Group Efficiency Evaluation Under Fixed-Sum Output Constraints: A Cross-EEF Approach with Application to Industrial Carbon Emissions in China

Abstract

1. Introduction

- (1)

- We provide a methodological framework to focus on the problem of competition among groups, and extend the methodology of fixed-sum output DEA to the group level, while the previous studies only assess the performance of DMUs from an individual perspective.

- (2)

- We extend the second model of the GEEFDEA methodology to take the concept of the group into account and combine the proposed method with the average criterion to develop a group performance evaluation approach. In addition, the efficiency of DMUs within the group may be greater than one, which can fully rank all DMUs based on efficiencies.

- (3)

- Compared with the group performance evaluation approach of Ang et al. [30], our proposed approach introduces the fixed-sum output constraint into group cases, in which we construct a common EEF for all groups, to guarantee the consistency of the evaluation criteria.

- (4)

- Compared to the previous fixed-sum output DEA approaches about the selection of EEF, the proposed group cross-EEF evaluation approach selects the same number of EEF as the groups for efficiency evaluation, providing rich decision information reflected in other EEFs.

2. Preliminary

2.1. CCR Model and Cross-Efficiency

2.2. Construction of the EEF

3. Proposed Models

3.1. Group Efficiency Assessment Model with Fixed-Sum Output

3.2. Group Cross-EEF Evaluation Model

4. Empirical Example

4.1. Data Collection and Description

4.2. Analysis of Assessment Results

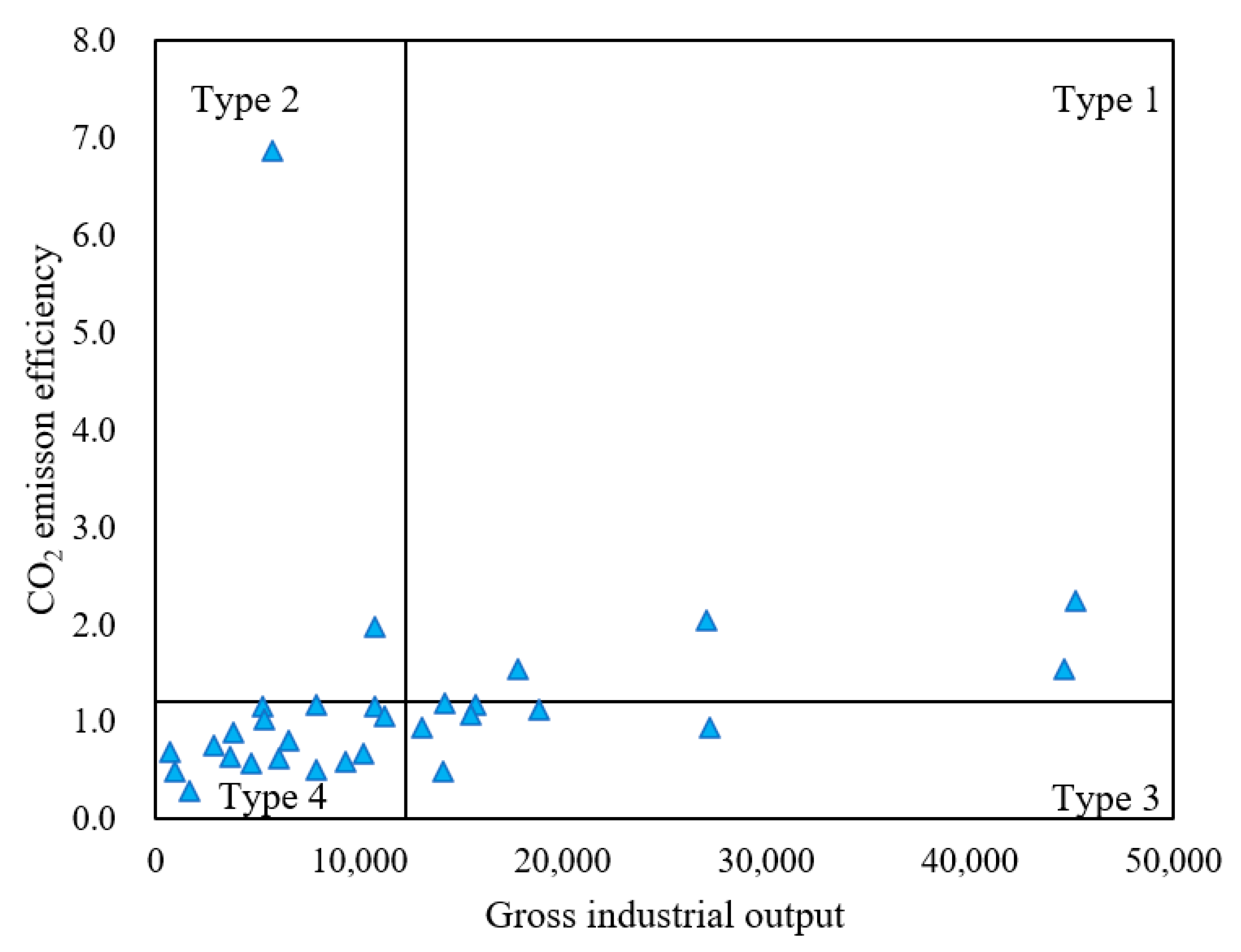

4.3. Competitive Strategy Analysis

4.4. Suggestions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision-making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Oukil, A.; El-Bouri, A.; Emrouznejad, A. Energy-aware job scheduling in a multi-objective production environment—An integrated DEA-OWA model. Comput. Ind. Eng. 2022, 168, 108065. [Google Scholar]

- Lozano, S. Bargaining approach for efficiency assessment and target setting with fixed-sum variables. Omega 2023, 114, 102728. [Google Scholar] [CrossRef]

- Wu, J.; Li, M.; Zhu, Q.; Zhou, Z.; Liang, L. Energy and environmental efficiency measurement of China’s industrial sectors: A DEA model with non-homogeneous inputs and outputs. Energy Econ. 2019, 78, 468–480. [Google Scholar] [CrossRef]

- Chu, J.; Dong, Y.; Yuan, Z. An improved equilibrium efficient frontier data envelopment analysis approach for evaluating decision-making units with fixed-sum outputs. Eur. J. Oper. Res. 2024, 318, 592–604. [Google Scholar] [CrossRef]

- Chen, L.; Guo, M.; Li, Y.; Liang, L.; Salo, A. Efficiency intervals, rank intervals and dominance relations of decision-making units with fixed-sum outputs. Eur. J. Oper. Res. 2021, 292, 238–249. [Google Scholar] [CrossRef]

- Feng, Q.; Li, D.; Zhou, G.; Wu, Z. Fairness based unique common equilibrium efficient frontier for evaluating decision-making units with fixed-sum outputs. Ann. Oper. Res. 2024, 341, 427–449. [Google Scholar] [CrossRef]

- Yu, S.; Lei, M.; Deng, H. Evaluation to fixed-sum-outputs DMUs by non-oriented equilibrium efficient frontier DEA approach with Nash bargaining-based selection. Omega 2023, 115, 102781. [Google Scholar] [CrossRef]

- Lins, M.P.E.; Gomes, E.G.; de Mello, J.C.C.S.; de Mello, A.J.R.S. Olympic ranking based on a zero sum gains DEA model. Eur. J. Oper. Res. 2003, 148, 312–322. [Google Scholar] [CrossRef]

- Gomes, E.G.; Lins, M.E. Modelling undesirable outputs with zero sum gains data envelopment analysis models. J. Oper. Res. Soc. 2008, 59, 616–623. [Google Scholar] [CrossRef]

- Feng, C.; Chu, F.; Zhou, N.; Bi, G.; Ding, J. Performance evaluation and quota allocation for multiple undesirable outputs based on the uniform frontier. J. Oper. Res. Soc. 2019, 70, 472–486. [Google Scholar] [CrossRef]

- Zhou, D.; Hu, F.; Zhu, Q.; Wang, Q. Regional allocation of renewable energy quota in China under the policy of renewable portfolio standards. Resour. Conserv. Recycl. 2022, 176, 105904. [Google Scholar] [CrossRef]

- Cui, X.; Zhao, T.; Wang, J. Allocation of carbon emission quotas in China’s provincial power sector based on entropy method and ZSG-DEA. J. Clean. Prod. 2021, 284, 124683. [Google Scholar] [CrossRef]

- Liu, T.; Zheng, Z.; Du, Y. Evaluation on regional science and technology resources allocation in China based on the zero sum gains data envelopment analysis. J. Intell. Manuf. 2021, 32, 1729–1737. [Google Scholar] [CrossRef]

- Yang, M.; Li, Y.J.; Chen, Y.; Liang, L. An equilibrium efficiency frontier data envelopment analysis approach for evaluating decision-making units with fixed-sum outputs. Eur. J. Oper. Res. 2014, 239, 479–489. [Google Scholar] [CrossRef]

- Yang, F.; Wu, D.D.; Liang, L.; O’Neill, L. Competition strategy and efficiency evaluation for decision making units with fixed-sum outputs. Eur. J. Oper. Res. 2011, 212, 560–569. [Google Scholar] [CrossRef]

- Yang, M.; Li, Y.J.; Liang, L. A generalized equilibrium efficient frontier data envelopment analysis approach for evaluating DMUs with fixed-sum outputs. Eur. J. Oper. Res. 2015, 246, 209–217. [Google Scholar] [CrossRef]

- Fang, L. A new approach for achievement of the equilibrium efficient frontier with fixed-sum outputs. J. Oper. Res. Soc. 2016, 67, 412–420. [Google Scholar] [CrossRef]

- Zhu, Q.; Wu, J.; Song, M.; Liang, L. A unique equilibrium efficient frontier with fixed-sum outputs in data envelopment analysis. J. Oper. Res. Soc. 2017, 68, 1483–1490. [Google Scholar] [CrossRef]

- Zhu, Q.; Song, M.; Wu, J. Extended secondary goal approach for common equilibrium efficient frontier selection in DEA with fixed-sum outputs. Comput. Ind. Eng. 2020, 144, 106483. [Google Scholar] [CrossRef]

- Zhu, Q.; Li, X.; Li, F.; Wu, J.; Sun, J. Analyzing the sustainability of China’s industrial sectors: A data-driven approach with total energy consumption constraint. Ecol. Indic. 2021, 122, 107235. [Google Scholar]

- Sun, J.; Li, G.; Wang, Z. Optimizing China’s energy consumption structure under energy and carbon constraints. Struct. Change Econ. Dyn. 2018, 47, 57–72. [Google Scholar] [CrossRef]

- Amirteimoori, H.; Amirteimoori, A.; Karbasian, M. Performance measurement of gas companies with fixed-sum inputs: A DEA-based model. J. Econ. Stud. 2020, 47, 1591–1603. [Google Scholar] [CrossRef]

- Ding, T.; Zhang, Y.; Zhang, D.; Li, F. Performance evaluation of Chinese research universities: A parallel interactive network DEA approach with shared and fixed sum inputs. Socio-Econ. Plan. Sci. 2023, 87, 101582. [Google Scholar] [CrossRef]

- Wu, J.; An, Q.; Yao, X.; Wang, B. Environmental efficiency evaluation of industry in China based on a new fixed sum undesirable output data envelopment analysis. J. Clean. Prod. 2014, 74, 96–104. [Google Scholar] [CrossRef]

- Li, Y.; Hou, W.; Zhu, W.; Li, F.; Liang, L. Provincial carbon emission performance analysis in China based on a Malmquist data envelopment analysis approach with fixed-sum undesirable outputs. Ann. Oper. Res. 2021, 304, 233–261. [Google Scholar] [CrossRef]

- Li, F.; Zhang, D.; Zhang, J.; Kou, G. Measuring the energy production and utilization efficiency of Chinese thermal power industry with the fixed-sum carbon emission constraint. Int. J. Prod. Econ. 2022, 252, 108571. [Google Scholar] [CrossRef]

- Zhang, X.; Xia, Q.; Wei, F. Efficiency evaluation of two-stage parallel-series structures with fixed-sum outputs: An approach based on SMAA and DEA. Expert. Syst. Appl. 2023, 227, 120264. [Google Scholar] [CrossRef]

- Tsai, H.; Wu, J.; Sun, J. Cross-efficiency evaluation of Taiwan’s international tourist hotels under competitive and cooperative relationships. J. China Tour. Res. 2013, 9, 413–428. [Google Scholar]

- Ang, S.; Chen, M.; Yang, F. Group cross-efficiency evaluation in data envelopment analysis: An application to Taiwan hotels. Comput. Ind. Eng. 2018, 125, 190–199. [Google Scholar] [CrossRef]

- Cook, W.D.; Ruiz, J.L.; Sirvent, I.; Zhu, J. Within-group common benchmarking using DEA. Eur. J. Oper. Res. 2017, 256, 901–910. [Google Scholar] [CrossRef]

- Xia, M.; Chen, J.; Zeng, X.J. Data envelopment analysis based on team reasoning. Int. Trans. Oper. Res. 2020, 27, 1080–1100. [Google Scholar] [CrossRef]

- Liang, L.; Wu, J.; Cook, W.D.; Zhu, J. The DEA game cross-efficiency model and its Nash equilibrium. Oper. Res. 2008, 56, 1278–1288. [Google Scholar] [CrossRef]

- Wu, J.; Chu, J.; Sun, J.; Zhu, Q. DEA cross-efficiency evaluation based on Pareto improvement. Eur. J. Oper. Res. 2016, 248, 571–579. [Google Scholar] [CrossRef]

- Doyle, J.; Green, R. Efficiency and cross-efficiency in DEA: Derivations, meanings and uses. J. Oper. Res. Soc. 1994, 45, 567–578. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W. Programming with linear fractional functionals. Nav. Res. Logist. 1962, 9, 181–186. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, F.; Wei, F.; Wang, Y. Provincial CO2 emission efficiency analysis in China based on a game cross-efficiency approach with a fixed-sum undesirable output. Environ. Dev. Sustain. 2024, 26, 14535–14560. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, B.; Chen, Z. Carbon emissions reductions and technology gaps in the world’s factory, 1990–2012. Energy Policy. 2016, 91, 28–37. [Google Scholar] [CrossRef]

- Dong, C.; Dong, X.; Jiang, Q.; Dong, K.; Liu, G. What is the probability of achieving the carbon dioxide emission targets of the Paris Agreement? Evidence from the top ten emitters. Sci. Total Environ. 2018, 622, 1294–1303. [Google Scholar] [CrossRef]

- Zhang, N. Carbon total factor productivity, low carbon technology innovation and energy efficiency catch-up: Evidence from Chinese thermal power enterprises. Econ. Res. J. 2022, 57, 158–174. [Google Scholar]

- Wei, Y.; Du, M.; Huang, Z. The effects of energy quota trading on total factor productivity and economic potential in industrial sector: Evidence from China. J. Clean. Prod. 2024, 445, 141227. [Google Scholar] [CrossRef]

- Wang, F.; Harindintwali, J.D.; Yuan, Z.; Wang, M.; Wang, F.; Li, S.; Chen, J.M. Technologies and perspectives for achieving carbon neutrality. Innovation 2021, 2, 100180. [Google Scholar]

- Hanssen, S.V.; Daioglou, V.; Steinmann, Z.J.N.; Doelman, J.C.; Van Vuuren, D.P.; Huijbregts, M.A.J. The climate change mitigation potential of bioenergy with carbon capture and storage. Nat. Clim. Chang. 2020, 10, 1023–1029. [Google Scholar] [CrossRef]

- Liu, X.; Wang, B.; Du, M.; Zhang, N. Potential economic gains and emissions reduction on carbon emissions trading for China’s large-scale thermal power plants. J. Clean. Prod. 2018, 204, 247–257. [Google Scholar]

- Chen, X.; Gao, Y.; An, Q.; Wang, Z.; Neralić, L. Energy efficiency measurement of Chinese Yangtze River Delta’s cities transportation: A DEA window analysis approach. Energy Effic. 2018, 11, 1941–1953. [Google Scholar] [CrossRef]

- Wang, R.; Wang, Q.; Yao, S. Evaluation and difference analysis of regional energy efficiency in China under the carbon neutrality targets: Insights from DEA and Theil models. J. Environ. Manag. 2021, 293, 112958. [Google Scholar] [CrossRef]

- Wang, M.; Feng, C. The consequences of industrial restructuring, regional balanced development, and market-oriented reform for China’s carbon dioxide emissions: A multi-tier meta-frontier DEA-based decomposition analysis. Technol. Forecast. Soc. Change. 2021, 164, 120507. [Google Scholar]

- Du, M.; Antunes, J.; Wanke, P.; Chen, Z. Ecological efficiency assessment under the construction of low-carbon city: A perspective of green technology innovation. J. Environ. Plan. Manag. 2022, 65, 1727–1752. [Google Scholar] [CrossRef]

- Li, F.; Ye, S.; Chevallier, J.; Zhang, J.; Kou, G. Provincial energy and environmental efficiency analysis of Chinese transportation industry with the fixed-sum carbon emission constraint. Comput. Ind. Eng. 2023, 182, 109393. [Google Scholar] [CrossRef]

- Li, J.; Wei, F.; Chu, J. Analysis of CO2 emission performance of China’s thermal power industry: A meta-frontier Malmquist–Luenberger approach with fixed-sum CO2 emissions. J. Environ. Plan. Manag. 2024, 67, 1746–1774. [Google Scholar] [CrossRef]

- Liu, Z.; Deng, Z.; He, G.; Wang, H.; Zhang, X.; Lin, J.; Liang, X. Challenges and opportunities for carbon neutrality in China. Nat. Rev. Earth Environ. 2022, 3, 141–155. [Google Scholar] [CrossRef]

- Gao, P.; Yue, S.; Chen, H. Carbon emission efficiency of China’s industry sectors: From the perspective of embodied carbon emissions. J. Clean. Prod. 2021, 283, 124655. [Google Scholar] [CrossRef]

- Han, Y.; Long, C.; Geng, Z.; Zhang, K. Carbon emission analysis and evaluation of industrial departments in China: An improved environmental DEA cross model based on information entropy. J. Environ. Manag. 2018, 205, 298–307. [Google Scholar] [CrossRef]

- Wu, F.; Fan, L.W.; Zhou, P.; Zhou, D.Q. Industrial energy efficiency with CO2 emissions in China: A nonparametric analysis. Energy Policy. 2012, 49, 164–172. [Google Scholar] [CrossRef]

- Wu, J.; Xiong, B.; An, Q.; Sun, J.; Wu, H. Total-factor energy efficiency evaluation of Chinese industry by using two-stage DEA model with shared inputs. Ann. Oper. Res. 2017, 255, 257–276. [Google Scholar] [CrossRef]

- Xie, J.; Liang, Z.; Zhang, X.; Zhu, L. Efficiency evaluation of thermal power plants in China based on the weighted Russell directional distance method. J. Clean. Prod. 2019, 222, 573–583. [Google Scholar] [CrossRef]

- Wu, J.; Xia, P.; Zhu, Q.Y.; Chu, J. Measuring environmental efficiency of thermoelectric power plants: A common equilibrium efficient frontier DEA approach with fixed-sum undesirable output. Ann. Oper. Res. 2019, 275, 731–749. [Google Scholar] [CrossRef]

- Gitarskiy, M.L. The refinement to the 2006 IPCC guidelines for national greenhouse gas inventories. Fundam. Appl. Climatol. 2019, 2, 5–13. [Google Scholar] [CrossRef]

- Chen, Y.; Xue, C.Q.L.; Sun, C. American shopping malls in China: A mosaic analysis of databases. J. Asian Archit. Build. Eng. 2023, 22, 3224–3243. [Google Scholar] [CrossRef]

- Xu, T.; Xue, L.; Xiang, H. Regional gap and sustainable development of interpreting level in mainland China: A statistics and GIS-based study. PLoS ONE 2024, 19, e0295505. [Google Scholar] [CrossRef]

| Indicators | Previously Used in | |

|---|---|---|

| Inputs | Industrial energy consumption (IEC) | Gao et al. [52]; Han et al. [53]; Wu et al. [54];Wu et al. [55]; Zhang et al. [37] |

| Industrial labor force (ILF) | Gao et al. [52]; Wu et al. [54]; Zhang et al. [37]; Xie et al. [56] | |

| Industrial capital (IC) | Gao et al. [52]; Wu et al. [54]; Wu et al. [55]; Zhang et al. [37]; Xie et al. [56] | |

| Investment in industrial pollution control (IIPT) | Wu et al. [55]; Wu et al. [57] | |

| Outputs | Gross industrial output value (GIOV) | Han et al. [53]; Wu et al. [54]; Wu et al. [55]; Zhang et al. [37] |

| Industrial CO2 emissions (ICE) | Han et al. [53]; Wu et al. [54]; Zhang et al. [37]; Xie et al. [56] | |

| Energy | |||

|---|---|---|---|

| Raw Coal | 25.8 kgC/GJ | 20,908 kJ/kg | 1 |

| Coke | 29.2 kgC/GJ | 28,435 kJ/kg | 1 |

| Gasoline | 19.1 kgC/GJ | 43,070 kJ/kg | 1 |

| Kerosene | 19.6 kgC/GJ | 43,070 kJ/kg | 1 |

| Diesel | 20.2 kgC/GJ | 42,552 kJ/kg | 1 |

| Fuel Oil | 21.1 kgC/GJ | 41,816 kJ/kg | 1 |

| Liquefied Petroleum Gas | 17.2 kgC/GJ | 50,179 kJ/kg | 1 |

| Natural Gas | 15.3 kgC/GJ | 38,931 kJ/kg | 1 |

| Variables | Unit | Max | Min | Mean | Std. Dev | |

|---|---|---|---|---|---|---|

| Inputs | ILF | 104 persons | 1354.20 | 11.50 | 255.95 | 284.24 |

| IC | CNY 108 | 70,715.10 | 2612.00 | 23,771.88 | 16,413.81 | |

| IEC | 104 ton | 34,029.40 | 1106.30 | 11,463.92 | 7564.36 | |

| IIPT | CNY 106 | 3806.07 | 63.50 | 1117.45 | 961.60 | |

| Outputs | GIOV | CNY 108 | 45,142.90 | 683.60 | 12,279.32 | 11,151.95 |

| ICE | 104 ton | 35,693.18 | 440.39 | 10,598.64 | 7760.21 |

| Groups | Individuals (Provinces) |

|---|---|

| North China | Beijing, Tianjin, Hebei, Shanxi, Inner Mongolia |

| Northeast China | Liaoning, Jilin, Heilongjiang |

| East China | Shanghai, Jiangsu, Zhejiang, Anhui, Fujian, Jiangxi, Shandong |

| Central China | Henan, Hubei, Hunan |

| South China | Guangdong, Guangxi, Hainan |

| Southwest China | Chongqing, Sichuan, Guizhou, Yunnan |

| Northwest China | Shaanxi, Gansu, Qinghai, Ningxia, Xinjiang |

| Groups | Provinces | North China | Northeast China | East China | Central China | South China | Southwest China | Northwest China | Provinces | Groups | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Efficiency | Ranking | Efficiency | |||||||||

| North China | Beijing | 10.7564 | 1.9317 | 10.7564 | 9.9630 | 10.7564 | 1.9317 | 1.9317 | 6.8610 | 1 | 2.6138 |

| Tianjin | 1.1176 | 1.1207 | 1.1176 | 1.3391 | 1.1176 | 1.1207 | 1.1207 | 1.1506 | 11 | ||

| Hebei | 0.3412 | 0.6499 | 0.3412 | 0.4072 | 0.3412 | 0.6499 | 0.6499 | 0.4829 | 28 | ||

| Shanxi | 0.5304 | 0.8144 | 0.5304 | 0.6043 | 0.5304 | 0.8144 | 0.8144 | 0.6627 | 22 | ||

| Inner Mongolia | 0.3235 | 0.7508 | 0.3235 | 0.2927 | 0.3235 | 0.7508 | 0.7508 | 0.5022 | 27 | ||

| Northeast China | Liaoning | 0.4582 | 0.7429 | 0.4582 | 0.4958 | 0.4582 | 0.7429 | 0.7429 | 0.5856 | 25 | 0.8223 |

| Jilin | 0.8084 | 0.9655 | 0.8084 | 0.8241 | 0.8084 | 0.9655 | 0.9655 | 0.8780 | 18 | ||

| Heilongjiang | 0.5763 | 0.7599 | 0.5763 | 0.4520 | 0.5763 | 0.7599 | 0.7599 | 0.6372 | 23 | ||

| East China | Shanghai | 2.5639 | 1.4212 | 2.5639 | 1.8120 | 2.5639 | 1.4212 | 1.4212 | 1.9667 | 4 | 1.7112 |

| Jiangsu | 1.7530 | 1.1765 | 1.7530 | 2.0031 | 1.7530 | 1.1765 | 1.1765 | 1.5416 | 6 | ||

| Zhejiang | 2.5940 | 1.4162 | 2.5940 | 2.1885 | 2.5940 | 1.4162 | 1.4162 | 2.0313 | 3 | ||

| Anhui | 0.9304 | 0.9620 | 0.9304 | 0.8751 | 0.9304 | 0.9620 | 0.9620 | 0.9361 | 16 | ||

| Fujian | 1.9698 | 1.0344 | 1.9698 | 1.7891 | 1.9698 | 1.0344 | 1.0344 | 1.5431 | 5 | ||

| Jiangxi | 1.2541 | 1.0405 | 1.2541 | 1.2232 | 1.2541 | 1.0405 | 1.0405 | 1.1581 | 10 | ||

| Shandong | 0.9133 | 0.9774 | 0.9133 | 0.8423 | 0.9133 | 0.9774 | 0.9774 | 0.9306 | 17 | ||

| Central China | Henan | 1.1932 | 0.9635 | 1.1932 | 1.3307 | 1.1932 | 0.9635 | 0.9635 | 1.1144 | 12 | 1.2599 |

| Hubei | 1.2026 | 1.1543 | 1.2026 | 1.1608 | 1.2026 | 1.1543 | 1.1543 | 1.1759 | 8 | ||

| Hunan | 1.3081 | 1.0228 | 1.3081 | 1.2881 | 1.3081 | 1.0228 | 1.0228 | 1.1830 | 7 | ||

| South China | Guangdong | 3.5111 | 0.9213 | 3.5111 | 2.3577 | 3.5111 | 0.9213 | 0.9213 | 2.2364 | 2 | 1.5195 |

| Guangxi | 0.5118 | 0.7580 | 0.5118 | 0.5002 | 0.5118 | 0.7580 | 0.7580 | 0.6157 | 24 | ||

| Hainan | 0.5357 | 0.8809 | 0.5357 | 0.5409 | 0.5357 | 0.8809 | 0.8809 | 0.6844 | 21 | ||

| Southwest China | Chongqing | 1.1730 | 1.0811 | 1.1730 | 1.3699 | 1.1730 | 1.0811 | 1.0811 | 1.1617 | 9 | 1.0974 |

| Sichuan | 1.0530 | 1.0408 | 1.0530 | 1.1509 | 1.0530 | 1.0408 | 1.0408 | 1.0618 | 13 | ||

| Guizhou | 0.9311 | 1.1978 | 0.9311 | 0.7827 | 0.9311 | 1.1978 | 1.1978 | 1.0242 | 15 | ||

| Yunan | 0.5830 | 1.0700 | 0.5830 | 0.6239 | 0.5830 | 1.0700 | 1.0700 | 0.7976 | 19 | ||

| Northwest China | Shaanxi | 0.8919 | 1.2204 | 0.8919 | 0.9859 | 0.8919 | 1.2204 | 1.2204 | 1.0461 | 14 | 0.8058 |

| Gansu | 0.6116 | 0.9327 | 0.6116 | 0.5779 | 0.6116 | 0.9327 | 0.9327 | 0.7444 | 20 | ||

| Qinghai | 0.3266 | 0.6721 | 0.3266 | 0.3713 | 0.3266 | 0.6721 | 0.6721 | 0.4811 | 29 | ||

| Ningxia | 0.1766 | 0.4194 | 0.1766 | 0.1865 | 0.1766 | 0.4194 | 0.4194 | 0.2821 | 30 | ||

| Xinjiang | 0.4073 | 0.7846 | 0.4073 | 0.4023 | 0.4073 | 0.7846 | 0.7846 | 0.5683 | 26 | ||

| Average | 1.3769 | 0.9961 | 1.3769 | 1.2914 | 1.3769 | 0.9961 | 0.9961 | 1.2015 | - | 1.4043 | |

| Provinces | North China | Northeast China | Central China | ||||

|---|---|---|---|---|---|---|---|

| Before Adjustment | Adjustment Amount | After Adjustment | Adjustment Amount | After Adjustment | Adjustment Amount | After Adjustment | |

| Beijing | 440.39 | 4463.63 | 4904.01 | 7880.32 | 8320.71 | 5656.35 | 6096.73 |

| Tianjin | 4033.66 | 475.24 | 4508.90 | 1615.28 | 5648.94 | 1461.16 | 5494.82 |

| Hebei | 35,693.18 | −23,530.22 | 12,162.95 | −21,799.54 | 13,893.64 | −22,670.38 | 13,022.80 |

| Shanxi | 16,536.92 | −7775.17 | 8761.74 | −6646.77 | 9890.14 | −7346.70 | 9190.21 |

| Inner Mongolia | 21,120.30 | −14,303.03 | 6817.27 | −7536.60 | 13,583.71 | −21,120.30 | 0.00 |

| Liaoning | 17,603.81 | −9548.42 | 8055.39 | −9275.85 | 8327.96 | −10,492.00 | 7111.81 |

| Jilin | 4098.92 | −786.57 | 3312.34 | −393.87 | 3705.05 | −905.41 | 3193.51 |

| Heilongjiang | 5480.64 | −2325.92 | 3154.72 | −3318.48 | 2162.16 | −4900.09 | 580.55 |

| Shanghai | 3607.81 | 5662.66 | 9270.47 | 9134.79 | 12,742.60 | 5315.38 | 8923.19 |

| Jiangsu | 21,972.39 | 16,574.11 | 38,546.50 | 19,218.63 | 41,191.02 | 24,687.32 | 46,659.71 |

| Zhejiang | 8973.00 | 14,351.20 | 23,324.20 | 22,785.56 | 31,758.57 | 16,204.09 | 25,177.09 |

| Anhui | 12,138.34 | −845.36 | 11,292.97 | −1481.72 | 10,656.62 | −2061.46 | 10,076.88 |

| Fujian | 7790.53 | 7570.82 | 15,361.35 | 1695.54 | 9486.07 | 8665.52 | 16,456.05 |

| Jiangxi | 7416.15 | 1886.81 | 9302.96 | 1204.33 | 8620.49 | 2171.49 | 9587.65 |

| Shandong | 25,746.22 | −2235.62 | 23,510.60 | −1806.47 | 23,939.75 | −5632.18 | 20,114.05 |

| Henan | 13,589.89 | 2629.52 | 16,219.41 | −2045.20 | 11,544.69 | 5156.59 | 18,746.48 |

| Hubei | 11,264.53 | 2285.51 | 13,550.04 | 6021.69 | 17,286.22 | 2401.01 | 13,665.54 |

| Hunan | 9345.51 | 2883.83 | 12,229.34 | 906.60 | 10,252.11 | 3498.75 | 12,844.26 |

| Guangdong | 11,070.93 | 27,910.79 | 38,981.73 | −11,070.93 | 0.00 | 28,712.73 | 39,783.66 |

| Guangxi | 10,250.81 | −5009.74 | 5241.06 | −5565.95 | 4684.86 | −6703.35 | 3547.46 |

| Hainan | 1101.51 | −512.30 | 589.21 | −265.34 | 836.17 | −640.79 | 460.72 |

| Chongqing | 5806.09 | 1005.87 | 6811.96 | 1698.36 | 7504.45 | 2352.76 | 8158.85 |

| Sichuan | 12,643.71 | 671.86 | 13,315.56 | 1737.82 | 14,381.52 | 2234.63 | 14,878.34 |

| Guizhou | 4947.88 | −341.25 | 4606.63 | 2529.88 | 7477.76 | −1637.01 | 3310.87 |

| Yunan | 9709.08 | −4053.19 | 5655.89 | 1230.36 | 10,939.44 | −4365.45 | 5343.63 |

| Shaanxi | 10,893.93 | −1178.83 | 9715.10 | 5835.06 | 16,729.00 | −178.37 | 10,715.57 |

| Gansu | 4021.17 | −1564.45 | 2456.73 | −590.21 | 3430.96 | −2298.66 | 1722.51 |

| Qinghai | 2518.99 | −1698.72 | 820.27 | −1334.65 | 1184.34 | −1782.60 | 736.39 |

| Ningxia | 8200.68 | −6761.05 | 1439.63 | −6665.52 | 1535.16 | −8082.65 | 118.03 |

| Xinjiang | 9942.16 | −5901.97 | 4040.19 | −3697.15 | 6245.01 | −7700.39 | 2241.78 |

| Sum | 317,959.13 | 0 | 317,959.13 | 0 | 317,959.13 | 0 | 317,959.13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Wu, C.; Zhang, X.; Ren, B. Group Efficiency Evaluation Under Fixed-Sum Output Constraints: A Cross-EEF Approach with Application to Industrial Carbon Emissions in China. Systems 2025, 13, 946. https://doi.org/10.3390/systems13110946

Wang W, Wu C, Zhang X, Ren B. Group Efficiency Evaluation Under Fixed-Sum Output Constraints: A Cross-EEF Approach with Application to Industrial Carbon Emissions in China. Systems. 2025; 13(11):946. https://doi.org/10.3390/systems13110946

Chicago/Turabian StyleWang, Wanfen, Chenyan Wu, Xiaoqi Zhang, and Biaobiao Ren. 2025. "Group Efficiency Evaluation Under Fixed-Sum Output Constraints: A Cross-EEF Approach with Application to Industrial Carbon Emissions in China" Systems 13, no. 11: 946. https://doi.org/10.3390/systems13110946

APA StyleWang, W., Wu, C., Zhang, X., & Ren, B. (2025). Group Efficiency Evaluation Under Fixed-Sum Output Constraints: A Cross-EEF Approach with Application to Industrial Carbon Emissions in China. Systems, 13(11), 946. https://doi.org/10.3390/systems13110946