Linking Manufacturing Smart Transformation to Regional Economic Development in China: The Crucial Mediation of Regional Innovation Capacity

Abstract

1. Introduction

2. Literature Review

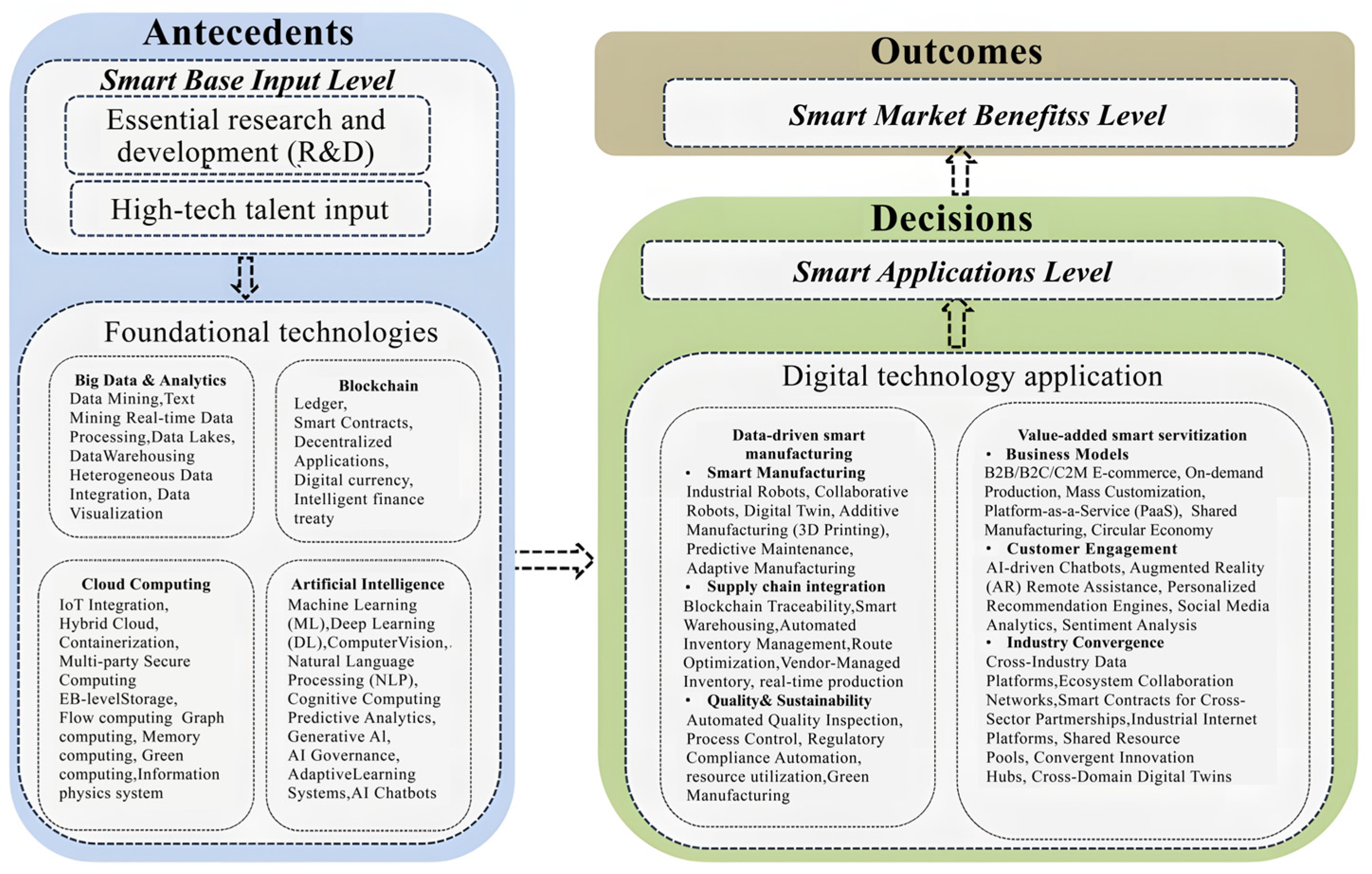

2.1. Smart Transformation

2.2. Regional Innovation Capacity

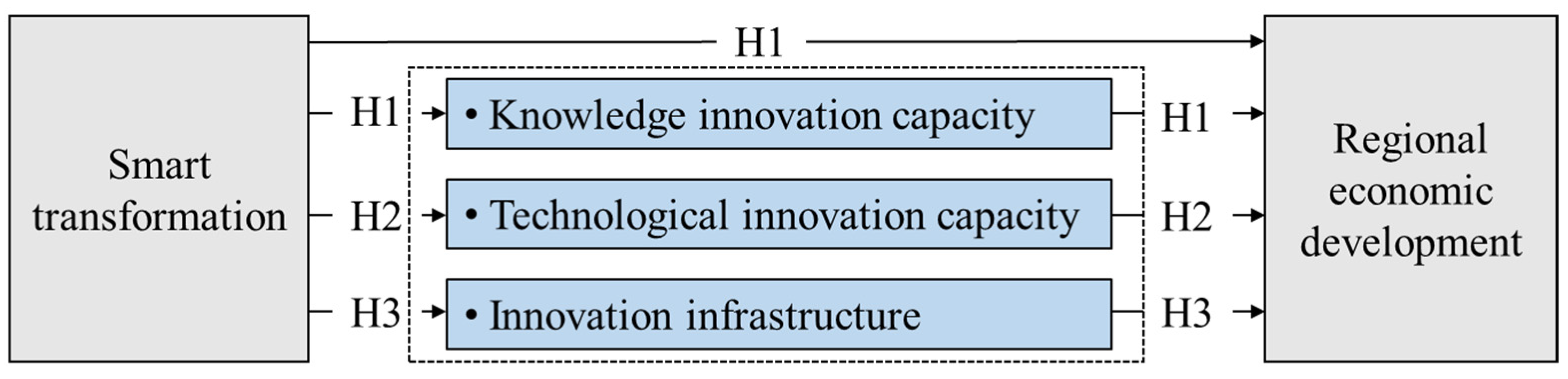

3. Theoretical Framework and Hypotheses

3.1. Smart Transformation and Regional Economic Development

3.2. The Mediating Effect of Regional Innovation Capacity

4. Methodology

4.1. Variable Measurement

4.1.1. Dependent Variable

4.1.2. Independent Variable

4.1.3. Mediating Variables

4.1.4. Control Variables

4.2. Data Sources and Processing

4.3. Model Building

5. Empirical Results and Analysis

5.1. Benchmark Regression

5.2. Endogenous Test

5.3. Heterogeneity Test

5.3.1. Heterogenous Analysis Based on Regions

5.3.2. Heterogenous Analysis Based on Manufacturing Sector

5.4. Robustness Test

5.4.1. Replace the Independent Variable

5.4.2. Replace the Dependent Variable

5.5. Mediating Effect

6. Discussion

6.1. Summary of Key Findings

6.2. Theoretical Implications

6.3. Practical Implications

7. Conclusions, Limitations, and Future Research

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, Y.; Li, S.; Xiang, X.; Bu, Y.; Guo, Y. How Can the Combination of Entrepreneurship Policies Activate Regional Innovation Capability? A Comparative Study of Chinese Provinces Based on fsQCA. J. Innov. Knowl. 2022, 7, 100227. [Google Scholar] [CrossRef]

- Fromhold-Eisebith, M.; Marschall, P.; Peters, R.; Thomes, P. Torn between Digitized Future and Context Dependent Past—How Implementing ‘Industry 4.0’ Production Technologies Could Transform the German Textile Industry. Technol. Forecast. Soc. Change 2021, 166, 120620. [Google Scholar] [CrossRef]

- Fu, Y.; Supriyadi, A.; Wang, T.; Wang, L.; Cirella, G.T. Effects of Regional Innovation Capability on the Green Technology Efficiency of China’s Manufacturing Industry: Evidence from Listed Companies. Energies 2020, 13, 5467. [Google Scholar] [CrossRef]

- Shukla, M.; Shankar, R. Modeling of Critical Success Factors for Adoption of Smart Manufacturing System in Indian SMEs: An Integrated Approach. Opsearch 2022, 59, 1271–1303. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, L.; Peng, L.; Zhou, H.; Hu, F. Enterprise Pollution Reduction through Digital Transformation? Evidence from Chinese Manufacturing Enterprises. Technol. Soc. 2024, 77, 102520. [Google Scholar] [CrossRef]

- Coronado-Medina, A.; Arias-Pérez, J.; Perdomo-Charry, G. Fostering Product Innovation Through Digital Transformation and Absorptive Capacity. Int. J. Innov. Technol. Manag. 2020, 17, 2050040. [Google Scholar] [CrossRef]

- Benitez, G.B.; Ayala, N.F.; Frank, A.G. Industry 4.0 Innovation Ecosystems: An Evolutionary Perspective on Value Cocreation. Int. J. Prod. Econ. 2020, 228, 107735. [Google Scholar] [CrossRef]

- Dai, Y.; Hasanefendic, S.; Bossink, B. A Systematic Literature Review of the Smart City Transformation Process: The Role and Interaction of Stakeholders and Technology. Sustain. Cities Soc. 2024, 101, 105112. [Google Scholar] [CrossRef]

- Rogers, E.M.; Singhal, A.; Quinlan, M.M. Diffusion of Innovations. In An integrated Approach to Communication Theory and Research; Routledge: London, UK, 2008. [Google Scholar]

- Xie, W.; Zheng, D.; Li, Z.; Wang, Y.; Wang, L. Digital Technology and Manufacturing Industrial Change: Evidence from the Chinese Manufacturing Industry. Comput. Ind. Eng. 2024, 187, 109825. [Google Scholar] [CrossRef]

- Xu, A.; Wang, W.; Zhu, Y. Does Smart City Pilot Policy Reduce CO2 Emissions from Industrial Firms? Insights from China. J. Innov. Knowl. 2023, 8, 100367. [Google Scholar] [CrossRef]

- Hamidi, S.; Zandiatashbar, A.; Bonakdar, A. The Relationship between Regional Compactness and Regional Innovation Capacity (RIC): Empirical Evidence from a National Study. Technol. Forecast. Soc. Change 2019, 142, 394–402. [Google Scholar] [CrossRef]

- Zhao, X.; Shen, L.; Jiang, Z. The Impact of the Digital Economy on Creative Industries Development: Empirical Evidence Based on the China. PLoS ONE 2024, 19, e0299232. [Google Scholar] [CrossRef]

- Ruan, R.; Chen, W. Research on the Impact of Geographic Distance on Corporate Technology for Social Good: From the Perspective of Institutional Environment and Regional Innovation Capability. J. Clean. Prod. 2024, 457, 142391. [Google Scholar] [CrossRef]

- Chen, J.; Wang, L.; Li, Y. Natural Resources, Urbanization and Regional Innovation Capabilities. Resour. Policy 2020, 66, 101643. [Google Scholar] [CrossRef]

- Ganau, R.; Grandinetti, R. Disentangling Regional Innovation Capability: What Really Matters? Ind. Innov. 2021, 28, 749–772. [Google Scholar] [CrossRef]

- Audretsch, D.B.; Belitski, M. Knowledge Complexity and Firm Performance: Evidence from the European SMEs. J. Knowl. Manag. 2021, 25, 693–713. [Google Scholar] [CrossRef]

- Calderini, M.; Fia, M.; Gerli, F. Organizing for Transformative Innovation Policies: The Role of Social Enterprises. Theoretical Insights and Evidence from Italy. Res. Policy 2023, 52, 104818. [Google Scholar] [CrossRef]

- Furman, J.L.; Porter, M.E.; Stern, S. The Determinants of National Innovative Capacity. Res. Policy 2002, 31, 899–933. [Google Scholar] [CrossRef]

- Medase, S.K.; Abdul-Basit, S. External Knowledge Modes and Firm-Level Innovation Performance: Empirical Evidence from Sub-Saharan Africa. J. Innov. Knowl. 2020, 5, 81–95. [Google Scholar] [CrossRef]

- Xu, A.; Qiu, K.; Jin, C.; Cheng, C.; Zhu, Y. Regional Innovation Ability and Its Inequality: Measurements and Dynamic Decomposition. Technol. Forecast. Soc. Change 2022, 180, 121713. [Google Scholar] [CrossRef]

- Ying, L.; Li, M.; Yang, J. Agglomeration and Driving Factors of Regional Innovation Space Based on Intelligent Manufacturing and Green Economy. Environ. Technol. Innov. 2021, 22, 101398. [Google Scholar] [CrossRef]

- Du, Z.-Y.; Wang, Q. Digital Infrastructure and Innovation: Digital Divide or Digital Dividend? J. Innov. Knowl. 2024, 9, 100542. [Google Scholar] [CrossRef]

- Zhu, C.; Li, N.; Ma, J.; Qi, X. Digital Technology Backgrounds and Enterprise Digital Transformation: The Mediating Effect of R&D Investment and Corporate Social Responsibility. Corp. Soc. Responsib. Environ. Manag. 2023, 31, 2557–2573. [Google Scholar] [CrossRef]

- Meindl, B.; Ayala, N.F.; Mendonça, J.; Frank, A.G. The Four Smarts of Industry 4.0: Evolution of Ten Years of Research and Future Perspectives. Technol. Forecast. Soc. Change 2021, 168, 120784. [Google Scholar] [CrossRef]

- Sofic, A.; Rakic, S.; Pezzotta, G.; Markoski, B.; Arioli, V.; Marjanovic, U. Smart and Resilient Transformation of Manufacturing Firms. Processes 2022, 10, 2674. [Google Scholar] [CrossRef]

- Bueno, A.; Godinho Filho, M.; Frank, A.G. Smart Production Planning and Control in the Industry 4.0 Context: A Systematic Literature Review. Comput. Ind. Eng. 2020, 149, 106774. [Google Scholar] [CrossRef]

- Kipper, L.M.; Furstenau, L.B.; Hoppe, D.; Frozza, R.; Iepsen, S. Scopus Scientific Mapping Production in Industry 4.0 (2011–2018): A Bibliometric Analysis. Int. J. Prod. Res. 2020, 58, 1605–1627. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 Technologies: Implementation Patterns in Manufacturing Companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Kim, M.; Lim, C.; Hsuan, J. From Technology Enablers to Circular Economy: Data-Driven Understanding of the Overview of Servitization and Product–Service Systems in Industry 4.0. Comput. Ind. 2023, 148, 103908. [Google Scholar] [CrossRef]

- Ambrogio, G.; Filice, L.; Longo, F.; Padovano, A. Workforce and Supply Chain Disruption as a Digital and Technological Innovation Opportunity for Resilient Manufacturing Systems in the COVID-19 Pandemic. Comput. Ind. Eng. 2022, 169, 108158. [Google Scholar] [CrossRef]

- Jaspert, D.; Ebel, M.; Eckhardt, A.; Poeppelbuss, J. Smart Retrofitting in Manufacturing: A Systematic Review. J. Clean. Prod. 2021, 312, 127555. [Google Scholar] [CrossRef]

- Frank, A.G.; Mendes, G.H.S.; Ayala, N.F.; Ghezzi, A. Servitization and Industry 4.0 Convergence in the Digital Transformation of Product Firms: A Business Model Innovation Perspective. Technol. Forecast. Soc. Change 2019, 141, 341–351. [Google Scholar] [CrossRef]

- Tian, J.; Coreynen, W.; Matthyssens, P.; Shen, L. Platform-Based Servitization and Business Model Adaptation by Established Manufacturers. Technovation 2022, 118, 102222. [Google Scholar] [CrossRef]

- Tariq, A.; Khan, S.A.; But, W.H.; Javaid, A.; Shehryar, T. An IoT-Enabled Real-Time Dynamic Scheduler for Flexible Job Shop Scheduling (FJSS) in an Industry 4.0-Based Manufacturing Execution System (MES 4.0). IEEE Access 2024, 12, 49653–49666. [Google Scholar] [CrossRef]

- Eriksson, T.; Heikkilä, M. Capabilities for Data-Driven Innovation in B2B Industrial Companies. Ind. Mark. Manag. 2023, 111, 158–172. [Google Scholar] [CrossRef]

- Nasiri, M.; Ukko, J.; Saunila, M.; Rantala, T. Managing the Digital Supply Chain: The Role of Smart Technologies. Technovation 2020, 96–97, 102121. [Google Scholar] [CrossRef]

- Wang, J.; Lim, M.K.; Wang, C.; Tseng, M.-L. The Evolution of the Internet of Things (IoT) over the Past 20 Years. Comput. Ind. Eng. 2021, 155, 107174. [Google Scholar] [CrossRef]

- Dwivedi, Y.K.; Hughes, L.; Ismagilova, E.; Aarts, G.; Coombs, C.; Crick, T.; Duan, Y.; Dwivedi, R.; Edwards, J.; Eirug, A.; et al. Artificial Intelligence (AI): Multidisciplinary Perspectives on Emerging Challenges, Opportunities, and Agenda for Research, Practice and Policy. Int. J. Inf. Manag. 2021, 57, 101994. [Google Scholar] [CrossRef]

- Weber, M.; Beutter, M.; Weking, J.; Böhm, M.; Krcmar, H. AI Startup Business Models Key Characteristics and Directions for Entrepreneurship Research. Bus. Inf. Syst. Eng. 2022, 64, 91–109. [Google Scholar] [CrossRef]

- Cimini, C.; Lagorio, A.; Cavalieri, S.; Riedel, O.; Pereira, C.E.; Wang, J. Human-Technology Integration in Smart Manufacturing and Logistics: Current Trends and Future Research Directions. Comput. Ind. Eng. 2022, 169, 108261. [Google Scholar] [CrossRef]

- Zhang, S.; Li, X.; Zhang, C.; Luo, J.; Cheng, C.; Ge, W. Measurement of Factor Mismatch in Industrial Enterprises with Labor Skills Heterogeneity. J. Bus. Res. 2023, 158, 113643. [Google Scholar] [CrossRef]

- Maddikunta, P.K.R.; Pham, Q.-V.; Prabadevi, B.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Ruby, R.; Liyanage, M. Industry 5.0: A Survey on Enabling Technologies and Potential Applications. J. Ind. Inf. Integr. 2022, 26, 100257. [Google Scholar] [CrossRef]

- Wang, B.; Zheng, P.; Yin, Y.; Shih, A.; Wang, L. Toward Human-Centric Smart Manufacturing: A Human-Cyber-Physical Systems (HCPS) Perspective. J. Manuf. Syst. 2022, 63, 471–490. [Google Scholar] [CrossRef]

- Ding, C.; Li, C.; Xiong, Z.; Li, Z. Computer Big Data Technology in Additive Manufacturing and Product Design in Sustainable Manufacturing. Int. J. Adv. Manuf. Technol. 2024, 135, 4855–4863. [Google Scholar] [CrossRef]

- Jackson, I.; Ivanov, D.; Dolgui, A.; Namdar, J. Generative Artificial Intelligence in Supply Chain and Operations Management: A Capability-Based Framework for Analysis and Implementation. Int. J. Prod. Res. 2024, 62, 6120–6145. [Google Scholar] [CrossRef]

- Kamalaldin, A.; Linde, L.; Sjödin, D.; Parida, V. Transforming Provider-Customer Relationships in Digital Servitization: A Relational View on Digitalization. Ind. Mark. Manag. 2020, 89, 306–325. [Google Scholar] [CrossRef]

- Machado, C.G.; Winroth, M.P.; Ribeiro Da Silva, E.H.D. Sustainable Manufacturing in Industry 4.0: An Emerging Research Agenda. Int. J. Prod. Res. 2020, 58, 1462–1484. [Google Scholar] [CrossRef]

- Zayat, W.; Kilic, H.S.; Yalcin, A.S.; Zaim, S.; Delen, D. Application of MADM Methods in Industry 4.0: A Literature Review. Comput. Ind. Eng. 2023, 177, 109075. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Liu, A.; Kusiak, A. Data-Driven Smart Manufacturing. J. Manuf. Syst. 2018, 48, 157–169. [Google Scholar] [CrossRef]

- Schiavone, F.; Paolone, F.; Mancini, D. Business Model Innovation for Urban Smartization. Technol. Forecast. Soc. Change 2019, 142, 210–219. [Google Scholar] [CrossRef]

- Raneri, S.; Lecron, F.; Hermans, J.; Fouss, F. Predictions through Lean Startup? Harnessing AI-Based Predictions under Uncertainty. Int. J. Entrep. Behav. Res. 2023, 29, 886–912. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, Digitization, and Opportunities for Sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Ko, M.; Lee, C.; Cho, Y. Design and Implementation of Cloud-Based Collaborative Manufacturing Execution System in the Korean Fashion Industry. Appl. Sci. 2022, 12, 9381. [Google Scholar] [CrossRef]

- Tödtling, F.; Trippl, M. One Size Fits All?: Towards a Differentiated Regional Innovation Policy Approach. Res. Policy 2005, 34, 1203–1219. [Google Scholar] [CrossRef]

- Teece, D.J.; Pisano, G.; Shuen, A. Dynamic Capabilities and Strategic Management. Strateg. Manag. J. 1997, 18, 509–533. [Google Scholar] [CrossRef]

- Clark, J.; Huang, H.-I.; Walsh, J.P. A Typology of “Innovation Districts”: What It Means for Regional Resilience. Camb. J. Reg. Econ. Soc. 2010, 3, 121–137. [Google Scholar] [CrossRef]

- Adamides, E.; Karacapilidis, N. Information Technology for Supporting the Development and Maintenance of Open Innovation Capabilities. J. Innov. Knowl. 2020, 5, 29–38. [Google Scholar] [CrossRef]

- Latan, H.; Chiappetta Jabbour, C.J.; Lopes de Sousa Jabbour, A.B.; de Camargo Fiorini, P.; Foropon, C. Innovative Efforts of ISO 9001-Certified Manufacturing Firms: Evidence of Links between Determinants of Innovation, Continuous Innovation and Firm Performance. Int. J. Prod. Econ. 2020, 223, 107526. [Google Scholar] [CrossRef]

- Lundvall, B.-Å.; Johnson, B.; Andersen, E.S.; Dalum, B. National Systems of Production, Innovation and Competence Building. Res. Policy 2002, 31, 213–231. [Google Scholar] [CrossRef]

- Pan, X.; Li, J.; Shen, Z.; Song, M. Life Cycle Identification of China’s Regional Innovation Systems Based on Entropy Weight Disturbing Attribute Model. Habitat Int. 2023, 131, 102725. [Google Scholar] [CrossRef]

- Huggins, R.; Thompson, P. Entrepreneurship, Innovation and Regional Growth: A Network Theory. Small Bus. Econ. 2015, 45, 103–128. [Google Scholar] [CrossRef]

- Jiao, H.; Zhou, J.; Gao, T.; Liu, X. The More Interactions the Better? The Moderating Effect of the Interaction between Local Producers and Users of Knowledge on the Relationship between R&D Investment and Regional Innovation Systems. Technol. Forecast. Soc. Change 2016, 110, 13–20. [Google Scholar] [CrossRef]

- Schiuma, G.; Lerro, A. Knowledge-based Capital in Building Regional Innovation Capacity. J. Knowl. Manag. 2008, 12, 121–136. [Google Scholar] [CrossRef]

- Park, H.; Anderson, T.R.; Seo, W. Regional Innovation Capability from a Technology-Oriented Perspective: An Analysis at Industry Level. Comput. Ind. 2021, 129, 103441. [Google Scholar] [CrossRef]

- Yi, S.; Xiao-li, A. Application of Threshold Regression Analysis to Study the Impact of Regional Technological Innovation Level on Sustainable Development. Renew. Sustain. Energy Rev. 2018, 89, 27–32. [Google Scholar] [CrossRef]

- Zhou, Q.; Cheng, C.; Fang, Z.; Zhang, H.; Xu, Y. How Does the Development of the Digital Economy Affect Innovation Output? Exploring Mechanisms from the Perspective of Regional Innovation Systems. Struct. Change Econ. Dyn. 2024, 70, 1–17. [Google Scholar] [CrossRef]

- Miao, Z. Industry 4.0: Technology Spillover Impact on Digital Manufacturing Industry. J. Enterp. Inf. Manag. 2022, 35, 1251–1266. [Google Scholar] [CrossRef]

- Zhou, X.; Song, M.; Cui, L. Driving Force for China’s Economic Development under Industry 4.0 and Circular Economy: Technological Innovation or Structural Change? J. Clean. Prod. 2020, 271, 122680. [Google Scholar] [CrossRef]

- Chung, D.; Jung, H.; Lee, Y. Investigating the Relationship of High-Tech Entrepreneurship and Innovation Efficacy: The Moderating Role of Absorptive Capacity. Technovation 2022, 111, 102393. [Google Scholar] [CrossRef]

- Culot, G.; Nassimbeni, G.; Orzes, G.; Sartor, M. Behind the Definition of Industry 4.0: Analysis and Open Questions. Int. J. Prod. Econ. 2020, 226, 107617. [Google Scholar] [CrossRef]

- Lu, H.; Du, D.; Qin, X. Assessing the Dual Innovation Capability of National Innovation System: Empirical Evidence from 65 Countries. Systems 2022, 10, 23. [Google Scholar] [CrossRef]

- Wang, Y.; Sutherland, D.; Ning, L.; Pan, X. The Evolving Nature of China’s Regional Innovation Systems: Insights from an Exploration–Exploitation Approach. Technol. Forecast. Soc. Change 2015, 100, 140–152. [Google Scholar] [CrossRef]

- Nambisan, S.; Wright, M.; Feldman, M. The Digital Transformation of Innovation and Entrepreneurship: Progress, Challenges and Key Themes. Res. Policy 2019, 48, 103773. [Google Scholar] [CrossRef]

- Zhou, X.; Hu, Q.; Luo, H.; Hu, Z.; Wen, C. The Impact of Digital Infrastructure on Industrial Ecology: Evidence from Broadband China Strategy. J. Clean. Prod. 2024, 447, 141589. [Google Scholar] [CrossRef]

- Skantsev, V.M.; Lovkova, E.S.; Kashitsina, T.N. The Impact of Innovation Infrastructure on the Economic Development of Regions. In Smart Technologies and Innovations in Design for Control of Technological Processes and Objects: Economy and Production; Solovev, D.B., Ed.; Springer International Publishing: Cham, Switzerland, 2019; pp. 380–387. [Google Scholar] [CrossRef]

- Cheng, C.; Wang, L. How Companies Configure Digital Innovation Attributes for Business Model Innovation? A Configurational View. Technovation 2022, 112, 102398. [Google Scholar] [CrossRef]

- Geng, D.; Evans, S. A Literature Review of Energy Waste in the Manufacturing Industry. Comput. Ind. Eng. 2022, 173, 108713. [Google Scholar] [CrossRef]

- Lee, B.; Kim, B.; Ivan, U.V. Enhancing the Competitiveness of AI Technology-Based Startups in the Digital Era. Adm. Sci. 2024, 14, 6. [Google Scholar] [CrossRef]

- Singh, S.K.; Jeong, Y.-S.; Park, J.H. A Deep Learning-Based IoT-Oriented Infrastructure for Secure Smart City. Sustain. Cities Soc. 2020, 60, 102252. [Google Scholar] [CrossRef]

- Okonta, D.E.; Vukovic, V. Smart Cities Software Applications for Sustainability and Resilience. Heliyon 2024, 10, e32654. [Google Scholar] [CrossRef]

- Li, H.; Yang, Z.; Jin, C.; Wang, J. How an Industrial Internet Platform Empowers the Digital Transformation of SMEs: Theoretical Mechanism and Business Model. J. Knowl. Manag. 2022, 27, 105–120. [Google Scholar] [CrossRef]

- Huang, Q.; Xu, C.; Xue, X.; Zhu, H. Can Digital Innovation Improve Firm Performance: Evidence from Digital Patents of Chinese Listed Firms. Int. Rev. Financ. Anal. 2023, 89, 102810. [Google Scholar] [CrossRef]

- Lu, Y.; Ning, X. A Vision of 6G–5G’s Successor. J. Manag. Anal. 2020, 7, 301–320. [Google Scholar] [CrossRef]

- Zhao, S.L.; Cacciolatti, L.; Lee, S.H.; Song, W. Regional Collaborations and Indigenous Innovation Capabilities in China: A Multivariate Method for the Analysis of Regional Innovation Systems. Technol. Forecast. Soc. Change 2015, 94, 202–220. [Google Scholar] [CrossRef]

- Yang, C.; Liu, Q. Driving Green Innovation Through Digital Transformation: Empirical Insights on Regional Variations. Sustainability 2024, 16, 10716. [Google Scholar] [CrossRef]

- Zhou, X.; Cai, Z.; Tan, K.H.; Zhang, L.; Du, J.; Song, M. Technological Innovation and Structural Change for Economic Development in China as an Emerging Market. Technol. Forecast. Soc. Change 2021, 167, 120671. [Google Scholar] [CrossRef]

- Du, M.; Antunes, J.; Wanke, P.; Chen, Z. Ecological Efficiency Assessment under the Construction of Low-Carbon City: A Perspective of Green Technology Innovation. J. Environ. Plan. Manag. 2022, 65, 1727–1752. [Google Scholar] [CrossRef]

- Hu, J.; Chen, H.; Fan, J.; He, Z. The Impact of Digital Infrastructure on Provincial Green Innovation Efficiency—Empirical Evidence from China. Environ. Sci. Pollut. Res. 2024, 31, 9795–9810. [Google Scholar] [CrossRef]

- Shen, L.; Sun, C.; Ali, M. Role of Servitization, Digitalization, and Innovation Performance in Manufacturing Enterprises. Sustainability 2021, 13, 9878. [Google Scholar] [CrossRef]

- Mijiyawa, A.G. Drivers of Structural Transformation: The Case of the Manufacturing Sector in Africa. World Dev. 2017, 99, 141–159. [Google Scholar] [CrossRef]

- Lin, S.; Cai, S.; Sun, J.; Wang, S.; Zhao, D. Influencing Mechanism and Achievement of Manufacturing Transformation and Upgrading Empirical Analysis Based on PLS-SEM Model. J. Manuf. Technol. Manag. 2019, 30, 213–232. [Google Scholar] [CrossRef]

- Luukkanen, J.; Kaivo-oja, J.; Vähäkari, N.; O’Mahony, T.; Korkeakoski, M.; Panula-Ontto, J.; Phonhalath, K.; Nanthavong, K.; Reincke, K.; Vehmas, J.; et al. Green Economic Development in Lao PDR: A Sustainability Window Analysis of Green Growth Productivity and the Efficiency Gap. J. Clean. Prod. 2019, 211, 818–829. [Google Scholar] [CrossRef]

- Taques, F.H.; López, M.G.; Basso, L.F.; Areal, N. Indicators Used to Measure Service Innovation and Manufacturing Innovation. J. Innov. Knowl. 2021, 6, 11–26. [Google Scholar] [CrossRef]

- Etzkowitz, H.; Leydesdorff, L. The Dynamics of Innovation: From National Systems and “Mode 2” to a Triple Helix of University–Industry–Government Relations. Res. Policy 2000, 29, 109–123. [Google Scholar] [CrossRef]

- Che, S.; Wen, L.; Wang, J. Global Insights on the Impact of Digital Infrastructure on Carbon Emissions: A Multidimensional Analysis. J. Environ. Manag. 2024, 368, 122144. [Google Scholar] [CrossRef]

- Wang, W.; Yu, P.; Zhou, Y.; Tong, T.; Liu, Z. Equivalence of Two Least-Squares Estimators for Indirect Effects. Curr. Psychol. 2023, 42, 7364–7375. [Google Scholar] [CrossRef]

- Coutts, J.J.; Hayes, A.F. Questions of Value, Questions of Magnitude: An Exploration and Application of Methods for Comparing Indirect Effects in Multiple Mediator Models. Behav. Res. 2023, 55, 3772–3785. [Google Scholar] [CrossRef]

- Hausman, J.A. Specification Tests in Econometrics. J. Econom. Soc. 1978, 46, 1251–1271. [Google Scholar] [CrossRef]

- Montgomer, D.C.; Peck, E.A.; Vining, G.G. Introduction to Linear Regression Analysis; John Wiley & Sons: Hoboken, NJ, USA, 2021. [Google Scholar]

- Wooldridge, J.M. Introductory Econometrics: A Modern Approach, 6th ed., student edition; Cengage Learning: Boston, MA, USA, 2016. [Google Scholar]

- Bao, J.; Li, Y. Has High-Tech Cluster Improved Regional Innovation Capacity? Evidence from Wuhan Metropolitan Area in China. Front. Environ. Sci. 2023, 11, 1180781. [Google Scholar] [CrossRef]

- Ma, D.; Zhu, Q. Innovation in Emerging Economies: Research on the Digital Economy Driving High-Quality Green Development. J. Bus. Res. 2022, 145, 801–813. [Google Scholar] [CrossRef]

- Cui, Y.; Tian, H.; An, D.; Jia, Y. Quality of Life and Regional Economic Development: Evidence from China. PLoS ONE 2024, 19, e0298389. [Google Scholar] [CrossRef]

- Bian, J.; Qin, Q.; Chen, X.; Wu, X. Stock Markets, Local Governments Leverage, and Regional Economic Development: Evidence from China. Pac.-Basin Financ. J. 2024, 85, 102326. [Google Scholar] [CrossRef]

- Guo, X.; Xu, D.; Zhu, K. Measuring Digitalization Effects in China: A Global Value Chain Perspective. China Econ. Rev. 2023, 81, 102021. [Google Scholar] [CrossRef]

- Tang, M.; Liu, Y.; Hu, F.; Wu, B. Effect of Digital Transformation on Enterprises’ Green Innovation: Empirical Evidence from Listed Companies in China. Energy Econ. 2023, 128, 107135. [Google Scholar] [CrossRef]

- Zhou, Y.; Zang, J.; Miao, Z.; Minshall, T. Upgrading Pathways of Intelligent Manufacturing in China: Transitioning across Technological Paradigms. Engineering 2019, 5, 691–701. [Google Scholar] [CrossRef]

- Wei, Z.; Sun, L. How to Leverage Manufacturing Digitalization for Green Process Innovation: An Information Processing Perspective. Ind. Manag. Data Syst. 2021, 121, 1026–1044. [Google Scholar] [CrossRef]

- Aboelmaged, M.G. Predicting E-Readiness at Firm-Level: An Analysis of Technological, Organizational and Environmental (TOE) Effects on e-Maintenance Readiness in Manufacturing Firms. Int. J. Inf. Manag. 2014, 34, 639–651. [Google Scholar] [CrossRef]

- Wu, S.R.; Shirkey, G.; Celik, I.; Shao, C.; Chen, J. A Review on the Adoption of AI, BC, and IoT in Sustainability Research. Sustainability 2022, 14, 7851. [Google Scholar] [CrossRef]

| Dimensions | Measurement Methods |

|---|---|

| Independent Variable: Smart Transformation (ST) | |

| Smart base input | High-tech manufacturing R&D funding |

| Telecommunications Fixed asset investment | |

| Fiber-optic cable line length/provincial area | |

| Number of personnel in information transmission and information technology services | |

| Smart applications | Software business revenue |

| Data processing and operational services revenue | |

| Effective invention patents for high technology manufacturing industry | |

| Smart market benefits | Total profit of high technology manufacturing industry |

| High-tech manufacturing industry main business income/number of employees | |

| Mediating Variable: Regional Innovation Capacity (RIC) | |

| Knowledge innovation capability (KIC) | The total number of ordinary universities and colleges |

| The total number of full-time teachers | |

| Number of scientific research papers | |

| Technological innovation capability (TIC) | Science and technology expenditure |

| Regional scientific and technological cooperation | |

| Technology transfer | |

| Number of total patent grants | |

| Innovative infrastructure (II) | Number of technology-driven industrial clusters |

| Number of internet broadband users | |

| Urban road area | |

| Dependent Variable: Regional Economic Development (RED) | |

| Economic development effectiveness | Total fixed assets investment/regional GDP |

| Labor force employment/regional GDP | |

| Economic sustainability | Consumer price index (CPI) |

| Industrial producer price index (IPPI) | |

| Economic openness | Net FDI inflows |

| Total amount of merchandise trade | |

| Green development | Greening coverage in built-up areas |

| Total wastewater, sulfur dioxide, general industrial solid waste/regional GDP | |

| Total energy consumption/regional GDP | |

| Control Variables | |

| Economic policy uncertainty (EPU) | Economic policy uncertainty index/industrial output value |

| Government subsidies (GSs) | Total spending/government spending to manufacturing industry |

| Manufacturing scale (MS) | The total assets of manufacturing enterprises |

| Social organizations (SOs) | Number of NGOs per capita in each province/region |

| Variables | RED | |||

|---|---|---|---|---|

| (1) | (2) | (3) | (4) | |

| ST | 0.710 *** | 0.435 *** | 0.478 *** | 0.632 *** |

| (24.956) | (4.799) | (4.810) | (20.861) | |

| EPU | 0.211 *** | 0.235 *** | 0.392 *** | |

| (3.800) | (3.760) | (6.893) | ||

| GS | 0.019 * | −0.114 * | −0.042 | |

| (1.942) | (1.823) | (−0.242) | ||

| MS | 0.012 | −0.016 | −0.043 * | |

| (0.531) | (−0.381) | (−1.916) | ||

| SO | 0.012 | −0.006 | −0.004 | |

| (0.646) | (−0.334) | (−1.098) | ||

| Constant | 0.103 *** | 0.028 *** | 0.031 *** | 0.034 ** |

| (31.650) | (7.576) | (3.661) | (2.545) | |

| N | 419 | 419 | 419 | 419 |

| R-squared | 0.716 | 0.605 | 0.685 | 0.765 |

| Province FE | YES | YES | NO | YES |

| Year FE | YES | NO | YES | YES |

| Variables | (1) | (2) | (3) | (4) |

|---|---|---|---|---|

| First-Stage | Second-Stage | First-Stage | Second-Stage | |

| ST | RED | ST | RED | |

| L.ST(IV1) | 0.650 *** | |||

| (19.842) | ||||

| ST | 0.573 *** | |||

| (16.858) | ||||

| IV2 | 0.219 *** | |||

| (2.900) | ||||

| ST | 0.401 ** | |||

| (2.220) | ||||

| Constant | 0.120 *** | 0.035 ** | 0.346 *** | 0.093 *** |

| (34.586) | (2.350) | (16.931) | (4.532) | |

| N | 387 | 387 | 419 | 419 |

| R-squared | 0.524 | 0.596 | 0.947 | 0.524 |

| Province FE | YES | YES | YES | YES |

| Year FE | YES | YES | YES | YES |

| Kleibergen–Paaprk LM statistic | 13.561 *** | 9.276 *** | ||

| Cragg–Donald Wald F-statistic | 103.971 | 16.380 | ||

| Kleibergen–Paaprk Wald F statistic | 393.688 | 19.750 | ||

| RED | ||||||||

|---|---|---|---|---|---|---|---|---|

| (1) | (2) Northeast | (3) North | (4) East | (5) Central | (6) South | (7) Southwest | (8) Northwest | |

| ST | 0.632 *** | 1.084 *** | 0.501 *** | 0.694 *** | 0.355 *** | 0.513 *** | 0.776 *** | 0.863 *** |

| (20.861) | (3.917) | (3.331) | (14.699) | (2.739) | (5.629) | (13.387) | (13.104) | |

| ERU | 0.392 *** | −0.040 | 0.620 *** | 1.317 *** | 1.221 *** | 0.983 *** | 0.261 *** | 0.021 |

| (6.893) | (−0.193) | (3.180) | (8.859) | (7.719) | (2.966) | (4.284) | (0.779) | |

| GS | −0.042 | −3.471 *** | −0.328 | 0.367 ** | −1.056 *** | −7.291 *** | −0.939 | 0.849 ** |

| (−0.242) | (−3.873) | (−0.429) | (2.198) | (−2.916) | (−3.345) | (−0.874) | (2.007) | |

| MS | −0.043 * | −0.101 | 0.001 | 0.188 *** | 0.088 * | −0.011 | 0.023 | 0.028 * |

| (−1.916) | (−1.592) | (0.006) | (3.773) | (1.926) | (−0.091) | (0.574) | (1.975) | |

| SO | −0.004 | −0.039 ** | −0.002 | 0.012 | 0.009 | −0.060 ** | 0.004 | −0.007 *** |

| (−1.098) | (−2.655) | (−0.106) | (0.888) | (0.587) | (−2.068) | (0.547) | (−5.244) | |

| Constant | 0.034 ** | 0.185 *** | 0.011 | −0.072 ** | −0.070 *** | 0.116 * | −0.020 | −0.001 |

| (2.545) | (4.417) | (0.250) | (−2.421) | (−3.336) | (1.697) | (−0.776) | (−0.111) | |

| N | 419 | 44 | 74 | 104 | 45 | 41 | 45 | 65 |

| R-squared | 0.665 | 0.647 | 0.586 | 0.882 | 0.913 | 0.789 | 0.899 | 0.905 |

| Province FE | YES | YES | YES | YES | YES | YES | YES | YES |

| Year FE | YES | YES | YES | YES | YES | YES | YES | YES |

| RED | ||||

|---|---|---|---|---|

| (1) | Textile-Manufacturing Industry | Machinery and Equipment Manufacturing Industry | Resource-Processing Industry | |

| ST | 0.632 *** | 0.975 *** | 0.643 *** | 0.499 *** |

| (20.861) | (9.067) | (10.624) | (11.939) | |

| ERU | 0.392 *** | −0.015 | 0.874 *** | 0.893 *** |

| (6.893) | (−0.259) | (5.966) | (8.119) | |

| GS | −0.042 | −2.258 *** | 0.443 * | −0.453 |

| (−0.242) | (−5.232) | (1.743) | (−1.580) | |

| MS | −0.043 * | −0.044 * | 0.059 | −0.032 |

| (−1.916) | (−1.874) | (1.150) | (−0.629) | |

| SO | −0.004 | −0.007 ** | −0.008 | −0.002 |

| (−1.098) | (−2.296) | (−0.413) | (−0.265) | |

| Constant | 0.034 ** | 0.096 *** | −0.034 | 0.003 |

| (2.545) | (5.720) | (−1.150) | (0.161) | |

| Observations | 419 | 139 | 119 | 161 |

| R−squared | 0.665 | 0.589 | 0.732 | 0.785 |

| Province FE | YES | YES | YES | YES |

| Year FE | YES | YES | YES | YES |

| Variables | (1) | (2) |

|---|---|---|

| RED | RED1 | |

| ST1 | 0.264 *** | |

| (9.513) | ||

| ST | 0.109 *** | |

| (7.408) | ||

| ERU | 0.245 *** | 0.357 *** |

| (7.704) | (12.963) | |

| GS | 0.115 | 0.077 |

| (1.435) | (0.920) | |

| MS | 0.020 * | −0.002 |

| (1.917) | (−0.149) | |

| SO | −0.004 ** | −0.005 *** |

| (−2.368) | (−2.889) | |

| Constant | 0.295 *** | 0.155 *** |

| (17.324) | (24.257) | |

| N | 419 | 419 |

| R-squared | 0.547 | 0.510 |

| Province FE | YES | YES |

| Year FE | YES | YES |

| Mediator | Effect | Observed Coef. | 95% CI | Proportion of Relative Effect | Mediation Results | Result |

|---|---|---|---|---|---|---|

| KIC | Direct effect | 0.539 | [0.885, 1.183] | 85.45% | Partial mediation | H2 supported |

| Indirect effect | 0.092 | [0.067, 0.144] | 14.55% | |||

| TIC | Direct effect | 0.350 | [−0.411, 0.856] | 55.53% | Complete mediation | H3 supported |

| Indirect effect | 0.281 | [0.254, 0.760] | 44.47% | |||

| II | Direct effect | 0.034 | [0.001, 0.122] | 5.36% | Partial mediation | H4 supported |

| Indirect effect | 0.597 | [0.932, 1.244] | 94.64% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Shen, L.; Ullah, F. Linking Manufacturing Smart Transformation to Regional Economic Development in China: The Crucial Mediation of Regional Innovation Capacity. Systems 2025, 13, 389. https://doi.org/10.3390/systems13050389

Liu Y, Shen L, Ullah F. Linking Manufacturing Smart Transformation to Regional Economic Development in China: The Crucial Mediation of Regional Innovation Capacity. Systems. 2025; 13(5):389. https://doi.org/10.3390/systems13050389

Chicago/Turabian StyleLiu, Yue, Lei Shen, and Fawad Ullah. 2025. "Linking Manufacturing Smart Transformation to Regional Economic Development in China: The Crucial Mediation of Regional Innovation Capacity" Systems 13, no. 5: 389. https://doi.org/10.3390/systems13050389

APA StyleLiu, Y., Shen, L., & Ullah, F. (2025). Linking Manufacturing Smart Transformation to Regional Economic Development in China: The Crucial Mediation of Regional Innovation Capacity. Systems, 13(5), 389. https://doi.org/10.3390/systems13050389