1. Introduction

Supply chain nervousness (SCN) is defined as the potential for events that could negatively impact the decisions and performance of supply chains (SCs). Nervousness is considered a source of confusion, instability, or ambiguity in the SC systems owing to disruptions or unexpected decisions. Every decision could affect some or all previous decisions, which raises the following questions: If the current decision cancels previous ones, which decision would be considered? Should past decisions be enforced for a set amount of time before they are enacted? If so, how long would this take? Should past decisions be considered or ignored? What impact would current decisions have on the future and final status of the SC system? Identifying, modeling, tracking, and evaluating decision-making indicators should not be a source of frustration for staff, especially if they are ready to put in the upfront effort. Organizations can confidently plan for future SC decisions if they comprehensively understand current nervousness and its impact on overall SC performance [

1,

2].

The global supply chain (GSC) was severely disrupted by COVID-19, necessitating ongoing supply chains (SCs) to survive crises effectively [

1]. Given SC costs and quality, such crises necessitate quick actions in a complex and demanding setting [

3]. Being dynamic and highly susceptible to worldwide uncertainty, the supply chain must exhibit resilience to withstand global disruptions [

4]. In today’s dynamic and unpredictable business climate, managing supply chain nervousness (SCN) is essential to maintaining the continuity of corporate operations. A solid basis that prioritizes SCN strategy factors is essential for mitigating SCN effect [

5]. Nervousness lowers the effectiveness of the SC overall, particularly since most SC instability is caused by outside factors that are out of the company’s control. SCN leads to uncertainty, increased SC expenses, and shaky vendor–client relationships [

2].

Enhancing SC resilience can save money by reducing risk and accelerating recovery. An accurate definition of nervousness metrics and indicators facilitates the practical management of such disruptions and recovery. This study presents a definition of nervousness that satisfies the criteria and explicitly connects to the metrics of key abstract notions of nervousness. These measures meet the logically consistent conditions derived from the SC measure, providing a solid foundation for developing effective SCN decision-making tools. Improving the robustness of a system to reach target levels necessitates a cost–benefit analysis of system augmentation options within a decision-making framework. Relevant decision analysis methods would normally consider nervousness in terms of how decision-makers value it. Based on the nervousness analysis and management concepts, this study presents a valuation and benefit analysis method in the SC.

This study first determined the various metrics in SCN and then calculated a clear priority for each metric. This study aimed to answer the following research questions:

RQ1: How can SCN be quantified? What steps are necessary to quantify nervousness in SCs?

RQ2: What are the main metrics necessary to assess SCN and help improve SC performance?

RQ3: How should SCN measures be modeled and evaluated?

RQ4: What is the importance of each nervousness metric in the SC? What are the interdependencies?

This study developed a supply chain nervousness measurement model (SCN-M). The model embeds the factors of SCN quantifying methodology, key SCN metrics, and modeling and evaluation of SCN. It can accurately evaluate SCN and, thus, enhance future SC performance and resilience. The main goals of this study are to determine comprehensive and relevant nervousness metrics in the SC and use a fuzzy decision-making trial and evaluation laboratory (FDEMATEL) process to determine the priorities of the identified SCN metrics. FDEMATEL can be used to analyze and resolve complicated, interconnected scenarios, as it can demonstrate how metrics are interdependent and form a map that illustrates their relative relationships. Using a visual structural model, FDEMATEL evaluates the interdependencies between elements and identifies the most important ones. As a structural modeling method, it is particularly useful for evaluating cause and effect interactions between system components.

To the best of our knowledge, this study is the first to investigate the metrics linked to SCN systems and to offer a nervousness model that includes guidance on how to withstand current and upcoming crises. By quantitative evaluation and prioritization of nervousness metrics under uncertainty, this study sought to close the research gap in the nervousness valuation of SC investigations. To investigate the links that aid in quantifying SCN, this study used the most recent data from various sources. In times of crisis, managers must react and make important choices in a potentially unpredictable and quickly changing environment. To achieve the function of SC in satisfying principal competencies, formulating strategic decisions, and converting them into workable, implementable plans, decision-making requirements and inputs are crucial during global crises. Organizations demand more innovation and future-ready planning, and SCs are forced to change. Assessment and measurement are necessary for ongoing improvements.

The remainder of this research proceeds as follows:

Section 2 introduces the literature related to SC nervousness, SCN measurements, and FDEMATEL.

Section 3 proposes the SCN measurement model.

Section 4 presents the FDEMATEL method.

Section 5 discusses a numerical case study of SCN measurements and metrics associated with nervousness.

Section 6 outlines findings and recommendations for further study.

2. Literature Review

Nervousness results from interference or frequent decision changes, affecting overall SC performance. SC nervousness drivers can be categorized as internal sources (inside the company and can be controlled) and external (outside the SC capabilities and mostly uncontrollable). The causes of internal nervousness include operational, financial, and other types of risk. External nervousness causes include political, social, economic, natural, and environmental factors. SC contains many risks, especially nervousness, resulting from crises. Risks and variations, demand fluctuations, market variations, economic pressure, and introducing new technology mainly cause nervousness. Companies experiencing SCN may include agri-food, semiconductors, automotive, pharmaceutical, online, and defense. Also changes in decisions led to nervousness among GSC partners, 3PL providers, and insurance companies.

Many studies touch on the topic of SC nervousness. Mousavi et al. focused on internal nervousness in an SC system by proposing a simulation approach that combined discrete and agent-based-simulation [

6]. Magableh and Mistarihi presented a model that analyzed SCN by its sources, causes, and impact and then arranged the causes according to their impact [

7]. Li explored the SC and MRP nervousness, a condition where suppliers face extreme variability in future order forecasts, and constructed a nervousness metric that, over time, weighted future forecast errors geometrically [

8]. Blackburn et al. considered strategies to address order instability in MRP systems, focusing on how changes at one level can affect others [

9]. Roberta and Davis investigated the effects of single decision rule on MRP nervousness in highly simplified environments [

10]. Tunc et al. provided a straightforward measure to evaluate the cost of system nervousness, considering its cost challenging to quantity [

11]. Yet Atadeniz and Sridharan indicated how capacity restrictions affected the efficacy of programs for reducing schedule nervousness [

12]. Sinha and Ubale suggested a framework to reduce nervousness, supply variability, and bullwhip influence [

13]. Alizadeh et al. introduced a simulation model to investigate nervousness and instability, considering nervousness inevitable in the complex systems [

14]. In the SC, nervousness is a major factor in cost growth and the disruption of SC flows. Nervousness usually results from decisions often altered by stochastic demand or changes in SCs.

It is important to establish a simple and useful multilevel trust measurement instrument for the intricate, multidimensional construct of relationship trust among SC participants [

15]. Production planning decisions must be made in SC environments, giving rise to uncertainty regarding demand related metrics [

16]. The fuzzy model offers various decision options with varying satisfaction levels for the decision-maker and effectively addresses every source of epistemic uncertainty seen in SC planning nervousness concerning the planned period and planned amount [

17]. The fuzzy model addresses every source of epistemic uncertainty observed in SC tactical planning issues, such as demand, process, and supply uncertainties [

18]. The degree to which schedule instability at the supplier–customer interface can be decreased can be evaluated by identifying and excluding complexity-added information flows [

19].

Planning nervousness is the frequency with which a planned order is rescheduled concerning timing. It reveals which elements in the market and production environment impact planning instability [

20]. Previous research considers SCN, risk, and instability indicators and measurements by analyzing the effects of four environmental and design factors and gathering performance measurements at the manufacturer, vendor, and system level [

21]; investigating nervousness in the system for businesses to plan their operations to satisfy future demand and reduce the bullwhip effect and system nervousness simultaneously [

22]; employing indicators to measure SC integration and efficiency performance to limit nervousness of planning [

23]; measuring the instability in the number of setups in each period to isolate setup-oriented instability [

20]; offering a paradigm for measuring nervousness and how to employ a number of metrics to minimize nervousness [

24]; demonstrating the importance of scheduling nervousness in practice and the need for attempts to measure nervousness and understand how it arose [

25]; introducing a reliable performance measurement system in their organization [

26]; examining performance metrics, like lost sales, the effect on SC revenue, and inventory holding costs, and the impact of risk on the performance of the circular SC [

27]; creating a validated generic measure of SC risk management maturity [

28]; developing a risk assessment scorecard for motor carrier enterprises using conjoint analysis [

29]; suggesting a novel metric that evaluates the total effectiveness of SC risk management, incorporating metrics like cost, quality, flexibility, capacity, time, consistency, and customer satisfaction [

30]; evaluating the efficacy of various risk reduction techniques by quantifying resilience to aid firms in quantifying and evaluating the resilience of their SCs and facilitates SC decision-making [

31]; assessing agri-food SCs by analyzing several performance measuring techniques [

32]; highlighting sustainability performance measurement and management to aid managers in selecting performance strategies for sustainability [

33]; presenting quantitative measurements of factors that define re-configurability [

34]; generating topological metrics and operational metrics to determine performance measurements for an SC network in the presence of disruptions [

35]; proposing broadening the performance measurements of total SC performance [

36]; and setting risk reduction measures for sustainable clothes SCs [

37].

On the other hand, numerous scientific research studied anxiety in the supply chain from different perspectives. Some of them discussed the decision-making and coordination of the automotive supply chain, taking into account range anxiety [

38]; explained the meaning of manufacturing in the chicken supply chain, addressing consumer anxiety and exploring the production spaces [

39]; introduced the impact of the TM Technique on anxiety, emotional intelligence, and trust, with implications for supply chain management [

40]; and explored the impact of modern logistics management optimization strategy on alleviating employee anxiety within the supply chain [

41].

Selecting measures of nervousness in the supply chain is one of the most important key elements in this study. The measures related to risks, nervousness, and disruptions in the supply chain, were investigated, identified, and analyzed through literature reviews. It was then presented to the expert team to choose the most important and relative metrics to develop the SCN model and apply them to the case study. Based on the extensive analysis, the suggested SCN metrics were developed.

Table 1 shows the SCN measurements, the associated references, and the measurement’s nature and use.

DEMATEL is an efficient technique for locating causal links in a complex system. It focuses on assessing the interdependencies between elements and identifying crucial elements using a visual-structural model. Numerous studies on the use of DEMATEL have been conducted over the last decade, and numerous versions have been proposed in the literature [

42]. For processes, the FDEMATEL approach is used to evaluate causal relationships. This combination is employed because human judgments are vague and subjective. In fuzzy set theory, interval sets are used instead of real numbers, and fuzzy numbers are created from linguistic phrases [

43]. Many prior studies have used FDEMATEL to study and evaluate different aspects of the SC. One forms a structural model to assess green SC practices using FDEMATEL [

44]; another proposes an approximate FDEMATEL approach to evaluate sustainable SCM and investigate ambiguous influencing elements [

45]; yet another assesses the relative significance of SC risks and their effects on business practices using the FDEMATEL approach [

46]; while another suggests a model to evaluate the effectiveness of the green SC management, and then utilizes the fuzzy-DEMATEL technique to investigate the causal links and factor prioritization [

47].

A significant way to make decisions in an uncertain environment is to use FDEMATEL. Constructing FDEMATEL to display expert options with linguistic factors is necessary. FDEMATEL is used in this study to identify fuzzy cause and effect connections between criteria. Decision-makers typically seek to estimate uncertain influential factors precisely. The suggested method offers justifiable fuzzy cause and effect correlations and may be examined across metrics in an uncertain environment.

Various studies were conducted on SCN and addressed the nervousness of the entire supply chain. A study investigates SCN in the Middle-East and North-Africa region, identifying factors and investigating its causes, effects, and measures [

7]. These studies prioritized nervousness parameters in supply chains, focusing on planning, visibility, stability, decision support systems, and flexibility to reflect the nervousness of supply chains [

48]; identified complete and pertinent strategies in the face of extraordinary corporate, economic, and technical changes by investigating supply chain nervousness strategies, factors, reduction techniques, and trends [

49]; proposed a framework for SCN management to provide a long-lasting competitive advantage for companies [

5]; and examined the drivers, effects, pillars, and suggested remedies of the global SCN [

2]. The proposed method in this study is distinguished and different from the previous studies as it introduces a model for measuring SCN, enhancing future SC performance and resilience through precise quantification and using FDEMATEL for indicators importance determination. The study contributes by addressing the gap in SC nervousness valuation by examining the quantitative assessment and prioritization of nervousness metrics under uncertainty. The proposed model was used for assessing and resolving complex, interconnected scenarios by illustrating the interdependence of metrics and creating a map illustrating their relative relationships.

Although several studies have examined SCN from different aspects, to our knowledge, no study has considered SCN metrics, their definition, interrelationships, quantification, modeling, and identifying the key SCN metrics in a single model; used matrixes to convert interdependency relations into a cause and effect group; or assessed the associations between SCN metrics and identified the crucial ones using a visual-structural model.

3. Methodology and Research Contribution

The SCN measurement model seeks to quantify SCN for inclusion in the SC structure. To assist organizations in determining the effect of nervousness on SCs and enhancing their general performance and competitiveness, this study quantifies SCN, defines SCN metrics, and models and assesses SCN indicators. The proposed SCN measurement model is based on expert opinions in the logistics and SC fields and an extensive literature review. The method involves gathering opinions on complex issues using expert group intuition. Initial assessment factors were identified through previous research and in-depth interviews with fourteen supply chain and logistics system experts with over seven years of experience, based on practical experience. This research thoroughly examines SCN measurements, identifies the relationships between metrics, quantifies the effects, and applies visual analysis based on cause and effect diagrams.

One of the most difficult decision-making challenges is determining the criteria for identifying and assessing SCN by analyzing, visualizing, and ranking SCN metrics. FDEMATEL is an efficient technique for locating linkages between causes and effects in a complicated system. Using a visual structural model, this approach evaluates component interdependencies and identifies crucial ones. The output represents the ideal values of expert ranking criteria and relationships between SCN indicators, whereas the input represents the expert pairwise comparison of the criteria.

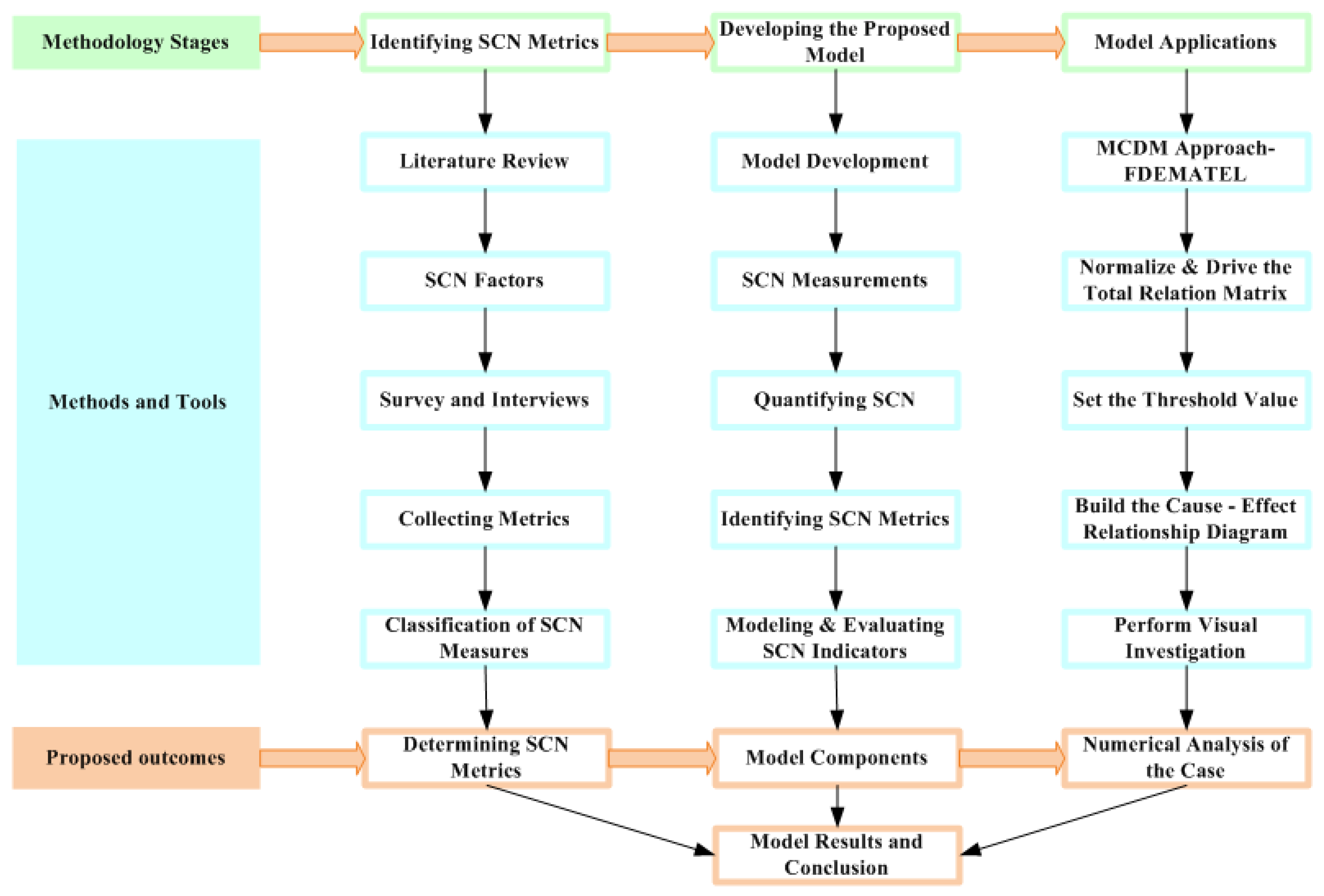

The research process has three main stages (

Figure 1). In stage one, SCN metrics are identified. Previous studies are reviewed to identify SCN factors using a survey and interviews with experts in the SC field to collect and classify SCN metrics as shown in

Table 1. After reviewing more than 115 prior studies on supply chain performance measures generally, 27 papers that specifically addressed supply chain nervousness were selected. More than 15 indicators of supply chain nervousness were found through these articles. Following their presentation to specialists, they were reduced to the six most crucial measures that were employed and examined in this work. The outputs from this stage, the selected nervousness measures, will be argued in the second stage and used third stage of the model.

The proposed model is developed in stage two, in which the main SCN measurements and indicators are determined, SCN is quantified, and SCN metrics are modeled and evaluated. The outcomes of this stage will be evaluated in stage three. Details of the model are discussed in the subsequent

Section 4. Stage three involves the model applications in which the fuzzy multiple criteria decision-making (MCDM) approach is used with a numerical case study to analyze and evaluate the SCN metrics and their interrelationships using the FDEMATEL technique. Finally, the model results and analysis are addressed. This stage will be discussed in detail in

Section 5 and

Section 6.

This study builds on and complements previous studies related to SCN. Studies on supply chain nervousness (SCN) have explored factors in the Middle East and North Africa region, prioritizing planning, visibility, stability, decision support systems, and flexibility. They also identified strategies for managing SCN, proposed a framework for competitive advantage, and examined global SCN drivers and remedies. No previous study has considered SCN metrics, their definition, interrelationships, quantification, modeling, and identifying key SCN metrics in a single model. This study introduces a model for measuring supply chain nervousness (SCN) and enhancing future supply chain performance and resilience. It addresses the gap in SC nervousness valuation by examining quantitative assessment and prioritization of nervousness metrics under uncertainty. The model is used to assess and resolve complex, interconnected scenarios by illustrating the interdependence of metrics and creating a map clarifying their comparative interactions.

The results of this study will support SC managers, specialists, and decision-makers in focusing on SCN concerns through planning phases, improving SC sustainability in the future, and advancing company and SC resilience. Researchers and SC practitioners can use these findings to enhance decision-making procedures and facilitate readjustment and restoration during and after the effects of SCN.

4. SCN Measurement Model

SCN measurements are critical for determining the performance of an SC, particularly for different types of interruptions. Disruptions should be part of any SC design, strategy, or plan. Recently, SCN has received more attention from decision-makers owing to the rise of new risks and global crises [

2,

5,

7,

49].

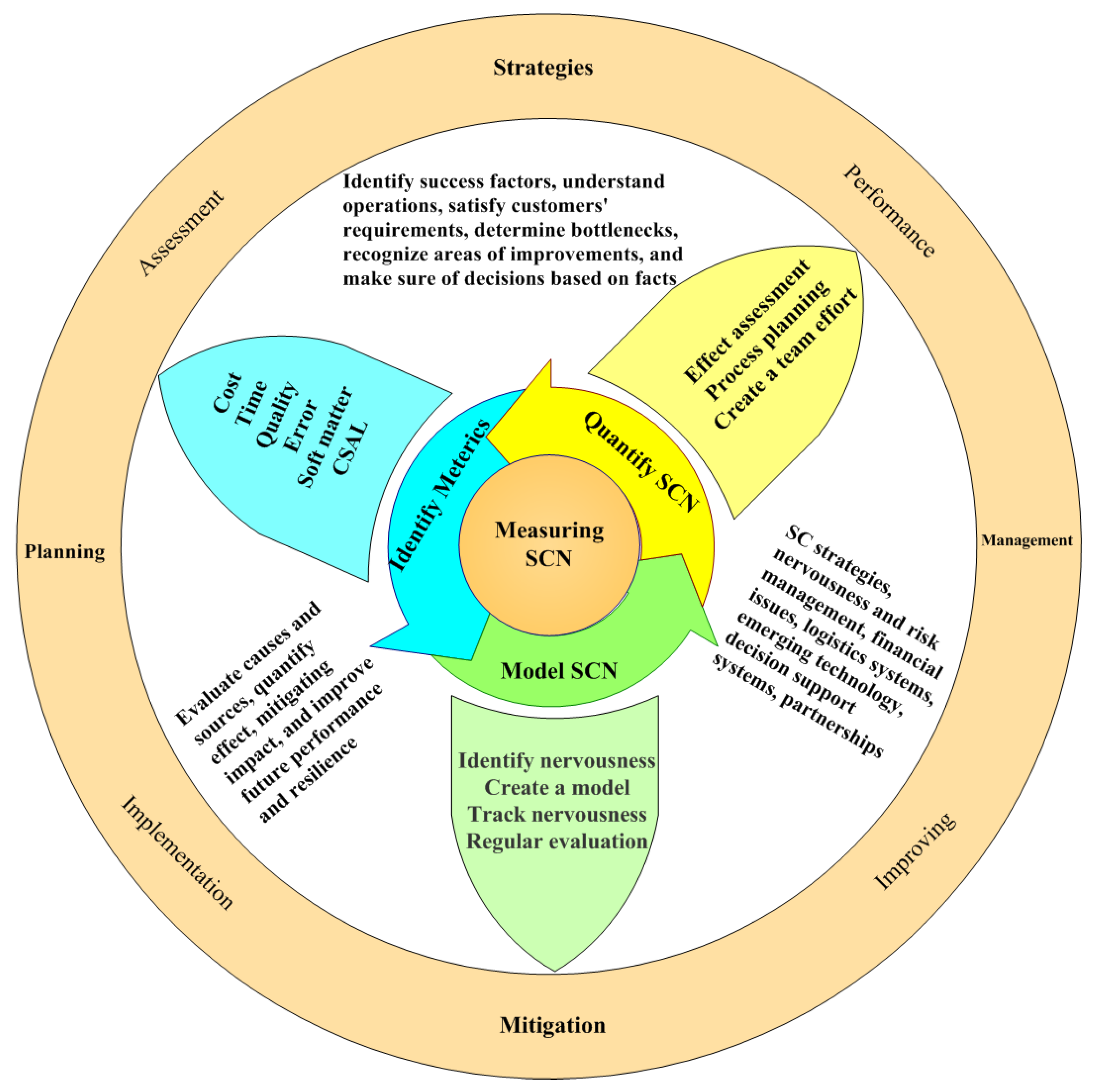

Figure 2 shows the SCN measurement model, which aims to quantify the nervousness of SCs and include them in the SC structure. The author developed the SCN measurement model section, based on literature reviews, expert input, and questionnaire outputs. They determined model components, metrics, and equations for each scale, based on practical and scientific experience.

The model was developed to accurately evaluate nervousness (SCN) through quantifying methodology, key metrics, and modeling, enhancing future SC performance and resilience by determining comprehensive and relevant metrics. SCN measurements are crucial for assessing SC performance, especially during interruptions. They are increasingly important in SC design, strategy, and planning due to rising risks and global crises. Therefore, the study proposes a SCN measurement model to quantify SCN for inclusion in supply chain structures. It quantifies SCN, defines metrics, and assesses indicators. It examines SCN measurements, relationships, effects, and visual analysis.

4.1. Identifying SCN Metrics

Identifying SCN metrics is a major step in dealing with an SCN in terms of evaluating its causes and sources, quantifying its effect, mitigating its impact, and improving its future performance and resilience.

To measure the impact of an SCN, assume a system in which previous decisions are not considered, and a new decision replaces the old one. This implies that the old decision’s impact is minor and insignificant. The system will not consider any prior decisions in the new one. Consequently, a new decision will probably positively or negatively impact the previous decision. Nervousness plays an important role in SC decisions; thus, decision-makers should consider system nervousness while making new decisions. They should consider the impact of decision changes on SC performance and instability. Normally, organizations often assess their decisions and inventory, and it is impractical to review transportation and inventory more frequently, given the amount of available data and demand fluctuations [

50].

The main measurement metrics when considering the entire SC performance are total SC costs and customer satisfaction [

51,

52]. Nervousness mitigation systems apply these two metrics to improve and vice versa. The current decision to interfere with old ones should be more cost-effective and improve the CSL. An intangible benefit from nervousness mitigation systems is SC partner satisfaction, as the current decision is executed as planned rather than one or more alterations being performed to the original decisions. The recent decision to meddle with existing ones should be less costly and improve the CSL. SC partners’ satisfaction should be considered when making decisions rather than making one or more changes to previous decisions; the present decision is carried out as planned.

Unplanned events were measured as a percentage of total events. As a result of unplanned events, much time is spent on potential delays in previously scheduled orders, extra machine setups, rescheduling, raw material and capacity constraints. Schedule changes result from changes or unexpected events owing to shortages of materials, equipment malfunctions, and challenges with staffing and quality.

Measurements can be categorized into financial, non-financial, internal and external, quantitative and qualitative, and SCN levels [

53]. In addition to efficiency, we consider staff morale, customer-related metrics, SC responsiveness, and employee productivity with value contribution. Best practices and changing actual knowledge are employed to improve performance compared to business standards.

Although SCN metrics can be challenging to develop, particularly for management and organizational activities, they are crucial for assessing and improving an SC’s processes and operations. As a result, the measurement variables utilized in this study show how nervousness affects the SC. These indicators include how nervousness affects the overall SC costs, how it affects the value of the SC, how errors from the SCN result in soft values, and how they affect the time between decisions. The following are the six most critical indicators to consider when making SCN decisions:

4.1.1. Costs

Nervousness cost (NC) is measured regarding the overall SC cost caused by decision interference. This is determined by the difference between the total SC costs of decisions made in the past and the costs resulting from decisions made at a specific time (current decisions). The total SC costs comprise manufacturing, shipping and handling, warehousing, internal operations, stock-out, order administration and processing charges, packing costs, and inventory costs. Nervousness cost,

at time

t is determined from the following equation:

where

is total SC cost of decision

i at time

t and

i = 1, 2, …,

n represent the number of decisions made by the SC at time

t that interfere with previous decisions.

All organizations measure the cost of making good decisions. To make the best decisions, all cost information should be available. Decision-making indicators should take a comprehensive view of SC and consider when the costs increase or decrease. If nervousness costs are positive, the impact on total supply costs is undesirable, and vice versa.

4.1.2. Time

Decision-interference counts upon the interval between decisions, number of decisions made in each period, and decisions affecting former decisions in a small period. Such decisions include reordering due to order deletion, changing the quantity (up and down), changing the specifications (e.g., features, upgrade, and downgrade), changing technology, changing the design of the products, in addition to changing the destination, bypass process, shipping company, freight forwarder, and timing of the shipment. The crucial question is how often the SC reviews decisions, such as every 1, 24, 48 h. Increased nervousness results in a shorter period. The following three metrics can be used to investigate the effects of decision timing on SCN:

Decision frequency (DF): The number of decisions taken in a specific period that affects other decisions in the same or previous periods. This depends on how frequently the SC reviews decisions, such as every hour, day, or week. The shorter the period, the greater the nervousness.

Mean time between decisions (MTBD): The mean time between the current and previous decisions. MTBD = total time in period p/number of decisions in period p. Mean Time to Decision (MTTD) is another measure that links time to decision. MTTD, which is similar to MTBD, is a time measurement method. It calculated the time required to make a decision.

Interference time: The period over which the current decision will interfere with the previous decision. Decision

i, for example, will take period τ to be executed, so if another decision is taken (

i + 1) before the completion of the implementation period of decision

i, then interference between decisions would have occurred. The following formula calculates the interference time between decisions, where

is the interference time,

is the end time of decision

i − 1 (previous decision), and

is the starting time of decision

i (current decision):

where a positive

ITi value represents time interference between decisions, which indicates potential nervousness.

4.1.3. Quality

Nervousness affects the effectiveness and quality of a GSC. Partners may have favorable or negative effects on SCN. Some partners may profit by lowering costs, improving customer happiness, or promptly responding to SC changes. For others, nervousness can be detrimental. It relies on the decisions made and the criteria used to make them, such as whether the new decision is based on alterations in demand, changes in supply, or the overall cost of the SC. In addition, the number of partners affected by any new decision in the SC may vary from one decision to another according to the nature and type of the decision. The decision can result from changes in demand, supply, competition in the market, introduction of modern technology, or new product design. In general, the following methods indicate the quality and nature of the effects of nervousness on the SC:

Number of partners affected by the new decision.

Impact on partners, including suppliers, which could be positively or negatively affected.

Impact on customers: the new decision could impact customer satisfaction/dissatisfaction.

Effect on employees: for example, nervousness may negatively impact drivers if they are asked to change their destination several times while on the road.

SC responsiveness: nervousness impacts GSC responsiveness to changes, as new decisions will increase or decrease the reaction to alterations in the GSC. Competitive responsiveness can increase if nervousness mitigation measures are implemented when decisions are made at the GSC level.

Other indicators may include SC effectiveness and efficiency, employee satisfaction, customer satisfaction, on-time delivery, profit development, and working efficiency, which are all factors to consider based on the nature of business. Quality is affected by the level of integration and SC performance measures used. Suppliers, manufacturers, customers, carriers, 3-5PL providers, freight forwarders, and insurance companies are examples of partners who may be affected by SCN. Quality issues, high raw material costs, overtime expenses, expensive shipping costs, and longer lead times are all factors affects SCN. To reduce the global supply chain nervousness (GSCN), it is essential to estimate the probability that the GSC is keeping awareness updated depending on the form of the responses to nervousness.

4.1.4. Errors

SC managers must be aware of and comprehend the recurrent errors in SC operations and processes. Error rate measurement can be a straightforward decision-making metric, but to collect data efficiently, businesses must cultivate a culture that supports identifying critical risk and nervousness indicators, then classifying and prioritizing them so that they can be promptly controlled according to their priorities. Instead of succumbing to the illusion that every error is the result of a one-of-a-kind, unrepeatable scenario, and companies should keep track of errors. When understanding the nature of errors and when and where they occur, organizations should notice trends leading to inquiries about why they occur and measures against the root causes. Error indicators may include the percentage of error-free decisions, total number of errors in any re-decision process, accuracy of decisions regarding customer satisfaction, negative impact on previous decisions, interference with other decisions, total profitability, and future SC resilience.

4.1.5. Soft Matters

The essential SC factors known as soft issues include worker morale, degree of integration, decision inclusiveness, buyer satisfaction, SC visibility, and management alignment, which are challenging to quantify using precise formulas and computations. Contrary to many managers’ beliefs, soft values and attributes are quantifiable and measurable. Decision-making metrics frequently require proxy measurements for these soft values, such as expert opinions, questionnaire results, or survey scores. Capturing and analyzing these data can be both strategic and creative. Companies can act based on acceptable techniques if they indicate how organizations perform in these soft-value areas. Companies have no basis for enhancing soft values if they simply disregard them because they believe they cannot be tracked. Benchmarking can also indicate the values and nature of soft matters. Soft matters should be reflected in total SC costs and customer service levels [

54].

4.1.6. Customer Satisfaction Level

Customer satisfaction level (CSAL) is a well-known and important metric for measuring SC performance. Cost and on-time deliveries are the most important elements of customer satisfaction. CSAL can be improved by using technology to improve customer visibility and allow customers to track orders continuously. Customer satisfaction score (CSAT) is a metric that assesses how well a business meets expectations with its products, services, and overall customer experiences. Showing how well consumers are served by products or services is a sign of a healthy business. Therefore, it is impossible to emphasize the importance of customer happiness. There is a direct correlation between revenue growth and client satisfaction levels. Customer loyalty, word-of-mouth referrals, repeat business, and business decisions are all influenced by the CSAT [

55].

CSAT has several levels of customer satisfaction of CSAL matrix, including being amazing, surpassing customer expectations, and gratifying customers. CSAT can be calculated by adding up all the scores and dividing the total by the number of respondents. CSAT is usually assessed on a scale of 1-3, 1-5, or 1-7. The most widely used score is the CSAT. As the name implies, the CSAT evaluates how satisfied consumers are with goods and services. It functions as a gauge of the present attitude of the client. The most widely used method for determining customer pleasure and satisfaction is the CSAT. The customer effort score (CES), net promoter score (NPS), and customer retention rate are additional metrics used to gauge customer satisfaction. Customer loyalty is gauged by CES. The customer effort and CSAT scores work similarly. However, staff workers asked clients about how simple their experience was to collect data for this statistic. This experience may have to do with making a purchase, picking up new knowledge, or fixing an issue. Net promoter rating (NPR) gauges overall satisfaction, customer contentment, and loyalty rather than just how a customer feels about the service now. The customer retention rate is a measure of both the company’s capacity to keep customers and its rate of client retention. It is an important measure of customer satisfaction. The literature has offered several additional metrics, indicators, and measures related to customer satisfaction. The following formula is used to determine the client retention rate as the following:

where

CE is the number of customers at the end of a cycle;

CD is the total number of new customers acquired during the cycle; and

CB is the number of customers at the beginning of the cycle.

The level of customer satisfaction can measure SCN. The impact of SCN can be determined in terms of differences in customer satisfaction levels. SCN may improve or decrease customer satisfaction based on outcomes or events that cause nervousness. An SCN resulting from decision changes, for example, may improve customer satisfaction of one location while increasing the cost or impacting the lead time, while in other locations, it may decrease customer satisfaction and improve all or part of the other performance metrics. The impact of SCN can be measured in terms of customer satisfaction level as follows:

where

NCSAL represents the net customer satisfaction level;

CSALt denotes the customer satisfaction level at time

t after the effect of the SCN event; and

CSALt−1 represents the customer satisfaction level at time

t − 1 before the impact of nervousness. If the value of

NCSAL is positive, then the impact is in favor of the company, whereas if it is negative, it is considered to have a negative impact on the customer satisfaction level of the company’s clients.

In summary, measurement is the key to successful SC quality and operational processes. It tracks planned versus actual progress, costs, errors, delays, and soft issues. SCN metrics are extremely useful for understanding processes and disruptions and determining correct solutions. This effectively managed the nervousness mitigation process. With clear SCN metrics, decision-makers can make critical and strategic decisions based on facts, measures, and practices.

By measuring nervousness, it is possible to understand how SCs perform activities, improve SC processes and quality, and use these measurements and methodologies to gather critical data to help make better decisions that lead to actions. The measures used should assist in judging productivity and efficiency, as quality-level improvements depend on them.

4.2. Quantifying SCN

Companies may be able to improve nervousness management plans and better prepare for prospective disasters owing to recent significant catastrophes and soft global commercial goods businesses. Numerous significant disasters in recent years have shown that managing nervousness involves more than efficient planning and crisis management. A solid understanding of the biggest hazards faced by a company is essential for effective management. Businesses that rely on intricate global supply networks cannot undervalue the effects of a local calamity or the possibility of a key supplier going offline [

56]. Predictive volume metrics may be used to assess schedule variations (nervousness of visible demand data), improve schedule error, and identify predictive forecasting features [

57].

Risk managers, SCs, and operations leaders must be extremely careful when measuring nervousness and prioritize nervousness based on the magnitude and probability of being ready for such situations. They may prioritize and use resources against the most critical vulnerabilities of a company by fully understanding the values at stake. Nervousness quantification also provides areas for cost reduction, identifies potentially major insurance coverage gaps, highlights crucial corporate interdependencies, and can boost the overall effectiveness of a company’s SC. Generally, there are three crucial steps in quantifying SCN as the following:

Assessment of economic effects. Determine the monetary impact of an SCN (both undesirable and desirable). Some of these factors are the impact of nervousness on these revenue streams, additional expenditures to limit the loss and continue running, short-term reduction in operating costs when suppliers are down, and market share consequences.

Process planning. Make a management checklist for measuring SCN that contains the following: planning the whole SC from origin to destination; evaluating the nervousness associated with each supplier, the sites of the facilities, the sources of the energy, the possible political and social exposures, the destinations, the freight and transport companies and routes, and the connected infrastructure issues; recognizing mitigation strategies such as the accessibility of surplus inventory anywhere it may be found; interdependence mapping; and quantifying and measuring the ultimate situations.

Creating a team effort. The team should include individuals working on some or all the following areas, depending on the kind of business, sector, and SC characteristics: SC strategies, management, and operations; nervousness and risk management; financial issues; logistics systems; legal and official issues; emerging technology; decision-making and support systems; partnerships; coordination and cooperation; human resources; product design and development; and customer relations.

Effective SCN quantification can be organized to fit the enterprise risk management framework. Given the limited resources available for nervousness management, nervousness quantification is particularly helpful for businesses to efficiently prioritize their investments in nervousness management. Additionally, the quantification process can assist in producing the documentation required to meet regulatory requirements for businesses in highly regulated sectors, such as the food and medical industries. Quantification supports regulatory documentation by providing objective proof, tracking production and process control, ensuring product safety and efficacy, supporting nervousness management, and creating traceability. It tracks deviations, helps identify risks, and documents remedial actions, ensuring product performance and safety throughout the supply chain. For instance, food sector documentation includes food designation, product characteristics, equipment, inventory parameters, SC procedures, transportation logistic, maintenance records, deviations, corrective measures, and equipment validation. Good documentation practices ensure data integrity and reliability over all supply chains.

4.3. Modeling and Evaluating SCN Measures

SCN modeling is a procedure for locating, evaluating, and reducing SCN for a business. An organization can work more effectively, decrease expenses, and improve customer service by incorporating GSCN modeling techniques [

48]. Organizations should begin by categorizing nervousness into known and unknown SCN. Establishments can utilize a combination of organized problem-solving and digital means to efficiently model their known nervousness in four stages as follows:

Stage 1: Recognize and record nervousness. A common method for identifying nervousness is to map and assess the value chains of all major items. Subsequently, each SC node, including suppliers, factories, warehouses, and transit routes, was thoroughly evaluated. Nervousness was meticulously tracked over time and placed in a risk register. For part of the SC with no data available, additional research is required in this step.

Stage 2: Creating a model for SCN. Each nervousness in the register should be scored according to three criteria to develop an integrated model for managing nervousness: the possibility that the nervousness will materialize, its effect on the business, and the organization’s preparedness to deal with that particular nervousness. Acceptance thresholds are useful for nervousness scores that reflect an enterprise’s desire for nervousness.

Stage 3: Track nervousness. When a nervousness management approach is implemented, persistent tracking is one of the most important success factors in spotting nervousness that could negatively impact a firm. The most recent advancements in computerized tools that recognize, track, and monitor the main markers of nervousness have made this feasible for even the most complex SCs. These metrics should be weighted wisely and monitored regularly to create a high-quality nervousness exposure score.

Stage 4: Regular evaluation. By routinely assessing SCN and identifying mitigation actions, a critical last step in improving the resilience and flexibility of SC is the establishment of a robust evaluation system.

The steps to measure GSCN compromise are to identify success factors, understand operations, satisfy customer requirements, determine bottlenecks, recognize areas of improvement, and make sure decisions are based on facts. When defining a clear SCN metric, organizations can swiftly identify possible SC failure points, assess their financial exposure, establish suitable mitigation policies and measures, and compare their resilience with their peers.

5. Fuzzy-DEMATEL

The following steps summarize the FDEMATEL approach employed in this research [

43,

44,

45,

46,

47]:

Step 1: Select a group of decision-makers. Several decision-makers, experts, practitioners, and executives should be chosen based on the target group to evaluate the alternatives. The survey was distributed to several experts in the field of supply chain and its risks and with experience in SCN. Fourteen experts responded to this questionnaire and their inputs were considered in the study.

Step 2: Select the evaluation criteria. In this step, the attributes should be determined with curiosity. Each criterion is considered a key factor in assessing alternatives, and the selection procedure for the criteria should be based on the opinions of prior experts and earlier investigations.

Step 3: Transfer the linguistic variables to triangular fuzzy numbers (TFNs). Typically, survey research is conducted by questioning experts on the subject. The survey contains a comparison scale to determine the direction and influence of several variables about professional judgment. The comparison scale has five levels (

Table 2). The linguistic variable is then transferred to the corresponding TFNs based on the values listed in

Table 2.

Step 4: Compute the average direct-relation-matrix (matrix A). After transferring the linguistic values into the TFN, calculate the average direct-relation-matrix based on the questionnaire results and experts’ evaluation. Then, the initial-direct-relation-matrix (matrix A) = [

] can be computed as the following:

where

is the degree of influence of factor

i on factor

j,

E is the total response (experts),

n is the number of factors,

is the degree of influence of factor

i on factor

j with respect to

kth response, and

is a

n ×

n non-negative matrix for the

kth expert.

Step 5: Normalize the TFNs. Using expressions linked to the overall fuzzy direct-relation matrix A, find the normalized fuzzy direct-relation-matrix D. Let

= (

,

,

); and there are

k experts, and

represents the fuzzy weight of the

criterion that affects the

criterion evaluated by the

expert as the following:

Step 6: Compute the left

and right

normalized values as the following:

Step 7: Obtain the crisp values

, which enable comparison and calculation as the following:

Step 8: Create the total normalized-crisp values

as the following:

Step 9: Accumulate the normalized crisp values from all experts to create the direct-relation-matrix as follows:

Step 10: Gather the normalized direct-matrix (

O) as the following:

Step 11: Establish an identity matrix (

I) as the following:

Step 12: Retain identity-matrix (I) minus normalized direct-matrix (O).

Step 13: Inverse matrix I-O .

Step 14: Multiply matrix by matrix to obtain total relation-matrix , where .

Step 15: Compute

and

values, where

is the sum of rows of matrix

S;

is the sum of columns of matrix

S is the importance of factor

i, and

is the net effect of factor

i as the following:

The causal diagram is built with horizontal axis and vertical axis . The horizontal axis prominence refers to the importance degree of the factor, whereas the vertical axis relation shows the extent of the influence. If the axis is positive, then the factor is in the cause group. Otherwise, if the axis is negative, the factor is in the effect group. Causal diagrams can convert complex relationships between factors into an easy-to-understand structural model, providing awareness of problem-solving.

Step 16: Map and analyze the cause-effect diagram. Find the threshold value from the total relation-matrix . Adopting a threshold value generates an effect matrix. The function retains its original value if it exceeds a threshold value. Identifying the effects among the criteria and identifying the degree of the effects. Arrows are mapped to represent the effects. Perform a visual investigation based on a cause-effect diagram. The direction of the arrows should check the matrix. Zero means there is no relationship between factors. If (R-D) has a positive value, it is a causal factor, whereas if it has a negative value, it is an effect factor.

6. Numerical Exploration and Analysis of Results

To evaluate and complete the numerical analysis, a survey was designed and distributed to several experts in the SCN field. A literature review was conducted to identify initial attributes. Fourteen experts with more than seven years of experience responded to the survey. The experts identified and approved the evaluation criteria. The SCN metrics used in this study include A1: cost (C), A2: time (T), A3: quality (Q), A4: error (E), A5: soft matters (S), and A6: customer satisfaction level (L). These criteria have been designated as having interrelationships with and impacting the main SC viability, such as sustainability, effectiveness, responsiveness, customer loyalty, resilience, and total SC costs.

Table 3 shows the linguistic evaluation of expert E1 regarding each criterion (SCN metrics). The evaluations of the other experts were considered similarly.

Based on the corresponding references numbers shown in

Table 1, the linguistic variables were transferred into the corresponding TFN values (

Table 4). ∆ max-min values were calculated as in Equation (2).

The calculation results for normalizing the using Equation (4) are listed in

Table 5.

Table 6 shows the calculations of the lift

and right

normalized values using Equation (4).

For comparison and further calculation, the crisp values

were computed using Equation (5) as shown in

Table 7.

Next, the total normalized-crisp values

were generated (

Table 8) using Equation (6).

The normalized crisp values were then accumulated from the experts. The aggregated values were calculated using Equation (7) to create the direct relation matrix (

Table 9).

In this step, the gathered normalized direct matrix (

O) was calculated using Equations (8) and (9) (

Table 10).

Next, we established the (6 × 6) identity matrix (I) (

Table 11).

Next, we retained identity-matrix (I) minus normalized direct-matrix (O) (

Table 12).

Then, the inverse matrix

was calculated as shown in

Table 13.

Subsequently, the

matrix was multiplied by the

matrix to obtain the total relation-matrix

as shown in

Table 14.

Di represents the importance of factor

i and

Ri represents the effect of factor

i.

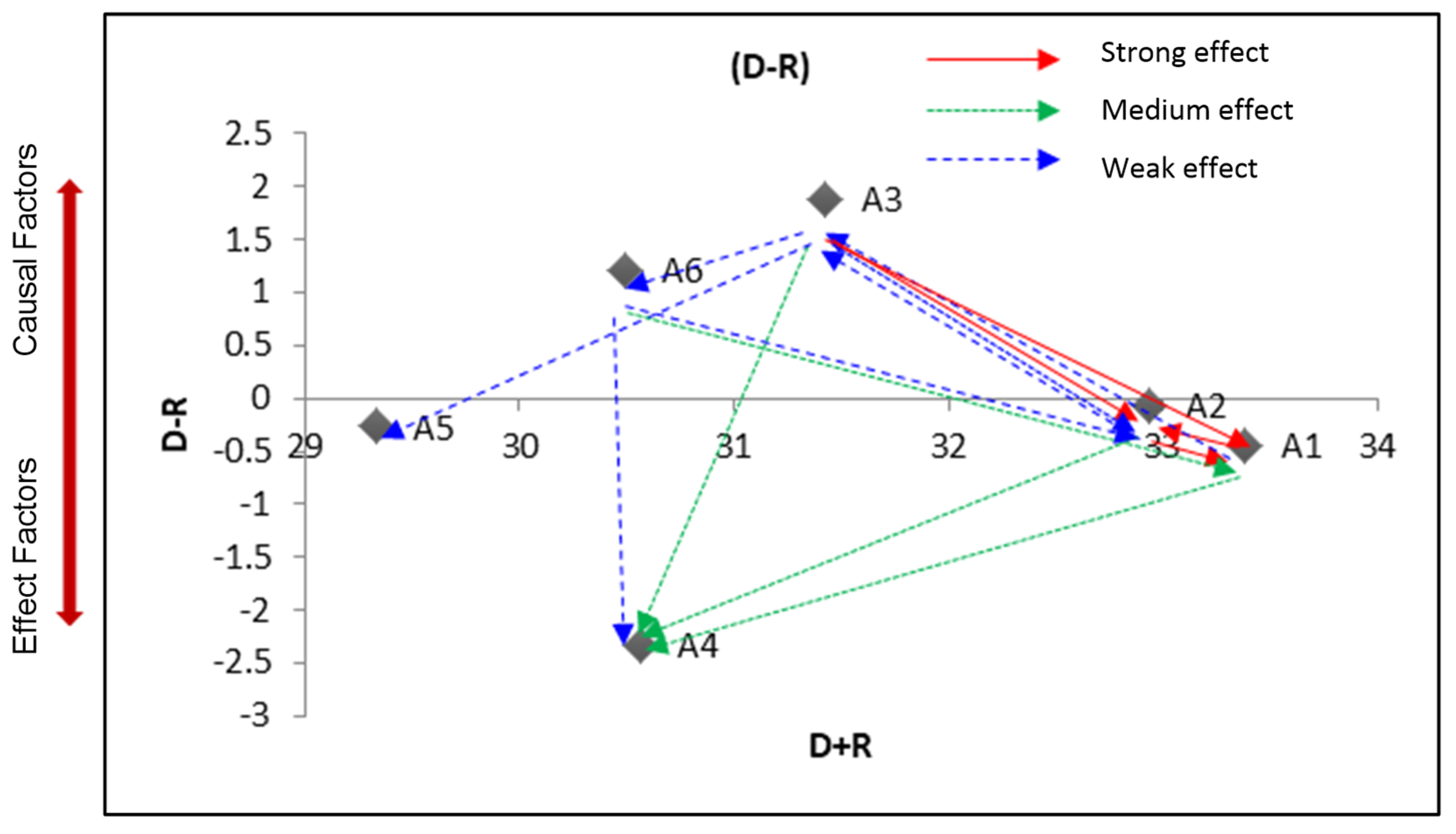

The following analysis includes calculations of

and

values to map the causal diagram and examine the cause and effect elements. The threshold value was determined from the total relation-matrix and used to produce the effect matrix. The analysis also includes determining the degree of impact and the effects among the criteria, demonstrating the effect and mapping the arrows, and using a cause and effect diagram as a guide for visual investigation. The arrows’ directions should be checked against the matrix; if they are zero, then there is no association between the variables.

is considered a causal factor if it has a positive value and an effect factor if it has a negative value. The next step involves computing of

and

using Equation (11). The results identify the effects of the criteria (

Table 15).

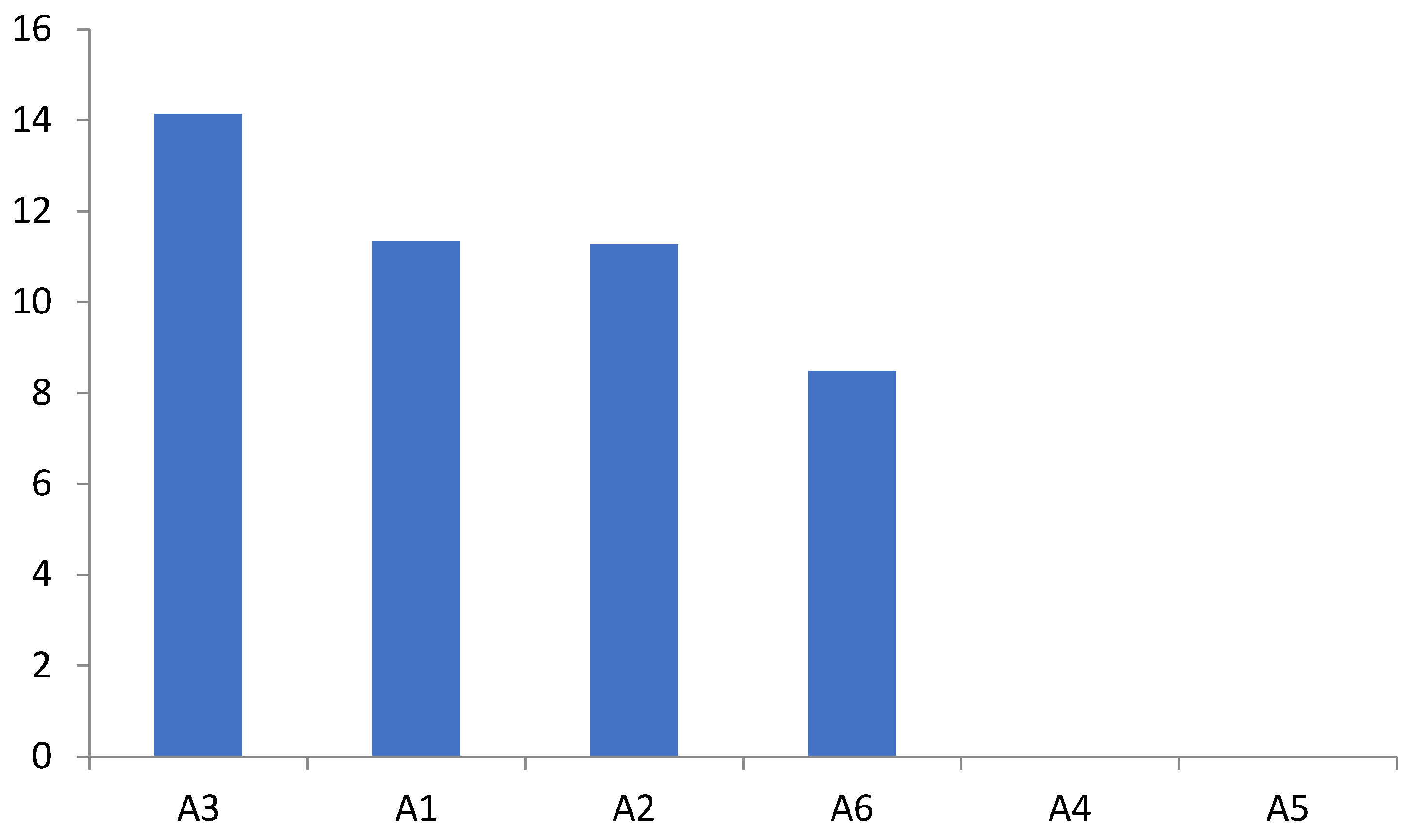

Table 15 shows that, the effect factors are A1, A2, A4, and A5, whereas A3 and A6 are the causal factors. Cost (C), time (T), error (E), and soft matters (S) are the effect elements, whereas quality (Q) and customer satisfaction level (CSAL) are the causal elements.

indicates the importance of a factor. Cost, which has the highest value, has the maximum impact on SCN measurement. Cost has the strongest relationship, and soft matters the weakest. This indicates that cost has a stronger relationship with other criteria than other factors, indicating its importance among the criteria. It is logical for the cost to have associations with many factors because it has interrelationships and interdependencies with the other criteria. By contrast,

indicates cause and effect. Effect means that the criteria are influenced by other criteria. Error is considered the most important criterion influenced by other criteria. Meanwhile, cause means that a criterion influences other criteria. Quality has the greatest influence on the other criteria. Quality and customer satisfaction influence other criteria, while other criteria influence cost, time, error, and soft matters.

The threshold value was calculated using the total relationship matrix (S).

. The threshold value equals 2.613.

Table 16 shows the results after adopting the threshold value to generate the effect matrix. The function retains its original value if it exceeds a threshold value. It then shows the effects of the criteria and the degree of the effects.

7. Discussion of the Results

The study identifies six SCN measurements including cost, time, quality, error, soft matters and customer satisfaction level. It proposes SCN measurement model to enhance SC performance and resilience by quantifying SCN through comprehensive metrics. It emphasizes the importance of SCN measurements in design, strategy, and planning, particularly amidst rising global risks. The model, based on expert opinions and literature reviews, includes in-depth interviews and visual analysis to assess SCN relationships and indicators.

The mathematical method and equations for calculating each metric value were determined. The study examined SCN metrics from various perspectives, focusing on their definitions, interrelationships, quantification, and modeling. It used matrices to convert interdependency relations into cause and effect groups and assessed the associations between SCN metrics to identify the crucial ones through a visual-structural model. The study employed a FDEMATEL process to prioritize SCN metrics according to their impact and priority. The model and results were also applied and evaluated through numerical analysis using a case study based on real data.

Figure 3 shows a cause and effect diagram. The mapping arrows indicate the effects by conducting a visual analysis based on the cause and effect diagram. The direction of the arrow represents the effect: a value of zero means there is no relationship. For example, A2 has direct relationships with A1, A3, and A4 but no relationships with A5 and A6. Visual inspection of the causal diagram shows that cost, time, and quality have a strong effect on SCN; error has a medium effect; and customer satisfaction has a weak effect.

A causal graph was used to better focus on the causal factors. FDEMATEL techniques rank the SCN metrics that every company is worried about. This approach analyzes the interrelations between the factors in the numerical data. As shown in the figure, the criteria quality and CSAL are above the horizontal line, indicating they are positive (causal factors) and have no effect on SCN. Cost, time, error, and soft matters are in the negative area, indicating they affect SCN. The effect of E is the highest, followed by C, S, and finally, T, because it is located near the line. For example, cost and time map each other; cost, time, error, and CSAL are impacted by the causal factor “quality”; and quality has a strong relationship with cost and time. Managerial implications indicate that attributes on the upper side have causal features and represent decisive factors. Attributes on the lower side have effect features and cannot be improved by themselves; they need causal factors to affect the improvements.

Figure 4 shows the ranking of the SCN measures based on their importance. Since A4 and A5 have no effect sum column as shown in the effect matrix table, their values are zeros. Quality is the most important criterion, followed by cost. Quality is the key factor in the value-added process involved in the sourcing and delivery of goods in the SC. Effective SC quality enables businesses to recognize and address product or operational issues before they become large. The quality of an SC can be enhanced by improving customer value or decreasing total cost. Cost is the second most important factor. The main target of SC management is to reduce costs, as it provides a competitive advantage. The third most important metric is time, as a quick response to demand, change, or supply interruption improves customer satisfaction and revenue. Customer satisfaction is the fourth most important factor. Customer satisfaction reveals the health of a company’s SC by demonstrating how effectively customers receive its products or services. Errors and soft matter metrics are ranked fifth and sixth, respectively. The final ranking of the alternatives is quality, cost, time, customer satisfaction level, errors, and soft matters (Q-C-T-CSAL-E-S).

Analyzing and visualizing the interrelations and ranking of SCN metrics is one of the most important decision-making problems which determining the factors that can indicate and measure SCN. FDEMATEL is an effective method for identifying cause and effect connections in complex systems. This process involves assessing the interdependencies between components and identifying the critical components using a visual structural model. The input represents the expert pairwise comparison of the criteria, whereas the output represents the optimal values of the expert ranking criteria and the interrelationships among the SCN indicators.

In a complex system, DEMATEL is an effective method for identifying causal relationships. It uses a visual-structural model to identify key measures and evaluate their interdependencies. FDEMATEL is a useful tool for decision-making in uncertain environments to properly display expert options with linguistic aspects. In this study, investigating unclear impacting factors and assessing SCN metrics can be accomplished using the FDEMATEL technique.

Previous research on SCN emphasizes planning and flexibility to minimize disruptions. This study presents a model for quantitatively assessing SCN to optimize performance through prioritized metrics and visualizing interdependencies. It underscores the necessity for clear definitions of nervousness metrics to support resilience and decision-making during crises. The proposed measurement model utilizes expert insights and literature review techniques such as fuzzy DEMATEL to clarify relationships among key SCN metrics. The findings aid supply chain managers and researchers in addressing SCN challenges, enhancing resilience, and improving management practices under uncertainty.

Decision-makers have been paying greater attention to SCN lately because of the emergence of new threats and worldwide crises. The proposed SCN measuring model aimed to measure SCN and incorporate it into future SC architecture. SCN measures are essential for assessing a SC’s performance and should be included in any strategy, plan, or design. Businesses may be able to enhance their nervousness management strategies and better equip themselves for impending risks by taking SCN measurements into account.

By measuring nervousness (SCN) and developing measures to improve performance and competitiveness in businesses, companies can increase supply chain resilience. Considering global crises and growing dangers, business can suggest a model for decision-making and readjustment both during and after SCN effects. Companies are able reduce global supply chain nervousness (GSCN) by improving supply chain processes and operations by including SC effectiveness, efficiency, employee satisfaction, customer satisfaction, on-time delivery, profit development, and working efficiency. Benchmarking can identify soft matters and reflect total SC costs and customer service levels. Businesses can enhance nervousness management strategies by using SCN quantification, which meets regulatory requirements in food and medical sectors. This quantification tracks production, process control, product safety, and creates traceability, ensuring data integrity and reliability. To sum up, Business can understand the impact of nervousness on supply chain management (SC), enabling better prioritization and mitigation of SCN, thereby enhancing SC sustainability and resilience.

In summary, measuring is essential to successful SC, comprehending how SCs carry out their tasks, and enhancing SC quality and processes. SCN measurements are very helpful in comprehending disturbances, identifying appropriate remedies, and efficiently managing the process of mitigating nervousness. Decision-makers may make important and strategic choices based on data, measurements, and best practices when accessing clear SCN metrics. Using a practical measure presented in this study, determine the true impact of certain nervousness on the SC and evaluate the significance of curing a particular SCN among other nervousness causes. It also helps in figuring out the relationship between the nervousness and their interactions. Decision-makers can more effectively prioritize, address, and mitigate the negative impacts of SCN by including this nervousness in their SCM planning and strategies. By determining the relationships between variables and how they interact, nervousness measurement assists decision-makers in setting priorities, addressing issues, and lessening its detrimental effects on the supply chain.

8. Conclusions

Decisions that are vulnerable to internal or external changes and interferences generally make the SC nervous. The ability to adapt SC plans in response to various business changes causes nervousness. Nervousness caused on by variations and changes in supply network and logistical decisions. In SC systems, nervousness is regarded as a source of ambiguity, instability, or confusion because of disruptions or frequent changes in decisions. Globalization has increased the need for new SC strategies to manage the rising SCN. SCN planning processes have an ongoing impact on partners’ plans and decisions. Nervousness affects the GSC, adding to inventories, expenses, and the bullwhip effect. Additionally, the organization has lost the confidence and credibility of its suppliers, customers, and other partners. SCN metrics are essential for evaluating and optimizing SC operations, even if they can be difficult to generate, particularly for management and organizational tasks. The measurement variables used in this study demonstrate how nervousness affects the SC. These indicators include how nervousness affects the overall expenses of the SC and the SC’s value, how SCN errors lead to soft values, and how they influence the interval between decisions. The six most important indicators to consider when making SCN decisions are identified and discussed.

This study aims to fill the knowledge gap in SC studies about the prioritization and quantitative assessment of nervousness indicators in the face of indecision. When defining clear SCN metrics, organizations can quickly identify potential SC failure sites, evaluate their financial risk, implement appropriate mitigation policies and actions, and assess their resilience compared to peers. The study shows the relationship between high nervousness, SC threats and hazards, and potential scenarios and effects that establish the SC’s vulnerability. This study proposes and develops a method for measuring SCN. The model incorporates SCN quantification technique components, critical SCN measurements, modeling, and SCN evaluation, which can improve future SC performance and resilience by allowing more accurate SCN quantification. The priorities of the selected SCN metrics are determined using a FDEMATEL approach.

The results distinguish between effect metrics and cause measures and their interrelationships. The results of the model and method reveal that cost and soft matters have the best and worst relationships, respectively, suggesting that expenses are more closely related to other criteria. That cost is a crucial factor, among other variables. This implies that the cost has many correlations with several elements. This makes sense because the cost depends on other criteria. Quality has the greatest impact on the other factors. Other parameters influence cost, time, error, and soft matters, whereas quality and customer satisfaction influence other criteria. The study has the following managerial implications. It shows that the higher-side attributes (quality and CSAL) have cause features and function as the deciding factors affecting the lower-side attributes. While lower-level characteristics (e.g., cost, time, error, and soft matters) have an effect feature and cannot be improved on their own, improvements must be affected by the causal factors. The results rank the SCN measures based on their importance.

The FDEMATEL technique is an effective tool for analyzing and ranking SCN metrics in complex systems. It uses a visual-structural model to identify interdependencies and critical components, allowing for expert pairwise comparisons. This method is particularly useful in uncertain environments, as it effectively displays expert options with linguistic aspects. Decision-makers are increasingly focusing on nervousness management (SCN) due to emerging threats and global crises. A proposed SCN measuring model aims to incorporate SCN into future SC architecture, enhancing nervousness management strategies and preparing businesses for potential risks. SCN measurements aid in understanding disturbances, identifying remedies, and managing stress mitigation, enabling strategic decisions. Increasing SC resilience can result in significant financial savings by lowering risk and hastening recovery. Practical management of such interruptions and recovery is facilitated by the appropriate characterization of nervousness measurements and supporting indicators. This study defines nervousness measures that meet several requirements and is explicitly linked to the metrics of the main abstract conceptions of nervousness. Additionally, these measurements satisfy logically consistent requirements of the SC measure, laying a strong foundation for developing efficient nervousness decision-making tools.

The findings of this study will assist SC managers, experts, and decision-makers in putting SCN concerns at the forefront during the planning process, enhancing SC sustainability, and further improving corporate and SC resilience. Researchers and businesses can use the findings to improve decision-making processes and make readjustment and restoration easier during and after SCN’s effects.

There are limitations to this study. The primary informants are drawn from a range of companies and sectors. This study was restricted to a narrow group of specialists to evaluate options and establish standards. This study identified six SCN metrics; further metrics have yet to be identified. The investigation was restricted to one case study. Furthermore, the authors anticipate future research on SCN measurement model validations and applications.

Future studies may employ different techniques for assessing criteria and assigning them correct weights, employing problem-appropriate MCDM techniques, like FAHP, FELECTRE, FTOPSIS, and FPROMETHEE, or using MATLAB to perform arithmetic operations. Further investigations include using combined or integrated fuzzy MCDM techniques and comparing their results with the methods used in this study and perhaps increasing the number of experts and evaluators. This research can be used as a foundation for future studies on SCN. This study clarifies the path for additional research on nervousness in the SC. Sustainable SC management, a plan for managing nervousness, and a thorough examination of the SC’s management mechanisms are necessary to reduce the effect of nervousness on SCs.