1. Introduction

As a basic service industry for China’s economic development, road cargo transportation plays a very important role in promoting economic development and safeguarding and improving people’s livelihoods. As of June 2021, the number of cargo vehicles in China reached 31.91 million, accounting for 10.91% of the total number of automobiles, and the number of newly registered cargo vehicles in the first half of 2021 amounted to 2.42 million, an increase of 29.12% compared with the same period last year [

1]. Although truck drivers play an important role in road transportation, their driving safety risks and the existence of hidden dangers have not received sufficient attention from the relevant departments. Based on relevant statistical information, in 2016, a total of 39,462 road traffic accidents occurred in China’s operating vehicles, resulting in 19,018 deaths, of which 26,649 accidents occurred in operating trucks, accounting for 67.53% of the total, resulting in 14,231 deaths, accounting for 74.83% of the total. In operational vehicle accidents, improper driving behaviors caused by drivers of operational trucks, such as speeding, fatigue driving, and the violation of traffic regulations, are the main causes of accidents [

2]. Unlike other vehicle drivers, truck drivers are usually required to drive alone for long periods of time and face physical and psychological fatigue [

3]. The fact that they need to reach their destinations within strict time limits can lead to dangerous driving behaviors [

4]. At the same time, in the current trend of expanding the scale of logistics and transportation enterprises, as a link in the logistics chain, a variety of safety hazards is also increasingly prominent in logistics transportation, and safety accidents occurring in the process of cargo transportation may bring a heavy blow to the enterprise [

5]. In view of the high driving safety risks of truck drivers in logistics and transportation enterprises, it is necessary to assess the impact of the driving risk of trucks in logistics and transportation enterprises for research.

The concept of the safety climate was first introduced by Israeli scholar Zoher in 1980 and is defined as the perception of a risky work environment shared by employees within an organization [

6]. In the decades since its introduction, numerous scholars have begun research on the safety climate in relation to production. Unlike safety culture, the safety climate is a measurable safety management mechanism, i.e., it can be quantitatively assessed [

7], and it is a reliable predictor of safety behavior and safety outcomes [

8]. Current research on the safety climate is centered around developing level-specific and industry-specific subscales of the safety climate and discovering relationships between the safety climate and antecedent variables, moderators, mediators, or other concepts [

9]. Yumin et al. explained the relationship between the PSC, work–family conflict, burnout, and unsafe behaviors through a survey of frontline coal miners [

10]. Chen Yanlin et al. introduced construction workers’ safety perceptions and safety self-efficacy as mediator variables to explain the intrinsic mechanism of the role of the construction company’s mismanagement climate on the safety performance of construction workers [

11]. Other researchers have tested the predictive effect of the safety climate on the driving behavior of truck drivers, using them as subjects. In these studies, the safety climate has been found to be associated with workplace injuries [

12], self-reported road traffic accidents, and truck driver distraction-related crashes [

13], and driver group distinctions have also been examined using an interpretable clustering approach to the safety climate analysis [

14]. Furthermore, the safety climate has a negative predictive and mediating effect on attempts to drive safe behavior [

15], while a two-year study verified that the safety climate has a sustained predictive ability for truck drivers’ driving safety behavior [

16]. Huang et al. conducted a long-term follow-up study on the measurement and number of safety climates among foreign long-haul truck drivers [

17]. Hussain et al. introduced the safety climate theory to Pakistan and argued that improving the “work safety climate” in the trucking industry could help control social cognitive factors and risky driving behaviors, and potentially improve road safety in Pakistan [

18]. Pattarachat M et al. demonstrated the effect of the safety climate on the safety behaviors of Thai civil aviation pilots [

19].

Whether to prioritize safety or efficiency, or even to compete with peers, is still a difficult and necessary choice for enterprises [

20]. China is still a developing country, and economic development is still a top priority at present [

21], so trucking companies in China are more likely than in developed countries to lower their safety priority in order to improve their efficiency. In addition, considering the significant differences between China and developed countries in terms of management models and cultural dimensions [

22], it is essential to establish a set of China’s own safety management assessment systems for truck drivers.

This study developed a set of safety atmosphere test scales for testing the safety atmosphere of logistics and transportation enterprises in China according to the actual situation of logistics and transportation enterprises in China. Combined with the actual driving situation of truck drivers, it evaluates the truck driving safety of China’s logistics and transportation enterprises, finds the potential risks and related relationships, and thus puts forward the corresponding opinions in order to improve the truck driving safety of China’s logistics and transportation enterprises and to provide reference for other logistics and transportation enterprises.

2. Research Methodology

In accordance with the relevant concepts and theories of the safety atmosphere, the structural relationship of the safety atmosphere managed by this enterprise was established by taking all the drivers of China Deppon Logistics Co., Ltd. in the Zhejiang region as objects for study. This was performed by establishing the preliminary test scale, and establishing the safety assessment system of the enterprise by adopting the qualitative and quantitative methods through interviews and tests, etc. Finally, the data were analyzed by comparing and contrasting them with the actual risk monitoring data of this enterprise on the transportation vehicles and the statistics of the accidents. It is necessary to ascertain the efficacy of this test system.

2.1. Corporate Safety Management and Safety Climate

The concept of the safety climate was first introduced by Zoher in 1980 in his research study on safety in the Israeli manufacturing industry. He defined it as “the common perception of hazardous work environments by employees within an organization”. Furthermore, he demonstrated that the safety climate is one of the strongest predictors of safety behavior and safety outcomes in a variety of environments [

23]. Researchers in various countries began to examine this theory and propose corresponding theories and research methods. Dedobbeleer and Niskanen posit that the safety climate is defined as the natural attributes of the managerial behavior of an enterprise organization at a particular moment. Cheyne, Cox, and Flin posit the following: “Safety awareness, safety attitudes, and safety behaviors exert a profound influence on the construction of enterprise safety climate”. According to Neal et al., the safety climate is an effective tool for objectively and accurately diagnosing the safety status of employees and organizations within the enterprise, as well as the characteristics of the location [

24,

25,

26,

27]. Neal et al. posit the following: “As an effective tool to measure and reflect the current state of enterprise safety culture in a particular moment, safety climate is able to objectively and accurately diagnose the safety status of employees/organizations on the enterprise in a particular moment, as well as the characteristics of the location”. In conjunction with the prevailing safety management paradigm in China, the safety climate can be defined as a “series of key elements that can be discerned by employees within a specific period of time, reflecting the current safety culture attributes within the target enterprise, as well as the current status quo of safety management of the enterprise’s organizational behavior”. Given that safety climate evaluation can objectively reflect the current state of organizational health and safety, quantitatively diagnose the safety culture of an enterprise, and continuously improve the performance of enterprise safety management, it is an inevitable development trend for solving and preventing accidents, and improving the level of enterprise safety management and safety performance.

2.2. Safety Climate Measurement Scale Design

The research process on the safety of truck drivers employed by transportation companies involved the measurement of the safety climate of truck drivers in transportation companies. The scale survey method was employed as a common survey method to study the safety climate of truck drivers.

2.2.1. Initial Question Design

Since the advent of safety climate theory in 1980, a considerable body of research has been conducted in this field by numerous scholars. In their review of the literature, Cooper et al. [

6] identified the following four key themes in safety climate research: the design of measurement tools, the development of theoretical models, the examination of the relationship between the safety climate and safety performance, and the examination of the relationship between the safety climate and the organizational climate. Zohar, in a review of over 30 years of related research in the field, observed that a significant proportion of the work has focused on methodology rather than on theoretical and conceptual issues [

9]. Additionally, numerous tools exist for assessing the safety climate, with questionnaires representing the most prevalent research methodology [

28].

The differing industries and companies under investigation have led to the development of the following two distinct research methodologies: qualitative research on safety culture and quantitative research on the safety atmosphere. However, despite these differences, the questionnaire composition structure and key elements are relevant in the investigation and analysis of both safety culture and the safety atmosphere. Furthermore, the methods and principles used are essentially similar. A combination of key elements developed by numerous researchers to describe the safety management climate of a company was employed, with the actual situation of the logistics industry in China serving as the basis for the investigation. Multiple interviews were conducted with truck drivers and their supervisors in the companies surveyed, focusing on job functions, communication patterns, work prioritization, supervisory interactions, and related workplace safety practices. A preliminary set of test scales was developed by synthesizing the above information. A total of 70 question items were developed, with 40 items utilized at the organizational level, 30 items at the fleet level, and 10 items for the acceptance and fairness of the in-vehicle monitoring system and for the validation of the test system.

2.2.2. Pre-Testing

Following the development of the survey questions, cognitive interviews of the test items were conducted with 43 truck drivers at the pilot station during the pilot station’s safety officer’s job summary. The purpose of these interviews was to examine the meaning of the items, identify language or content problems in completing the test (e.g., long pauses, inconsistent responses, indications of confusion), and determine the extent to which the items covered all the relevant safety measures. This procedure was employed to enhance the content and face validity of the instrument. The participants were drivers for the pilot fleet where the initial item-generated interviews were conducted. The item wording, order of presentation, and survey formatting were revised based on participant comments and suggestions. The revised scale, which was developed following the cognitive interviews, included 20 items at the organizational level and 20 items at the fleet level. This revised scale was then utilized in the subsequent step, with a 5-point Likert scale employed for all test items.

2.2.3. Formal Survey

At this juncture, there are a plethora of methodologies for disseminating questionnaires, including online distribution and on-site distribution, among others. However, truck drivers represent a single operation with low aggregation, which precludes the possibility of guaranteeing the effectiveness of on-site distribution in the event of a long recovery period. Consequently, following the conclusion of the agreement, the questionnaire was disseminated and subsequently collected via the company’s internal employee platform. In this study, the questionnaire was distributed among all truck drivers in the Zhejiang region of Deppon Logistics Company. This was performed in order to collect data from all truck drivers in the Zhejiang region of the company.

The revised questionnaire was subjected to an online test with a sample of fleet drivers in the company’s Zhejiang region. At the same time, the personal data of the test drivers and the on-board data of the vehicles they drove were collected, resulting in the acquisition of 422 test questionnaires. The collected questionnaires were subjected to statistical analysis, with those that lacked sufficient quality being excluded. Initially, the basic information of the drivers was statistically classified. Subsequently, the validity and reliability of the remaining questionnaires were tested, and they were then used for subsequent exploratory factor analysis. Subsequently, the questionnaires were distributed for a second time, with the intention of being filled out and subsequently collected for the purpose of validating the factor analysis.

2.3. Exploratory and Confirmatory Factor Analysis

2.3.1. Exploratory Factor Analysis

A reliability analysis and internal consistency test for the sample can be employed to further ensure the reasonableness of the scale. In this study, the total correlation coefficient (CITC) and Cronbach’s alpha were employed to assess the reliability of the scale’s question items, while exploratory factor analysis was utilized to ascertain the validity of the survey scale.

The Cronbach’s α coefficient is a number between 0 and 1. The higher the value, the higher the internal consistency of the scale items. If the Cronbach’s α coefficient is greater than 0.8, the reliability is high. If it is between 0.7 and 0.8, the reliability is better. If it is between 0.6 and 0.7, the reliability is acceptable. If it is lower than 0.6, the reliability is poor, and a certain part of the question items need to be removed. In general, the Cronbach’s alpha coefficient for the overall scale should be greater than 0.7, and the Cronbach’s alpha coefficients for the dimensions measured by each factor should be greater than 0.6. In addition to the reliability test, the item total correlation coefficient should be evaluated for each item on the scale. Items with an item total correlation of less than 0.4 should be deleted. Once the scale has been tested for reliability, it is necessary to proceed to a test of its validity. In this paper, exploratory factor analysis was employed for validation purposes. The KMO (Kaiser–Meyer–Olkin) test and Bartlett’s sphere test were performed on the scale data to ascertain the scale’s validity. When the requisite conditions are met, it can be indicated that the scale is valid.

2.3.2. Confirmatory Factor Analysis

The CFA was employed to ascertain the structural validity of the safety climate scale (SCS), which was evaluated on data from pilot companies in order to guarantee the factorial structural validity of the SCS. The comparative fit index (CFI), Tucker–Lewis Index (TLI), and root mean square approximation error (RMSEA) were employed to assess the quality of the model fit. The values of the CFI and TLI ranged from 0 to 1, with values closer to 0 indicating a poorer fit and values closer to 1 indicating a better fit. In general, a model fit is considered to be good when the CFI and TLI values are ≥0.9. A value of the RMSEA below 0.05 indicates a good model fit, while a value between 0.05 and 0.08 indicates a reasonable fit. Conversely, a value above 0.10 indicates a poor fit.

2.4. Practical Validity Test of the Safety Climate Test Scale

The objective of this study is to examine the correlation between safety climate scores and self-reported driving safety behaviors, as well as objective safety outcomes, which will be evaluated through the use of both subjective and objective safety criteria.

2.4.1. Subjective Safety Criteria

Because the fleet-level safety climate scale includes self-reported driving safety behaviors from participating truck drivers, it was selected to include the following six items: When I am about to go overtime on a delivery, I speed up to get it there on time; Sometimes I take shortcuts and rush for important customers; I increase my speed after unloading to save time; I do not pay much attention to the warning system in my car; I do not think that using my cell phone while driving will interfere with my driving; I will continue to drive even if I feel tired or uncomfortable during transportation. As shown in

Table 1, the data from the freight companies were tested for these six items with a correlation Cronbach’s alpha coefficient of 0.776. The mean score of these six items was used as an indicator of the construct. One-way and multiple regression analyses were used to analyze the relationship between the safety climate and self-reported safety behaviors.

2.4.2. Objective Safety Standards

As measures of driving safety behavior are based on subjects’ self-reports, this may affect the validity of the measure. To address this issue, objective safety data were collected as criteria for predictive validity testing. Two of the objective safety criteria were the number of in-vehicle system warnings and the number of accidents. The number of incidents (over a six-month period) of drivers’ safe driving behaviors (e.g., talking on the phone, smoking, not wearing seatbelts, deviating from driving, yawning, and distracted driving) were intercepted and regressed against the safety climate scale through the Telematics platform jointly built by Deppon and G7 E-Flow, as well as the implementation of monitoring data from the on-board equipment. A Poisson log-chain generalized linear model was then applied to the number of thousand-kilometer accidents per driver over the six-month period to observe whether changes in the scale scores would have an impact on the number of thousand-kilometer accidents.

3. Results

3.1. Statistical Analysis of Survey Data

3.1.1. Basic Information

According to the questionnaire design, the questionnaire partially included basic information about the respondents and safety climate issues, and the respondents were the drivers–workers of the transportation companies. The questionnaire was based on a five-point Likert scale (one = strongly disagree, five = strongly agree). Based on the way other researchers have surveyed the safety climate in the transportation industry, and the way the results were collected and screened [

18,

19,

21], the target business subjects were asked to score the question items based on their perceptions of fleet and business safety. As shown in

Table 2, excluding the unqualified as well as incomplete questionnaires (a total of 50), the formal experiment collected a total of 347 questionnaires, and finally obtained 297 valid questionnaires; the recovery rate of the valid questionnaires was 85.6%, so the data collected after this screening were valid and could be analyzed in the next step.

3.1.2. Scale Reliability and Validity Tests

As illustrated in

Table 3A,B, the overall Cronbach’s alpha coefficient of the organizational-level scale is 0.916, while the overall Cronbach’s alpha coefficient of the fleet-level scale is 0.811. These values fall within the interval of high reliability, indicating that the overall reliability of the pre-survey is assured. This suggests that the overall reliability of the scale is consistent with the standard of goodness and exhibits good stability.

Once the scale had been subjected to reliability testing, the KMO test and Bartlett sphere test were required for the scale data. As shown in

Table 4, the KMO value for the organizational level of the scale was 0.909, while the KMO value for the fleet level was 0.921, both of which exceeded 0.7, thus satisfying the fundamental criteria. Furthermore, the significance of the Bartlett sphere test for the scale was found to be significant (

p < 0.05), thereby paving the way for the exploratory factor analysis to be conducted.

3.2. Construction of Scale Factors and Factor Structure

3.2.1. Scale Reliability and Validity Test dimensions

The principle of principal component number extraction is that the principal component corresponds to the first m principal components whose eigenvalues are greater than one. The eigenvalue can be regarded as an indicator of the strength of the influence of the principal component to some extent. If the eigenvalue is less than one, it indicates that the explanatory strength of the principal component is not as robust as that of the average explanation of the original variable, which was introduced directly. Therefore, the eigen-value of more than one can be used as a criterion for the inclusion of the principal component.

The aggregate contribution of the variance of the organizational-level indicators can be derived from

Table 5A. Three principal components can be obtained by selecting the components with eigenvalues greater than one. Using the maximum variance rotation method of exploratory factor analysis (EFA), three factors of the organizational-level safety climate were generated separately. The factor structure, factor loadings, and content validity were employed to identify three main factors for the organizational-level safety climate. These factors were derived from

Table 5A and are as follows: safety management, safety monitoring, and driver safety priority.

Table 5B presents the cumulative variance contributions of the fleet-level indicators. The selection of components with eigenvalues greater than one yielded three principal components. The EFA maximum variance rotation was employed to generate three independent factors for the fleet safety climate.

Table 5B indicates that three principal factors for the fleet-level safety climate were identified based on factor structure, factor loadings, and content validity. These factors are positive communication, safety awareness, and self-regulation.

3.2.2. CFA

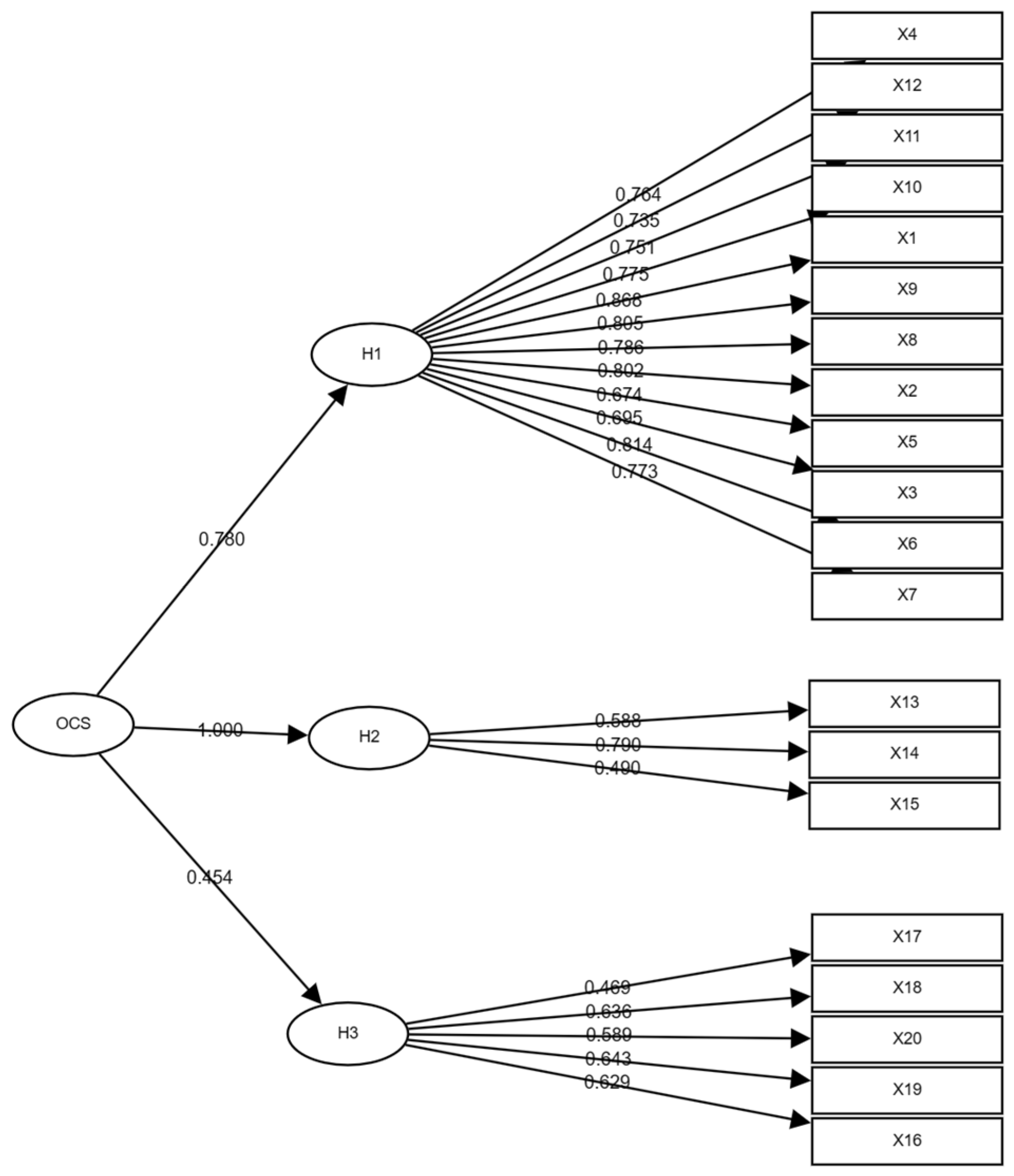

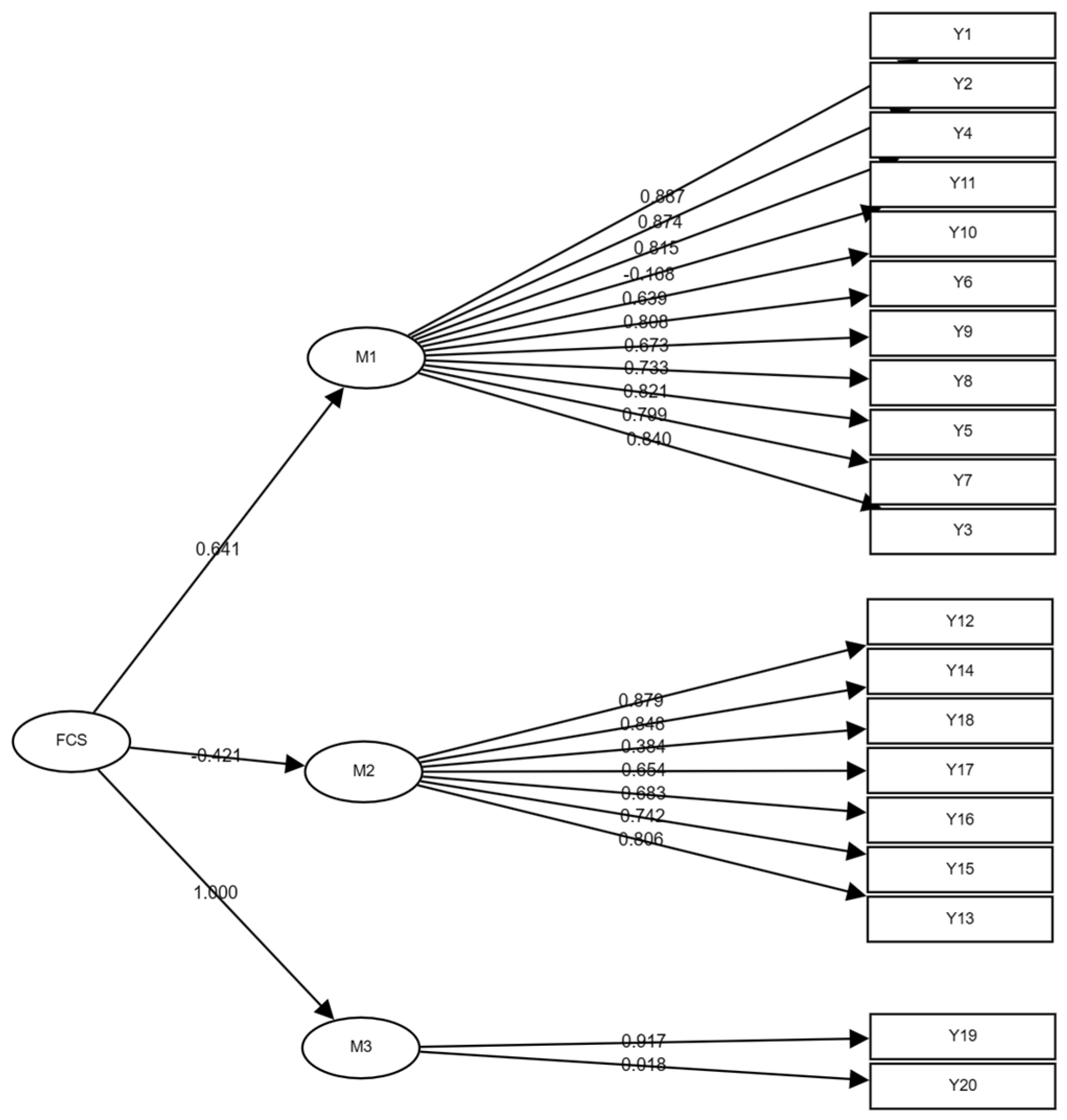

As can be seen in

Figure 1, the chi-square statistic of the OSC model (χ2 = 611.814,

p < 0.001), the comparative fit indices (CFIs) ≥ 0.90, Tucker–Lewis Index (TLI) ≥ 0.90, and root mean square error of approximation (RMSEA) < 0.10 indicate that the test model fits the data well. As can be seen in

Figure 2, the chi-square statistic of the FSC model (χ2 = 567.752,

p < 0.001), the comparative fit indices (CFIs) ≥ 0.90, Tucker–Lewis Index (TLI) ≥ 0.90, and root mean square error of approximation (RMSEA) < 0.10 indicate that the test model also fit the data well.

3.3. Practical Validity Test of the Safety Climate Test Scale

3.3.1. Overall Safety Climate Score and Subjective Safety Criteria

In the subsequent analysis, the predictive validity of the newly developed organizational- and group-level safety climate scales was tested using regression analyses with data from the freight forwarding companies that participated in this study. As illustrated in

Table 6, the regression analysis utilizing safety management as the independent variable and self-reported safety behaviors as the dependent variable yielded a B-value of 0.283 (95% confidence interval = [0.32,0.434],

p < 0.01) and an R-squared value for the model of 0.054, respectively, indicating that safety management explains 5% of the variance in self-reported safety behaviors. The regression analysis using safety supervisors as the independent variable and self-reported safety behaviors as the dependent variable revealed that 4% of the variations in self-reported safety behaviors could be explained by safety supervision. The regression analysis yielded a B-value of 0.006 (95% confidence interval = [−0.150,0.135],

p > 0.01), with a model R-squared value of 0.005. This implies that safety supervision could explain the zero value. A regression analysis was conducted to determine the relationship between driver safety priority and self-reported safety behavior. The results indicated that 5% of the variation in self-reported safety behavior could be explained by the independent variable, driver safety priority. The B-value was 0.493 (95% confidence interval = [0.375,0.617],

p < 0.01), while the model R-squared value was 0.224. This implies that driver safety priority could explain 22% of the variation in self-reported safety behavior. A regression analysis using the organizational level as an independent variable and self-reported safety behaviors as a dependent variable revealed that 4% of the reasons for the change in self-reported safety behaviors can be attributed to the organizational level. The B-value was 0.698 (95% confidence interval = [0.490,0.906],

p < 0.01) and the model R-squared value was 0.168, indicating that the organizational level explains 16.8% of the variation in self-reported safety behaviors.

As shown in

Table 7, regression analyses using positive communication as the independent variable and self-reported safety behaviors as the dependent variable yielded a B-value of 0.295 (95% confidence interval = [0.144,0.445],

p < 0.01), with a model R-squared value of 0.062, respectively. This implies that positive communication explains 6% of the variation in self-reported safety behaviors. The regression analysis revealed that 2% of the variation in self-reported safety behaviors could be attributed to safety awareness. Using safety awareness as the independent variable and self-reported safety behaviors as the dependent variable, the regression analysis yielded a B-value of 1.014 (95% confidence interval = [0.973,1.005],

p < 0.01), with a model R-squared value of 0.913. This implies that safety awareness could explain 91% of the variation in self-reported safety behaviors. Three percent of the reasons for the changes in self-reported safety behaviors can be attributed to self-regulation. With self-regulation as the independent variable and self-reported safety behaviors as the dependent variable in the regression analysis, the B-value was 0.473 (95% confidence interval = [0.339,0.607],

p < 0.01), with a model R-squared value of 0.178. This implies that self-regulation can explain 17% of the variance in self-reported safety behaviors. A regression analysis using the fleet level as an independent variable and self-reported safety behaviors as a dependent variable yielded a B-value of 1.071, with a 95% confidence interval of [0.939,1.203] and a

p-value of less than 0.01. This indicates that the fleet level explains 53.2% of the reasons for a change in self-reported safety behaviors.

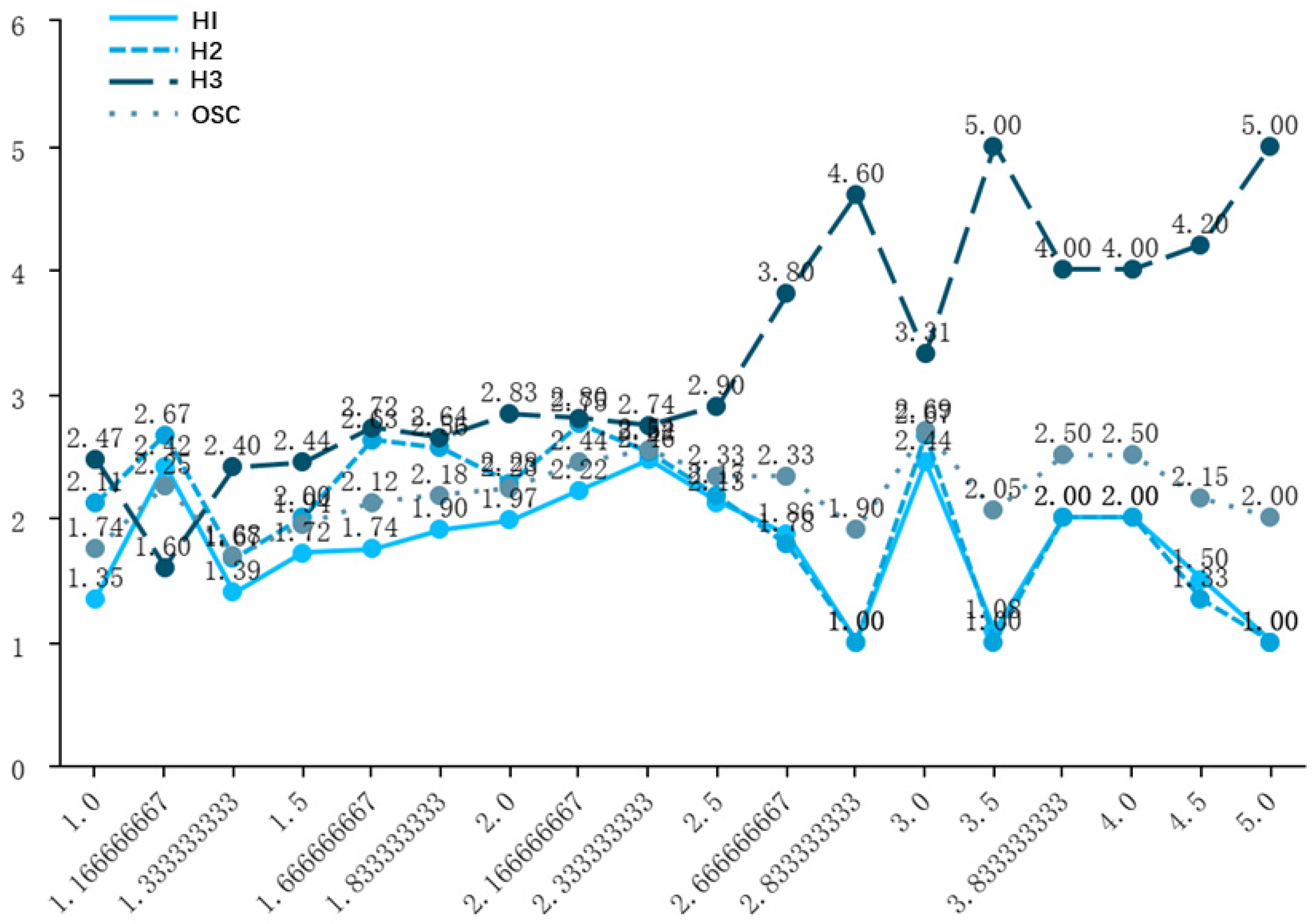

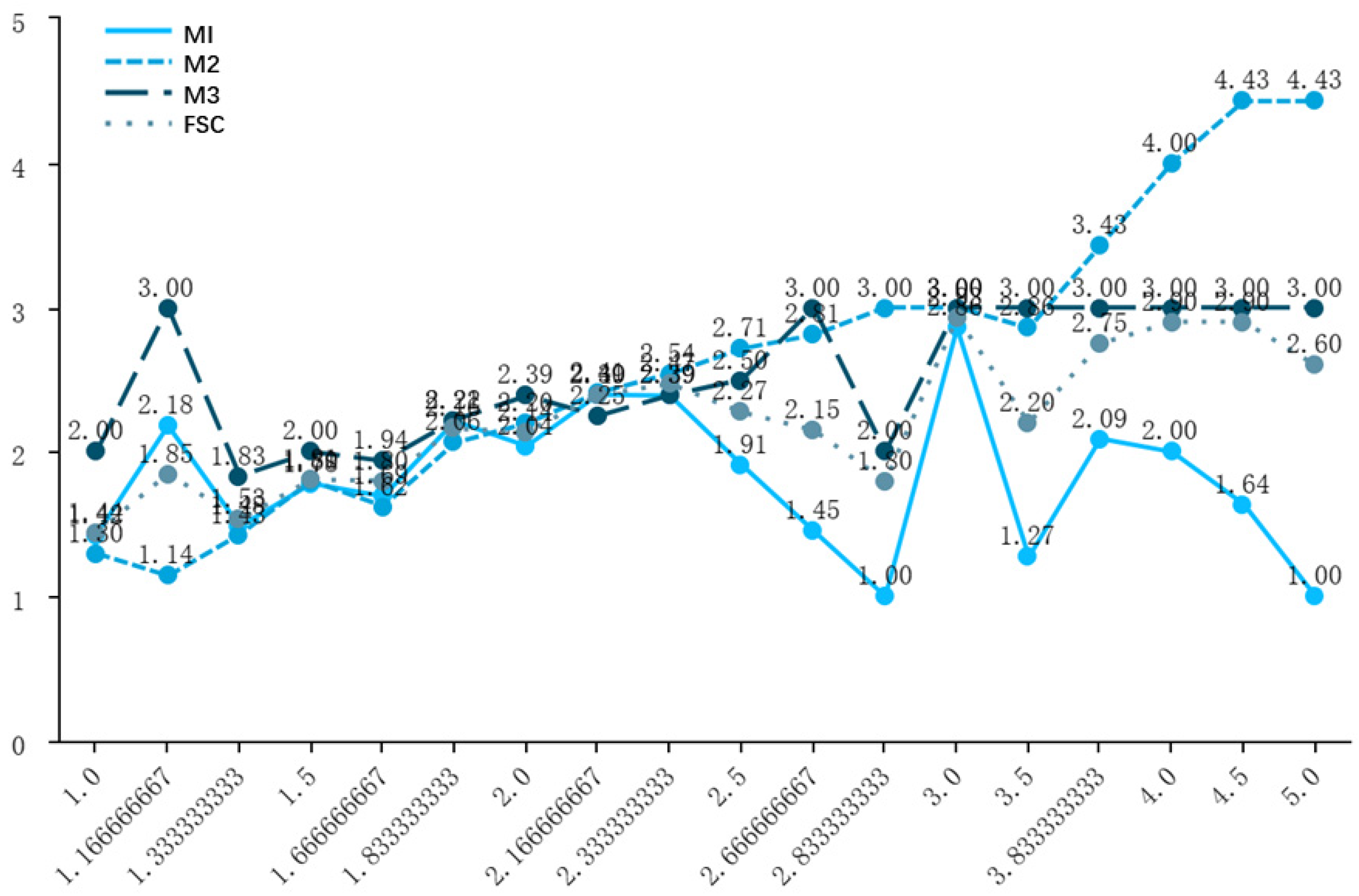

As illustrated in

Figure 3 and

Figure 4, the variability of self-reported safety behaviors, with a total of eight items, namely, safety management, safety supervision, driver safety priority, organizational level, positive communication, safety awareness, self-regulation, and fleet level, was investigated using ANOVA (all referred to as one-way ANOVA). As can be seen in the figures, the self-reported safety behaviors of different samples in safety management, safety supervision, driver safety priority, organizational level, positive communication, safety awareness, self-regulation, and fleet level were found to be statistically significant (

p < 0.05). This indicates that different samples of self-reported safety behaviors exhibit differences in safety management, safety supervision, driver safety priority, organizational level, positive communication, safety awareness, self-regulation, and fleet level (

p < 0.05); that is, the various self-reported safety behavior samples exhibited differential patterns in relation to the following variables: safety management, safety supervision, driver safety priority, organizational level, positive communication, safety awareness, self-regulation, and fleet level.

3.3.2. Overall Safety Climate Score and Objective Safety Criteria

In order to test the predictive validity of the newly developed safety climate scale at the organizational and fleet levels, driving in-vehicle risk data from the freight companies participating in this study were utilized. The in-vehicle device utilized to obtain the data was the G7 Extreme Intelligence Safety Management Service V2.0. The alarm events included the following six items: talking on the phone, smoking, not wearing a seatbelt, deviating from driving, yawning, and distracted driving. Regression analyses of the data indicated that the total scores at the organizational level and fleet level were significantly associated with drivers’ driving safety behaviors. The first-order coefficient B-values were 0.031 (SE = 0.002, 95% confidence interval = [0.023,0.048],

p < 0.01) and 0.028 (SE = 0.001, 95% confidence interval = [0.024,0.031],

p < 0.01), respectively. The R2 statistic indicated that the organizational-level safety climate score explained 52.8% of the variance in driving safety behavior, while the fleet-level safety climate score explained 48.8% of the variance in driving safety behavior (see

Table 8. Automatic linear modeling was also conducted using the six variables of driver driving safety behavior as independent variables and the organizational-level safety climate and fleet-level scores as target variables. The results are presented in

Table 8 and

Table 9. The importance of distracted driving and deviated driving was 0.491 and 0.490, respectively, at the organizational level, and 0.525 and 0.416 at the fleet level.

For the purpose of predicting the volume of accidents involving drivers who have driven for 1000 km, the results indicated that the organizational- and fleet-level safety climate scores significantly predicted the number of 1000 km accidents. The first-order coefficient B-values were −0.286 (SE = 0.004, 95% confidence interval = [−0.293,−0.278],

p < 0.01) and −0.268 (SE = 0.003, 95% confidence interval = [−0.274,−0.261]), respectively (

p < 0.01) (

Table 9). As illustrated in

Figure 5 and

Figure 6, the data points in the organizational-level and fleet-level P-P plots appear to approximate a straight line, suggesting that the data conform to the formulated distribution. The negative B-value indicates that the accident rate is negatively correlated with the safety climate score, indicating that, as the safety climate score increases, the number of accidents decreases.

In summary, the criterion-related validity of the developed safety scale is supported.

4. Discussion

This paper employed the following two levels of measurement to assess the safety climate of the company being analyzed: the organizational level and the fleet level. The statistical analysis of the test results revealed that the Cronbach’s alpha coefficients for both the organizational-level and fleet-level scales were above 0.8, indicating that the scale content exhibited an acceptable level of reliability. The statistical analysis of the results demonstrated that the KMO values of both the organizational-level and fleet-level scales were above 0.6. Additionally, the significance probability value of the Bartlett test of sphericity, p = 0.000 < 0.05, indicated that the data exhibited a high degree of correlation and that their variables were suitable for factor analysis. The principal component analysis yielded three factors with eigenvalues greater than one, which were subsequently designated as principal factors at the organizational and fleet levels. At the organizational level, these factors were identified as safety management, safety supervision, and driver safety priority. At the fleet level, the factors were designated as proactive communication, safety group awareness, and self-restraint. The cumulative variances of all extracted factors were greater than 60%, thereby demonstrating the reliability of the extracted factors. The structure of the measurement models and the standardized path coefficients were subjected to validation factor analysis. The fit results of both measurement models for the OSC and FSC were deemed to be acceptable, with all indicators meeting the requisite criteria.

A regression analysis of the data on the volume of accident alerts triggered by the dependent firms’ driving risk behaviors revealed a significant correlation between the total test scores at the organizational and fleet levels and their driving risk behaviors. The results of the automated linear modeling indicated that six driving risk behaviors, namely, talking on the phone, smoking, not wearing a seatbelt, deviating from driving, yawning, and distracted driving, were the most significant independent variables. The scores on the organizational-level and fleet-level scales were identified as the target variables. The analysis revealed that distracted driving and deviating from driving behaviors had the greatest impact on safety and should be the focus of corporate driver safety education. As previously stated, the importance of safety training and education in the context of heavy goods vehicle operational driving has been widely acknowledged [

29,

30,

31]. Consequently, it follows that both the behaviors of distracted driving and deviated driving must be controlled by management at the organizational level. Furthermore, it is the responsibility of corporate supervisors to monitor and remind drivers in real time. In light of this, it can be concluded that the management of transport companies must implement systems thinking in the road transport organizational approach to implement a safety management system. Finally, it is important to note that drivers should not be held fully responsible for unsafe driver behavior. In this study, the safety climate was measured from two dimensions to understand the driver’s perception and the actual implementation of safety management at the organizational level of the company through real situation feedback, and to understand the specifics of safety management from the bottom up. Therefore, through the score of the safety atmosphere test scale, transportation companies can improve the safety training of drivers, targeting training for drivers, while the management can also find, in a timely manner, inapplicable safety management programs as well as their own management loopholes so as to make adjustments to reduce the occurrence of the road traffic accidents of truck drivers.

The results of the linear regression analyses indicated a linear and negative correlation between the organizational-level and fleet-level scale scores and accidents per 1,000 km. It was found that higher safety climate scores were associated with lower accident rates. The aforementioned analyses indicate that the scale scores in this study can be utilized as an efficacious indicator to elucidate drivers’ driving safety behaviors, and can also be employed to predict driving risks in enterprises. Consequently, the scale scores can be employed to reveal deficiencies or loopholes in management from multiple dimensions for managers and employees, and to provide an efficacious basis for managers to improve the safety climate in their enterprises.

According to the results obtained above, the safety management of truck driving in transportation enterprises can start from the following aspects:

Driver training and assessment: Regularly organize safe driving training for drivers, including traffic rules, driving skills, emergency treatment, etc., to ensure that drivers have basic driving skills and safety awareness. A driver assessment system can be implemented to assess the driving skills, safety awareness, and service attitudes of drivers on a regular basis, and those who are not qualified can be retrained or adjusted in their positions.

Safe driving rules and regulations: Formulate detailed rules and regulations for the safe driving of trucks, including the speed limit, traveling distance, rest time, etc., to ensure that drivers comply with the relevant regulations. Seriously deal with drivers who violate the rules and regulations, and strengthen the enforcement of the rules and regulations.

Risk assessment and prevention: Evaluate the risks that may be encountered in the process of truck driving and formulate corresponding preventive measures. The implementation of the preventive measures should be regularly checked to ensure the effectiveness of the preventive measures.

Cultivation of safety culture: Through publicity and education, improve the safety awareness of drivers and enterprises, and form a positive safety culture. Encourage drivers to actively participate in safety management, put forward suggestions for improvement, and jointly maintain the safety and stability of the enterprise.

The limitations of this study include the conditions under which the driver data were collected. The data originate from different fleets of the same enterprise, and there is no comparison with other enterprises in terms of application. To address this, subsequent studies should increase the experimental samples of different enterprises to reduce the differences. The investigation area was limited to Zhejiang Province, which is considered to be one of the more economically developed provinces in China. However, there are differences between this province and inland provinces. Therefore, in the next study, different parts of the country will be selected to reduce the differences in the comparative study. This will enable the unified application of the logistics and transportation enterprise safety atmosphere test scale in China. Furthermore, this paper is directed towards the employees of logistics and transportation enterprises, and does not undertake targeted research on drivers of other modes of operation (such as bus drivers, dangerous goods drivers, self-employed drivers, etc.). Subsequently, the research will be analyzed and compared across these different groups, thereby increasing the diversity and practicality of the study. Furthermore, this paper does not provide a comprehensive analysis of in-vehicle data. Consequently, subsequent in-depth studies of in-vehicle data are necessary to address this limitation.

The final objective of this study on the safety assessment of truck drivers in logistics and transportation enterprises is the construction of a safety atmosphere test platform based on the safety atmosphere test scale. This platform will enable the real-time monitoring of the safety atmosphere of enterprises, the identification of safety hazards, the improvement of driving safety, and the reduction in accidents.

5. Conclusions

The “safety climate” test theory has been employed to develop a set of safety risk assessment systems for logistics and transportation enterprises in accordance with the prevailing management and cultural climates in China. These assessment systems have been implemented in the form of test scales, enabling the safety risk assessment of China’s logistics and transportation enterprises and fleets.

The scales were constructed and analyzed for reliability and validity at the business organizational level and at the fleet level. Exploratory factor analysis of the test data yielded valid test items on the dimensions of safety management, safety monitoring, and safety prioritization at the organizational level, and proactive communication, safety awareness, and self-regulation at the fleet level, respectively. Validation factor analyses at the organizational and fleet levels, respectively, demonstrated the validity of the system architecture and the satisfactory fit of the model.

The correlation analysis of the overall safety atmosphere scores of truck drivers and the objective safety performance data of onboard equipment indicate a significant correlation between the total test scores of the organizational level and fleet level and their driving risk behaviors. Distracted driving and deviated driving behaviors have the greatest impact on safety. Therefore, these behaviors should be used as the key point of a company’s driving safety education. The scores of the organizational and fleet levels are negatively correlated with the number of accidents per 1000 km, indicating a high degree of consistency between the test results and actual risky accidents. Therefore, these scales can be used as a valid means of evaluating the safety risk of a company.

Author Contributions

J.X.: conceptualization, methodology, literature analysis, theoretical analysis, topic guide, data organization and analysis, and writing. Z.C.: literature analysis, theoretical analysis, data organization and analysis, and writing. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Some or all of the data supporting the results of this study can be obtained from the corresponding author upon reasonable request.

Acknowledgments

The authors are grateful to all research staff that contributed to the data collection required for this study.

Conflicts of Interest

We have no conflicts of interest to disclose. We confirm that this work is original and has not been published elsewhere, nor is it currently under consideration for publication elsewhere. We confirm that all authors have approved the manuscript for submission.

References

- 2020 China Statistical Yearbook. Statistical Theory and Practice. 2021, p. 2. Available online: https://www.chinayearbooks.com/china-statistical-yearbook-2020.html (accessed on 3 April 2024).

- Matthias Gsul; Hu, Y.; Zhou, X. Road Traffic Transportation Safety Development Report (2017); China Emergency Management: Beijing, China, 2018; pp. 48–58. [Google Scholar]

- Zhou, T.; Zhang, J. Analysis of commercial truck drivers’ potentially dangerous driving behaviors based on 11-month digital tachograph data and multilevel modeling approach. Accid. Anal. Prev. 2019, 132, 105256. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.-X.; Wang, X.-Y.; Wang, Z.-X.; Li, X.-D. Dangerous driving behavior clustering analysis for hazardous materials transportation based on data mining. J. Transp. Syst. Eng. Inf. Technol. 2020, 20, 183–189. [Google Scholar]

- Choi, T.M.; Chiu, C.H.; Chan, H.K. Risk management of logistics systems. Transp. Res. Part E: Logist. Transp. Rev. 2016, 90, 1–6. [Google Scholar] [CrossRef]

- Zohar, D. Safety climate in industrial organizations: Theoretical and applied implications. J. Appl. Psychol. 1980, 65, 96–102. [Google Scholar] [CrossRef] [PubMed]

- Cooper, M.D.; Phillips, R.A. Exploratory analysis of the safety climate and safety behaviour relationship. J. Saf. Res. 2004, 35, 497–512. [Google Scholar] [CrossRef] [PubMed]

- Christian, M.S.; Bradley, J.C.; Wallace, J.C.; Burke, M.; Christian, M.S.; Bradley, J.C.; Wallace, J.C.; Burke, M.J. Workplace safety: A meta-analysis of the roles of person and situation factors. J. Appl. Psychol. 2009, 94, 1103–1127. [Google Scholar] [CrossRef] [PubMed]

- Zohar, D. Thirty years of safety climate research: Reflections and future directions. Accid. Anal. Prev. 2010, 42, 1517–1522. [Google Scholar] [CrossRef]

- Yu, M.; Li, J.; Qin, W. Effects of psychosocial safety climate on miners’ unsafe behavior. Chin. J. Saf. Sci. 2022, 32, 34–40. [Google Scholar]

- Chen, Y.; Huang, W.; Li, H. Relationship between error management climate and worker safety performance in construction companies. Chin. J. Saf. Sci. 2022, 32, 28–34. [Google Scholar]

- Anderson, N.J.; Smith, C.K.; Byrd, J.L. Work-related injury factors and safety climate perception in truck drivers. Am. J. Ind. Med. 2017, 60, 711–723. [Google Scholar] [CrossRef]

- Swedler, D.I.; Pollack, K.M.; Agnew, J. Safety climate and the distracted driving experiences of truck drivers. Am. J. Ind. Med. 2015, 58, 746–755. [Google Scholar] [CrossRef] [PubMed]

- Sun, K.; Lan, T.; Goh, Y.M.; Safiena, S.; Huang, Y.H.; Lytle, B.; He, Y. An interpretable clustering approach to safety climate analysis: Examining driver group distinctions. Accid. Anal. Prev. 2024, 196, 107420. [Google Scholar] [CrossRef] [PubMed]

- Zohar, D.; Huang, Y.-h.; Lee, J.; Robertson, M.M. Testing extrinsic and intrinsic motivation as explanatory variables for the safety climate–Safety performance relationship among long-haul truck drivers. Transp. Res. Part F Traffic Psychol. Behav. 2015, 30, 84–96. [Google Scholar] [CrossRef]

- Lee, J.; Huang, Y.-H.; Sinclair, R.R.; Cheung, J.H. Outcomes of Safety Climate in Trucking: A Longitudinal Framework. J. Bus. Psychol. 2019, 34, 865–878. [Google Scholar] [CrossRef]

- Huang, Y.-H.; Zohar, D.; Robertson, M.M.; Garabet, A.; Lee, J.; Murphy, L.A. Development and validation of safety climate scales for lone workers using truck drivers as exemplar. Transp. Res. Part F Traffic Psychol. Behav. 2013, 17, 5–19. [Google Scholar] [CrossRef]

- Hussain, G.; Batool, I.; Kanwal, N.; Abid, M. The moderating effects of work safety climate on socio-cognitive factors and the risky driving behavior of truck drivers in Pakistan. Transp. Res. Part F Traffic Psychol. Behav. 2019, 62, 700–715. [Google Scholar] [CrossRef]

- Pattarachat, M.; Wisanupong, P. The impact of fleet-level and organization-level safety climates on safety behavior among Thai civilian pilots: The role of safety motivation. Saf. Sci. 2022, 147, 105614. [Google Scholar]

- Zohar, D. Safety climate and beyond: A multi-level multi-climate framework. Saf. Sci. 2008, 46, 376–387. [Google Scholar]

- Qu, W.; Luo, X.; Wang, Y.; Ge, Y. Effects of personality on driving behaviors among professional truck drivers: The mediating effect of safety climate. Transp. Res. Part F Traffic Psychol. Behav. 2022, 89, 289–302. [Google Scholar] [CrossRef]

- Nordfjærn, T.; Jørgensen, S.; Rundmo, T. Cultural and socio-demographic predictors of car accident involvement in Norway, Ghana, Tanzania and Uganda. Saf. Sci. 2012, 50, 1862–1872. [Google Scholar] [CrossRef]

- Huang, Y.H.; Lee, J.; McFadden, A.C.; Rineer, J.; Robertson, M.M. Individual employee’s perceptions of “Group-level Safety Climate” (supervisor referenced) versus “Organization-level Safety Climate” (top management referenced): Associations with safety outcomes for lone workers. Accid. Anal. Prev. 2017, 98, 37–45. [Google Scholar] [CrossRef]

- Dedobbeleer, N.; Beland, F. A safety climate measure for construction sites. Journal of Safety Research 1991, 22, 97–103. [Google Scholar] [CrossRef]

- Cheyne, A.; Cox, S.; Oliver, A.; Tomás, J.M. Modelling safety climate in the prediction of levels of safety activity. Work. Stress 1998, 12, 255–271. [Google Scholar] [CrossRef]

- Cox, S.; Flin, R. Safety culture: Philosopher’s stone or man of straw. Work. Stress 1998, 12, 189–201. [Google Scholar] [CrossRef]

- Flin, R.; Mearns, K.; O’Connor, P.; Bryden, R. Measuring safety climate: Identifying the common features. Saf. Sci. 2000, 34, 177–192. [Google Scholar] [CrossRef]

- O’Connor, P.; Buttrey, S.E.; O’Dea, A.; Kennedy, Q. Identifying and addressing the limitations of safety climate surveys. J. Saf. Res. 2011, 42, 259–265. [Google Scholar] [CrossRef] [PubMed]

- Mooren, L.; Grzebieta, R.; Williamson, A.; Olivier, J.; Friswell, R. Safety management for heavy vehicle transport: A review of the literature. Saf. Sci. 2014, 62, 79–89. [Google Scholar] [CrossRef]

- Grytnes, R.; Shibuya, H.; Dyreborg, J.; Grøn, S.; Cleal, B. Too individualistic for safety culture? Non-traffic related work safety among heavy goods vehicle drivers. Transp. Res. Part F Traffic Psychol. Behav. 2016, 40, 145–155. [Google Scholar] [CrossRef]

- Katrine, K. Road Transport Safety in Northern Norway: How Buyers of Road Transport Services Can Contribute to a Road Transport with fewer Accidents and Near-misses. Arct. North 2021, 42, 81–102. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).