A Sector-Specific Digital Maturity Model for Inland Waterway Transport

Abstract

1. Introduction

- Customer Area: manages orders and cargo handling;

- System Management and Compliance: covers documentation and regulatory processes;

- Ship Maintenance: focuses on moving from reactive to predictive maintenance;

- Operational Management: enhances navigation and communication for safer and more efficient operations.

- Developing a framework for a new digital maturity assessment model dedicated to IWT;

- Definition of a 5-degree maturity assessment scale for the formulated assessment criteria;

- Characterization of selected IWT systems in terms of ongoing digital transformation processes;

- Assessment of the studied systems’ digital maturity levels using the proposed digital maturity assessment model;

- Comparative analysis of the two inland navigation systems.

2. Theoretical Background

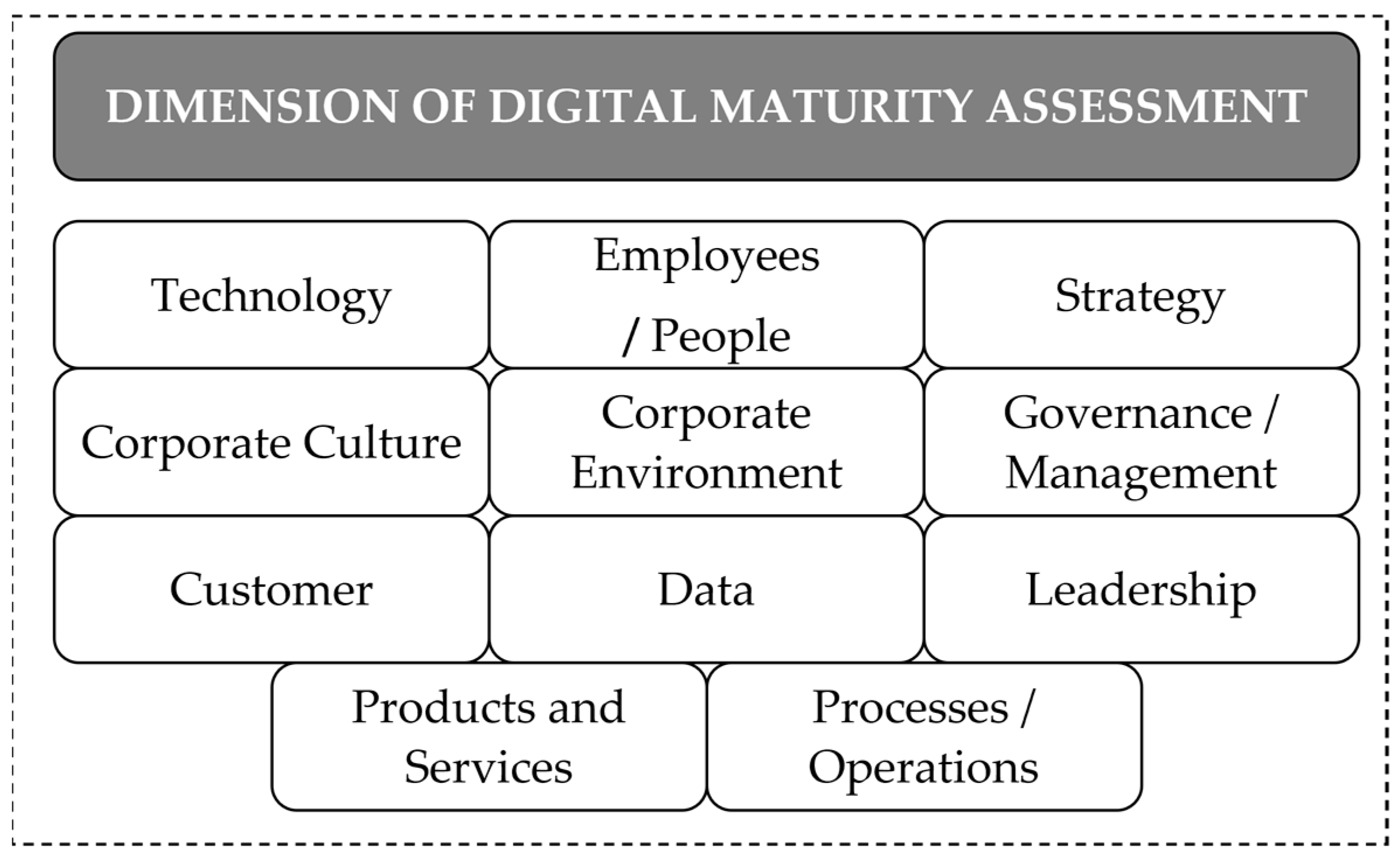

- The frameworks of the DMMs created are based on the same principles or similar to those used in CMMI (Capability Maturity Model Integration);

- The DMM framework defines the areas to be assessed, which are then characterized by graded maturity levels;

- The assessment is carried out according to the defined areas, which can be further extended into sub-areas within the model;

- The assessment levels are arranged logically—from lowest to highest—and each level is assigned its name and the requirements that the organization must meet to achieve it;

- In some models, the assessment can be expressed quantitatively as a maturity index.

- Dimensions must describe specific areas of capability of the facility being assessed in different aspects. The dimensions must be simple yet comprehensive;

- The maturity status of an object is usually assessed on a 5- or 4-point scale;

- Maturity principles may require a continuous maturity model (an object’s rating is the average of the scores obtained in the different dimensions—the possibility of achieving different levels of maturity in each dimension) or a staged model (moving to a higher level of maturity requires full compliance with the requirements of the previous stage in all dimensions).

- Assessing the use of the potential of digital transformation in improving maritime transport safety [26];

- Improving organizational intelligence in ship management companies [27];

- Assessing digital maturity in the shipping industry [28];

- Assessing the readiness to implement blockchain technology in maritime logistics [34].

3. Methodology

- Q1: What influences the efficient and effective handling of cargo transported by a river carrier?;

- Q2: Which areas of the inland waterway system determine the transport service level offered to the customer?;

- Q3: Which areas of cooperation between shipping companies and authorities are required for efficient freight handling?;

- Q4: What information do shipping companies need regarding the condition of their transport fleet to implement effective maintenance strategies?;

- Q5: What information is needed during freight operations?;

- Q6: Are the areas and information needs defined within the answers to Q2–Q5 currently being digitized, and how?;

- Q7: How should digital transformation occur in the highlighted areas from a baseline level (no digital transformation in the system) to advanced digital transformation using the latest technological developments?;

- Q8: Is the assessment model built to meet the needs of real systems?

- Customer Service Area (Order and Cargo Handling)The first parameter group includes customer order handling (communication and document exchange) and cargo handling (identification, tracking, and information on delivery time).This area focuses on how customer orders and cargo handling processes are managed. It includes communication channels, order tracking, and integration with digital systems such as websites, mobile apps, and customer relationship management (CRM) tools.Initially, processes rely on manual communication and paper documentation. Over time, digital tools such as web platforms, CRM systems, and RFID improve efficiency. At the highest level, automation, AI, and IoT-based tracking enable real-time, fully integrated customer service.

- System Management and Regulatory ComplianceThe second parameter group includes system administration culture, focused on digitalization, monitoring compliance with regulations (via waterway and inland navigation administrations), and data on ship traffic monitoring.This area focuses on document management, regulatory compliance, and cooperation between shipping companies and authorities. It ensures that vessels meet the legal and operational requirements.It starts with informal, paper-based documentation and slow communication. Gradually, digital records, standardized procedures, and online platforms improve efficiency. Ultimately, AI-driven compliance, automated reporting, and real-time vessel tracking streamline regulatory oversights.

- Operational Ship MaintenanceThe third parameter group includes the conditions of the engine, operating fluids, and component monitoring, as well as monitoring the times between repairs, fire safety systems, and ship loading systems.This area involves ship maintenance strategies, including inspections, repairs, and preventive measures to ensure operational reliability.Initially, maintenance is reactive, based on manual records and damage-driven repairs. Over time, structured inspections, IT-based monitoring, and predictive analytics are introduced. The most advanced stage integrates AI, real-time sensor data, and automated diagnostics for proactive maintenance.

- Operational Process ManagementThe fourth parameter group includes used navigation, communication with administration, and cargo handling services.This area addresses the navigation and communication systems used in shipping operations. It includes navigation tools, the integration of digital communication with authorities, and the automation of information exchange. The implementation of real-time data processing, traffic management systems, and AI-driven tools enhances operational safety and efficiency.It begins with basic navigation tools and manual communication and progresses with the integration of radar, AIS, ECDIS, and mobile applications. At the highest level, fully automated data exchange, AI-assisted navigation, and predictive decision-making optimize operational efficiency.

4. Model Validation

4.1. Case Study—Inland Navigation on the Oder

- ▪

- The upper free-flowing Oder from Racibórz to Koźle—Class Ia waterway;

- ▪

- The upper canalized Oder from Koźle to Malczyce (Class III waterway), including the Gliwice Canal (Class III waterway) and the Kędzierzyn Canal (Class II waterway), which extend the navigable route to Gliwice;

- ▪

- The regulated middle section of the Oder from Malczyce to the confluence with the Warta River (Class II waterway);

- ▪

- The regulated lower Oder from the confluence with the Warta River to Lake Dąbie (Class III waterway from the Warta to Ognica, and Class Vb waterway thereafter).

- ▪

- At km 98.1, the Oder connects with the Gliwice Canal, which extends the Oder Waterway by 41.2 km toward Upper Silesia;

- ▪

- At km 553.4, the Oder connects with the Oder–Spree Canal, one of three routes linking Poland with Western Europe’s waterways. The Oder–Spree Canal connects Eisenhüttenstadt with Berlin;

- ▪

- At km 617.6, the Warta River joins the Oder, opening a route to Eastern Europe and serving as part of the European waterway E-70. From this point, it is possible to navigate to any inland destination in Poland;

- ▪

- The lower section of the Oder connects with the Oder–Havel Canal at km 667.0 (Hohensaaten) and via the Schwedt Canal at km 697.0 (Ognica), with the Hohensaaten-Friedrichsthal Waterway (HFW). These routes, through the Niederfinow ship lift (km 78 of the Oder–Havel Canal), link Poland’s inland waterway system with Germany’s.

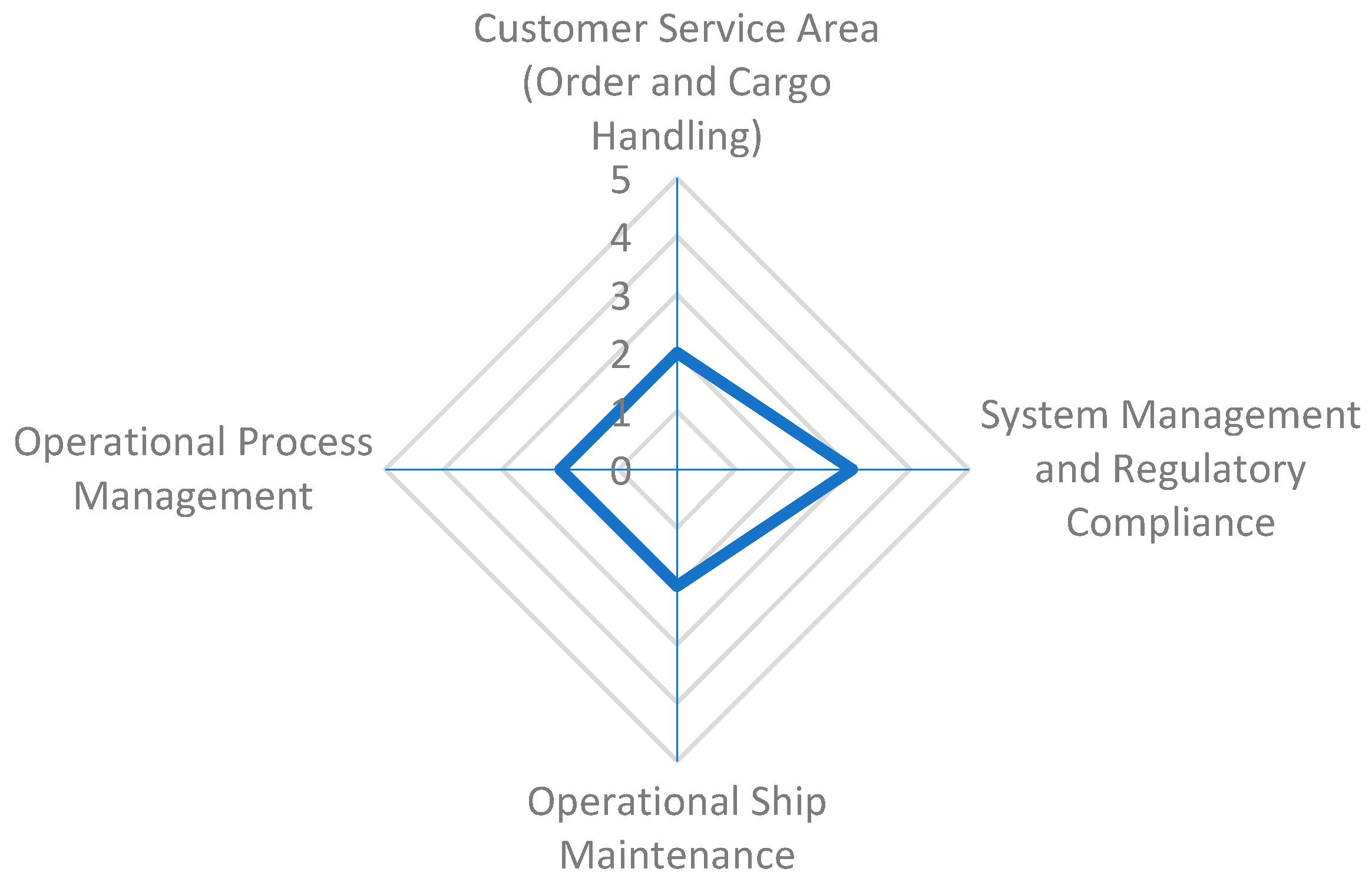

- Customer Service Area (Order and Cargo Handling)—IIBasic communication technologies, such as email and telephone, are used to communicate with the customer, supporting the exchange of current information initiated by the customer. Paper document circulation is regulated by using standard templates and specific paths of their flow in the organization. Customer service is carried out by a dedicated employee who monitors the execution of orders and informs customers using basic communication channels. The company uses basic communication technologies, has standardized documents, and employs dedicated people who deal with marketing, forwarding, and logistics.

- System Management and Regulatory Compliance—IIIDigital documentation is standard, with paper versions required only for specific certified documents. The company fully utilizes the possibilities of digital signature and document transmission. It is a member of the Association of Polish Inland Shipowners and actively participates in meetings with the waterway and shipping administration to improve safety. Inspections follow central procedures and utilize the electronic Ship Database for vessel and crew records. Data on ship traffic is recorded using IT tools in accordance with the central guidelines, and the administration provides digital waterway maps with international parameters. Ships use RISs and the AIS, as well as the national WIR system, which allows for route planning, access to navigation maps, and verification of the possibility of passing through limiting places.

- Operational Ship Maintenance—IIFluids and components are replaced in accordance with the company’s internal standards, which go beyond the manufacturer’s standards. Data on the operation of vessels are recorded in paper form according to a uniform standard. Repairs are carried out mainly in the event of failures, and general repairs of vessels are carried out during cyclical class surveys every five years. The company has a technical department that is responsible for the supply of vessels and monitoring of surveys. In terms of safety systems, vessels are equipped with basic fire protection equipment and additional smoke and carbon monoxide detectors. Alarm systems are partially automated. The loading and stowing of cargo is carried out according to established procedures supervised by the captain. The company does not have a loading support system—planning is carried out in the transport department, and the crew supervises the process.

- Navigation and Communication—IIRadar, the AIS, and ECDIS are used based on captains’ preferences and experience. Navigation maps are operated on computers. The AIS is also used to monitor the positions of their own vessels. Communication with the administration, lock, port, and transhipment staff is mainly carried out via mobile phone and VHF radio. Email is used less frequently. The WIR system allows for ticket purchase and access to lock contact details, but does not offer additional communication functions. Thanks to the RISs and WIR systems, units have access to dedicated navigation applications that allow for route planning and the verification of waterway parameters in relation to the ship’s specifications.

4.2. Case Study—Inland Navigation on the Rhine

- ▪

- High Rhine (Hochrhein): From Lake Constance to Basel, characterized by a fast current, numerous rapids, and weirs and regulated by weirs and canals. This section is primarily used for tourism. The Rhine is navigable from approximately 47 km downstream of the Rhine Falls to km 160, near Basel. However, freight navigation is not conducted in this section;

- ▪

- Upper Rhine (Oberrhein): From km 161 (Basel) to km 528 (Bingen/Rüdesheim am Rhein), classified as a Class VIb waterway. This section is regulated, with numerous ports and industrial centres, and experiences heavy navigation traffic;

- ▪

- Middle Rhine (Mittelrhein): From km 528 (Bingen/Rüdesheim) to km 694 (Cologne), also classified as a Class VIb waterway. This section is known for its picturesque landscape, with numerous castles and vineyards, and is an important tourist route;

- ▪

- Lower Rhine (Niederrhein): From km 695 (Cologne) to the river’s mouth in the North Sea, classified as a Class VIc waterway. This section features a wide riverbed, numerous ports and industrial centres, heavy navigation traffic, and an extensive river delta.

- ▪

- Km 296—Strasbourg: Connection with the French canal network, including the Rhine–Rhône Canal and the Rhine–Marne Canal;

- ▪

- Km 428.2—Mannheim: Connection with the Neckar River;

- ▪

- Km 496.3—Mainz: Connection with the Rhine–Main–Danube Canal, linking the Rhine with the Danube and creating a waterway connecting the North Sea with the Black Sea;

- ▪

- Km 586—Nieder-Lahnstein: Connection with the Lahn River;

- ▪

- Km 592—Koblenz: Connection with the Moselle River;

- ▪

- Rhine–Rhône Canal: Links the Rhine with the Rhône, enabling the transport of goods to southern France and the Mediterranean Sea;

- ▪

- Km 780.2—Duisburg: Connection with the Rhine–Herne Canal;

- ▪

- Km 813.2—Wesel: Connection with the Wesel–Datteln Canal;

- ▪

- Both of the above canals connect with the Dortmund–Ems Canal, which links the Rhine with the Ruhr region and ports on the North Sea. Through the Mittelland Canal, they also connect to Hamburg, Berlin, and Eastern Europe, including Poland;

- ▪

- Numerous canals in the Netherlands and Belgium: These enable the transport of goods to various regions of Western Europe.

- ▪

- German federal authorities (Wasserstraßen- und Schifffahrtsverwaltung des Bundes—WSV): Responsible for maintaining and developing waterways, navigation marking, and managing hydrotechnical infrastructure in Germany;

- ▪

- French services (Voies navigables de France—VNF): Responsible for the administration of waterways in France;

- ▪

- Dutch services (Rijkswaterstaat): Responsible for the administration of waterways in the Netherlands;

- ▪

- Swiss services (Bundesamt für Verkehr—BAV): Responsible for the administration of waterways in Switzerland.

- ▪

- RISs (River Information Services): A river information system that includes electronic navigational charts, electronic vessel reporting, Notices to Skippers, and vessel traffic management systems;

- ▪

- AIS (Automatic Identification System): A system for the automatic identification of vessels, enabling the exchange of data about the vessel, its position, course, and speed;

- ▪

- Inland ECDIS (Electronic Chart Display and Information System): An Electronic Chart Display and Information System that allows for safe and precise navigation.

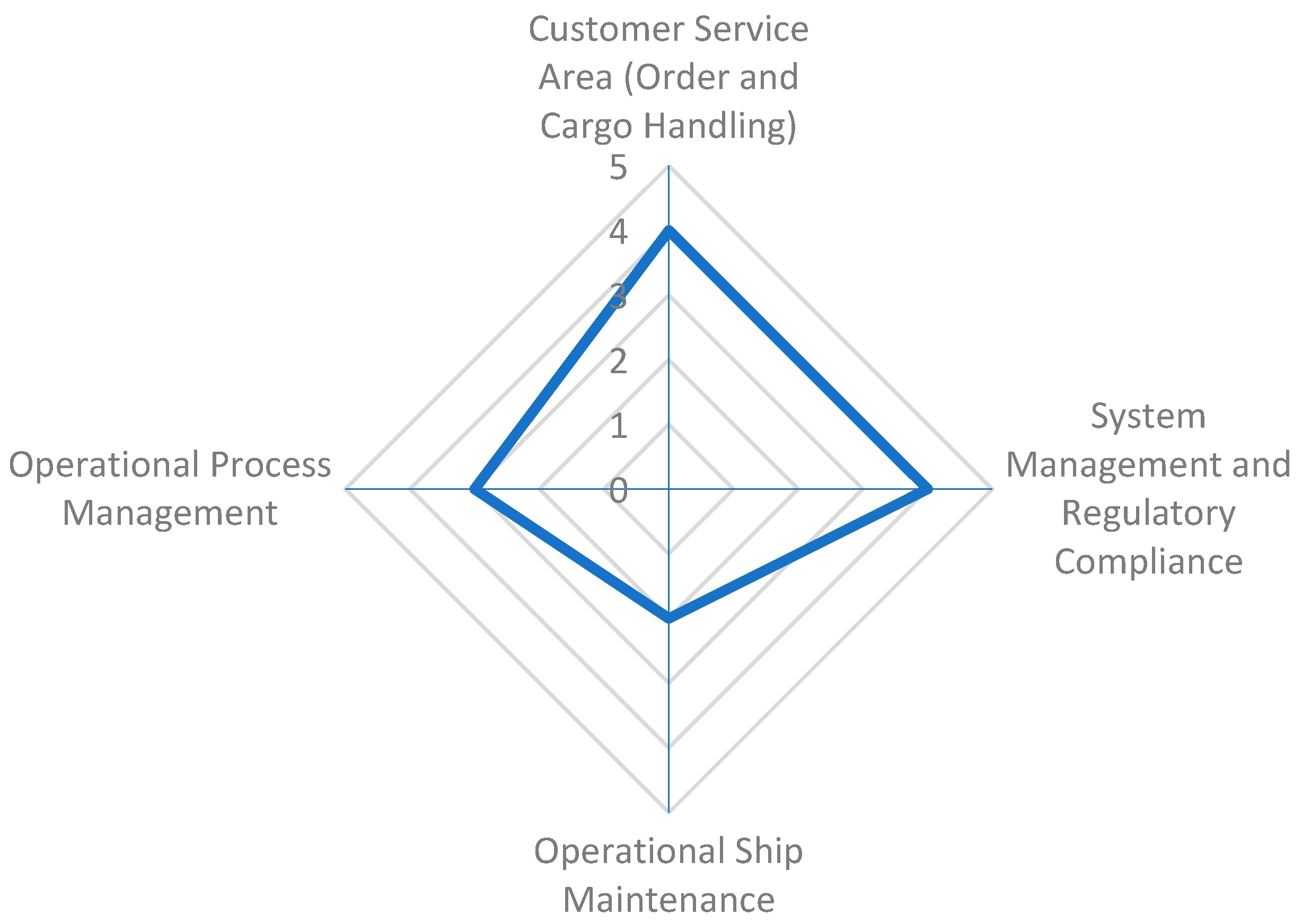

- Customer Service Area (Order and Cargo Handling)—IVCustomer orders are accepted via a dedicated web and mobile application, which allows for the personalization of the profile and efficient order management. The application is integrated with the CRM system, which improves the analysis of customer data and communication, both traditional and electronic. The cargo handled is identified and monitored using RFID technology, and information on the stage of order fulfilment is available to customers in real time. Additionally, the shipowner uses the ISS system, which allows for the exchange of information between the customer, the shipowner and the ship.

- System Management and Regulatory Compliance—IVThe administration operates on the basis of electronic document circulation and digital platforms, which allow process participants to independently handle selected operations, such as the transport and transhipment of dangerous goods. The service model is based on open access to information and the flexible responses of the administration to the needs of digitalization. Vessel inspections are carried out using a mobile application that provides access to the inspection history and current inspection results. In Germany, information about inspections is entered into a central system, and inspections are carried out regularly—on average every three months by the police and every six months as part of EBIS Check, run by classification societies. Vessel traffic is monitored via RISs and AIS systems, which cover all cargo and passenger vessels. The reporting obligation applies to all vessels, and the administration provides digital waterway maps with at least class III parameters.

- Operational Ship Maintenance—IIThe ship maintenance strategy is based on planned inspections and maintenance, supported by quantitative analyses. The ship is equipped with an ISS system, which monitors the operating hours and automatically calculates the dates for the next technical inspections and filter and oil changes. The ship’s crew regularly completes the data in the system, drawing up weekly checklists and monthly inspections of alarm and safety systems. Additionally, the ISS system stores all ship certificates in electronic form and automatically sets reminders about their approaching expiry date. In terms of fire protection systems, the vessel is equipped with a central computer with a touch screen that displays safety alarms. Additionally, there is an independent gas detection system that allows the captain to determine the location of the threat, but that does not send automatic notifications—the captain must do this manually using the AIS or VHF radio. The process of loading and stowing cargo is supervised using two separate systems: one to calculate the ship’s load plan and stability and the other to monitor the loading, including the level, temperature, and cargo flow.

- Navigation and Communication—IIIThe vessel is navigated using integrated tools such as radar, the AIS, ECDIS, and a steering assistance system (autopilot). The vessel uses current Navigo PC software for route planning and Radar pilot with a combination of radar and ECDIS Periskal, as well as the Argonics Track pilot and Titan 500 systems, which allow the vessel to automatically be guided along a designated line on the river. Communication with the administration is mainly via the BICS system, which integrates with the RISs, but at locks and administrative boundaries, reporting presence via VHF radio is still required. The unit mainly uses websites and emails to obtain navigation information and administrative messages. The ISS application provides information on water levels, while navigation messages regarding route closures can be downloaded in PC Navigo, but the system does not automatically notify about new messages. In the event of an emergency, reports are transmitted via VHF radio on the administration channel.

| Characteristic | Rhine-based Company | Oder-based Company |

| Year of establishment | 1994 | 1995 |

| Ownership structure | Family-managed | Family-managed |

| Number of employees | 75 | 50 |

| Main operational area | Rhine, Moselle, Elbe, and connecting canals | Oder Waterway, Mittelland Canal, and the Elbe |

| Geographic scope | International (Germany, Netherlands, France, and Switzerland) | International (Poland, Germany, and Czechia) |

| Fleet size | Over 30 vessels | Over 20 vessels |

| Vessel types | Mixed fleet (tanker, bulk cargo, and specialized vessels) | Mixed fleet (bulk cargo, pontoons, and pushed barges) |

| Cargo specialization | Bulk materials, chemicals, and hazardous goods | Bulk materials and oversized cargo |

| Navigation system | Integrated tools (radar, AIS, ECDIS, and autopilot) | Basic tools (phone, AIS, and radar) |

| Maintenance approach | Planned inspections with ISS system support | Reactive maintenance |

| Customer interface | Web and mobile applications and CRM integration | Basic communication tools (email and phone) |

| Environmental technology | Hybrid-powered vessels and fuel optimization systems | Not specified |

| Main waterway class | Class VIb-VIc (Rhine) | Class Ia-Vb (Oder) |

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Modal Split of Inland Freight Transport. Available online: https://ec.europa.eu/eurostat/databrowser/view/TRAN_HV_FRMOD/default/table?lang=en (accessed on 20 January 2025).

- Plotnikova, E.; Vienažindienė, M.; Slavinskas, S. Development of Inland Waterway Transport as a Key to Ensure Sustainability: A Case Study of Lithuania. Sustainability 2022, 14, 10532. [Google Scholar] [CrossRef]

- Huang, X.; Wen, Y.; Zhang, F.; Sui, Z.; Cheng, X. A Comprehensive Risk Assessment Framework for Inland Waterway Transportation of Dangerous Goods. J. Mar. Sci. Eng. 2021, 9, 858. [Google Scholar] [CrossRef]

- Kotowska, I.; Mańkowska, M.; Pluciński, M. Planning the Development of Inland Shipping in the Seaport-Hinterland Transport: A Case Study of the Oder River in Poland. Sci. J. Marit. Univ. Szczec. 2019, 58, 84–92. [Google Scholar]

- Thordsen, T.; Murawski, M.; Bick, M. How to Measure Digitalization? A Critical Evaluation of Digital Maturity Models. In Responsible Design, Implementation and Use of Information and Communication Technology–I3E 2020–Lecture Notes in Computer Science; Hattingh, M., Matthee, M., Smuts, H., Pappas, I., Dwivedi, Y., Mäntymäki, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; Volume 12066, pp. 358–369. [Google Scholar]

- Perera, S.; Jin, X.; Das, P.; Gunasekara, K.; Samaratunga, M. A Strategic Framework for Digital Maturity of Design and Construction through a Systematic Review and Application. J. Ind. Inf. Integr. 2023, 31, 100413. [Google Scholar] [CrossRef]

- Antony, J.; Sony, M.; McDermott, O. Conceptualizing Industry 4.0 Readiness Model Dimensions: An Exploratory Sequential Mixed-Method Study. TQM J. 2023, 35, 577–596. [Google Scholar] [CrossRef]

- Haryanti, T.; Rakhmawati, N.A.; Subriadi, A.P. The Extended Digital Maturity Model. Big Data Cogn. Comput. 2023, 7, 17. [Google Scholar] [CrossRef]

- Schumacher, A.; Erol, S.; Sihn, W. A Maturity Model for Assessing Industry 4.0 Readiness and Maturity of Manufacturing Enterprises. Procedia CIRP 2016, 52, 161–166. [Google Scholar] [CrossRef]

- Ehie, I.; Ferreira, L.M.D.F. Conceptual Development of Supply Chain Digitalization Framework. IFAC-PapersOnLine 2019, 52, 2338–2342. [Google Scholar] [CrossRef]

- Ho, W.R.; Tsolakis, N.; Dawes, T.; Dora, M.; Kumar, M. A Digital Strategy Development Framework for Supply Chains. IEEE Trans. Eng. Manag. 2022, 70, 2493–2506. [Google Scholar] [CrossRef]

- Klötzer, C.; Pflaum, A. Toward the Development of a Maturity Model for Digitalization within the Manufacturing Industry’s Supply Chain. In Proceedings of the Hawaii International Conference on System Sciences, Hilton Waikoloa Village, HI, USA, 4–7 January 2017. [Google Scholar]

- Skupień, E.T. The Maturity Model as a Tool for Assessing Transportation Systems on the Example of Inland Navigation. Sustainability 2025, 17, 1577. [Google Scholar] [CrossRef]

- Zoubek, M.; Simon, M. Evaluation of the Level and Readiness of Internal Logistics for Industry 4.0 in Industrial Companies. Appl. Sci. 2021, 11, 6130. [Google Scholar] [CrossRef]

- Oleśków-Szłapka, J.; Stachowiak, A. The Framework of Logistics 4.0 Maturity Model. In Intelligent Systems in Production Engineering and Maintenance–ISPEM 2018; Burduk, A., Chlebus, E., Nowakowski, T., Tubis, A., Eds.; Advances in Intelligent Systems and Computing; Springer: Berlin/Heidelberg, Germany, 2019; Volume 835, pp. 771–781. [Google Scholar]

- Facchini, F.; Oleśków-Szłapka, J.; Ranieri, L.; Urbinati, A. A Maturity Model for Logistics 4.0: An Empirical Analysis and a Roadmap for Future Research. Sustainability 2019, 12, 86. [Google Scholar] [CrossRef]

- Comuzzi, M.; Patel, A. How Organisations Leverage Big Data: A Maturity Model. Ind. Manag. Data Syst. 2016, 116, 1468–1492. [Google Scholar] [CrossRef]

- Proença, D.; Borbinha, J. Maturity Models for Information Systems—A State of the Art. Procedia Comput. Sci. 2016, 100, 1042–1049. [Google Scholar] [CrossRef]

- Tubis, A.A.; Koliński, A.; Poturaj, H. Digital Maturity of Logistics Processes Assessed in the Areas of Technological Support for Performance Measurement, Employees, and Process Management. Appl. Sci. 2024, 14, 7893. [Google Scholar] [CrossRef]

- Schumacher, A.; Nemeth, T.; Sihn, W. Roadmapping towards Industrial Digitalization Based on an Industry 4.0 Maturity Model for Manufacturing Enterprises. Procedia CIRP 2019, 79, 409–414. [Google Scholar] [CrossRef]

- Carrijo, P.; Alturas, B.; Pedrosa, I. Similarities and Differences Between Digital Transformation Maturity Models: A Literature Review. In Intelligent Systems in Digital Transformation; Kahraman, C., Haktanır, E., Eds.; Lecture Notes in Networks and Systems; Springer: Berlin/Heidelberg, Germany, 2023; Volume 549, pp. 33–52. [Google Scholar]

- Tubis, A.A. Digital Maturity Assessment Model for the Organizational and Process Dimensions. Sustainability 2023, 15, 15122. [Google Scholar] [CrossRef]

- Hein-Pensel, F.; Winkler, H.; Brückner, A.; Wölke, M.; Jabs, I.; Mayan, I.J.; Kirschenbaum, A.; Friedrich, J.; Zinke-Wehlmann, C. Maturity Assessment for Industry 5.0: A Review of Existing Maturity Models. J. Manuf. Syst. 2023, 66, 200–210. [Google Scholar] [CrossRef]

- Angreani, L.S.; Vijaya, A.; Wicaksono, H. Systematic Literature Review of Industry 4.0 Maturity Model for Manufacturing and Logistics Sectors. Procedia Manuf. 2020, 52, 337–343. [Google Scholar] [CrossRef]

- Hellweg, F.; Lechtenberg, S.; Hellingrath, B.; Thomé, A.M.T. Literature Review on Maturity Models for Digital Supply Chains. Braz. J. Oper. Prod. Manag. 2021, 18, 1–12. [Google Scholar] [CrossRef]

- Gulen, M.F.; Uflaz, E.; Gumus, F.; Orhan, M.; Arslan, O. An Integrated SWOT-Based Interval Type-2 Fuzzy AHP and TOPSIS Methodology for Digital Transformation Strategy Selection in Maritime Safety. Ocean. Eng. 2025, 323, 120518. [Google Scholar] [CrossRef]

- Cicek, K.; Celik, M.; Demirci, S.M.E. Digital Maturity Assessment of Ship Management Companies Towards Organizational Intelligence: Blue Digital Focus. In Intelligent Systems in Digital Transformation; Kahraman, C., Haktanır, E., Eds.; Lecture Notes in Networks and Systems; Springer: Berlin/Heidelberg, Germany, 2023; Volume 549, pp. 537–560. [Google Scholar]

- Al Mazroui, T.S.S.; Al Alawi, M.M.S.; Al Wahaibi, K.S.H.; Al Amri, B.B.S.; Thottoli, M.M.; Thottoli, M.M. Maturity of Digital Transformation in the Shipping Industry: Case Study among Enterprises in Gulf Cooperation Council Countries. Kapal J. Ilmu Pengetah. Dan. Teknol. Kelaut. 2023, 20, 115–123. [Google Scholar] [CrossRef]

- Resende, L.M.; Bilcati, T.; Pontes, J.; Betim, L.M. Assessing Digitalization Maturity in Port Environments: A Comprehensive Tool for Logistics, Operations, and Planning Management. Aust. J. Marit. Ocean Aff. 2024, 1–22. [Google Scholar] [CrossRef]

- Boullauazan, Y.; Sys, C.; Vanelslander, T. Developing and Demonstrating a Maturity Model for Smart Ports. Marit. Policy Manag. 2023, 50, 447–465. [Google Scholar] [CrossRef]

- Charlampowicz, J.; Karas, A. Smart Ports Process Maturity Model—Theoretical Framework. Eur. Res. Stud. J. 2024, XXVII, 893–903. [Google Scholar] [CrossRef]

- de la Peña Zarzuelo, I.; Freire Soeane, M.J.; López Bermúdez, B. Industry 4.0 in the Port and Maritime Industry: A Literature Review. J. Ind. Inf. Integr. 2020, 20, 100173. [Google Scholar] [CrossRef]

- Klar, R.; Fredriksson, A.; Angelakis, V. Assessing the Maturity of Digital Twinning Solutions for Ports. In Proceedings of the 2023 IEEE International Conference on Pervasive Computing and Communications Workshops and other Affiliated Events (PerCom Workshops), Atlanta, GA, USA, 13–17 March 2023; pp. 552–557. [Google Scholar]

- Hamidi, S.M.M.; Hoseini, S.F.; Gholami, H.; Kananizadeh-Bahmani, M. A Three-Stage Digital Maturity Model to Assess Readiness for Blockchain Implementation in the Maritime Logistics Industry. J. Ind. Inf. Integr. 2024, 41, 100643. [Google Scholar] [CrossRef]

- Remane, G.; Hanelt, A.; Wiesboeck, F.; Kolbe, L. Digital Maturity in Traditional Industries—An Exploratory Analysis. In Proceedings of the 25th European Conference on Information Systems (ECIS), Guimarães, Portugal, 5–10 June 2017. [Google Scholar]

- Asadamraji, E.; Rajabzadeh GHatari, A.; Shoar, M. A Maturity Model for Digital Transformation in Transportation Activities. Int. J. Transp. Eng. 2021, 9, 415–438. [Google Scholar]

- Varol, B.; Er, G.; Temur, G.T. Digital Transportation Maturity Measurement. In Intelligent Systems in Digital Transformation, Lecture Notes in Networks and Systems; Kahraman, C., Haktanır, E., Eds.; Springer: Berlin/Heidelberg, Germany, 2023; pp. 561–577. [Google Scholar]

- European Agreement on Main Inland Waterways of International Importance (AGN), Geneva, 19 January 1996, Anex III; Geneva. 1996. Available online: https://treaties.un.org/pages/viewdetails.aspx?src=treaty&mtdsg_no=xi-d-5&chapter=11&clang=_en (accessed on 20 January 2025).

- Available online: https://Www.Elwis.De (accessed on 20 January 2025).

- Available online: https://Wir.Wody.Gov.Pl (accessed on 20 January 2025).

| Customer Service Area (Order and Cargo Handling) | System Management and Regulatory Compliance | Operational Ship Maintenance | Operational Process Management | |

|---|---|---|---|---|

| Level I | Basic communication technologies (email, phone) are used for customer interactions, supporting the exchange of real-time information initiated by the customer. Order fulfilment updates are manually entered into the system after being provided by the responsible person. Customers receive order status updates only upon request, typically via phone. The entire customer service process follows a traditional approach, with paper documentation playing a significant role. No standardized document templates are defined for customer service processes. | Paper documents serve as the primary means of information exchange, with a limited scope of shared data and long response times. Ship inspections by the authorized bodies (waterway administration, inland navigation administration, police, customs office, and border services, etc.) are conducted in an informal manner, relying on the inspector’s individual knowledge and experience. Data on vessel traffic are recorded manually without specific guidelines on what information should be collected or how. | Ship maintenance follows a reactive approach, with fluids replaced as per the manufacturer’s guidelines and repairs performed only when damage occurs. Basic operational data are manually recorded in a logbook, but the absence of standardization results in inconsistencies in notations. The vessel is equipped with basic mandatory safety and alarm systems. Cargo loading and distribution are determined solely by the captain, based on personal experience. | The vessel is equipped with basic, mandatory navigation tools. Communication with authorities, lock operators, ports, and transhipment points is conducted via VHF radio. Navigational messages and other administrative information are obtained in person or by phone. |

| Level II | Basic communication technologies (email, phone) continue to be used for customer interactions. However, the paper document flow is now regulated by standardized templates and predefined internal procedures. A designated employee assigned to customer service is responsible for periodically monitoring order fulfilment and informing the client through basic communication channels. | The exchange of documents remains predominantly paper based, but is partially supported by selected digital systems. The scope of digital documentation and communication is strictly defined, and initial solutions facilitating cooperation with shipowners are being introduced. Inspections are conducted according to locally established procedures, ensuring a degree of standardization. Vessel traffic data are still recorded manually, but locally defined guidelines are now followed specifying what data should be collected and how. | A structured maintenance approach is introduced, with fluid and component replacements following internal company standards, which exceed the manufacturer’s recommendations and are based on best practices. Operational data are recorded on paper following a standardized format, ensuring data consistency. Repairs remain damage driven. The vessel is equipped with mandatory safety systems and partially automated alarm systems. The captain determines cargo loading and distribution based on predefined procedures. | The vessel navigates using paper charts and a geolocation system. Communication with authorities, lock operators, ports, and transhipment points is carried out via mobile phone and email. Navigational messages and other administrative information are obtained via email or official websites. |

| Level III | Customer orders are received through a website, and non-integrated informatics systems support order fulfilment. Paper documentation still accompanies cargo and is used for billing (e.g., paper invoices). Basic digital solutions, such as the AIS (Automatic Identification System), are used to monitor cargo, while barcoded logistic labels enable automatic cargo identification. | Digital documentation now supplements paper-based records, which are limited to a narrowly defined group of documents. Various communication channels are used in interactions between authorities and stakeholders, and the administration follows a customer-centric approach to improve communication. Ship inspections follow centrally established procedures, ensuring uniformity across jurisdictions. Vessel traffic data are still recorded manually, but adhere to central guidelines specifying mandatory data collection standards. | A preventive maintenance strategy is in place, with planned inspections and maintenance work. Maintenance decisions are supported by quantitative analysis, and operational parameters are monitored daily. Data are collected and processed using basic IT tools (e.g., spreadsheets). The vessel is equipped with mandatory safety systems and partially automated alarm systems. The captain determines cargo loading and distribution by following established procedures and using IT tools for calculations. | The vessel navigates using radar, the AIS (Automatic Identification System), and ECDIS (Electronic Chart Display and Information System). Communication with authorities, lock operators, ports, and transhipment points remains carried out via mobile phone and email. Navigational messages and other administrative information are obtained via email or official websites. |

| Level IV | Customer orders are handled via a dedicated web and mobile application, where customers have personalized profiles to manage their orders efficiently. The application is integrated with a CRM system, allowing for detailed customer data analysis and improving both traditional and electronic communication between the shipping company and its clients. RFID technology is used for cargo identification and monitoring. Order status updates are available in real time within the application. | A digital document management system is fully operational, and administrative authorities provide online platforms that allow stakeholders to independently manage selected processes (e.g., transport and handling of hazardous goods). An open-access information model with two-way communication enables flexible adaptation to stakeholders’ digitalization needs. Inspection results are now stored in an application accessible to the inspecting body, ensuring structured reporting. Vessel traffic data are collected using IT tools, in accordance with central regulations, and authorities provide digital waterway maps meeting international standards. | A predictive maintenance strategy is implemented. Ships are equipped with sensors for the real-time monitoring of selected operational parameters. Advanced diagnostics help to prevent failures before they occur. Sensor data are integrated with operational and maintenance data in a unified IT system. The vessel is equipped with mandatory safety systems and fully automated onboard alarm systems. The captain determines cargo loading and distribution using multiple, but not yet fully integrated, IT tools. | The vessel is navigated using an integrated suite of tools, including radar, the AIS, ECDIS (displaying combined information on a single screen), and an autopilot system. Communication with authorities, lock operators, ports, and transhipment points is handled via a dedicated application or the RISs (River Information Services). Navigational messages and other administrative information are received through the dedicated application. |

| Level V | The shipping company’s customer service systems are fully integrated with the ERP systems of key clients, allowing for the autonomous monitoring of transport demand. RFID technology is used for cargo identification, while IoT-based solutions enhance cargo tracking. Big Data analytics support customer relationship management, and real-time order fulfilment data are shared with clients. The entire document exchange is conducted electronically, with paper documents issued only upon explicit client request. | Best practices from other sectors are adopted in the continuous digital transformation of the system. Authorities implement models of ongoing improvement based on experience sharing and cooperation with stakeholders. Digital technologies and change management strategies play a key role in designing administrative cooperation frameworks. Ship inspections are conducted using a mobile application, which provides access to previous inspection records and allows for the immediate entry of new findings. Vessel traffic data are automatically collected through traffic management support systems like the RISs (River Information Services) and AIS, with reporting requirements covering all cargo and passenger vessels. Additionally, authorities provide digital waterway maps that are compliant with at least Class III waterway parameters. | A proactive maintenance strategy is in place, leveraging real-time continuous monitoring to forecast potential failures. Digital simulation tools (e.g., digital twins) anticipate damage scenarios, while data are integrated with voyage planning systems. Artificial intelligence and machine learning algorithms support data analysis and predictive maintenance. The vessel is equipped with mandatory safety systems and fully automated alarm systems integrated with navigation systems and shore-based safety centres. The captain approves cargo loading and distribution using fully integrated IT tools, which aggregate sensor data and automation systems. | The vessel navigates using radar, the AIS, ECDIS, ERI (Electronic Reporting International) system, an autopilot system, automatic steering, Bridge Scout/Secure, and Darad Pilot. Direct communication with authorities, lock operators, ports, and transhipment points is minimal, as standard messages are exchanged automatically between IT systems. Navigational messages and other administrative information are received automatically through real-time updates in IT systems. |

| Assessment Areas | Rhine Waterway | Oder Waterway |

|---|---|---|

| Customer Service | IV | II |

| System Management and Regulatory Compliance | IV | III |

| Operational Ship Maintenance | II | II |

| Navigation and Communication | III | II |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tubis, A.A.; Skupień, E.T.; Jędrzychowski, K.K.; Jędrzychowski, H. A Sector-Specific Digital Maturity Model for Inland Waterway Transport. Systems 2025, 13, 347. https://doi.org/10.3390/systems13050347

Tubis AA, Skupień ET, Jędrzychowski KK, Jędrzychowski H. A Sector-Specific Digital Maturity Model for Inland Waterway Transport. Systems. 2025; 13(5):347. https://doi.org/10.3390/systems13050347

Chicago/Turabian StyleTubis, Agnieszka A., Emilia T. Skupień, Kasper K. Jędrzychowski, and Hubert Jędrzychowski. 2025. "A Sector-Specific Digital Maturity Model for Inland Waterway Transport" Systems 13, no. 5: 347. https://doi.org/10.3390/systems13050347

APA StyleTubis, A. A., Skupień, E. T., Jędrzychowski, K. K., & Jędrzychowski, H. (2025). A Sector-Specific Digital Maturity Model for Inland Waterway Transport. Systems, 13(5), 347. https://doi.org/10.3390/systems13050347