Abstract

This study aims to investigate the role of Industry 4.0 (I4.0) technologies in facilitating the transition towards a circular economy (CE) in the manufacturing sector, exploring four key circular economy strategies—reuse, repair, refurbishment, and remanufacturing. This study combines a comprehensive literature review with case studies of ten manufacturing organisations from various sectors, including electronics, information and communication technologies, and the household and furniture industries. The research focuses on three main areas: the adoption of circular strategies, the challenges associated with implementing Industry 4.0 technologies, and the role of these technologies in enabling the transition to a circular economy. Data were collected through ten interviews with managers responsible for sustainability, corporate social responsibility, or circular economy projects and initiatives, as well as through documentary analysis of archival materials. The study found that organisations typically adopt multiple circular strategies, with repair being the most prevalent strategy across all sectors and adopted in every case analysed. However, the adoption of I4.0 technologies faces challenges such as scalability issues, digital expertise shortages, and outdated infrastructure. Advanced adopters of I4.0 technologies benefit from robust delivery systems supported by collaborative networks, which enhance knowledge transfer and development among stakeholders.

1. Introduction

The circular economy (CE) and Industry 4.0 (I4.0) have gained attention in both academic and industrial contexts as frameworks to address resource limitations, climate change, and operational efficiency. CE proposes a shift from the traditional linear “take-make-dispose” economy to a “cradle-to-cradle” model, emphasizing product lifecycle extension through reuse, repair, remanufacturing, and refurbishment [1,2,3]. This transition decouples economic growth from resource depletion, creating opportunities for cost reduction, revenue generation, and value creation [4].

I4.0, defined by the integration of information and communication technologies (ICTs) into manufacturing systems, enables real-time monitoring, performance optimization, and informed decision-making [5]. While I4.0 enhances competitiveness and operational efficiency [6], its implementation faces challenges such as skill shortages, financial constraints, and outdated infrastructure [7]. Effective adoption requires leadership support and knowledge-sharing networks involving research institutions [8]. However, studies on I4.0 adoption patterns in manufacturing remain limited, particularly those providing empirical evidence on implementation strategies [9].

The integration of CE and I4.0 offers additional opportunities for sustainable manufacturing. Digital technologies facilitate resource management, decision-making, and supply chain efficiency, enabling the adoption of circular strategies [10,11]. Yet, research exploring the interplay between CE and I4.0 remains scarce. Most studies lack empirical evidence and fail to specify the technological contributions to CE implementation [12,13]. There is insufficient analysis of the degree to which I4.0 technologies support circular strategies, such as the 9R framework, or their impact on sustainability goals [14]. Furthermore, limited attention has been given to developing practical roadmaps for I4.0 adoption in the context of CE [13].

To address these gaps, this study investigates the adoption of the 9R circular economy strategies within the manufacturing sector, with particular emphasis on reuse, repair, refurbishment, and remanufacturing, due to their strong relevance in manufacturing contexts, as suggested by [1]. Based on these objectives, the following research question is posed:

RQ1: “How are the 9R circular economy strategies implemented in the manufacturing industry?”

RQ2: “What are the primary challenges that the manufacturing industry encounters when transitioning to a circular model?”

RQ3: “Which I4.0 technologies are employed by the manufacturing industry to mitigate the challenges related to the transition to a circular model and how can they contribute to CE?”

For answering these questions, we employed a case studies approach, gathering data from ten manufacturing organisations.

Findings indicate that organisations often adopt multiple circular strategies, with repair being the most prevalent. Barriers to I4.0 adoption include scalability issues, limited expertise, and infrastructure gaps. Advanced adopters demonstrate robust delivery systems supported by collaborative networks that enhance knowledge transfer among stakeholders. The study suggests potential synergies between circular economy practices and Industry 4.0 technologies, though the direction and nature of this relationship remain under investigation. Organisations excelling in CE implementation often achieve similar success in I4.0 adoption, underscoring their interdependence. Conversely, firms with limited CE adoption show minimal integration of I4.0 technologies. These findings emphasize the need for transformative strategies over incremental changes to maximize the potential of CE and I4.0 in achieving sustainability.

2. Research Methods

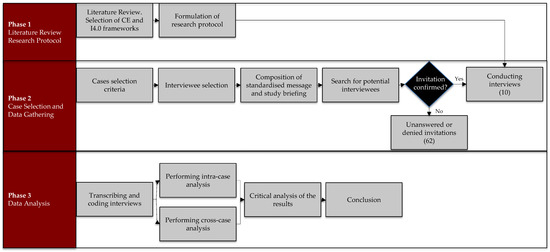

The in-depth literature review identified a research gap and guided the development of the research protocol, following recommendations from [15,16]. A multiple-case approach was adopted, selecting manufacturing companies undergoing the transition to a circular model. Experts from these companies, who implement circular business models and use CE approaches in product development, were interviewed to explore the technologies used to address challenges in the transition. Figure 1 presents an overview of the research design.

Figure 1.

Research flow.

2.1. Literature Review and Research Protocol

The keyword searches relied on two databases: Web of Science and SCOPUS. Both platforms provide structured metadata needed for bibliometric investigations [17]. SCOPUS offers the most extensive coverage of peer-reviewed documents [18], while Web of Science integrates journals listed in the Journal Citation Report (JCR) [17].

The search was carried out in August 2023, using keywords derived from the re-search questions. Two sets of terms were combined: those related to Circular concepts and those associated with Industry 4.0. In Web of Science, the query was applied under the “topic” field, whereas in SCOPUS the same string was applied to “title, abstract, and keyword.” After filtering for document type (articles and reviews), the datasets were 81 documents in Web of Science and 44 in SCOPUS, respectively.

The two datasets were then merged in R Studio 4.2.1 to remove duplicates. This step eliminated 41 repeated items, leaving 84 unique records. Titles and abstracts were subsequently screened according to the exclusion criteria. In this process, 41 records were removed, mainly due to sectors not related to manufacturing. The final sample used for analysis comprised 43 articles.

The first step, literature review, helped in developing theory from case studies is defining the research questions clearly [19,20]. Two conceptual frameworks were adopted: the 9R Framework for CE [21] and the Industry 4.0 framework [9]. The CE framework was chosen for its prominence in the literature, while the Industry 4.0 framework helped structure questions on enabling technologies, categorizing them into base and front-end technologies.

The second step involved creating the interview protocol, which included self-generated questions based on the chosen frameworks, as well as questions adapted from [22,23,24,25]. The protocol aimed to improve the reliability and validity of the case studies. It was designed to capture interviewees’ perspectives without influencing their responses. A semi-guided questionnaire was developed to explore digital technology adoption in the circular economy transition and support the interviewer. The full interview protocol is outlined in Appendix A.

2.2. Case Selection and Data Gathering

Case study selection aimed to enhance understanding of circular economy integration within products and the technologies used, while ensuring access to stakeholders and relevant documents [16].

The first step was defining the case selection criteria. We have included this clarification in the manuscript. A theoretical sampling technique was applied, selecting manufacturing companies based on two criteria: the company must operate in the manufacturing sector and have implemented a CE project involving at least two of the following CE strategies: reuse, repair, refurbishment, or remanufacturing. These four CE strategies were chosen due to their strong relevance in manufacturing contexts, as suggested by [1,26]. While this criterion helped identify suitable cases, the analysis itself considered all 9R strategies to ensure a comprehensive view.

The second step determined the sample size. The literature suggests an optimal number of cases between four and ten. With more than ten, managing data complexity becomes challenging; fewer than four can hinder theory development [19]. In this study, each interview counted as a separate case, with 10 interviews conducted.

A standardized message and study briefing were prepared in English and German for consistent outreach. Experts in the manufacturing sector were contacted through email and LinkedIn, chosen for its effectiveness in locating professionals and companies fitting the study criteria. The search used terms like “Circular Economy” and “Sustainability.”

The invitation phase ran from late August to early November 2023. Seventy-two professionals were contacted (44 via LinkedIn and 28 via email). The response rate was 13.9%, with email outreach proving more successful (25%) compared to LinkedIn (6.8%).

The study involved 10 manufacturing companies from sectors such as electronics, ICT, household goods, and furniture, with ten interviews with managers responsible for sustainability, corporate social responsibility, or circular economy projects and initiatives. Table 1 provides an overview of the organisations and interviewee profiles. Company names were kept confidential.

Table 1.

Companies and interviewee profiles.

The case study, PILOT, is a pilot conducted in a learning factory at a university. Five cases, ELECTRO1, ELECTRO2, ELECTRO3, ELECTRO4, and ELECTRO5, belong to the electronic and ICT sector. Two cases, HOUSE1 and HOUSE2, are from the household appliances industry, while the other two cases, FURNI1 and FURNI2, are from the furniture sector.

Interviews were conducted via video conference, and each interview lasted about 37 min, followed by transcription and coding of the scripts. Secondary sources, such as company websites, were also consulted.

2.3. Data Analysis

The data analysis began with transcribing and coding the interviews. An intra-case analysis followed, detailing the implementation of circular strategies, challenges faced, and capabilities developed. After completing the intra-case analysis, a cross-case analysis was performed across the 10 organisations. The goal of the cross-case analysis was to identify similarities, differences, and patterns among the organisations. The results of these analyses are presented in the following section.

3. Literature Review

This section reviews the literature on circular economy (CE) and examines how Industry 4.0 technologies enable the adoption of the 9R circular economy strategies.

3.1. Circular Economy

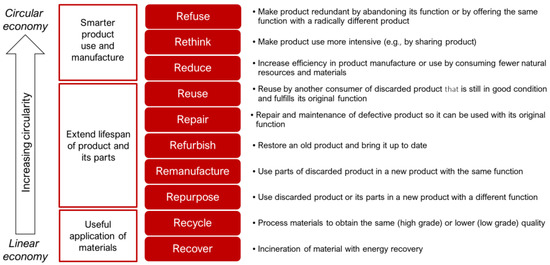

The global economy has traditionally followed a linear model, originating during the Industrial Revolution. This model, initially adopted for its cost-effectiveness in mass production, improved the quality of life (Azevedo, 2015) [27]. However, the environmental drawbacks of this approach, including the depletion of natural resources, have raised concerns for future generations. In response, the need for a more sustainable model arose, leading to the emergence of the circular economy (CE), a shift away from the linear process of extraction, production, use, and disposal. CE advocates for a regenerative system, emphasizing the reuse and value retention of materials and products (Deutz, 2020) [28]. The circular economy employs various strategies to optimize material use, minimize waste, and maximize value. A central element in CE is the R-strategy framework, which focuses on different approaches for achieving circularity. Although the precise number of strategies remains debated in the academic community, this study adopts the 9R framework by [21], as shown in Figure 2. This framework includes refuse (R0), rethink (R1), reduce (R2), reuse (R3), repair (R4), refurbish (R5), remanufacture (R6), repurpose (R7), recycle (R8), and recover (R9). According to the framework proposed by [29], the strategies at the top of Figure 2 (R0–R2) represent higher levels of circularity, whereas those closer to R8–R9 correspond to lower levels of circularity.

Figure 2.

9R Framework (Adapted from [21,29,30]).

The R-strategies are categorized into three groups. The first group (R0–R2), which includes refuse, rethink, and reduce, focuses on smarter product use and manufacturing, aiming to eliminate waste early in the product life cycle [30]. Refuse addresses harmful products, rethink encourages seeing waste as a resource, and reduce works towards raw material efficiency.

The second group (R3–R7) includes reuse, repair, refurbish, remanufacture, and repurpose. These strategies extend product lifespans and maintain or enhance their value. These strategies, however, require more external resources due to the need for reverse logistics, market receptivity, and varied business models [30]. Reuse involves the second-hand use of products or components, often in Product Service Systems (PSS), where products are shared or leased rather than sold [31]. Repair restores a product to its functional state, while Refurbish involves upgrading products by replacing worn parts [32]. Remanufacture goes a step further by disassembling products and testing components to meet performance standards [32]. Repurpose, in contrast, involves using discarded products or components for entirely different purposes [30].

The final category (R8–R9) includes strategies with lower circularity potential. Recycling involves processing materials into new or lower-quality materials, while Recovery, the least preferred, involves incinerating waste for energy recovery. Recovery has environmental downsides, as it destroys materials and competes with more circular strategies [30].

In our study, we place particular emphasis on Value-Retention Processes (VRPs) more deeply integrated into manufacturing contexts, such as reuse, repair, refurbishment, or remanufacturing [1,26]. Nonetheless, the analysis covers all nine R strategies to provide a comprehensive perspective.

3.2. Enabling CE Through I4.0 Technologies

This study examines how specific Industry 4.0 technologies facilitate the adoption of circular economy practices. Unlike previous studies that address the general interaction between Industry 4.0 and the circular economy, this study focuses on the potential of individual technologies to support specific circular economy strategies.

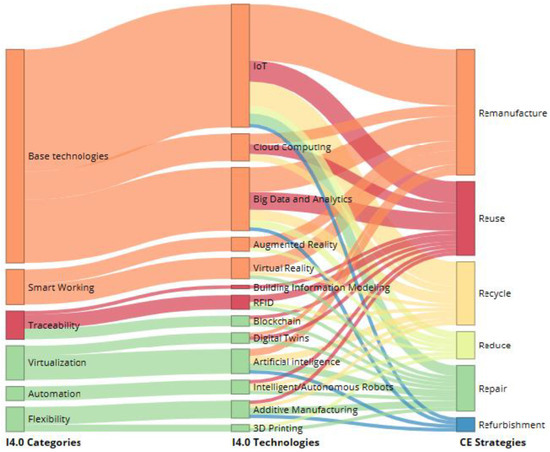

A Sankey chart was created to visualize the relationship between circular economy strategies and Industry 4.0 technologies, categorized according to the framework of [9] (Figure 3). We adopted the framework proposed by [9] due to its wide acceptance in both academic and policy communities, and its specific focus on the manufacturing sector. Figure 3 shows that remanufacturing was the most prevalent strategy, followed by reuse. Previous studies on the impact of Industry 4.0 technologies on circular economy practices often emphasize the strategies of reduction and recycling [33], but these were not highlighted here due to the focus on value retention processes. The following subsections explore the most valuable enabling technologies for each value retention process.

Figure 3.

Sankey chart—Enabling technologies and circular economy strategies. Note: Each color represents a CE Strategy as follows: Orange: Remanufacture, Red: Reuse, Yellow: Recycle, Light Green: Reduce, Green: Repair, and Blue: Refurbishment.

The content analysis of the surveyed literature allowed identifying enabling technologies for circular economy strategies. Table 2 presents a cross-analysis of these enabling technologies, based on the framework of [9], and their corresponding circular economy strategies.

Table 2.

Enabling technologies for circular economy strategies.

3.2.1. Reuse Strategy

The literature highlights the crucial role of smart manufacturing technologies, particularly traceability technologies, in supporting the reuse strategy within the circular economy. A major challenge in reusing recovered building components is ensuring their quality and performance. Digital technologies facilitate the identification, tracking, monitoring, and management of building components, helping assess their physical suitability for reuse and enabling additional services for quality and performance assurance [42].

The integration of physical objects with their digital counterparts, or “digital twins,” via a data management system allows stakeholders to access and share lifecycle data for informed decision-making [44]. Technologies such as RFID tags and Building Information Modelling (BIM) enable designers to track components with unique IDs and incorporate them into BIM models for new buildings. These models provide detailed data on the physical and functional attributes of building components, including their state, function, and behaviour under specific conditions [42].

Information stored on RFID tags, such as lifespan, ownership, and location, can be linked to the BIM model as component attributes. This data can be securely stored on a cloud-based server, and any changes to the components can be updated in real-time through a bidirectional cyber–physical data exchange system. By integrating lifecycle data, this approach enhances decision-making and supports effective asset management strategies to assess the reuse potential of building components, ensuring they meet the required standards for reuse [42].

3.2.2. Repair Strategy

The repair strategy within the circular economy is enhanced by several Industry 4.0 technologies, including traceability, virtualisation, automation, and flexibility technologies. Traceability tools, particularly blockchain, are essential for tracking products, components, and materials throughout their lifecycle. Technologies that enable traceability, such as blockchain, digital twins, or IoT, play a crucial role in repair operations by providing detailed component histories to guide decision-making, supporting precise and efficient repair strategies. Blockchain’s immutable ledger, combined with IoT sensors, provides real-time updates on product status, aiding decision-making on repair or disposal [50].

Virtualisation technologies such as digital twins and artificial intelligence (AI) support repair processes by allowing manufacturers to create virtual models for simulations, offering real-time status and degradation data that directly inform maintenance actions, optimizing repair strategies in a risk-free environment [51]. AI assists with data-driven decision-making, enabling more efficient repair assessments by capturing design and process information, which improves consistency and product quality [45].

Automation technologies, like intelligent robots, facilitate equipment inspection and diagnosis. These robots, equipped with sensors and AI, autonomously detect defects and assist in automated repair processes, improving efficiency in disassembly and reassembly and reducing environmental impacts [39].

Flexibility technologies such as additive manufacturing (AM) and 3D printing further support repair by enabling the production of custom parts when traditional replacements are impractical. AM allows for quick production of tailored parts, reducing tooling costs and lead times and supporting complex repairs [46]. AM’s flexibility in repairing products during their middle-of-life phase, particularly when combined with IoT, contributes to sustainability, though ongoing research is evaluating its impact on end-of-life processing [43].

3.2.3. Refurbishment Strategy

The circular strategy of refurbishment is less correlated with Industry 4.0 technologies compared to other value retention processes, primarily due to the overlap between refurbishment and remanufacturing practices. Manufacturers and customers often struggle to distinguish between these two processes, as terms like “reconditioned,” “refurbished,” and “recertified” are frequently used interchangeably with remanufacturing. This ambiguity complicates the integration of Industry 4.0 technologies into refurbishment processes and hampers the development of effective circular value retention strategies [35]. For [29], refurbishment refers to the process of restoring a used product to good working condition and updating it, while remanufacturing involves disassembling a discarded product and using its functional components to build a new product with equivalent performance to a newly manufactured one.

Research on refurbishment in the context of Industry 4.0 is limited [35], possibly overshadowed by studies focused on remanufacturing and broader Industry 4.0 topics due to inconsistent terminology. Given the similarities between refurbishment and remanufacturing, future research is expected to clarify the role of Industry 4.0 in both processes and improve understanding of value retention strategies.

Refurbishment aligns with base technologies like IoT, Big Data, and AI, as well as smart manufacturing technologies such as additive manufacturing (AM). IoT enables real-time monitoring across the supply chain, providing valuable insights into product condition and performance, allowing for early detection of defects [46]. Big Data analytics complements IoT by processing data to identify patterns, predict maintenance needs, and recommend interventions that reduce downtime. AI algorithms leverage insights from IoT and Big Data to optimize resource use, recommending actions such as repair or refurbishment to extend product lifecycles [46].

AM supports refurbishment by remanufacturing complex parts, particularly for end-of-life products where traditional methods are ineffective. AI algorithms enhance AM optimization, promoting resource efficiency and contributing to circular economy goals by extending product lifecycles [46].

3.2.4. Remanufacture Strategy

Remanufacturing is the most frequently cited strategy in relation to enabling technologies within the circular economy, and it is strongly influenced by base technologies such as IoT, Big Data, cloud computing, and Smart Working technologies. Despite its potential, remanufacturing processes face challenges such as fluctuations in demand, supply, and the value of used components, which create uncertainties in costs and returns on investment. Discrepancies in information flow regarding the condition, availability, and location of in-service assets exacerbate these issues [34].

IoT is highlighted as a key enabler in remanufacturing by facilitating real-time monitoring, control, and tracking of product conditions throughout the remanufacturing cycle [9,52]. It strengthens connections between manufacturers, users, and remanufacturers, supporting circular economy principles by reducing risks and enhancing resource circulation. By integrating design specifications with performance data, IoT improves traceability, inventory management, quality control, and regulatory compliance, thereby optimizing resource allocation and ensuring the quality of remanufactured products [34].

Big Data and analytics further support remanufacturing by enabling data-driven decision-making based on extensive datasets [53]. Big Data aids in identifying suitable customers and improving customer satisfaction. It enhances strategic decisions in supply chain management, cleaner production, and product lifecycle management. By mapping relationships between disassembly attributes and real-time data, Big Data optimizes remanufacturing for greater efficiency and sustainability. However, challenges related to standardization, security, and interface stability need to be addressed to fully leverage Big Data in remanufacturing [43,46,54].

Cloud computing improves remanufacturing by enabling efficient data storage and processing without the need for constant internet transmission, thus reducing costs associated with database investment. Cloud platforms store and retrieve product lifespan and recycling data, which inform remanufacturing decisions [55]. Additionally, cloud services enhance collaboration across supply chains by supporting continuous monitoring and information sharing, offering both economic and environmental benefits [56].

Smart Working technologies, including virtual reality (VR) and augmented reality (AR), offer further opportunities to transform remanufacturing. VR aids in disassembly planning at the design stage, allowing designers to optimize disassembly sequences [54,55]. AR provides real-time guidance during remanufacturing tasks, streamlining disassembly, inspection, and reassembly processes by delivering instructions and part diagrams directly within the technician’s view. These technologies also enable virtual testing and validation of remanufactured products, improving quality and reducing time-to-market. In workforce training, VR and AR offer interactive simulations, allowing technicians to practice in a risk-free environment [53].

4. Case Studies

4.1. Circular Strategies Adoption

4.1.1. 9R Strategies Adoption

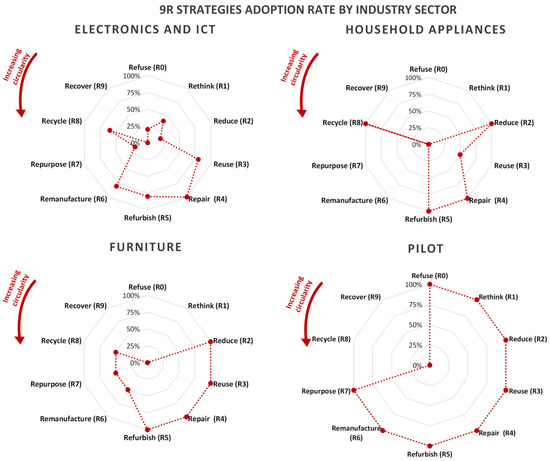

The literature outlines a hierarchy of the 9R strategies for achieving CE, with strategies focused on smarter product use and manufacture (R0–R2) being the most valuable, followed by strategies extending product lifespan (R3–R7), and finally, strategies for the useful application of materials (R8–R9) [21]. The organisations studied loosely follow this hierarchy, with all implementing strategies related to product lifespan extension, while fewer have adopted smarter product design and manufacture or useful material application strategies, as shown in Table 3. From the 9R framework, the studied cases adopted between a minimum of four and a maximum of eight circular economy strategies (see Table 3), indicating that businesses often implement multiple approaches at once. Figure 4 shows the adoption rates of the 9R Framework across the three sectors (electronics, household appliances, furniture), compared to the pilot case.

Table 3.

Overview of 9R CE strategies adoption by case.

Figure 4.

9R strategy adoption per industry sector.

Repair (R4) was used in all case studies, followed by refurbish (R5) in nine, reuse (R3) in eight, and reduce (R2), remanufacture (R6), and recycle (R8) in six case studies each. This sample emphasizes Value-Retention Process (VRP) strategies, meeting a key requirement of the study. However, it deviates from the common trend in CE initiatives, which tend to prioritize recycling over VRP strategies. Most initiatives continue to focus on optimizing resource use incrementally rather than addressing the ongoing use of resources in total, often neglecting upstream waste reduction strategies.

Additionally, refurbishment is more widely used than remanufacturing, maybe because it typically involves less technical complexity, lower costs, and fewer regulatory requirements, making it more accessible for firms. Remanufacturing, by contrast, usually requires more advanced infrastructure, technical validation, and standardized processes, which may limit its adoption.

Figure 4 illustrates the adoption patterns of the 9R circular economy strategies across the electronics and ICT, household appliances, and furniture sectors, revealing distinct differences in circularity patterns. Among the sectors studied, the furniture industry demonstrates the highest overall adoption of circular strategies, particularly in those focused on product life extension such as repair (R4), refurbish (R5), and reuse (R3). This trend may be attributed to the inherent characteristics of furniture products, which are often more durable, modular, and less technologically complex, making them more amenable to refurbishment and component-level repairs. In contrast, the electronics and ICT sector displays moderate engagement with CE strategies, adopting a wider range of Rs but with less intensity. The adoption of remanufacturing (R6) and repair (R4) is notable in this sector, likely due to the presence of valuable internal components and growing regulatory pressure related to e-waste management. However, the technological complexity, frequent model obsolescence, and data security concerns may hinder higher adoption rates of reuse and refurbishment. On the other hand, the household appliances sector presents the lowest overall circularity, with a strategy mix that favours reduce (R2) and recycle (R8) rather than repair or remanufacturing. This may reflect structural and design constraints, where appliances are built for efficiency and compactness but not necessarily for disassembly or component reuse. These results suggest that sector-specific product characteristics, technological complexity, and consumer expectations significantly shape the adoption of CE strategies, highlighting the need for tailored policy and business approaches to foster circularity in different manufacturing contexts.

4.1.2. VRP Adoption

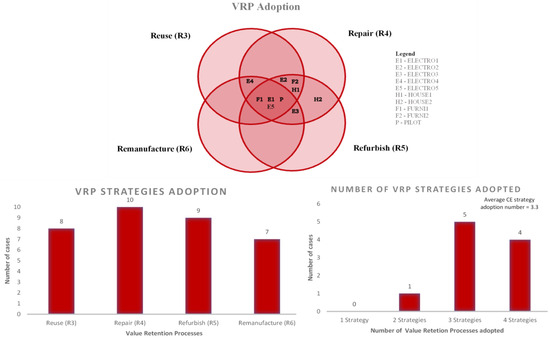

Figure 5 presents three elements related to the adoption of value retention processes (VRPs). The Venn diagram at the top shows how organisations adopt reuse (R3), repair (R4), refurbish (R5), and remanufacture (R6) strategies. The overlaps indicate cases where firms combine two or more strategies. For example, cases E1, E5, F1, and P appear at the intersection of all four strategies. The bar chart on the lower left reports the number of cases for each VRP strategy. Repair (R4) appears in ten cases, refurbish (R5) in nine, reuse (R3) in eight, and remanufacture (R6) in seven. The bar chart on the lower right shows how many strategies each organisation adopted. No firm adopted only one strategy, one firm adopted two strategies, five firms adopted three strategies, and four firms adopted four strategies. The average number of strategies adopted equals 3.3.

Figure 5.

VRP adoption in the case studies.

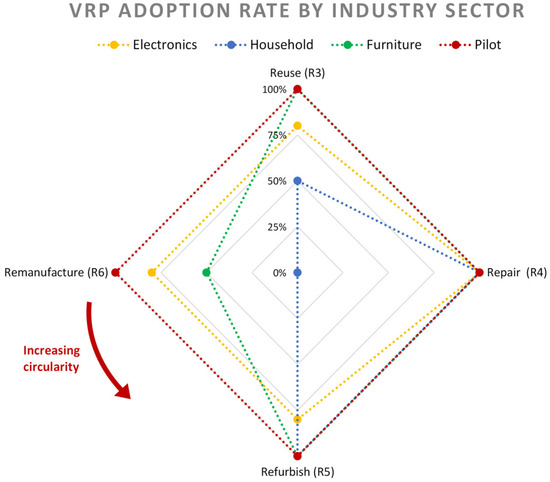

Figure 6 illustrates the adoption rates of four circular economy strategies—reuse (R3), repair (R4), refurbish (R5), and remanufacture (R6), collectively referred to as VRPs—across the pilot case and the three industrial sectors: electronics, household appliances, and furniture. The pilot case stands out as the most advanced in terms of circularity, demonstrating a 100% adoption rate across all four VRPs. The electronics sector follows, with relatively high adoption rates, particularly for repair (R4). In contrast, the furniture sector exhibits a different adoption profile. While repair (R4) and refurbish (R5) show strong implementation, remanufacturing (R6) is less prevalent. Finally, the household appliances sector demonstrates the lowest adoption rates, particularly showing no implementation of remanufacturing (R6). This can be explained by several barriers, such as the lower economic value of individual appliances, the difficulty of disassembly and reassembly due to integrated design, and the absence of dedicated infrastructure for remanufacturing. Furthermore, safety and regulatory concerns in dealing with refurbished electrical components may also deter remanufacturing efforts in this sector.

Figure 6.

VRP adoption rate by industry sector.

Overall, the figure highlights how sector-specific constraints, including product complexity, standardization levels, and economic feasibility, influence the strategic choices companies make regarding circular value retention. It underscores the importance of tailoring circular economy initiatives to the technological, logistical, and economic realities of each industry.

4.1.3. Challenges in Circular Economy Implementation

This section examines the main challenges faced by organisations in implementing circular economy (CE) strategies, based on the framework provided by [22,23,24]. Table 4 presents the challenges faced by companies when adopting circular economy approaches, grouped into categories. The PILOT case was excluded from this analysis because it represents a university rather than a company. Two categories were mentioned by all cases. In “product characteristics and process challenges” category, 100% reported “lack of knowledge and expertise”, and in “standards and regulations” category, all nine firms cited “lack of standards”.

Table 4.

Challenges faced in the CE implementation by case studies.

The most frequently encountered challenges were related to product characteristics and processes, as shown in Table 4. The “lack of knowledge expertise” was a common issue across all case studies, as many organisations initially lacked professionals with circular economy expertise. To address this, research and training were necessary. Six enterprises highlighted difficulties with product complexity, as new procedures and tools were required to implement CE strategies. The presence of various devices also posed challenges for refurbishers and remanufacturers. ELECTRO1, ELECTRO2, and ELECTRO3 reported this issue, while ELECTRO1 and ELECTRO2 also noted challenges related to OEM product design, where original equipment manufacturers typically do not consider repair or reuse during the design phase, making disassembly difficult for circular business models.

The second most common group of challenges related to standards and regulations. All organisations mentioned the lack of standards for processes, materials, and activities as a barrier to CE implementation. Some companies noted the absence of appropriate indicators and metrics for circularity, as existing ones were designed with a linear economy focus, emphasizing throughput and sales. CE requires a shift towards a more holistic perspective, incorporating economic, environmental, and social dimensions. Additionally, political influence from OEMs was reported as a barrier, potentially hindering the transition to a more circular economy. One case study mentioned the absence of taxation, incentive policies, and relevant legislation, which further complicated their efforts, particularly for small companies that lacked evidence of their quality and commitment processes.

Supply chain management standards also presented challenges, especially concerning return flows. Circular business models often introduce uncertainty about the quantity, quality, timing, and location of returned products, affecting economic scalability and capacity planning. ELECTRO4 identified the uncertainty of returned product volumes as a significant issue, which also impacts technology assessment. Transportation and infrastructure challenges were particularly pertinent for remanufacturers and refurbishers, who experience higher transportation needs due to reverse logistics flows. The availability of suitable supply chain partners was another obstacle. The FURNI2 case study highlighted reverse logistics challenges, particularly in the furniture sector, where large and expensive-to-transport goods further complicated circular economy initiatives. Additionally, a limited number of transportation partners willing to engage in reverse logistics made it harder for companies to implement circular strategies.

Table 4 also outlines the challenges identified in the case study sample, focusing on technological, user behaviour, and market-related obstacles. Technological challenges were particularly prominent in the electronics and ICT sectors, which are heavily affected by rapid technological advancements. One key issue is that products designed for long-term use may struggle to keep pace with ongoing technological improvements. The ELECTRO1 case highlighted that technology updates from major tech companies may not be compatible with older devices, creating difficulties for remanufacturing and refurbishing companies that cannot update these devices to align with new technologies.

Another significant technological challenge is data privacy and security, particularly in the electronics industry. Users are often reluctant to return used devices due to concerns about personal data being compromised. To address this, companies handling end-of-use devices must implement specific data-clearing procedures. ELECTRO2 developed a data erasure software in collaboration with another company, allowing the secure deletion of data from devices before they are refurbished or remanufactured.

A major hurdle for many organisations is convincing top management that adopting circular economy (CE) practices is economically viable and offers a competitive advantage. The novelty of CE can be seen as a financial risk, especially for large companies in the household appliance sector. These companies, which typically operate in a linear manufacturing model, faced difficulties in persuading management of the feasibility and long-term benefits of CE initiatives.

Challenges related to user behaviour also emerged, particularly in shifting customer mindsets from a linear to a circular economy approach. Customers often resist purchasing second-hand products due to perceptions of lower quality or outdated designs, or for reasons related to status and fashion. The ELECTRO1 case study emphasized the importance of educational campaigns to raise awareness and challenge the perception that remanufactured devices are inferior to new ones. Additionally, industries with entrenched linear mindsets often experience limited awareness and commitment from both management and employees, complicating the adoption of CE strategies.

Finally, challenges related to market and competition arise due to unauthorized distribution channels. Grey markets, which offer products at significantly lower prices, pose a substantial threat to CE efforts. Companies like ELECTRO3, which focus on circular practices, struggle to compete with these lower-priced alternatives, hindering the implementation of their CE initiatives.

4.2. Enabling Technologies to CE Adoption

This section explores the implementation of Industry 4.0 technologies within the circular economy context, as well as their application in other manufacturing settings, according to the framework outlined by [9]. The study uses technology radars, which visualize technology adoption by combining technologies with ring assessment results. This method provides valuable insights into the most significant industry trends [57,58].

Table 5 organises the adoption of Industry 4.0 technologies in the case studies, using categories defined in the ring assessment and the framework from the literature review. The analysis also incorporates evidence from the intra-case study results. Within each category, the technologies appear in a sequence of increasing complexity, following the recommendation of [9]. The study identifies four categories of technological adoption: ADOPT, TRIAL, ASSESS, and HOLD. ADOPT refers to technologies that have already been implemented within the circular economy context. TRIAL encompasses technologies that have been successfully implemented in other contexts unrelated to the circular economy, or those that are planned for adoption within the circular economy in the future. ASSESS refers to technologies that are considered promising, with clear potential to add value to the organisation. Organisations classify technologies under HOLD when they decide not to recommend them for new projects, since these options do not justify investment. Other technologies remain at the stage of research and prototyping, without plans for adoption in the circular economy. According to [9], the level of complexity in base technologies increases in the sequence of cloud computing, IoT, big data, and analytics. The analysed cases only partially reflected this order. Six organisations adopted cloud computing and analytics, five adopted big data, and three adopted IoT, which appeared as the least used technology in the sample.

Table 5.

Technology radar.

Table 5 highlights how a range of Industry 4.0 (I4.0) technologies are being adopted across different case studies and how these adoptions can influence the circular economy (CE). Base technologies such as cloud computing, IoT, Big Data, and analytics are foundational for enabling real-time monitoring, predictive maintenance, and resource optimization, all of which are essential for extending product life cycles and supporting reuse, repair, refurbishment, and remanufacturing. Vertical integration tools like ERP, CRM, and MRP facilitate better coordination across the supply chain, ensuring that material flows are optimized and waste is minimized. Traceability solutions, including blockchain and RFID, are crucial for verifying the origin and condition of components, thus enabling safe reuse and compliant remanufacturing. Smart manufacturing and automation technologies such as AI, robotics, and virtual simulations enhance production flexibility and efficiency, reducing scrap and energy use. Smart supply chain platforms improve collaboration with suppliers and customers, aligning logistics with circular goals. Finally, Smart Working tools like collaborative robots and VR/AR can support worker training and safe handling of refurbished or remanufactured components. Together, these technologies illustrate the interdependence between I4.0 and CE, where digital and automation capabilities provide the intelligence, connectivity, and flexibility needed to close material loops and increase overall system circularity.

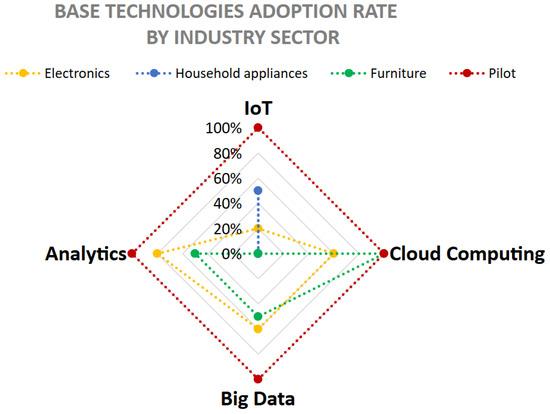

Figure 7 shows the adoption rate of base technologies by industry sector, including electronics, household appliances, furniture, and the pilot case. The base technologies represented are cloud computing, IoT, big data, and analytics. The pilot case reached full adoption across all four technologies. In electronics, use focused more on analytics, followed by cloud computing and big data, with IoT less frequent. Furniture firms concentrated on cloud computing, with limited use of big data and analytics, and no adoption of IoT. Household appliances reported only IoT.

Figure 7.

Base technologies’ adoption rate by industry sector.

When comparing the adoption of Smart Manufacturing technologies across the case studies, the pilot case study demonstrates the highest implementation, having adopted technologies from all categories of Smart Manufacturing. The electronics and furniture sectors show intermediate levels of adoption. The electronics sector has integrated some vertical integration tools, trialled automation, and is assessing traceability and virtualisation technologies. The furniture sector, in comparison, has adopted more complex categories of Smart Manufacturing, such as flexibility technologies, and is also evaluating virtualisation tools. However, the electronics sector has displayed more resistance to adoption, particularly with artificial intelligence (AI), which one case study classified as a “HOLD” technology due to concerns about its high risk and lack of trust.

The household appliances sector shows the lowest adoption of Smart Manufacturing technologies, as it has yet to fully implement any of the tools and is only evaluating vertical integration and traceability, with resistance to automation and virtualisation. This can be attributed to the incremental nature of circular solutions in this sector, which do not demand advanced technologies. It is also noticeable that the Smart Manufacturing adoption patterns in these sectors generally follow the Industry 4.0 (I4.0) adoption patterns proposed by [9]. Vertical integration tools are the most widely adopted category, followed by flexibility technologies and traceability tools.

Regarding base technologies, the study finds a correlation between the adoption of advanced Smart Manufacturing technologies and the presence of base technologies, as suggested by [9]. The pilot case shows the highest adoption of base technologies, followed by the furniture and electronics sectors, and the household appliances sector with the least adoption. Contrary to [9]’s suggested I4.0 adoption pattern, where IoT, cloud computing, Big Data, and analytics are ranked by implementation complexity, cloud computing and analytics were the most frequently adopted technologies in the case studies, with five implementations each. Big Data was adopted in four instances, while IoT was adopted in only two.

Digital platforms with suppliers appear more frequently than platforms with customers, which indicates their role as an initial step towards horizontal integration, consistent with the complexity patterns discussed in [9]. The electronics sector shows the broadest use, as firms adopted platforms with both suppliers and customers. In the household appliances sector, servitization models created the need for platforms that collect data on product use. The furniture sector did not report adoption of Smart Supply Chain technologies in the circular economy context. The pilot case introduced supplier platforms only, since customer interactions were not part of its scope.

For Smart Working technologies, only the pilot case has implemented them, while the electronics industry remains in the trial phase. This aligns with the findings of [9], who observed that advanced I4.0 adopters, like the pilot case, are more likely to implement such tools compared to intermediate or lower adopters.

The comparison of circular economy strategies, base technologies, and Smart Manufacturing shows that the pilot case leads in adoption, followed by the furniture sector, then electronics, and finally household appliances. The cases indicate that greater application of circular economy principles occurs in conjunction with the adoption of advanced base technologies and Smart Manufacturing practices. Additionally, the use of base technologies appears to support the implementation of Smart Manufacturing technologies, as proposed by [9], as both types of technologies show similar adoption patterns across industries. However, the adoption of Smart Supply Chain and Smart Working technologies does not follow the same trend. The pilot case, being the most advanced adopter, leads all technology categories, except for Smart Supply Chain, as it lacks customer interactions and thus does not require platforms for customers.

4.3. Barriers to I4.0 Adoption in Circular Business Models

Despite the progress of Industry 4.0 (I4.0) technologies in linear production lines, many industries remain hesitant to implement them within circular business models (CBMs) due to the additional challenges these models impose [59]. Table 6 outlines the primary barriers identified in the case studies, with the pilot case excluded from the analysis as it is a university rather than a company.

Table 6.

Barriers of I4.0 adoption for CE by case.

The most common barrier identified across the case studies was the limited scalability of CBMs compared to traditional linear business models. This limitation stems from the novelty of CBMs, creating uncertainty around the availability of technical and financial resources. The lack of scalability in I4.0 may also be attributed to poor technology implementation [59]. The FURNI2 case study highlights this challenge, with the interviewee noting that limited resources hinder the scalability of CE initiatives, thereby restricting the implementation of new technologies.

Another significant barrier, observed in seven of the eight case studies, is the lack of a consistent roadmap for implementing I4.0 technologies. Without effective planning, which must account for both technical and financial considerations [60], successful implementation becomes highly unlikely. The ELECTRO4 case stands out for its strategic approach, which includes partnerships with universities to leverage their technical expertise.

In six out of eight organisations, a barrier was the complexity of changing organisational culture. The focus on short-term goals, which demand quick results, often impedes the adoption of new policies and the alteration of workflows [61]. For example, in the FURNI2 case, the interviewee noted that CE initiatives were deprioritised because they were associated with long-term goals, while in FURNI1, senior management initially resisted establishing targets for remanufactured products due to a lack of conviction in the value of CE initiatives.

The lack of knowledge expertise and awareness of digital technology implementation was also a common barrier. Some organisations lack comprehensive plans for digitalisation across their supply chains, and there are few standard tools available for I4.0 adoption, which complicates the process [62]. This issue was highlighted in the ELECTRO2 and ELECTRO3 case studies, where interviewees displayed limited knowledge of I4.0 adoption, suggesting a lack of awareness in their organisations regarding the implementation of these technologies. Similarly, in the HOUSE2 case, the absence of standards for CE solutions hindered the adoption of standard tools for these initiatives.

Industries progress at different rates in the adoption of I4.0 technologies. The household appliances sector has integrated these tools more consistently in linear production lines, while firms in the furniture sector reported difficulties in applying automation and virtualisation because manufacturing relies heavily on manual processes. Limited technological development also constrains adoption on a larger scale. Many organisations continue to use outdated systems, and in some sectors, awareness of technological advances remains low. These conditions may generate security concerns and reinforce negative perceptions of new technologies [63].

A further barrier is the lack of infrastructure. Some organisations do not have the updated system infrastructure necessary to integrate diverse components or devices, which is essential for enabling I4.0 [64]. The ELECTRO3 and FURNI2 case studies face challenges due to their limited financial and technical resources to update their infrastructure.

Additionally, in two case studies, the high dependence on third-party technology providers posed an obstacle. These companies lacked the internal IT resources and infrastructure to develop technologies in-house, which led them to hire external companies for technology development [65]. This was particularly evident in the ELECTRO2 and ELECTRO3 case studies.

Finally, the introduction of I4.0 technologies has raised concerns about job losses, as reported by [37]. This fear, stemming from a lack of awareness about sustainability and the failure to adapt to the needs of the supply chain, has led to resistance to I4.0 adoption in some organisations [66]. In the ELECTRO1 and ELECTRO2 case studies, respondents expressed concerns about job insecurity as a result of new technology implementation.

5. Discussion

This study provides a comprehensive investigation into the integration of Industry 4.0 (I4.0) technologies to facilitate the transition to a circular economy (CE) within the manufacturing industry. The findings, drawn from both theoretical insights and empirical evidence, address the adoption of CE strategies, the challenges encountered during this transition, and the enabling role of I4.0 technologies.

5.1. Implications for Theory

Studies on Industry 4.0 (I4.0) and the circular economy often remain at a conceptual level or lack empirical validation [12]. This research expands the discussion in two directions. It investigates the ways in which firms integrate I4.0 technologies into their 9R strategies, addressing a gap recognised in earlier work [12]. It also examines how particular I4.0 technologies contribute to each stage of the 9R framework, with a focus on strategies that extend product lifespans [13].

Evidence from the cases indicates that manufacturing firms employ multiple circular economy practices. Repair, refurbishment, and reuse appear most frequently, alongside remanufacturing, while recycling is less emphasised because it takes place at the end of a product’s use. This pattern reflects a preference for value retention processes (VRPs), which aim to maintain materials and products in circulation. In contrast to much of the literature that highlights recycling, the cases examined here demonstrate stronger adoption of practices that extend product lifecycles and improve resource retention [30].

The study also highlights the varying stages of CE adoption within the manufacturing sector. Companies such as ELECTRO1 and PILOT show advanced integration of CE principles, demonstrating robust strategies for extending product lifecycles through reuse, repair, and remanufacturing. In contrast, organisations like HOUSE2 and ELECTRO2 face challenges in implementing these strategies due to resource limitations and strategic prioritization issues, reflecting the phased nature of CE adoption in the industry.

Secondly, the research identifies several significant barriers to the adoption of I4.0 in circular business models, consistent with the literature [8]. These include limited scalability of circular models, uncertainty due to I4.0’s novelty, lack of awareness, and a digital skills gap. Outdated infrastructure further hampers adoption. The main challenge faced by the organisations is related to product characteristics and process complexities, such as the lack of knowledge in circular practices and high product complexity due to new procedures and tools. Other barriers include the lack of standards and regulations, supply chain management challenges, and technology-related issues like keeping up with constant technological advancements and data security concerns. Additionally, consumer behaviour poses a challenge, as customers often prefer new products over second-hand ones. Resistance to CE initiatives may also arise due to a dominant linear mindset.

The study reveals the contrasting experiences of advanced adopters like ELECTRO5 and ELECTRO1 and early-stage participants like HOUSE2 and ELECTRO2. While advanced adopters focus on integrating circular practices within existing frameworks, early-stage participants face foundational barriers, such as technology gaps and insufficient managerial support. Regardless of their stage, all companies recognize the need to invest in technology and employee training to overcome these barriers and foster innovation for a successful transition to a circular economy.

The third research question examines how Industry 4.0 (I4.0) technologies interact with the transition to a circular economy (CE). Both the literature and the case evidence indicate that CE and I4.0 shape sustainable production and operational practices. The analysis highlights base technologies together with front-end applications such as Smart Manufacturing, Smart Products, Smart Supply Chains, and Smart Working. These tools strengthen supply chain visibility and help firms respond to uncertainty and low responsiveness [8]. The cases show higher adoption of cloud computing and analytics, moderate use of big data, and more limited application of IoT, which partially reflects the increasing complexity model for base technologies proposed in [9].

The evidence also suggests that firms investing in advanced technologies engage more deeply with circular strategies. Yet meaningful advances in CE demand structural changes in processes and strategies rather than incremental adjustments. Integrating I4.0 with CE principles generates implications for theory by emphasising the role of technological development in sustainable production and operations. The cases point to synergies between CE and I4.0 technologies, although the precise direction and dynamics of this relationship remain open for further investigation [10,25].

5.2. Implications for Practice

The study offers valuable practical insights for manufacturing firms seeking to align their CE and I4.0 strategies. It demonstrates that leveraging advanced I4.0 technologies—such as cloud computing, Big Data, IoT, AI, and blockchain—can enhance operational efficiency, reduce waste, and improve resource utilization. These technologies enable greater visibility across supply chains, facilitate circular practices, and support smart manufacturing processes.

Empirical findings indicate that organisations implementing a wide range of I4.0 technologies, such as PILOT and ELECTRO5, serve as benchmarks, illustrating the benefits of integrating digital transformation with circular strategies. Conversely, firms face foundational challenges, such as technological gaps, outdated infrastructure, and resistance to change, highlighting the importance of strategic planning and capacity-building initiatives.

5.3. Limitations and Future Research Agenda

Despite its contributions, this study has several limitations. The empirical sample is relatively small, consisting of ten case studies, which restricts the generalizability of the findings. Additionally, the research could not identify specific I4.0 technologies for each value retention process due to data constraints. These limitations highlight the need for further empirical studies with larger and more diverse samples to validate the findings and expand their applicability.

Future research should delve into several key areas to advance the understanding of the intersection between Industry 4.0 (I4.0) technologies and circular economy (CE) strategies. One essential area of focus is a granular analysis of specific I4.0 technologies that can address the unique challenges faced in implementing virtual reality production systems, particularly in processes like repair, refurbishment, and remanufacturing. This research should aim to uncover actionable insights that can be directly applied by industry practitioners to improve operations and efficiency. Another important avenue is bridging the digital skills gap. As digital expertise remains a critical barrier to the widespread adoption of I4.0 technologies, it is crucial to explore strategies that provide comprehensive training programs. These programs could be bolstered through collaborative networks that include suppliers, research institutions, and universities, ensuring a skilled workforce ready to support the digital transformation. Additionally, developing sector-specific frameworks is vital. Different manufacturing sectors, such as electronics, furniture, and household appliances, face distinct challenges and opportunities. Tailored frameworks will be necessary to address these sector-specific needs and ensure the effective integration of I4.0 and CE practices. Longitudinal studies will also be crucial for assessing the sustainability and economic impacts of combining I4.0 technologies with circular economy strategies over time. Such studies would provide valuable insights into the long-term potential and transformative benefits of this integration, enabling better-informed decision-making. Lastly, there is a need to explore the role of radical innovations in driving transformative shifts toward a circular economy. While incremental improvements have their place, it is the disruptive innovations that may hold the key to achieving the deeper changes required for a truly sustainable and resilient manufacturing ecosystem.

6. Conclusions

This study examined the adoption of circular economy (CE) strategies across ten manufacturing companies from diverse sectors, with a particular focus on value-retention processes and the enabling role of Industry 4.0 (I4.0) technologies. Drawing on a structured literature review and multiple case studies, the research identified patterns of technology adoption, sectorial differences in circular strategies, and barriers to integrating I4.0 into circular business models.

Findings show that while certain CE strategies, such as repair and refurbishment, are widely implemented, others, like remanufacturing, vary considerably by sector. Foundational I4.0 technologies, including cloud computing, IoT, Big Data, and analytics, emerged as critical enablers of CE, particularly by enhancing traceability, operational efficiency, and resource optimization. Organisations typically adopt multiple CE strategies, with repair being the most prevalent across all sectors and present in every case analysed.

However, the adoption of I4.0 technologies is hindered by scalability challenges, shortages of digital expertise, and outdated infrastructure. Companies further along in I4.0 adoption benefit from stronger delivery systems and collaborative networks, which foster knowledge transfer and capability development among stakeholders, thereby accelerating the transition toward circular business models.

Author Contributions

Conceptualization, B.M.F. and M.M.d.C.; methodology, B.M.F., A.M., L.M. and M.M.d.C.; validation, B.M.F., A.M., L.M. and M.M.d.C.; formal analysis, B.M.F. and M.M.d.C.; investigation, B.M.F.; data curation, B.M.F.; writing—original draft preparation, B.M.F. and M.M.d.C.; writing—review and editing, B.M.F. and M.M.d.C.; supervision, A.M., L.M. and M.M.d.C.; funding acquisition, M.M.d.C. All authors have read and agreed to the published version of the manuscript.

Funding

The authors are grateful for the financial support from the São Paulo Research Foundation—FAPESP, Thematic Project No. 2020/16011-5 and the scholarship CNPq 309643/2020-1.

Data Availability Statement

All utilized data are available upon request.

Acknowledgments

The authors would like to thank the anonymous reviewers and the editors for their insightful comments and valuable suggestions on improving this study.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AI | Artificial Intelligence |

| AGV | Automated Guided Vehicle |

| BIM | Building Information Modelling |

| CAD | Computer-Aided Design |

| CE | Circular Economy |

| CRM | Customer Relationship Management |

| ERP | Enterprise Resource Planning |

| I4.0 | Industry 4.0 |

| IoT | Internet of Things |

| MRP | Materials Requirements Planning |

| RFID | Radio Frequency Identification |

| VR | Virtual Reality |

| VRP | Value-Retention Process |

Appendix A

Table A1.

Research Protocol.

Table A1.

Research Protocol.

| Phase | Content/Goal |

|---|---|

| Phase 0: Presentation and general instructions | - introduction of the research topic and objectives, general instructions. - presentation of the confidentiality agreement |

| Phase 1: General questions about the company | - identification of the main activities of the company, size, and role of the interviewee in the company - identification of the scope and motivation of the CE project carried out |

| Phase 2: Questions about the CE project carried out | - assessment of the level of CE adoption in the company and the relative importance of circular manufacturing compared to other manufacturing capabilities - identification of circular economy strategies from the 9R framework adopted by the company |

| Phase 3: Questions on CE challenges | - recognition of the challenges faced by the company - recognition of core skills required to meet the challenges - recognition of key benefits gained from the implementation of the CE project - identification of the role of digitalization in the CE project |

| Phase 4: Questions about enabling technologies adoption | - assessment of the level of I4.0 technologies adoption in the company - identification of base technologies’ adoption - identification of Smart Manufacturing technologies adoption and the purpose of this adoption - recognition of product’s capability improvement - identification of Smart Working technologies adoption - identification of Smart Supply Chain technologies adoption - identification of possible future technologies adoption |

| Phase 5: Final questions and conclusion | - assessment on how technologies can be used to attain CE - identification of partners along the supply chain that help make the business viable - finalization of the interview and elucidation of remaining questions |

References

- Bocken, N.M.P.; De Pauw, I.; Bakker, C.; Van Der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Homrich, A.S.; Galvão, G.; Abadia, L.G.; Carvalho, M.M. The Circular Economy Umbrella: Trends and Gaps on Integrating Pathways. J. Clean. Prod. 2018, 175, 525–543. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Morioka, S.N.; de Carvalho, M.M.; Evans, S. Business models and supply chains for the circular economy. J. Clean. Prod. 2018, 190, 712–721. [Google Scholar] [CrossRef]

- Manninen, K.; Koskela, S.; Antikainen, R.; Bocken, N.M.P.; Dahlbo, H.; Aminoff, A. Do circular economy business models capture intended environmental value propositions? J. Clean. Prod. 2018, 171, 413–422. [Google Scholar] [CrossRef]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Rosa, P.; Sassanelli, C.; Urbinati, A.; Chiaroni, D.; Terzi, S. Assessing relations between circular economy and industry 4.0: A systematic literature review. Int. J. Prod. Res. 2020, 58, 1662–1687. [Google Scholar] [CrossRef]

- Sung, T.K. Industry 4.0: A korea perspective. Technol. Forecast. Soc. Change 2018, 132, 40–45. [Google Scholar] [CrossRef]

- Bag, S.; Telukdarie, A.; Pretorius, J.H.C.; Gupta, S. Industry 4.0 and supply chain sustainability: Framework and future research directions. Benchmarking Int. J. 2021, 28, 1410–1450. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Lopes de Sousa Jabbour, A.B.; Jabbour, C.J.C.; Godinho Filho, M.; Roubaud, D. Industry 4.0 and the circular economy: A proposed research agenda and original roadmap for sustainable operations. Ann. Oper. Res. 2018, 270, 273–286. [Google Scholar] [CrossRef]

- Kristoffersen, E.; Blomsma, F.; Mikalef, P.; Li, J. The smart circular economy: A digital-enabled circular strategies framework for manufacturing companies. J. Bus. Res. 2020, 120, 241–261. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Papadopoulos, T.; Luo, Z.; Wamba, S.F.; Roubaud, D. Can big data and predictive analytics improve social and environmental sustainability? Technol. Forecast. Soc. Change 2019, 144, 534–545. [Google Scholar] [CrossRef]

- Laskurain-Iturbe, I.; Arana-Landín, G.; Landeta-Manzano, B.; Uriarte-Gallastegi, N. Exploring the influence of industry 4.0 technologieson the circular economy. J. Clean. Prod. 2021, 321, 128944. [Google Scholar] [CrossRef]

- Prause, G.; Atari, S. On sustainable production networks for industry 4.0. Entrep. Sustain. Issues 2017, 4, 421–431. [Google Scholar] [CrossRef]

- Yin, R.K. Case Study Research and Applications: Design and Methods, 6th ed.; Sage: Thousand Oaks, CA, USA, 2018. [Google Scholar]

- Eisenhardt, K.M.; Graebner, M.E. Theory building from cases: Opportunities and challenges. Acad. Manag. J. 2007, 50, 25–32. [Google Scholar] [CrossRef]

- Carvalho, M.M.; Fleury, A.; Lopes, A.P. An overview of the literature on technology roadmapping (trm): Contributions and trends. Technol. Forecast. Soc. Change 2013, 80, 1418–1437. [Google Scholar] [CrossRef]

- Morioka, S.N.; Carvalho, M.M. A systematic literature review towards a conceptual framework for integrating sustainability performance into business. J. Clean. Prod. 2016, 136, 134–146. [Google Scholar] [CrossRef]

- Eisenhardt, K.M. Building theories from case study research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Voss, C.; Tsikriktsis, N.; Frohlich, M. Case research in operations management. Int. J. Oper. Prod. Manag. 2002, 22, 195–219. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Bressanelli, G.; Adrodegari, F.; Perona, M.; Saccani, N. Exploring how usage-focused business models enable circular economy through digital technologies. Sustainability 2018, 10, 639. [Google Scholar] [CrossRef]

- Bressanelli, G.; Saccani, N.; Perona, M.; Baccanelli, I. Towards circular economy in the household appliance industry: An overview of cases. Resources 2020, 9, 128. [Google Scholar] [CrossRef]

- Bressanelli, G.; Perona, M.; Saccani, N. Challenges in supply chain redesign for the circular economy: A literature review and a multiple case study. Int. J. Prod. Res. 2019, 57, 7395–7422. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Rocha-Lona, L.; Tortorella, G. Exploring industry 4.0 technologies to enable circular economy practices in a manufacturing context. J. Manuf. Technol. Manag. 2019, 30, 607–627. [Google Scholar] [CrossRef]

- Russell, J.D.; Nasr, N.Z. Value-retained vs. impacts avoided: The differentiated contributions of remanufacturing, refurbishment, repair, and reuse within a circular economy. J. Remanuf. 2023, 13, 25–51. [Google Scholar] [CrossRef]

- Lei, Z.; Cai, S.; Cui, L.; Wu, L.; Liu, Y. How do different industry 4.0 technologies support certain circular economy practices? Ind. Manag. Data Syst. 2023, 123, 1220–1251. [Google Scholar] [CrossRef]

- Xing, K.; Kim, K.P.; Ness, D. Cloud-bim enabled cyber-physical data and service platforms for building component reuse. Sustainability 2020, 12, 10329. [Google Scholar] [CrossRef]

- Rizvi, S.W.H.; Agrawal, S.; Murtaza, Q. Circular economy under the impact of it tools: A content-based review. Int. J. Sustain. Eng. 2021, 14, 87–97. [Google Scholar] [CrossRef]

- Chen, M.; Ogunseitan, O.A. Zero e-waste: Regulatory impediments and blockchain imperatives. Front. Environ. Sci. Eng. 2021, 15, 114. [Google Scholar] [CrossRef]

- Preut, A.; Kopka, J.-P.; Clausen, U. Digital twins for the circular economy. Sustainability 2021, 13, 10467. [Google Scholar] [CrossRef]

- Yusoh, S.S.M.; Abd Wahab, D.; Habeeb, H.A.; Azman, A.H. Intelligent systems for additive manufacturing-based repair in remanufacturing: A systematic review of its potential. PeerJ Comput. Sci. 2021, 7, e808. [Google Scholar] [CrossRef]

- Daneshmand, M.; Noroozi, F.; Corneanu, C.; Mafakheri, F.; Fiorini, P. Industry 4.0 and prospects of circular economy: A survey of robotic assembly and disassembly. Int. J. Adv. Manuf. Technol. 2023, 124, 2973–3000. [Google Scholar] [CrossRef]

- Liu, L.; Song, W.; Liu, Y. Leveraging digital capabilities toward a circular economy: Reinforcing sustainable supply chain management with industry 4.0 technologies. Comput. Ind. Eng. 2023, 178, 109113. [Google Scholar] [CrossRef]

- Caterino, M.; Fera, M.; Macchiaroli, R.; Pham, D.T. Cloud remanufacturing: Remanufacturing enhanced through cloud technologies. J. Manuf. Syst. 2022, 64, 133–148. [Google Scholar] [CrossRef]

- Ghiaci, A.M.; Ghoushchi, S.J. Assessment of barriers to IoT-enabled circular economy using an extended deci-sion-making-based FMEA model under uncertain environment. Internet Things 2023, 22, 100719. [Google Scholar] [CrossRef]

- Awan, U.; Sroufe, R.; Shahbaz, M. Industry 4.0 and the circular economy: A literature review and recommendations for future research. Bus. Strat. Environ. 2021, 30, 2038–2060. [Google Scholar] [CrossRef]

- Massaro, M.; Secinaro, S.; Dal Mas, F.; Brescia, V.; Calandra, D. Industry 4.0 and circular economy: An exploratory analysis of academic and practitioners’ perspectives. Bus. Strat. Environ. 2021, 30, 1213–1231. [Google Scholar] [CrossRef]

- Ingemarsdotter, E.; Jamsin, E.; Kortuem, G.; Balkenende, R. Circular strategies enabled by the internet of things—Aframework and analysis of current practice. Sustainability 2019, 11, 5689. [Google Scholar] [CrossRef]

- Delpla, V.; Kenné, J.P.; Hof, L.A. Circular manufacturing 4.0: Towards internet of things embedded closed-loop supply chains. Int. J. Adv. Manuf. Technol. 2022, 118, 3241–3264. [Google Scholar] [CrossRef]

- Taddei, E.; Sassanelli, C.; Rosa, P.; Terzi, S. Circular supply chains in the era of industry 4.0: A systematic literature review. Comput. Ind. Eng. 2022, 170, 108268. [Google Scholar] [CrossRef]

- Fofou, R.F.; Jiang, Z.; Wang, Y. A review on the lifecycle strategies enhancing remanufacturing. Appl. Sci. 2021, 11, 5937. [Google Scholar] [CrossRef]

- Tiwari, D.; Miscandlon, J.; Tiwari, A.; Jewell, G.W. A review of circular economy research for electric motors and the role of industry 4.0 technologies. Sustainability 2021, 13, 9668. [Google Scholar] [CrossRef]

- Kerin, M.; Pham, D.T. A review of emerging industry 4.0 technologies in remanufacturing. J. Clean. Prod. 2019, 237, 117805. [Google Scholar] [CrossRef]

- Subramoniam, R.; Sundin, E.; Subramoniam, S.; Huisingh, D. Riding the digital product life cycle waves towards a circular economy. Sustainability 2021, 13, 8960. [Google Scholar] [CrossRef]

- Chau, M.Q.; Nguyen, X.P.; Huynh, T.T.; Chu, V.D.; Le, T.H.; Nguyen, T.P.; Nguyen, D.T. Prospects of application of iot-based advanced technologies in remanufacturing process towards sustainable development and energy-efficient use. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 47, 1994057. [Google Scholar] [CrossRef]

- Sun, X.; Wang, X. Modeling and Analyzing the Impact of the Internet of Things-Based Industry 4.0 on Circular Economy Practices for Sustainable Development: Evidence From the Food Processing Industry of China. Front. Psychol. 2022, 13, 866361. [Google Scholar] [CrossRef]

- Chen, X.; Despeisse, M.; Johansson, B. Environmental Sustainability of Digitalization in Manufacturing: A Review. Sustainability 2020, 12, 10298. [Google Scholar] [CrossRef]

- Kerdlap, P.; Low, J.S.C.; Ramakrishna, S. Zero waste manufacturing: A framework and review of technology, research, and implementation barriers for enabling a circular economy transition in Singapore. Resour. Conserv. Recycl. 2019, 151, 104438. [Google Scholar] [CrossRef]

- Okorie, O.; Salonitis, K.; Charnley, F. Remanufacturing and refurbishment in the age of industry 4.0: An integrated research agenda. In Sustainable Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 87–107. [Google Scholar]

- Potting, J.; Hekkert, M.P.; Worrell, E.; Hanemaaijer, A. Circular Economy: Measuring Innovation in the Product Chain; PBL Netherlands Environmental Assessment Agency: The Hague, The Netherlands, 2017; Available online: https://research-portal.uu.nl/en/publications/circular-economy-measuring-innovation-in-the-product-chain (accessed on 13 September 2025).

- Kandasamy, J.; Venkat, V.; Mani, R.S. Barriers to the adoption of digital technologies in a functional circular economy network. Oper. Manag. Res. 2023, 16, 1541–1561. [Google Scholar] [CrossRef]

- Swan, M. Blockchain for business: Next-generation enterprise artificial intelligence systems. In Blockchain Technology: Platforms, Tools and Use Cases; Raj, P., Deka, G.C., Eds.; Advances in Computers; Elsevier: Amsterdam, The Netherlands, 2018; Volume 111, pp. 121–162. ISBN 9780128138526. [Google Scholar]

- Tönnissen, S.; Teuteberg, F. Analysing the impact of blockchain-technology for operations and supply chain management: An explanatory model drawn from multiple case studies. Int. J. Inf. Manag. 2020, 52, 101953. [Google Scholar] [CrossRef]

- Manavalan, E.; Jayakrishna, K. An analysis on sustainable supply chain for circular economy. Procedia Manuf. 2019, 33, 477–484. [Google Scholar] [CrossRef]

- Kouhizadeh, M.; Saberi, S.; Sarkis, J. Blockchain technology and the sustainable supply chain: Theoretically exploring adoption barriers. Int. J. Prod. Econ. 2021, 231, 107831. [Google Scholar] [CrossRef]

- Jaeger, B.; Upadhyay, A. Understanding barriers to circular economy: Cases from the manufacturing industry. J. Enterp. Inf. Manag. 2020, 33, 729–745. [Google Scholar] [CrossRef]

- Yadav, G.; Luthra, S.; Jakhar, S.K.; Mangla, S.K.; Rai, D.P. A framework to overcome sustainable supply chain challenges through solution measures of industry 4.0 and circular economy: An automotive case. J. Clean. Prod. 2020, 254, 120112. [Google Scholar] [CrossRef]

- Luthra, S.; Mangla, S.K.; Yadav, G. An analysis of causal relationships among challenges impeding redistributed manufacturing in emerging economies. J. Clean. Prod. 2019, 225, 949–962. [Google Scholar] [CrossRef]

- Suarez-Eiroa, B.; Fernández, E.; Méndez, G. Integration of the circular economy paradigm under the just and safe operating space narrative: Twelve operational principles based on circularity, sustainability and resilience. J. Clean. Prod. 2021, 322, 129071. [Google Scholar] [CrossRef]

- Morseletto, P. Targets for a circular economy. Resour. Conserv. Recycl. 2020, 153, 104553. [Google Scholar] [CrossRef]

- Mendoza, J.M.F.; Sharmina, M.; Gallego-Schmid, A.; Heyes, G.; Azapagic, A. Integrating backcasting and eco–design for the circular economy: The bece framework. J. Ind. Ecol. 2017, 21, 526–544. [Google Scholar] [CrossRef]

- den Hollander, M.C.; Bakker, C.A.; Hultink, E.J. Product design in a circular economy: Development of a typology of key concepts and terms. J. Ind. Ecol. 2017, 21, 517–525. [Google Scholar] [CrossRef]

- Huang, L.; Zhen, L.; Wang, J.; Zhang, X. Blockchain implementation for circular supply chain management: Evaluating critical success factors. Ind. Mark. Manag. 2022, 102, 451–464. [Google Scholar] [CrossRef]

- Huang, Y.; Chen, H.; Liu, B.; Huang, K.; Wu, Z.; Yan, K. Radar technology for river flow monitoring: Assessment of the current status and future challenges. Water 2023, 15, 1904. [Google Scholar] [CrossRef]

- Cwiklicki, M.; Wojnarowska, M. Circular economy and Industry 4.0: One-way or two-way relationships? Eng. Econ. 2020, 31, 387–397. [Google Scholar] [CrossRef]