A Model-Based Systems Engineering Approach for Effective Decision Support of Modern Energy Systems Depicted with Clean Hydrogen Production

Abstract

1. Background

2. Decision-Making for Complex Systems

2.1. Humans and Decision-Making

2.2. Decision-Making for Energy Systems

- Pugh concept selection method: Uses a matrix for comparing alternatives as worse, same, or better but does not consider the varying importance of different attributes to the decision-makers [23].

- The multi-attribute utility theory (MAUT): Involves creating a utility function based on the decision-maker’s preferences to rank options, typically using a weighted additive function for different attributes, though more complex functions like multiplicative can be used if attributes are interdependent [23,24].

- The analytic hierarchy process (AHP): Relies on pairwise comparisons by experts to measure intangible criteria and establish a hierarchy of priorities. The outranking methods also use pairwise comparisons but allow for the possibility that alternatives may be incompatible [16].

- Agent-based simulation models: These are increasingly popular for energy applications, modeling complex systems with diverse agents and rules, capable of capturing nonlinearity, emergence, heterogeneity, and coevolution, making them effective for evaluating policy impacts on investment decisions and energy markets [19].

2.3. Shortcomings of Currently Used Decision-Making Methods

2.4. The Need for a New Approach

3. Proposed Evaluation Framework to Support Decision-Making in Energy Systems

3.1. Framework Concept

3.1.1. Systems Thinking

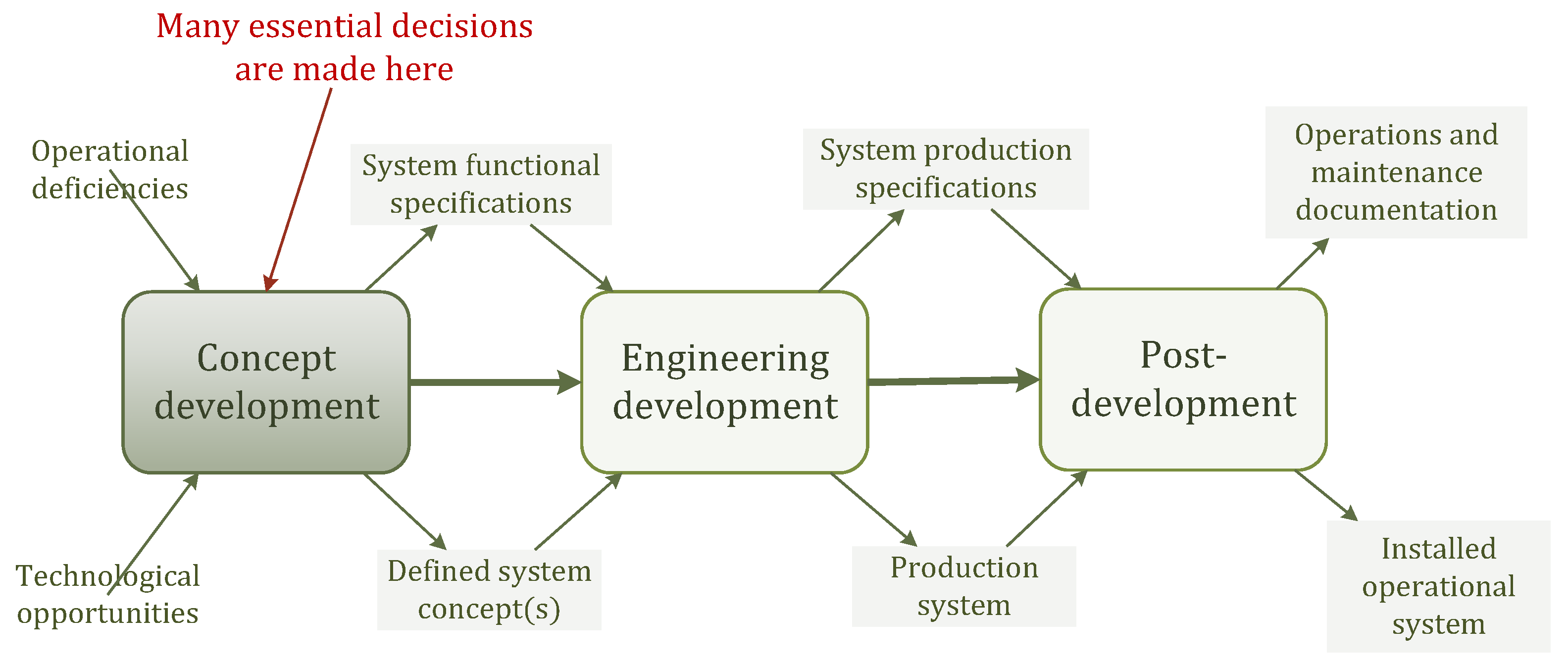

3.1.2. Systems Engineering

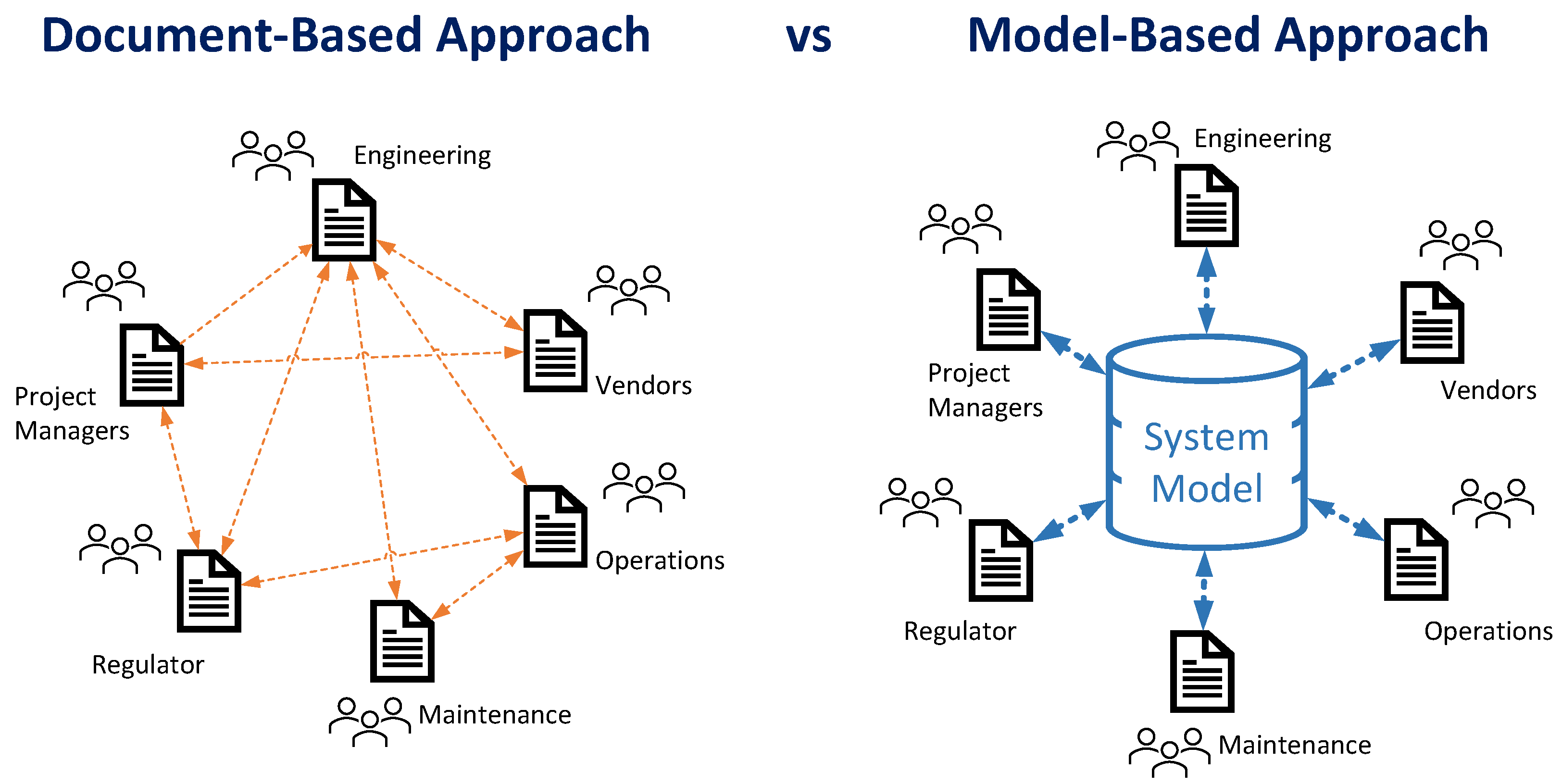

3.1.3. Model-Based Systems Engineering

3.1.4. Lifecycle Modeling Language with Innoslate

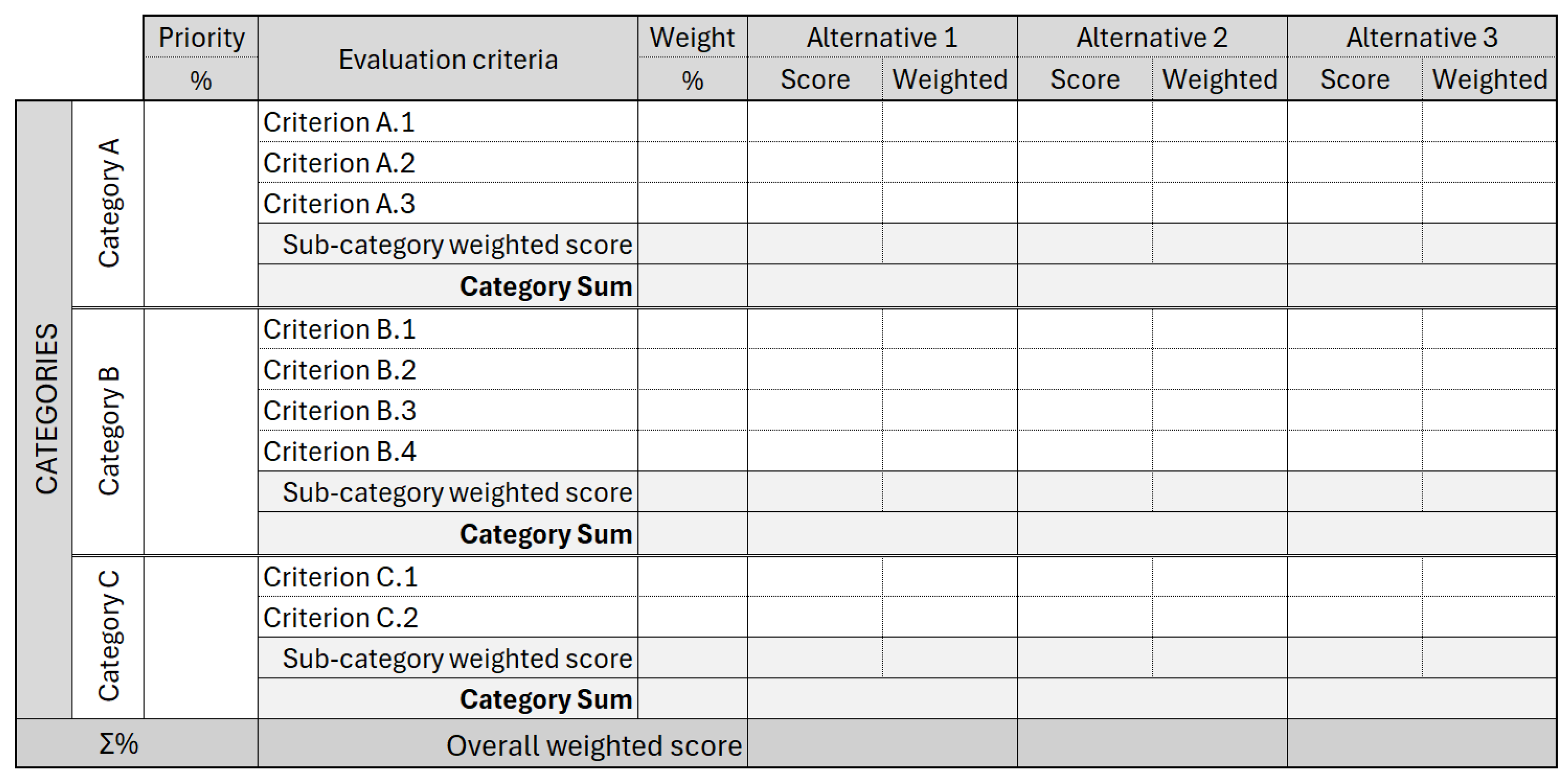

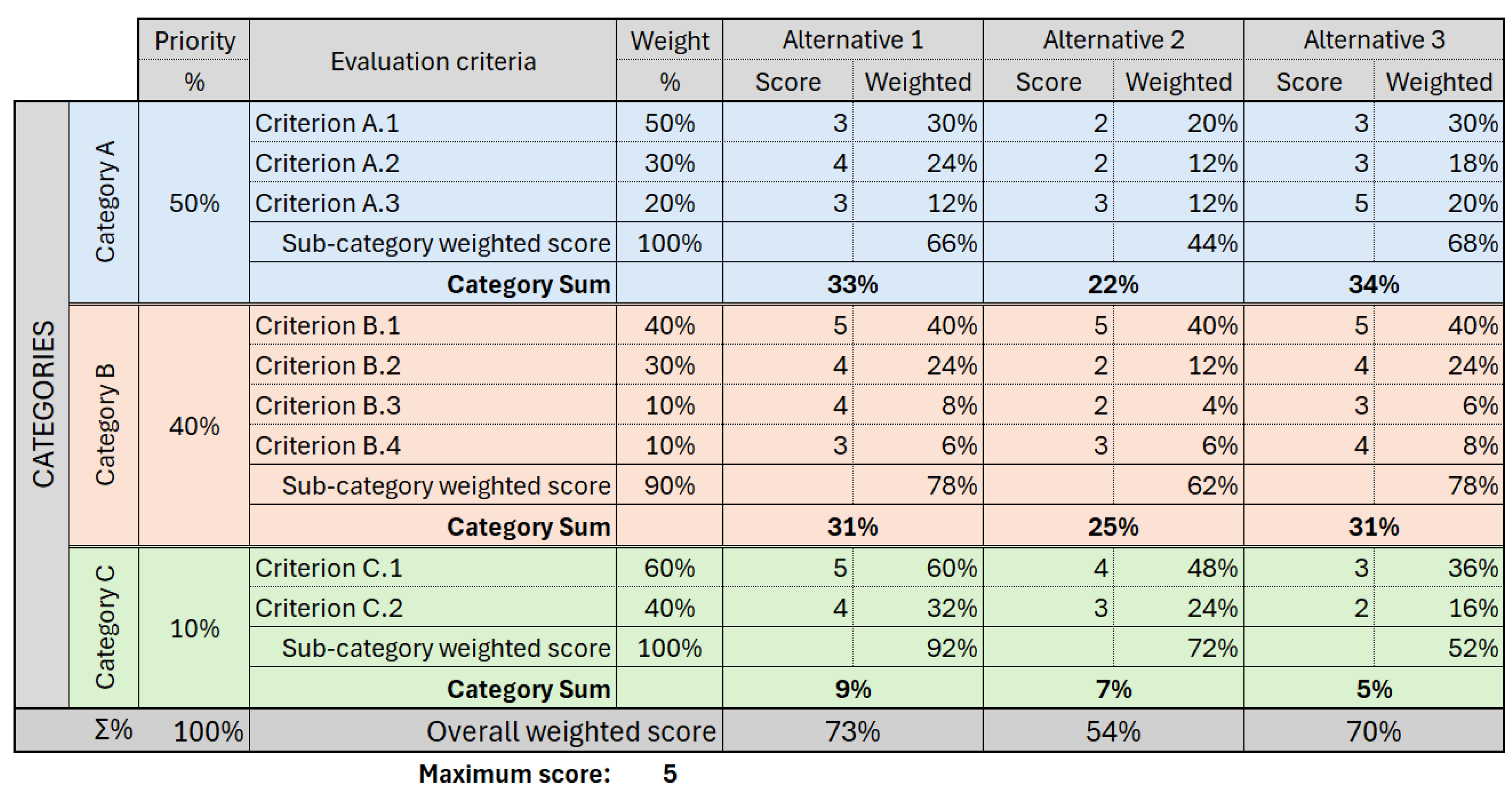

3.1.5. Multicriteria Decision Analysis

- Much worse than required;

- Somewhat worse than required;

- As required;

- Somewhat better than required;

- Much better than required.

- Not compliant;

- Major compliance gap;

- Compliance gap;

- Minor compliance gap;

- Insignificant compliance gap;

- Fully compliant.

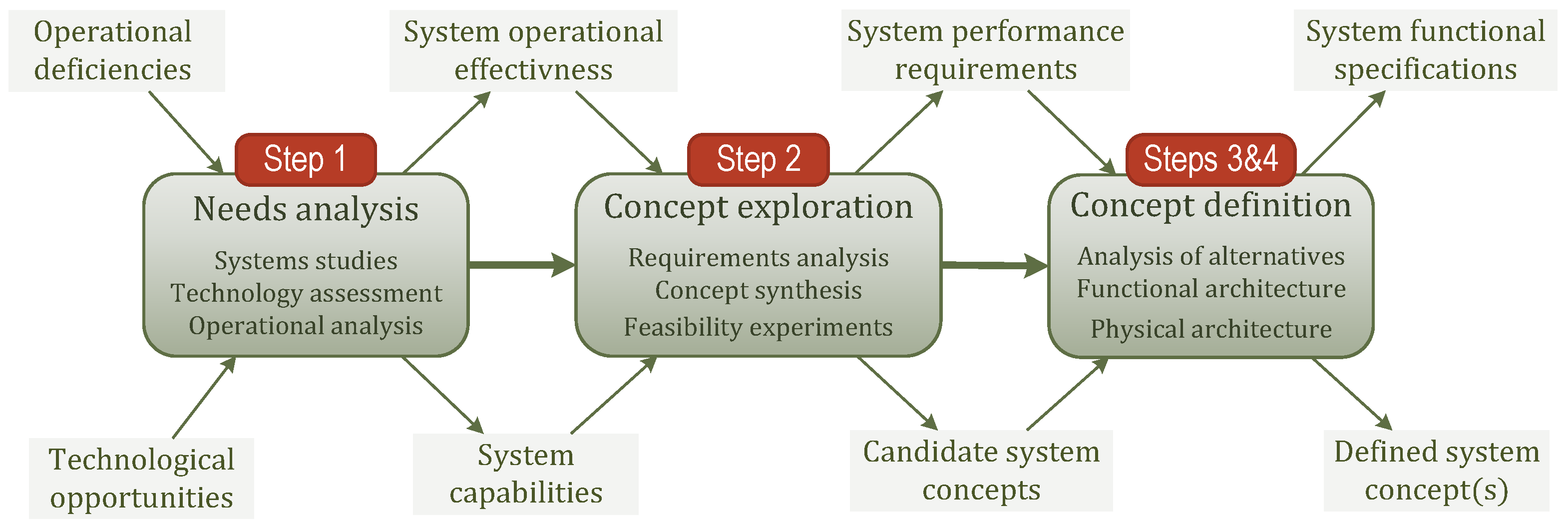

3.2. Framework Processes

- Identify the problem;

- Generate solution alternatives;

- Evaluate alternatives;

- Select the best alternative.

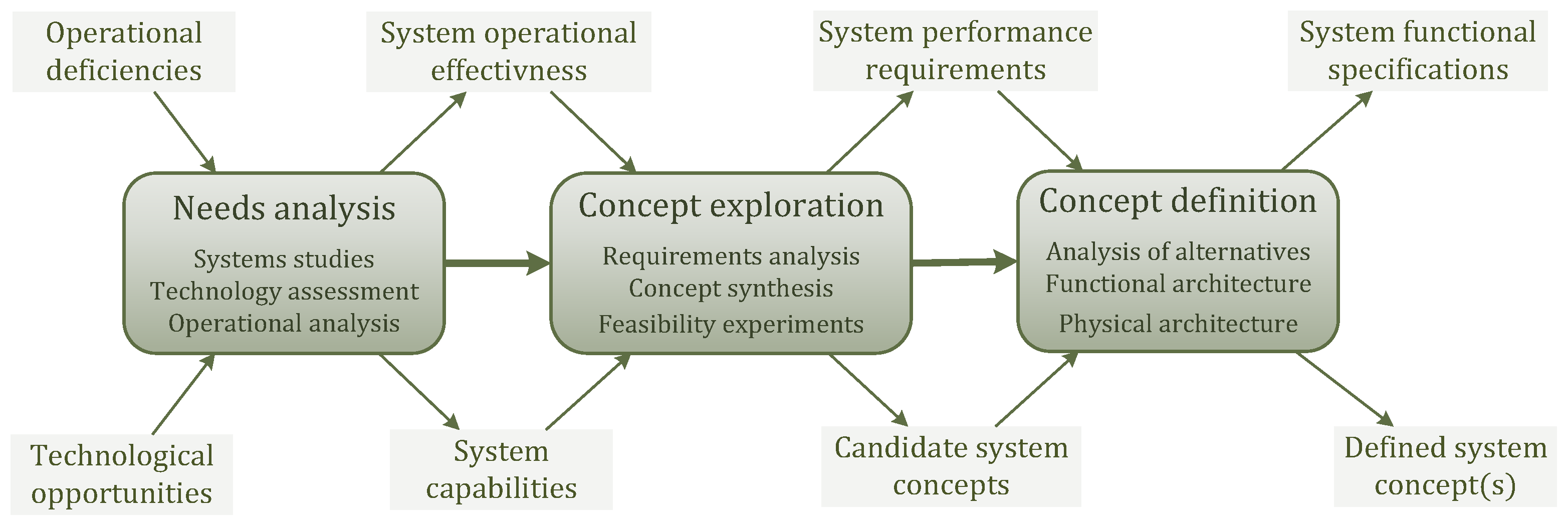

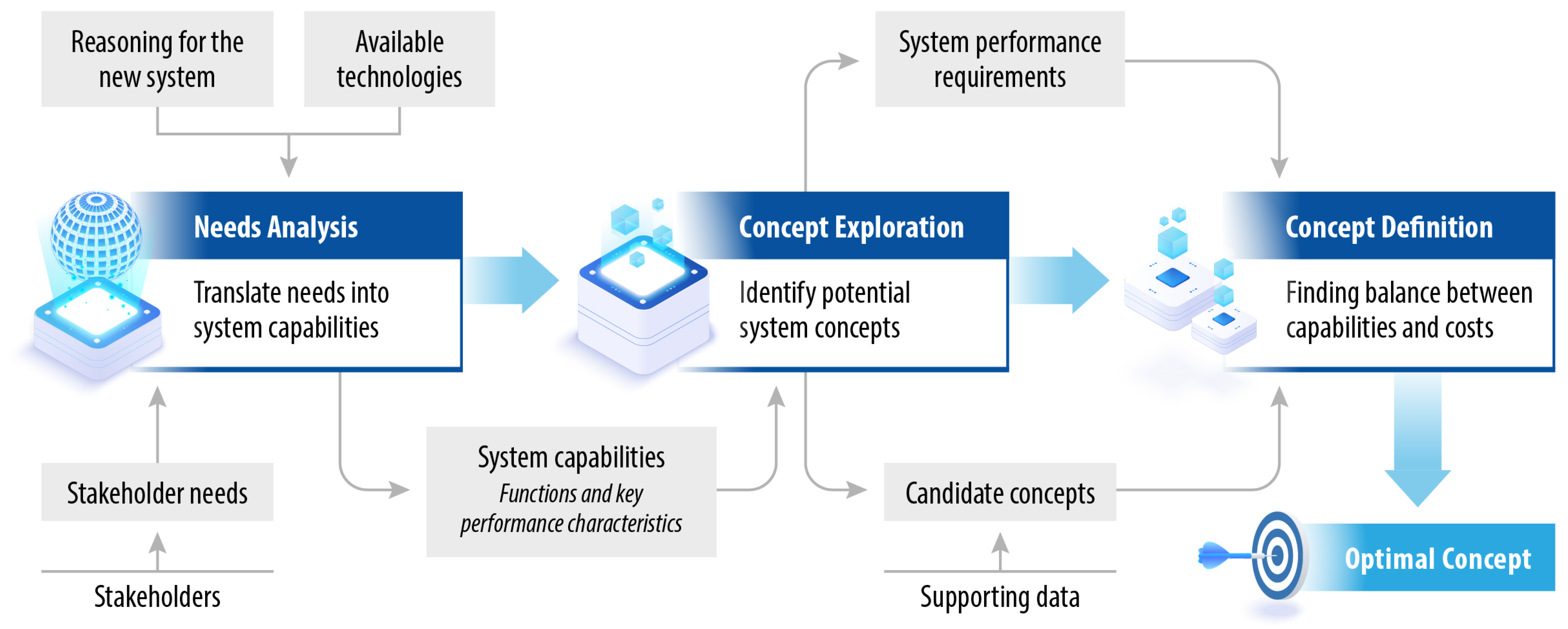

3.2.1. Needs Analysis

3.2.2. Concept Exploration

3.2.3. Concept Definition

4. Case Study on Clean Hydrogen Production

4.1. Phase 1: Needs Analysis

4.1.1. Problem Definition

4.1.2. Available Technologies

- An SMR with a CCS system, often referred to as blue hydrogen;

- Electrolysis using LTE technology;

- Electrolysis using HTSE technology.

- Hydrogen production capacity: the main input to the system initial design. The system capacity depends on specific customer needs as well as current and projected market demands. Capacity dramatically affects the unit cost of hydrogen due to the economies-at-scale factor; that is, a larger capacity results in a lower unit price. The capacity is also the main factor affecting capital costs and, therefore, the economics of the system.

- Hydrogen storage capacity: determined based on how much hydrogen should be stored before it is transported to the customer. The availability of hydrogen, that is, the consistent delivery of hydrogen, is important to industrial hydrogen consumers, and storage capacity could serve as the means to ensure hydrogen availability even if the facility is down for a short period of time (e.g., for maintenance).

- Transportation of hydrogen: options are determined based on the location of the hydrogen generation facility compared to the points of use. Possible solutions are high-pressure hydrogen tube trailers, liquefied hydrogen tankers, or pipelines. Other transportation solutions are currently being developed, but they are not ready for commercial deployment and are not considered for this case study.

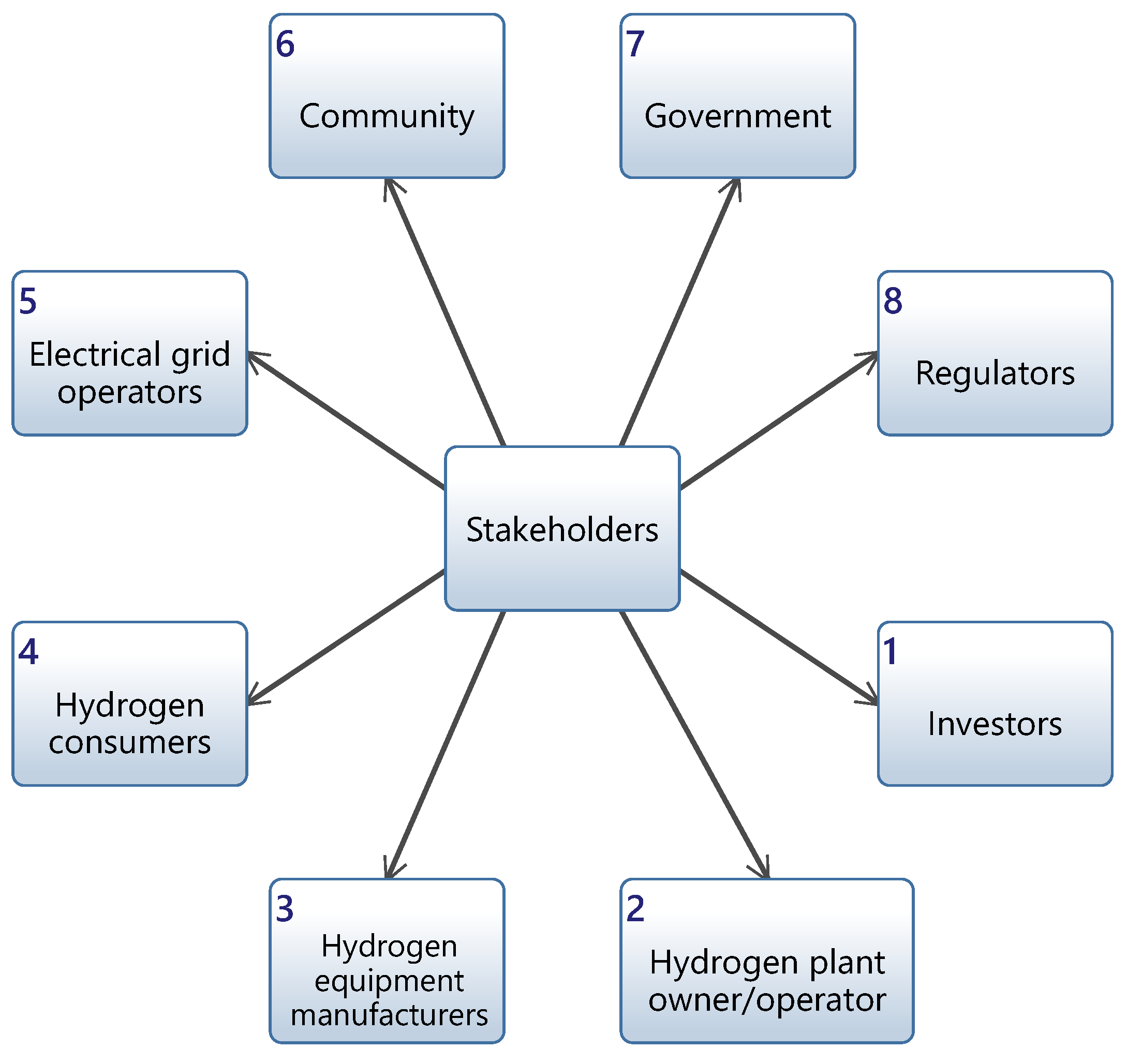

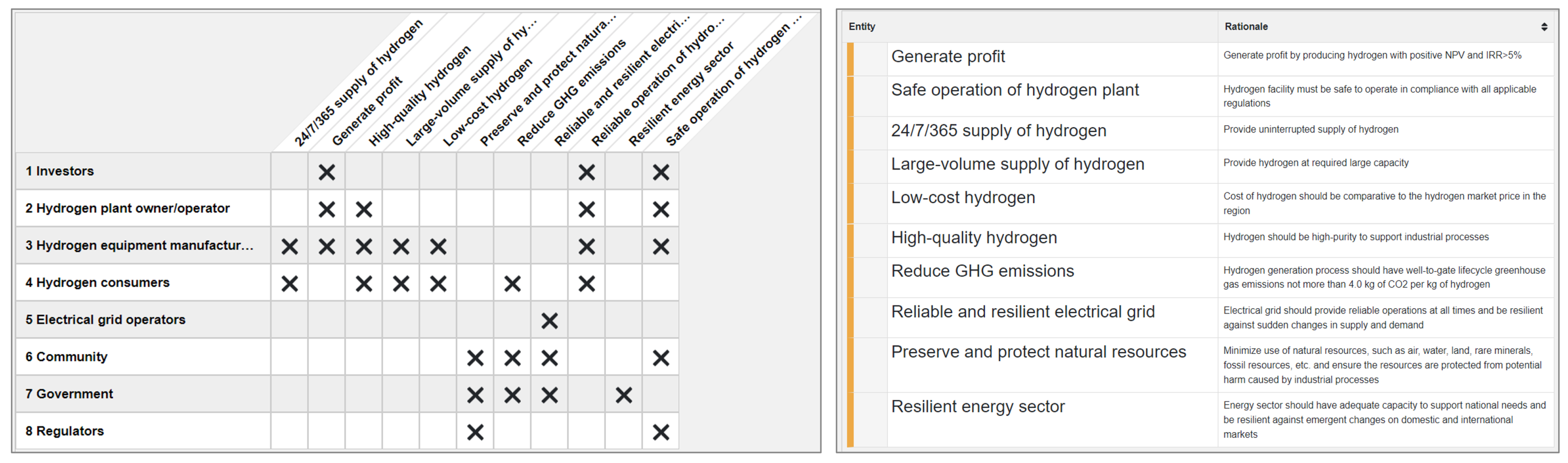

4.1.3. Stakeholders

- Investors: a single investment company or a set of investors.

- Hydrogen plant owner or operator: a company that owns a single facility or a utility owns and operates multiple energy systems, potentially including generation, transmission, and in some cases, distribution energy systems in their portfolio.

- Hydrogen equipment manufacturers: companies manufacturing main hydrogen production systems and components (e.g., electrolyzers) and supporting systems (e.g., hydrogen storage systems and components).

- Hydrogen customers: existing and potential large-scale commercial hydrogen users. A hydrogen consumer could be a large industrial facility that already uses hydrogen as the feedstock for their processes (e.g., ammonia production), industrial enterprises with an interest in novel hydrogen applications (e.g., synthetic fuel producers), or large-scale hydrogen suppliers, like hydrogen hubs supporting smaller hydrogen consumers.

- Electrical grid operators: companies that operate regional and national electrical grids. The relevance of the electrical grid is twofold. First, the concern about electricity otherwise available to the grid being diverted to generate hydrogen, which is the case with existing NPPs. Secondly, the benefit of using hydrogen as an energy storage to supplement grid demands during emergent electricity shortages (e.g., weather-related unavailability of renewable electricity generators).

- Local community: cities, towns, indigenous tribes, etc.

- Government: federal, state, and local governments.

- Regulators: federal, state, and local entities whose objectives and obligations are to ensure public and environmental safety of the new energy system throughout its entire life cycle.

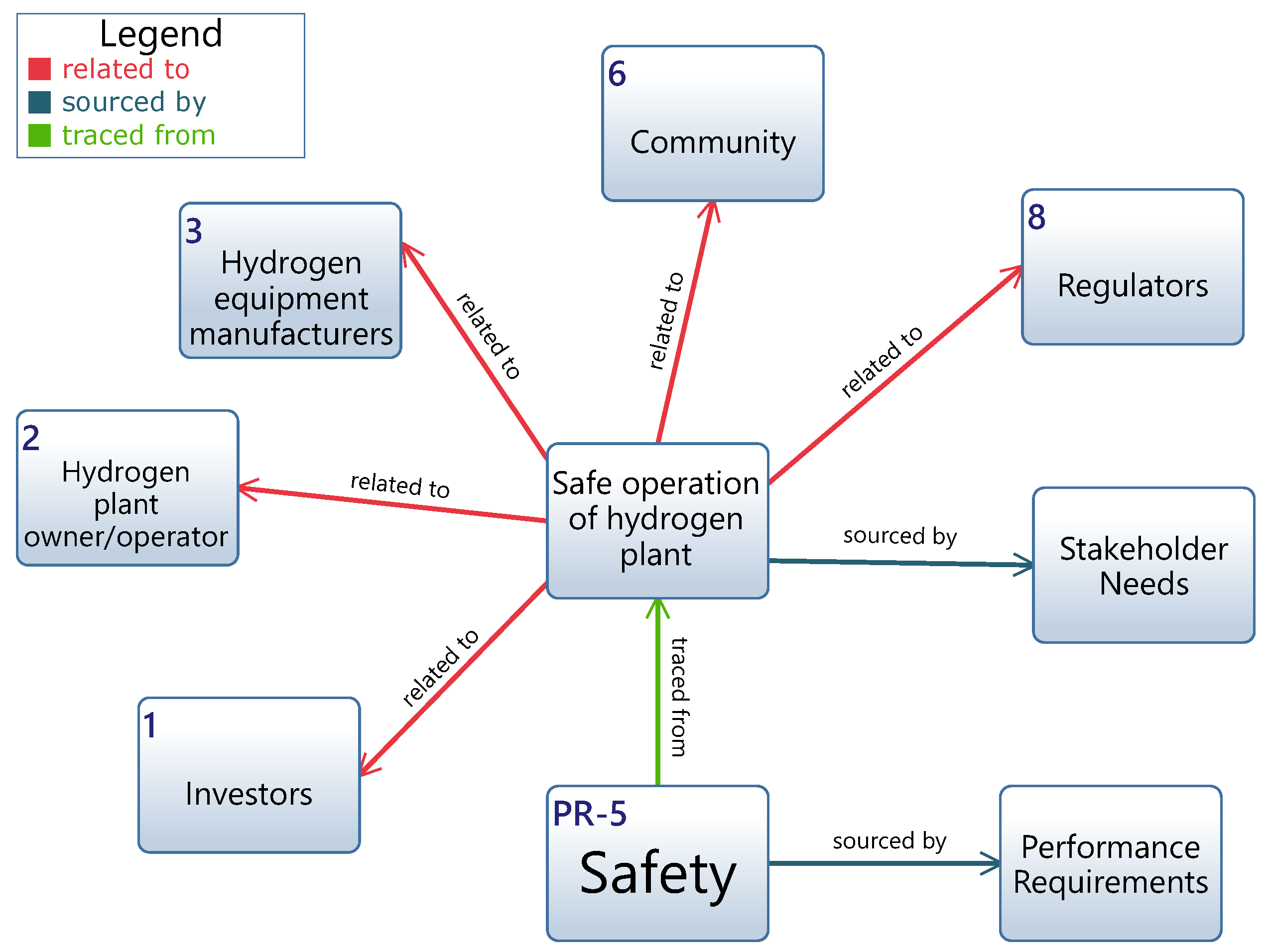

4.1.4. Stakeholder Needs

- Investors: The need for the new energy system is to generate profit.

- Hydrogen plant owner or operator: The main objective is the safe and profitable operation of the facility. An objective that recently became the top priority for many utilities is reducing GHG emissions. Driven by the net-zero goals set at the enterprise level, many electrical utilities are developing long-term strategies for an integrated energy system where preferences are being shifted from fossil-based to clean energy sources. The decarbonization goals become even more important given the plans of shutting down coal-driven power plants, where the lost energy sources must be efficiently and urgently replaced with clean energy sources.

- Hydrogen equipment manufacturers: The main objective is to generate profit from manufacturing hydrogen-related systems and components with supporting objectives of growing capacity, improving technical characteristics, and ensuring the safe and reliable operation of their equipment. Climate-related goals are also often an important objective.

- Hydrogen customers: The main objective is to have consistent access to a large volume of high-quality hydrogen at a reasonable price. The secondary objective that is becoming progressively more important for many enterprises is reducing GHG emissions from their processes.

- Electrical grid operators: The objectives of the grid operators are to have reliable grid operations and an adequate system capacity to provide electricity without interruptions to all their customers. This objective is supported by the goal of having a diverse set of generators to ensure grid resiliency in cases of an expected increase in electricity demands (e.g., peak hours) or during emergent conditions when some sources become unavailable.

- Local community: The main objectives of a local community are uninterrupted access to electricity and other energy sources, climate-related goals, safe operations of the industrial facilities, and economic goals, such as employment opportunities and tax revenue from the businesses. An equally important objective is the preservation of natural resources—the amount of resources needed to support a new energy system, the environmental quality of natural resources, and the protection of the visual appeal of the local area and its surroundings.

- Government: The main objectives of the government for energy systems are to ensure equitable, realizable, and affordable access to energy sources for the people, ensuring environmental quality and the protection and preservation of natural resources, all while supporting the nation’s economic goals. Driven by the urgency to combat climate change and the need to enhance energy sector security, resilience, and independence, the government has a large focus on the technological advancement of novel energy solutions and technologies. The government’s support of the energy sector is provided through various incentives (e.g., the production and investment tax credits offered in IRA). The incentives are often offered at both federal and state levels, promoting the commercial advancement of certain energy solutions.

- Regulators: These agencies include the Nuclear Regulatory Commission, Federal Energy Regulatory Commission, Environmental Protection Agency, Occupational Safety and Health Administration, etc.

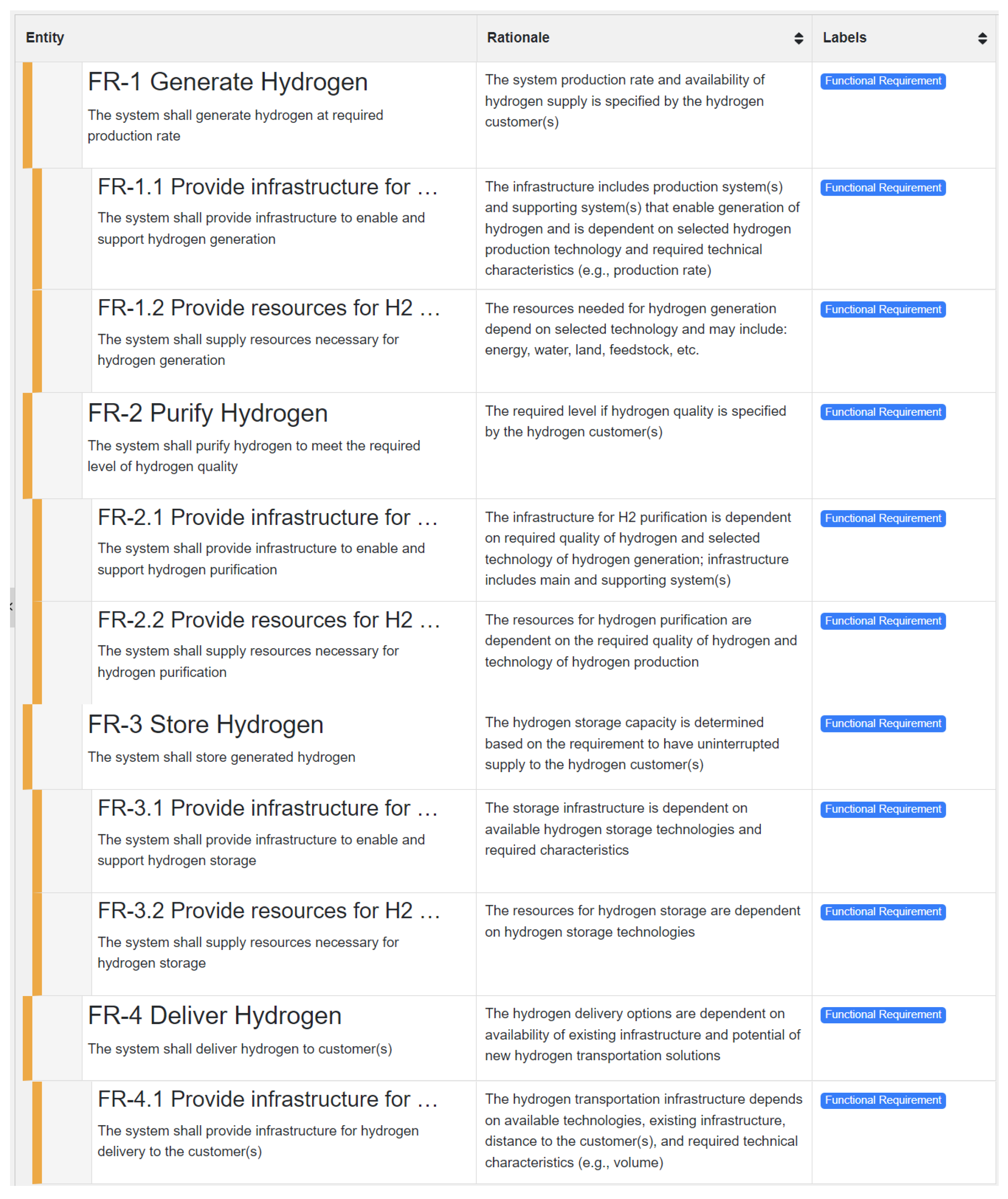

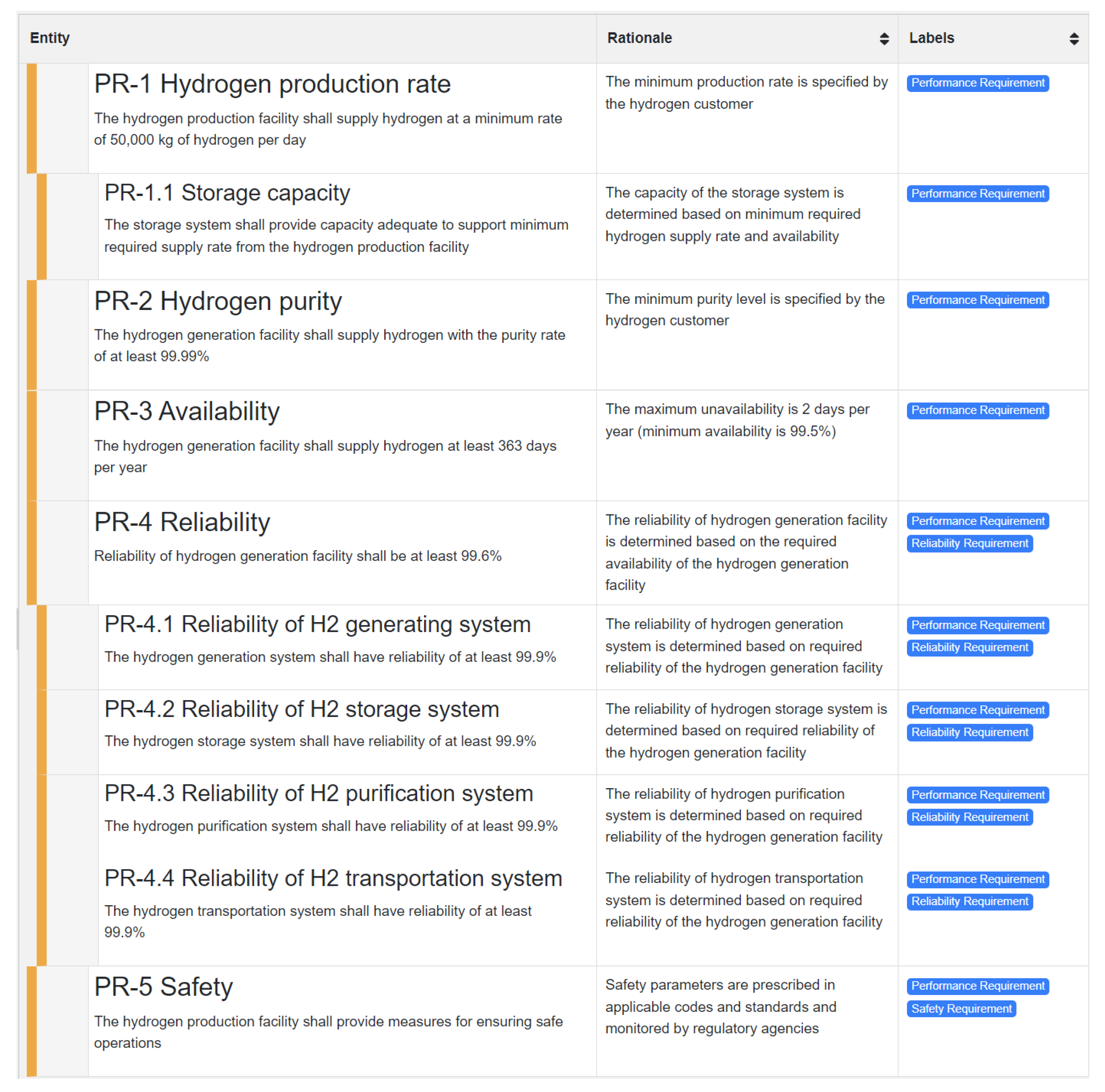

4.1.5. System Capabilities

4.2. Phase 2: Concept Exploration

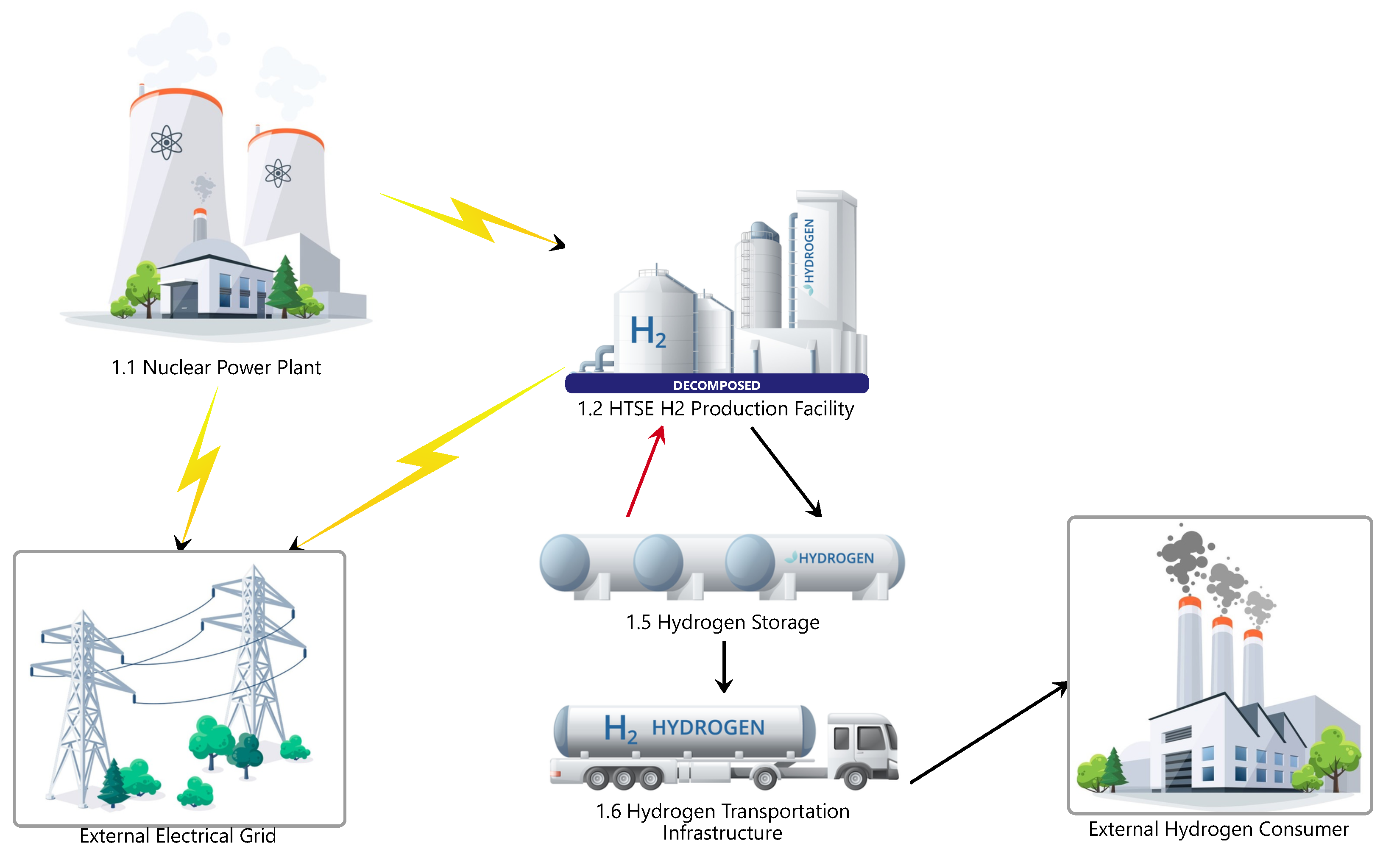

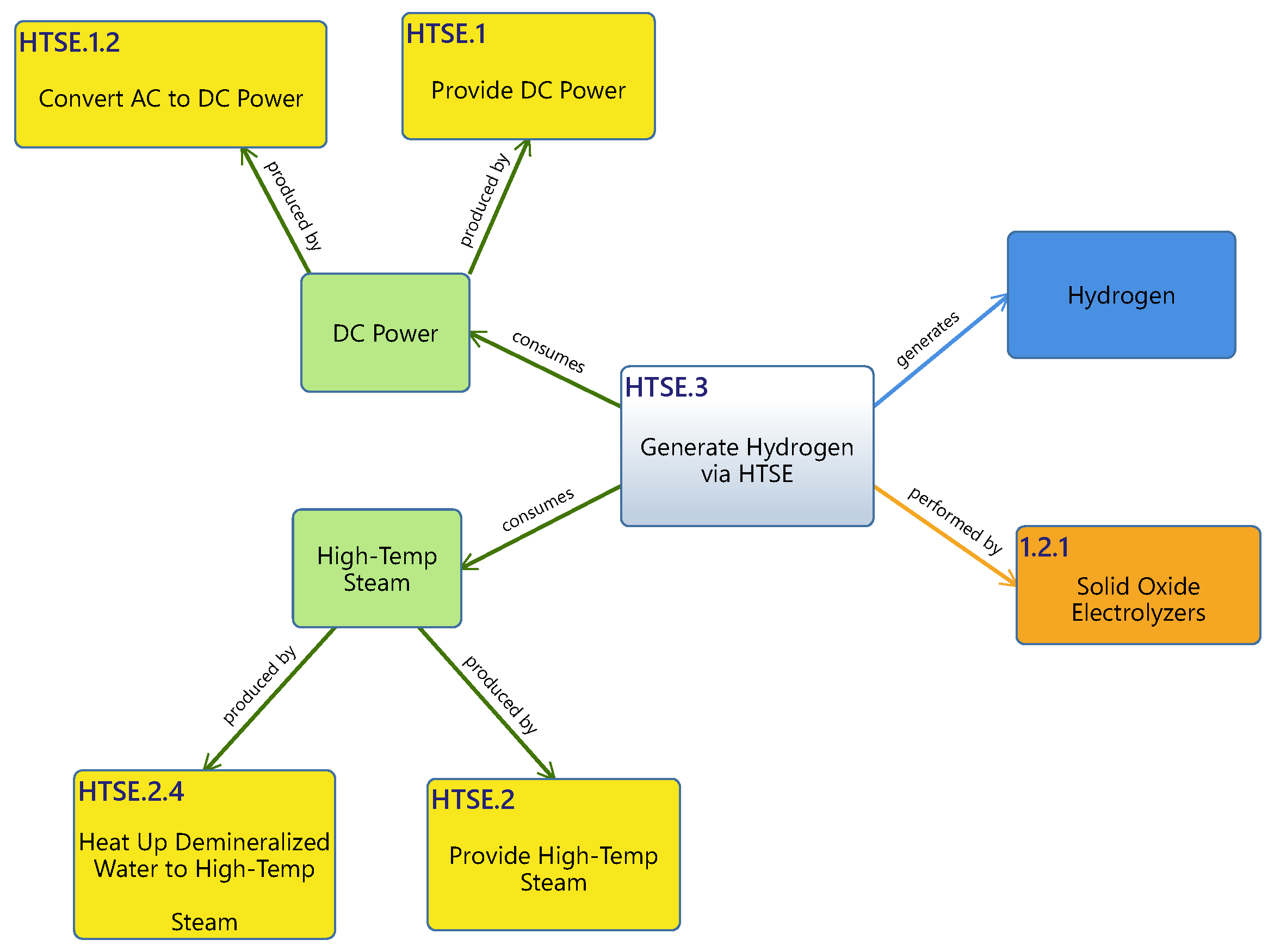

4.2.1. Solution 1—HTSE and Nuclear Energy Source

- An NPP provides thermal energy and electricity to the hydrogen generation facility

- The hydrogen generation facility is located next to the NPP.

- Modifications for the NPP are needed to support thermal energy (i.e., steam) extraction to support HTSE.

- The NPP continues to supply the remaining electricity to the grid.

- Produced hydrogen is already high purity, but remaining moisture and oxygen must be removed to meet the required ultra-high purity level.

- The storage capacity is driven by the requirement of an uninterrupted supply of hydrogen to the customer. Given the constant hydrogen production, storage must be sized for the unavailability of hydrogen generation caused by either planned or unplanned downtime of the hydrogen facility. Maintenance of the hydrogen facility is planned to be performed online supported by the built-in redundancies in the configuration of the hydrogen generation system. However, the energy supply by the NPP is interrupted when the plant is offline for refueling outages, which typically last 15–40 days every 2 years. During the planned NPP outages, the hydrogen generation facility will be powered by the electrical grid, which will cause reduced profitability due to the inability to claim clean hydrogen production tax credits because grid electricity does not satisfy the low GHG emissions requirement. This period also causes stresses for grid operation since the normal electricity supply from the NPP is unavailable, and additional electricity from the grid is being used to produce hydrogen.

- Transportation infrastructure is required since the hydrogen customer is located approximately 20 miles from the hydrogen generation facility adjacent to the NPP (an assumed condition). The regional circumstances pose significant constraints on building a dedicated pipeline; therefore, a traditional mode of transporting hydrogen in high-pressure tube trailers is the selected transportation solution after a quick comparison of costs with the hydrogen transportation approach.

- Stored hydrogen could be used to produce electricity if needed to support emergent grid operations by reversing SOECs to act as solid oxide fuel cells to generate electricity instead of hydrogen.

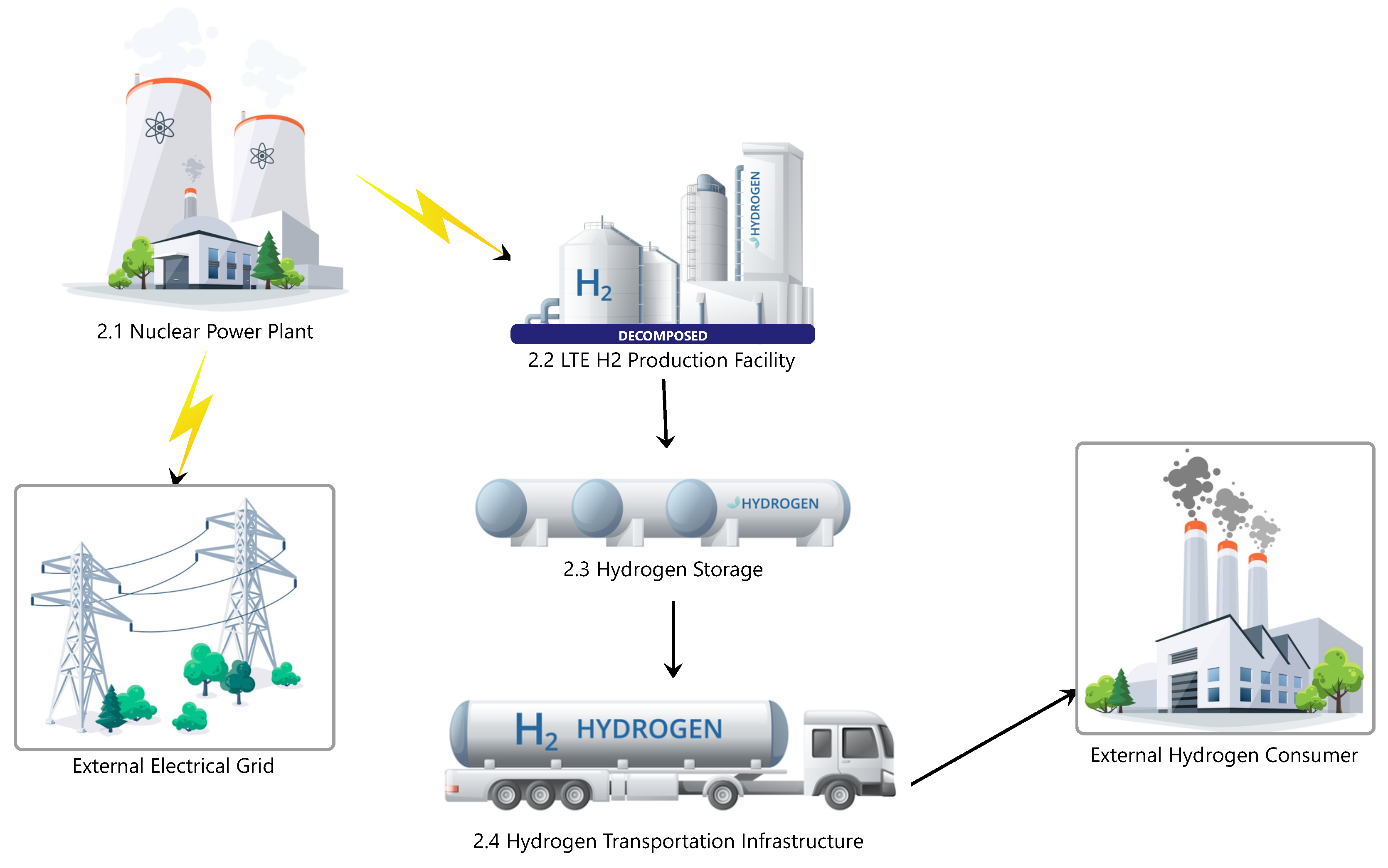

4.2.2. Solution 2—LTE and Nuclear Energy Source

- An NPP provides electricity as the only energy source to the hydrogen generation facility.

- The hydrogen generation facility is located next to the NPP.

- The NPP continues to supply the remaining electricity to the grid.

- Storage and transportation aspects are the same as in Solution 1.

- Instead of HTSE, LTE PEM is the electrolysis technology.

- No modifications are required for the NPP since thermal energy is not extracted.

- A purification system is not required as the hydrogen generated from PEM electrolysis is already at the required level of purity.

- There is no reverse operation option of electricity generation from stored hydrogen, but there is still an option to curtail hydrogen production to supply electricity generated by the NPP to the grid instead of producing hydrogen.

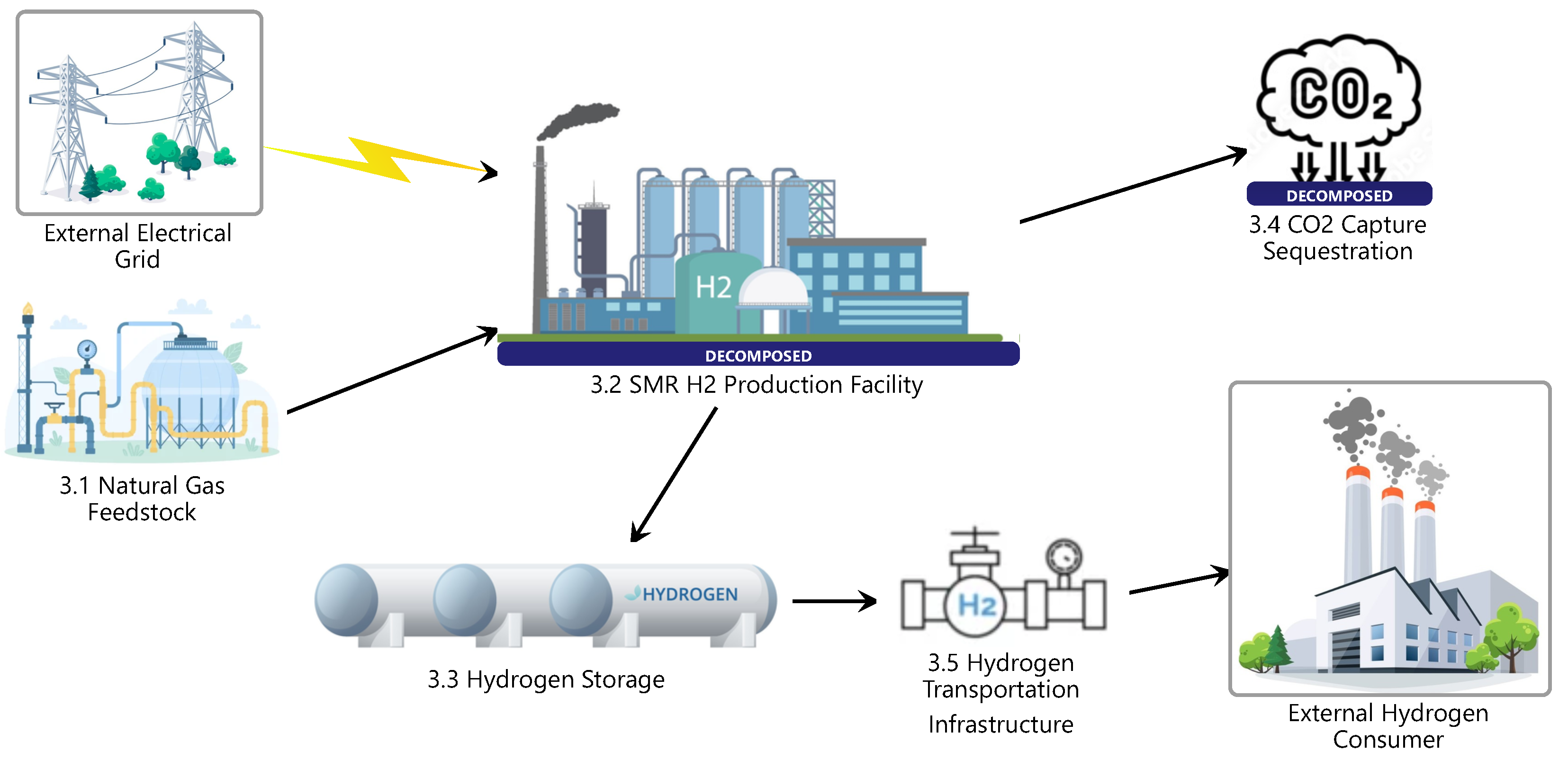

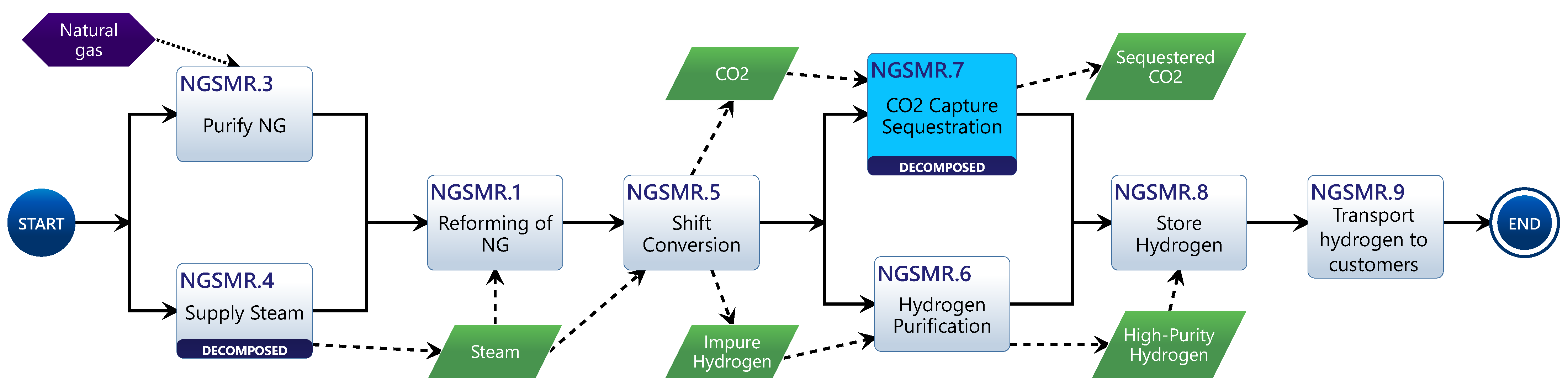

4.2.3. Solution 3—SMR with a CCS System

- Currently used technology for hydrogen generation.

- The new hydrogen generation facility will include a CCS system to qualify as a low-carbon hydrogen technology.

- Electrical grid supplies electricity to supporting systems (i.e., hydrogen purification, compression, and storage).

- The hydrogen generation facility, in this case, will be located in close proximity to the industrial consumer, and a dedicated newly built pipeline infrastructure will be used as the transportation system.

- Captured CO2 is transported via specialized truck trailers and stored offsite in an underground CO2 sequestration repository.

- Feedstock is natural gas instead of water.

- Significant CO2 emissions necessitate a CCS system, processes, and infrastructure.

- The purification process is much more extensive as produced hydrogen is a low-level purity with many byproducts that must be removed.

- There is no flexible operation option to support the grid other than curtailing hydrogen generation, which only conserves a limited amount of electricity.

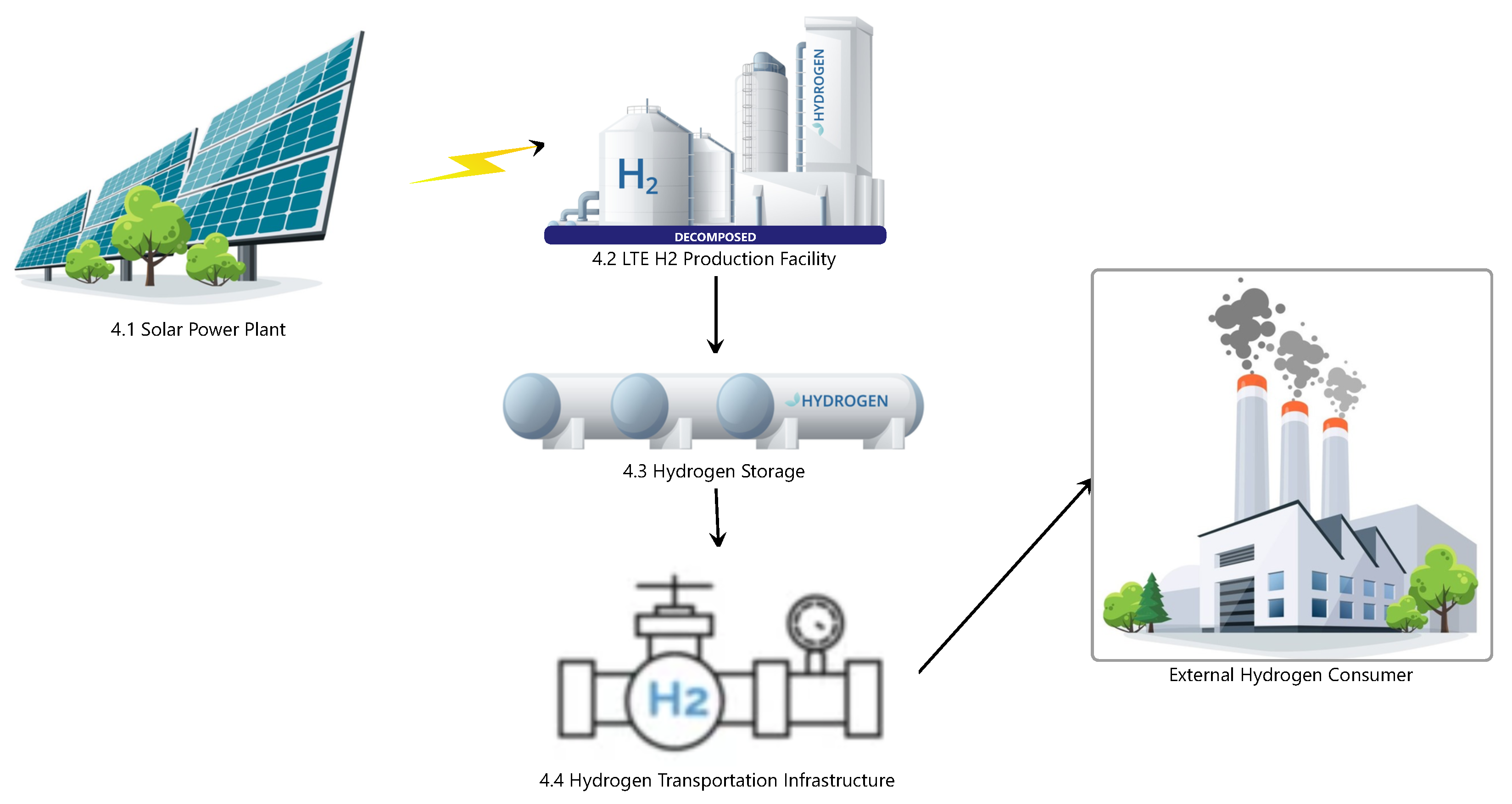

4.2.4. Solution 4—LTE and Solar Energy Source

- A solar power plant located next to the hydrogen generation facility provides electricity to the hydrogen generation facility. The hydrogen generation is performed when a solar power plant supplies electricity, where the daylight duration and meteorological conditions affect the availability and efficiency of solar power generation. To ensure the critical requirement of a consistent hydrogen supply to the customer, the solar power plant is sized accordingly to produce a large amount of hydrogen during the day, store generated hydrogen, and not produce hydrogen when solar power is unavailable. Battery energy storage is another possible solution to overcome the challenge of the intermittent availability of solar energy, but this option was less cost-efficient than overproducing and storing hydrogen.

- A purification system is not required as the hydrogen generated from PEM electrolysis is already at the required level of purity.

- Storage capacity is driven by the requirement of an uninterrupted supply of hydrogen to the customer. The hydrogen production rate during the day is much larger than the rate of hydrogen discharge to the customer, requiring a large-capacity storage unit.

- Transportation infrastructure is required since the hydrogen customer is located approximately 10 miles from the hydrogen generation facility (an assumed condition). The shorter distance and regional circumstances allow for the construction of a dedicated pipeline infrastructure, which will be used as the transportation system.

- A new energy source, a solar power plant, needs to be built to support hydrogen generation.

- A much larger storage capacity is needed to account for the consistent hydrogen supply to the customer.

- Hydrogen transportation infrastructure is simpler as the new hydrogen generation facility supported by a solar power plant is located closer to the hydrogen consumer.

- The hydrogen facility combined with a solar power plant requires a large parcel of land to support the large energy demands.

4.2.5. Supporting Data

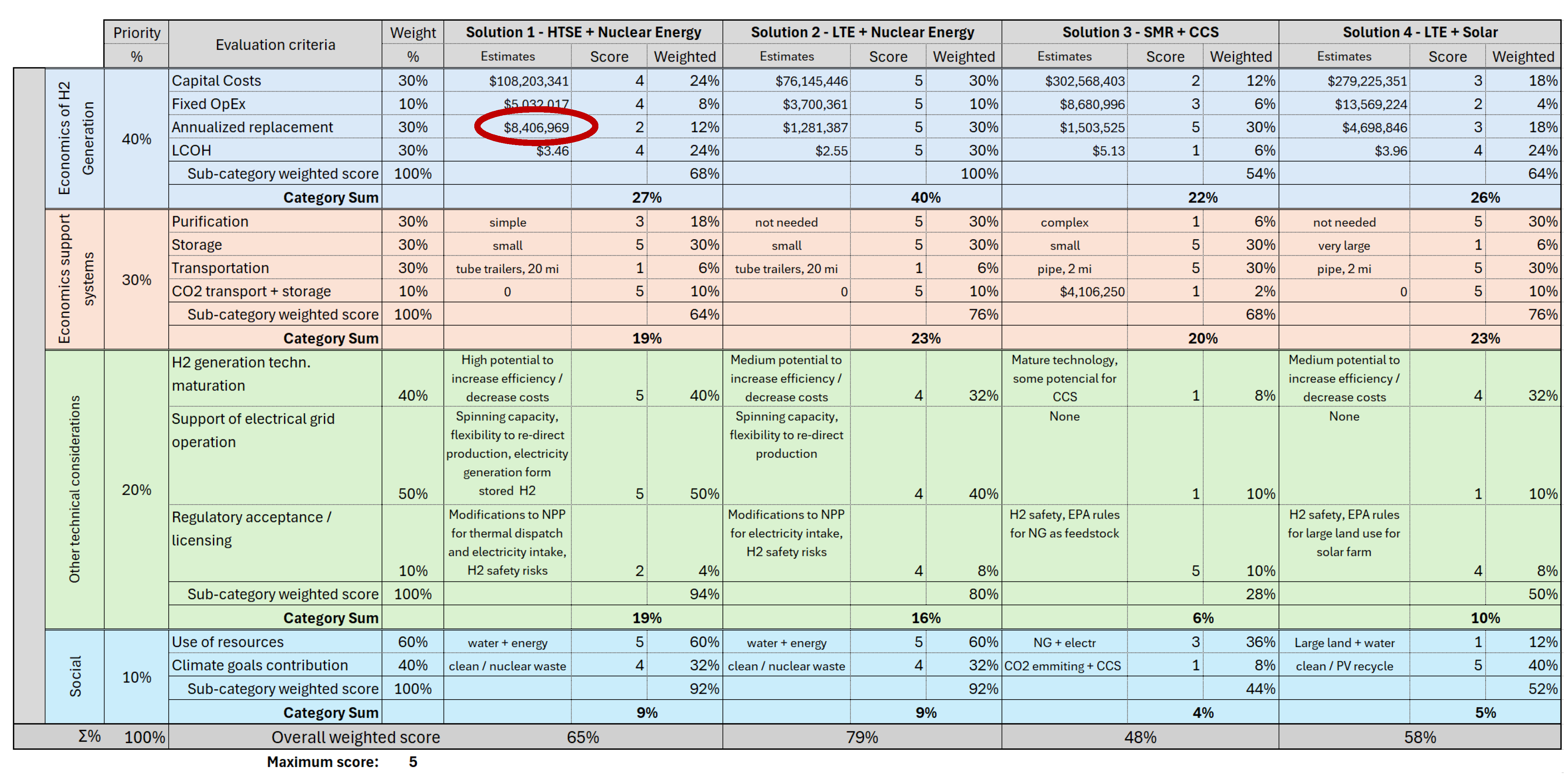

4.3. Phase 3: Concept Definition

5. Conclusions

Future Research

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MBSE | model-based systems engineering |

| SE | systems engineering |

| DM | decision-making |

| HTSE | high temperature steam electrolysis |

| LTE | low temperature electrolysis |

| FOAK | first-of-a-kind |

| SSOT | single source of truth |

| NOAK | N-of-a-kind |

| SysML | Systems Modeling Language |

| IRA | Inflation Reduction Act |

| LCOE | levelized cost of energy |

| IRR | internal rate of return |

| NPV | net present value |

| MAUT | multi-attribute utility theory |

| GHG | greenhouse gas |

| AHP | analytic hierarchy process |

| DSS | decision support systems |

| LML | Lifecycle Modeling Language |

| SMR | steam methane reforming |

| CCS | carbon capture and sequestration |

| AEM | anion exchange membrane |

| PEM | polymer electrolyte membrane |

| SOEC | solid oxide water electrolysis cell |

| R&D | research and development |

| NPP | nuclear power plant |

| O&M | operations and maintenance |

| LCOH | levelized cost of hydrogen |

References

- Shugar, D.; Aldinger, O.; Fugere, D. Road to Zero Emissions: 100 Companies Ranked on Net Zero Progress; Technical Report; As You Sow: Berkeley, CA, USA, 2023. [Google Scholar]

- Murdoch, H.; Munster, J.; Satyapal, S.; Rustagi, N.; Elgowainy, A.; Penev, M. Pathways to Commercial Liftoff: Clean Hydrogen; Technical Report; U.S. Department of Energy: Washington, DC, USA, 2023.

- The White House. Fact Sheet: The Bipartisan Infrastructure Deal. Available online: https://www.whitehouse.gov/briefing-room/statements-releases/2021/11/06/fact-sheet-the-bipartisan-infrastructure-deal/ (accessed on 8 June 2024).

- The White House. Inflation Reduction Act Guidebook. Available online: https://www.whitehouse.gov/cleanenergy/inflation-reduction-act-guidebook/ (accessed on 8 June 2024).

- Wright, D. Net Present Value and Internal Rate of Return. In Solarnomics, 1st ed.; Routledge: London, UK, 2022; pp. 65–72. [Google Scholar] [CrossRef]

- Bora, B. Comparison between net present value and internal rate of return. Int. J. Res. Financ. Mark. 2015, 5, 61–71. [Google Scholar]

- Blume, L.E.; Easley, D. Rationality. In The New Palgrave Dictionary of Economics; Palgrave Macmillan: London, UK, 2016; pp. 1–13. [Google Scholar] [CrossRef]

- Gigerenzer, G.; Selten, R. (Eds.) Bounded Rationality: The Adaptive Toolbox; The MIT Press: Cambridge, MA, USA, 2002. [Google Scholar] [CrossRef]

- Tversky, A.; Kahneman, D. Judgment under Uncertainty: Heuristics and Biases. Science 1974, 185, 1124–1131. [Google Scholar] [CrossRef] [PubMed]

- Payne, J.W.; Bettman, J.R.; Johnson, E.J. The Adaptive Decision Maker; Cambridge University Press: Cambridge, UK, 1993. [Google Scholar] [CrossRef]

- Kutty, A.D.; Shee, K.; Himanshu; Pathak, R.D. Decision-making: Too much info! Monash Bus. Rev. 2007, 3, 8–9. [Google Scholar] [CrossRef]

- Miller, G.A. The magical number seven, plus or minus two: Some limits on our capacity for processing information. Psychol. Rev. 1956, 63, 81–97. [Google Scholar] [CrossRef] [PubMed]

- Hall, C.C.; Ariss, L.; Todorov, A. The illusion of knowledge: When more information reduces accuracy and increases confidence. Organ. Behav. Hum. Decis. Processes 2007, 103, 277–290. [Google Scholar] [CrossRef]

- Agusdinata, D.B. Specification of System of Systems for Policymaking in The Energy Sector. In Proceedings of the IEEE/SMC International Conference on System of Systems Engineering, Los Angeles, CA, USA, 24–26 April 2006; pp. 197–203. [Google Scholar] [CrossRef]

- Zhou, P.; Ang, B.W.; Poh, K.L. Decision analysis in energy and environmental modeling: An update. Energy 2006, 31, 2604–2622. [Google Scholar] [CrossRef]

- Strantzali, E.; Aravossis, K. Decision making in renewable energy investments: A review. Renew. Sustain. Energy Rev. 2016, 55, 885–898. [Google Scholar] [CrossRef]

- Wang, Q.; Poh, K.L. A survey of integrated decision analysis in energy and environmental modeling. Energy 2014, 77, 691–702. [Google Scholar] [CrossRef]

- Christensen, J.L.; Hain, D.S. Knowing where to go: The knowledge foundation for investments in renewable energy. Energy Res. Soc. Sci. 2017, 25, 124–133. [Google Scholar] [CrossRef]

- Barazza, E.; Strachan, N. The co-evolution of climate policy and investments in electricity markets: Simulating agent dynamics in UK, German and Italian electricity sectors. Energy Res. Soc. Sci. 2020, 65, 101458. [Google Scholar] [CrossRef]

- Liu, Q.; Sun, Y.; Wu, M. Decision-making methodologies in offshore wind power investments: A review. J. Clean. Prod. 2021, 295, 126459. [Google Scholar] [CrossRef]

- Graham, J.; Harvey, C. How do CFOs Make Capital Budgeting and Capital Structure Decisions? J. Appl. Corp. Financ. 2002, 15, 8–23. [Google Scholar] [CrossRef]

- Vernimmen, P.; Quiry, P.; Fur, Y.L. Corporate Finance: Theory and Practice, 6th ed.; Wiley-Blackwell: West Sussex, UK, 2022. [Google Scholar]

- Herrmann, J.W. Engineering Decision Making and Risk Management; Wiley: Hoboken, NJ, USA, 2015. [Google Scholar]

- Jansen, S.J.T. The Multi-attribute Utility Method. In The Measurement and Analysis of Housing Preference and Choice; Springer: Dordrecht, The Netherlands, 2011; pp. 101–125. [Google Scholar] [CrossRef]

- Berjawi, A.; Walker, S.; Patsios, C.; Hosseini, S. An evaluation framework for future integrated energy systems: A whole energy systems approach. Renew. Sustain. Energy Rev. 2021, 145, 111163. [Google Scholar] [CrossRef]

- Fattahi, A.; Sijm, J.; Faaij, A. A systemic approach to analyze integrated energy system modeling tools: A review of national models. Renew. Sustain. Energy Rev. 2020, 133, 110195. [Google Scholar] [CrossRef]

- Selva, D.; Cameron, B.; Crawley, E. Patterns in System Architecture Decisions. Syst. Eng. 2016, 19, 477–497. [Google Scholar] [CrossRef]

- Hoffmann, M.; Wei, C.; Kurrat, M. Requirement Analysis with SysML for Concept Design of Offshore Wind Farm Grid Connection. In Proceedings of the ETG Congress 2021, Online, 18–19 March 2021. [Google Scholar]

- Shoshany-Tavory, S.; Peleg, E.; Zonnenshain, A.; Yudilevitch, G. Model-based-systems-engineering for conceptual design: An integrative approach. Syst. Eng. 2023, 26, 783–799. [Google Scholar] [CrossRef]

- Alkaraan, F.; Northcott, D. Strategic capital investment decision-making: A role for emergent analysis tools?: A study of practice in large UK manufacturing companies. Br. Account. Rev. 2006, 38, 149–173. [Google Scholar] [CrossRef]

- Talbot, P.W.; Soto Gonzalez, G.J.; Poudel, B.; Phillips, T.B.; Griffith, A.; Epiney, A.S. 2023 FORCE Development Status Update; Technical Report INL/RPT-23-74915-Rev000; Idaho National Laboratory: Idaho Falls, ID, USA, 2023. [Google Scholar] [CrossRef]

- Epiney, A.; Rabiti, C.; Talbot, P.; Alfonsi, A. Economic analysis of a nuclear hybrid energy system in a stochastic environment including wind turbines in an electricity grid. Appl. Energy 2020, 260, 114227. [Google Scholar] [CrossRef]

- Morgan, D.; Sheriff, A.; Wallace, M.; Wijaya, N.; Vikara, D.; Liu, G. FECM/NETL Hydrogen Pipeline Cost Model (2024): Description and User’s Manual; Technical Report DOE/NETL-2024/4841; National Energy Technology Laboratory: Albany, OR, USA, 2024. [CrossRef]

- Penev, M.; Bush, B.; Melaina, M. H2FAST: Hydrogen Financial Analysis Scenario Tool [SWR 15-06]; Computer Software; National Renewable Energy Laboratory: Golden, CO, USA, 2019. [CrossRef]

- Levene, J. HyDRA: Hydrogen Demand and Resource Analysis Tool (Presentation); Presentation at DOE Hydrogen Program Annual Merit Review and Peer Evaluation NREL/PR-540-41534; National Renewable Energy Laboratory: Golden, CO, USA, 2007.

- Hadian, S.; Madani, K. A system of systems approach to energy sustainability assessment: Are all renewables really green? Ecol. Indic. 2015, 52, 194–206. [Google Scholar] [CrossRef]

- Gallego Carrera, D.; Mack, A. Sustainability assessment of energy technologies via social indicators: Results of a survey among European energy experts. Energy Policy 2010, 38, 1030–1039. [Google Scholar] [CrossRef]

- Witt, T.; Dumeier, M.; Geldermann, J. Combining scenario planning, energy system analysis, and multi-criteria analysis to develop and evaluate energy scenarios. J. Clean. Prod. 2020, 242, 118414. [Google Scholar] [CrossRef]

- Santoyo-Castelazo, E.; Azapagic, A. Sustainability assessment of energy systems: Integrating environmental, economic and social aspects. J. Clean. Prod. 2014, 80, 119–138. [Google Scholar] [CrossRef]

- Troldborg, M.; Heslop, S.; Hough, R.L. Assessing the sustainability of renewable energy technologies using multi-criteria analysis: Suitability of approach for national-scale assessments and associated uncertainties. Renew. Sustain. Energy Rev. 2014, 39, 1173–1184. [Google Scholar] [CrossRef]

- Evans, A.; Strezov, V.; Evans, T.J. Assessment of sustainability indicators for renewable energy technologies. Renew. Sustain. Energy Rev. 2009, 13, 1082–1088. [Google Scholar] [CrossRef]

- Gracceva, F.; Zeniewski, P. A systemic approach to assessing energy security in a low-carbon EU energy system. Appl. Energy 2014, 123, 335–348. [Google Scholar] [CrossRef]

- Volkart, K.; Weidmann, N.; Bauer, C.; Hirschberg, S. Multi-criteria decision analysis of energy system transformation pathways: A case study for Switzerland. Energy Policy 2017, 106, 155–168. [Google Scholar] [CrossRef]

- Senge, P.M. The Fifth Discipline: The Art & Practice of The Learning Organization; Doubleday: New York, NY, USA, 2004. [Google Scholar]

- INCOSE Systems Engineering Competency Framework. Systems Engineering Competency Framework; Technical Report INCOSE-TP-2018-002-01.0; INCOSE: San Diego, CA, USA, 2018. [Google Scholar]

- INCOSE. Systems Engineering Handbook, 5th ed.; Number INCOSE-TP-2003–002-05; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2023. [Google Scholar]

- Meadows, D.H. Thinking in Systems; Earthscan: Streling, VA, USA, 2009. [Google Scholar]

- Kossiakoff, A.; Seymour, S.J.; Flanigan, D.A.; Biemer, S.M. Systems Engineering Principles and Practice, 3rd ed.; Wiley: Hoboken, NJ, USA, 2020. [Google Scholar] [CrossRef]

- Noguchi, R.A. Recommended Best Practices based on MBSE Pilot Projects. In Proceedings of the INCOSE International Symposium; INCOSE: San Diego, CA, USA, 2019; Volume 29, pp. 753–770. [Google Scholar] [CrossRef]

- Dassault Systèmes. Cameo Systems Modeler. Available online: https://www.3ds.com/products/catia/no-magic/cameo-systems-modeler (accessed on 8 June 2024).

- SPEC Innovations. INNOSLATE. Available online: https://specinnovations.com/innoslate (accessed on 8 June 2024).

- Spec Innovation. Innoslate Help center. Available online: https://help.specinnovations.com/ (accessed on 10 June 2024).

- Dam, S.H. Real MBSE; SPEC Innovations: Manassas, VA, USA, 2019. [Google Scholar]

- Lifecycle Modeling Lanquage. Lifecycle Modeling Language (LML) Specification 1.4. Available online: https://22132398.fs1.hubspotusercontent-na1.net/hubfs/22132398/LML%20specification%201.4.pdf (accessed on 11 June 2024).

- Pugh, S. Total Design: Integrated Methods for Successful Product Engineering; Addison-Wesley: Boston, MA, USA, 1990. [Google Scholar]

- Lønmo, L.; Muller, G. Concept Selection - Applying Pugh Matrices in the Subsea Processing Domain. INCOSE Int. Symp. 2014, 24, 583–598. [Google Scholar] [CrossRef]

- Wang, M.; Elgowainy, A.; Lee, U.; Baek, K.H.; Balchandani, S.; Benavides, P.T.; Burnham, A.; Cai, H.; Chen, P.; Gan, Y.; et al. Summary of Expansions and Updates in R&D GREET® 2023; Technical Report ANL/ESIA-23/10; Argonne National Laboratory: Argonne, IL, USA, 2023. [CrossRef]

- Kazemifar, F. A review of technologies for carbon capture, sequestration, and utilization: Cost, capacity, and technology readiness. Greenh. Gases Sci. Technol. 2022, 12, 200–230. [Google Scholar] [CrossRef]

- U.S. Energy Information Administration. What is U.S. Electricity Generation by Energy Source? Available online: https://www.eia.gov/tools/faqs/faq.php?id=427&t=3 (accessed on 8 June 2024).

- Kumar, S.; Lim, H. An overview of water electrolysis technologies for green hydrogen production. Energy Rep. 2022, 8, 13793–13813. [Google Scholar] [CrossRef]

- Lahrichi, A.; El Issmaeli, Y.; Kalanur, S.S.; Pollet, B.G. Advancements, strategies, and prospects of solid oxide electrolysis cells (SOECs): Towards enhanced performance and large-scale sustainable hydrogen production. J. Energy Chem. 2024, 94, 688–715. [Google Scholar] [CrossRef]

- Krishnan, S.; Corona, B.; Kramer, G.J.; Junginger, M.; Koning, V. Prospective LCA of alkaline and PEM electrolyser systems. Int. J. Hydrogen Energy 2024, 55, 26–41. [Google Scholar] [CrossRef]

- Sterman, J.D. Business Dynamics, Systems Thinking and Modeling for a Complex World; McGraw Hill: New York, NY, USA, 2010. [Google Scholar]

| SysML Diagram | LML Diagram | LML Entities (Ontology) |

|---|---|---|

| Activity | Action Diagram | Action, Input/Output |

| Sequence | Sequence | Action, Asset |

| State Machine | State Machine | Characteristic (State), Action (Event) |

| Use Case | Asset Diagram | Asset, Connection |

| Block Definition | Class Diagram, Hierarchy Chart | Input/Output (Data Class), Action (Method), Characteristic (Property) |

| Internal Block | Asset Diagram | Asset, Connection |

| Package | Asset Diagram | Asset, Connection |

| Parametric | Hierarchy, Spider, Radar | Characteristic |

| Requirement | Hierarchy, Spider | Requirement and Related Entities |

| Criteria | Alternative 1 | Alternative 2 | Alternative 3 |

|---|---|---|---|

| Criterion A | + | S | + |

| Criterion B | - | + | S |

| Criterion C | - | - | + |

| Total (+) | 1 | 1 | 2 |

| Total (-) | 2 | 1 | 0 |

| Total (S) | 0 | 1 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lawrence, S.; Herber, D.R. A Model-Based Systems Engineering Approach for Effective Decision Support of Modern Energy Systems Depicted with Clean Hydrogen Production. Systems 2024, 12, 290. https://doi.org/10.3390/systems12080290

Lawrence S, Herber DR. A Model-Based Systems Engineering Approach for Effective Decision Support of Modern Energy Systems Depicted with Clean Hydrogen Production. Systems. 2024; 12(8):290. https://doi.org/10.3390/systems12080290

Chicago/Turabian StyleLawrence, Svetlana, and Daniel R. Herber. 2024. "A Model-Based Systems Engineering Approach for Effective Decision Support of Modern Energy Systems Depicted with Clean Hydrogen Production" Systems 12, no. 8: 290. https://doi.org/10.3390/systems12080290

APA StyleLawrence, S., & Herber, D. R. (2024). A Model-Based Systems Engineering Approach for Effective Decision Support of Modern Energy Systems Depicted with Clean Hydrogen Production. Systems, 12(8), 290. https://doi.org/10.3390/systems12080290