1. Introduction

The pharmaceutical industry is widely recognized as a “rapidly expanding” sunrise sector with clear prospects for future development. Demographic aging, rapid urbanization, rising health awareness, and the expansion of disease profiles collectively drive a continuous rise in pharmaceutical demand [

1]. The expansion of China’s pharmaceutical industry is intricately linked to the national economic growth, making it as a vital component of the healthcare system. It is a distinctive sector that blends traditional and modern practices and integrates both secondary and tertiary industries. This dual-role is vital for promoting public welfare and maintaining social stability [

2]. The pharmaceutical sector is essential to public health and has a distinct competitive advantage owing to its significant technological barriers. Its indispensable contribution in protecting and enhancing public health, elevating quality of life, stimulating economic growth, and promoting social advancement is substantial [

3].

Since the reform era, China’s pharmaceutical industry has expanded swiftly, markedly enhancing economic output and emerging as a new growth catalyst. However, recent data suggest emerging headwinds. The Economic Operation Report of the pharmaceutical industry for the first half of 2024 indicates a decline in overall revenues and profits, with approximately one-third of firms reporting growth and about two-thirds experiencing declines. In addition to economic pressures, the pharmaceutical manufacturing sector faces growing environmental and social challenges, including significant pollution and waste that can harm the environment and public health if not properly managed, as well as ongoing concerns over product safety due to the risks posed by counterfeit and substandard medications [

4]. As a result, the pharmaceutical manufacturing bears heightened responsibilities—not only to ensure the continuous supply of essential medicines but also to optimize resource use, enhance customer satisfaction, and mitigate the environmental impact of pharmaceutical waste [

5].

In general, While the long-term outlook for sustainable development in China’s pharmaceutical industry remains promising, its risk-averse nature has resulted in slower advancement compared to other industries [

6,

7]. This lag highlights the urgent need to explore the key drivers of sustainable performance to support the industry’s ecological transformation and long-term growth. Although the pharmaceutical industry faces significant sustainability challenges [

8], its sustainable performance remain largely underexplored in current research [

9,

10,

11,

12].

The pharmaceutical supply chain in China is fragmented, characterized by systemic obstacles in strategy formulation, planning coordination, and demand response among decision-makers, which constrains overall operational efficiency [

13]. The China’s pharmaceutical industry confronts three critical challenges [

14]: (1) overly simplistic business models, (2) lagging online regulatory systems, and (3) insufficient supply chain management capabilities. These deficiencies frequently lead to production disruptions and drug shortages, resulting in economic losses amounting to tens of billions of dollars annually and may threatening the stability of the pharmaceutical industry itself [

15]. Addressing these inefficiencies requires urgent and comprehensive supply chain integration, targeting improvements in strategic coordination, environmental compliance, demand forecasting, and logistics agility. Strengthening these functions will enable pharmaceutical enterprises to build a high-standard, agile, and environmentally sustainable supply platforms [

14].

As the competitive perspective shifts from firm-level to a supply chain-level [

9], enterprises must fully coordinate with their supply chain partners and leverage complementary resources to achieve sustainable development [

8]. This trend is particularly evident in the pharmaceutical industry, where the supply chain is highly complex due to product perishability, stringent regulatory requirements, and the critical importance of accurate demand forecasting [

8,

16]. To efficiently control costs while guaranteeing environmental, economic, and social sustainability, pharmaceutical supply chains are becoming increasingly intricate [

17]. The intricate nature of pharmaceutical supply chains demands more than just internal optimization; it calls for robust collaboration between upstream suppliers and downstream retailers to improve risk resistance and resilience in the face of growing uncertainty [

16,

18]. NRBV addresses this challenge by emphasizing the importance of accessing and integrating external resources that lie beyond a firm’s direct control [

19]. According to NRBV, the diverse resources and unique capabilities that enterprises develop in response to environmental challenges play a critical role in enhancing sustainability. By promoting the synchronization of eco-friendly practices across all supply chain partners, NRBV emphasizes the importance of collective efforts in driving long-term organizational sustainability [

20,

21]. Consequently, overcoming organizational boundaries and proactively pursuing collaboration with supply chain partners to acquire complementary resources has emerged as the principal method for enhancing sustainable performance.

This recognition has drawn increasing attention to collaborative mechanisms in the supply chain, among which GSCI has emerged as a critical strategic response [

22]. GSCI refers to a firm’s ability to coordinate and integrate green practices across internal functions, suppliers, and customers, ensuring the alignment of sustainability goals and promoting efficient resource utilization [

23]. It fosters information sharing, joint problem-solving, and synchronized environmental strategies among supply chain partners, thereby contributing to reduced environmental impacts and improved operational effectiveness. GSCI encompasses a wide array of green practices, including green procurement, green manufacturing, green marketing, and reverse logistics. By improving real-time information sharing and enhancing responsiveness to environmental changes [

24].

Importantly, GSCI entails working with environmentally responsible suppliers and exchanging sustainability-related information to identify environmental hotspots [

25]. In this context, the implementation of GSCI in the pharmaceutical manufacturing enterprises is both essential and urgent [

8,

26]. Nonetheless, research on GSCI within the pharmaceutical industry remain limited, with current studies predominantly addressing the potential risks of green supply chain management and the identification of environmentally sustainable suppliers [

27]. Consequently, it is essential to investigate the extent and mechanisms through which the GSCI influences the sustainable performance of the pharmaceutical industry.

Throughout the years, scholars have widely advocated for the use of GSCI to enhance performance [

27,

28,

29,

30,

31,

32]. GSCI allows enterprises to acquire substantial resources [

29], however, a pile of resources is insufficient for achieving sustainable development in turbulent environments [

33,

34]. To remain competitive requires firms to possess dynamic capability that flexibly reconfigure and redeploy both internal and external resources [

35]. In resource-based theory, capabilities are described as “the capacity to deploy resources” and play a central role in transforming resources into strategic advantage [

36,

37,

38]. Dynamic capabilities represent a critical component of the NRBV. They enable firms to support environmental strategies by guiding the evolution and transformation of existing resources in response to environmental pressures [

39,

40,

41]. These capabilities emphasize organizational agility—the ability to identify and shape emerging opportunities and threats, reconfigure strategic assets, and build competitive resilience [

42].

Among various dynamic capabilities, SCA plays a pivotal role. SCA enhances a firm’s ability to respond quickly and efficiently to market volatility by dynamically coordinating resources and adapting to shifting demand and supply conditions [

43,

44]. It is considered a “seizing” capability that enables firms to rapidly align their operational competencies with dynamic market conditions and environmental objectives [

42,

45]. The competitive advantage that integrates dynamic capabilities is more sustainable than that achieved solely through resource possession [

46,

47].

Thus, when GSCI is successfully transformed into SCA, firms can leverage their foundational supply chain resources to attain superior sustainable performance outcomes. Despite ample evidence indicating a correlation among GSCI, SCA, and sustainable performance [

8,

31,

48,

49,

50], the specific mechanisms through SCA mediates the relationship between GSCI and sustainable performance remain insufficiently explored.

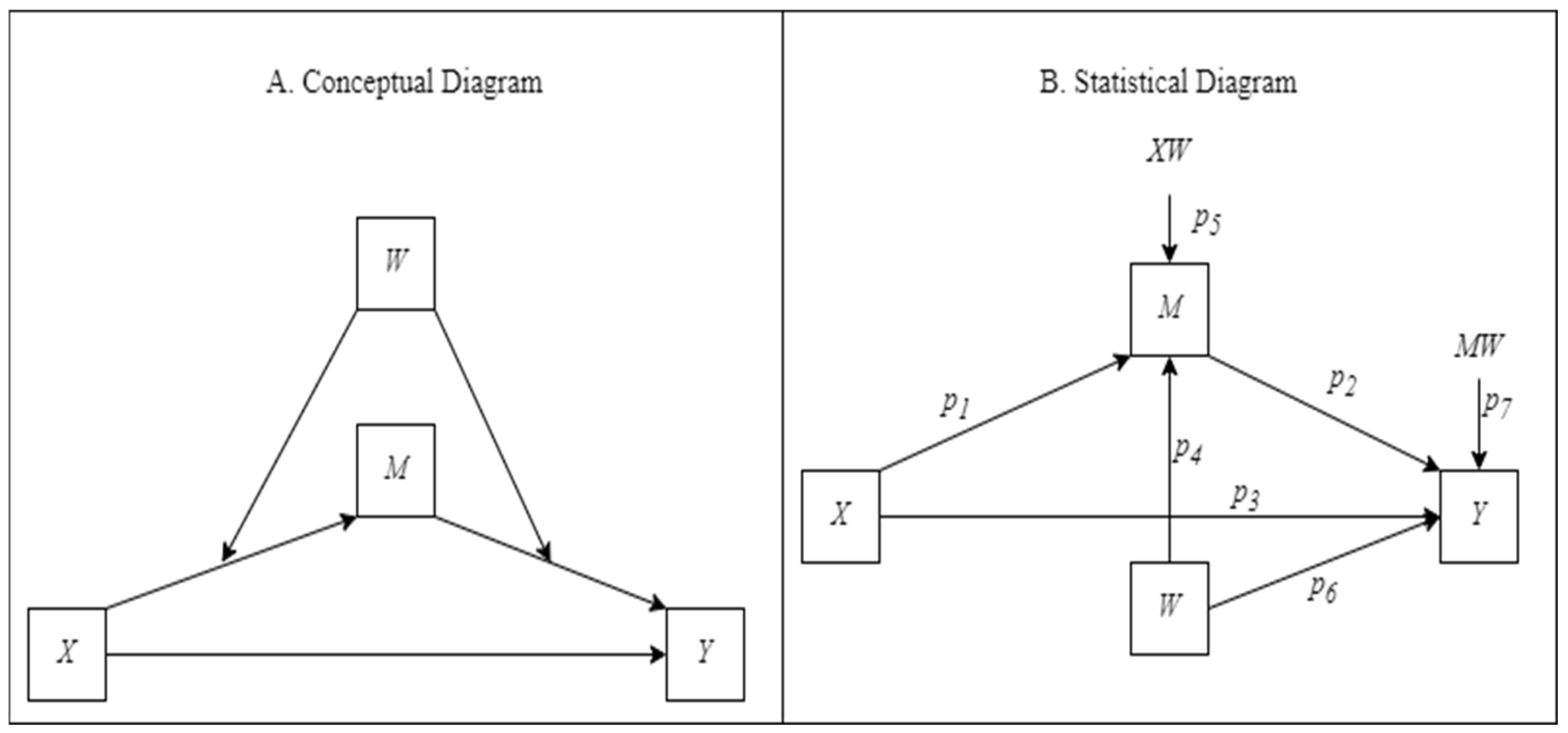

Incorporating both mediating and moderating variables inside the same model can yield a more thorough and robust explanation of the interactions present in the model [

51,

52,

53]. Moderated mediation analysis elucidates how independent variables’ direct and indirect effects on dependent variables (mediation) depend on the moderating variables [

54]. CT suggests that organizational outcomes depend on external contingencies that influence how resources and capabilities translate into performance [

55]. Although extensive research has indicated a positive relationship between GSCI and SCA, the strength of this relationship varies significantly across different contexts [

31,

35,

56,

57,

58]. Similarly, the relationship between SCA and sustainable performance is not consistently significant [

59,

60,

61]. Thus, from both theoretical and empirical perspectives, the relationships between GSCI and SCA, as well as between SCA and sustainable performance, appear to be unstable and are shaped by contextual moderating factors.

DO, as a strategic posture, reflects an organization’s recognition of the value of digital technologies and its overarching commitment to digital transformation. It governs which digital activities are pursued, how these activities are integrated, and how digital resources are allocated across the organization [

62]. Over time, DO shapes how firms deploy resources, thereby contributing to the development of digital capabilities [

63]. Digital technologies enhances information processing by enabling real-time connectivity and seamless data exchange within organizations and across supply chain partners [

12]. This improves information processing capacity and promotes coordination and responsiveness. Moreover, DO helps overcome information silos by enabling firms to accumulate and integrate green knowledge and technology resources. It facilitates the real-time coordination of operations, allowing firms to make timely decisions and reconfigure resources efficiently—key components of SCA [

64]. Firms with strong DO streamline operations and boost process efficiency through digital technologies, enabling faster and more adaptive responses to market changes, boosting agility [

49,

65]. Leveraging diverse data sources further improves resource efficiency and accelerates the achievement of sustainable growth [

66]. Despite the critical role of DO, limited research has explored its moderating effect on the pathway from GSCI to sustainable performance.

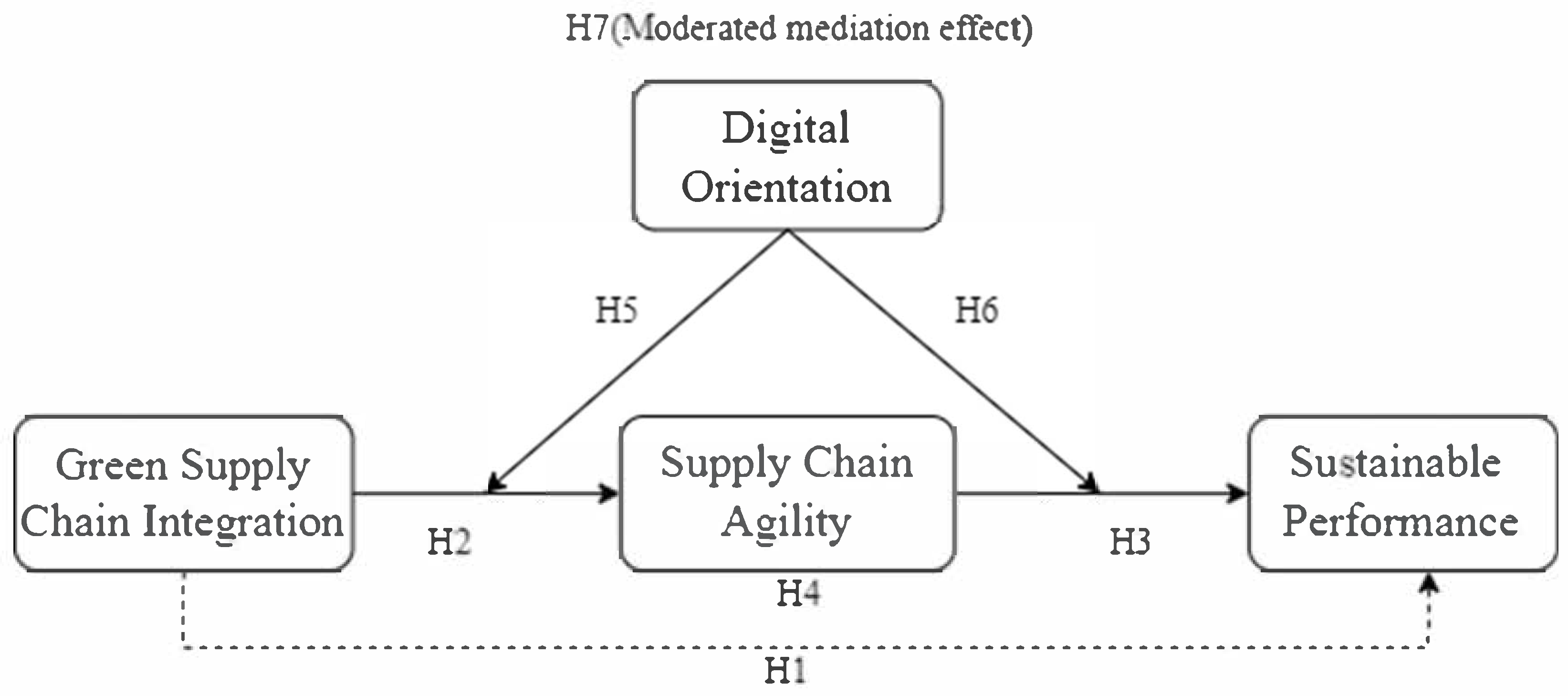

This study, based on NRBV and CT, investigates the mechanisms through which GSCI affects sustainable performance, and how DO shapes this relationship to fill the existing research gap. Specifically, the study has three objectives: (1) Evaluate whether SCA mediates the relationship between GSCI and sustainable performance; (2) Examine whether DO moderates the relationship between GSCI and SCA, as well as between SCA and sustainable performance; and (3) Assess whether DO moderates the mediating effect of SCA. This study elucidates the influence of GSCI on sustainable performance and its implementation trajectory, while also highlighting DO as a contingent factor in the digitalization context.

5. Discussion

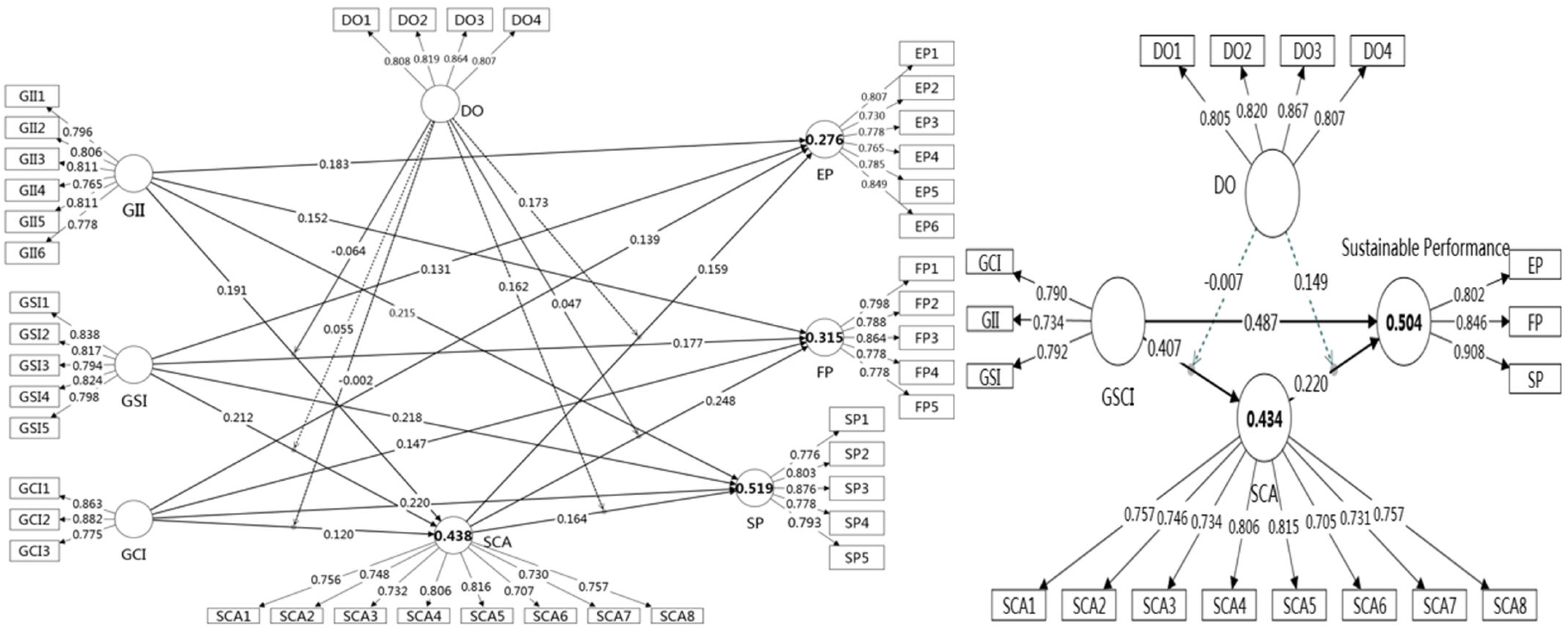

This study explores the relationships between GSCI, SCA, DO, and sustainable performance. The results of hypothesis testing yield several key findings that offer both theoretical insights and practical implications for enterprises seeking to enhance sustainable performance in a digitalized environment.

In alignment with prior research findings, both hypothesis H1, H2 and hypothesis H3 were supported [

31,

59]. These findings indicate that the supply chain collaboration network built by GSCI enable firms to access critical resources and strengthen communication among supply chain partners and augmenting SCA. SCA is a crucial prerequisite for organizations to effectively adopt sustainable performance. Hypothesis H4 was also supported, which further verifies NRBV; that is, the combination of valuable resources and dynamic capabilities helps to build competitive advantages and thus improve sustainable performance.

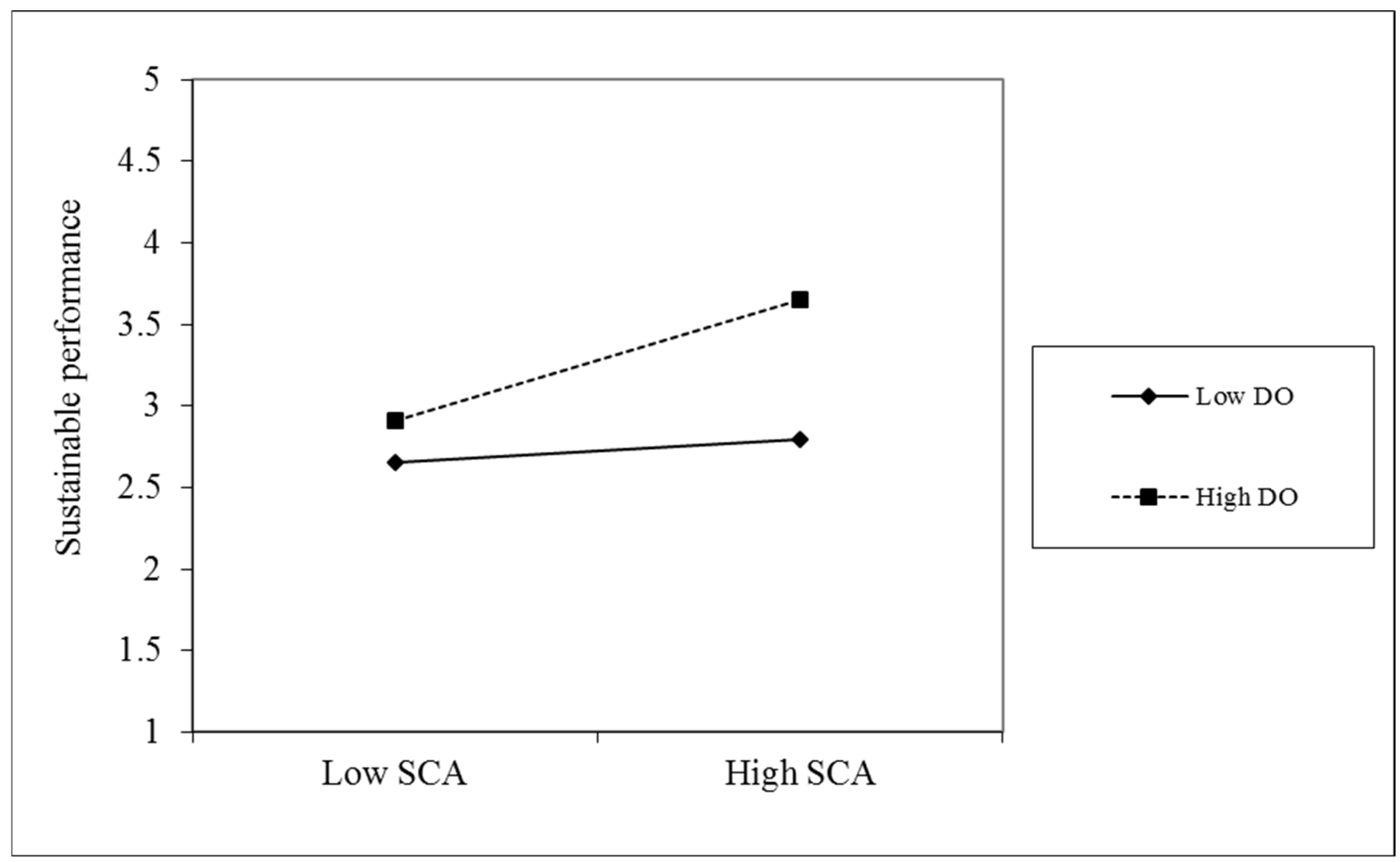

However, hypothesis H5 was not supported, which means that DO does not enhance the effect of GSCI on SCA. There may be the following reasons: (1) DO may require supportive infrastructure and an enabling organizational culture to be effectively implemented; (2) The implementation of GSCI may already rely on standardized protocols and relational trust with partners, which may not necessarily require digital capabilities to improve agility [

67,

68]; (3) The integration of GSCI with digitalization might lead to a high degree of interdependence among supply chain partners, potentially diminishing their individual autonomy and reducing their agility in responding to market dynamics and unforeseen disruptions. Finally, hypotheses H6 and H7 were supported, indicating that enterprises can significantly improve their sustainable performance when DO is combined with SCA.

Furthermore, the PLSpredict results indicate that the model demonstrates strong predictive power. This is further supported by the Q2 values and lower RMSE, confirming the model’s high predictive relevance and empirical applicability. The strong predictive performance not only highlights the model’s practical utility but also suggests the robustness and contextual validity of the theoretical relationships among constructs. These findings enhance the model’s credibility and reinforce its value for both theoretical exploration and real-world application.

5.1. Theoretical Implications

Firstly, the study extends NRBV by demonstrating that GSCI, while representing a valuable and rare organizational practice, must be complemented by dynamic capabilities such as SCA to achieve sustainable performance. This finding responds to recent calls to move beyond the static treatment of resources in NRBV, emphasizing the critical role of resource reconfiguration and dynamic capabilities in realizing the value of green resources for achieving competitive advantage. By empirically validating the mediating role of SCA between GSCI and sustainable performance, this research refines the resource–capability–performance logic and enriches our processual understanding of NRBV.

Secondly, this study advances CT by introducing DO as a critical boundary condition. The moderated and moderated mediation findings demonstrate that the effectiveness of GSCI and SCA depends not only on internal alignment but also on contextual fit with digital strategies. This reflects CT’s principle that organizational success is contingent upon the match between internal systems and external environmental conditions. DO is not merely a technological variable, but a strategic and cultural orientation that shapes how resources and capabilities interact to produce sustainable performance. Finally, this study employed the PLSpredict procedure to systematically assess the model’s predictive performance, offering a valuable perspective that bridges theoretical explanation and practical application in structural equation modeling. From a theoretical perspective, the strong predictive power observed confirms the robustness, stability, and internal consistency of the proposed structural model in explaining the relationships between GSCI, SCA, DO, and sustainable performance. Moreover, the high level of predictive accuracy reinforces the theoretical validity of the resource–capability–performance logic, while also suggesting potential avenues for future research—such as integrating additional constructs or refining measurement dimensions to further enhance generalizability. These findings provide a solid foundation for future research on the synergy between GSCI and dynamic capabilities and support the continued development of the resource–capability–performance logic under the NRBV and CT frameworks.

5.2. Managerial Implications

First, pharmaceutical industry leaders should recognize the strategic value of GSCI. Pharmaceutical manufacturers should dismantle interdepartmental barriers, enhance internal integration, and optimize products and processes through information sharing and collaborative decision-making. As the core of supply chain, pharmaceutical enterprises should integrate supplier and customer resources to boost production planning accuracy, accelerate delivery, and reduce costs. Customer integration enables rapid responses to market demand and enhances service quality. Additionally, supply chain partners serve as valuable sources of innovation knowledge. Leveraging such knowledge can shorten product development cycles, boost responsiveness, and contribute to sustainable development.

Second, the study indicates that GSCI fosters SCA and can drive sustainable performance through SCA. Enterprises must strengthen their ability to respond and adapt to environmental changes, market volatility, and unexpected disruptions. To support agility, enterprises must reinforce information-sharing and collaboration with supply chain partners, especially within GSCI framework. Enterprises should encourage cross-organizational information transparency to reduce resource waste from information delays. Agility also depends on rapid decision-making and internal collaboration capabilities. Enterprises should establish flexible processes and cross-functional collaboration to support SCA. For instance, embedding green supply chain sustainability goals into departmental assessments can promote coordinated efforts in eco-friendly production across departments.

Third, since DO can enhance both the impact of SCA on sustainable performance and the mediating role of SCA, pharmaceutical enterprises should establish a clear digital strategy that defines digitalization’s role in future development with long-term goals and key outcomes. This strategy should be embedded across the entire value chain—from R&D and production to supply chain management and marketing. For instance, integrating b enterprise-wide data systems can eliminate data silos and improve data utilization. Enterprises should also build professional digital teams by training and recruiting talents with expertise in digital technology and data analytics.

Finally, while implementing GSCI through digital technologies, enterprises need to be mindful of potential dependency risks. Over-reliance on or improper use of a certain technology or platform may limit the flexibility of supply chain partners and weaken their ability to respond quickly to market demand. Enterprises can use distributed systems and blockchain technologies for managing and storing supply chain data, enhancing both transparency and data security. Enterprises can also help supply chain partners improve their digital capabilities through training and technical support to independently manage digital systems and reduce t reliance on core enterprises. Enterprises can further formulate standardization of digital systems in the supply chain to ensure compatibility, allowing partners to flexibly adopt compliant technologies without being locked into a specific vendor or platform.

To support managerial application of the study’s findings, a concise roadmap (

Figure 5) is proposed to guide pharmaceutical firms in enhancing GSCI, SCA, and DO for sustainable performance.