1. Introduction

As China’s economic growth model shifts from a factor-driven stage to an innovation-driven stage, the value chain of China’s manufacturing industry has evolved from low-end processing to diversification and increased high-value inputs [

1]. Thus, the functional upgrading of the manufacturing sector has become key to China’s economic transformation. The concept of functional upgrading was first introduced by Humphrey and Schmitz (2002) in summarising the advancement of global value chains, which includes process upgrading, product upgrading, functional upgrading and inter-sectoral upgrading [

2]. Coveri et al. (2024) and Capello et al. (2024) more recently defined it as ‘the shift of a country’s enterprises or industries to the higher-end production functions, beyond the fabrication function, within the value chain’ [

3,

4]. Timmer et al. (2018) divided the functions of the value chain into four areas: R&D, management, fabrication, and marketing [

5]. They highlighted that the competitiveness of developed countries in the functions of R&D, marketing and management has been improving, with the corresponding Functional Specialisation (FS) Index rising from 1.09, 1.03 and 1.01 at the end of the 20th century to 1.12, 1.06 and 1.07 in 2011, respectively. Industrialised nations such as Germany and the United States have historically been more competitive in R&D, management and marketing. In contrast, China has long maintained a comparative advantage in the fabrication function, with relatively low value-added gains. Therefore, many researchers and policymakers have called for China to upgrade its functions promptly and shift its production chain toward higher value-added activities [

6,

7].

In recent years, the attraction of foreign-invested enterprises (FIEs) has been widely regarded as a key way for China to integrate into the global value chain, expand exports and promote industrial transformation and upgrading [

8]. According to the data from OECD, China’s foreign direct investment regulatory restrictiveness index (FIRPI) declined from 0.62 in 1997 to approximately 0.25 in 2018 [

9]. The Global Investment Report indicates that the scale of China’s actual utilisation of inward foreign direct investment (FDI) increased from less than US

$50 billion in 2000 to around US

$190 billion in 2022, with its share of global FDI rising from less than 4% in 2000 to approximately 15% in 2022. As FDI inflows into China continue to grow, multinational firms (MNEs) have become deeply embedded in China’s industrial chain through the establishment of subsidiaries, co-production and mergers and acquisitions, cementing their position in China’s manufacturing production, purchasing and sales networks. In 2022, the total value of China’s imported goods was

$2.71 trillion, of which FIEs contributed

$953 billion, accounting for 35.1% of market share [

10]. The total value of exported goods was US

$3.57 trillion, with FIEs contributing US

$1.12 trillion, accounting for 31.5%. With the growth of the FDI stock size, the participation of FIEs in China’s industrial chain activities has been deepening, representing increased embeddedness. Understanding whether the embeddedness of FIEs has an impact on the functional upgrading of China’s value chain is therefore crucial. Existing studies have not yet explored the effects of increased FIE embeddedness on China’s value chain nor the mechanisms behind it.

Numerous studies have shown that by attracting FIEs, it is possible to promote productivity upgrades and output increases in China by leveraging the technology transfer, technology spillover, competition, demonstration and vertical linkage effects of FIEs [

11,

12]. However, as pointed out by Van et al. (2018), such industrial upgrading, although reflected in improvements in productivity and value-adding, is primarily confined to process upgrading, which involves the introduction of new production technologies, or product upgrading, which focuses on improving product design and quality [

13]. Different from process upgrading and product upgrading, functional upgrading emphasises the upgrading of workers’ skills and structural changes as the driving force of industrial advancement [

14]. Since the key to determining the direction of functional specialisation and ultimately the impact of functional upgrading on a country’s value chain is workers and their skills, existing studies mostly focus on the impact of FIEs on product quality or export structure. However, they do not provide any theoretical basis to explain the structural changes in the value chain triggered by FIEs, thus failing to explain how the embeddedness of FIEs affects functional upgrading. In addition, existing studies do not provide insight into the relationship between the embeddedness of FIEs and the skills of workers, which determines the direction of functional upgrading [

15,

16,

17,

18]. Existing studies have been unable to elucidate whether the embeddedness of FIEs promotes or inhibits the upgrading of workers’ skills [

19,

20]. This study, therefore, seeks to analyse the relationship between the embeddedness of FIEs and the functional upgrading of China’s manufacturing industry.

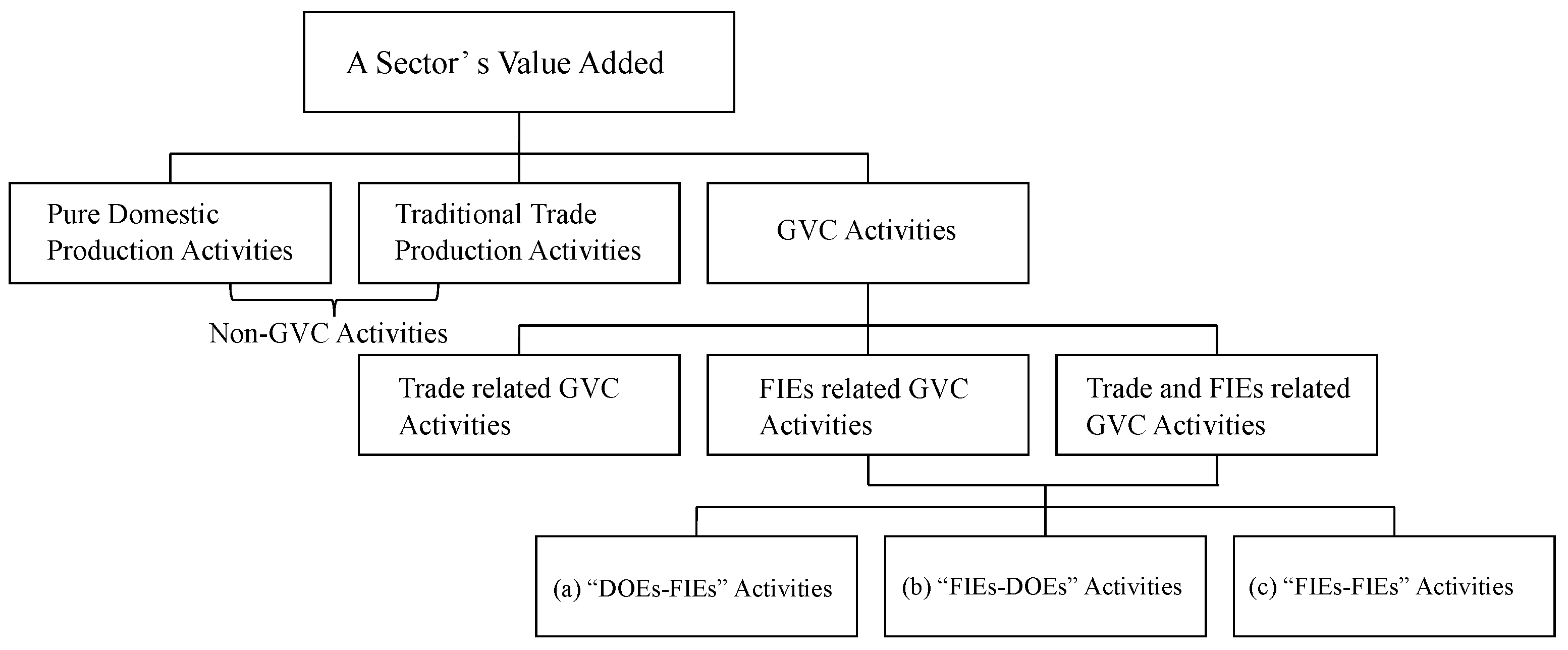

The purpose of this study is to adopt a systems perspective to deconstruct the complex system of FIEs and DOEs and, on this basis, examine the relationship between the embeddedness of FIEs and the functional upgrading of China’s manufacturing value chain. In this study, the embeddedness of FIEs is identified based on the Activity of Multinational Enterprises (AMNE) database released by OECD in 2024. Referring to the studies by Stöllinger et al. (2021) and Kordalska et al. (2022) [

16,

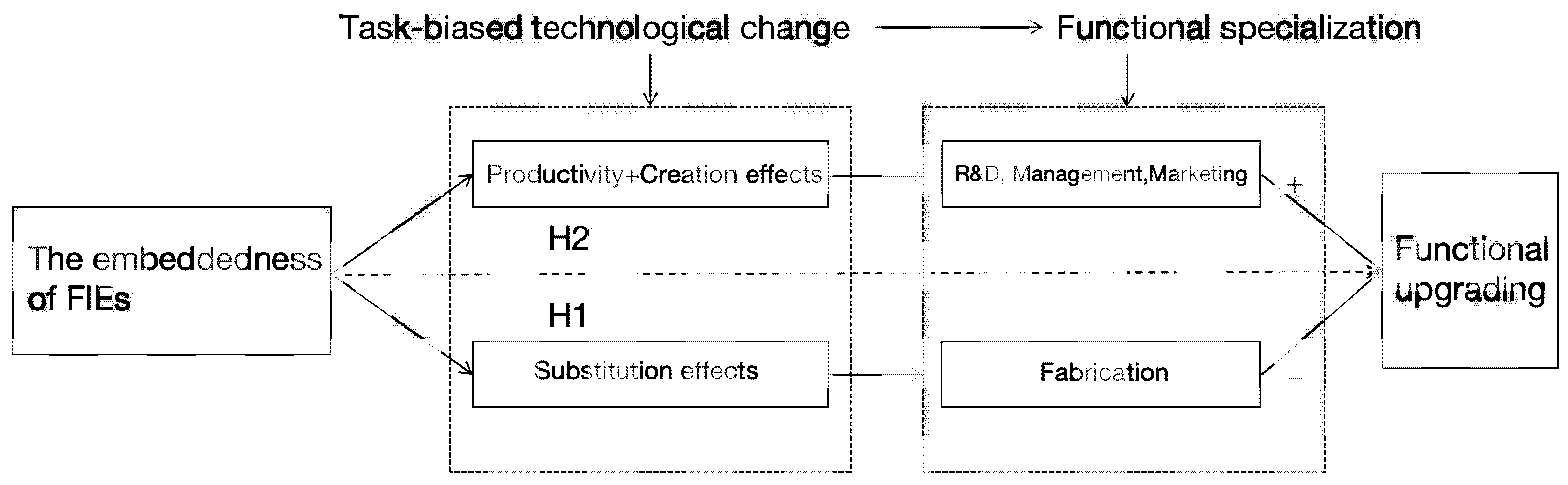

21], measurement indicators of functional upgrading at the overall industry level and sub-functional level are constructed, so as to explore the impact of the embeddedness of FIEs on functional upgrading of the value chain. It is found that, first, the embeddedness of FIEs has a clear positive effect on the overall functional upgrading of China’s manufacturing value chain. At the sub-functional level, it inhibits the specialization of fabrication functions but has a significant positive effect on the upgrading of R&D and management functions, while its impact on marketing functions is not significant. These results remain robust to changes in estimation models and to a one-period lag of the explanatory variables. Second, the mechanism analysis shows that the embeddedness of FIEs has a creative effect on the demand for skills related to R&D and management functions, which extends the related production chain. The embeddedness of FIEs also has a productivity effect on R&D and management skills. Finally, the heterogeneity analysis shows that “DOEs–FIEs” and “FIEs–DOEs” value chain activities have a positive effect on the upgrading of R&D functions, while “FIEs–FIEs” activities positively influence management upgrading, and “FIEs–DOEs” activities negatively affect marketing upgrading.

In summary, the main contributions of this study include the following three aspects. First, in terms of research content, this study starts with examining the embeddedness of FIEs in the Chinese manufacturing value chain, analyses its impact on functional upgrading and bridges and expands two groups of literature on FIE embeddedness and the functional upgrading of value chains. In the literature on value chain upgrading, although the influence of trade, technology and other factors is fully considered, the role of FIE embeddedness is neglected. More focus is given to the characteristics of the embeddedness of FIEs and their impact on the structure of labour skills and inequality, paying little attention to impacts on functional upgrading. Second, in terms of research perspectives, this study introduces ‘task-biased technological progress’ as a theoretical mechanism to analyse the embeddedness of FIEs affecting the functional upgrading of value chains, combining the ‘technology spillover effect’ of FIEs with the ‘functional’ specialisation of the manufacturing value chain. It also examines the impact of the embeddedness of FIEs on the functional upgrading of the value chain at the overall level and in each functional dimension, thus expanding the scope of ‘task-biased technological progress’. Third, from a systems perspective, this study identifies and distinguishes three types of FIE embeddedness within the host-country production network—DOEs–FIEs, FIEs–DOEs and FIEs–FIEs—and, on this basis, explores in-depth their differentiated impacts on the functional upgrading of China’s manufacturing industry. This provides new theoretical perspectives and empirical evidence to explain the inconsistency between observations of the embeddedness of FIEs and findings from industrial upgrading-related studies [

22,

23].

3. Materials and Methods

3.1. Model Construction

In this section, the relationship between the embeddedness of FIEs and the functional upgrading is empirically examined through econometric analysis. This study constructs a fixed effect benchmark model (1) based on panel data to examine the impact of the embeddedness of FIEs on the functional upgrading at the overall industry level.

In the formula, the subscripts i and t represent the manufacturing sub-industry and the year, respectively. The explanatory variable is FS_Total, which denotes the focus of functional specialization in the value chain. The explanatory variable is the percentage of value chain activities of FIEs in each industry. is the control variable of industry level. and denote the fixed effect of year and industry, respectively, which are used to control the unobservable macro-factor impacts in the time dimension and the industry shocks that do not change over time. is a random disturbance term.

In order to further examine the impact of the embeddedness of FIEs on value chain upgrading at the “functional” level, this study constructs model (2) as follows:

In the Formula (2), the subscripts denote function, industry and year, respectively. The explanatory variable FS (i = 1,2,3,4) denotes the shift in the country’s industries in four different functions relative to the focus of production in Fabrication (FS_FAB), R&D (FS_RD), Management (FS_MGT) and Marketing (FS_MAR).

3.2. Selection of Variables

3.2.1. Explained Variable

The explanatory variable of this study is functional upgrading. Two primary approaches are currently used to measure functional upgrading [

21]. One approach is the induction approach of enterprise business activity, and the other is the decomposition approach of labor compensation structure. The induction approach, which is based on a micro-level analysis, identifies the functional division of labor within the business activities of enterprises. These activities are then generalized to the industry level, and classified into upstream, midstream, and downstream positions within the value chain. This approach constructs an index of the upstream and downstream functional division of labor in the value chain, thereby reflecting dynamic changes in functional upgrading. A larger index indicates a greater degree of functional upgrading within the industry [

48]. The decomposition approach, which is based on the value-added structure of the industry, integrates input-output and labor occupation data. This approach estimates the share of labor remuneration for workers with different occupational skills, allowing the calculation of an index of specialization for each function. This index can then be used to measure the upgrading process across sub-functional dimensions [

49]. Both approaches incorporate functional divisions of labor into the industrial structure and are capable of reflecting dynamic changes in the production chain. Therefore, their measurement results are consistent [

48]. A key advantage of the induction approach is its ability to directly reflect the functional division of labor through enterprise business activities. However, it does not account for value-added compensation across different functions or structural changes, meaning it can only reflect the overall process of functional upgrading. In contrast, the decomposition approach, while accounting for value-added compensation and structural changes, and analyzing the specialization levels of different functions, provides a more detailed view of the specific structural path of functional upgrading. However, it is less effective at capturing the process of upgrading in its entirety. Thus, the induction approach is particularly useful for measuring the overall process of functional upgrading, while the decomposition approach is better suited to elucidating the specific direction of upgrading. To more accurately capture the process of functional upgrading and understand the relationship between the embeddedness of FIEs and functional upgrading, both approaches are adopted in this study.

- (1)

The Induction approach

We use Stöllinger et al. (2021)’ s methodology and the fDi Markets database to link each greenfield investment project’s primary activities in the host country to five functional modules that cover upstream, midstream, and downstream value chain segments, including headquarter economy, R&D and design, production, and logistics [

16]. An index of the value chain’s functional division of labor is calculated by comparing China’s manufacturing sector’s greenfield investment projects to the global proportion of upstream and downstream functional activities. The index tracks China’s manufacturing sectors’ functional upgrading toward the top of the “smile curve” in a more comprehensive manner. The calculating formula is:

In year t, represents the total number of greenfield investment projects in global manufacturing sector i covering upstream headquarters economy, R&D, design, downstream logistics, retail services, and after-sales services, while represents the same in China’s manufacturing sector i. In China’s manufacturing sector i, indicates the number of upstream and downstream investment projects in year t, whereas represents the overall number of real investment projects in the sector. In order to prevent sample loss due to the absence of greenfield investment in certain years, this study applies a logarithmic transformation to the value chain functional upgrading variable in the regression analysis.

- (2)

The Decomposition approach

In this study, the updated Occupational Skills Database by Zaveri et al. (2023)., in conjunction with the Asian Development Bank’s (ADB) Input-Output Database, is used to measure functional upgrading indicators at sub-functional dimensions [

50]. First, we categorize the production function within the value chain based on workers’ occupations. Using the ISCO-88 Occupational Classification and the Production Functions Comparison Table provided in the Appendix of Kordalska and Olczyk, we classify the production functions into four categories: (1) R&D function, which corresponds to occupations in engineering, health, teaching, etc.; (2) Management function, primarily covering occupations such as legislators and senior managers; (3) Fabrication function, which includes practical occupations such as technicians, machine operators, and transportation equipment operators; (4) Marketing function, involving occupations such as clerical workers and salespersons.

Second, the degree of specialization in the functional division of labor is measured with reference to the export comparative advantage approach proposed by Timmer et al. [

5]. Specifically, the functional division of labor of a country’s industry i in function k is measured as follows:

Finally, with the help of the input-output table, total exports are decomposed and labor compensation in each functional dimension is identified. Drawing on the value-added decomposition method proposed by [

51], the compensation of laborers in different occupations in the value chain is calculated to measure the functional specialization division of labor in the industry. The specific calculation formula is:

In the formula, the K × G matrix W comprises entries w sub k g, representing the proportionate earnings share for workers in function k in industry g. Given that the distribution of functions across industries in the global production process evolves annually, this study controls for the average distribution of each production function. Based on this, a centralized functional specialization index is computed to act as a proxy variable for functional upgrading.

3.2.2. Explanatory Variable

The explanatory variable in this study is the embeddedness of FIEs, which refers to the local production, purchasing and selling activities of FIEs in the host country. This study adopts the value-added decomposition method, which is common in the literature, to identify and decompose the different production and trading activities of FIEs in the host country’s industry by tracing all the value-added creation activities involved in MNCs along the value chain (measured in percentage terms), with reference to the study by Wang et al. [

51].

3.2.3. Control Variable

As for control variables, based on existing empirical studies on functional upgrading [

52], this study also controls for the following industry-level variables: (1) The level of economic development (LnGDPpc), measured using the natural logarithm of per capita GDP at the industry level; (2) industry scale (Lnscale), measured using the natural logarithm of output at the industry level; (3) capital intensity (Lncapital), measured using the total fixed asset formation of each industry in the manufacturing sector; (4) trade openness (Open), measured using the industry-level total import and export as a share of GDP; (5) State capital (Lnstate), measured as the natural logarithm of industry-level state-owned capital to control for government involvement; (6) Technological intensity (TechIntensity), which classifies industries into low- and high-technology groups according to their R&D intensity.

3.3. Data Sources and Descriptive Statistics

The data for measuring functional upgrading using the induction approach of enterprise business activity are sourced from fDi Markets. For the decomposition approach of labor compensation structure, data are obtained from the ADB-MRIO and the corresponding data from the International Labor Organization’s Occupational Skills Database. The explanatory variable regarding the embeddedness of FIEs is derived from the most recent version of the OECD’s AMNE Dataset, released in 2024. Data for the explanatory variable the embeddedness of FIEs come from the latest version of the OECD’s AMNE Dataset, released in 2024, which is an extension of the Input-Output Tables in the dimensions of firm ownership (DOEs vs. FIEs), ensuring consistency with the unit of analysis of the Functional Upgrading. Compared to the previous version, the statistical criteria for FIEs in China have been upwardly adjusted in the 2024 dataset, changing the minimum shareholding ratio for FIEs from 25% to 50%. This adjustment prevents the overestimation of foreign firms and the role of FIEs in China. Data on control variables are obtained from OECD database.

It should be emphasized that during the sample processing, it is necessary to match the manufacturing industry classification criteria of several databases, including the OECD-AMNE database, the fDi Markets database, and ADB-MRIO. Specifically, the industry classification standard of the OECD-AMNE database follows the International Standard Industrial Classification (ISIC Rev4), which contains 17 manufacturing sub-sectors. fDi Markets database adopts the industry classification standard of the General Industrial Classification of Economic Activities of the European Community (NACE Rev2.0), which specifically includes 24 manufacturing sub-sectors. In contrast, the industry classification standard in ADB-MRIO corresponds to the International Standard Industrial Classification (ISIC Re 3). Based on prior research, this study uses ISIC Rev.3 as the benchmark to align NACE Rev.2.0 and ISIC Rev.4.0, resulting in 14 manufacturing subsectors. The descriptive statistics of variables are shown in

Table 1.

5. Discussion

Based on the task-biased theory of technological progress, this study introduces the embeddedness of FIEs as a crucial factor influencing functional upgrading in value chains and establishes a coherent framework examining the relationship between FIE embeddedness and functional upgrades. Task-biased technological progress emphasises that technological change is not neutral—it systematically alters the relative demand for tasks and skills, favouring high-skill, non-routine functions such as R&D and management. Within this framework, the embeddedness of FIEs serves as a key transmission channel through which technological progress affects domestic industries. Through technology spillovers, management learning and capital–skill complementarities, FIEs reshape the skill composition and task structure of domestic production, thereby driving the transition from low-end fabrication toward higher-value-added functional specialisation. By integrating this mechanism into the analysis, the study bridges two strands of literature—one on FIE embeddedness, which focuses mainly on technology spillovers and productivity effects, and another on functional upgrading, which examines technological progress and globalisation but often neglects the role of FIEs. Using data from China’s manufacturing industries, this study empirically tests this theoretical chain, confirming that FIE embeddedness significantly promotes upgrading toward R&D and management functions.

Further, this study highlights how the task-biased technological progress effect induced by FIE embeddedness fundamentally shapes the functional division of labour within China’s manufacturing value chain. In the Chinese context, FIEs not only transmit advanced technologies but also alter the structure of task demand, creating productivity and innovation-driven upgrading effects. The productivity effect enhances efficiency and profitability through technological diffusion, while the creation effect expands new high-skill tasks and extends the value chain length. By identifying these mechanisms, this study extends the application of task-biased technological progress theory to the field of value chain upgrading and clarifies how FIE embeddedness serves as both the carrier and catalyst for functional upgrading.

Finally, by adopting a systems perspective to deconstruct three types of FIE-related activities in the value chain, this study provides new perspectives for future empirical research through the analysis of their heterogeneity. Especially in the context of the increasing proportion of FIE-embedded value chain activities and the increasing diversification of FIEs in the host country’s value chain activities, this study helps to identify the characteristics of different types of FIE embeddedness in value chain activities and then provides strong support for the use of FIEs to promote the upgrading of the country’s value chain. This study argues that the inconsistency between the existing conclusions on FIEs and skill upgrading and skill inequality may be due to the heterogeneity of the embeddedness of FIEs [

59,

60]. This study identifies FIE value chain activities as ‘DOEs—FIEs’, ‘FIEs—DOEs’ and ‘FIEs—FIEs’, and it is found that the embeddedness of FIE activities has differentiated impacts on the functional upgrading of different value chains, which makes the analysis of the embeddedness of FIEs and value chain upgrading more comprehensive and in-depth.

6. Conclusions

This study examines how FIE embeddedness affects the functional upgrading of the value chain and its mechanism in 14 subsectors of China’s manufacturing industry from 2003 to 2020 using the OECD AMNE database in 2024. A summary of the primary research results is given as follows: First, FIE embeddedness positively affects functional upgrading across the manufacturing sector. FIE embeddedness facilitates the functional upgrading of R&D and management but not marketing at a sub-functional level. Mechanism analysis shows that FIE integration in China’s manufacturing value chain predominantly fosters functional upgrading through productivity-enhancing and innovation-driven benefits. Heterogeneity analysis shows that both “DOEs–FIEs” and “FIEs–DOEs” activities improve R&D, “FIEs–FIEs” activities improve management, and “FIEs–DOEs” activities inhibit marketing.

This study suggests the following policy changes based on its findings. First, the Chinese government must increase its efforts to attract FIEs, as these enterprises catalyse the functional upgrading of China’s industrial value chain. Second, to promote functional upgrading in China’s manufacturing value chain, the government must create incentive policies for the labour market that fully leverage both the productivity and creation effects of FIEs on high-skilled labour. Third, investment attraction strategies that promote functional upgrading should consider FIEs’ embeddedness to improve their efficacy and precision. Heterogeneity analysis shows that FIEs’ functional upgrading effects vary by embedding mode. Thus, FIE attraction strategies that promote functional upgrading must consider the relevance of these policies to upgrading across functional dimensions.

This study has limitations, but future research can address and enhance them. First, the current classification of functional division of labour is based on the first main category of ISCO-88 from the International Labour Organization, making it difficult to obtain more granular data. This study focuses on the four types of functional divisions of labour, which may limit real-world diversity. More data on the functional division of labour linked with occupational skills is expected to expand our understanding of functional upgrading, including functional specialisations related to value chain connections. Second, the study’s focus on FIE embeddedness and functional upgrading in China’s value chain limits its generalisability. Future study can be extended to other countries to permit cross-country comparisons and investigate FIEs’ favourable impact on functional upgrading in specific countries, laying the groundwork for targeted FIE policies. Third, while this study highlights FIEs’ embeddedness in value chain functional upgrading at the macro-industry level, it lacks micro-enterprise empirical evidence, limiting its analytical framework. Micro-enterprise data can be used to study FIEs’ economic effects on value chain functional upgrades.