1. Introduction

Recent Industry 4.0-driven technological trends are reshaping manufacturing facilities into smarter and more autonomous systems, empowering companies to optimize material flow, implement predictive decision-making schemes, enable agile reconfiguration, and optimally allocate partners for cost minimization [

1]. These revolutions introduce ubiquitous connectivity to the manufacturing environment, facilitating the collection of significant volumes of dispersed information and supporting distributed decision-making in manufacturing [

2,

3]. Blockchain technology enables a distributed and decentralized knowledge management system to connect manufacturer crowds in an open environment [

4], while the synergy of cloud computing and edge computing explores connections through a virtual platform, transforming manufacturing into an agile and intelligent process [

5,

6].

This technological progress lays the foundation for future manufacturing paradigm shifts. Open manufacturing explores the technical prerequisites and information architecture for companies to adopt open business models, aiming to achieve an open yet agile enterprise architecture and integrate external resources into their fulfillment workflow based on a crowdsourcing information platform [

5]. The open architecture envisions a transformation towards a large-scale cooperative product fulfillment model, connecting a large manufacturer peer crowd and reconfiguring a collaborative network to satisfy volatile customer needs. This requirement implies the adoption of a service-oriented paradigm, which installs X-as-a-Service (XaaS) in the manufacturing regime as service manufacturing [

7]. Social manufacturing studies the interactive relationship among manufacturer crowds, formulating the construction of a manufacturing network as an autonomously organizing process [

8,

9]. The paradigm of cloud-based design and manufacturing offers a framework for connecting smart entities across a population of companies, enabling a demand–capacity matching mechanism to serve collaboration for product realization [

10].

Crowdsourced manufacturing, based on the application of cloud-based design and manufacturing, organizes a dynamic resource-sharing mechanism across manufacturers in a crowd to achieve production network construction from a large manufacturer population [

11]. The coordination mechanism provided by the crowdsourcing platform synchronizes manufacturing activities across companies, allowing manufacturers to own excessive capacity from cooperation with partners in the production network [

12]. Resource matching and pricing mechanisms enable a cloud-based capability and knowledge exchange marketplace to accelerate the production network reconfiguration process [

13]. From a variety management perspective, crowdsourced manufacturing offers a rapidly responsive reconfiguration of existing resources and knowledge to serve volatile customer needs [

14].

In this regard, this paper reviews emerging trends in manufacturing systems and the fundamental issues of crowdsourced manufacturing towards a paradigm of delivery of manufacturing as a service. The next section reviews the common consensus and recent development in crowdsourced manufacturing. The following section analyzes the decision agents in crowdsourced manufacturing in the appropriate industries and presents an illustrative case to examine the potential of crowdsourced manufacturing. The subsequent sections examine the fundamentals and essential concepts to formulate the crowdsourced manufacturing problem in terms of the workflow and a holistic view, as well as networked information and material flow across multiple decision agents.

2. Recent Trends in Manufacturing Systems Management

2.1. Open Business Model

The open business strategy has been recognized as an efficient method for companies to develop quick-response problem-solving systems by utilizing external assets and knowledge to enhance their own capabilities [

15]. This strategy involves participating in an open initiative to capture value, which can be divided into reliance on external assets or knowledge and access to project results by external partners [

16]. A growing number of companies have adopted open business strategies and geared themselves toward implementing open business models through their business activities, achieving an agile enterprise structure and expanding their capability arsenal [

17]. The open business model facilitates the creation of complementary links in a value chain by explicitly arranging stakeholders along positions of value creation, delivery, and capture [

18]. This openness provides a structure to integrate various external partners, easing the installation of new technologies and scaling up capabilities.

In a manufacturing environment, external suppliers act as subcontractors serving the value chain with their core competencies, while the core company outsources its peripheral economic activities to focus on its essential competitive edges [

19]. This outsourcing decomposes volatile and complex value chains into simpler tasks, enabling subcontractors to handle variety by exploring commonalities among jobs to maximize the reutilization of their competitive edges [

20]. Focusing on competitive edges enhances production volume in the company’s core manufacturing activities, achieving economies of scale despite high product and production variety and significant demand variance [

21]. The mass cooperation of manufacturers entails a highly interactive manufacturing network that relies on a cooperative collaboration mechanism along the value chain [

22].

2.2. Platform-Driven Crowdsourcing

Crowdsourcing has emerged as a crucial approach for implementing the open business model by transcending organizational boundaries to leverage resources and capabilities across distributed stakeholders [

23]. Unlike traditional outsourcing strategies in supply chain management that focus on assigning tasks to designated agents, crowdsourcing employs an open call to a crowd to maximize the exploitation of external resources [

24]. This method fosters a new value-based model, functioning as a socio-economic cyber platform where products and services are created and delivered collaboratively and in a distributed manner [

25]. As a cyber production platform, crowdsourcing leverages Internet technologies to coordinate, negotiate, and manage crowds for specific organizational tasks [

26]. It involves a superior broker system that facilitates the coordination of information and material flows among stakeholder crowds, allowing companies to outsource peripheral activities and focus on core competitive advantages [

27].

This paper adopts a platform-driven approach to crowdsourcing, emphasizing the platform’s role in coordinating and negotiating responsibilities, thereby simplifying the application of the open business model for product innovation and development. Following a “four pillars” taxonomy—the crowd, the crowdsourcer, crowdsourced tasks, and the crowdsourcing platform—the platform serves as an intermediary between the crowdsourcer and the crowd [

28]. This intermediary role helps the crowdsourcer explore external knowledge and resources by coordinating designers and manufacturers’ activities, facilitating a collaborative product fulfillment network [

29].

Advances in information and communications technologies (ICT) and industry trends enable platforms to transcend partner borders, building extensive information exchange networks that drive the crowdsourcing product fulfillment process. This platform-driven, collaborative integration of various business and operational processes forms an extended enterprise, where crowdsourcing and early involvement of partner crowds become new competitive edges for innovative product development [

30]. The integration of smart sensors and networked manufacturing systems has created a cyber–physical manufacturing environment. Here, the synergy of the Internet of Things (IoT), big data analysis, machine intelligence, and conventional manufacturing technologies, such as computer-integrated manufacturing systems, supply chain management, and production logistics, stimulates significant technological advancements in crowdsourcing product realization, collectively envisioned as Industry 4.0 [

31]. Decentralization, recognized as a core characteristic of Industry 4.0, enhances collaboration across multiple entities within an enterprise with an open yet virtual architecture [

32].

New enterprise information technologies, such as discrete event simulation, model-based system engineering, and CAX software, enable the remote modeling of manufacturing activities [

33]. The synergy of cyber-physical systems (CPS) and manufacturing execution systems (MES), along with enterprise resource planning (ERP), vertically integrates real-time data from equipment fleets with the cyber architecture based on a digitized platform [

34].

A successful application of the open business model necessitates collaboration among external partner crowds, sharing resources and capabilities along a coherent product fulfillment flow [

35]. The platform-driven method penetrates partner boundaries, utilizing data streams to enhance collaborative crowdsourcing product fulfillment activities [

36]. The platform offloads peripheral activities from manufacturers, providing complementary services by linking a large network of partners [

37]. It drives the collaborative crowdsourcing product fulfillment workflow by defining functions, interactions, and processes [

38].

2.3. Smart Manufacturing

Recent technological trends are reshaping the product realization process, transforming it into a smarter and more autonomous system [

39]. These advancements enable manufacturing companies to optimize material flows within extensive manufacturing networks, implement predictive decision-making schemes for dynamic responses, achieve agile reconfiguration for end-to-end throughput improvement, and optimize partner allocation to minimize costs [

1]. These innovations facilitate ubiquitous connectivity in manufacturing environments, allowing for the collection of significant volumes of dispersed information and supporting distributed decision-making in manufacturing contexts [

2,

40]. Blockchain technology further supports this paradigm by enabling a distributed and decentralized knowledge management system, enhancing connectivity among manufacturer crowds in an open environment [

4]. Moreover, the synergy of cloud computing and edge computing creates connections through virtual platforms, transforming manufacturing into an agile and intelligent process and paving the way for adopting open business models via the autonomous reconfiguration of distributed manufacturing resources [

5,

6].

Such technological progress lays the groundwork for future shifts in manufacturing paradigms. Open manufacturing explores the technical prerequisites and information architecture necessary for companies to implement open business models, aiming to achieve an open yet agile enterprise architecture that integrates external resources into its fulfillment workflow through a crowdsourcing information platform [

5]. This open architecture envisions a transformation towards a large-scale cooperative product fulfillment model, which connects a vast network of manufacturer peers and reconfigures collaborative networks to meet volatile customer needs. Accommodating a dynamic and collaborative network necessitates adopting a service-oriented paradigm, installing X-as-a-Service (XaaS) within the manufacturing regime as service manufacturing [

7,

41]. Social manufacturing examines the interactive relationships among manufacturer crowds, framing the construction of manufacturing networks as an autonomously organizing process [

8]. The paradigm of cloud-based design and manufacturing provides the framework for connecting smart entities across multiple companies, enabling a demand-capacity matching mechanism that facilitates collaboration for product realization [

42].

Specifically, crowdsourced manufacturing builds on cloud-based design and manufacturing by organizing a dynamic resource-sharing mechanism among manufacturers, creating a production network from a large population of manufacturers [

11]. The coordination mechanism provided by the crowdsourcing platform synchronizes manufacturing activities across companies, allowing manufacturers to leverage excessive capacity through partner cooperation within the production network [

12]. Resource matching and pricing mechanisms enable a cloud-based marketplace for capability and knowledge exchange, accelerating the production network reconfiguration process [

13]. From a variety management perspective, crowdsourced manufacturing offers rapid reconfiguration of existing resources and knowledge to address volatile customer needs effectively.

3. Prevailing Industry Initiatives Towards Crowdsourcing

Crowdsourcing has been widely applied across various industries worldwide, capitalizing on the “wisdom of crowds” to drive significant growth in this sector. This expansion is evidenced by substantial investments in the incubation of crowdsourcing companies over the past decade.

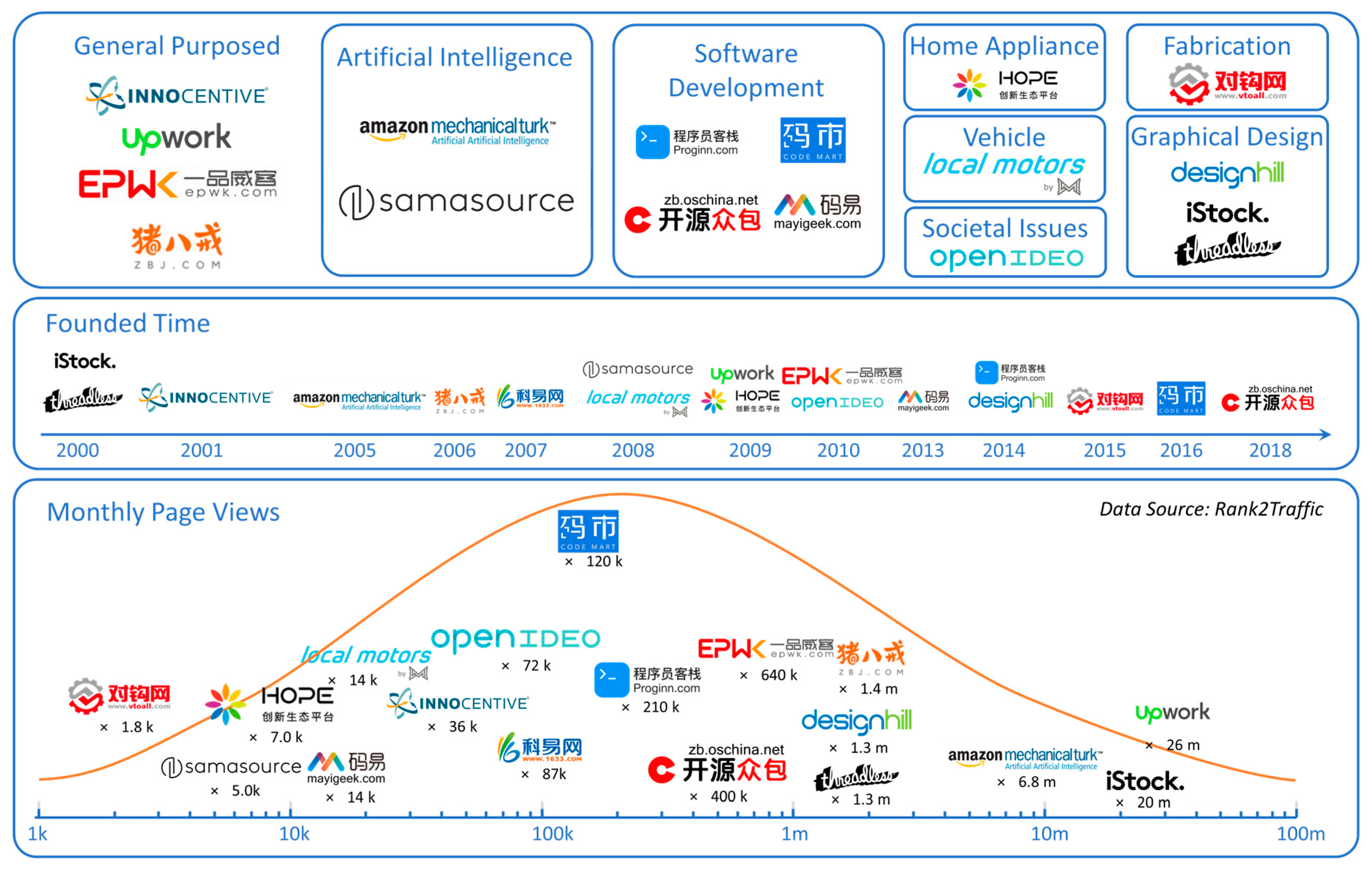

Figure 1 summarizes representative crowdsourcing platform companies, detailing their target markets, founding dates, and the latest monthly page views of their domain pages. A high monthly page view count indicates a thriving crowd ecosystem and substantial fulfillment capability, with the average monthly page view count for these companies around 300,000.

Platforms like Amazon Mechanical Turk (

mturk.com, accessed on 2 January 2025) and Samasource (

sama.com, accessed date on 2 January 2025) exemplify the power of crowdsourcing by connecting vast labor resources to companies for fulfilling micro-tasks at relatively low costs. Leveraging the massive number of internet users, Amazon Mechanical Turk sustains a large and diverse crowd to perform tasks such as human-subject surveys, data annotation, and data cleaning and verification, thereby accelerating the development of artificial intelligence-related projects [

43]. Similarly, Samasource, founded in 2008, taps into the exponentially growing global internet user base by employing low-income workers in developing countries to provide high-quality, large-scale training data for profit [

44]. The thriving application of crowdsourcing platforms highlights their significant role in modern industries, providing efficient and scalable solutions to various business needs.

Figure 1.

Representative crowdsourcing platform companies [

45].

Figure 1.

Representative crowdsourcing platform companies [

45].

Compared to micro-task crowdsourcing, which typically requires participants to have general capabilities, crowdsourcing can also link expert crowds to tackle more specialized tasks. In China, crowdsourcing platforms such as proginn.com (

http://proginn.com, accessed on 27 February 2025), zb.oschina.net (

http://zb.oschina.net, accessed on 18 December 2021), Local Motors (

http://localmotors.com, accessed on 14 June 2021) connect a large pool of developers to serve ICT giants like Alibaba (

http://alibaba.com, accessed on 27 February 2025) with diverse capabilities and rapid response times. Beyond IT, leading home appliance and consumer electronics manufacturer Haier (

http://haier.com, accessed on 27 February 2025) has implemented an open business model through its HOPE platform, transforming the centralized enterprise into a “sea of entrepreneurs” to foster a vast innovation ecosystem for product research and development [

46]. HOPE facilitates crowdsourcing services for both internal teams and external partners, leading to a series of successful products by leveraging the “wisdom of crowds” [

47].

Local Motors (

http://localmotors.com, accessed on 14 June 2021), a US vehicle manufacturing company founded in 2009, harnesses crowdsourced design ideas and collaborates with a network of manufacturers to produce its vehicles [

48]. Crowdsourcing also extends to mechanical fabrication, connecting demand with fabrication capabilities such as machining, metal sheet forming, and heat treating. Vtoall.com (

https://vtoall.com, accessed on 2 January 2025), a Chinese platform, serves as a two-sided marketplace for demand-capability matching in mechanical fabrication.

In industries less reliant on physical assets, like graphical design, crowdsourcing connects designer crowds. Designhill (

https://www.designhill.com, accessed on 2 January 2025) provides a wide range of design services, linking a large crowd of designers for projects like logos, websites, and apparel. Threadless operates an online artist community and e-commerce platform to meet the fluctuating demands for t-shirts and other apparel. iStock, a stock photography company, offers a crowdsourced marketplace for photos and videos, catering to a vast community of creators. OpenIDEO (

https://www.openideo.com, accessed on 2 January 2025), a social impact platform, connects companies to crowds to address complex societal issues [

49].

As crowdsourcing and internet technologies have evolved, some platforms have expanded their target markets and restructured into general-purpose platforms. InnoCentive, initially funded by Eli Lilly and Company to enhance internal research, has evolved into a general-purpose open innovation and crowdsourcing company. It enables organizations to publish problems and allows solvers to earn monetary rewards and reputation. ZBJ.com (

https://www.zbj.com, accessed on 2 January 2025) started with a focus on industrial design and has expanded to include legal services, marketing, ICT development, software engineering, engineering design, and graphical design, utilizing a diverse solver crowd. Upwork (

https://www.upwork.com, accessed on 2 January 2025) is a virtual labor marketplace that facilitates demand–expertise matching and remote collaboration across various industries. EPWK.com (

https://www.epwk.com, accessed on 2 January 2025) is a creative crowdsourcing service company in China that supports small and medium-sized enterprises with project planning, marketing services, knowledge, and software development transactions. These industry initiatives exemplify the feasibility and potential of crowdsourcing, showcasing the value of the “wisdom of crowds.” They pave the way for integrating crowdsourcing into the manufacturing environment, forging collaborative and coordinated manufacturing networks.

4. Crowdsourced Manufacturing for Open Product Fulfillment

4.1. From Open Business Model to Open Manufacturing

A business model is defined as a framework that encompasses the gathering of stakeholders, as well as the methods for creating, delivering, and capturing value [

50]. The purpose of a business model is to provide a set of heuristic logic that connects technical ideas with economic value realization [

51]. By opening the borders of conventional enterprises, companies can explore a larger volume of ideas and knowledge, and utilize a broad spectrum of external assets, resources, and positions, thus making value capturing more efficient [

52].

Chesbrough coined the term “open business model” to describe the practice of linking organizations outside the company’s borders to create new products or services by leveraging the power of the division of labor [

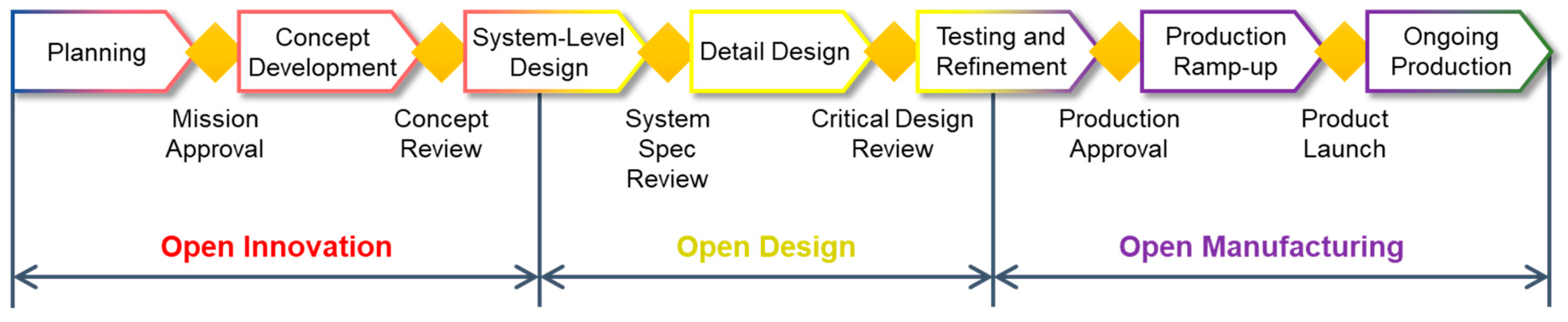

53]. This model aligns with the widely accepted generic product development process in engineering design [

54], transitioning conventional product fulfillment to a series of open activities. The mapping relationship of open innovation, open design, and open manufacturing with the generic product development process is depicted in

Figure 2.

As an earlier base of the open business model, open innovation is applied to depict the distributive innovation process based on purposively managed knowledge flow across the boundaries of organizations [

55]. Companies widely recognize open innovation as an accelerator for transitioning from research to development and market expansion by acquiring external knowledge [

56]. In contrast to the traditional vertical integration model, open innovation structures a dynamic, interactive network for various clusters of autonomous firms throughout the innovation process [

57].

From a value chain perspective, an increasing number of industries organize firms around a central platform structure. Here, the core firm seeks an inflow of external knowledge for their targeted markets, while surrounding firms outflow their knowledge, helping the core company reduce costs from doing everything internally [

58]. Through this innovation network, participating firms can identify market opportunities, link to advanced research and technology, collect a variety of product concepts, and initiate the configuration of product family architecture [

59]. From a product development perspective, open innovation provides a systematic method to install the open business model, covering product planning, concept development, and the transition stage of system-level design.

Targeting the later stages of product innovation and development, open design extends the open business model by involving design communities, collaborating with external designers, and achieving more flexible design capabilities [

60]. The concept of open design originates from the free/libre open-source software (F/LOSS) movement, which has created successes like Linux and Wikipedia [

61]. Open design enables a decentralized development process, a dynamic development structure, and the involvement of a crowd of developers [

62]. As physical products become increasingly data-driven and digitalized, the open business model extends from digital information processing to the design of tangible products [

63]. Open design allows external partners to access, modify, and derive from the product design [

64]. It structures a collaborative design team from external designer crowds, integrating design outcomes via the Internet [

65]. Open design supports parametric design of modularized tasks based on a given product architecture [

66] and aggregates design results through systematic computation to coordinate numerical conflicts [

67]. These developments imply that open design can facilitate the transition from system-level design to detailed design and the start of product testing and refinement towards more open activities.

The rise of smart manufacturing enables a highly democratized manufacturing network, characterized as decentralized, service-oriented, and easy to access [

68]. This democratization leads to the installation of the open business model, empowered by a dynamic network of agents acquiring technologies and resources in a self-directed and ad hoc manner [

69]. The marketing system that incorporates these post-Fordism sociotechnical trends can be described as open manufacturing. Open manufacturing integrates resources and knowledge from the distributed manufacturing community via a decentralized network to support operations [

5]. The collaboration of manufacturing crowds utilizes cloud computing technologies to access manufacturing agents and blockchain for production knowledge and information exchange [

4]. An open-source exchange marketplace will provide a variety of external manufacturing technologies and share excessive resources and capabilities, easing the configuration of manufacturing crowds into collaborative teams for fulfilling various product orders [

70].

4.2. Collaborative Crowdsourcing Product Fulfillment

Among the approaches of accessing external knowledge and resources to implement an open business model, crowdsourcing has been highlighted as an ICT-enabled and social media-based innovation tool [

71,

72]. This concept has been introduced to describe the utilization of open calls to form a peer-production for a task from a crowd of undefined people [

73]. Thanks to the wisdom of crowds, the collection of intelligence from a large group of heterogeneous participants is believed to show the superiority of a limited group of elites [

74]. Several factors have been highlighted as the impulses of the participants, including self-market or promotion, tangible or intangible compensation, social fame, and reputation, to name but a few [

75].

Since the crowdsourcing mechanism has been recognized as beneficial to problem-solving, a stream of research has geared forward the formulation of crowdsourcing. Surowiecki [

76] identifies four essential prerequisites to ensure successful crowdsourcing decision-making: (1) diversity, i.e., each participant can offer unique knowledge or capabilities; (2) independence, i.e., avoiding influences from peers; (3) decentralization, i.e., participants can share the information for local processes; (4) aggregation, i.e., the fulfilled crowdsourcing tasks can be collectively aggregated. Bonabeau [

77] divides the crowdsourcing decision-making process into two stages: the generation of possible solutions and the evaluation of these solutions. The essential cornerstones of crowdsourcing have been summarized as: (1) the application of open calls to explore the crowd; (2) a task set that needs to be fulfilled; (3) compensation of the contribution [

78]. Considering the complexity of the crowdsourcing task set, the success of crowdsourcing emphasizes independence and decentralization in the solution generation process to ensure the cognitive diversity, as well as the semantic coherence of the most successful solution sets to ensure the aggregation [

79].

The advancement of ICT brings ubiquitous connectivity to the decision-making entities worldwide through mobile network and social media. Meanwhile, the synergy of industrial IoT and CPS paves the way for an extensive collaboration among practitioners from the industry. Several industry pioneers have started installing crowdsourcing. These practices can be generally divided into two categories. The first category collects the existing giants which operate designated platforms to reach the external resources via crowdsourcing to majorly serve their market, like Haier Open Partnership Ecosystem (HOPE) by Haier (

https://www.haier.com, accessed on 2 January 2025). The second category collects the third-party companies which operate a crowdsourcing platform to serve their customer’s market, like Amazon Mechanical Turk (

mturk.com, accessed on 2 January 2025) and ZBJ.com (

https://www.zbj.com, accessed on 2 January 2025) in China.

A stream of research summarizes the classification methodology to analyze the type of various crowdsourcing practices. Based on the types of requirements and ways that contributions are collected, two dimensions have been summarized as subjective or objective contents, as well as aggregated or filtered contributions [

80]. Crowdsourcing research has revealed a series of crowdsourcing models from the industry application based on the characteristics of the demands, including: “winner-takes-all” or multiple responses; defined tasks or unresolved problems; individual efforts or collaborative manners; crowd qualification; activity-targeted or fundraising; requirements for quality of responses; and participation activity, among others [

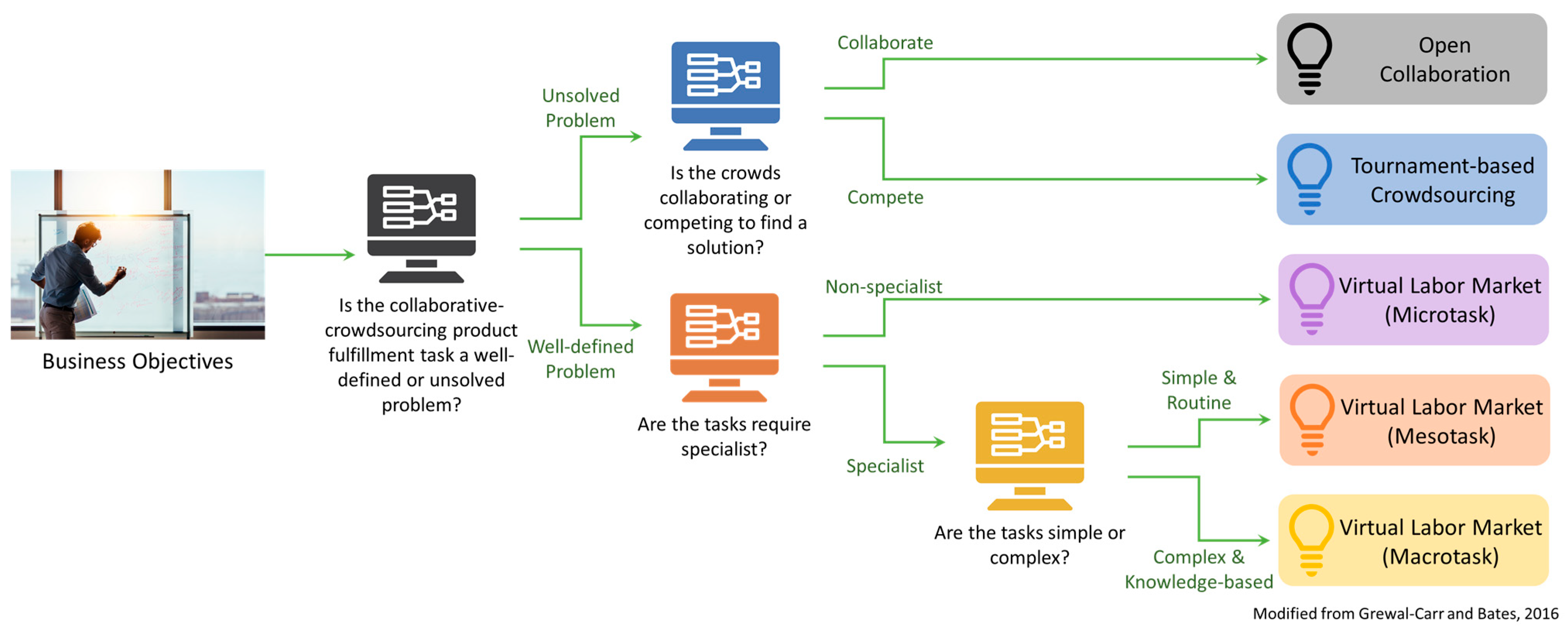

81]. Since collaborative-crowdsourcing product fulfillment is a process to realize the innovative product planning, the crowdsourcing tasks can be identified as an explicitly defined design or manufacturing requirement. Thus, it requires qualified designers and manufacturers to fulfill the tasks through a series of design solution derivations and fabrications, respectively. The crowdsourcing models for the collaborative-crowdsourcing product fulfillment task are shown in

Figure 3.

The crowdsourcing models for defined crowdsourcing tasks can be classified into three categories based on their openness, business motivations, and operation management issues: (1) Open collaboration, (2) Tournament based crowdsourcing, and (3) Virtual labor market [

78]. Open collaboration is a social media-based idea searching approach, where the organizations publish crowdsourcing tasks to a community of agents and aggregate the responses in the community to make decisions. In this approach, the crowdsourcing task can be identified as an unsolved problem, which has no sophisticated problem definition but expects innovative contributions after a mass collaboration of the community. This crowdsourcing type usually has no monetary incentives for the agent crowds, and the agents usually do not expect qualifications to be an entrance barrier. Tournament-based crowdsourcing formulates a series of activities to let the seeker connect to the solvers and select the winner after the sourcing competition. The existence of the tournament implies more objective incentives and a relatively open environment, as well as the stimulation of competition among solver crowds. In contrast, the virtual labor market entails a web-based cyber platform that plays an intermediate role between the crowdsourcer and a crowd with required qualifications. The platform can match the capabilities in the crowd and the requirement of a crowdsourcing task. It has also been observed that the platform can play an evaluation role to test the program or service monitoring.

The crowdsourcing tasks in the virtual labor market can be further classified by the problem scale, how well the problem is defined, and the specialty of required skills. The microtask model serves as a well-defined problem structure, which is easy enough to be classified as an everyday task. This model can be identified as an extension of traditional subcontracting, which explores the natural resources externally from the company. Emerging companies like Instacart (

https://www.instacart.com, accessed on 2 January 2025) and Uber (

https://www.uber.com, accessed on 2 January 2025) exemplify a kind of microtask crowdsourcing applications in the service industry sector. The Mechanical Turk by Amazon (

mturk.com, accessed on 2 January 2025) can serve as a user-involved product design by hiring a crowd of potential customers for a prototype survey. The mesotask is a well-defined task that expects the specialist to provide routine and straightforward solutions. It has an explicit expectation on solution quality, delivery quantity, and methods, as well as violation terms. This model can be used for software development as well as mechanical fabrication, which has a clear process routine and a set of specified qualifications. The efforts in the mesotask are less complicated and innovative in comparison with the macrotask model. The macrotask serves the complex crowdsourcing objective, which is often installed on the research and development side of the product or strategic consultant. The efforts for macrotask are more knowledge-based and subjective, which can help the crowdsourcer to expand their knowledge and resource arsenal without owning a designated department or signing a long-term subcontract. For example, the HOPE platform enables Haier to develop broad connections to an ocean of research groups to develop new products.

Although recognized as an emerging paradigm of product development by both industries and academia fields, there is not a systematical installation roadmap of crowdsourced product development [

82]. Crowdsourcing can be utilized for product idea generation, concept design, detailed design, physical prototyping, and design evaluation, which are the essential product innovation and design stages in new product development [

83]. The generic crowdsourcing process for new product development can be summarized as five consecutive stages, namely, task definition, task broadcasting, response collection, response evaluation, and winner awarding [

84]. After the product planning and design stage, crowdsourcing has been explored to install on the production stage [

85]. The concept of crowdsourced manufacturing originates from the cloud-based manufacturing system, which reflects a manufacturing capability sharing and production organizing mechanism among the cloud-based and widely connected manufacturing network [

86].

5. Emerging Consensus on Industry 4.0 Driven Manufacturing Paradigms

As an emerging technology vision, smart manufacturing reshapes the landscape of manufacturing industries with sensors, computing platforms, communication technologies, as well as data-intensive modeling and predictive engineering [

87]. Driven by the advancement of the knowledge exchange marketplace, sharing economies on the manufacturing shop floor, as well as increasingly democratizing and opening trends, smart manufacturing is characterized as decentralized, service-oriented, and platform-based [

7]. Originating from network manufacturing that uses centralized crowdsourcing [

88], open manufacturing adopts decentralization ideology. It utilizes blockchain and edge computing to construct a cross-enterprise knowledge and service sharing framework [

5]. Open manufacturing can be viewed as an incubator for small and medium manufacturers since it regulates the knowledge and service sharing standards and protocols. It can support manufacturers to develop scalable and flexible business scale at a lower cost and eventually improves the overall quality, efficiency, and effectiveness of manufacturing services. From a supply chain aspect, open manufacturing decouples design, logistics, and service layers from physical assets [

7]. Targeted at achieving this capability, the open manufacturing enterprises will be amenable to the XaaS mode, where X represents manufacturing, supply chain, and logistics. This manufacturing paradigm is also called service manufacturing. Recognizing the great benefit of resource and service sharing, several technical challenges have been highlighted as bottlenecks for creating an extensively opened manufacturing environment, including crowdsourcing contract design, diversified supply chain reconfiguration, and distribution coordination mechanisms, among others [

89].

The implications of social media and the Internet change the consumption-manufacturing relationship in industries from four aspects: production socialization, role shift of consumers, the driving force of production innovation, and virus-like information propagation in social media [

90,

91]. These aspects drive the current manufacturing paradigm to a more decentralized, open, adaptive, and socialized one, which is coined as social manufacturing. Focus on this new manufacturing paradigm, a large volume of research has geared forward the content of social manufacturing, which includes, the blockchain-based tracking system for the self-organizing process [

92], RFID-based execution systems for inter-enterprise monitoring and dispatching [

93], the socialized production network generation framework [

94], and outsourcer-supplier coordination mechanisms [

95,

96], to name but a few. These research streams hold the opinion that small and medium service-oriented enterprises can be aggregated into different kinds of horizontal manufacturing communities to enlarge their bargain power and common profits through initial clustering and self-organization. As a systematical software solution, social manufacturing provides a series of demands-capability matching functions, includes requirement and capacities releasing, intelligent matchmaking, production monitoring, and participator collaboration management [

97]. However, current related research has a limited exploration of the coordination for manufacturing networks, collaborative-negotiation contracting among stakeholders, and an evaluation for solution validation and quality control.

Cloud manufacturing follows the successful application of cloud computing, in which diversified resources and abilities are intelligently sensed and connected into the broader Internet, and automatically managed and controlled using IoT technologies [

98]. In this manufacturing environment, users search and invoke the qualified manufacturing cloud services from a related cloud based on their requirements and organize them to be a virtual manufacturing environment or solution to complete their manufacturing tasks [

99]. In line with this concept, Helo [

100] proposed a cloud-based design and manufacturing model which identifies consumer, provider, broker, and carriers from the cloud as its stakeholders and a distributed infrastructure with an interfacing system. Thanks to the dynamic characteristic of cloud manufacturing, the manufacturing equipment across multiple dispersed manufacturing sites can be rapidly reconfigured and repurposed [

101]. Thus, the significance of automation and digitization of manufacturing operations is highlighted in cloud manufacturing, which implies a widely connected community of manufacturers [

102]. The researchers in cloud manufacturing pay more attention to the cloud-based technologies, including a consumer-provider interactive framework, cloud-based equipment automation, and web-based service-oriented system for resource monitoring and controlling, but minimal research has focused on the construction of a manufacturing network to serve the targeted market and cooperation architecture for different business entities along the product fulfillment workflow.

The cloud-based framework enables the manufacturing companies to be widely connected while transcending the conventional enterprise borders. This manufacturing network paves the way for installing negotiation-based cooperation between the factories to share their excessive capabilities and outsource their peripheral manufacturing capabilities. The reconfigurable supply chain system can support the quick-responsive construction of a product fulfillment chain for both the production network and the knowledge marketplace [

103]. This dynamic production network enables the realization of a highly personalized product family [

104], achieving efficient manufacturing resource sharing among federated production networks [

105].

6. Stakeholder Analysis of Crowdsourced Manufacturing

Crowdsourced manufacturing forms a dynamic supply chain with a trichotomy of its stakeholder roles, namely client, requester, and provider [

103]. This concept describes a broadcasting and searching process based on the crowdsourcing model. Considering the adoption of open business model, it entails a “maker-platform operator” business model as an upgrade of the current peer-to-peer manufacturing network based on the maker to platform model [

106]. The client serves as an open innovator in the open business model as well as a crowdsourcer in the crowdsourcing model, and they install the open business model, design a new product, and seek a structured supply chain to fulfill the corresponding product. The requester serves as the operator of the crowdsourcing platform, and they broadcast the crowdsourcing tasks, collect and evaluate the responses, and award the winner with contracts. The provider serves as a participant of the manufacturer crowd, and they share their expertized manufacturing capabilities to capture value.

Moreover, various industries have different driven forces, showing different ways of adapting to open business models, as well as adaptabilities to the crowdsourcing model. The following sector will focus on the applicable analysis of the innovative products and variant product industries. The differences among decision agents imply different expected benefits from the participation of crowdsourced manufacturing, which significantly diversify the decision-making processes among the agents in crowdsourced manufacturing. To explore the driving force of decision agents in crowdsourced manufacturing in the applicable industries, the sector after the next examines their current challenges, potential contributions to the entire community, and specific needs from the crowdsourced manufacturing paradigm. In the end, a running illustrative case of tank trailer is kicked-off to demonstrate the installation map of crowdsourced manufacturing on the existing production network.

6.1. Industrial Applicability

As an emerging manufacturing paradigm, various industries show different accordance with the distinctive context of company and compatibilities to crowdsourced manufacturing. Generally, there is a common dichotomy to analyze the pulse of innovative product development, namely, market pull versus technology push [

107]. Market-pull industries innovate the value chain to address insufficient satisfaction of current customer needs and restructure the existing value chain to create product variations. In contrast, technology push industries invent new technologies when the target market is ambiguous, then find paths to target markets and commercialize the new technical know-how [

108].

Because new technical invention is reckoned to be the prerequisite and core competitive edges in companies by technology push industries, the benefits of large manufacturer crowds and the resulting quickly responsive manufacturing network are less attractive to these companies. The effect of intellectual property as a barrier to market entry will filter a large proportion of manufacturers to participate in crowdsourced manufacturing. Meanwhile, the risk of mismanagement of intellectual property may harm these companies. For example, Gore-Tex suggested itself to be an effective technology for pushing innovative products. It is an expanded Teflon sheet made by W. L. Gore and Associates. The commercialization of Gore-Tex starts with the successful development of a porous form of polytetrafluoroethylene with a microstructure characterized by nodes interconnected by fibrils [

109]. Utilizing this innovative material and related process, W.L. Gore developed a series of products, including apparel fabrics, medical devices, and insulation layers for advanced electric cables, to name but a few. Several apparel companies use Gore-Tex material and core processes to accelerate commercialization by collecting customer needs and provide access to the market. In this case, W. L. Gore’s ownership of the intellectual property of Gore-Tex means that it lacks access to the market and instead acts as a material supplier and process solution provider. Thus, the company entails a manufacturer in crowdsourced manufacturing and serves other innovators, like apparel companies, surgical apparatus start-ups, or electric device manufacturers. These industries are close to the market and have a different innovation impulse; they involve Gore-Tex as an incremental improvement.

Unlike technology push, market pull industries are based on the existing connections to the customers. Companies sense the volatile customer needs from their customers in targeted markets, translate these customer needs into specific requirements for new function realizations, then find an appropriate technology to achieve maximum satisfaction. Market-pull industries create value by bringing reconfigured available technologies and capabilities to customers for the purpose of achieving “Make-to-Order” (MTO). In this regard, they provide a reconfiguration roadmap which a crowdsourcing platform can use to arrange manufacturers into a network. Since the product development decisions in market pull industries are customer-driven, these companies provide the directions and evaluation criteria for the contributions of manufacturer crowds.

6.2. Decision Agents in Crowdsourced Manufacturing

(1) Open Innovators: open innovators have evolved from the conventional Original Equipment Manufacturer (OEM), which collects customer needs and serves the customer after-sales, develops the product concept, and designs the products. The open innovators have a large peer population with highly specialized targeted markets and corresponding highly customized orders in an industry sector. Thanks to the mass customization paradigm, the combination of platform-based design and modular design can serve a highly responsive product configuration using existing technologies and sub-systems [

110].

One of the motivations for open innovators to participate in crowdsourced manufacturing is the need to seek out a larger population of heterogeneous manufacturers to realize product innovation. Although the existence of a crowdsourcing platform creates the approach to manufacturer crowds, the set-up time and risk of initiating crowdsourced manufacturing with the platform are still barriers to open innovators. That set-up time can be decomposed to the negotiation between open innovators and platform, the crowdsourcing contracting between platform and manufacturers, and the lead time to fulfilling the crowdsourcing tasks. The risks for open innovators lie in leaking the intellectual property of innovative products, involving under-qualified manufacturers, and crowdsourcing task aggregation failure. These requirements imply a systematic product variety coordination system to serve the crowdsourcing product information management, and an information system to monitor the manufacturing process.

Moreover, the transformation of product innovation to fulfilled products requires the collaboration of platforms and manufacturers per se. The platform decomposes the product design to subtasks, then packages to crowdsourcing tasks for broadcasting. This restructuring process relies on semantic coherence from product design to crowdsourcing tasks, and a guideline for open innovators can accelerate this transition process. Since the review and evaluation are essential in the product development process, the task fulfillment evaluation criteria set struggles for the evaluator. The targets are not always explicit, while the criteria are dependent [

111]. A system of methods to ease the monitoring of the manufacturing activities and measurement of contribution from the manufacturer crowds is essential.

(2) Manufacturers: The manufacturers are advanced from the supplier tiers in the current supply chain configuration, and they operate the factories and provide materials, sub-assembly, and products according to orders from open innovators. The manufacturer crowd can be divided into several sub-clusters according to the position along the value chain, such as raw material providers, secondary suppliers, direct suppliers, assemblers, and so on. The primary pursuit of the manufacturers is approaching the broader market via collaboration between open innovator crowds and the crowdsourcing platform. With a broader explored market, a larger volume of the value chains can be brought to the manufacturing network. These value chains constructed a cross-link relationship, while a manufacturer can achieve maximum reusability based on the commonality of the process. Thus, with the expansion of the customer clusters, manufacturers can focus on their core competitive edges and achieve economies of scale.

With the adoption of the open business model, these manufacturing enterprises participate in the crowdsourced manufacturing model in two different scenarios. The first scenario entails a group of manufacturers who use crowdsourced manufacturing as their primary economic activities and plan their schedule in the center of crowdsourced tasks. They rely on the assignment of crowdsourcing tasks from the platform and access to target markets from the open innovators. An inferior task allocation solution will lead to inefficiency supply chain configuration at the platform level and order congestion or avoidable production line idle at the manufacturer level. A successful task allocation system should be anchored to modeling of the manufacturer’s plant and the logistic system, as well as a global production planning for platform and manufacturers. As the participation in crowdsourced manufacturing implies an increasing number of value chains going through the manufacturer, the material flow among the upstream and downstream partners is increasingly complex. As they approach the realization of material flow, the logistics issue is a rising challenge for manufacturers. Coordination along the material flow is established using information exchange about manufacturing activities, logistics, and inventory among the manufacturing networks. Thus, a fusion of the current MES/ERP system which accommodates the open structure is needed in crowdsourced manufacturing.

In the second scenario, the manufacturers use their value chain to serve their major manufacturing activities while sharing their excess manufacturing capabilities along with the manufacturing network. Manufacturers in this scenario operate the production line with a mix of existing tasks from their own value chain and crowdsourcing tasks from the platform. In addition to the common challenges which are mentioned in the first scenario, manufacturers in the second scenario struggle with balancing the existing tasks and the crowdsourcing tasks. Introducing crowdsourcing tasks occurs after a high-frequency negotiation contracting process among those in the manufacturing network, which entails a resource matching process of innovation demands and sharable capabilities. This two-sided matching process requires the manufacturers to discover their shareable capabilities in terms of compatible products, time windows, and quantity. Sharable capability is calculated by manipulating the order sequencing, batching, and balancing on the shop floor. A system of methods to help manufacturers maximize their shareable capabilities can be recognized as a significant barrier to participating in crowdsourced manufacturing.

(3) Platform: A platform can be considered as a multi-sided market, which serves distinct crowds of third-party users and provides them with network benefits [

112]. It is operated as a marketplace to enable the match of demands and supplies [

113]. From a manufacturing network perspective, a crowdsourcing platform is a two-sided market, where the open innovators publish their innovations as a set of manufacturing demands and manufacturers publish their manufacturing capabilities as supplies. Following a platform model, the crowdsourcing platform company integrates external open innovators and manufacturers, and thereby creates and captures value from that manufacturing network.

This integrating process entails a reconfiguration of the manufacturing capabilities to serve the innovations. The crowdsourcing platform performs as an intermediator among the manufacturing activities. It reallocates the existing skills in the manufacturer crowds to accommodate the emerging innovating value chains based on a system of reconfiguration mechanisms. It can help the open innovator peel off the process-related and organization-related configuration activities and utilize the services from the platform and the manufacturing capabilities from manufacturer crowds instead. On the other side of the platform, manufacturer crowds no longer need to find target markets while also coordinating with upstream and downstream manufacturer partners.

In the crowdsourcing model, the platform is continually attempting to expand the population of manufacturers and open innovators. A larger open innovator population leads to an increasing number of paths to the market and a wider variety of customer needs. At the same time, more manufacturers linked to the platform implies a bigger arsenal of capability and knowledge to fulfill the customers’ needs. Since the expansion of the open innovator scale leads to a rising number of value chains, the platform is challenged by installing a system of configuration strategies to allocate crowdsourcing tasks as an intermediator in the platform. A population of manufacturers and dynamic manufacturing networks significantly raises the complexity of the decision-making process in the platform. The decision support for sustaining partner crowds is required by the platform under the paradigm of crowdsourced manufacturing.

7. An Example of Tank Trailer Crowdsourced Manufacturing

The running example in this paper is the transformation of the tank trailer industry [

114] to crowdsourced manufacturing. The tank trailer industry is driven by customers and rearranges manufacturing capabilities and technologies to achieve maximum satisfaction. Most tank trailer companies connect to the market by themselves and plan the products considering the customer needs they collected. A large volume of essential parts and systems rely on the corporation and external partners, including axles, braking systems, pump assemblies, and accessories, among others. From the after-sale service, tank trailer companies can sense some customer needs, such as the need for minimizing maintenance efforts, meters of trailer mileage, tire pressure adjustment, etc. A broad search for solution suppliers can achieve the innovation of the tank trailer by defining a series of requirements to collect the solution. For example, the automatic tire inflation system can be a solution for tire pressure adjustment, and the corresponding manufacturer can serve the realization of this new tank trailer. The synergy of the existing capabilities and technologies builds up the backbone of the reconfiguration of manufacturers.

The volatile customer needs and a large population of suppliers bring a large amount of product variety to the tank trailer industry, as shown in

Figure 4. The different fluids in various market sectors will lead to an extensive product variety; some of the fluids are flammable or explosive, some fluids may cause fouling issues, some chemicals are erosional, and some fluids must be kept away from edibles through transportation, for example. Each specific customer has their personalized requirements for the accessories, including but not limited to ladders, pump systems, toolboxes. Since the laws and regulations are distinctive in different markets, the products vary in length and tonnage, cross-section shape, as well as the end shape. Currently, configure-to-order is a prevailing strategy to handle this variety. The practitioners integrate the modules and organize the manufacturing according to the customer orders.

This specific example of tank trailer manufacturing shows how manufacturing is fulfilled through a crowdsourcing manufacturing network. Nearly 100 tank trailer companies have opened in Quanpuzhen, Shandong Province in the past three decades, and the total output of this industry cluster takes about two-thirds of the national market share [

101]. The satellite map of this industrial cluster is shown in

Figure 5, in which the red label represents a related manufacturer. The cooperation of these manufacturer crowds relies on the long-term outsourcing and personal relationship of the owners. For successful implementation, it is imperative that transformation roadmaps for installation of crowdsourced manufacturing in the conventional manufacturing industries be developed. By applying state-of-the-art technologies, the construction of the cooperative manufacturing relationship can be fully digitalized. At the same time, coordination among the manufacturers can be achieved by pervasive connections and transferable engineering software.

8. Industry 4.0 Driven Crowdsourced Manufacturing

In accordance with the principles of axiomatic design [

117], the product fulfillment process encompasses a series of cascading mappings of “what–how” relationships across four consecutive domains: the customer, functional, physical, and process domains. Systematic design decisions within each domain are delineated by Customer Needs (CNs), Functional Requirements (FRs), Design Parameters (DPs), and Process Variables (PVs), respectively. Traditionally, these mapping decisions are centralized within one enterprise [

118]. However, with the adoption of open business models, such decisions are becoming decentralized across multiple decision agents, transcending organizational boundaries to leverage resources and capabilities through crowdsourcing [

119].

It is of practical significance to analyze the workflow of crowdsourced manufacturing along a value chain. This elucidates the fundamental mechanism underlying the workflow, encompassing decision agents, domains, processes, and crowdsourcing contracting mechanisms. The subsequent section presents a comprehensive framework of crowdsourced manufacturing workflow in cases where multiple value chains link customer clusters and manufacturing agent crowds through the same platform companies. It also examines the networked flow in crowdsourced manufacturing, including information flow and manufacturing flow among customers, open innovators, platforms, and manufacturing agent crowds.

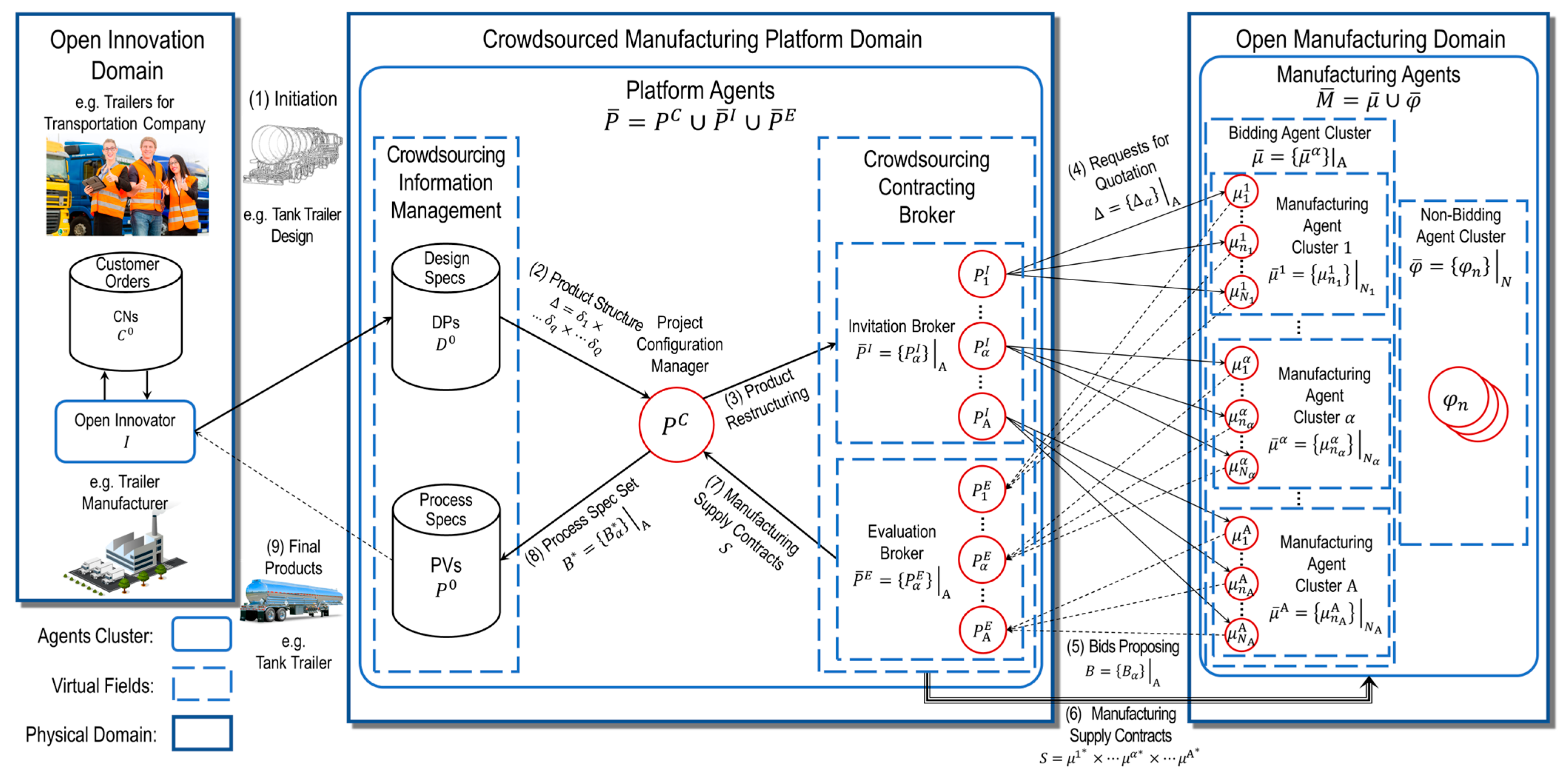

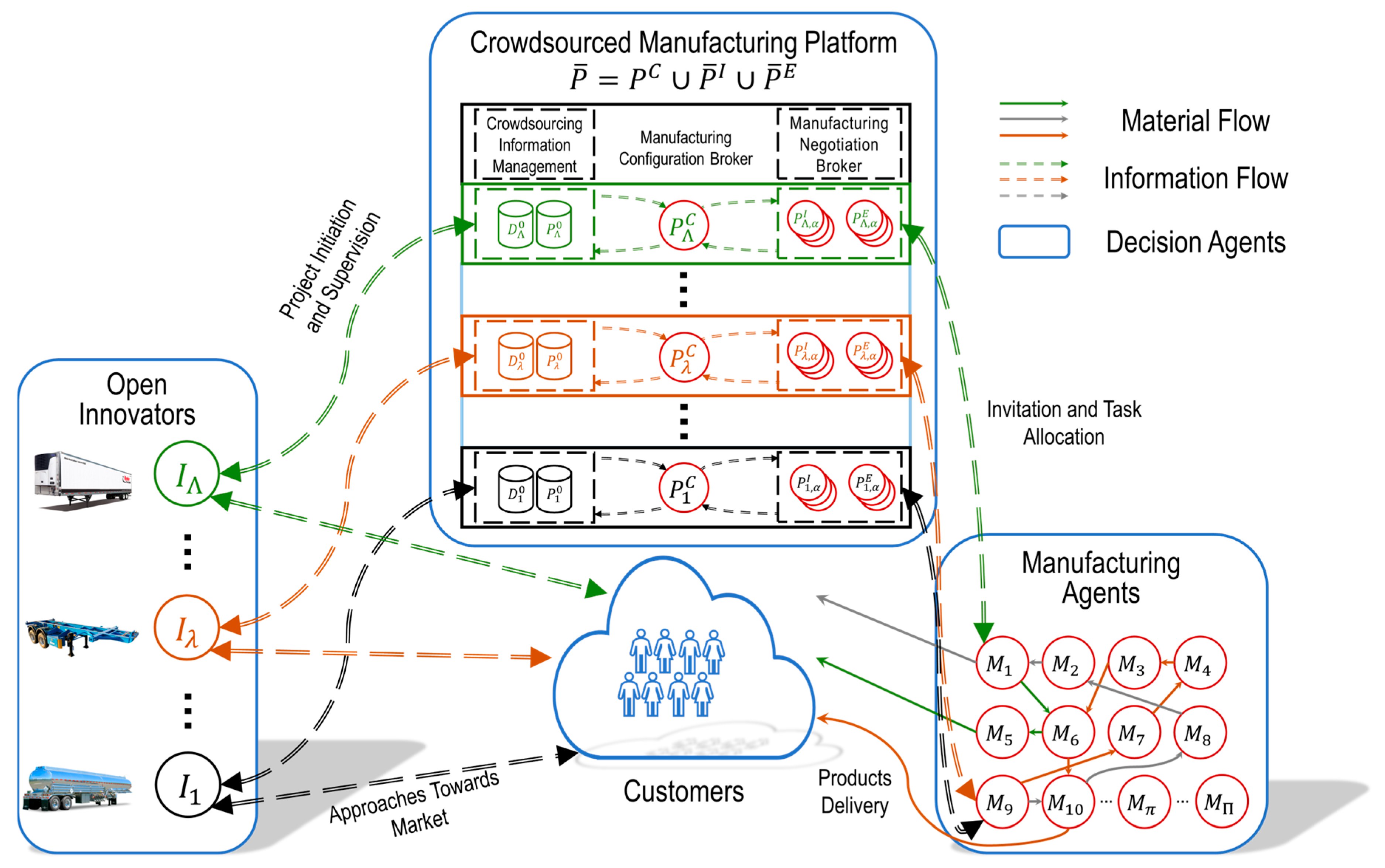

The paradigm shift to crowdsourced manufacturing entails integrating external partners into all activities in value creation and capture along the value chain. Consequently, product manufacturing is fulfilled through collaboration among multiple parties in three physical domains: open innovation, crowdsourced manufacturing platform, and open manufacturing domain [

120].

8.1. Problem Formulation

The open innovation domain, situated at the front-end, establishes connections with customers. The primary decision agent in this domain, identified as open innovator , is responsible for collecting CNs, drafting product designs, and handling sales and after-sales service of the final product. Using the tank trailer example, represents a tank trailer manufacturing company that adopts the open business model and implements the crowdsourcing model as a crowdsourcer. The company serves customers akin to a transportation company by innovating products to meet their needs. collects CNs and records them into customer orders , marking the start of the product fulfillment process. Upon completing product design, initiates the crowdsourced manufacturing process with the platform by submitting the product design files. Upon completion of product manufacturing, final products are handed over to , facilitating their sale to customers.

The manufacturing agents () serve as decision agents in the backend of crowdsourced manufacturing, constituting the manufacturing agent domain. possesses knowledge of generating manufacturing plans, considering process constraints, resource utilization limitations, and fulfillment capabilities of actual manufacturing tasks. In the tank trailer example, represents suppliers in the trailer industry cluster, segmented into various clusters based on specialty. Each cluster, indexed by , where denotes the total number of clusters, encompasses, for example, the manufacturers in tank trailer industries, such as frame suppliers, axle companies, steel sheet factories, and welding workshops, among others.

The bidding agents within each cluster are denoted as , representing manufacturers bidding on manufacturing tasks. Each individual manufacturer within a cluster is denoted as , where is the index of the bidding manufacturer in cluster , with and representing the total number of manufacturers in cluster . The aggregation of bidding manufacturers across all clusters forms the bidding agent cluster, denoted as . However, due to operational heterogeneity, some manufacturing agents may choose not to participate in crowdsourced manufacturing, forming the non-bidding agent cluster . Each individual manufacturer within this cluster is denoted as , , where represents the index of agents in the non-bidding cluster, with denoting the total size of .

The crowdsourced manufacturing platform domain serves as the intermediary between the front-end open innovation and the open manufacturing domain. The primary agents in this domain are the platform brokers (), responsible for tasks processing and deliveries to , contracting and coordination with , and submission of crowdsourcing contracting results.

Two virtual fields exist within the crowdsourced manufacturing platform domain: crowdsourcing information management and crowdsourcing contracting broker. The field of crowdsourcing information management interfaces with the open innovation domain and comprises two databases that store DPs as design specs and PVs as process specs . The other virtual field, the crowdsourcing contracting broker, sends open calls to the open manufacturing domain to invite , collects responses from manufacturer crowds, and awards preferred with supply contracts.

8.2. Workflow of Crowdsourced Manufacturing

The open call broadcasting and response collection are facilitated by two brokers. The invitation broker initiates the invitation function of the crowdsourcing contracting mechanism, with individual corresponding to the manufacturing cluster , . Similarly, the collection and evaluation functions are managed by manufacturing evaluation brokers , with individual evaluation brokers for each manufacturing cluster. The index follows the manufacturing cluster , which indicates the accountability of and .

The manufacturing configuration manager

coordinates the front-end and backend interfaces, receiving product design specs

and restructuring the product design into crowdsourcing tasks. It also summarizes manufacturing contracts and stores process specs in

. The union of

,

, and

constitutes the platform brokers

, denoted as

. The workflow of crowdsourced manufacturing, illustrated with the tank trailer industries example, is depicted in

Figure 6.

The workflow of crowdsourced manufacturing commences with the project initiation process by following the completion of product design. The deliverables of this initiation process are the saved product design files. Subsequently, the manufacturing configuration manager accesses the product structure from . The product structure, denoted as Δ, is structured as , where , representing specific manufacturing subtasks such as a trailer frame or pump system. is the subtask index, and is the total number of subtasks.

The structured depicts the internal relationships of the product, such as the assembly structure. Upon retrieval of , restructures it into manufacturing requests for quotation , where comprises a set of manufacturing subtasks . The number of requests for quotation corresponds to the number of manufacturing agent clusters, thus sharing the cluster index with . is broadcasted by as an invitation, and receives it, analyzes the requirements, and makes participation decisions.

Participating agents respond with a set of manufacturing bids,, collected in , where . evaluates these bids, selecting preferred bids and the corresponding winners . The winners are rewarded with manufacturing supply contracts , organizing the winner in each cluster by a cartesian product to form a manufacturing network. The manufacturing supply contracts are also sent to , and the corresponding manufacturing bids are saved to as process spec sets . Following the execution of crowdsourced manufacturing, final products are manufactured by and delivered to customers. As the final stage, product-related information is sent to , facilitating product sales and providing after-sales services.

In contrast to the “cascading” model in axiomatic design, the product fulfillment process in the crowdsourced manufacturing paradigm is depicted as “zigzagging.” This deviation is attributed to the engagement of external partners. Consequently, innovative product fulfillment is attained through the collaboration of all decision agents in the fulfillment process. However, this collaboration is established through contracting, and the coordination of product material flow [

20]. Therefore, the workflow in crowdsourced manufacturing can be characterized as a collaborative-negotiation-based supply contracting process.

9. A Holistic View of Crowdsourced Manufacturing

As an intermediate marketplace for open innovators and manufacturers, the platform serves a population of distinctive open innovators to connect a broader market, meanwhile invites extensive manufacturers to expand the capability arsenal and gain network benefits. This expansion impulse leads to many value chains going through the platform company, which can be treated as a series of projects. The platform company uses crowdsourced information management fields to serve open innovators in the front-end, which provides databases to manage design and process specs. The project configuration manager

serves as a coordinator to manage the project workflow. The manufacturers are accommodated by the platform through the crowdsourcing contracting mechanism fields, where they broadcast the crowdsourcing tasks and collect the responses. A synergy of these three constructs a module to serve a value chain. The increasing number of value chains requires the platform to scale up an appropriate number of serving modules to serve the manufacturing of the products. The conceptual framework, as shown in

Figure 7, demonstrates the workflow execution of platform-driven crowdsourced manufacturing to accommodates multiple projects.

A larger population of open innovators attracts a variety of customers, such as tank trailers, container trailers, and refrigerated trailers, among others. These open innovators initiate various value chains as product design projects, which are indexed by , where is the total number of initiated projects. The platform develops the corresponding interfaces to serve these open innovators and corresponding manufacturing agents clusters. The corresponding open innovator and platform brokers of project can be represented as and , respectively. Each has a broadcasting output and bid collecting interfaces to connect the manufacturers in the manufacturer agent population, which is indexed by , . The total number of the manufacturer agent population is denoted as . The scaling up of the platform company leads to a stacking of the serving modules, which transforms the two-dimensional perspective of the crowdsourced manufacturing workflow to a three-dimensional holistic framework.

The horizontal dimension is the direction of the workflow. The front-end is the open innovators, while the backend is the manufacturing agent crowds. This dimension realizes the crowdsourced manufacturing workflow with all the processes shown in

Figure 7. The vertical dimension is the functions of the platform. The upper interfaces serve the workflow from front-end to backend, and the lower interfaces serve the opposite direction. At the front-end, the upper interfaces are the data management module to receive the project initiation from

and save the product design specs into

. The upper interfaces at the backend let the

send the request for a quotation to connect the

. The lower interfaces towards backend handle the bid proposals from the

to enable the evaluation by

. The lower interfaces towards the front-end manage the process specs in

and interact with

to inform the product delivery. The third dimension represents the depth, which entails a variety of value chains in this holistic view. The corresponding open innovator

and a serving module

in crowdsourced manufacturing platform

are arranged along each value chain, where

.

10. Information and Material Flows in Crowdsourced Manufacturing

Based on the holistic conceptual framework of crowdsourced manufacturing,

Figure 8 illustrates the information flow and the networked material flow in crowdsourced manufacturing. The open innovator establishes the information connections to the customers to serve the collection of the CNs for product innovation, as well as sales and aftersales service for the final product. Meanwhile, the platform leads the manufacturing agent crowds to realize product manufacturing. After the final assembly, the products can be sent from the last manufacturing agents in the network to the customers. Therefore, two flows build up the linkage to the customer, the information flow from and to open innovators

as the stimulus of the crowdsourced manufacturing paradigm, as well as the material flow from manufacturing agent crowds as the physical delivery of the products. In this case, the platform company acts as a bridge to link the information flow and material flow. The information flows between

and

initiate the crowdsourcing projects and set the product configuration to serve the crowdsourcing product fulfillment. Moreover, it also establishes the monitoring approach for the

to supervise the manufacturing process.

At the backend of the platform company, the contracting information flow enables invitation of the and allocates the tasks to forge the manufacturing network. In the following manufacturing execution stage, the information flow also serves as the handler to coordinate the material flow inside the manufacturer agent crowds. Because the manufacturers utilize their specialties to maximize the economies of scale, one can participate in multiple value chains. For instance, because of the commonalities between the value chains, a trailer axle company can participate in three value chains to connect the tank trailer, container trailer, and refrigerate trailer markets. Moreover, various value chains imply difference in the process precedence, and a manufacturer can serve distinct positions.

From the analysis of information and material flow in crowdsourced manufacturing, the operation of companies in one decision agent cluster is influenced by the collaboration with companies in the rest of the decision agent clusters. For instance, the operation of the platform companies relies on the characteristics of the participated open innovators, as well as the capabilities and the varieties of manufacturer crowds with which it is linked. The performance of these external partners restricts the economic behaviors of the companies themselves, similar to how the platform can only link to the targeted market through collaboration with the related open innovators and manufacturers. Meanwhile, the capabilities of external partners can technically support the expansion of the companies. The other crowds of partners structure a two-dimensional decision-making plane, which presents a decision space to choose a value chain and a position along with it. The company can explore the portfolio of collaboration potentials in that decision space, where the abundance and diversity of the partner crowds will determine the limits of participating in crowdsourced manufacturing. From a service-oriented perspective, the other two crowds collaboratively construct a service system to serve the company as a user. This two-dimensional decision-making scheme generally exists in all three decision agent clusters, namely open innovators, platforms, and manufacturers.

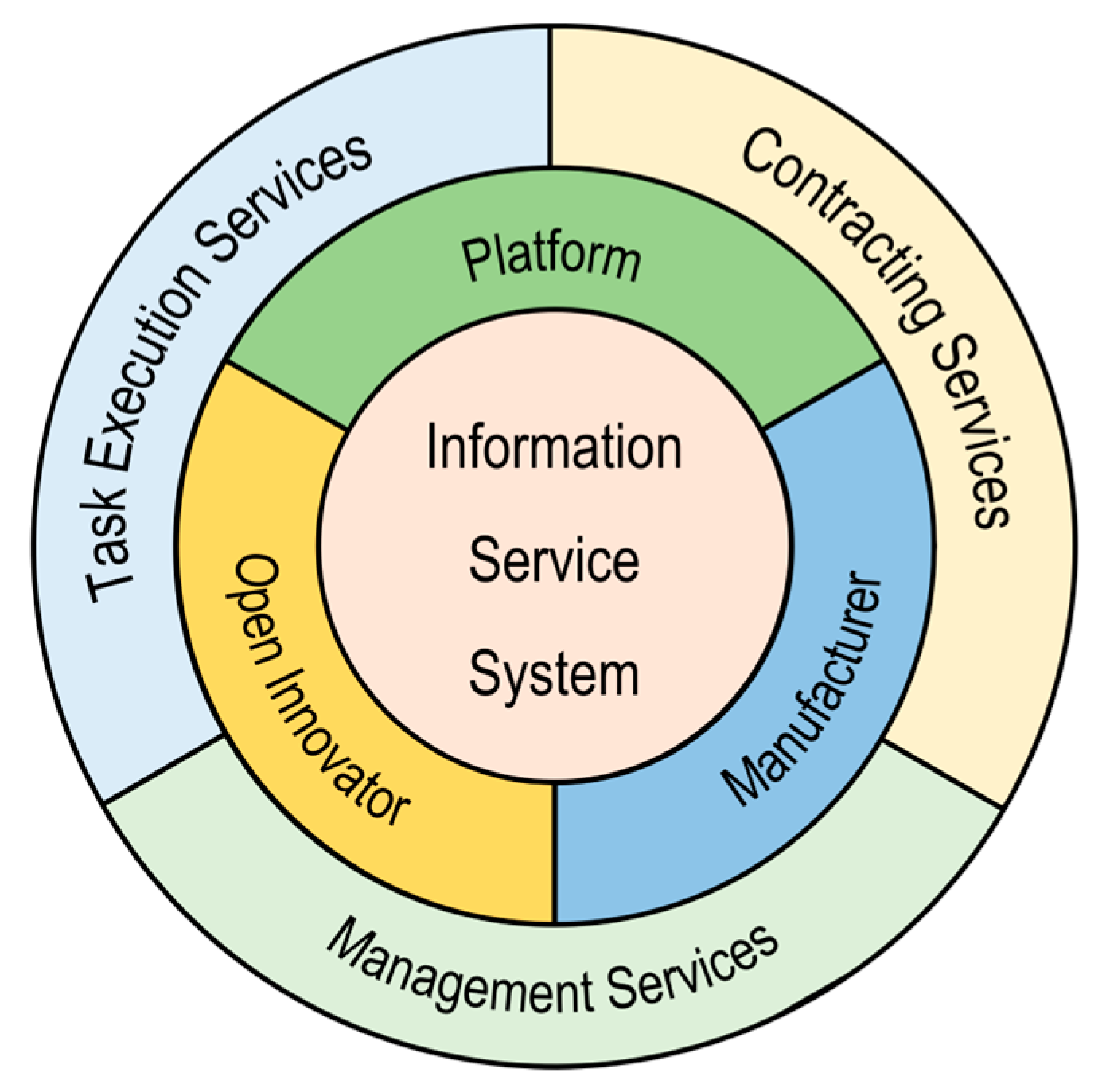

From the trichotomy analysis of decision agents in crowdsourcing, each of three decision agent clusters have their own standpoints as well as motivations. Thus, the views of each decision agent cluster originate from the different contexts of companies and seek various operational objectives. The distinctiveness of decision agents implies perpendicular relationships among the resulting views. In this regard, a cubic structure is proposed to represent this system of perpendicular view and corresponding decision-making planes.

There are three dimensions to represent the views of open innovators, platforms, and manufacturers. From each view, the other two structure a discretized decision-making plane and acts as a portfolio of product fulfillment functions of a service system. The synergy of the three views of the decision agent cluster leads from two-dimensional discretized decision-making planes to a three-dimensional block array to represent the selection and collaborative relationships among the decision agents. Each block represents the engagement of three specific decision agents to construct a collaborative manufacturing relationship for innovative product fulfillment. The mapping of each pair of decision agent clusters implies a collaborative relationship to form a functional area for accommodating the external partners. This collaboration can accelerate the execution of the value chain for targeted users. Three manufacturing functional areas entail the XaaS paradigm, in which each functional area aims to allow crowdsourced manufacturing to be user-friendly and allow it to respond quickly and accommodate a variety of partners. In this regard, three service systems underscore how to serve the decision agents’ views in crowdsourced manufacturing.

11. Crowdsourced Manufacturing for Maas

In line with the functional, behavioral, and structural (noted as FBS) views, a crowdsourced manufacturing system empowers production and operations to integrate diverse business functions within a coherent framework of manufacturing-as-a-service (MaaS). This integration is realized through the mappings between the FBS views of the three-dimensional architecture of crowdsourced manufacturing, as shown in

Figure 9. The mapping from one view to another implies a service system to serve the other views. Therefore, the combination of mapping relationships among the open innovator’s functional view, the manufacturer’s behavioral view, and the platform’s structural views articulates a cyclic MaaS reference model that implies an important research agenda for crowdsourced manufacturing.

The view mapping between the behavioral view from manufacturers to the structural view from the platform reflects digitalized contracting evaluation function of an MaaS system. It ensures the quality of product fulfillment services that the open innovator could receive. An important research topic is the contracting mechanism incorporating explicit and inexplicit criteria evaluation for quality assurance of the bidding and customer satisfaction.

The mapping from a functional view and a structural view reflects reconfiguration and operation of a manufacturing network. It enables the manufacturer to utilize core competing capabilities and links other manufacturers to outsource the peripheral activities. This material flow network requires the execution of crowdsourcing tasks to be incorporated as a critical functional module of the MaaS system. Recognizing manufacturers as the targeted user, many worthwhile research opportunities exist in relation to the task execution service, a manufacturer-friendly service architecture that includes task derivation and decomposition methods, and inter-manufacturer material flow planning, as well as task acceptance and shop floor scheduling interactive framework, and so on [

121].

The mapping between the functional view from open innovators and the behavioral view from manufacturers entails a large volume of digitalized product fulfillment demands for crowds of manufacturers and the corresponding clusters. This mapping implies a management service functional module of MaaS for the platform to monitor and derive an optimal managerial protocol. A promising research topic is population-dynamics-based modeling for analyzing the cohort behavior and performance among multi-cluster manufacturer crowds. It is also important to investigate protocol deriving methods based on an evolutionary game for collaborative negotiation among the open manufacturer crowds. A valuable research topic is developing the information service system by implementing blockchain-based smart contracts as a distributed database. It provides the technical cornerstones for the platform, the manufacturers, and open innovator to solidify their collaboration relationship and information exchanging platform without security concerns.

12. Concluding Remarks

Crowdsourced manufacturing represents an emerging business model that establishes extensive connections with customer crowds and the manufacturing shop floor through a platform-based structure. This structure supports a diverse and large capability arsenal by maintaining a population of manufacturers and leveraging a crowdsourcing mechanism to extensively search for available solutions. The widely accepted paradigm of mass customization necessitates a rapid response to fluctuating customer demands, requiring an agile, reconfigurable manufacturing network. Crowdsourced manufacturing facilitates a job decomposition process within an innovative product value chain and reconfigures manufacturing networks to meet made-to-order (MTO) requirements. Reviews of state-of-the-art research and industry practices indicate a growing consensus on a shift towards crowdsourced manufacturing as the future manufacturing paradigm. Stakeholder analysis in this context categorizes decision agents along the crowdsourcing value chain into three groups: open innovators, platforms, and manufacturers, each playing distinct roles in value capture, structuring, and creation.

The proposed workflow of the crowdsourcing value chain includes task decomposition, solution searching, response collection evaluation, and awarding to optimize the manufacturing network. Effective platforms attract diverse value chains and are required to offer comprehensive information management and crowdsourcing contracting mechanisms to support both open innovators and manufacturing crowds. This platform strategy emphasizes the maximum reuse of manufacturers, leading to shared information and material flows, positioning manufacturers at a pivotal point in the network. The interconnected flows of information and materials in crowdsourced manufacturing underscores the need for an integrated approach to information, logistics, and production coordination services. A service reference model is outlined to provide systematic support to open innovators, manufacturers, and platforms.