaswari, R.; Fathia, S.N.; Amaradhanny, R.D.; Muslim, E.; Alfian, E.T. Towards a Sustainable Coffee Supply Chain: The Role of Digital Platform Capability in Increasing Organisational Agility. Int. J. Sustain. Eng. 2024, 17, 80–97. [Google Scholar] [CrossRef]

- Hashem, G.; Aboelmaged, M.; Ahmad, I. Proactiveness, Knowledge Management Capability and Innovation Ambidexterity: An Empirical Examination of Digital Supply Chain Adoption. Manag. Decis. 2024, 62, 129–162. [Google Scholar] [CrossRef]

- Dharmayanti, N.; Ismail, T.; Hanifah, I.A.; Taqi, M. Exploring Sustainability Management Control System and Eco-Innovation Matter Sustainable Financial Performance: The Role of Supply Chain Management and Digital Adaptability in Indonesian Context. J. Open Innov. Technol. Mark. Complex. 2023, 9, 100119. [Google Scholar] [CrossRef]

- Aldhaheri, R.T.; Ahmad, S.Z. Factors Affecting Organisations’ Supply Chain Agility and Competitive Capability. Bus. Process Manag. J. 2023, 29, 505–527. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Mubarak, M.F.; Mubarik, M.; Rejeb, A.; Nilashi, M. Identifying Industry 5.0 Contributions to Sustainable Development: A Strategy Roadmap for Delivering Sustainability Values. Sustain. Prod. Consum. 2022, 33, 716–737. [Google Scholar] [CrossRef]

- Ivanov, D. The Industry 5.0 Framework: Viability-Based Integration of the Resilience, Sustainability, and Human-Centricity Perspectives. Int. J. Prod. Res. 2023, 61, 1683–1695. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B. Cloud Supply Chain: Integrating Industry 4.0 and Digital Platforms in the “Supply Chain-as-a-Service”. Transp. Res. E Logist. Transp. Rev. 2022, 160, 102676. [Google Scholar] [CrossRef]

- Yadav, S.; Singh, S.P. Blockchain Critical Success Factors for Sustainable Supply Chain. Resour. Conserv. Recycl. 2020, 152, 104505. [Google Scholar] [CrossRef]

- de Mattos Nascimento, D.L.; de Oliveira-Dias, D.; Moyano-Fuentes, J.; Maqueira Marín, J.M.; Garza-Reyes, J.A. Interrelationships between Circular Economy and Industry 4.0: A Research Agenda for Sustainable Supply Chains. Bus. Strategy Environ. 2023, 33, 575–596. [Google Scholar] [CrossRef]

- Gupta, S.; Modgil, S.; Choi, T.-M.; Kumar, A.; Antony, J. Influences of Artificial Intelligence and Blockchain Technology on Financial Resilience of Supply Chains. Int. J. Prod. Econ. 2023, 261, 108868. [Google Scholar] [CrossRef]

- Deiva Ganesh, A.; Kalpana, P. Future of Artificial Intelligence and Its Influence on Supply Chain Risk Management—A Systematic Review. Comput. Ind. Eng. 2022, 169, 108206. [Google Scholar] [CrossRef]

- Dwivedi, A.; Agrawal, D.; Jha, A.; Mathiyazhagan, K. Studying the Interactions among Industry 5.0 and Circular Supply Chain: Towards Attaining Sustainable Development. Comput. Ind. Eng. 2023, 176, 108927. [Google Scholar] [CrossRef]

- Berry, K.; Singh, A. AI-Driven Service Marketing; IGI Global Scientific Publishing: Hershey, PA, USA, 2024; pp. 35–56. [Google Scholar] [CrossRef]

- Nguyen, K.; Akbari, M.; Quang, H.T.; McDonald, S.; Hoang, T.-H.; Yap, T.L.; George, M. Navigating Environmental Challenges through Supply Chain Quality Management 4.0 in Circular Economy: A Comprehensive Review. Sustainability 2023, 15, 16720. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. A Review of Internet of Things (IoT) Embedded Sustainable Supply Chain for Industry 4.0 Requirements. Comput. Ind. Eng. 2019, 127, 925–953. [Google Scholar] [CrossRef]

- Liu, L.; Song, W.; Liu, Y. Leveraging Digital Capabilities toward a Circular Economy: Reinforcing Sustainable Supply Chain Management with Industry 4.0 Technologies. Comput. Ind. Eng. 2023, 178, 109113. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Tabish, M.; Zhang, Y. Embracement of Industry 4.0 and Sustainable Supply Chain Practices under the Shadow of Practice-Based View Theory: Ensuring Environmental Sustainability in Corporate Sector. J. Clean. Prod. 2023, 398, 136609. [Google Scholar] [CrossRef]

- Zhou, Z.; Shen, Y. Free Riding of Vehicle Companies under Dual-Credit Policy: An Agent-Based System Dynamics Model. World Electr. Veh. J. 2024, 15, 227. [Google Scholar] [CrossRef]

- Farooque, M.; Zhang, A.; Liu, Y.; Hartley, J.L. Circular Supply Chain Management: Performance Outcomes and the Role of Eco-Industrial Parks in China. Transp. Res. E Logist. Transp. Rev. 2022, 157, 102596. [Google Scholar] [CrossRef]

- Gayialis, S.P.; Kechagias, E.P.; Papadopoulos, G.A.; Masouras, D. A Review and Classification Framework of Traceability Approaches for Identifying Product Supply Chain Counterfeiting. Sustainability 2022, 14, 6666. [Google Scholar] [CrossRef]

- Zhang, A.; Tay, H.L.; Alvi, M.F.; Wang, J.X.; Gong, Y. Carbon Neutrality Drivers and Implications for Firm Performance and Supply Chain Management. Bus. Strategy Environ. 2023, 32, 1966–1980. [Google Scholar] [CrossRef]

- Mutambik, I.; Almuqrin, A. The Best of Both Worlds: How Financial Growth Can Engender Improved Sustainability for Businesses. Sustainability 2024, 16, 4821. [Google Scholar] [CrossRef]

- Rolf, B.; Jackson, I.; Müller, M.; Lang, S.; Reggelin, T.; Ivanov, D. A Review on Reinforcement Learning Algorithms and Applications in Supply Chain Management. Int. J. Prod. Res. 2023, 61, 7151–7179. [Google Scholar] [CrossRef]

- Culot, G.; Podrecca, M.; Nassimbeni, G. Artificial Intelligence in Supply Chain Management: A Systematic Literature Review of Empirical Studies and Research Directions. Comput. Ind. 2024, 162, 104132. [Google Scholar] [CrossRef]

- Jackson, I.; Ivanov, D.; Dolgui, A.; Namdar, J. Generative Artificial Intelligence in Supply Chain and Operations Management: A Capability-Based Framework for Analysis and Implementation. Int. J. Prod. Res. 2024, 62, 6120–6145. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, C. Designing a Two-Stage Model for the Resilient Agri-Food Supply Chain Network under Dynamic Competition. Br. Food J. 2024, 126, 662–681. [Google Scholar] [CrossRef]

- Wong, D.T.W.; Ngai, E.W.T. An Empirical Analysis of the Effect of Supply Chain Innovation on Supply Chain Resilience. IEEE Trans. Eng. Manag. 2024, 71, 8562–8576. [Google Scholar] [CrossRef]

- Seo, J.; Lee, B.K.; Jeon, Y. Digitalization Strategies and Evaluation of Maritime Container Supply Chains. Bus. Process Manag. J. 2023, 29, 1–21. [Google Scholar] [CrossRef]

- Perano, M.; Cammarano, A.; Varriale, V.; Del Regno, C.; Michelino, F.; Caputo, M. Embracing Supply Chain Digitalization and Unphysicalization to Enhance Supply Chain Performance: A Conceptual Framework. Int. J. Phys. Distrib. Logist. Manag. 2023, 53, 628–659. [Google Scholar] [CrossRef]

- Tian, Y.; Song, S.; Bao, S.; Zhou, D.; Wei, C. Canonical Triangular Interval Type-2 Fuzzy Linguistic Distribution Assessment EDAS Approach with Its Application to Production Supplier Evaluation and Ranking. Appl. Soft Comput. 2024, 154, 111309. [Google Scholar] [CrossRef]

- Shakur, M.S.; Lubaba, M.; Debnath, B.; Bari, A.B.M.M.; Rahman, M.A. Exploring the Challenges of Industry 4.0 Adoption in the FMCG Sector: Implications for Resilient Supply Chain in Emerging Economy. Logistics 2024, 8, 27. [Google Scholar] [CrossRef]

- Wang, W.; Chen, Y.; Wang, Y.; Deveci, M.; Cheng, S.; Brito-Parada, P.R. A Decision Support Framework for Humanitarian Supply Chain Management—Analysing Enablers of AI-HI Integration Using a Complex Spherical Fuzzy DEMATEL-MARCOS Method. Technol. Forecast. Soc. Change 2024, 206, 123556. [Google Scholar] [CrossRef]

- Pettigrew, A.M. Information Control as a Power Resource. Sociology 1972, 6, 187–204. [Google Scholar] [CrossRef]

- Chakraborty, A.; Persis, J.; Mahroof, K. Exploring the Academic–Industry Collaboration in Knowledge Sharing for Supplier Selection: Digitalizing the OEM. IEEE Trans. Eng. Manag. 2024, 71, 7968–7978. [Google Scholar] [CrossRef]

- Lee, K.L.; Teong, C.X.; Alzoubi, H.M.; Alshurideh, M.T.; Khatib, M.E.; Al-Gharaibeh, S.M. Digital Supply Chain Transformation: The Role of Smart Technologies on Operational Performance in Manufacturing Industry. Int. J. Eng. Bus. Manag. 2024, 16, 18479790241234986. [Google Scholar] [CrossRef]

- Seikh, M.R.; Mandal, U. Interval-Valued Fermatean Fuzzy Dombi Aggregation Operators and SWARA Based PROMETHEE II Method to Bio-Medical Waste Management. Expert Syst. Appl. 2023, 226, 120082. [Google Scholar] [CrossRef]

- Zeb, A.; Ahmad, W.; Asif, M.; Hou, M. A Comprehensive Decision Support System for Optimizing Solar Power Projects Using Fermatean Fuzzy Soft Einstein Aggregation Operators. Comput. Electr. Eng. 2024, 119, 109519. [Google Scholar] [CrossRef]

- Darko, A.; Chan, A.P.C.; Ameyaw, E.E.; Owusu, E.K.; Pärn, E.; Edwards, D.J. Review of Application of Analytic Hierarchy Process (AHP) in Construction. Int. J. Constr. Manag. 2019, 19, 436–452. [Google Scholar] [CrossRef]

- Kumar, R.; Dwivedi, A.; Sethi, M.; Mehra, K.S.; Goel, V. A Comprehensive Assessment of Working Fluids Selection in Heat Pipe-Assisted Battery Thermal Management Systems: An Integrated Multi-Criteria Decision-Making Approach. Proc. Inst. Mech. Eng. Part A J. Power Energy 2024, 239, 160–185. [Google Scholar] [CrossRef]

- Rimadeni, Y.; Sofyan, H.; Rahman, S.; Pramana, S.; Juellyan. Determination of Logistics Distribution Centers: A Combination of Spatial Analysis and Analytical Hierarchy Process. J. Eur. Syst. Autom. 2024, 57, 609–624. [Google Scholar] [CrossRef]

- Nila, B.; Roy, J. Analysis of Critical Success Factors of Logistics 4.0 Using D-Number Based Pythagorean Fuzzy DEMATEL Method. Decis. Mak. Adv. 2024, 2, 92–104. [Google Scholar] [CrossRef]

- Zaman, S.I.; Khan, S.A.; Kusi-Sarpong, S. Investigating the Relationship between Supply Chain Finance and Supply Chain Collaborative Factors. Benchmarking Int. J. 2024, 31, 1941–1975. [Google Scholar] [CrossRef]

- Cui, L.; Wang, Z.; Liu, Y.; Cao, G. How Does Data-Driven Supply Chain Analytics Capability Enhance Supply Chain Agility in the Digital Era? Int. J. Prod. Econ. 2024, 277, 109404. [Google Scholar] [CrossRef]

- Singh, R.; Khan, S.; Dsilva, J.; Centobelli, P. Blockchain Integrated IoT for Food Supply Chain: A Grey Based Delphi-DEMATEL Approach. Appl. Sci. 2023, 13, 1079. [Google Scholar] [CrossRef]

- Ali, S.M.; Ashraf, M.A.; Taqi, H.M.M.; Ahmed, S.; Rob, S.M.A.; Kabir, G.; Paul, S.K. Drivers for Internet of Things (IoT) Adoption in Supply Chains: Implications for Sustainability in the Post-Pandemic Era. Comput. Ind. Eng. 2023, 183, 109515. [Google Scholar] [CrossRef]

- Ecer, F.; Pamucar, D. Sustainable Supplier Selection: A Novel Integrated Fuzzy Best Worst Method (F-BWM) and Fuzzy CoCoSo with Bonferroni (CoCoSo’B) Multi-Criteria Model. J. Clean. Prod. 2020, 266, 121981. [Google Scholar] [CrossRef]

- Oubrahim, I.; Sefiani, N.; Happonen, A. The Influence of Digital Transformation and Supply Chain Integration on Overall Sustainable Supply Chain Performance: An Empirical Analysis from Manufacturing Companies in Morocco. Energies 2023, 16, 1004. [Google Scholar] [CrossRef]

- Jauhar, S.K.; Jani, S.M.; Kamble, S.S.; Pratap, S.; Belhadi, A.; Gupta, S. How to Use No-Code Artificial Intelligence to Predict and Minimize the Inventory Distortions for Resilient Supply Chains. Int. J. Prod. Res. 2024, 62, 5510–5534. [Google Scholar] [CrossRef]

- Agrawal, R.; Surendra Yadav, V.; Majumdar, A.; Kumar, A.; Luthra, S.; Arturo Garza-Reyes, J. Opportunities for Disruptive Digital Technologies to Ensure Circularity in Supply Chain: A Critical Review of Drivers, Barriers and Challenges. Comput. Ind. Eng. 2023, 178, 109140. [Google Scholar] [CrossRef]

- Lahane, S.; Paliwal, V.; Kant, R. Evaluation and Ranking of Solutions to Overcome the Barriers of Industry 4.0 Enabled Sustainable Food Supply Chain Adoption. Clean. Logist. Supply Chain. 2023, 8, 100116. [Google Scholar] [CrossRef]

- Ardra, S.; Barua, M.K. Inclusion of Circular Economy Practices in the Food Supply Chain: Challenges and Possibilities for Reducing Food Wastage in Emerging Economies like India. Environ. Dev. Sustain. 2023, 25, 13825–13858. [Google Scholar] [CrossRef] [PubMed]

- Grover, A.K.; Ashraf, M.H. Autonomous and IoT-driven Intralogistics for Industry 4.0 Warehouses: A Thematic Analysis of the Literature. Transp. J. 2024, 63, 42–61. [Google Scholar] [CrossRef]

- Grover, A.K.; Ashraf, M.H. Leveraging Autonomous Mobile Robots for Industry 4.0 Warehouses: A Multiple Case Study Analysis. Int. J. Logist. Manag. 2024, 35, 1168–1199. [Google Scholar] [CrossRef]

- Zaman, S.I.; Khan, S.; Zaman, S.A.A.; Khan, S.A. A Grey Decision-Making Trial and Evaluation Laboratory Model for Digital Warehouse Management in Supply Chain Networks. Decis. Anal. J. 2023, 8, 100293. [Google Scholar] [CrossRef]

- Deepu, T.S.; Ravi, V. Supply Chain Digitalization: An Integrated MCDM Approach for Inter-Organizational Information Systems Selection in an Electronic Supply Chain. Int. J. Inf. Manag. Data Insights 2021, 1, 100038. [Google Scholar] [CrossRef]

- Priyanka, R.; Ravindran, K.; Sankaranarayanan, B.; Ali, S.M. A Fuzzy DEMATEL Decision Modeling Framework for Identifying Key Human Resources Challenges in Start-up Companies: Implications for Sustainable Development. Decis. Anal. J. 2023, 6, 100192. [Google Scholar] [CrossRef]

- Dwivedi, A.; Moktadir, M.A.; Chiappetta Jabbour, C.J.; de Carvalho, D.E. Integrating the Circular Economy and Industry 4.0 for Sustainable Development: Implications for Responsible Footwear Production in a Big Data-Driven World. Technol. Forecast. Soc. Change 2022, 175, 121335. [Google Scholar] [CrossRef]

- Wong, L.-W.; Tan, G.W.-H.; Ooi, K.-B.; Lin, B.; Dwivedi, Y.K. Artificial Intelligence-Driven Risk Management for Enhancing Supply Chain Agility: A Deep-Learning-Based Dual-Stage PLS-SEM-ANN Analysis. Int. J. Prod. Res. 2024, 62, 5535–5555. [Google Scholar] [CrossRef]

- Tiwari, S.; Sharma, P.; Choi, T.-M.; Lim, A. Blockchain and Third-Party Logistics for Global Supply Chain Operations: Stakeholders’ Perspectives and Decision Roadmap. Transp. Res. E Logist. Transp. Rev. 2023, 170, 103012. [Google Scholar] [CrossRef]

- Jabbar, S.; Lloyd, H.; Hammoudeh, M.; Adebisi, B.; Raza, U. Blockchain-Enabled Supply Chain: Analysis, Challenges, and Future Directions. Multimed. Syst. 2021, 27, 787–806. [Google Scholar] [CrossRef]

- Wang, Y.; Singgih, M.; Wang, J.; Rit, M. Making Sense of Blockchain Technology: How Will It Transform Supply Chains? Int. J. Prod. Econ. 2019, 211, 221–236. [Google Scholar] [CrossRef]

- Mora Lozano, P.E.; Montoya-Torres, J.R. Global Supply Chains Made Visible through Logistics Security Management. Logistics 2024, 8, 6. [Google Scholar] [CrossRef]

- Hammi, B.; Zeadally, S.; Nebhen, J. Security Threats, Countermeasures, and Challenges of Digital Supply Chains. ACM Comput. Surv. 2023, 55, 1–40. [Google Scholar] [CrossRef]

- Xu, M.; Ma, S.; Wang, G. Differential Game Model of Information Sharing among Supply Chain Finance Based on Blockchain Technology. Sustainability 2022, 14, 7139. [Google Scholar] [CrossRef]

- Han, Y.; Fang, X. Systematic Review of Adopting Blockchain in Supply Chain Management: Bibliometric Analysis and Theme Discussion. Int. J. Prod. Res. 2024, 62, 991–1016. [Google Scholar] [CrossRef]

- Costa, A.; Ossmane, E.S.R.M.; Santos, H.; Camargo, J.; Carvalho, L.C. ReSOLVE Framework; IGI Global Scientific Publishing: Hershey, PA, USA, 2023; pp. 313–334. [Google Scholar] [CrossRef]

- Das, C. Synthesising and Conceptualising Circular Supply Chains: A State-of-the-Art Literature Review. J. Environ. Dev. 2024, 33, 339–369. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Srivastava, S.; Majumdar, A. Circular Supply Chains in Manufacturing—Quo Vadis? Accomplishments, Challenges and Future Opportunities. Bus. Strategy Environ. 2024, 33, 4397–4423. [Google Scholar] [CrossRef]

- Lin, J.; Fan, Y. Seeking Sustainable Performance through Organizational Resilience: Examining the Role of Supply Chain Integration and Digital Technology Usage. Technol. Forecast. Soc. Change 2024, 198, 123026. [Google Scholar] [CrossRef]

| Details | n | % |

|---|---|---|

| Gender | ||

| Female | 14 | 42.4 |

| Male | 19 | 57.6 |

| Education | ||

| Post-graduate | 14 | 42.4 |

| Doctorate | 11 | 33.3 |

| Post-doc | 8 | 24.3 |

| Field of Expertise | ||

| Information systems | 7 | 21.2 |

| Stock control | 6 | 18.2 |

| Forecasting | 6 | 18.2 |

| Purchase department | 5 | 15.2 |

| Transportation department | 4 | 12.1 |

| SC management | 3 | 9.1 |

| Logistics and transportation | 2 | 6.1 |

| Designation | ||

| Operations supervisor | 6 | 18.2 |

| Transport specialist | 8 | 24.3 |

| Procurement officer | 7 | 21.2 |

| Storage and distribution manager | 5 | 15.2 |

| SC Director | 4 | 12.1 |

| Head of Logistics | 3 | 9.1 |

| Experience | ||

| Up to 10 years | 9 | 27.3 |

| 10–15 years | 11 | 33.3 |

| Above 15 years | 13 | 39.4 |

| Age Group | ||

| 25–34 | 13 | 39.4 |

| 35–44 | 12 | 36.4 |

| 45–54 | 8 | 24.3 |

| Industry Experience | ||

| Manufacturing | 11 | 33.3 |

| Retail | 12 | 36.4 |

| Technology | 10 | 30.3 |

| Code | Critical Success Factor | Description |

|---|---|---|

| CSF1 | Collaborative and integrated product design | Enhancing product development through cross-functional teamwork and integration across the SC. |

| CSF2 | Information platform | Implementing robust IT systems to facilitate seamless data exchange and real-time communication. |

| CSF3 | Data reliability and relevance | Ensuring accuracy and pertinence of data used for decision-making processes. |

| CSF4 | Data integration | Combining data from diverse sources to create a unified and coherent dataset for analysis. |

| CSF5 | Top management support | Securing commitment and active involvement from senior leadership to drive SC4.0 initiatives. |

| CSF6 | Performance monitoring | Continuously tracking key performance indicators to assess and improve SC operations. |

| CSF7 | Research environment | Promoting a culture that encourages innovation and supports research and development activities. |

| CSF8 | Trust and collaboration | Building strong, trust-based relationships among SC partners to enhance cooperation. |

| CSF9 | Establishment of a smart work environment | Creating workplaces equipped with advanced technologies like the IoT and AI to improve efficiency. |

| CSF10 | Aligning SC4.0 initiatives with organizational strategy | Ensuring that SC4.0 efforts are in harmony with the company’s overall strategic objectives. |

| CSF11 | Reliance on knowledge transfer | Facilitating the sharing and dissemination of knowledge within and between organizations. |

| CSF12 | Organizational agility | Developing the capability to quickly adapt to market changes and new technological advancements. |

| CSF13 | Data security | Implementing measures to protect data from cyber threats and unauthorized access. |

| CSF14 | Adaptability of software innovations | Being open and able to integrate new software solutions effectively into existing systems. |

| CSF15 | Managing and analyzing data quality | Maintaining high standards for data accuracy, completeness, and consistency, and employing effective analytical methods. |

| CSF16 | Ownership and control of data | Clearly defining data ownership rights and control mechanisms within the SC network. |

| Linguistic Variables | Influence Score | Membership Value | Non-Membership Value |

|---|---|---|---|

| No Impact (NI) | 0 | 1.0 | 0.0 |

| Very Low (VL) | 1 | 0.15 | 0.70 |

| Low (L) | 2 | 0.45 | 0.55 |

| High (H) | 3 | 0.72 | 0.05 |

| Very High (VH) | 4 | 0.92 | 0.12 |

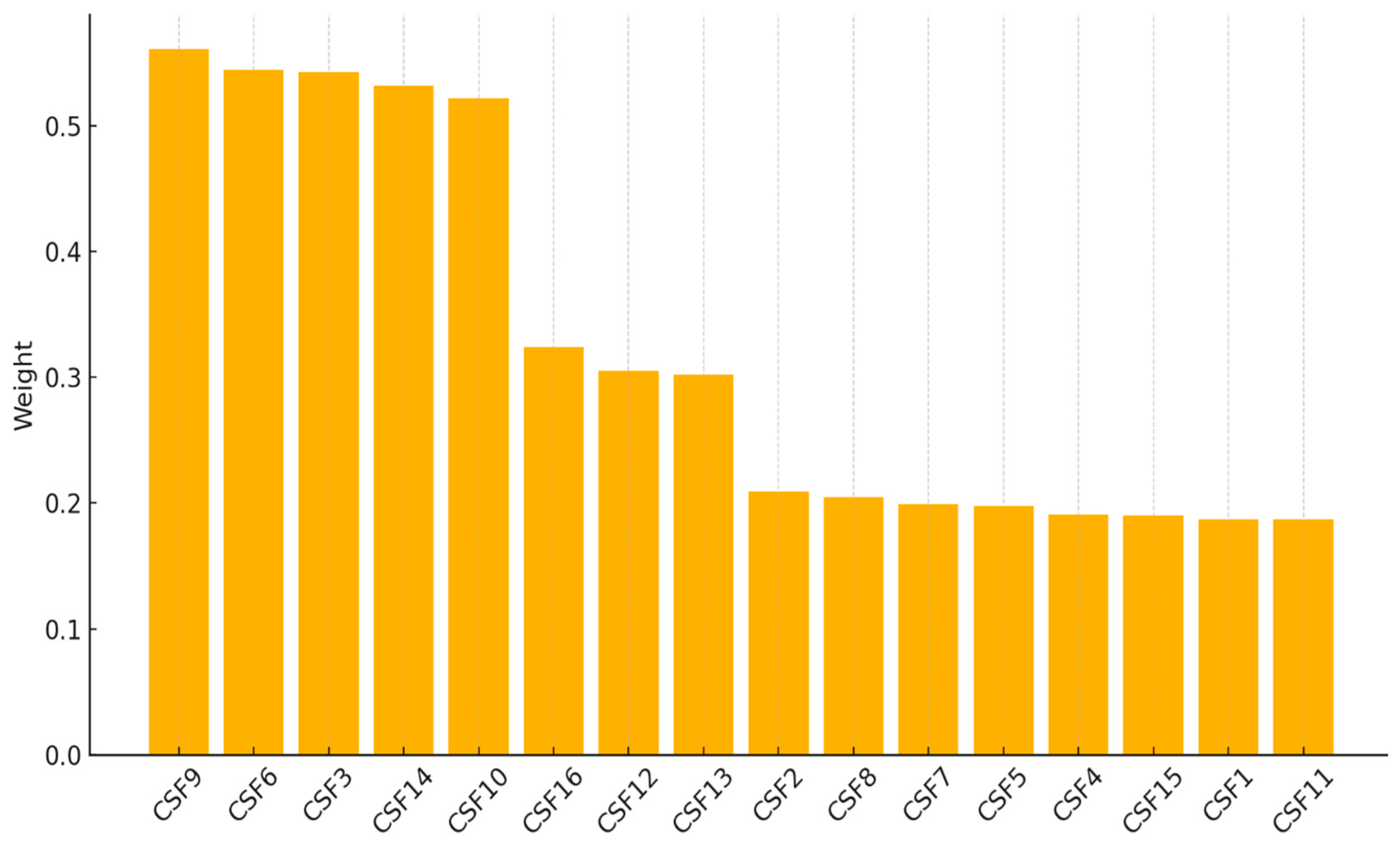

| CSF | P | QP | Q | P × Q | Category | Rank P × Q | Weight | Rank Weight |

|---|---|---|---|---|---|---|---|---|

| CSF1 | 0.75 | 1.18 | 1.92 | 0.425 | Effect | 21 | 0.187 | 20 |

| CSF2 | 0.85 | 1.16 | 1.99 | 0.310 | Effect | 20 | 0.209 | 11 |

| CSF3 | 2.07 | 1.12 | 3.18 | 0.965 | Cause | 7 | 0.543 | 3 |

| CSF4 | 0.76 | 1.00 | 1.75 | 0.245 | Effect | 19 | 0.191 | 18 |

| CSF5 | 0.78 | 0.97 | 1.73 | 0.195 | Effect | 18 | 0.198 | 15 |

| CSF6 | 2.09 | 0.94 | 3.00 | 1.150 | Cause | 6 | 0.545 | 2 |

| CSF7 | 0.79 | 0.81 | 1.60 | 0.035 | Effect | 17 | 0.199 | 14 |

| CSF8 | 0.82 | 0.77 | 1.58 | 0.040 | Cause | 15 | 0.205 | 12 |

| CSF9 | 2.14 | 0.75 | 2.87 | 1.400 | Cause | 2 | 0.561 | 1 |

| CSF10 | 2.00 | 0.62 | 2.60 | 1.380 | Cause | 3 | 0.522 | 5 |

| CSF11 | 0.73 | 0.53 | 1.24 | 0.210 | Cause | 14 | 0.187 | 19 |

| CSF12 | 1.17 | 0.48 | 1.65 | 0.690 | Cause | 10 | 0.305 | 8 |

| CSF13 | 1.18 | 0.44 | 1.60 | 0.730 | Cause | 9 | 0.302 | 9 |

| CSF14 | 2.03 | 0.39 | 2.40 | 1.660 | Cause | 1 | 0.532 | 4 |

| CSF15 | 0.74 | 0.26 | 1.00 | 0.490 | Cause | 13 | 0.190 | 17 |

| CSF16 | 1.25 | 0.23 | 1.48 | 1.030 | Cause | 5 | 0.324 | 6 |

| Strategies | Ka | Kb | Kc | K | Rank |

|---|---|---|---|---|---|

| S1 | 0.18 | 6.65 | 0.46 | 3.30 | 3 |

| S2 | 0.37 | 30.12 | 1.03 | 13.00 | 1 |

| S3 | 0.06 | 2.15 | 0.15 | 1.05 | 5 |

| S4 | 0.10 | 3.24 | 0.28 | 1.62 | 4 |

| S5 | 0.35 | 28.08 | 0.97 | 12.00 | 2 |

| Strategies | λ = 0 K | λ = 0 K Rank | λ = 0.1 K | λ = 0.1 K Rank | λ = 0.2 K | λ = 0.2 K Rank | λ = 0.3 K | λ = 0.3 K Rank | λ = 0.4 K | λ = 0.4 K Rank |

|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 3.34 | 3 | 3.27 | 3 | 3.26 | 3 | 3.29 | 3 | 3.28 | 3 |

| S2 | 12.80 | 1 | 12.68 | 1 | 12.72 | 1 | 12.82 | 1 | 12.84 | 1 |

| S3 | 1.00 | 5 | 0.98 | 5 | 0.97 | 5 | 0.98 | 5 | 0.97 | 5 |

| S4 | 1.67 | 4 | 1.63 | 4 | 1.62 | 4 | 1.63 | 4 | 1.64 | 4 |

| S5 | 11.82 | 2 | 11.75 | 2 | 11.77 | 2 | 11.86 | 2 | 11.85 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mutambik, I. Assessing Critical Success Factors for Supply Chain 4.0 Implementation Using a Hybrid MCDM Framework. Systems 2025, 13, 489. https://doi.org/10.3390/systems13060489

Mutambik I. Assessing Critical Success Factors for Supply Chain 4.0 Implementation Using a Hybrid MCDM Framework. Systems. 2025; 13(6):489. https://doi.org/10.3390/systems13060489

Chicago/Turabian StyleMutambik, Ibrahim. 2025. "Assessing Critical Success Factors for Supply Chain 4.0 Implementation Using a Hybrid MCDM Framework" Systems 13, no. 6: 489. https://doi.org/10.3390/systems13060489

APA StyleMutambik, I. (2025). Assessing Critical Success Factors for Supply Chain 4.0 Implementation Using a Hybrid MCDM Framework. Systems, 13(6), 489. https://doi.org/10.3390/systems13060489