Abstract

This study focuses on the development of an integrated smart manufacturing system (ISMS) that centers on custom design experiences, utilizing virtual reality (VR) and cloud integration to enhance operational value. Through a Design for Excellence (DFX) approach, this system aims to seamlessly incorporate customer-specific designs into the manufacturing process, thus aligning closely with consumer needs. The research contributes significantly by (1) implementing a customer-focused design system that enhances sales benefits, (2) enabling a smooth transition from design drawings to automated production, thereby increasing manufacturing efficiency, and (3) establishing a digital transformation framework that integrates design, production, and marketing to boost overall business value.

1. Introduction

In today’s rapidly changing technological environment, integrated smart manufacturing systems (ISMS) have become central to driving industrial innovation and enhancing consumer experiences. This study focuses on the development of an integrated smart manufacturing system that utilizes virtual reality (VR) and cloud integration technologies. Not only does it optimize operational efficiency, but it also significantly enhances design experiences tailored to individual customers through a Design for Excellence (DFX) approach. As system cabinets are a design industry closely intertwined with people’s lives [1], this study demonstrates the unique value of applying these technological innovations to enhance the personalization and functionality of living spaces, showcasing its distinct value in this industry.

The uniqueness of this research lies in its implementation of a customer-oriented design system that seamlessly transforms design drawings into automated production, thereby increasing manufacturing efficiency. Further, we have established a digital transformation framework that integrates design, production, and marketing, greatly enhancing overall business value. Moreover, this study explores the advancements in smart production technologies and the integration of interdisciplinary management approaches, demonstrating the capability to provide innovative solutions in a competitive market. These solutions not only meet market demands but deeply satisfy customer needs.

By combining initiatives from industry, academia, and government in areas such as “Design for Excellence”, “VR experience”, “cloud integration”, “smart production”, and “Internet of Things”, our system demonstrates how products can be produced on-demand when needed, thus validating these concepts in practice. This not only highlights the innovativeness of our research but also provides a practical reference for businesses, aiding them in achieving success in their digital transformation efforts.

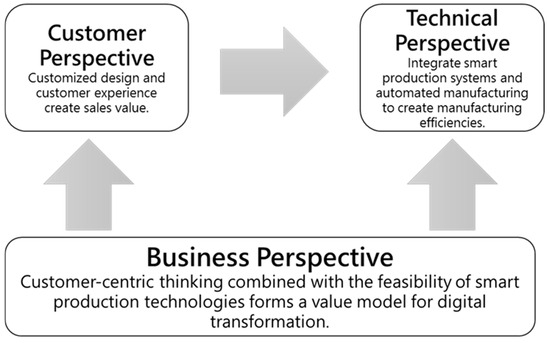

Design for Excellence (DFX) is a systematic approach to achieving objectives where “X” can represent the goals or characteristics of a product or process. To maintain success in the market, it is crucial for companies to meet customer expectations by constructing operations that align with the principles of excellent design. Historically, smart production systems have focused on enhancing efficiency and increasing production value. In the context of digitalization, customization, and the impact of innovative technologies, significant transformations are expected within businesses. Antonova, A. (2018) [2] suggests conducting innovation analysis from three main perspectives: technical (infrastructure), customer (service delivery and value co-creation), and business (value proposition). This approach enables the construction of customer-centric thinking combined with the feasibility of smart production technologies, forming a digital transformation value model. This study aims to use the system cabinet industry as an example, integrating customer design and experience with smart production to propose comprehensive research on digital transformation value. By employing DFX thinking, the study seeks to integrate system values to enhance competitive factors for businesses. This study aims to employ the qualitative design guidelines of the Design for Excellence (DFX) method to propose the following research objectives, as illustrated in Figure 1. The first objective is to use customized design to create sales value through enhanced customer experiences. The second objective is to integrate customized design with smart production systems to achieve manufacturing efficiencies. Finally, the study aims to provide a customer-oriented integration of smart production systems, forming a transformative value.

Figure 1.

Research objectives.

2. Literature Review

2.1. Excellence in Design and Smart Manufacturing Practices

Excellence in design, also known as “X” Design (DFX), encompasses a wide range of concepts and methodologies. Here, “design” is broadly defined as representing system and product design, while “X” is used to denote any specific design goal or requirement [3]. The scope of DFX includes various aspects such as Design for Manufacturing (DFM), Design for Assembly (DFA), Design for Variety (DFV), Design for Quality (DFQ), Design for Reliability (DFR), Design for Disassembly (DFD), and Design for Maintainability (DFMA) [4]. In fields such as customized product design and manufacturing, like the automotive industry, Benabdellah et al. [5] emphasize the challenges of sustainability and highlight the importance of DFX strategies in improving product quality, reducing development time, lowering costs, and meeting customer demands. DFX aims to integrate and select various facets, facilitating collaboration between designers and project teams throughout the product lifecycle, thereby optimizing the implementation of these strategies. This approach not only supports continuous product innovation but also fosters organizational transformation and development. In the context of digital transformation and Industry 4.0, DFX, integrated with customer-centric strategies, enhances smart manufacturing practices, providing customized services that transform traditional manufacturing methods and elevate a company’s value creation and business model.

2.2. Customer Design and Experience: A Key Competitive Advantage and Challenge in Smart Manufacturing

In the practice of smart manufacturing, customer design and experience are not only crucial for enhancing product value and business competitiveness but also represent a major challenge in achieving the goals of smart manufacturing. Modern service design conceptualizes service as a multi-stage process, with each stage delivering unique value to customers based on functional benefits and subjective experience [6]. Wechsler and Schweitzer [7] note that more organizations are adopting customer-centric innovation practices to increase business value, although the factors driving such innovation and the conditions for its success are still not well understood. Their case study examines the role of design artifacts in mediating customer-centric innovation strategies, showing how design products can act as flexible and persuasive tools to meet social and interactive needs, fostering innovation and organizational change. This customer-centric design requires manufacturing processes to be flexible enough to meet individualized customer needs while ensuring production efficiency and cost control. Product design must accurately reflect the holistic needs of customers, with these needs being defined through the complex interactions between various product components. The concept of the customer journey further emphasizes the importance of accumulating customer experience across multiple touchpoints, which may occur before and after the “core” touchpoints traditionally focused on in service design [8]. In a smart manufacturing environment, achieving these objectives requires companies to invest in advanced technologies such as the Internet of Things (IoT) and data analytics to capture and respond to customer demand changes in real time, optimizing production processes to support highly customized product manufacturing. The challenge of creating substantial value for customers without compromising production efficiency is a key innovation in smart manufacturing and a decisive factor in securing competitive advantage in the global market

2.3. The Innovation Engine and Digital Transformation

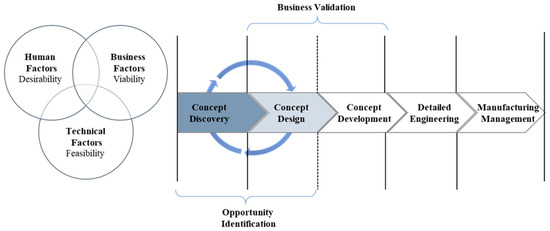

Weiss [9] presents the innovation engine framework, which combines expertise in human, technical, and business factors to create a practical process from design to delivery (Figure 2). This framework emphasizes the integration of commercial viability (market-oriented thinking), technical feasibility (through DFX in smart manufacturing processes), and operability (via cloud computing, VR, and other digital technologies) to drive innovation value. While previous research has demonstrated the benefits of smart production for business practices, there remains a lack of in-depth analysis of the connection between customer-centric smart manufacturing. This framework offers a method for integrating DFX and digital technologies to enhance manufacturing efficiency and increase sales value, thus supporting the empirical analysis of digital transformation in this study.

Figure 2.

Innovation engine framework [9].

3. Research Design and Conceptual Framework

3.1. Conceptual Framework

The conceptual framework for integrating smart production systems with customer design experiences can be approached from three perspectives, as suggested by Antonova, A. [2]

Technical Perspective: It should encompass technological architecture that ensures connectivity and infrastructure, and the implementation of analysis and foundational designs.

Customer Perspective: The framework should be built on commercial scenarios and customized services, while employing data analysis and scenario recognition to provide customers with tailored modes and experiential services.

Business Perspective: The integration of internal resources and operational processes should be expanded to include company partners, suppliers, and cloud connections with customers.

This tri-dimensional approach ensures that the design and integration of smart production systems are comprehensive, covering essential aspects that influence both the efficiency of production and the enhancement of customer experiences. It aims to leverage technological capabilities to meet specific customer needs while aligning with business goals to create a sustainable competitive advantage.

3.2. Setting System Objectives Using the DFX Methodology

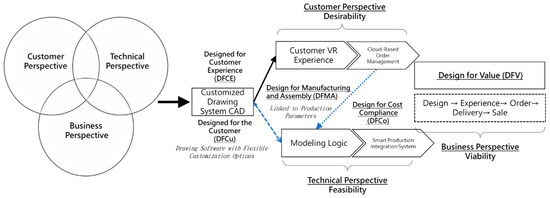

Based on the conceptual framework, the system objectives are set using the DFX methodology from a technical, customer, and business perspective, as follows:

Design for Customer (DFCu):

Kang, J. Y. M. [10] notes that co-creation, mass customization, consumer-driven customization, personalization, and co-design enable customers to assemble prefabricated parts into new creations. This is essential for maintaining competitiveness in a rapidly growing global market that is competitive and user-oriented. The system building process should transform identified customer needs into ideal products. Koomsap, P. [11] suggests that the design objective is to establish the basic parameters of the product, viewing each customer as a designer, especially in meeting their own needs. Customers, being the most knowledgeable about their needs, should have complete control over specifying product parameters to meet their requirements. The manufacturer’s role is to assist customers in turning their envisioned designs into reality, where the design activities are limited to selecting the final product (mass production) or choosing and combining predefined parts (mass customization), significantly enhancing customer satisfaction, as they obtain exactly what they want without compromise.

Design for Customer Experience (DFCE):

Customer experience arises from a series of interactions between the customer and the service provider [12]. Therefore, customer experience can be conceptualized holistically, including multiple interactions across touchpoints involving cognitive, emotional, social, and sensory elements. Verhoef, P. C., et al. [13] emphasize that the customer experience occurs across many interactions related to the core service product, including multiple “key moments” that influence customer outcomes. Companies have prioritized customer experience as a key strategy for achieving sustainable competitive advantages [14], and it is at the forefront of almost all companies’ priorities [15]. Experiences also include product features, service quality, price, personal and situational factors, all affecting customer satisfaction [16]. Therefore, realistic VR experiences that include customized product features can enhance the value of services provided and unique customization factors, thereby enhancing their sales value.

Design for Manufacturing and Assembly (DFMA):

This is an effective method for selecting materials, processes, and assembly methods early in the design stage to design products that reduce part count, material choices, and costs, resulting in easier-to-manufacture and assemble products that remain competitive [17]. The main advantage of DFMA is the reduction in the number of parts, increased manufacturability, and ease of assembly, which lowers the overall cost of the product. Reducing the number of components in a product is a major challenge for designers, and simplifying design and reducing assembly time can lower product costs. The development of new methods for manufacturing and assembly design, incorporating quality needs at the design stage, and recent attention to transparent design work and communication have all generated a demand for a more structured approach to design. For the initial system setup, considering custom design production conditions and the feasibility of connecting to smart production systems is critical.

Design for Cost (DFCo):

Cost estimation involves forecasting costs associated with a set of activities before they are actually carried out. Cost estimation or Design to Cost (DtC) methods can be broadly divided into intuitive methods, parametric techniques, variable-based models, and generative cost estimation models. However, the most accurate cost estimations are conducted during the detailed design stage using iterative methods [18]. The initial process planning should be used to obtain a proper estimate of manufacturing costs. Initial process planning includes the generation and selection of machining processes, their sequence, and their machining parameters [19]. For efficiency, DtC needs to be applied simultaneously with DfM and DfA (conceptual design stage) to compare and devise cost-effective design alternatives.

Design for Value (DFV):

For years, the manufacturing sector has used the Design to Value (DtV) model to manufacture goods at lower costs while retaining the features necessary for competition. These principles have evolved into the design for value and growth model, a new way of creating products that offer an excellent customer experience. Under the design for value and growth, the design not only creates value but also transforms customers into loyal fans through the product’s features, form, and functions, thus generating value growth [20].

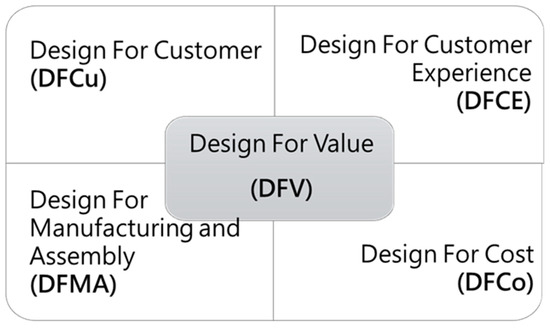

In summary, under customer design and experience, how to integrate smart production systems to enhance enterprise operational value is the focus of this study. This research proposes DFX setup and reference construction design system objectives, as shown in Figure 3.

Figure 3.

System Objectives Setup Using DFX.

3.3. Smart Integrated Systems Framework

Zhou, J., Li, P., Zhou, Y., Wang, B., Zang, J., and Meng, L. [16] discuss three characteristics of digital manufacturing: Widespread application of digital technologies in products: Digital technologies are extensively integrated into products, enhancing their functionalities and enabling advanced features like connectivity, smart control, and personalization.

Extensive use of digital design, modeling, simulation, and digital device information management: These tools facilitate the detailed planning and simulation of manufacturing processes before actual production begins, improving precision and efficiency. Digital design also encompasses the management of device information, streamlining operations and maintenance.

The integrated optimization of production processes: By employing digital technologies, production processes are optimized for efficiency, quality, and flexibility. This integration is crucial for reducing waste, minimizing production times, and adapting quickly to market changes.

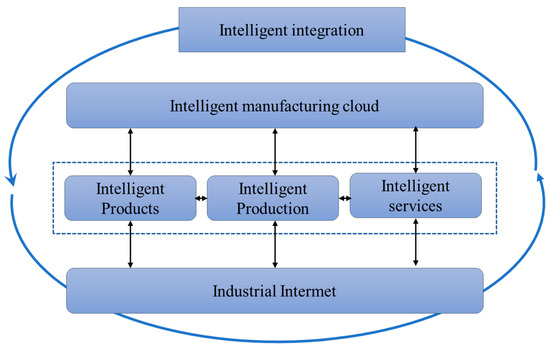

Based on these characteristics, Zhou et al. propose a smart production cloud system framework (Figure 4), which leverages cloud computing to enhance manufacturing operations. This framework allows for greater scalability, real-time data analysis, and better collaboration across different sections of a manufacturing company.

Figure 4.

Smart production cloud system framework [16].

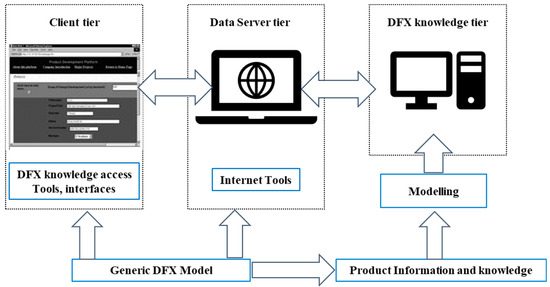

Xie and Zhou [21] discuss how using the Internet to provide DFX functionalities can enhance various aspects of product development and collaboration. Here’s an overview of the benefits they highlight:

Improved Communication: The Internet facilitates better communication channels that are instantaneous and accessible globally, allowing for real-time updates and feedback.

Closer Collaboration: With online tools, teams can collaborate more effectively, regardless of geographical distances. This setup enables more frequent interactions and alignment on projects.

Consistency and Transparency: Online platforms ensure that all team members have access to the same information, leading to consistent approaches and transparent processes.

Enhanced Participation from Customers and Suppliers: The Internet enables easier integration of feedback and participation from both customers and suppliers early in the design process, which can lead to better-tailored products and services.

Easier Project Management: Online tools streamline project management by providing platforms for task management, progress tracking, and resource allocation.

Team Building in Design Work: The digital environment supports the development of team cohesion by facilitating shared spaces for interaction, idea exchange, and collective problem-solving.

Rationalization and Structuring of the Product Development Process: The use of DFX functionalities helps in organizing and structuring the product development process, making it more systematic and efficient through stages like design, testing, and modification.

Figure 5 illustrates these aspects, showing how Internet-based DFX functionalities integrate into the product development cycle to enhance effectiveness and efficiency.

Figure 5.

System setup using DFX [21].

In modern design processes, the use of software systems is almost inevitable, especially for customer-specific product design. Consequently, Computer-Aided Design (CAD) is extensively utilized by enterprises to maintain competitive market standing. However, existing CAD systems focus too much on graphic representation, providing only 3D models and suffering from limitations in conveying design information, thus failing to deliver an effective customer experience. In the context of Design for X (DFX), where “X” could relate to various quality standards—ranging from general aspects such as reliability, assembly suitability, robustness, and maintainability, to more specific ones like environmental impact, ergonomics, and aesthetic value—it becomes increasingly clear that integrating intelligence into existing computer-aided tools, like CAD systems, can significantly enhance the effectiveness and reliability of executing various engineering tasks, including design.

Therefore, it is crucial to consider how current CAD systems, through application transformation, can offer customizable flexible designs, 3D rendering, and conversion to VR experiences. This transformation should also include cloud integration and production parameter modeling to align with and integrate into smart production systems.

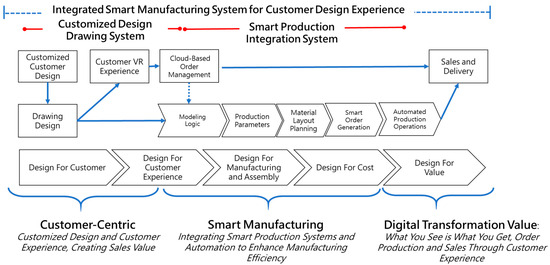

Summarizing the above, this research proposes a system design that incorporates the three conceptual perspectives of transformation drivers, referencing both the smart production cloud system framework and the DFX system setup framework. The system design, supplemented by DFX objectives, aims to combine a customer-oriented approach with the drawing software system. By adopting a customer-centric perspective, utilizing customized design software, and achieving VR experience software, the integration into smart production systems can ensure comprehensive benefits—from customer experience and design to automated production and sales—thereby generating value in digital transformation. The research system design is shown in Figure 6.

Figure 6.

Integrating smart production systems with customer design experience.

4. Case Study Analysis

The case company is the leader in the system kitchen cabinet industry in Taiwan, with self-production, self-marketing, and self-managed distribution channels. It owns the largest chain of system kitchen cabinet stores in Taiwan, with about 92 outlets province-wide, and its products have penetrated over 73% of Taiwanese households, demonstrating its commitment to in-depth research into the lifestyle of kitchens in Taiwan. This case study investigates the company’s digital transformation project for system kitchen cabinets from 2019 to 2022, focusing on the transition from custom kitchen design to smart manufacturing processes.

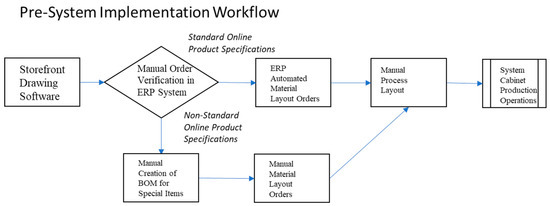

4.1. Operational Process before Implementation at the Case Company

Initially, the case company’s system involved using 3D drawing software coupled with manual ERP order entry. The operation process included the following:

Manual Verification of Orders: The personnel had to manually check order details. If the order corresponded to standard online specifications, it would be processed directly by manual entry, followed by manual layout and preparation for production.

Non-Standard Orders: For designs that did not meet standard online specifications, manual drafting of the Bill of Materials (BOM) was required. This involved resizing and annotating the material layout manually.

Compilation and Scheduling: After compiling all the material layouts, orders were manually scheduled.

Production: Finally, the orders were input into the system kitchen cabinet production operations.

This workflow is illustrated in Figure 7, showcasing a process that heavily relied on manual intervention from the receipt of an order to the production phase, indicating potential areas for improvement through digital transformation.

Figure 7.

Pre-implementation workflow of the case company.

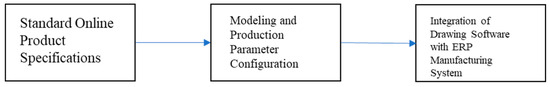

4.2. Construction of Smart Production Integration System

According to the system design framework of this study, an analysis and explanation of the smart production integration system based on the DFX model is conducted.

4.2.1. Phase One: System Cabinet Modeling Logic

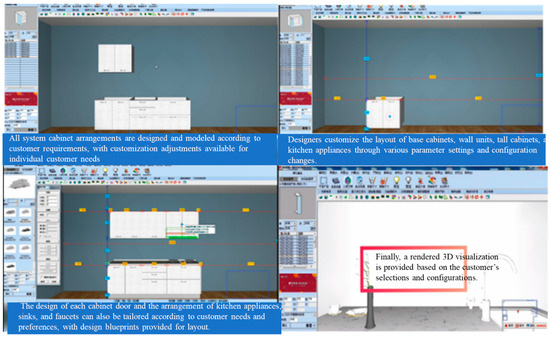

The custom drawing software is constructed using the system cabinet modeling logic, with precise modeling logic that synchronizes with the production logic to ensure that production parameters are interconnected, as shown in Figure 8.

Figure 8.

Custom drawing software and production modeling interface.

- (1)

- Over 10,000 online cabinet sizes are modeled, and dimensional parameters are set. This reduces the number of cabinet bodies to over 2000 standard units that can be adjusted according to size. These data are integrated into the custom drawing software to achieve custom drawing and ensure that production parameters are connected to manufacturing and assembly.

- (2)

- The system modeling supports flexible product design due to the varied custom order requirements, with the manufacturing system’s instant connection to smart production manufacturing.

- (3)

- All design links can be highly customized in real-time: designers, through different parameter settings and size adjustments, can dynamically generate virtual furniture. This is depicted in Figure 9.

Figure 9. Custom drawing software design simulation.

Figure 9. Custom drawing software design simulation.

- (4)

- The system instantly generates corresponding structural diagrams and related data reports, including material lists, hardware lists, cost accounting, hole positioning diagrams, and packaging list data linked to the production and manufacturing end for precise material arrangement and manufacturing.

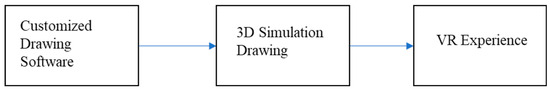

4.2.2. Phase Two: Storefront Simulation Scenario Drawing Process for Production Operations (Figure 10)

- (1)

- A virtual reality (VR) is generated in real-time for the customer, allowing them to preview and experience the product design details and structural layout. The precise modeling and design enable customers to browse the physical installation scenarios of the products, as illustrated in Figure 11.

Figure 10.

Drawing software interface with smart production operations.

Figure 11.

Custom drawing software-generated VR experience.

- (2)

- Through the storefront scenario drawing software, data are uploaded to the cloud at the storefront level, extending to the smart manufacturing system. The modeling operations directly interpret all product combinations, leading to the production of BOM tables, which then transition to smart manufacturing.

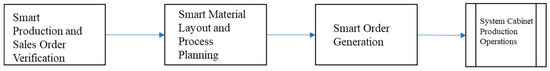

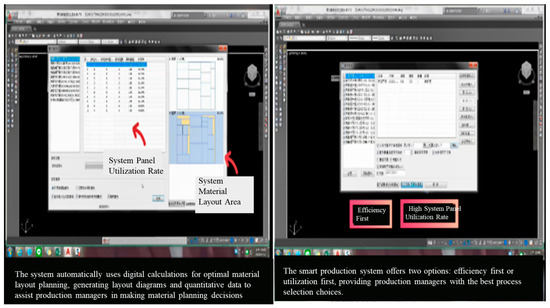

4.2.3. Phase Three: Smart Production Integration Operations as Depicted in Figure 12

- (1)

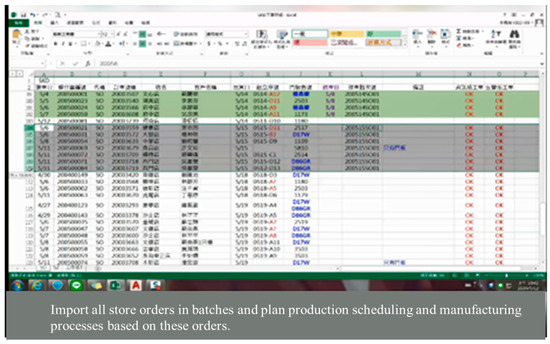

- Smart Production and Sales Order Verification: Production control personnel use the system to receive and review orders in real-time. Once the review is complete, optimal order scheduling is conducted using the Sakura system based on delivery deadlines, regions, etc. This is illustrated in Figure 13.

Figure 12.

Smart production integration process.

Figure 13.

Smart production and sales order verification.

- (2)

- Order Decomposition: After automatic order breakdown, Artificial Intelligence (AI technology) is applied to compute the best order combination, automatically calculating the most optimal material production or the fastest production mode, as shown in Figure 14.

Figure 14. Optimal production mode simulation.

Figure 14. Optimal production mode simulation.

- (3)

- Automatic Material Requisition: Material requisition, usage forms, and processing orders with QR codes for the materials are automatically generated. Each processing station can simply scan the code to retrieve the material information and processing instructions, thereby enhancing production efficiency.

- (4)

- Smart Production Line and Intelligent Layout: With zero layout errors, there is a reduction in material waste and an increase in production efficiency. Processing machines can flexibly adjust processing based on the characteristics of the materials and custom requirements.

- (5)

- Process Optimization: The system helps to eliminate redundant production processes, reduce production loss and product anomalies, and enhance on-time delivery capabilities. The aim is to achieve manufacturing precision and further improve production efficiency.

- (6)

- Production Control: By managing the production process via the system, batch production replaces the past practice of single-set production. This streamlined process shortens product delivery times by 30%, reduces the error rate, and creates a new production and supply model.

5. Research Findings and Discussion

5.1. Research Results

Based on the case company’s implementation of the custom kitchen design into smart manufacturing production plan, the research results are presented as follows in Figure 15:

Figure 15.

Research results.

- (1)

- Customized Design and Value of Customer Integrated Virtual and Physical Experience: Designers personally measure the actual dimensions of consumers’ kitchens and use a 3D design system to depict the future look of the kitchen based on family needs and habits. This integrated approach not only enhances the visual presentation but also significantly impacts key operational metrics in stores.

To quantitatively validate the effectiveness of this 3D design system, a statistical analysis was conducted across 96 stores, focusing on the following two primary metrics: average design days (representing design efficiency) and customer satisfaction (indicating customer experience quality). The results are summarized in Table 1.

Table 1.

Changes in average design days and customer satisfaction before and after 3D design system implementation.

- Average Design Days: Prior to the implementation of the 3D design software, the average time required for design completion across stores was 9.52 days (SD = 3.73). After adopting the system, this time decreased to 8.47 days (SD = 3.82). The paired sample t-test showed a t-value of 6.86 and a highly significant p-value of 7.08 × 10−10 (p < 0.001), confirming a statistically significant improvement in design efficiency

- Customer Satisfaction: Similarly, the system’s impact on customer satisfaction was notable. Before the system’s implementation, the average satisfaction score was 5.60 (SD = 1.70), which increased to 6.89 (SD = 1.65) after implementation. A paired sample t-test yielded a t-value of −12.27 and a p-value of 2.63 × 10−21 (p < 0.001), demonstrating a significant enhancement in customer satisfaction.

These results provide clear quantitative evidence of the 3D design system’s effectiveness. By allowing customers to visualize and engage with their future kitchen spaces more interactively, the system has shortened the design cycle and increased customer satisfaction.

- (2)

- Manufacturing Benefits of Automated Smart Production Integration System: With one-click ordering at the storefront, the manufacturing system groups orders based on order characteristics, schedules production, and automatically reviews and breaks down each order, calculating the best use of materials or the fastest production mode. The automatic generation of instructions, drawings, and documentation for machinery significantly improves production efficiency and reduces error rates.

- (3)

- Integrated System Benefits of Design, Production, and Quotation Capability: The system integrates production information to automatically calculate the materials, panels, parts used, instantly analyzes product quotes, and automates all operations, reducing manual order transfer, verification, and sales-production reconciliation.

- (4)

- Digital Transformation for Value Design: Differentiating from competitors, with realistic design outputs and in-store VR experiences, achieving design, production, and sales capabilities. Customers can experience their future kitchen directly in the store and proceed to purchase after the experience. For the system kitchen cabinet industry, this moves beyond price competition by offering home living proposals, enhancing industry value after digital transformation.

5.2. Research Contributions and Managerial Implications

From an academic perspective, the thinking behind smart production should extend to sales value. This study constructs a customer-centric smart production integration system, emphasizing the importance of digital transformation. Additionally, it interprets the value of digital transformation through the DFX methodology used by the case company, providing a reference for future qualitative research in DFX.

From a practical viewpoint, all innovations should have clear indicators and strategic implications, not just transformation for the sake of transformation or innovation for the sake of innovation. This study constructs a system integration with DFX thinking, clarifying innovation goals and performance indicators, embodying the value of introducing smart production, and focusing on customer orientation to maximize value and minimize costs, allowing enterprises to reflect the significance and value of their resource investment.

From an industry perspective, the system kitchen cabinet industry sells not just a product but a process, a completely customized product and service that involves on-site assembly. All related parts must be precise and in place at once. Any shortage or size error necessitating second-time construction not only prevents cancelling the order and collecting payment but also reduces customer satisfaction due to the lengthy process of supplying and redoing. By applying DFX thinking and customer-centric integration into smart production systems, one can achieve design visualization through virtual reality (VR) and 3D technology at the store level. Furthermore, connecting the sales end with the manufacturing end and using AI to autonomously determine optimized production scheduling based on order type and features can significantly shorten operation time from design to final kitchen installation, enhancing the value of the bi-directional operational process from production to sales.

5.3. Research Limitations and Future Research Suggestions

The focus of this study is on the construction of a customized drawing software integrated into a smart production system and its benefits and value, expressed qualitatively through DFX, without specific quantitative data. The emphasis is on presenting a feasible system framework and model through qualitative research. Future scholars may conduct more concrete quantitative evaluations of benefits using ABC (Activity-Based Costing) and ABM (Activity-Based Management) to provide a more credible basis for transformation value.

Moreover, this study’s primary goal is to construct an integrated system model and highlight its value to sales and production to demonstrate the benefits of transformation. It does not delve deeply into the technical and information communication structures of the smart production integration system. Future scholars can further research technical feasibility, providing practical reference significance for those interested in venturing into this field.

Author Contributions

Methodology, W.-J.H.; Validation, W.-J.H.; Data curation, L.-H.L.; Writing—original draft, W.-J.H.; Writing—review & editing, Y.-J.H.; Supervision, L.-H.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author due to (specify the reason for the restriction).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sun, X.; Ji, X. Integrated kitchen design and optimization based on the improved particle swarm intelligent algorithm. Comput. Intell. 2020, 36, 1638–1649. [Google Scholar] [CrossRef]

- Antonova, A. Smart services as scenarios for digital transformation. Industry 4.0 2018, 3, 301–304. [Google Scholar]

- Bralla, J.G. Design for Excellence; McGraw-Hill Professional Publishing: New York, NY, USA, 1996. [Google Scholar]

- Chiu, M.C.; Okudan, G.L.E. Evolution of design for X tools applicable to design stages: A literature review. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Montreal, QC, Canada, 15–18 August 2010; Volume 44144, pp. 171–182. [Google Scholar] [CrossRef]

- Benabdellah, A.C.; Benghabrit, A.; Bouhaddou, I.; Benghabrit, O. Design for relevance concurrent engineering approach: Integration of IATF 16949 requirements and design for X techniques. Res. Eng. Des. 2020, 31, 323–351. [Google Scholar] [CrossRef]

- Ulrich, K.T.; Ellison, D.J. Holistic customer requirements and the design-select decision. Manag. Sci. 1999, 45, 641–658. [Google Scholar] [CrossRef]

- Wechsler, J.; Schweitzer, J. Creating customer-centric organizations: The value of design artefacts. Des. J. 2019, 22, 505–527. [Google Scholar] [CrossRef]

- Bhavnani, R.; Sosa, M. IDEO: Service Design (A&B); INSEAD Case Study; INSEAD: Fontainebleau, France, 2006; Volume 11, pp. 2006–5276. [Google Scholar]

- Weiss, L. Developing tangible strategies. Des. Manag. J. Former Ser. 2002, 13, 33–38. [Google Scholar] [CrossRef]

- Kang, J.Y.M. Customer interface design for customer co-creation in the social era. Comput. Hum. Behav. 2017, 73, 554–567. [Google Scholar] [CrossRef]

- Koomsap, P. Design by customer: Concept and applications. J. Intell. Manuf. 2013, 24, 295–311. [Google Scholar]

- Gentile, C.; Spiller, N.; Noci, G. How to sustain the customer experience: An overview of experience components that co-create value with the customer. Eur. Manag. J. 2007, 25, 395–410. [Google Scholar] [CrossRef]

- Verhoef, P.C.; Lemon, K.N.; Parasuraman, A.; Roggeveen, A.; Tsiros, M.; Schlesinger, L.A. Customer experience creation: Determinants, dynamics, and management strategies. J. Retail. 2009, 85, 31–41. [Google Scholar] [CrossRef]

- Gitman, L.J.; Carl, M.D. The Future of Business: The Essentials; South-Western College Publishing: Cincinnati, OH, USA, 2005. [Google Scholar]

- Jiao, J.R.; Zhang, Y.; Helander, M. A Kansei mining system for affective design. Expert Syst. Appl. 2006, 30, 658–673. [Google Scholar] [CrossRef]

- Zhou, J.; Li, P.; Zhou, Y.; Wang, B.; Zang, J.; Meng, L. Toward new-generation intelligent manufacturing. Engineering 2018, 4, 11–20. [Google Scholar] [CrossRef]

- Naiju, C.D. DFMA for product designers: A review. Mater. Today Proc. 2021, 46, 7473–7478. [Google Scholar] [CrossRef]

- Hoque, A.S.M.; Halder, P.K.; Parvez, M.S.; Szecsi, T. Integrated manufacturing features and Design-for-manufacture guidelines for reducing product cost under CAD/CAM environment. Comput. Ind. Eng. 2013, 66, 988–1003. [Google Scholar] [CrossRef]

- Shehab, E.M.; Abdalla, H.S. Manufacturing cost modeling for concurrent product development. Robot. Comput.-Integr. Manuf. 2001, 17, 341–353. [Google Scholar] [CrossRef]

- Roto, V.; Heikkila, M. Design for value in a digital supply chain ecosystem. In Proceedings of the ACM Conference on Designing Interactive Systems, Edinburgh, UK, 10–14 June 2017. [Google Scholar]

- Xie, S.Q.; Zhou, Z.D. Internet-based DFX for rapid and economical tool/mould making. Int. J. Adv. Manuf. Technol. 2004, 24, 821–829. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).