1. Introduction

Air cargo has a significant role in not only global trade but also in the overall development of the worldwide logistics industry. It enables the fast and secure transportation of high value and time-sensitive goods [

1]. Air transportation as one of the most important modes of transportation is determined by the latest development trends in e-commerce. Orzoł and Szopik-Depczyńska [

2] state that consumer changing habits due to digitalization require companies to invest in new technologies. Therefore, it can be stated that the digitalization of the air cargo supply chain is conceptually based on the principles of systems theory and systems thinking. The supply chain in this study is understood as a complex dynamic system—a set of interconnected elements, including different organizations, resources, information flows, and technologies operating in a common process. This approach is consistent with the general systems theory provision that complex problems (such as logistics chain management) must be analyzed holistically, assessing the interrelationships between components. The scientific literature analysis about supply chain systems management emphasizes that chain efficiency is achieved not by optimizing individual companies, but by their strategic cooperation and process coordination on a holistic scale.

The significant growth of e-commerce during the last decade [

3] has transformed the ways [

4] in which enterprises involved in manufacturing, sales, and logistics operate. For example, Mentzer et al. [

5] argue that supply chain management is the systematic, strategic coordination of traditional business functions both within and between companies which can improve the long-term efficiency of the entire chain. Thus, the implementation of digital innovation in the air cargo chain under consideration should be treated as an improvement for the entire system and not just a modernization of its individual parts.

Air cargo is divided into two categories [

6]; however, it should be noted that air cargo regulations are not fully standardized [

7] and are applied by IATA, the International Civil Aviation Organization (ICAO), the European Aviation Safety Agency (EASA), and others. Due to the transportation of passengers taking priority, the air cargo business [

8] is considered a secondary business. Bartulović et al. [

9] focus on air cargo as a component of supply chains connecting different countries.

Thums et al. [

10] acknowledges the necessity of automation and digitalization in air transportation. In turn, digital innovations from the perspective of the stakeholders and their impact on customer experience and financial performance [

11] are reflected on by Heiets et al. Forecasts of annual flights and number of passengers [

12] are seen as critical factors in decision-making.

However, it should be remembered that the role of digitalization in air cargo development is significant. And integrated, coordinated digitalization across the entire chain [

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29,

30,

31,

32,

33] vital—this approach is supported by the results of our research, which emphasize the need for a unified platform. However, Taschner and Charifzadeh [

34] state that the air cargo supply chain is not digital, and Poleshkina [

35] highlights manual processes increasing the lead time for documentation, air cargo booking, and tracking.

Therefore, to address those issues, several technologies can be used. Blockchain technology ensures that after the storage, the data cannot be changed [

36], and all stakeholders must hold a public–private key [

37] for access to the data. In turn, AI technology can be used to analyze and interpret external data [

38], which resonates with Downie and Finn [

39], highlighting its importance in the decision-making and improvement of operational efficiency. Similarly, IoT technology can be used for gathering and proceeding with real time data [

40]. Meanwhile, Spandonidis et al. [

41] focus on IoT as the foundation of low-energy-consuming sensors that can detect critical events like fire, smoke, impacts, and accidental misuse.

Lang [

42] describes a digital twin as a virtual representation of digital processes, while other scholars [

43] reflect on this technology as the result of emerging technologies such as AI, cloud computing, IoT, and virtual reality. Unlike previously mentioned technologies, cloud computing can enhance real time communication [

44] and cloud-based marketplaces [

45] to facilitate air cargo [

46,

47,

48,

49,

50,

51,

52,

53] slot booking.

In academic research, Bombelli et al. [

8] analyze air cargo as a complex network and emphasize the importance of system connectivity and data visibility to optimize routing and capacity use. Thums et al. [

11] extend this by identifying key barriers to air transport digitalization, including low stakeholder alignment and a lack of real-time communication platforms. Moreover, Gonzalez-Feliu et al. [

54] emphasize that digital integration projects often fail in small- and medium-sized countries due to fragmented infrastructure and inconsistent regulatory environments.

However, it should be remembered that the analyzed supply chain should be considered a socio-technical system, since its activity depends on both technical components (e.g., IT systems, data transmission technologies, and vehicles) and social elements (organizations, people, and legal norms). The socio-technical system theory emphasizes that when implementing new technologies in a complex system, it is necessary to combine technical solutions with human factors—employee skills, managerial decisions, organizational structures, and inter-institutional cooperation. In our case, this means that in order to successfully digitize the air cargo logistics chain, it is no less important to consider organizational readiness and culture (e.g., partner trust in data sharing, employee training to work with the new system, process redesign) than the functionality of the technology itself. In this study, the Latvian air cargo supply chain is conceptualized as a socio-technical system wherein various stakeholders—such as freight forwarders, customs authorities, and ground handling agents—interact through both organizational structures and digital interfaces. The adoption of the IATA ONE Record standard is interpreted not merely as a technical upgrade, but as a systemic intervention aiming to restructure communication flows and operational logic across the network. Informed by systems theory, we approach digitalization as a multi-layered transformation that aligns human, institutional, and technological subsystems toward a shared objective: improved interoperability and decision-making capacity within the national logistics infrastructure. Such an integrated approach reflects systemic thinking—which assesses technological innovation in a broader context—as a change in the entire system and not just the implementation of a new IT tool in isolation and the need for strategic management integration.

Recent international studies highlight the strategic relevance of air cargo digitalization for global supply chain resilience and transparency. For example, McKinsey & Company [

55] notes that next-generation supply chains, enhanced by real-time data sharing and standardized interfaces, can reduce operating costs by up to 30% and improve service levels across logistics segments, including air cargo.

The literature traditionally highlights three levels of strategic management [

56]—operational, functional, and business strategy. To assess the most suitable strategy framework based on five strategic management steps [

57], the following strategic frameworks were analyzed: Balanced Scorecard (BSC); Objectives and Key Results (OKR); Hoshin Kanri, Objective, Goals, Strategies, and Measures (OGSM); and MBO [

58].

Strategic management frameworks were compared in accordance with five strategic management steps and evaluated to identify if they included mission, vision, and values as well as the strategic management stages of strategy formulation, strategy implementation, and strategy review. We also evaluated the inclusion of environmental analysis in the strategy development process. We concluded that the MBO framework, which only addresses two strategic management steps, is the least comprehensive framework. Strategic management frameworks such as OGSM, Hoshin Kanri, and OKR cover three strategic management steps. The most comprehensive framework among those compared is the BSC. It covers four steps of the process by lacking only environmental analysis, making it the most suitable for the development of the Latvian air cargo digitalization strategy.

In summary, it can be stated that, guided by the aforementioned theoretical principles, this study analyzes the problem of digitization of the Latvian air cargo supply chain in a comprehensive manner. The study identifies the main interdependencies of subsystems: the links between information flows and the physical chain of cargo movement, the coordination of business processes between different companies, and the interaction of technologies with legal regulation. Applying multi-criteria assessment (AHP methodology), we evaluated different digitization solutions according to criteria that include both technical and organizational aspects. This method allowed us to reveal which solution is most suitable for the entire system and not just for an individual participant. For example, the “standardization” criterion was designed to check whether the solution will ensure a common data format and process interaction between all members of the chain—this is a critical factor in creating an integrated system. The “implementation” (integration) criterion allowed us to assess whether the new digital platform can be connected to the existing internal systems of various organizations, which is directly related to the architecture and compatibility of the system. The “user-friendliness” criterion reflected the socio-technical component—we checked whether the solution was flexible to the needs of different users, as this will determine how well the system participants will accept and use it. Finally, the “sustainability” aspect assessed the long-term benefits for the entire system (including economic and environmental impacts), and the “security” aspect assessed the reliability and resilience of the system to threats. We considered all these criteria when determining which digital innovation to recommend for implementation. In this way, the study ensured that the selected solution was not optimized only along one dimension but was balanced across the entire system. This consistent systemic analysis corresponds to best practices in systems management, which aims to comprehensively align technologies, processes, and people. Our results and proposals (implementing a unified platform, strengthening cooperation, training personnel) stem from the systemic insight that only synchronized improvement of all elements of the chain will achieve maximum effect. In this way, the research content is organically linked to the topic of systems—both at the theoretical level (by applying the concepts of systems theory) and at the level of practical application (by proposing specific solutions for the implementation of systemic innovation).

These contributions aim to provide a useful and practically applicable solution for the Latvian air cargo industry stakeholders while strengthening the theoretical foundation in the context of air cargo supply chain digitalization. Synthesizing these perspectives, our study contributes by adapting global frameworks such as IATA ONE Record and the Balanced Scorecard approach to a specific national context. This highlights how standardized models can address structural inefficiencies in under-digitalized logistics environments like Latvia’s air cargo supply chain.

As a result, researchers and practitioners looking for methods to improve supply chain efficiency through digitalization can use this study as a reference.

The study contributes to the theoretical knowledge of air cargo digitalization and is customized to the national level supply chain. As the result of the study, a strategy developed incorporates PESTEL analysis, AHP, and expert interviews.

The article is structured into several key elements: an introduction, methods and methodology, results, discussions, and conclusions.

2. Materials and Methods

This study includes an integrated methodological framework aimed at developing a digitalization strategy for the Latvian air cargo supply chain. At first, PESTEL analysis was conducted to identify internal and external factors influencing Latvian air cargo supply chain stakeholders and supply chain processes. This analysis was based on a literature review, statistical data, and industry reports analysis. Secondly, the Analytical Hierarchy Process (AHP) was applied to evaluate potential digitalization solutions using multi-criterial decision-making approaches.

Lastly, we conducted expert interviews to assess the issues associated with the air cargo supply chain.

Using the methods highlighted, the authors evaluate the significance of the air cargo supply chain in global trade as well as the main challenges related to the Latvian air cargo supply chain. The authors examined the loading and unloading of cargo within the context of airports and supply chains.

The following research questions and hypothesis were formulated:

Hypothesis (H)—The adoption of the IATA ONE Record Standard will provide the most effective and sustainable digitalization solution for Latvian air cargo. The literature review was used to discuss the main digitalization technologies used in supply chain digitalization as well as the main strategic management approaches that must be followed while developing a strategy. The literature analysis was based on the results of the initial examination from the following databases: Web of Science, Scopus, and ScienceDirect. The following keywords were used: digitalization, air cargo, supply chain digitalization, and technologies in supply chain. Primary literature sources were carefully assessed based on the aim and topic of the research as well as the availability of full-text articles.

The study was developed based on different data sources associated with air cargo. The primary sources used were the Official Statistics Portal of Latvia, Eurostat, and data available on the website of Riga International Airport. The research period covered in the statistical analysis ranged from 2013 until 2023. The statistical data analysis focused on air cargo volumes, infrastructure development, and supply chain performance indicators. The data collected was used in the identification of the factors related to the influencing of Latvia’s air cargo digitalization included in the PESTEL analysis.

PESTEL analysis was used to evaluate internal and external factors influencing the implementation process of the air cargo supply chain and potentially affecting all stakeholders involved. Each of the factors was evaluated by its impact, significance, and its potential implications on the Latvian air cargo supply chain. The factors included in PESTEL analysis were identified based on the statistical analysis of air cargo volumes loaded and unloaded, benchmarking of similar supply chains, and industry reports.

The Analytical Hierarchy Process (AHP) was applied to evaluate the potential digitalization solutions based on the selected criteria: standardization, implementation, customization, data security, and sustainability. Pairwise comparison was conducted using Saaty’s 1–9 scale, but normalized weights were calculated using the geometric mean method. The methods—tailored software and IATA ONE Record—were evaluated, and final scores were determined.

Given that in a rapidly globalizing economic environment, the air cargo supply chain is becoming extremely important for effective logistics management, the speed, reliability, and ability to respond to market changes directly depend on the efficiency and innovation of the supply chain. Therefore, both in scientific research and in practice, it is particularly important to evaluate each participant in the chain, determine their significance, possible limitations, and solutions that can increase the efficiency of the entire system.

One way to objectively assess the importance of chain participants or factors is expert assessment. In this study, a group of eight experts was used, who quantitatively assessed the objects—in this case, the criteria related to the air cargo supply chain. Expert assessments formed a table (matrix) R with m rows and n columns. Each expert provided their opinion according to the selected assessment scale.

The expert assessment method allows us not only to determine the priorities of the criteria but also to assess the compatibility of the opinions themselves. This is especially relevant when assessing complex or diverse phenomena, such as elements of the logistics chain, their interaction, and their influence on the entire supply system. In this analysis, the Kendall rank concordance coefficient W was used, which shows how much the experts’ assessments coincide. If the concordance of opinions is high, this means that the obtained data can be considered reliable and suitable for further use.

Assessments can be presented on various scales—from numerical values to pairwise comparison, in accordance with the Saaty scale. However, in order to ensure the reliability of the ranking and subsequent processing, all data were transferred to a rank system, where the most important criterion is given the rank of 1, the second most important is given the rank of 2, etc. Such a method allows for data unification and facilitates statistical analysis [

59,

60,

61,

62].

This methodological approach ensures that all aspects related to the model development are systematically addressed, ensuring that the developed supply chain model with integrated IATA ONE Record is both comprehensive and practically applicable for the industry stakeholders.

3. Results

In this section, the authors analyze the latest Latvian air cargo industry development trends, including the main participants of the Latvian air cargo supply chain. In addition to this, the authors identify the main problem related to Latvian air cargo and propose a digitalization solution.

3.1. Latvian Air Cargo Industry Development

It must be highlighted that the Latvian air cargo industry has a rich history. The literature analysis [

63] shows that as the turning point for the aviation industry development of Latvia is considered to be the building of the first aircraft in the country in 1670. In addition, the first aircraft factory was established in Riga in 1909, while the first flight took place in 1910. The rapid development of the industry required a more regulated framework, thus in the 1930s, the Department of Air Traffic as established as part of the Ministry of Transport and took over the registration of Latvian civil aircraft. During the Soviet Union’s 1945–1991 occupation, the Board of Civil Aviation of Latvia regulated Latvian aviation despite being under the USSR Ministry of Civil Aviation.

According to Markova and Stola [

64], seven civil aviation airfields, two air transportation airfields, and a military base at Lielvārde airfield are currently certified and considered to be part of Latvia’s aviation sector. Despite this, currently the only airport serving passengers and air cargo [

65] is Riga International Airport (RIX). It must be highlighted that the capacity of RIX [

66] is as follows:

The airport has one runway that measures 3200 m in total length and 45 m in width.

Capacity of flights: 29 flights per hour;

More than 5000 m2 of indoor cargo storage;

More than 10,000 m2 of outdoor cargo storage;

The aviation fuel capacity: 6000 m3.

The total capacity of RIX resonates with the continuously growing flight network. According to RIX [

67], in the summer season of 2024, Riga was connected to over 100 passenger flight destinations within Europe as well as Uzbekistan, Iceland, Egypt, and Dubai. RIX hosts several airlines, for example, low-budget airlines such as WizzAir, Ryanair, and Norwegian, as well as other airlines, such as airBaltic, Turkish Airlines, Finnair, LOT, Lufthansa, Aegean, FlyDubai, and Uzbekistan Airlines.

The airlines mentioned fly to around 80 destinations [

68]; moreover, RIX is served by regular air cargo flights for enterprises such as FedEx, UPS, and DHL. Those flights are implemented by ASL Airlines, SprintAir, SwiftAir, and European Air Transport to destinations in Europe. In addition, on an irregular basis, RIX hosts airlines such as Fly Khyva and Atlas Air, which also operate transcontinental flights to China and Hong Kong. Finally, military air forces from NATO countries such as France, Spain, the Czech Republic, Canada, and Italy use RIX to load and unload civil and non-hazardous cargo [

69].

The latest statistics [

70] show that in the first quarter of 2024, the three busiest air cargo routes to and from RIX were Copenhagen Kastrup Airport (2365 tons of cargo), Paris Charles de Gaulle Airport (678 tons of cargo), and Frankfurt Airport (623 tons of cargo). Other important air cargo destinations in 2024 are Kaunas and Vilnius International Airports in Lithuania, Tallinn Lennart Meri Airport in Estonia, and Oslo Gardermoen Airport in Norway. Oxford Research shows [

71] that in 2020, a total of 29 companies worked directly in the air transport sector, and 46 were indirectly connected to the air transport sector, leading to a significant contribution to the Latvian economy with 665 million EUR in 2022.

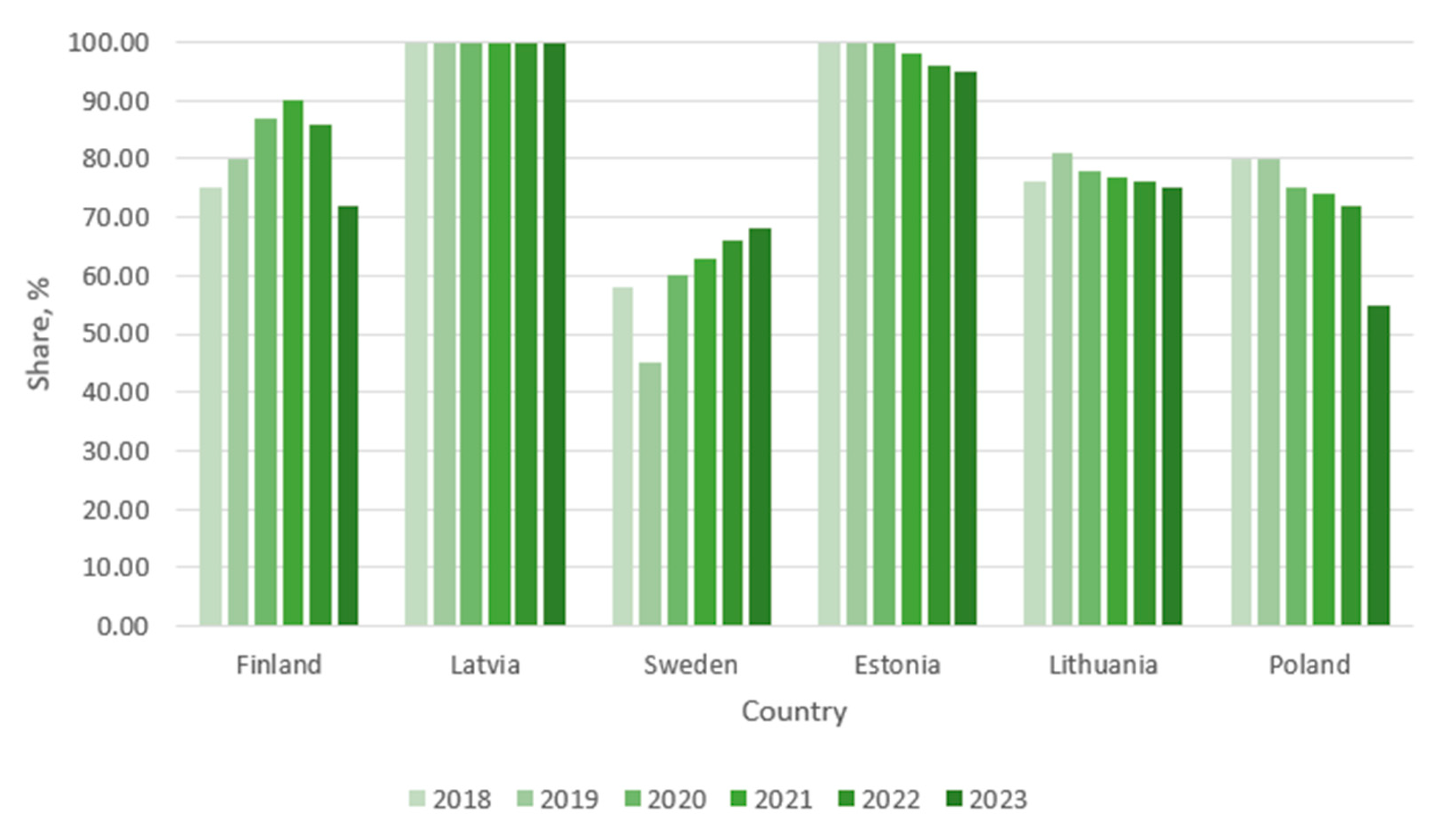

During the industry trends analysis, the authors collected the data and summarized the key findings regarding the volume of air cargo loaded and unloaded in airports and supply chains [

72,

73,

74,

75,

76,

77] for the chosen countries: Latvia, Lithuania, Estonia, Poland, Sweden, and Finland for the period of 2018–2023. Based on the data analyzed, the authors computed the growth rate for the transported cargo volumes compared to the baseline year, i.e., 2018 (

Table 1).

The findings show that the total volume of air cargo loaded and unloaded increased in Lithuania (18.13%) and Poland (55.06%) but significantly decreased in all remaining countries—Finland (−20.19%), Latvia (−27.09%), Estonia (−27.24%), and Sweden (−20.19%). An analysis of air cargo volumes per airport in selected countries revealed a similar situation.

The main reason behind this pattern is related to countries’ actions in terms of ensuring continuity of the air cargo supply chain. For example, Poland [

78] and Lithuania [

79] have invested in modernizing their logistics infrastructure, thus making these countries more attractive to international carriers and cargo operators. In addition, e-commerce growth [

80] has increased the demand for air cargo services, and due to their strategic location, these countries could be considered regional distribution hubs.

In turn, the decline of cargo volumes loaded and unloaded in Latvia [

81], Estonia [

82], Finland, and Sweden [

83] is related to the several challenges in the region. For example, the Russia–Ukraine war [

84] and airspace related restrictions have changed traditional flight and logistics routes in region. In addition, these countries have a smaller export market shares compared to other countries in the region, thus outbound air cargo volumes are limited. Moreover, air cargo handling in these countries is concentrated in one or two airports, which means that any disruptions, such as COVID-19, have a significant impact on air cargo-related operations.

The authors conclude that these differences are pointing out issues related to the airports’ competitiveness, meaning that factors such as higher costs, slower adoption of digital systems, and lack of investment in infrastructure development made some of these countries less attractive to international carriers and cargo operators. This emphasizes that the most important factors for the development of the air cargo supply chain are flexibility, speed, and cost-efficiency.

To identify the centralization level of airports in the context of selected countries, the authors calculated the airport share of national volume for the period of 2018–2023 for Riga International Airport in Latvia, Tallinn Lennart Meri Airport in Estonia, Vilnius International Airport in Lithuania, Stockholm Arlanda Airport in Sweden, Warsaw Chopin Airport in Poland, and Helsinki-Vantaa Airport in Finland.

Figure 1 summarizes the findings.

The figure illustrates the total share of national air cargo from the leading airports in selected countries during the period of 2018–2023. The calculation of the share is based on the total air cargo volume in each country.

The findings demonstrate that Latvia and Estonia have full centralization, meaning that 100%, or close to 100%, of cargo is handled by Riga International Airport or Tallinn Airport, confirming the dominance of these airports in air cargo operations. Conversely, Sweden and Poland have more decentralized cargo handling structures, with their leading airports handling between 45 and 70% of the total air cargo loaded and unloaded. In comparison, Finland and Lithuania have relatively high but declining leading airport shares, indicating the development of alternative logistics networks or the changing of the air cargo handling strategies.

The authors conclude that differences in air cargo handling practices as a result of centralized or decentralized approaches highlight the potential issues related to the adaptation of digitalization strategies, infrastructure planning, and potential usage of data integration systems such as IATA One Record.

3.2. Latvian Air Cargo Supply Chain

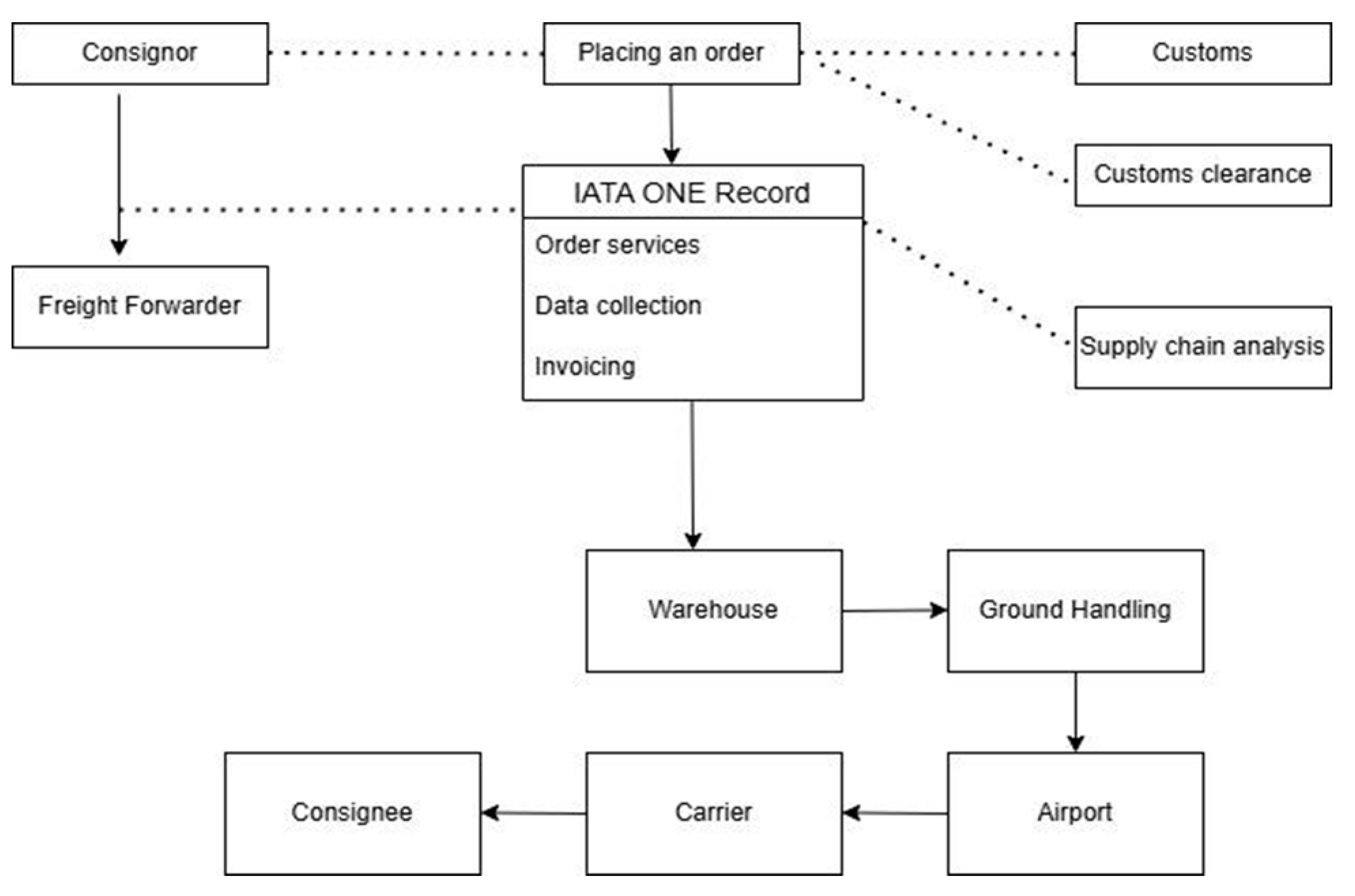

Following the industry analysis, the authors summarized findings and created a schematic representation of the current stakeholders involved in the Latvian air cargo supply chain.

Figure 2 provides a summary of the results.

It should be emphasized that the Latvian air cargo supply chain includes several key stakeholders who play a significant role in ensuring the continuity of transporting processes. The process of air cargo supply chain and parties involved in their implementation were further analyzed.

It should be noted that the Latvian air cargo supply chain starts with shippers who intend to send goods by air transport. When the cargo is ready to be flown out from Riga Airport, the ground handling services at Riga Airport coordinate to support the safe transport of the cargo to the carrier’s aircraft. There are two different ground handling services that are available at Riga Airport: the Turkish company Havas and RIX Ground Handling [

85]. Acting on behalf of Riga Airport, both companies have contracts with various carriers that operate on the landing field, thus forming a duopoly.

Carriers can be split into four categories [

86]: belly cargo, integrators, air cargo charter, and military. Being a member of the North Atlantic Treaty Organization (NATO), the Republic of Latvia the military personnel of allied countries are allowed access to the country [

87]. In addition to which, allied air forces, including the French and Canadian Air Forces, use Riga Airport to deliver their troops alongside civilian necessities, such as food and clothing.

The Latvian air cargo supply chain finally ends when a carrier’s aircraft leaves Riga airport. The freight forwarder uses the transportation tool specified above so that the cargo is dispatched to the final receiver/consignee.

In conclusion, the developed process model of the Latvian air cargo supply chain does not include an overview of collaboration between stakeholders and digital tools used in communication and process coordination; thus, there is the need to follow future trends and have stronger digital data integration in a unified digitalization model.

3.3. PESTEL Analysis of the Current Air Cargo Supply Chain

To identify the problems related to the Latvian air cargo supply chain, the authors conducted a PESTEL analysis based on an industry statistical data analysis, market reports, and an analysis of Latvian air cargo supply chain stakeholders and legal frameworks. The selection of the factors included in PESTEL analysis was based on a combination of the following: the statistical analysis of air cargo volumes, the benchmarking of competing airports, and the review of industry-specific reports and research related to supply chain digitalization.

Each of the factors included in the PESTEL analysis was evaluated using Likert’s 5-point scale [

88], where “1” means very low impact, “3” means medium impact, and “5” means very high impact. The scale was adapted to evaluate each factor’s impact on the Latvian air cargo supply chain.

Table 2 summarizes the results of the PESTEL analysis.

Political factors were assessed based on the industry’s statistical data and legal framework analysis. The results of the research show that Latvia has a significant advantage in terms of the digitalization of public services, which aligns with the EU digital strategy [

89]. It should be noted that 88.2% of government services [

90] are available for its citizens online, which means that in the context of the air cargo supply chain, there are digitalized processes already implemented, such as customs clearance, cargo security checks, and compliance checks within existing regulations. On the other hand, in terms of political stability, Latvia has significant geopolitical risks [

91] due to the Russia–Ukraine war, which has influenced regional logistics stability, including air freight operations and has caused uncertainties for long-term infrastructure investments.

The evaluation of economic factors took into account decisions related to infrastructure investments and digital incentives. The volume of air cargo handled by Riga Airport in 2023 reached 19,160 tons [

92], thus highlighting the importance of air cargo in the context of the development of regional logistics networks and ensuring the country’s economic activity. The external importance in the industry could be highlighted by the important public and private sector investments allocated for upgrading cargo infrastructure and including automation solutions and digital cargo handling platforms. The allocated resources for incentives reached 22 million EUR in 2023.

Social factors were determined based on the deployment of digital tools alongside the air cargo supply chain. It must be emphasized that around 8% of the workforce in Latvia is employed in the transport and storage industry [

93]; therefore, there is a need for the development of workforce training, digital literacy programs, and the modernization of business operations. Externally, one of the most significant strengths should be mentioned: the adaptation rate of digital platforms and their usage in the implementation of air cargo supply chain activities. For example, airBaltic cargo [

94] has implemented a digital booking solution in collaboration with the platform “cargo.one”, which ensures smooth online cargo booking.

Technological factors include different automatization solutions, and research shows these as being the most positive and important aspects of the air cargo supply chain. A good example of the application of this technology is AG Handling at Riga Airport, which has automated critical cargo handling operations through the implementation of the Qstep platform and improved transparency, accuracy, and turnaround [

95]. However, one of the challenges related to technology adaptation can be considered low levels of data integration alongside air cargo supply chain stakeholders. It must be emphasized that many external systems remain siloed [

96], which results in inefficiencies as the flow of real-time information is blocked across the air cargo value chain.

A novel mechanism for energy-efficient and eco-friendly technologies supports Riga Airport’s investment in modern cargo [

97], aligning with Latvia’s sustainability agenda. The logistics ecosystem at the regional level is changing to incorporate IoT tools for tracking and monitoring emissions, which signals that environmentally friendly processes and digital innovation are mutually beneficial [

98].

Finally, legal factors were assessed on the basis of local and regional levels. Internally, Latvia adheres to the EU’s general data protection regulation (GDPR), and therefore, digital systems are held to high standards of data privacy and security. This is considered an essential requirement for the integration of cargo management systems [

99]. External analysis reveals that the creation of international air transport agreements, such as recent treaties under negotiation [

100] with partner countries, makes it easier to achieve the legal harmonization and interoperability of digital platforms across borders.

After applying the PESTEL analysis, it becomes evident that the supply chain environment is complex and involves both opportunities and constraints related to the digitalization of Latvia’s air cargo supply chain. Political and economic considerations are a good basis, especially through the EU’s investments into digital maturity and dedicated infrastructure. Social and technological dimensions demonstrate the increasing willingness of stakeholders to employ digital solutions, but integration gaps and skills development are the areas of necessary improvements. Issues related to the environment and law, together with EU standards, result in a positive correlation between sustainable digital growth and compliance.

In conclusion, Latvia has a good environment for improving its air cargo supply chains through air cargo digitalization. The insights gained from this PESTEL analysis will help future policy recommendations as well as infrastructure planning and strategic alliances in the context of a modern, effective, and resilient air cargo ecosystem.

3.4. Expert Survey Results

Given that the air cargo supply chain consists of eight key players, it was important to identify how experts assess the contribution and importance of these players in the overall air cargo supply chain (

Table 3).

The assessment data obtained showed that the experts’ opinions were consistent and reliable, so it was possible to determine the importance of each criterion. The expert analysis allowed us to identify which participants are essential for achieving effective air cargo transportation:

Shippers—The most important participants in the chain, who initiate the entire logistics process. Without their effective involvement and cooperation, cargo delivery is impossible. They are responsible for cargo preparation, documentation, and logistics planning.

Freight Forwarders—Intermediaries between the shipper and other participants in the chain, who ensure a smooth transportation process, the preparation of documents, and coordination with other institutions.

Warehouses—These are used for cargo storage, sorting, and the proper preparation before transportation. The presence of modern warehouses allows for optimizing time costs.

Ground Handling—These companies perform the functions of loading, unloading, and transporting cargo within the airport territory. This directly affects the speed and safety of transportation.

Customs—A necessary stage of cargo inspection and clearance, which has a decisive impact on the speed of delivery, especially in international transportation.

Carriers—Companies that carry out actual transportation by air. The quality of their activities determines the delivery time and reliability of the service.

Customs Brokers—These participants facilitate the formalities required by customs and represent the interests of customers, ensuring the faster delivery of cargo.

Road Transport—This is necessary for transporting cargo to and from the airport and is especially important for last-mile logistics.

Airports—Infrastructure hubs where various supply chain functions intersect.

Consignees—End-users of cargo, who can also affect the quality of feedback and optimization of supply.

During the expert assessments, the main factors limiting the competitiveness of the Latvian air cargo supply chain were identified. Two important aspects were highlighted: limited infrastructure and manual supply processes. These shortcomings lead to inefficient cargo movement, a higher probability of errors, and increased costs.

Therefore, it was important to assess the challenges of information availability and dissemination. Since air cargo supply often takes place internationally, data exchange between institutions of different countries has become a crucial factor. During the study, experts identified the main information areas where difficulties most often arise.

Shipment information—Inaccurate or incomplete data about the shipment can slow down the entire process.

Customs declarations and clearance status—Insufficient transparency in this area leads to additional time for inspection or even the detention of shipments.

Cargo tracking details—Insufficient transparency of tracking data prevents supply chain participants from responding in a timely manner to possible delays.

These problems indicate the need to implement digital solutions that would ensure real-time information availability for all participants in the chain.

To assess digital solutions in the Latvian air cargo logistics system, experts were asked to evaluate possible digitalization solutions (

Table 4).

To increase the efficiency of the supply chain, various digital solutions were evaluated. The experts’ opinions were also consistent in this case, and their analysis showed clear priorities:

IATA ONE Record is an integrated data system that allows all supply participants to share information in a single format, thereby improving transparency and reducing the likelihood of errors.

Electronic Air Waybill (eAWB) is a digital version of a waybill allows for the elimination of paper documents, speeds up processes, and reduces administrative burden.

GPS tracking and geolocation helps the monitoring of cargo movement in real time, the identification of possible delays, and the optimization of routes.

Digital cargo platforms allow various participants to collaborate on a single platform, share documents, and ensure prompt information transfer.

Blockchain technologies allow for data security, integrity and transparency throughout the entire logistics process.

In summary, the results of the expert assessment indicated that the Latvian air cargo supply chain has great potential, but its competitiveness depends on the ability to effectively manage information and implement modern technologies. The expert opinions allowed us to identify both critical supply chain participants and the most advanced digital solutions. In order to remain competitive, it is necessary to prioritize information transparency, technology implementation, and the continuous optimization of supply processes.

3.5. Defining the Latvian Air Cargo Supply Chain and Possible Solutions

To identify the issues related to the Latvian air cargo supply chain, the authors used a PESTEL analysis derived from an industry trends analysis. The research results show that one of the main problems related to the air cargo supply chain is related to the data exchange between the stakeholders involved in the supply chain process.

As the solution to address the data integration issues between the stakeholders of the Latvian air cargo supply chain, the authors focused on two possible SaaS Cloud Computing solutions: tailored software and IATA ONE Record. It must be highlighted that the tailored software can be used between two parties involved in the air cargo supply chain but could result in problems when applied to another entity. IATA develops and supports ONE Record, which has a standardized API.

For further analysis, the authors compared the solutions provided by enterprises specializing in providing customized software solutions, and it was identified that the companies GoFreight [

101], CargoWise [

102], and CargoAI [

103] provide targeted solutions for different air cargo supply chain stakeholders. Consequently, IATA ONE Record [

104] emphasizes the standardization of data exchange between different stakeholders involved in the air cargo supply chain.

To define which of the solutions should be included in an improved air cargo supply chain process model, an AHP analysis was conducted. The criteria included in the AHP analysis were established based on both industry analysis and the previous literature review.

The “standardization” criterion emphasizes the importance of a uniform standard alongside the whole supply chain stakeholders and can be considered not only as part of data sharing but also as part of other supply chain processes. The “implementation” criterion assesses the ease of access to the software and its integration with other systems. The “customization” criterion refers to software’s adaptability to customers’ needs. The “data security” criterion describes aspects related to the software’s security against internal and external threats. Lastly, the “sustainability” criterion refers to the solution’s adaptability to the industry’s future requirements.

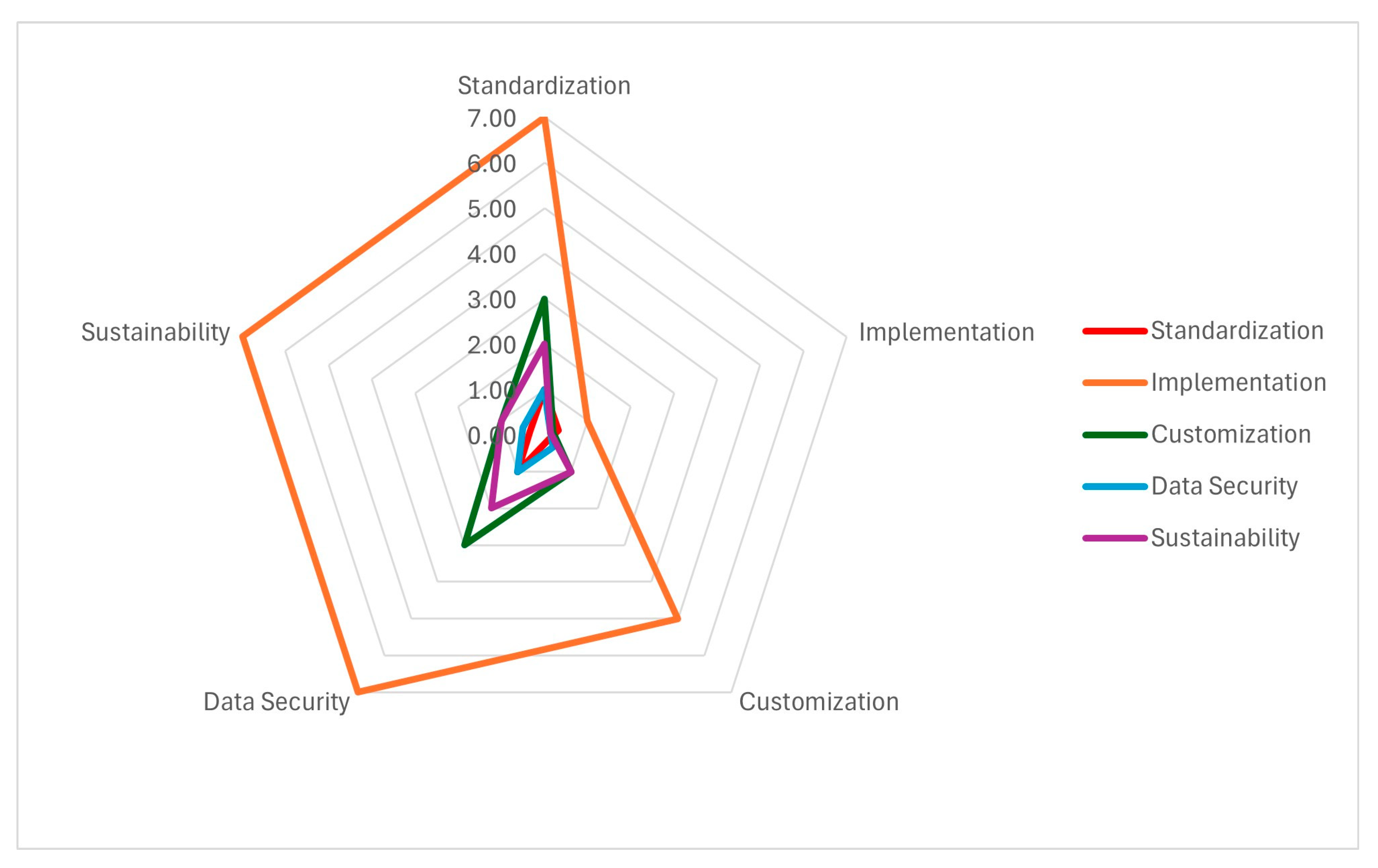

Initially, the authors prioritized the criteria to create a ranking, as illustrated in

Figure 3, and assigned weights for each criterion. Subsequently, the authors assessed both solutions according to the criteria to determine their relative performance value based on the previous analysis. Lately, the weight assigned to each criterion will be multiplied by the corresponding performance values to determine a final score.

The authors developed a radar chart to visually represent the rankings and relative weights of the criteria. This radar chart summarizes the comparative importance of the criteria, which were chosen based on Latvian air cargo supply chain trends and practices identified in the literature related to digitalization. To determine the weights for each criterion, the authors performed a pairwise comparison of the criteria and assigned them a relative importance using Saaty’s 1–9 fundamental scale [

105], where “1” means equal importance, “3” is moderate importance, “5” is strong importance, and “9” is the extreme importance of one factor over another.

Each axis represents one criterion, but the plotted variables are computed weights derived through the geometric mean method. The comparison of the weighted criteria shows that the significant spike alongside the “implementation” axis indicates its significance in the context of the Latvian air cargo supply chain. On the contrary, the relatively low weights of criteria such “data security” and “sustainability” highlight that despite the importance of these criteria, they could be considered secondary aspects influencing the Latvian air cargo supply chain. The evaluation of the criteria was based on the assumption that all criteria had equal importance, but their prioritization was based on their compliance with industry standards and data security.

Once the relative importance of each criterion was assigned, the geometric mean method was used to normalize the outcomes and weights of each criterion. The calculation results indicate that the most important criteria were “standardization” and “data security”, with both assigned an equal weight of 32.02%, thus highlighting their importance in the Latvian air cargo supply chain, especially in ensuring the technological compatibility and secure exchange of information. In turn, the “sustainability”, “customization”, and “implementation” criteria received weights of 15.00%, 12.93%, and 4.02%, respectively. The results show that it is important consider the strategic importance of environmentally responsible practices, but the practical aspects related to the implementation of the new systems are less important than their long-term potential and security concerns.

Further, the relative performance values for each of the solutions proposed were assessed through a pairwise comparison across various criteria. The geometrical mean method yielded the results and subsequently normalized them.

The comparative performance evaluation for each solution was performed through pairwise assessment alongside all evaluation criteria. These evaluations were conducted utilizing the geometric mean method, which was followed by the normalization of the results.

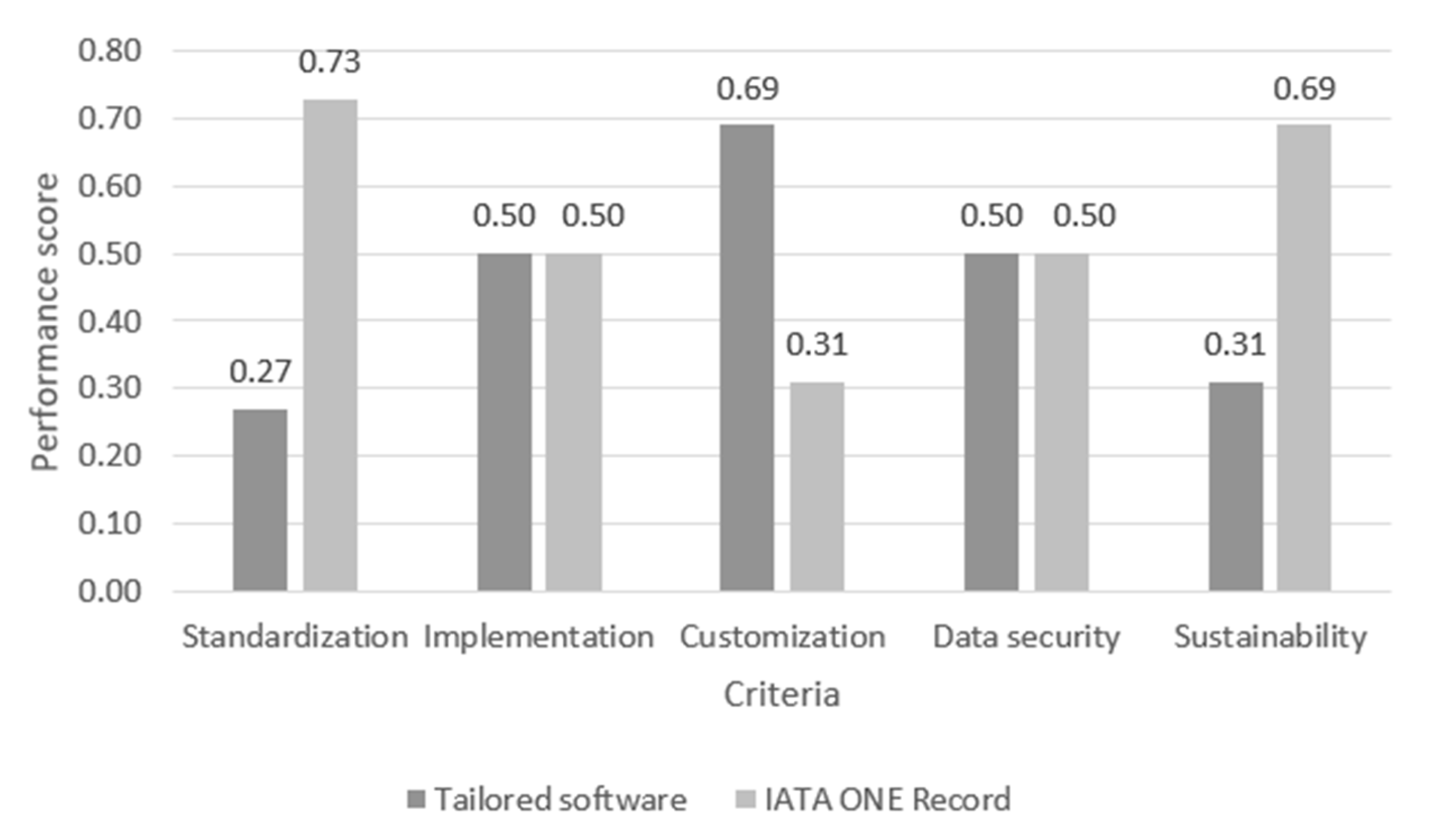

Figure 4 presents the comparison of normalized AHP performance scores between tailored software and IATA ONE Record.

The results indicate that IATA ONE Record significantly overperforms in the categories of “standardization” and “sustainability”, but tailored software overperforms in the “customization” category. These findings correspond to the previous findings which highlighted that tailored software provides enhanced adaptability to specific air cargo supply chain stakeholders needs, but in the context of “implementation” and “data security”, both solutions were assessed as having equivalent performance levels.

To determine the final scores, the normalized performance values were multiplied by the corresponding weights assigned for each criterion. The final scores for each of the methods were obtained by multiplying the performance values by the corresponding weight of the criteria and summarizing the results for each of the solutions. The results indicate that IATA ONE Record received a higher score in categories with higher significance. Calculation results show that IATA ONE Record scored 0.58, while the tailored software scored 0.42. Therefore, based on the results of the analysis, IATA ONE Record was selected as the most suitable digitalization solution for the Latvian air cargo digitalization supply chain.

It should be highlighted that the AHP model involved only five criteria and two methods, but the pairwise comparison was based on industry analysis and PESTEL analysis.

Given that the Analytical Hierarchy Process (AHP) was applied to evaluate possible digitization solutions in regard to the selected criteria, namely standardization, implementation, adaptability, data security, and sustainability, it was supplemented by the calculation of the consistency ratio (CR) and a sensitivity analysis, which are necessary to ensure methodological reliability and transparency. These components help to ensure that the expert assessments are consistent and that the final solution is stable despite small changes.

The following results were obtained when performing consistency index (CR) calculations (

Table 5).

After performing consistency index calculations, the results obtained are as follows: λ_max—5.1045; CI—0.0261; and CR—0.0233 (when RI = 1.12). In summary, it can be stated that the results of the calculations apply equally to all criteria since a common pairwise comparison matrix was used. Since CR < 0.1, the expert assessments are considered sufficiently consistent.

In addition to calculating the CR, a sensitivity analysis was also performed to assess the stability of the model. The sensitivity analysis used tailored software (original) at 0.4178 and ONE Record (original) at 0.5821, and for each criterion, their weights increased by 10% and the remaining criterion weights were proportionally normalized. The results are presented in

Table 6.

Considering the above results, the following conclusions can be drawn:

- (a)

It can clearly be seen that the ONE Record method retains its advantage over tailored software even after increasing the weight of the standardization criteria. This trend indicates the reliability of the solution and the stability of the model despite small changes. It can be concluded that the solution is not sensitive to variations in the weights; therefore, the selected digitization solution is robust and justified.

- (b)

After increasing the weight of the “Implementation” criterion, the AHP scores of both methods changed slightly. The tailored software score increased slightly, but ONE Record remained the better solution, according to the overall AHP assessment. This shows that the selected solution—ONE Record—is resistant to small variations in the importance of the criteria and maintains stability, which is important in strategic decision-making.

- (c)

After increasing the weight of the “customization” criterion by 10%, the values of the methods changed slightly. Tailored software maintained a slightly higher score according to this criterion; therefore, its results improved slightly. Nevertheless, ONE Record still remains the leader in terms of the overall assessment. This shows that the model is sufficiently stable, and the decision is not significantly affected by the change in the weight of this criterion.

- (d)

By increasing the weight of the “data security” criterion by 10%, the scores of both methods remain very close to the initial ones. This shows that this criterion has a balanced influence on both methods. ONE Record, as in previous cases, remains the most acceptable solution according to the overall AHP assessment, which confirms the stability of the solution and the reliability of the methodology.

- (e)

The calculations of the “sustainability” criteria also confirm that ONE Record is the most important.

In summary, it can be stated that tailored software assessments decrease as the weight of the most important criterion increases, while the value of ONE Record increases. This shows that ONE Record is characterized by greater compliance with the essential criteria—standardization and sustainability. It is these aspects that ensure long-term efficiency and better applicability in the context of supply chain digitalization. Such analysis is particularly relevant in the formation of a national strategy, where it is necessary to assess whether the chosen model will withstand strategic changes and remain effective in the face of changing external or internal environments. In summary, the visual analysis and its analysis confirm that IATA ONE Record is a better alternative for digitalization in the Latvian air cargo supply chain, even in the face of various weight changes.

4. Discussion

4.1. Integration of IATA ONE Record into the Latvian Air Cargo Supply Chain

The research results indicate that the model of the Latvian air cargo supply chain must be improved. The theoretical literature and the industry analyses conducted revealed the following issues:

The initially developed Latvian air cargo supply chain model does not include the information about the companies involved in the transportation process, such as road transport services providers.

The integration of digital solutions in the context of collaboration among Latvian air cargo supply chain participants (stakeholders) could give Latvia a competitive advantage due to its geographical location and comparatively well-developed air cargo handling processes.

There is a lack of unified digitalization solutions that are able to ensure the continuity of the air cargo supply chain process and ease for all stakeholders.

The integration of digitalization solutions is comparatively difficult, as the usages of digital technologies and the stakeholders involved in the Latvian air cargo supply chain vary.

As these factors are important for countries involved in the Latvian air cargo supply chain, the authors created guidelines for integrating IATA ONE Record into the Latvian air cargo supply chain.

Figure 5 shows the guidelines.

The figure above illustrates the integration process of IATA ONE Record into the Latvian air cargo supply chain. The first step in the integration of IATA ONE Record into Latvian air cargo supply chain involves stakeholder mapping and problem identification. During this step, all stakeholders involved in the supply chain (e.g., airlines, ground handlers, freight forwarders, warehouse operators, customs authorities, and IT support) must not only be identified but must also evaluate the current IT systems and their willingness to incorporate digital solutions. For this process, the authors suggest using the IATA ONE Record readiness checklist.

The second step includes policy alignment and government support. This means that, during this step, not only must compliance with GDPR principles be ensured but also alignment with the EU Digital Strategy and the Union Customs Code (UCC). In addition, it is recommended that actors collaborate with the Ministry of Transport and Ministry of Economics and State Revenue Services Customs Department to verify that the solution aligns with the current legal framework and development strategy of the state.

The third step includes the technical alignment and the integration of IATA ONE Record. This step involves preparing the infrastructure and integrating the API into the software. It should be noted that a very significant aspect is the adaptation of the current process to the IATA ONE Record standard and project piloting. During this process, we must confirm that the data exchange process adheres to all data governance standards and incorporates IATA role-based access control.

The fourth step focuses on training and IATA ONE Record implementation evaluation. We recommended that training is conducted for all stakeholders involved in the air cargo supply chain to be certain that the process of collaboration with these entities is smooth and does not require any activities that need to be carried out manually, thus decreasing the time needed to transport air cargo. In addition, the KPIs, such as reduction in data errors, faster customs clearance, and API response time, must be evaluated within the defined measures to be achieved.

The final step in the integration of IATA ONE Record includes continuous improvements. This step includes the steady monitoring of supply chain implementation speed, the behavior of stakeholders, and the results of KPI monitoring. The author suggests defining a period for assessing results, periodically evaluating the implementation of the supply chain process, and integrating necessary changes.

In the authors’ opinion, these steps not only ensure that Latvia is compliant with IATA’s standards but would also prepare it to be a digital and competitive air cargo hub within the European logistics ecosystem.

4.2. Model of Latvian Air Cargo Supply Chain with Integrated IATA ONE Record

In order to show the integrated process of the IATA ONE Record into the Latvian air cargo supply chain, the authors developed a model that outlines a solution for the data integration problem for air cargo supply chain stakeholders.

Figure 6 summarizes the model.

Figure 6 depicts the authors’ proposed model of the Latvian air cargo supply chain with integrated IATA ONE Record with the aim of providing a unified digital solution for all stakeholders. This figure illustrates the way the freight (illustrated with solid arrows) and the data (illustrated with dotted arrows) are exchanged by the main stakeholders in the air cargo logistics ecosystem.

The process begins with the orders provided by a consignor. Through IATA ONE Record, the overall order placement cycle is automated as order service management, data handling, and invoice generation are centralized. During this process, a freight forwarder is working with the consignor, taking care of cargo booking, paperwork, and logistics.

At the operational level, the cargo is moved from the freight forwarder to a warehouse before the ground handling agents receive the cargo delivery. The main responsibility of a ground handling team is loading and dispatching cargo to airports, which is responsible for cargo processing and transferring to carriers. The final stage is a carrier, which in turn oversees the delivery process to the consignee.

These findings reinforce the systems theory-related assumption that improvements in one subsystem (i.e., digital data exchange) have ripple effects across the broader supply chain ecosystem. In contrast to studies focusing primarily on functional optimization (e.g., lead time reduction), our application of socio-technical systems theory emphasizes the reconfiguration of relationships between actors and technologies. For example, the shift toward a unified data standard via ONE Record not only increases efficiency but also facilitates new forms of organizational coordination, trust-building, and institutional learning within Latvia’s air cargo sector.

The authors conclude that the developed model highlights the importance of IATA ONE Record as the platform facilitating real-time data sharing and exchange throughout the whole shipment process, including all stakeholders involved. In addition, data monitoring and real time processing enable insights into lead times and reasons for shipment delays as well as ensuring data compliance with the system. In addition, IATA ONE Record integrates fragmented data sources and recognizes outdated standards such as Cargo-IMP and Cargo-XML, thus improving the digitalization process of the Latvian air cargo supply chain.

5. Conclusions

The study results have significant practical implications despite being focused on the development of a digitalization strategy rather than its actual application. Through the application of the IATA ONE Record standard, the suggested approach offers Latvian air cargo supply chain stakeholders a tangible, step-by-step plan for improving data integration and operational efficiency. By implementing this concept into practice, the number of manual supply chain processes as well as operating expenses should decrease, but supply chain visibility and service quality should increase. In addition, the model of integrating IATA One Record can aid industry stakeholders in assessing the viability of similar digitalization approaches.

The study identified the key problems associated with the Latvian air cargo supply chain and proposed possible solutions for addressing these issues through digitalization. The main entities involved in the Latvian air cargo supply chain were identified. The assessment of those entities showed that the main problems of the Latvian air cargo supply chain are a result of extensive manual workarounds.

The analysis of the volumes of air cargo loaded and unloaded for the period of 2018–2023 revealed that the competitiveness of airport operations is related to investment in their infrastructure and digitalization. In addition, the decline in air cargo operations has been identified in Latvia, Estonia, Finland, and Sweden, with an average decline of 20.00% compared to 2018, while in Poland and Lithuania, an increase in air cargo operations of 5.55% and 18.13%, respectively, was observed

The Analytical Hierarchy Process was carried out based on five previously determined criteria for two potential digitalization methods that could be integrated into the Latvian air cargo supply chain: tailored software and IATA ONE Record. The results of the analysis demonstrated that the most suitable solution is IATA ONE Record. The applicability of this solution was shown through the development of the guidelines for integrating IATA ONE Record into the Latvian air cargo supply chain as well as by developing a Latvian air cargo supply chain model with the included IATA ONE Record.

This study aimed to develop a digitalization model for the Latvian air cargo supply chain, integrating findings from the PESTEL analysis and the Analytical Hierarchy Process (AHP). The findings of this study answered previously formulated research questions and hypotheses positively. The findings indicate that the IATA ONE Record standard is the most appropriate solution, which is justified by both the strategic assessment and evaluation of model applicability.

The methodological innovativeness of the study is found in its blended economic evaluation, quantitative prioritizing, and strategic environmental analysis. The model advances theoretical knowledge of how national and regional logistics environments can be tailored to global digitalization standards, thus providing an adjustable approach for other small- and medium-sized markets. In practice, the results provide a clear and financially justified framework for Latvian freight forwarders and cargo handlers, focusing on increasing the efficiency of their business operations.

Theoretically, this study contributes to the ongoing discourse on digital transformation in logistics by demonstrating how socio-technical integration can be operationalized at the national level. The case of Latvia shows that digital standardization (through IATA ONE Record) is not only a technical project but also a systems intervention that reshapes stakeholder interdependencies and information architectures. This perspective advances current knowledge by applying systems theory beyond abstract modeling and creates a practical strategy design framework, which is particularly relevant for small-to-medium economies seeking scalable digital solutions.

The main restrictions of the study are related to its concentration on commercial air cargo. In this research, processes related to the passengers’ luggage are excluded. The narrow focus of the study also excludes the incorporation of several digital solutions and focuses only on IATA ONE Record.

This study highlights how global digitalization approaches can be adopted to local industry needs through a structured multi-method evaluation, providing theoretical and practical insights into future digitalization strategies in logistics. For future studies, it is recommended that the integration of digital solutions such as blockchain technology, IoT, cloud computing, and others is assessed in the context of other entities involved in the Latvian air cargo supply chain. As this study is limited by the lack of approbation data, future research should focus on piloting the developed strategy in practice and adjusting it based on the operational outcomes of a company.

We suggest that future studies should focus on integrating broader conceptual frameworks, such as BANI or ESG, to further analyze the resilience and sustainability aspects in the context of air cargo digitalization.