Abstract

Stress is a critical concern in manufacturing environments, as it impacts the well-being and performance of workers. Accurate measurement of stress is essential for effective intervention and mitigation strategies. This paper introduces a holistic and human-centered protocol to measure stress in manufacturing settings. The three-phased protocol integrates the analysis of physiological signals, performance indicators, and the human perception of stress. The protocol incorporates advanced techniques, such as electroencephalography (EEG), heart rate variability (HRV), galvanic skin response (GSR), and electromyography (EMG), to capture physiological responses associated with stress. Furthermore, the protocol considers performance indicators as an additional dimension of stress measurement. Indicators such as task execution time, errors, production rate, and other relevant performance metrics contribute to a comprehensive understanding of stress in manufacturing environments. The human perception of stress is also integrated into the protocol, recognizing the subjective experience of the individual. This component captures self-assessment and subjective reports, allowing for a more nuanced evaluation of stress levels. By adopting a holistic and human-centered approach, the proposed protocol aims to enhance our understanding of stress factors in manufacturing environments. The protocol was also applied in the automotive industry and plastic component manufacturing. The insights gained from this protocol can inform targeted interventions to improve worker well-being, productivity, and overall organizational performance.

1. Introduction

The well-being of workers is a central pillar of Industry 5.0 [1]. When introducing new technologies into the manufacturing industry, it is crucial for developers to assess the extent to which the proposed system satisfies individual, collective, and production needs [2]. Technological advancements have predominantly driven industrial transitions [3], resulting in economic growth as well as increased social and environmental challenges [1]. Concerns regarding the health and safety of workers have intensified [4], particularly due to the introduction of new stressors, such as worker displacement or complete replacement by emerging technologies [5].

Peruzzini et al. [6] revealed that a range of incorrect movements during task execution directly increases a worker’s exposure to risk. These movements include the manual handling of heavy loads, improper postures between different tasks, a high mental workload, and stressful conditions induced by time pressure or unexpected events. Effective control and management of these risk factors, including uncomfortable body positions, repetitive tasks, and elevated stress levels, provide companies with the ability to avert accidents, enhance production efficiency, promote the psychosocial well-being of employees, and ultimately realize substantial cost savings by minimizing rejection rates and associated costs [6]. In addition, excessive stress from work may cause mental or physical ailments, such as anxiety, depression, heart disease, and gastrointestinal disorders. These conditions can cause employees to take more sick days, leave their jobs at a higher rate, and experience decreased productivity and job satisfaction [7,8,9,10,11].

Consequently, the analysis of workers’ stress has gained significant importance due to its profound impact on employee well-being, productivity, and organizational effectiveness [12]. Such analysis is crucial to the development of solutions that effectively mitigate stress and concurrently enhance a company’s productivity and efficiency.

Perceived work stress, as defined by the World Health Organization (WHO), pertains to the array of responses individuals experience when confronted with job limitations and pressures that are incongruent with their skills and capabilities [13]. Seyle [14] classified stress into two distinct categories: positive stress and negative stress. Positive stress, often referred to as eustress or beneficial stress, is typically experienced briefly and serves as a motivational force, enhancing concentration, bolstering employees’ coping mechanisms, generating enthusiasm, and ultimately fostering improved performance. In contrast, negative stress—also termed distress or unfavorable stress—can result in feelings of anxiety, a sense of ineffectiveness, and mental or physical issues. This type of stress has the potential to diminish performance in both the short and long term [15].

The discourse on stress extends beyond individual attributes. Organizational and environmental factors also impact work-related stress and have implications for health and productivity. In this regard, an exploration of stress’s intricate manifestations, which encompass physiological, psychological, and behavioral dimensions, can provide crucial insights into its effects in the workplace [15]. Chronic stress has significant repercussions, manifesting as adverse physiological and cognitive changes, which underscore the necessity of comprehensive strategies to mitigate stress-related health and productivity challenges [15].

Brunner et al. [16] conducted an extensive investigation into stress factors and their effects on health-related productivity losses in work environments. Their approach introduces a novel perspective that considers both task-related and social stressors and highlights the potential adverse impact of social stressors on employee well-being. Within the context of the manufacturing industry, the experience of stress assumes particular significance, shaping both short-term and long-term dynamics. Operating within a dynamic and fast-paced milieu, the manufacturing sector often faces high-pressure demands and intricate production processes. Short-term stressors in this context may encompass stringent production timelines, complex operational tasks, and volatile market demands, all of which are capable of eliciting acute stress responses among employees. While short-term stress can confer a temporary surge in motivation and focus, prolonged exposure to such stressors without adequate recovery periods can lead to negative health outcomes, thereby impeding overall productivity.

Conversely, long-term stress in the manufacturing industry often emerges from persistent challenges, such as repetitive tasks, occupational hazards, and elevated physical demands. These enduring stressors may culminate in cumulative physiological strain, resulting in adverse health conditions and heightened absenteeism over time. Furthermore, the unrelenting pressure to meet production targets and sustain quality standards can contribute to sustained distress, ultimately eroding both employee well-being and organizational performance.

The existing literature reveals gaps primarily attributed to the limited exploration of the stress phenomenon in relation to other investigated human factors, as well as the lack of uniformity between stress evaluation methods [6,17]. Furthermore, the introduction of innovative technologies within work environments brings about changes in production tasks, which, when combined with environmental factors and the demographic profile of workers, impact the potential sources of stress. It becomes imperative to thoroughly analyze and evaluate these factors by comparing various stress measurement methods.

To the authors’ knowledge, there is a lack of common references and structured protocols for stress assessment specifically tailored to industrial workers [17]. While the concept of stress assessment is well-recognized, its application within industrial settings requires a unique approach that considers the distinct stressors and demands inherent in these environments. Without standardized protocols, accurate and reliable evaluation of workers’ stress levels becomes arduous, hindering the development of targeted interventions and effective management strategies.

Therefore, there is a critical need for the establishment of comprehensive and context-specific assessment protocols to better understand and address the stress experienced by industrial workers. Such protocols would enable organizations to identify stressors, evaluate their impact, and implement appropriate measures to promote worker well-being, enhance productivity, and foster a healthier work environment. This paper aims to contribute to this pressing need by presenting an experimental protocol for human stress investigation in manufacturing contexts, with a specific application in the NO-STRESS project.

The present study was focused on the examination of stress within working environments in the manufacturing industry. More specifically, it aimed to develop a comprehensive framework for stress analysis and an advanced technological infrastructure for monitoring the levels of human stress and comfort. Employing a human-centered approach, this research sought to evaluate industrial workplaces in a holistic manner. Protocol analysis was utilized to define key evaluation metrics and provide guidance for data collection, while a sophisticated human monitoring system was employed to gather data on both mental and physical stress experienced by individuals in real-life work settings.

The rest of this paper is structured as follows: Section 2 offers a research background, outlining the existing literature on work-related stress and its assessment. Section 3 presents the theoretical foundations and taxonomy of factors that influence stress in manufacturing environments, establishing a conceptual framework. Section 4 focuses on the research protocol, encompassing ethical considerations, participant recruitment, and task execution. Section 5 engages in a thorough discussion of the findings, and lastly, Section 6 provides the conclusions.

2. Research Background

In the context of an evolving industrial landscape driven by Industry 5.0, which places human experiences and technological integration at its core, the exploration of work-related stress becomes increasingly significant. This section delves into the intricate interplay between human-centered manufacturing, the challenges posed by work-related stress, and the methodologies employed to measure and understand stress dynamics within the industrial context.

2.1. Human-Centered Manufacturing Industry

The emergence of Industry 5.0 signifies a milestone in the industrial revolution, bringing about transformative changes to the manufacturing sector. As technology continues to advance, adopting a human-centered approach becomes imperative to effectively address the challenges and opportunities presented in this new era [18]. Industry 5.0 places human needs, preferences, and experiences at the forefront of industrial design and production. Unlike previous revolutions, this paradigm acknowledges the crucial integration of technology with human factors to achieve sustainable and inclusive industrial systems [1,2]. Prioritizing a human-centered approach allows us to tackle the negative environmental and social impacts associated with traditional industrial systems and foster the development of equitable and sustainable practices [19].

Industry 5.0 brings forth a new wave of digital transformation, revolutionizing manufacturing processes and operations. However, it also reveals the existence of a digital divide characterized by differences in access, generational gaps, cognitive disparities, and gender imbalances. Addressing this digital divide becomes essential to ensure that all workers can effectively navigate and leverage the technological advancements associated with Industry 5.0. Enhancing technological familiarization among workers is crucial to harness the full potential of digital tools and technologies in the manufacturing environment and maximize their benefits [20].

In this sense, design plays a pivotal role in shaping the future manufacturing industry, where products are seen as platforms for service experiences and functionalities. Designing for human factors and user experiences becomes paramount for creating an environment that promotes worker well-being, productivity, and job satisfaction. Employing design thinking methodologies and tools allows for addressing the diverse needs and preferences of workers and improving the overall industrial experience [21].

Achieving a comprehensive understanding of workers is fundamental to promoting their well-being and optimizing their performance. This understanding encompasses cognitive processes, ergonomic requirements, and emotional well-being. Stress-related indicators, such as workers’ thoughts, actions, and emotions, provide valuable insights into their experiences. By identifying and addressing these indicators, manufacturers can create a safe and supportive work environment that enhances worker satisfaction, motivation, and engagement. Understanding and mitigating work-related stress is essential for fostering a positive work environment and improving overall productivity [17].

According to Romero et al. [22], Operator 4.0 refers to the development of future factory work toward knowledge work, which is more demanding but also more enriched and flexible. It involves the use of human cyber-physical systems and adaptive automation toward human–automation symbiosis work systems. The goal of Operator 4.0 is to increase work well-being by carefully designing future factory tools and work practices from the worker’s point of view. The design of Operator 4.0 solutions should prioritize individual worker perspectives, ensuring that new work tools and practices contribute to meaningful, motivating, and engaging tasks. The approach by Kaasinen et al. [23] aims to enhance work well-being and yield company benefits. To achieve this, a comprehensive framework was developed to guide the design, evaluation, and impact assessment of these solutions. Their framework focuses on antecedents, immediate implications, and impacts. Antecedents encompass the work environment, organization, and worker characteristics. Immediate implications pertain to workers’ experiences with new tools and practices. Impacts, which include work well-being and company benefits, are assessed through positive indicators like job satisfaction, work engagement, and motivation. The design and evaluation process involves gathering feedback from users during piloting and subsequently assessing company-level benefits.

While the transition from Operator 4.0 to Operator 5.0 is anticipated, it is important to acknowledge that both paradigms are currently in developmental stages [24]. On the other hand, the concept of the “Healthy Operator 4.0” category arose as part of the broader Operator 4.0 framework [22] as a direct response to growing apprehensions regarding the escalating levels of stress among the workforce and the overall state of psychological and social well-being [25,26,27] and empowerment [28]. It involves integrating data from wearable technologies, the Internet of things (IoT), ambient intelligence, and modeling techniques to create a digital twin of the operator.

In the context of assessing worker well-being, a comprehensive overview was presented by Wijngaards et al. [29] that encompassed conventional methodologies such as surveys and interviews, as well as innovative approaches like wearable sensors, for evaluating workers’ well-being. The authors categorized these assessment sources into four distinct types: closed-question surveys, word-based analyses, behavioral observations, and physiological measurements. Further differentiation was made between unobtrusive, reaction-based obtrusive, and observation-based obtrusive methods.

Diener [30] articulated the constituents of subjective well-being, highlighting the inclusion of long-term levels of positive affect, absence of negative affect, and overall life satisfaction. Although self-report measures have demonstrated validity and reliability, emerging methodologies in the field point toward more advanced and diversified techniques. Drawing from advancements in psychology, a multimethod approach to appraising subjective well-being was proposed to yield a more holistic representation of this phenomenon [30].

The knowledge about users’ needs and ergonomics is fundamental to optimizing workers’ well-being, working conditions, and industrial results [31]. Khamaisi et al. [31] presented a strategic framework for evaluating worker experience, emphasizing a human-centric perspective within industrial settings to enhance overall sustainability. Employing wearable devices, such as eye-tracking technology, electrocardiograms, and electrodermal activity monitoring, they collected physiological data and paired it with subjective self-assessments, utilizing the NASA-TLX questionnaire. This comprehensive strategy allowed for the monitoring of human activities within virtual reality environments and facilitated a deeper understanding of worker well-being and its implications on industrial outcomes.

In light of the rapidly evolving landscape ushered in by Industry 5.0 and the growing emphasis on human-centricity, it becomes evident that a standardized protocol for measuring stress in manufacturing contexts is not just a convenience, but an imperative need. The profound integration of technology and human factors in Industry 5.0 underlines the urgency of comprehensively assessing the well-being of workers. While the transition from Operator 4.0 to Operator 5.0 holds promise, the developmental stages of both paradigms underscore the critical role of addressing stress-related challenges.

2.2. Work-Related Stress Measurement in the Industrial Context

The concept of work-related stress is widely researched [17]. The most commonly accepted definition for this phenomenon derives from the cognitive model and suggests that it is due to a missing balance between job demands and the ability of workers to execute them [32] and it is affected by the social and organizational context where subjects operate [33].

The effects of stress on workers’ well-being are not limited in time. Indeed, this phenomenon has long-term consequences on an employee’s physical health, such as heart disease and chronic pain, and on psychological health since it leads to persistent anxiety and depression [34].

As a consequence, workers’ turnover and absenteeism due to stress-related disorders affect a company’s productivity, increasing costs. In addition, higher stress levels increase the probability of negative stress consequences, such as accidents and errors, leading to decreased efficiency in the workplace [32]. Finally, the literature still lacks details about work-related stress; therefore, further research and new solutions have to be developed to improve the health status of workers and mitigate the impact on companies.

In the existing literature, there are only a few studies that have specifically looked into the topic of work-related stress measurement in industrial or manufacturing environments [17]. These studies often dive deep into examining a particular method or tool for assessing stress, and they suggest specific ways to design solutions in this context [17]. Rescio et al. [35] introduced a novel heterogeneous multi-sensory hardware–software architecture devised to facilitate the automated detection of stress conditions and is particularly tailored for applications within industrial environments. The authors adopted a dual-pronged approach that encompasses distinct sensor categories, namely, ambient and wearable sensors, thus orchestrating a versatile and efficient monitoring mechanism that is adaptable to diverse contextual demands. This strategic configuration ensures continued operability in instances of sensor incapacitation or malfunction. In the domain of wearable sensors, Rescio et al. [35] meticulously devised a specialized system to facilitate unobtrusive monitoring while mitigating perturbations arising from motion artifacts. On the ambient sensor facet, a judicious selection criterion centered on accessibility and affordability was employed, resulting in the choice of readily accessible and economical technology. Notably, the study undertook an evaluative consideration of cardiac activity, electrodermal activity, and RGB signals, collectively forming a robust framework for the evaluation of psychophysical conditions.

The human stress indicators most commonly adopted to study this phenomenon in manufacturing contexts can be separated into objective and subjective categories. The former includes indicators calculated on the basis of workers’ physiological signals since they monitor the biological and unconscious processes of individuals, which are not influenced by personal perceptions and feelings. On the other hand, the subjective category consists of stress indicators, which refer to the psychological perception of stress and the emotional states of workers.

In literature, physiological processes, such as skin sweating, cardiac and brain activity, and respiration, are the most frequent processes observed for stress assessment. The electrodermal activity (EDA) technique is commonly adopted for evaluating stress in terms of dermal sweat levels [36], where skin conductance is the most used indicator related to this technique for measuring stress levels [37,38]. In this sense, Sriramprakash et al. [39], Anusha et al. [40], and Vila et al. [41] used the galvanic skin response (GSR) as an equivalent to EDA for stress evaluation. On the other hand, the electrocardiogram (ECG) technique allows for the monitoring of the electrical activity of the heart, where the two derived stress indicators are heart rate (HR) and heart rate variability (HRV), which depend on the time between two successive beats and the variability of this period [37,42]. The scientific validity of stress detection through HRV assessment is substantiated by neurobiological evidence [43]. Nevertheless, Tran et al. [44] suggested that HRV does not fully reflect the work-content-related stress during work, and it is problematic to measure the effect of work-content-related stress on HRV in the real manufacturing environment. Tran et al. [44] stated that since HRV strongly depends on too many factors (e.g., work context, individual physical and mental status), its real-time usage for stress monitoring can be problematic. They emphasized the need for more comprehensive studies to distinguish work-related stress from typical stress types, as existing studies lacked solid scientific conclusions about the relationship between work-related stress and HRV [44]. In the literature, authors such as Zhang et al. [45], Sriramprakash et al. [39], Anusha et al. [40], and Vila et al. [41] used ECG to measure work-related stress.

The electroencephalogram (EEG) technique monitors brain activity by tracking the electrical signals generated by neurons. The frequency range of the signal recorded through this technique is from 0.5 to 45 Hz, and specifically, the frequency band between 23 and 38 Hz is most significantly affected by stress [46]. In the end, variations in respiratory frequency are estimated as a physiological indicator of work-related stress [6].

In contrast, the psychological assessment of stress relies on the subjects’ responses to questionnaires, which investigate their feelings, perceptions, and emotions related to a specific task execution. In the literature, standard questionnaires for the investigation of work-related stress can be found. The National Aeronautics Space Administration Task Load Index (NASA-TLX) is traditionally adopted and aims to investigate an individual’s perception of comfort [42]. On the other hand, the Subjective Workload Assessment Technique (SWAT) investigates time and mental load in addition to the feeling of psychological stress [47], while the Perceived Stress Scale (PSS) and the Short State Questionnaire (SSSQ) investigate stress by asking individuals to express the frequency of positive and negative feelings related to the executed task [48,49]. These questionnaires are frequently filled in both during and after the conclusion of a complete task cycle in order to assess how respondents’ perceptions have evolved over time.

Finally, stress monitoring is a complex practice in industrial contexts and the measurements are affected by some limitations. First of all, physiological data collection is conducted through wearable biometric devices, which could make the participant uncomfortable, negatively impacting the psychological state of the individual while performing the activity. On the other hand, individuals’ feelings and emotions have impacts on human biological processes that are beyond their direct control, affecting physiological stress assessments as well. Therefore, Peruzzi et al. [42], Panchetti et al. [49], and Caterino et al. [50] combined the psychological results with physiological evaluations in order to validate the findings through cross-analysis of the different signals and data collected improving the accuracy of the estimation.

3. Taxonomy of Factors Shaping the Manufacturing Context and Theoretical Foundations for the Stress Measurement

The manifestation of work-related stress is subject to a multitude of intricate and interconnected factors, collectively shaping a complex matrix of interactions. Hence, for an accurate quantification of an individual’s stress experience, a holistic understanding of their entire contextual framework becomes imperative. In pursuit of this objective, the following section introduces the human–task–context taxonomy, accentuating the essentiality of comprehending the dynamic interplay encompassing the individual, the task at hand, and the contextual milieu. This comprehension is deemed foundational, establishing a requisite foundation for precise stress assessment. Moreover, this segment presents a diverse array of metrics tailored for evaluating stress levels. Notably, the significance of context remains paramount, functioning as a guiding compass for the judicious selection of the most suitable metric and facilitating a nuanced interpretation of its resultant findings.

3.1. Human–Task–Context Taxonomy

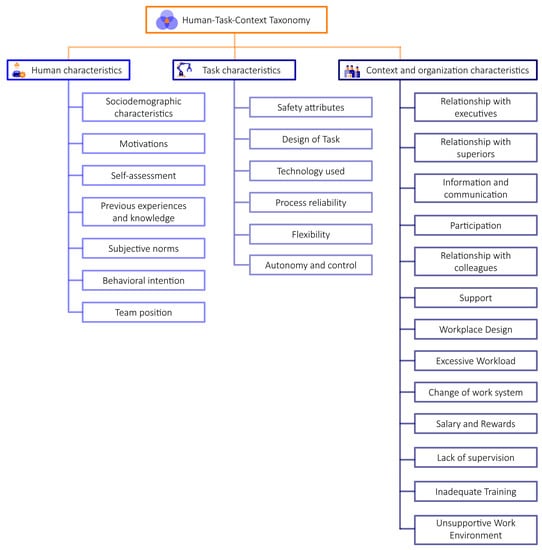

The effective measurement and understanding of stress in manufacturing contexts are key for enhancing operator well-being, productivity, and overall organizational success. This section seeks to comprehensively examine the complex interplay among human operators, tasks, and the contextual and organizational factors that contribute to stress experiences in manufacturing environments, which are shown in Figure 1. Additionally, this section establishes a theoretical foundation for stress measurement, which serves as the basis for the subsequent description of the protocol.

Figure 1.

The human–task–context taxonomy.

3.1.1. Human Characteristics

Individual characteristics of the person play a crucial role in the way in which such interaction is established and the way the stress is perceived. To start with, socio-demographic characteristics, such as gender, age, and level of education, influence human expectations, skills, social norms, and preferences. In this sense, understanding the sociodemographic background of a person can provide valuable insights into the unique stressors and coping mechanisms operators may encounter. Motivation serves also as a driving force behind operators’ engagement in their tasks and influences their ability to cope with stress. By assessing operators’ motivation levels, researchers and practitioners can gain insights into their commitment, resilience, and willingness to adopt stress management strategies. This knowledge is instrumental in designing interventions tailored to individual needs. On the other hand, self-assessment, referring to the individual’s control beliefs regarding their ability to perform a task [51], is an important concept that affects how workers perceive their ability to adapt to new situations or find new occupations. It is mostly addressed by the concept of self-efficacy [52]. This aspect considers the fact that workers not only have to deal with new technology at work but with the whole change process. Previous experiences and knowledge also influence stress. The role of experiences and knowledge in the acceptance of technologies can be complex and multifaceted. While positive experiences can enhance robot acceptance and use, negative experiences, such as an inability to interact with technology due to skill impairment, can have the opposite effect, leading to more stress.

Subjective social norms reflect operators’ perceptions of social expectations and norms regarding stress management also influence stress perception. By understanding how operators perceive societal, organizational, and cultural pressures, researchers can tailor interventions to promote adaptive stress management behaviors. Adhering to positive subjective norms can enhance operators’ well-being and foster a supportive work environment. Operators’ behavioral intentions are crucial in enhancing their well-being. Assessing their readiness and inclination to engage in stress management strategies, seek support, and adopt self-care practices can inform intervention design.

Team position can have a significant impact on workers’ attitudes toward a task. According to Meissner et al. [52], workers in leadership positions with additional responsibilities beyond assembly tasks tend to view the robot as an opportunity to familiarize themselves with innovative technology. Conversely, those solely responsible for assembly may feel threatened by the introduction of a robot, as it may lead to job displacement and a loss of occupational security. These divergent perspectives highlight the importance of considering workers’ roles and responsibilities in the workplace.

3.1.2. Task Characteristics

Within manufacturing contexts, task characteristics play a significant role in influencing the stress levels experienced by operators. This section explores key task-related factors that contribute to the overall stress in such environments.

To start with, safety considerations are paramount in manufacturing environments and have a direct impact on the stress experienced by operators. Hazards, potential accidents, and the presence of risky conditions can significantly contribute to heightened stress levels. Ensuring a safe work environment, implementing appropriate safety measures, and providing adequate training and resources are essential for minimizing stress related to safety concerns.

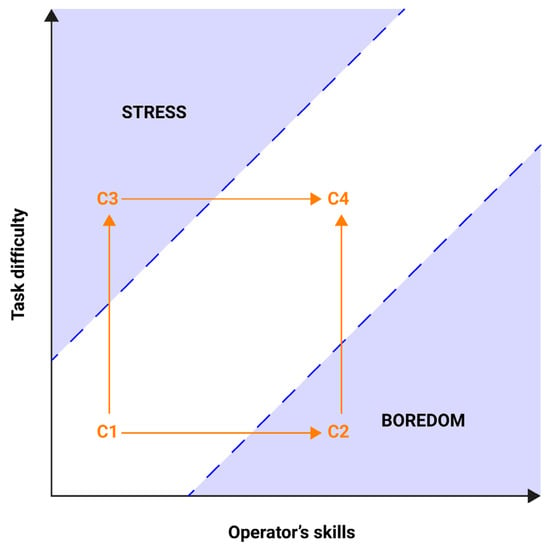

Then, the design of tasks and work processes can influence stress levels among operators. Poorly designed tasks that involve excessive physical exertion, repetitive motions, or time pressure can contribute to increased stress and the risk of musculoskeletal disorders. Conversely, well-designed tasks that optimize ergonomics, minimize physical strain, and provide clear instructions and feedback can reduce stress levels and enhance operator well-being. The design of a task is a critical factor in the relationship between operator skills and task difficulty. In Figure 2, the X-axis represents operator skill and the Y-axis represents task difficulty. We can analyze how these two elements are related and how they can influence the level of stress experienced by the operator. When the task is easy and the operator’s skill level is low, it can be considered an optimal situation (C1). The operator can perform the task efficiently and without difficulties, which does not generate significant stress. On the other hand, if the task is easy but the operator’s skill level is high, a feeling of boredom may arise (C2). The operator may find the task monotonous or unchallenging due to their superior skills, leading to a decrease in motivation and a sense of tedium. When the task is difficult and the operator’s skill level is low (C3), a significant level of stress is likely to occur. The operator may feel overwhelmed by the task’s difficulty and experience difficulties in effectively completing it. This situation can generate anxiety, frustration, and a higher level of stress. However, if the task is difficult but the operator’s skill level is high (C4), it can be considered an acceptable situation. Although the task presents a challenge, the operator has the necessary skills to cope with it and overcome it effectively. In this situation, the operator may feel competent and experience a manageable level of stress. Therefore, as the operator’s skills and capabilities improve, it is necessary and beneficial to correspondingly increase the complexity and difficulty level of the task. However, it is crucial to strike a balance and avoid excessive increments in task difficulty, as this can lead to heightened stress levels. Finding the optimal level of challenge ensures a productive and motivating environment for the operator’s ongoing skill enhancement.

Figure 2.

Flow channel when designing tasks in the manufacturing industry. Adapted from [53].

The integration of technology within the manufacturing process has the potential to influence stress levels among operators. The impact can vary depending on the type of technology employed, such as machine tools, robotic arms, or automated systems. Also, the process reliability of manufacturing processes has a significant impact on operator stress levels. Unreliable processes characterized by frequent breakdowns, equipment malfunctions, or unpredictable delays can create a stressful work environment. Conversely, stable, and well-maintained processes that operate smoothly and consistently can reduce uncertainty and enhance operator confidence, thereby lowering stress levels. On the other hand, the level of flexibility afforded to operators in performing their tasks can influence their stress levels. Highly rigid and inflexible task structures may limit autonomy, hinder problem-solving abilities, and increase stress. Conversely, tasks that allow for some degree of flexibility in decision-making, resource allocation, and problem-solving can empower operators and reduce stress levels.

The degree of autonomy and control that operators have over their work processes can impact their stress levels. A lack of autonomy, micromanagement, and limited decision-making authority can increase feelings of stress and frustration. On the other hand, granting operators a sense of autonomy and control over their tasks, such as allowing them to make decisions and participate in process improvement initiatives, can contribute to reduced stress levels and increased job satisfaction.

3.1.3. Context and Organizational Characteristics

The work environment and organizational factors within manufacturing contexts play a significant role in influencing stress levels among workers. This section examines various factors that can impact stress levels and operator well-being.

The nature of the relationship between operators and executives within the organizational hierarchy can influence stress levels. A supportive and open relationship characterized by effective communication, mutual respect, and trust can contribute to a positive work environment, reducing stress levels. Conversely, a lack of communication, limited involvement in decision-making processes, or perceived unfair treatment can elevate stress levels among operators. The relationship between operators and their immediate supervisors also plays a crucial role in determining stress levels. Supportive and understanding superiors who provide clear instructions, feedback, and guidance can foster a positive work environment and mitigate stress. Conversely, unsupportive or authoritarian leadership styles, lack of recognition, or inconsistent feedback can contribute to increased stress levels among operators.

The availability of accurate and timely information, as well as effective communication channels, is vital for reducing stress in manufacturing contexts. Transparent communication about work expectations, changes in procedures, and organizational updates can minimize uncertainty and facilitate a sense of control, thereby reducing stress levels. Inadequate or unclear communication, on the other hand, can lead to confusion, misinterpretation, and increased stress among workers.

Moreover, opportunities for active participation and involvement in decision-making processes can empower operators and enhance their sense of control over their work environment. Participatory approaches that value worker input, ideas, and suggestions can foster a positive work environment and reduce stress levels. Conversely, a lack of participation, exclusion from decision-making processes, or disregard for worker perspectives can contribute to feelings of powerlessness and increased stress.

Relationships with colleagues also play a key role. Positive relationships between colleagues, characterized by mutual support, teamwork, and camaraderie, can create a supportive work environment and buffer against stress. Strong social support networks within the workplace can provide emotional and practical assistance during challenging situations. Conversely, conflict, interpersonal issues, or a lack of support from colleagues can contribute to increased stress levels among workers.

Adequate support mechanisms within the organization, such as employee assistance programs, counseling services, or access to resources for managing stress, can contribute to a healthier work environment. Providing support for workers facing personal or work-related challenges can help to alleviate stress and promote well-being.

The physical design of the workplace can also impact stress levels. Factors such as noise levels, lighting, ergonomics, and the availability of rest areas or relaxation spaces can influence operator well-being. A well-designed and comfortable work environment that promotes safety, comfort, and productivity can contribute to lower stress levels among workers.

High work demands, such as an excessive workload or unrealistic production targets, can lead to chronic stress among operators. Finding a balance between workload and available resources is crucial for maintaining a healthy work environment and preventing burnout. Implementing changes in work systems, such as new procedures or technologies, can introduce uncertainty and disrupt established routines, potentially leading to increased stress levels. Proper planning, communication, and support during times of change are essential for minimizing stress and facilitating a smooth transition. Regarding salary, the adequacy of compensation and recognition for the work performed can impact stress levels. Fair and competitive salary structures, along with appropriate recognition and rewards, can contribute to job satisfaction and reduce stress related to financial concerns.

Insufficient supervision or a lack of clear guidance can create ambiguity and contribute to stress among workers. Adequate supervision, feedback, and support from supervisors are important for clarifying expectations, providing guidance, and ensuring that workers feel supported and valued. Also, insufficient training and development opportunities can lead to feelings of incompetence, anxiety, and stress among operators. Providing comprehensive and ongoing training programs that address skill gaps and equip workers with the necessary knowledge and competencies is crucial for reducing the stress associated with inadequate training. A work environment that lacks support, recognition, and resources can be a significant source of stress for operators. Organizations should strive to create a supportive culture that values employee well-being, provides resources for managing stress, and promotes a healthy work-life balance.

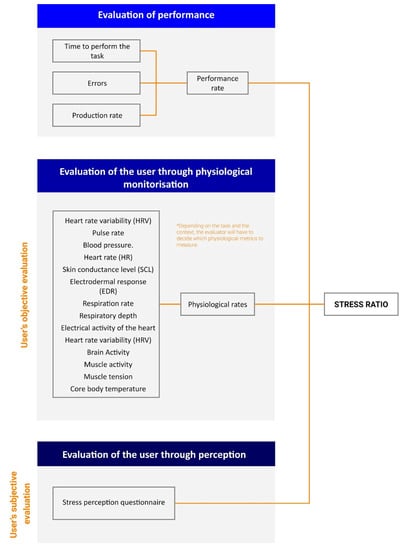

3.2. Stress Measurement

In order to effectively measure stress in manufacturing contexts and enhance operators’ well-being, a comprehensive approach is employed. This section outlines the three main blocks utilized for stress measurement, namely, the evaluation of performance, physiological monitoring, and the use of a stress perception questionnaire, as shown in Figure 3. Together, these blocks provide valuable insights into the stress ratio experienced by operators.

Figure 3.

Theoretical foundations for the experimental protocol.

By integrating these three blocks of stress measurement, the research protocol provides a holistic assessment of stress levels and their impact on operators in manufacturing environments. The combination of objective performance evaluation, physiological monitoring, and subjective stress perception questionnaires allows for a multidimensional understanding of stress, enabling the development of targeted interventions and strategies to enhance operators’ well-being and mitigate the negative effects of stress.

3.2.1. Evaluation of Performance

The evaluation of performance serves as an objective measure of stress by assessing various performance indicators, including time, errors, and production rate. These metrics allow researchers to quantify how the task has been executed and complement the indicators obtained from physiological measurements and perceived stress, providing a comprehensive understanding of the operator’s performance.

While performance evaluation may not directly measure stress itself, it provides valuable insights into the execution of tasks and contributes to a holistic assessment of stress levels. By analyzing factors such as the time taken to complete tasks, frequency of errors, and production rate, researchers can gain a better understanding of how stress influences the efficiency and accuracy of operators’ work.

The evaluation of performance acts as a supporting component alongside physiological measurements and perceived stress, enabling evaluators to comprehend the task at hand and obtain a holistic view of the operator’s performance and stress levels. This integrated approach allows for a more comprehensive understanding of the relationship between stress and performance, facilitating the identification of potential stress-related challenges and the development of targeted interventions to enhance operators’ well-being in manufacturing contexts.

3.2.2. Evaluation of the User through Physiological Monitoring

Physiological monitoring provides an objective assessment of operators’ stress responses by measuring physiological signals, such as heart rate, electrodermal, electroencephalogram, and electromyogram activities, helping researchers to identify stress markers and quantify stress levels, thus overcoming subjective biases and providing valuable data on the physiological impact of stress on operators’ well-being. Our previous studies conducted an SLR to identify experimental studies that employed physiological monitoring for UX assessment [54]. The inclusion of physiological tools offers several advantages, including the potential for more objective measurements and the ability to capture real-time data without retrospective biases, as the information is collected seamlessly during a task. Table 1 shows the physiological metrics and devices used to assess stress.

Table 1.

Physiological devices and metrics associated with the stress measurement.

3.2.3. Evaluation of the User through a Stress Perception Questionnaire

As mentioned in Section 2.2, in addition to objective measures, the subjective experience of stress should be assessed through a stress perception questionnaire. This self-report instrument allows operators to reflect on their perceived level of stress, identify stressors in their work environment, and express their subjective experiences of stress. Despite being a subjective measurement, questionnaires allow us to gather quantifiable data on individuals’ stress levels, providing a deeper understanding of their psychological well-being.

3.2.4. Data Processing and Stress Ratio Calculation Overview

The present study involved the comprehensive processing of data acquired from the instrumentation devices, as well as pertinent general information collected prior to, during, and after the experimental sessions. The objective of this phase was to derive a comprehensive stress ratio that was reflective of the operators’ experienced stress levels. The subsequent exposition delineates the methodologies adopted for data processing and the subsequent calculation of stress ratios in congruence with the multi-dimensional stress measurement framework. It is imperative to note that the specific calculation modality is contingent upon the chosen indicators. However, an initial panoramic perspective is offered herein.

Following the data acquisition phase, the amassed data was meticulously compiled and exported in a structured format, typically CSV files. Subsequently, the data underwent a series of meticulous preprocessing steps, including filtering and resampling techniques. These procedures were implemented with various time intervals, such as minute-by-minute segments and per experimental trial, employing specialized algorithms tailored to the nature of the data. The quantification of physiological phenomena, such as physical activity intensity, entailed referencing well-defined thresholds in alignment with established criteria. Finally, the perceptual indicators were acquired through questionnaires. For these, an arithmetic mean of the items may suffice. Alternatively, in the case of standardized questionnaires, the procedures posited by the authors of such instruments were adhered to for the calculation of overall scores.

In closing, it is paramount to emphasize the importance of conducting a triangulation of outcomes across the three distinct indicator domains. The results derived from each bloc should be subjected to meticulous inter-comparison and contrast to ensure a comprehensive and nuanced understanding of the stress experienced by the operators. This involves synergistically analyzing and juxtaposing data gleaned from the physiological, performance, and perceptual indicators. Several methods can be employed for data triangulation, such as convergent triangulation, multimethod triangulation, cross-validation, and sequential triangulation. By systematically comparing and contrasting data across these domains using appropriate triangulation methods, a more robust and holistic understanding of the operators’ stress experience can be achieved.

4. Experimental Protocol for Measuring Work-Related Stress in Manufacturing Industry

In this section, we present the experimental protocol for measuring stress in manufacturing contexts. The protocol consisted of three distinct phases designed to comprehensively assess and address stress factors among human operators. Before delving into the protocol itself, we first present the recruitment process and ethical principles that underpinned this research. Ensuring ethical considerations and proper participant recruitment were essential for maintaining the integrity and validity of this study. Subsequently, we present the detailed protocol.

4.1. Recruitment and Ethical Principles

4.1.1. Participant Recruitment Strategies

Recruiting participants is a crucial aspect of the research design process, although it can be time consuming. It is essential to strive for a representative and meaningful sample, while also ensuring gender equality in participant selection. Building a positive participant experience and establishing trust are paramount for long-term project success, as word-of-mouth referrals can expand the pool of potential participants. To effectively recruit individuals for the project, the following steps are recommended:

- Project Description: Provide a concise overview of the project, including information about the organizing institution, objectives, scope, and project timeline. Clearly specify the date, time, and location of the event, along with instructions for accessing the venue. Communicate the conditions of participation and outline the expected tasks or activities for participants. If any filming, physiological monitoring, or observation will take place, it should be mentioned. Additionally, inform participants about any expenses involved and any incentives offered as part of their involvement. It is crucial to provide comprehensive contact details for the organizing institution. An adequate notice period should be provided, where a two-week timeframe is generally insufficient.

- Direct Contact: Reach out to potential participants by establishing direct contact with relevant industry associations, trade unions, or professional organizations associated with the industrial manufacturing sector.

- Detailed explanation: Ensure that the conditions of participation are explained in detail to potential participants. Ideally, provide a digital copy of the informed consent letter, allowing participants ample time to review and consider the terms. This enables individuals to make an informed decision and withdraw from the project if they choose to do so.

4.1.2. Obtaining Informed Consent

Securing individuals’ commitment to the design project and persuading them to participate is just the initial step; it is also crucial to meet an ethical requirement by ensuring that informed consent is obtained. Informed consent entails providing sufficient information about the project and ensuring that there is no coercion, allowing potential participants to make an informed and voluntary decision regarding their potential involvement. The primary objective is to conduct the research transparently and without deception, prioritizing the protection of participants from physical and mental harm throughout the research process.

Each participant must be fully informed of their right to refuse participation or withdraw from the project at any time and for any reason they deem fit. There should be no pressure or coercion to participate in the research. In the case of adult participants, a modest monetary reimbursement may be provided to compensate for their time and expenses, or non-monetary incentives, such as books or shop vouchers, may be offered. For commercial projects, participants should receive a mutually agreed-upon fee.

While informed consent is a fundamental principle, there may be certain research contexts where its application is less relevant, such as in studies involving crowd behavior. Covert research, where observation is conducted without participants’ awareness, may be justified when it offers unique evidence or when overt observation could potentially alter the phenomenon under study. However, the general principle should be that covert research is only warranted when it addresses significant questions and is likely to uncover essential issues that would otherwise remain hidden.

4.1.3. Confidentiality: Safeguarding the Shared Information

Once the user group has been identified and participants have been persuaded to commit to and engage with the project, it is essential to prioritize privacy and confidentiality when handling the information entrusted to the research team.

Researchers must be cognizant of the risks associated with identification and breaches of privacy and confidentiality stemming from various forms of information storage and processing. This includes computer and paper files, email records, photographic material, audio recordings, and any other data that could potentially identify individuals.

In order to ensure fair and lawful processing of personal data, the following guidelines shown in Table 2 should be adhered to.

Table 2.

Guidelines for privacy and confidentiality in research data handling.

4.1.4. Behavior: Ethical Conduct and Considerations

The manner in which researchers engage with participants during the design process plays a pivotal role in establishing the ethical foundation of a study. Conducting oneself appropriately entails a combination of common sense and adherence to legislated behaviors. This section outlines the recommended behavior and considerations when interacting with participants in research.

- Audio and video recording: When conducting tests that involve recording, monitoring, or observation, it is imperative to inform participants of these activities during the recruitment phase and at the commencement of the interview. Participants should be made aware of how the recordings will be used and their consent to the use of such recordings should be clearly outlined in the consent form. Upon request, participants should be provided with a duplicate copy of the recorded material. Respecting participants’ wishes for identity concealment through pixelation or other technical means should be honored. For task-related research, focusing solely on the relevant body parts, such as the hands, or filming from behind the subject can help to address privacy concerns. Video and audio recordings of participants should be securely stored and not shared with third parties without proper consent.

- Sensitive issues: Qualitative research, due to its potentially intrusive nature, necessitates particular attention to the emotional well-being of participants. Researchers must maintain respect for individuals’ values and be mindful of any distress their questions may cause, regardless of the topic under examination. In terms of sensitivity, thematic areas can be categorized as follows: (1) topics universally deemed sensitive due to their inherent nature and (2) topics that may be sensitive for specific individuals based on their personal history. While precautions cannot be taken for the latter case before the interview, researchers can approach each case with sensitivity and individuality, providing respondents with a genuine opportunity to disengage if needed. It is important to recognize that any topic can be sensitive to someone. Respondents who perceive that their privacy and personal sensitivities are not acknowledged and respected may be less forthcoming in their responses, ultimately impacting the nature of their participation. Similarly, respondents who feel they have not been treated with honesty and openness may experience a sense of patronization, which can influence the quality of their responses. Therefore, it is crucial to uphold participant dignity, privacy, and trust throughout the research process.

4.1.5. Gender Considerations in Research Design and Reporting

Incorporating an understanding of sex and gender differences is essential for conducting rigorous and inclusive research across various domains. While progress has been made in including diverse gender populations in studies, there remains a need for the comprehensive reporting of sex and gender variables. This section emphasizes the importance of disaggregating data by sex/gender and effectively describing sex/gender differences and similarities in research findings.

To ensure a comprehensive analysis, it is imperative to present data in a disaggregated manner, specifically considering sex and gender as key variables. Disaggregation allows for a more nuanced understanding of how outcomes, responses, or experiences may differ between males and females or among diverse gender identities. By examining sex/gender-specific patterns, researchers can uncover valuable insights into potential variations that may have been masked by a generalized analysis. Consequently, reporting sex/gender-disaggregated data enhances the scientific validity and applicability of research findings.

In addition to presenting disaggregated data, it is crucial to effectively describe the observed sex/gender differences and similarities within the research context. Researchers should provide a comprehensive analysis of the findings, highlighting any statistically significant variations between sexes/genders. Moreover, it is important to acknowledge and explain any unexpected similarities or lack of differences observed. This analysis can help identify potential underlying factors that contribute to the observed patterns and shed light on the complexity of sex and gender influences within the studied phenomenon.

4.1.6. Determining Optimal Sample Size

Works such as Virzi [56], Lewis [57], and Nielsen [58] proposed that a sample size of five participants is sufficient to uncover approximately 80% of a system’s problems. However, it is essential to critically evaluate the implications of relying solely on such small sample sizes. Cazañas et al. [59] cautioned that using smaller samples can introduce significant variability in test results, which cannot be effectively adjusted for. Faulkner [60] conducted a study to highlight the risks associated with relying on only five participants and the advantages of increasing the sample size. In the study by Faulkner [60], the analysis included 60 users, and random sets of five or more participants were sampled from the pool to assess the effectiveness of various sample sizes. Faulkner’s [60] results demonstrate a wide range of outcomes, with some randomly selected sets of five participants identifying 99% of problems, while others detected only 55%. However, as the sample size increased to 10 users, the lowest percentage of problems identified by a set increased to 80%. With a further increase to 20 users, the lowest percentage rose to 95%.

While it may be tempting to rely on small sample sizes for the sake of efficiency, researchers should exercise caution and consider the potential risks of inadequate representation and limited generalizability of findings. To achieve robust and reliable results in testing, it is advisable to aim for sample sizes beyond the minimum threshold. Although there is no definitive consensus on the optimal sample size, researchers should strive for a balance between feasibility and statistical power, considering factors such as the complexity of the system, target user population, and specific research objectives. By incorporating larger sample sizes, researchers can enhance the precision of their findings, minimize variability, and improve the overall quality of usability evaluations.

4.2. Test Execution

4.2.1. Experimental Procedure

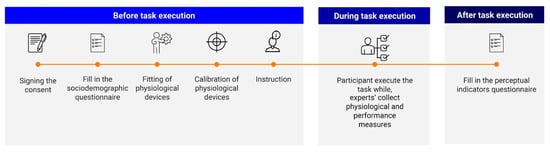

This section outlines a three-phase protocol design for investigating stress in manufacturing contexts, encompassing the pre-, during, and post-phases of the experiment (Figure 4). Each phase serves a specific purpose in collecting data and ensuring the integrity and validity of the research findings.

Figure 4.

The three-phased protocol for work-related stress measurement.

- Pre-phase (before the task execution): The pre-phase is the initial stage of the protocol, where participants are introduced to the experiment and provided with essential information. Firstly, participants will receive a comprehensive overview of the test’s objectives, procedures, and potential risks, and they will be required to provide informed consent by signing a consent form. This ensures that the participants are fully aware of the study’s nature and willingly agree to participate. Furthermore, participants undergo a preparatory process, which includes clear instructions regarding the specific tasks they perform during the experiment. Additionally, physiological devices will be carefully fitted and calibrated to accurately collect relevant physiological data throughout the study.

- During the task execution: The task execution phase constitutes the core of the protocol, during which the participants carry out the assigned tasks while the researchers collect data. It is essential to maintain a controlled environment to minimize confounding factors and ensure the accuracy and reliability of the collected data. A controlled setting allows the researchers to isolate the effects of the tasks and investigate stress-related factors without interference from external variables. The experimental conditions are carefully monitored to guarantee the validity of the data obtained, enabling accurate analysis and interpretation.

- Post-phase (after the task execution): Following the completion of the tasks, the participants enter the post-phase, which involves the assessment of perceptual measures through the administration of a questionnaire. This questionnaire serves as a valuable tool for evaluating the participants’ subjective perceptions and experiences related to the performed tasks. By capturing the participants’ self-reported measures, the researchers can gain insights into their cognitive and emotional responses, aiding in the understanding of the stress-inducing factors within the manufacturing context. The post-phase contributes to the comprehensive analysis of the data collected, complementing the physiological measures obtained during task execution.

4.2.2. Before the Task Execution

Prior to the execution of any research study involving human participants, certain essential steps are taken to ensure ethical conduct and the collection of reliable data. This section focuses on the pre-task preparations that are crucial in establishing a solid foundation for the research process. These preparations include obtaining informed consent, administering a socio-demographic questionnaire, fitting and calibrating physiological devices, and providing clear instructions to participants:

- Consent: In any research study involving human participants, it is crucial to adhere to ethical standards and obtain informed consent prior to conducting any tests or collecting data. Informed consent entails a comprehensive process wherein participants are provided with complete information regarding the research study, including its purpose, procedures, potential risks and benefits, and the rights they possess as participants. Subsequently, participants voluntarily agree to take part in the study, making their informed consent an integral aspect of ethical research conduct. A fundamental component of obtaining informed consent is the utilization of a consent form. This document serves as a written record that delineates the essential details participants need to be aware of, along with their rights and responsibilities as research subjects. By affixing their signature to the consent form, participants acknowledge their comprehension of the provided information and express their voluntary consent to participate in the study.

- Socio-demographic questionnaire: The socio-demographic questionnaire constitutes a valuable tool for researchers as it enables the collection of pertinent information regarding participants’ backgrounds. By gathering data on various socio-demographic factors, such as age, gender, education, and occupation, researchers can gain insights into how these variables may influence participants’ responses to the primary test or study. For instance, demographic characteristics might impact cognitive functions, emotional responses, or perceptions, thereby potentially influencing the interpretation of research findings. Integrating a socio-demographic questionnaire into the research protocol enhances the comprehensiveness and depth of data collected, contributing to a more nuanced understanding of participant perspectives.

- Fitting and calibration of physiological devices: In studies involving physiological measurements, it is essential to appropriately fit and calibrate the physiological devices employed. This process ensures accurate and reliable data collection during the research study. Proper fitting involves ensuring that the devices are appropriately positioned and secured on the participants’ bodies to obtain precise measurements. Calibration, on the other hand, involves adjusting and verifying the accuracy of the physiological devices to guarantee optimal functioning. Adequate fitting and calibration procedures are crucial to maintain data integrity and minimize potential errors or inconsistencies in the collected physiological measurements.

- Provision of instructions to participants: Clear and concise instructions are imperative when conducting research with human participants. Participants need to be thoroughly informed about the tasks or activities they are expected to perform, as well as any specific guidelines or protocols they need to follow. Detailed instructions should be provided in a standardized manner to ensure consistency across participants and mitigate potential confounding factors that may influence their performance. By providing explicit instructions, researchers promote a standardized and controlled environment for data collection, thereby enhancing the validity and reliability of the study outcomes.

4.2.3. During Task Execution

The during-task-execution phase represents a critical stage in research studies involving human participants. It is the period when participants actively engage in performing the assigned tasks while researchers collect relevant data and observations. This phase encompasses various aspects aimed at capturing participants’ performance, assessing physiological indicators, and conducting observational analysis to gain comprehensive insights into participants’ behavior and responses.

- Designing the task: The design of tasks in research studies involving human participants is a crucial aspect that directly influences the quality and validity of the collected data. A well-designed task should align with the research objectives, provide a clear and structured framework for participant engagement, and effectively elicit the desired responses or behaviors of interest. Researchers need to define the scope and purpose of the task, considering the specific research questions to be addressed and the hypotheses to be tested. This clarity of purpose enables researchers to design tasks that align with the intended outcomes and facilitate the measurement of relevant variables. Researchers must carefully consider the task instructions, stimuli, and any materials or equipment required. Clear instructions are essential to ensure that participants understand the task requirements and objectives. In addition to considering the task content and instructions, researchers should also pay attention to the task format and presentation. The choice of task format, such as computer-based tasks, paper-based tasks, or real-world simulations, should be guided by the research objectives and the nature of the variables being investigated. The task format should be conducive to capturing the desired responses or behaviors and should be easily understood and engaging for participants. Pilot testing is an essential step in task design. Conducting pilot tests allows researchers to identify and address any issues or challenges with the task design before implementing it in the main study. Pilot testing enables researchers to refine task instructions, identify potential ambiguity or confusion, and ensure that the task effectively measures the desired variables. When designing tasks for research studies that involve human participants, several considerations should be taken into account to ensure the tasks are effective in eliciting meaningful feedback and capturing relevant information. Table 3 outlines key principles for designing tasks that align with the user’s goals and needs, are clearly defined, specific yet flexible, focused on testing usability aspects, and varied in difficulty level.

Table 3.

Guidelines for designing the task in experiments to measure stress.

Table 3.

Guidelines for designing the task in experiments to measure stress.

| Principles for Designing the Tasks | Description |

|---|---|

| Realism and relevance to stressful situations | Tasks should simulate realistic and relevant stress-inducing situations. By recreating scenarios that evoke stress, participants can provide feedback that reflects their real experiences and the impact of stress on usability. |

| Clear definition and comprehensibility | Tasks should be clearly defined and easy for participants to understand, even in stressful conditions. Ambiguity or confusion in task instructions can add to participants’ stress levels and affect their performance and feedback. Providing clear and concise instructions helps participants to focus on the task requirements. |

| Specificity and flexibility | Tasks should be specific enough to elicit stress responses while allowing participants the flexibility to navigate through the tasks based on their coping mechanisms. Clear objectives should guide participants, but they should have some freedom in their actions to reflect real-life stress management approaches. |

| Focus on stress-related usability aspects | Tasks should be designed to measure the impact of stress on specific usability aspects, such as decision-making, task completion time, or error rates. By focusing on these stress-related usability aspects, researchers can evaluate the system’s performance under stress and identify areas where stress may hinder usability. |

| Variation in stress levels | Tasks should be designed to induce different levels of stress, accommodating participants with varying stress thresholds. This variation allows researchers to observe how the system performs under different stress levels and identify stress-related usability challenges across a range of user experiences. |

- Performance indicators: In the protocol, various performance indicators are considered to measure the participants’ task performance (Table 4).

Table 4.

Performance indicators to measure in the protocol.

Table 4.

Performance indicators to measure in the protocol.

| Performance Indicator | Description |

|---|---|

| Task execution time | The task execution time measures the duration taken by participants to complete a given task and provides valuable insights into the efficiency and speed of task performance. |

| Errors | This indicator captures the occurrence and frequency of errors made by participants during task execution. It helps to identify usability issues and areas where participants encounter difficulties or make mistakes. |

| Variability in production times | This indicator assesses the variability in the time required to produce certain items or complete specific actions. It highlights consistency or inconsistency in performance and helps identify areas for improvement. |

| Production rate | The production rate measures the rate at which pieces or preforms are produced within a specified time interval. It provides an indication of the productivity and efficiency in terms of output. |

- Physiological indicators: The measurement of work-related stress is a critical aspect of understanding the impact of occupational environments on individuals’ well-being. In recent years, there has been a growing interest in incorporating physiological indicators as a means of quantifying and evaluating work-related stress levels. In the specific case of the NO-STRESS project, we made the decision to utilize the EMG on the trapezius, forearm, and biceps muscles due to the task requirements. Additionally, we incorporated a band to measure the HR and HRV, an EEG helmet to capture brain activity, and a ring on one of the non-dominant hand’s fingers to measure the GSR. These sensor placements were chosen to comprehensively assess physiological responses relevant to stress evaluation in the study.

4.2.4. After the Task Execution

Following the completion of the task, the participants’ perceived stress was assessed using a 7-item questionnaire. This questionnaire was adapted from the Perceived Stress Scale (PSS) developed by Taylor [61] to ensure its relevance to the specific task and context under evaluation. The participants were required to rate their responses on a seven-point Likert scale, with 1 representing “Never” and 7 representing “All the time.” The questionnaire items included are shown in Table 5. Notably, participants were provided with the complete Likert scale during their questionnaire completion, ensuring comprehensive input (Table 6).

Table 5.

The proposed questionnaire used to measure the perceived stress.

Table 6.

Example of how questions and answer options are displayed in the questionnaire.

4.3. The Application of the Protocol

This section presents the application of the experimental protocol in two distinct contexts within the manufacturing industry: the automotive industry and plastic component manufacturing.

4.3.1. Application in the Automotive Industry

Ensuring the health and safety of workers in the automotive industry is of paramount importance in kitting assembly and image compliance processes. These tasks have a direct impact on the well-being and performance of workers, as well as the overall quality and efficiency of the products. However, numerous challenges arise in these processes, including ergonomic hazards, exposure to harmful substances or environments, and the potential for human errors or accidents [62]. Consequently, it is crucial to implement appropriate measures to prevent or mitigate these risks.

Table 7 provides a detailed exploration of two applications of the experimental protocol within the context of automation tasks, namely, full kitting and quality assessment. These tasks have unique requirements and involve distinct considerations.

Table 7.

The application of the experimental protocol in two case studies in the automotive industry.

In the context of full kitting, several requirements must be met to ensure efficient and safe assembly processes. These include having a clear and accurate bill of materials (BOM) that lists all the required components and quantities [63]. Additionally, a well-organized and efficient storage system is essential to facilitate the easy access and retrieval of components [64]. Furthermore, a reliable and fast transportation system is necessary to deliver the kits to the assembly line or workstation without delays or damage.

Regarding quality assessment, image compliance in the automotive industry necessitates adherence to various quality conformity requirements. This involves ensuring that images meet the specified standards and specifications for resolution, color, contrast, sharpness, and other relevant parameters. Additionally, compliance with regulatory requirements for data protection, privacy, and security is crucial. Aligning with the company’s goals and customer expectations in terms of quality, safety, efficiency, and sustainability is also imperative. To monitor and verify compliance, automated tools and techniques can be employed in real time or periodically to detect and prevent potential non-compliance issues. Continuous improvement is facilitated through feedback, data analysis, and the incorporation of best practices [65]. Furthermore, adherence to relevant industry standards and regulations, such as ISO 9001 for quality management, ISO 14001 for environmental management, and ISO 45001 for occupational health and safety, is essential [66].

The applications were accompanied by a comprehensive overview of the output metrics and assessment methods employed in this study. The protocol encompassed several distinct stages, starting with the administration of a sociodemographic questionnaire to gather pertinent participant information. Subsequently, participants engaged in task execution under carefully controlled environmental conditions. Throughout the tasks, meticulous measurements and recordings were made of various research variables, including speed, time, temperature, and noise level. Furthermore, thorough data collection of physiological indicators, such as HR, HRV, and GSR/EDA, was conducted. Additionally, EEG measurements were employed to analyze factors like memorization, engagement, valence, and attention. EMG measurements using surface electrodes were utilized to assess maximal voluntary isometric contraction. It is worth noting that EEG measurements were not employed in the “Full Kitting” task due to its dynamic nature and the potential for noise artifacts, while in the “Quality Assessment” task characterized by more static conditions, EMG measurements were not utilized, and EEG was selected as the primary modality. Importantly, data collection involving exoskeleton, voice, and eye tracking was not carried out in this particular study. Finally, performance indicators, including time, errors, and production, were evaluated and complemented by a post-task questionnaire specifically designed to assess perceptual indicators.

4.3.2. Application in Plastic Component Manufacturing

In addition to the automotive sector, two other case studies were set in the context of the plastic components industry. The two case studies focused on two different tasks. The first one consisted of the manual assembly of extruded plastic parts for the production of the final product. This task started with the customers’ order check in order to assemble the parts customized to the customer’s requirements. Next, the worker proceeded with the recovery of the components to be modified and assembled from the warehouse and then cut and drilled the parts according to the customer’s specifications. Finally, the operator verified the conformity of the real measurements of each part with those desired by the customer and proceeded with the assembly and packaging of the final products. The second task was based on the quality monitoring of an automated production process; in this case, the worker’s role involved checking the quality of the parts produced, verifying that the dimensions met any standards and that the parts had no defects. Defective parts were then put away and reused during the process, while parts that passed the check were packed.

As in the automotive case studies, the protocol included the filling in of a questionnaire with socio-demographic data; the performance of the task; and subsequently, the filling in of a final questionnaire for the stress perceptions of the worker (Table 8). The questionnaires for the sociodemographic data and the stress perceptions were equivalent to the automotive case. On the other hand, during the execution of the tasks, physiological data were recorded for the analysis of the cardiac activity through the HR and HRV indicators; the muscle activity was monitored using the EMG technique; the galvanic skin response was recorded for the analysis of the skin conductance indicator; and finally, respiration cycles data were recorded. In addition to these, other measurements were carried out to assess the ergonomics of the task. Then, the stress perceptions questionnaire was administered twice, both during and after the task execution. For each task, three repetitions were carried out at different times of the day.

Table 8.

The application of the experimental protocol in two case studies in plastic component manufacturing.

5. Discussion