1. Introduction

Scientific experiments are universal and encompass research methods in various scientific fields—from physics and biology to social sciences. Chemical experiments are an important aspect of scientific experiments, which focus on unique issues and methods in the field of chemistry. As chemical experiments become more complex, their inherent risks and potential hazards also increase [

1,

2]. Incorporating risk assessments into chemical experiments is, therefore, crucial to safeguard the safety and well-being of laboratory personnel, prevent environmental hazards, and improve the reliability and precision of experimental results. However, the traditional risk evaluation method does not consider the weight of risk evaluation criteria. It cannot effectively address problems through hierarchical analysis, as well as imprecise and ambiguous information inherent in human cognition.

Various methods can be used to assess risks in chemical experiments. One of the most widely adopted methods is the failure mode and effects analysis (FMEA) method. The FMEA method was first applied in the aerospace industry in the 1960s and has been widely applied as a risk evaluation methodology for examining and identifying all possible or expected failures [

3]. The main goal of FMEA is to initiate actions to proactively mitigate or eliminate failures, starting with the most serious failures. Many studies have applied the FMEA method over the years to explore risk assessment problems [

4,

5]. Potential failure modes (FMs) are prioritized in the conventional FMEA based on the risk factors of severity (

S), occurrence (

O), and detection (

D). Each of these three factors is assigned a value between 1 and 10 (with higher values indicating a higher degree of the factor). In recent years, the FMEA methodology has gained significant popularity in various studies owing to its easy computation, such as in liquid hydrogen storage systems [

6], electronic equipment [

7], manufacturing systems [

8], lithium-ion batteries [

9], fire-induced domino effects [

10], and the petrochemical industry [

11]. However, there remain certain limitations in the solution of the risk priority number (RPN) method. For example, the three criteria,

S,

O, and

D, are supposed to be equal in weight [

12], which cannot effectively address problems through hierarchical analysis [

13]. The aforementioned limitations have an impact on the precision of the solutions. Certain scenarios may result in lower RPN values of serious failure mode compared to minor failure mode, thereby posing potential risks.

Currently, many research methods can analyze and solve problems hierarchically. One of them is the analytic hierarchy process (AHP), which can organize decision-making factors hierarchically (including levels of objectives, criteria, sub-criteria, and alternatives). AHP was developed by Saaty in 1980 as a practical multi-criteria decision-making tool for analyzing choice problems [

14]. This hierarchy facilitates evaluation through a series of pairwise judgments and uses qualitative and quantitative analysis, comparisons, and rankings of relative weights. The key factors with greater influence can be identified to assist decision-makers or management in making more informed choices. The AHP methodology has been used to address obstacles in several fields such as solar thermal plant demand [

15], flood disaster identification [

16], flood risk [

17], and nuclear power plants [

18]. In addition, the AHP method can effectively evaluate the weight of each criterion and overcome the limitation of PRN by assuming the same weight, providing more realistic results. However, it is limited to handling crisp information and lacks the capability to address imprecise and ambiguous information inherent in human cognition.

Human judgment is often affected by uncertainty and ambiguity of information, where decisions are made even despite insufficient key information. Moreover, people who assess something or make decisions also tend to describe information based on natural language expressions rather than relying on precise numerical values. The fuzzy set (FS) theory, first proposed by Professor Zadeh in 1965, has now been around for nearly 60 years [

19,

20]. The theory takes advantage of the degree of membership (MD) to express fuzzy phenomena. However, there are situations in which the fuzzy set approach cannot deal with the ambiguity posed by degrees of non-membership. To address this gap, Atanassov [

21] put forth the notion of the intuitionistic fuzzy set (IFS) and considered non-membership degrees (NMDs) and combined them with the membership degree of FS to deal with uncertain situations while adhering to the condition that the sum of membership degrees and non-membership degrees should not exceed 1 [

22]. In recent decades, FS and IFS have been used with numerous research techniques to address practical problems in various domains, including medical diagnoses [

23], risk assessments [

24], cluster analyses [

25], fuzzy controls [

26], emergency location selections [

27], and supplier selections [

28].

In addressing the limitations of the FMEA method in assessing safety-related risks in chemical experiments, this study proposed a novel IFS-based RPN method that integrates the conventional FMEA method with the IFS and AHP methods. By incorporating the IFS technique, the proposed research method can manage imprecise data in uncertain situations and overcome the inherent non-numeric cognitive biases of human decision-making. The novel IFS-based RPN method calculates the weight of the AHP method and determines the related importance of the evaluation criteria for S, O, and D. Finally, this method considers the chemical experiment damage recovery (R) as an evaluation criterion, aligns with the needs of practical chemical experiments, and enhances the efficacy and rationality of the final ranking of failure modes in chemical experiments.

The remainder of the paper is structured as follows. A brief overview of the FMEA method, AHP method, and IFS is provided in

Section 2. In

Section 3, this paper proposes an IFS-based RPN approach that integrates the AHP method, IFS, and the RPN approach and describes the solution steps in detail.

Section 4 presents a numerical example of the “preparation of hydrogels” for use in general chemistry courses. Then, the results of the calculations are compared with those of the other approaches. The conclusion and future direction of this research are presented in the final section.

3. Research Method

3.1. The Plan of the Proposed Method

Chemical laboratories have high degrees of risk. Faced with the diversity of experiments and many potential hazards, any danger in the experiment directly affects the surrounding environment and the health and safety of experimenters. Correctly assessing and fully grasping the hazard risks in chemical experiments and eliminating the possibility of hazards is the primary key to experimental safety. The traditional FMEA method can identify and rank the risks of all possible failure modes in the system and take the corrective approach to reduce or even eliminate the occurrence of high-risk items, among which RPN is the most common method used. In contrast, the traditional RPN method has some limitations and shortcomings. For instance, it dismisses the relative importance of the risk factors and supposes the same weight of the evaluation criteria. In the process of risk assessment, due to differences in experts’ educational backgrounds and practical experience, the information provided may have cognitive differences. Therefore, it is difficult to use a precise value of 1 to 10 to evaluate risk items. Moreover, the traditional RPN only considers the use of S, O, and D for risk assessment and ignores the consideration of recovery degree factor. These situations lead to some difficulties in assessing the risk of chemistry experiments and affect the applicability of experimental risk assessment. Considering these gaps, this study proposes a novel IFS-based RPN method, which integrates the RPN method, the AHP method, and IFS to address the gaps in chemical experiment risk assessments. In particular, this study uses IFS to deal with the uncertainty and ambiguity of information of experts’ risk assessment appropriately and adds consideration of the risk evaluation criteria recovery degree (R). The AHP method is also used to consider the relative importance of the four risk factors. Further, this study uses the RPN to calculate the assessment scores of risk items that affect experimental safety and complete the ranking. Therefore, it can be considered a more authentic chemical experiment risk assessment, which can prevent risk occurrences in chemistry experiments.

3.2. The Procedure of the Research Method

In order to evaluate the potential risk items during chemical experiments, the novel IFS-based RPN approach comprises seven sequential steps, briefly expounded as follows.

Invite scholars or experts with several years of experience in chemical experiments to form a chemical experiment risk assessment team.

According to the research objectives, clearly define the nature of the problem and the research structure and determine the risk assessment criteria for the risk factors of chemical experiments.

Complete the design of expert questionnaires based on the objectives, evaluation criteria, and risk factors of the risk assessment problems. Then, conduct questionnaire surveys.

After completing the questionnaire, fully consider the available information provided by the experts. According to the linguistic level in

Table 4, the linguistic scores provided by the experts in the questionnaire are transformed into intuitionistic fuzzy (IF) information. Then, Equations (8)–(12) are used to calculate the mean score.

Use Equations (3)–(5) to calculate and determine the weight of the four risk assessment criteria, including S, O, D, and recovery (R).

After obtaining the weights of the four risk evaluation criteria, multiply them by the experts’ ratings of the risk items in Step 4 to obtain the weighted average score of each risk item.

Rank the weighted average scores of each risk item so that managers or decision-makers can understand the hazards and severity of each risk item. Then, employ necessary safety management methods and approaches to effectively reduce the probability of laboratory hazards and ensure the experimental process safety of personnel and equipment.

4. An Illustrative Example

4.1. Overview

As far as laboratory safety is concerned, an “accident” refers to the negligence of laboratory personnel or failure to operate according to regulations, resulting in experiment failure, loss of control, or forced stop, resulting in personal injury and property loss. In recent years, researchers have been committed to strengthening risk assessment in chemical laboratories to reduce the occurrence of hazards. For example, Li et al. proposed a method to assess the risk of unsafe behaviors in university laboratories using the human factors analysis and classification system for university laboratories (HFACS-UL) and a fuzzy Bayesian approach. This method addresses the factors contributing to unsafe human behavior in laboratories and provides further prevention and control measures [

37]. Fatemi introduced a method to identify, evaluate, and classify chemicals with higher hazards in academic laboratories, enabling a risk assessment of potentially hazardous chemicals and their prioritization. This awareness of the potential hazards and user risks associated with chemicals used in academic laboratory operations helps reduce risks [

38]. Li et al. employed a semi-quantitative method combining material element expansion theory (MEET) and combined ordered weighted average (C-OWA) operators to manage comprehensive risks related to hazards during chemical laboratory operations [

39]. Zhao analyzed the risks in hazardous chemical laboratories and used the SHELL model and HACCP system to establish a risk assessment index, effectively reducing laboratory risks [

40]. Ozdemir proposed a methodology that integrates 5S (Sort, Set in Order, Shine, Standardization, and Sustain), interval two fuzzy sets (IT2FS), AHP, FMEA, and VlseKriterijumska Optimizacija I Kompromisno Resenje (VIKOR) to address significant hazard risks in university laboratory operations, contributing to safety improvement measures in the education sector [

41]. The RPN is the most common and effective method used to reduce experimental risks in order to prevent laboratory accidents. It helps accurately predict and assess risks, enabling the implementation of necessary precautions and management approaches. However, the traditional RPN method has some shortcomings. While it dismisses the relative importance of the

S,

O, and

D risk factors, it only considers the above three risk assessments. In addition, it does not consider the ability to return to the original situation and continue the chemical experiment even after an accident occurs. Moreover, due to differences in experts’ educational backgrounds and practical experience, the information provided may have cognitive differences. It is difficult to use a precise value of 1 to 10 on the RPN scale to evaluate risk items, which is different from the actual chemical experiments and affects the applicability of experimental risk assessments.

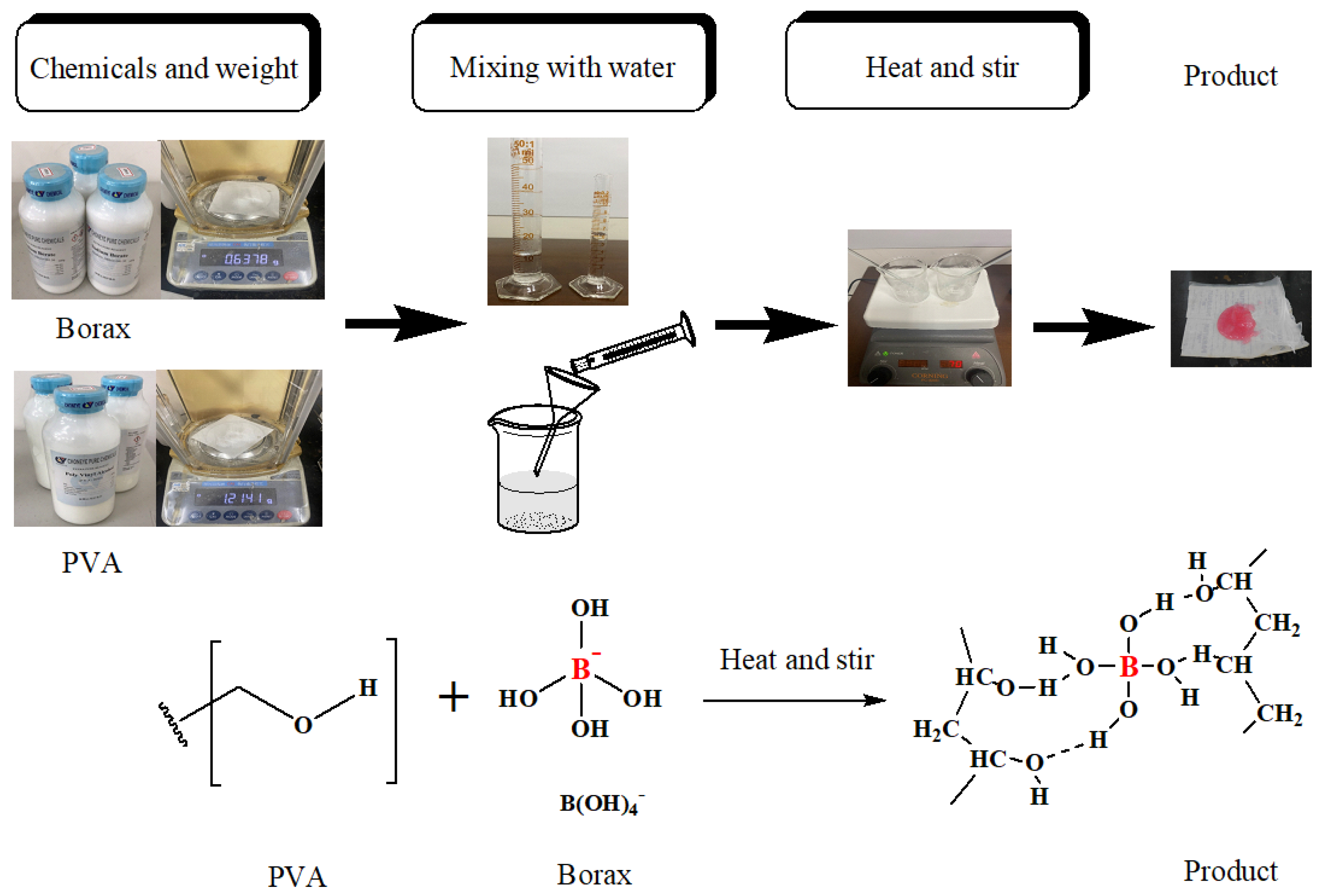

This study takes a “preparation of hydrogels” chemical experiment at a university in Taiwan as an example. The procedure of preparation of hydrogels is shown in

Figure 1. It uses the cross-linking effect of borax and polyvinyl alcohol, resulting in hydrogels, which can be applied for medical consultation, health care, beauty, food, and agriculture. This study invited three scholars and experts with more than 10 years of teaching and practical experience in the field of chemical experimentation. In this risk assessment for the preparation of hydrogels in a chemical experiment, the evaluation criteria include severity (

S), occurrence (

O), detection (

D), and recovery (

R). Based on the rating scale of the FMEA evaluation in

Table 5, the three scholars (E1, E2, and E3) rated the 20 failure modes from 1 to 10 according to the linguistic levels in

Table 4 to complete the scoring of the four evaluation criteria of

S,

O,

D, and

R, as shown in

Table 6. Then, based on the nine scales of the AHP method in

Table 2, a comparison matrix of four risk assessment criteria was formulated, as shown in

Table 7.

4.2. Solution Based on Risk Priority Number Method

The FMEA method is a widely used technique and tool for risk evaluation. Capable of identifying the root causes of failures and preventing or mitigating their consequences, it has been widely used in the military and industries. Traditional FMEA usually uses the RPN to assess the risk level of a failure mode. This method is carried out by multiplying the value of risk factors

S,

O, and

D. If the RPN of a certain factor in the system is high, the probability of occurrence of risk may also be extremely high. A higher risk priority should be given to prevent its failure risk from happening. Juan et al. [

42] combined statistical methods and the RPN to analyze and estimate the number of operating errors or delays per unit of time in construction projects. It can assist construction managers to prioritize and determine the need for construction improvements. This study also uses the RPN method to calculate a real case, as described in

Section 4.1. According to

Table 6, the arithmetic mean of three expert opinions was calculated, and Equation (1) was used to calculate the RPN. For example, the RPN of FM1 is

. The RPN of other failure modes was also generated in the same way. The computation results and rank are shown in

Table 8.

4.3. Solution Based on Analytic Hierarchy Process and Risk Priority Number Method

The AHP-RPN methodology can overcome the limitation of assuming equal weights for evaluation criteria by applying the AHP method to determine the priority of criteria and using the RPN methodology to assess identified risk items, which are then weighted to generate risk index prioritization. Li et al. [

43] combined the AHP and RPN methods to analyze the causes of failure of floating offshore wind turbines. This approach minimizes the catastrophic failure of long-term floating offshore wind turbines. This section adopts the AHP-RPN methods to deal with cases of chemical experiments. First, the AHP method is used to determine the weight of risk assessment criteria. Based on

Table 7, Equations (3)–(5) are applied to conduct the weight calculation of risk criteria by calculating

= 3.001—the CI value is 0.001, and the CR value is 0.002. The calculation process is as follows:

After checking the consistency of expert assessment opinions (CR < 0.1), the weights from high to low are obtained—that is,

(0.442),

(0.344), and

(0.214). Second, the weights of the above three criteria (

S,

O, and

D) are multiplied by the average value, as presented in

Table 6. Then, Equation (1) is applied to calculate the RPN. For example, the RPN of FM1 is

. The RPN of other failure modes is also generated in the same way. The results and rank are expressed in

Table 9.

4.4. Solution Based on the Analytic Hierarchy Process and Fuzzy Risk Priority Number Method

When experts conduct a risk assessment, it is often difficult to score the assessment items with precise values due to professional differences or personal preferences. The traditional FS approach can deal with ambiguous situations in daily life, as well as handle problems of human judgment that cannot objectively deal with, for example, fuzzy and uncertain conditions. Jin et al. [

44] proposed this approach to analyze the causes of logistics system failures during the COVID-19 pandemic. This approach could improve the most effective way for logistics companies to engage with supply chain partners and their customers on risk management issues during the COVID-19 pandemic.

The traditional FS approach uses the value of MD (

α)—where NMD equals 1 minus the value of MD (

α)—to conduct the numerical calculation and determine the cause of a failure affecting a chemical experiment. For example, Expert 1 commented that the assessment value of the failure mode of “the laboratory has had a power outage” is L5 for the assessment criteria of severity in

Table 6. According to

Table 4, the linguistic variable L5 expresses the value of MD (

α) as 0.5; thus, NMD (1–

α) equals 0.5. Other failure modes also use the same way to determine the values of MD and NMD. Subsequently, multiplied with the weight of three risk factors obtained in

Section 4.3, the weights from high to low are

(0.442),

(0.344), and

(0.214), obtaining the weight average score of the risk factor. Then, Equations (8)–(11) were used to calculate the arithmetic mean of fuzzy information from three experts, as well as Equation (12) to defuzzify fuzzy information and obtain the score of failure modes under three risk factors, as shown in

Table 10. Finally, Equation (1) was adopted to multiply the weight average score of the three risk factors to obtain the value of RPN of each failure mode, also shown in

Table 10.

4.5. Solution Based on the Proposed Method

With the demand for education and research rising, the continuous increase in the number of chemical experiments and related safety accidents is gradually showing an upward trend. Therefore, effectively preventing, controlling, and managing laboratory safety risks is the primary problem to be addressed in laboratory management. To avoid disrupting the coherence of subsequent chemical experiment courses due to laboratory accidents, this study introduces chemical experiment damage recovery (R) into the risk assessment indicators as a key factor in restoring laboratory operations. Due to the many factors that need to be considered in the risk management and control of chemical experiments, experts have different experiences and perceptions. It is difficult to give evaluation information by crisp value, which often leads to bias in solution results. To address these problems, this paper proposes a flexible IFS-based RPN approach that integrates the typical AHP, FMEA, and IFS methods to deal with the possible risk problems in chemical experiments. The following steps are taken:

Steps 1 and 2 include organizing a risk assessment committee, constructing a research structure for risk assessment issues, and determining the assessment criteria for safety factors in chemical experiments.

Step 3: Complete the questionnaire design and implement the questionnaire.

According to the structure and elements of the risk assessment problem (including the objectives, evaluation criteria, and risk factors), complete the design of expert questionnaires and conduct surveys.

In order to consider the available information provided by the experts fully and based on

Table 6, the rating scale of

Table 4 to convert it into IF information was used to calculate the arithmetic mean of IF information from three experts. Then, Equation (12) was applied to defuzzify IF information and obtain the score of failure modes under four risk factors.

Due to adding the consideration of recovery of chemical experiment accidents in this study, according to

Table 2, use Equations (3)–(5) to calculate the CR value. By calculating

= 4.058, the CI value is 0.019, then the CR value is 0.021, and the calculation process is as follows:

While the CR value is confirmed to be <0.1, it can be demonstrated that the experts’ judgments of the pairwise comparison matrix are consistent. After the calculation, the weight (eigenvector) can be obtained: (0.347, 0.147, 0.221, 0.285)T. The result shows that the weight value of (0.347) is the most important, followed by the weight of (0.285), (0.221), and (0.147).

After obtaining the IF score of each failure mode, multiply the corresponding weight of the risk factors, S, O, D, and R, to obtain the weight average score of the 20 FMs.

For example, expert E1 determines the IFN to be (0.1, 0.9) for the risk factor S of FM1, and with

(0.347) by Equation (10), it is found that

Apply Equations (8)–(11) to calculate the arithmetic mean of IF information from three experts.

For example, three experts determine the IFN to be (0.036, 0.964), (0.036, 0.905), and (0.036, 0.964), respectively, for the risk factor S of FM1 by Equation (10), and it is found that

By Equation (8), it is found that

Apply Equation (9) to calculate the aggregated weighted average score for the risk items. Then, employ Equation (12) to defuzzify IF information and obtain the score of failure modes under four risk factors, as shown in

Table 11.

For example, when

,

, and

in FM1, by Equation (9), it is found that

By Equation (12), it is found that

Risk ranking is determined by ordering the RPN values from highest to lowest. While ranking the weighted average scores of each FM (refer to

Table 11), the scholars or managers of the chemical laboratory can understand the hazards and severity of each FM. Subsequently, they can take necessary safety management approaches to effectively reduce the probability of laboratory hazards and ensure the safety of the experimental processes, as well as that of the personnel and equipment.

4.6. Comparisons and Discussion

In order to verify the effectiveness and necessity of the proposed novel IFS-based RPN method, this study used the case of a chemical experiment in a university laboratory to test and prove the results of different research approaches. This study used the same data (

Table 6) and adopted four different research methods, including the traditional RPN, the AHP-RPN, the AHP-FRPN, and the proposed methods. The different calculation results of the analysis presented in

Table 8,

Table 9,

Table 10 and

Table 11 are summarized in

Table 12. Based on the analysis and comparison in

Table 13, the advantages of the method proposed in this study are described in detail.

First, during the evaluation of risk criteria in the chemical experiments, risk factors and concepts are encountered, which can only be described qualitatively and not quantitatively. Thus, they cannot be included in risk assessments. The proposed method presented in this study can take into account both qualitative and quantitative information simultaneously and combines the above different attribute analyses, as well as objectively synthesizes the subjective judgments of decision-makers on various risk assessment criteria in chemical experiments.

Second, in the solution process of the traditional RPN, all evaluation criteria are assumed to have the same weight, implying that prioritizing risk assessment criteria can be difficult. Meanwhile, in the AHP-RPN, the AHP-FRPN, and the proposed methods in this study, the importance of various risk assessment criteria in chemical experiments can be effectively measured. It is more in line with the actual situation and needs of chemical experiments.

Third, the traditional RPN and AHP-RPN methods can only process crisp and determined information but cannot deal with fuzzy and undetermined information. However, AHP-FRPN and the proposed novel IFS-based RPN method in this study can deal with situations where there is uncertainty in the information. They can fully consider the information provided by experts’ real thoughts, which is closer to the real-world situation.

Fourth, this study added chemical experiment damage recovery (R) as an important consideration factor in the risk assessment criteria. Due to the traditional FMEA method only considering risk factors (S, O, and D) to ensure laboratory safety and improve experimental quality, there is still an obvious problem in disrupting the coherence of experimental courses after chemical experiment risk accidents. However, in the proposed method of this study, the advantages of the R evaluation criteria increase the consideration of restoring laboratory operations after an experimental accident. Once an accident occurs, how to restore the laboratory environment and restore personnel operation capabilities in the fastest time needs to be determined. It can minimize the impact of chemical experiment accidents and restore school laboratory operations, and it is more in line with the particularity of the real situation of university chemistry experiments.

5. Conclusions

In academia, the scope covered by scientific experiments is extensive, spanning various scientific fields, such as biology, physics, and social sciences. The field of chemistry frequently employs chemical experiments to delve into research and develop new disciplinary knowledge. Due to the involvement of drugs, reagents, and operating procedures in chemical experiments, potential dangers and risks may arise. These risks not only impact the personal safety of laboratory members but also have implications for the health and safety of the environment and the public. Thus, the importance of safety in laboratory chemical experiments cannot be overlooked. It is imperative to ensure laboratory safety through appropriate hazard management and safety measures. However, the typical FMEA method has some limitations, such as the fact that three criteria, S, O, and D, are equal in weight, do not effectively address problems through hierarchical analysis, and cannot address imprecise and ambiguous information inherent in human cognition. Therefore, this paper proposed a novel IFS-based RPN method that integrates the AHP, FMEA, and IFS methods to evaluate the risk factors associated with chemical experiments in the laboratory. Through numerical analysis and comparison with various research methods, it has been demonstrated that this research methodology effectively evaluates the risk factors of chemical experiments and facilitates their sorting. Furthermore, this approach incorporates the consideration of evaluation criteria for chemical experiment damage recovery in chemical laboratories. This approach enables them to implement appropriate laboratory risk management actions and provide relevant management units with valuable insights, thereby reducing the likelihood of accidents.

The advantages of this research method can be summarized as follows:

- (1)

The proposed novel IFS-based RPN method can consider both qualitative information and quantitative information in the risk assessment of chemical experiments.

- (2)

The proposed novel IFS-based RPN method can consider the weight of risk assessment criteria in chemical experiments.

- (3)

The proposed novel IFS-based RPN method handles the uncertainty and fuzziness that are present in the information.

- (4)

The proposed novel IFS-based RPN method adds the consideration of recovery in chemical experiments’ damage.

Although the RPN calculation can effectively rank risk factors, it relies on subjective judgments and the accuracy of available data. Therefore, when utilizing the RPN for risk assessment and decision-making, it is crucial to fully consider the professional knowledge and experience of experts and scholars. This research could be further explored in different expert information environments, such as a picture fuzzy set, Pythagorean fuzzy set, or spherical fuzzy set, in terms of considering expert-provided information. This approach can lead to more reliable and accurate results that are better aligned with real-world conditions.