Abstract

An integral aspect of global businesses and economic activities is the supply chain networks. Importantly, the coronavirus (COVID-19) pandemic scenario has further shown that the outbreak of diseases can create a global network-scale disruption to supply chain or logistics, thereby damaging several aspects of economic activities and business life. Hence, this study aims to assess the resilient supplier selection (RSS) process in the wake of the COVID-19 outbreak. A two-stage hybrid decision model using Pythagorean fuzzy sets was proposed as a case study from the automotive industry to deal with RSS during the COVID-19 outbreak. In the first stage, significant criteria and their corresponding sub-criteria were determined through a vast review of the literature and nominal group technique, while the relative weights for RSS were obtained through the Pythagorean Fuzzy Analytic Hierarchy Process (PFAHP) method. In the second stage, nine suppliers were evaluated with Pythagorean Fuzzy VIKOR (PFVIKOR) method. The results of the hybrid approach revealed that flexibility is the most important criterion among resilience criteria that constitute the most significant dimensions for RSS. In many studies, strategic criteria such as quality, cost, and delivery are found to be the most important criteria in supplier selection, however, in the wake of the COVID-19 outbreak, the opinions of decision-makers were significantly changed as the present study reveals that flexibility is the most important criterion to improve the operations of the supply chain for RSS. Next to flexibility is process capabilities, while quality (Q), and cost (C) existed as the first and second in the category of influential criteria for strategic supplier selection criteria, respectively. The managerial and practical implication is that, in the wake of COVID-19 disruptions, suppliers need to be re-evaluated based on resilience-related indicators.

1. Introduction

In recent years, supply chain networks have been confronted with unexpected incidents such as epidemics, climate change, and various natural disasters [1]. For instance, when the SARS epidemic hit China in 2003, China’s domestic trade suffered a reduction in its growth from 11.1% to 9.1% in the first quarter of the year [2,3]. Aside from epidemics, cases of natural disasters such as Iceland’s volcano eruption in March 2010, the Japan earthquake and tsunami in March 2011, and the flood in Thailand in August 2011 have also caused diverse degrees of disruptions in business activities and various companies’ supply chains. As a result of these events, companies are increasingly recognizing the need for effective supply chain risk management to find new ways in the face of uncertainty and changes [4]. The impacts of these developments are thus far limited, and there is no doubt that the evolving uncertainties that come with the coronavirus (COVID-19) outbreak are still destabilizing the global economy with respect to the known status quo of the pre-pandemic era [5,6]. Therefore, it is expected that companies aim to minimize the negative effects of disruptions by creating resilient supply chain networks.

When searching for suppliers, companies might wish to consider flexibility as one of the selection factors. If companies need to make modifications to customers’ orders in the future, the supplier’s flexibility in responding to companies’ shifting demands may become very helpful. The most crucial weapon to combat and manage risks and uncertainties in today’s unpredictable markets is supply chain flexibility [7]. It may also be viewed as developing tactics to outperform rivals and remain in an advantageous position in the market. In this regard, the overall profit can be raised, overall quantities can be optimized, and unanticipated occurrences can be responded to more swiftly with the help of cooperating flexible providers. The substantial correlations between sourcing flexibility, delivery performance, and product financial performance highlight the need for supply chain managers to pay attention to sourcing flexibility when choosing suppliers and making purchases [8]. A flexible supply chain is an indicator of how quickly, easily, inexpensively, or poorly a system can change or respond by adjusting to shifts in demand or supply [9]. A resilient supply chain describes a supply chain system’s adaptive ability to react and respond to unanticipated circumstances with the appropriate measures, to respond to risks and disruptions, and to recover from them by sustaining and managing the operations at the desired level [10]. Thus, high cooperation levels and flexibility with suppliers are the driving forces of resilience [11].

As indicated by many researchers, supplier selection is a Multi-criteria decision-making (MCDM) problem [12,13] and a lack of knowledge of decision-makers or insufficient information about suppliers can expose the supplier selection decision-making process to a high degree of uncertainty, as noted by [14]. In the resilient supplier selection (RSS) problem, most researchers use MCDM methods based on ordinary fuzzy sets to determine weights of criteria and rank suppliers. However, extensions of fuzzy sets could be considered a stronger tool for handling higher uncertainty. For example, [10] investigated RSS using linguistic neutrosophic numbers. To our knowledge, no one has applied Pythagorean fuzzy sets (PFSs) in the RSS problem. PFSs, which are an extension of Intuitionistic Fuzzy Sets, capture the uncertainty and vagueness in a better way through more flexibility while revealing decision-makers judgments [15,16,17]. PFSs have generated a great deal of interest by providing more freedom to decision-makers in their assessment of MCDM problems.

Automobile sales, which dropped to 64 million worldwide in 2020, had a downward trend with the emergence of the coronavirus outbreak [18]. The coronavirus outbreak was observed to have led to cuts in China’s parts exports, large-scale production cuts across Europe, and the closure of assembly facilities in the United States. Furthermore, suppliers facing liquidity issues can cause a disruption in the global automotive supply chain and potentially create catastrophic consequences [19]. The automotive industry in Turkey, besides comprising the first three largest sectors, has a vast 60 years of history, and Turkey ranks fifth in Europe’s automotive production list [18]. However, despite being a prominent industry for Turkey, automotive production and exports decreased by 11% and 27%, respectively, year-on-year in 2020 [18]. Therefore, there is a need to examine the resilience of the Turkish automotive industry, especially in times of global disruption, as is the case for the novel coronavirus COVID-19 pandemic.

Generally, it has been reported that there are two main issues in supplier selection, namely determining appropriate criteria and corresponding sub-criteria, and developing an accurate model to rank the suppliers [20]. In many studies, resilience criteria were considered stand-alone, and the RSS under a uncertainty environment has not been adequately addressed by researchers [10,21]. Hence, in this study, we propose a novel hybrid approach based on Pythagorean fuzzy numbers (PFNs) while intending to investigate the following important research questions.

- (i)

- What are the most important criteria and sub-criteria that affect the resilience performance of suppliers during the COVID-19 outbreak?

- (ii)

- How can the importance levels of the resilience criteria be obtained under the Pythagorean fuzzy environment?

- (iii)

- How can the performances of the suppliers be evaluated under the Pythagorean fuzzy environment with the resilience criteria?

The review of extant studies on RSS in the automotive industry showed that the case of Turkey is rarely addressed, especially with respect to the resilience performance of suppliers using a multi-criteria approach. Hence, given the outbreak of COVID-19, the current study examines whether RSS has gained importance in overcoming disruptions, and to further examine how the evaluation process can deal with uncertainties, thereby facilitating experts’ judgments and comparisons. In specific terms, the study fills research gaps in the literature by: (i) specifying and providing detailed assessment criteria and their corresponding sub-criteria, (ii) developing a novel hybrid approach using PFNs, (iii) calculating weights of the criteria according to the decision-makers opinions using PFAHP, (iv) evaluating the resilience performance of suppliers by PFVIKOR, (v) performing a comprehensive sensitivity analysis, and (vi) presenting detailed theoretical and managerial implications.

The remainder of this study is provided as follows. The literature review is presented in Section 2. The necessary materials and methods are explained in Section 3. The case study and results are presented in Section 4 and Section 5, respectively, while the conclusions, alongside the policy implications and limitations of the study, are captured in Section 6.

2. Literature Review

We provide a systematic review of the relevant literature regarding RSS and the used methods in this section. This section is organized into three parts. The first part details RSS studies (see Table 1) and their findings, the second section focuses on the review of PFAHP and PFVIKOR (see Table 2), while the third part essentially highlights the research gaps.

Table 1.

RSS studies.

Table 2.

Review of recent studies using PFAHP and/or PFVIKOR methods.

Contribution to Literature

The COVID-19 outbreak has hit several aspects of business life and its undesirable impacts have spread across various industries, including the automotive industry. Since suppliers are critical parts of supply chain management, addressing RSS appears to be an important topic during and in the aftermath of the COVID-19 outbreak. However, the selection of resilient supplier can be considered a difficult decision-making problem due to the identified challenges of COVID-19, as well as periodic and sectoral differentiating factors.

Although many MCDM methods have been used for RSS, as seen in the literature review tables, no study has attempted to combine resilience and supplier selection during the COVID-19 outbreak. In addition, different MCDM methods were discussed in most of the previous studies, however, PFNs were not evaluated. Here, PFNs are evaluated, as they provide a better opportunity to cope with the uncertainty in the evaluations of decision-makers in the problem of RSS. Furthermore, although different MCDM methods were discussed in most of the previous studies, the automotive industry was not discussed in RSS. Therefore, in addition to having a new MCDM approach, this study also contributes to the literature by researching RSS in the automotive industry during the COVID-19 outbreak. As such, the study suggested theoretical and managerial implications of the proposed approach for the automotive sector to increase the resilience of suppliers.

Moreover, the criteria system is suitable for general supplier selection for industries including the automotive industries, and we have mainly utilized the case of the Turkish automotive industry as a suitable scenario presentation. There are several reasons why the automotive industry was specifically chosen. First, just as it plays a major role in the Turkish’s economy, it also plays significant roles in several other economies across the globe. In the case study country, for instance, the leading three largest industries are all in the automotive sector, which saw significant sales disruptions in 2020. The capability of crucial suppliers, including those of steel, glass, plastic, and advanced electrical systems, is essential to the success of car manufacturing companies. Second, most car items are put together from several sub-components. Finding and selecting the right supplier in the automotive industry is like picking a book out of a mountain of books. The selection of a company will be based on a wide range of variables, including the reliability and quality of the service provided, followed by the cost. Thirdly, the COVID-19 epidemic has caused shortages that have affected every vehicle manufacturer in the world, resulting in production halts and backlogs. The automotive industry, semiconductor manufacturers, and governments have concentrated on mitigation strategies to ensure sourcing and capacity expansion. To minimize business uncertainty and maintain themselves in an environment of international competitiveness, manufacturers should prioritize the integration of resilience viewpoint with supplier selection.

3. Materials and Methods

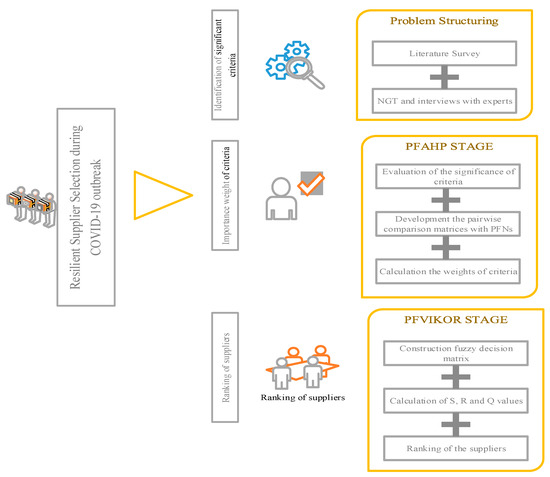

The proposed hybrid approach for RSS is presented in Figure 1, and the details of the methods used are given as follows. The hierarchical criterion structure is created in this study to specify the standards for selecting suppliers who will provide service during the pandemic. Three steps of analysis constitute the current study. A literature review was conducted in the first step, during which research gaps were found. The Pythagorean Fuzzy-based Analytic Hierarchy Process (PF-AHP) calculates the weights of each main and sub-criteria in the second stage, and the Pythagorean Fuzzy-based VlseKriterijumska Optimizacijia I Kompromisno Resenje (PF-VIKOR) approach was then used to rank the suppliers in the third stage once appropriate suppliers have been assessed. AHP and VIKOR methods are widely popular MCDM techniques that provide more reliable solutions, especially when integrated. AHP assesses the problem as it is presented at various levels of hierarchy and uses pairwise comparisons of criteria to specify the importance level of criteria [56]. VIKOR presents compromising solutions based on the proximity to the ideal solution [57]. Since the preferences of decision-makers are unable to accurately capture exact numbers, fuzzy numbers can be utilized to handle imprecise information in the judgments of decision-makers [55]. Therefore, AHP and VIKOR methods are integrated under the Pythagorean fuzzy environment.

Figure 1.

The framework of the proposed hybrid approach.

3.1. The PFAHP

The steps of PFAHP are presented as follows.

Step 1: The pairwise comparison matrix is constructed based on the linguistic evaluation of experts. The linguistic terms that are given [37] are presented in Table 3.

Table 3.

Linguistic terms for importance weights of criteria [37].

Step 2: The difference matrices between the lower and upper values of the membership and nonmembership functions are calculated using Equations (1) and (2):

Step 3: Interval multiplicative matrix is computed using Equations (3) and (4):

Step 4: The determinacy value is calculated using Equation (5):

Step 5: The determinacy degrees are multiplied with matrix for obtaining the matrix of weights, before normalization using Equation (6).

Step 6: The priority weights of criteria are normalized by using Equation (7):

3.2. The PFVIKOR

The Vlse Kriterijumska Optimizacija I Kompromisno Resenje (VIKOR) method is an effective tool to reach compromise solutions. In this study, the VIKOR method under Pythagorean fuzzy environment namely (PFVIKOR) was employed and briefly reviewed as follows:

Step 1: The Pythagorean fuzzy decision matrix is constructed by aggregation of decision-makers’ judgments. Let be a collection of PFNs. The following Pythagorean fuzzy weighted averaging (PFWA) operator is utilized to aggregate different opinions [40]:

where is the weight vector of with and .

Step 2: Pythagorean fuzzy positive ideal solution (PFPIS) and Pythagorean fuzzy negative ideal solution (PFNIS) of alternatives are computed using Equations (18) and (19):

Step 3: and values are computed through generalized Pythagorean fuzzy ordered weighted standardized distance operator (GPFOWSD) in the following [40]:

where represents the th largest of the standardized Pythagorean fuzzy distance, is the weights of criteria, and is the operator in GPFOWSD.

Step 4: values are computed using Equation (12):

where and is a weight for the strategy of the maximum group utility, whereas is the weight of the individual regret.

Step 5: Rank the alternatives according to the values , and in ascending order.

Step 6: Propose, as a compromise solution, the alternative (), which is the best ranked by the measure and was proposed if the conditions in [55] were satisfied.

4. A Case Study

To evaluate the performance of the proposed hybrid decision-making approach, a real case study was conducted for a company from the automotive industry in Turkey. The company manufactures basic transfer systems such as vacuum lines, air suspension lines, ventilation lines, and fuel lines. The company meets the production needs of many automobile manufacturers with more than 400 employees and a production facility of 10 thousand square meters. The company, which creates plans within the framework of resilience, harmony, and cooperation with its suppliers, seeks a methodology that will enable them to understand the principles of RSS process and to minimize disruptions in the supply chain. Company executives support nine suppliers to improve their production and operation activities to supply materials, even in the case of disruption. Five experts from the case study company were invited to the data collection process. The first specialist is the company’s 15-year-experienced logistics manager who is responsible for supply chain operations. The second expert is the purchasing manager with 10 years of experience. Third is the production manager with 25 years of experience. Finally, an industrial engineer who is responsible for the distribution business with 10 years of experience also took part in the research. Decision-makers were assigned the following weights, based on years of experience in the company: 0.12, 0.16, 0.16, 0.12, 0.08, 0.12, 0.12, 0.06, and 0.06.

4.1. Identifying Criteria and Obtaining the Weights of the Criteria

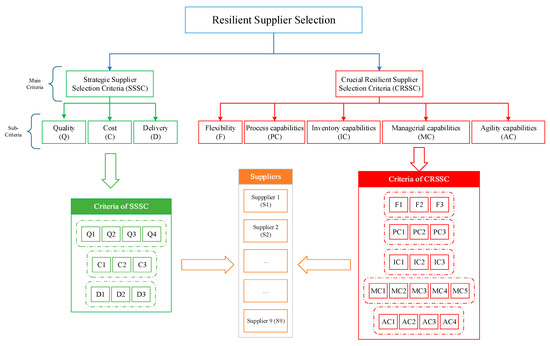

After the goal was determined, the criteria and sub-criteria to be used to evaluate the performance and ranking of the suppliers were subsequently determined. A nominal group technique was composed and implemented through face-to-face interviews with decision-makers. Following the literature review and interviews with decision-makers, the hierarchical structure that is presented in Figure 2 of the two main criteria, eight sub-criteria, and 28 criteria RSS problems were created. Definitions of the assessment criteria are explained in Table 4.

Figure 2.

The hierarchical structure of the RSS problem.

Table 4.

Identified criteria of RSS assessment.

In the first step towards determining the criterion weights, each of the decision-makers created the pairwise comparison matrices using the linguistic scale presented in Table 3. Following that, the consistency of the pairwise comparison matrices of each decision-maker was checked, and it was found that the consistency rates were below . Table 5 shows the interval-valued PFSs with corresponding linguistic variables for the main criteria. Other pairwise comparison matrices were performed (results are not provided here because of space constraints). Following that, the aggregated pairwise comparison matrix, which is indicated in Table 6 of the main criteria, was carried out using the interval-valued Pythagorean fuzzy weighted geometric operator given in [89]. All these procedures are also applied to the sub-criteria and criteria, and the final priority weights for all criteria are given in Table 7.

Table 5.

Pairwise comparison matrix for main criteria.

Table 6.

Aggregated pairwise comparison matrix for the main criteria.

Table 7.

The weights of the criteria.

4.2. Ranking of Suppliers

In the second stage, the applicable suppliers were ranked by applying the PFVIKOR method with the weights obtained in the previous stage. The decision-makers evaluated nine suppliers using the linguistic variables presented in Table 8 and the corresponding PFNs. The linguistic evaluations of decision-makers for nine suppliers were performed (results are not provided here because of space constraints). Decision-makers’ evaluations were aggregated using the previous equation. The aggregated Pythagorean fuzzy decision matrix is given in Table 9. Applying the steps given in Section 3.2, the ranking of the suppliers was obtained as shown in Table 10.

Table 8.

Linguistic scale for rating of suppliers.

Table 9.

Aggregated fuzzy decision matrix of suppliers.

Table 10.

S, R, and Q values and ranking orders for suppliers.

5. Sensitivity Analysis and Validation of the Results

The robustness of the obtained results was investigated in three subsections. In the first part, 50 different scenario analyses were carried out by changing the weight of the most important criterion. In the second part, the dependence of the obtained results on the change of the parameter is analyzed. In the third part, a comparison of ranking results with different MCDM methods is explained.

5.1. Variation of Criteria Weights

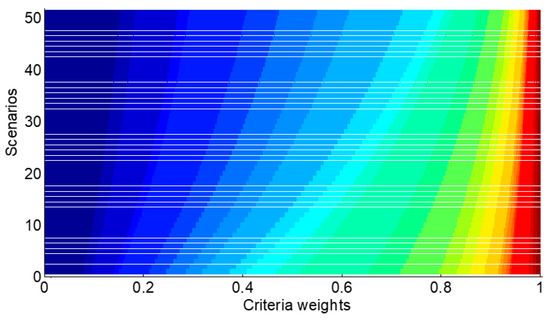

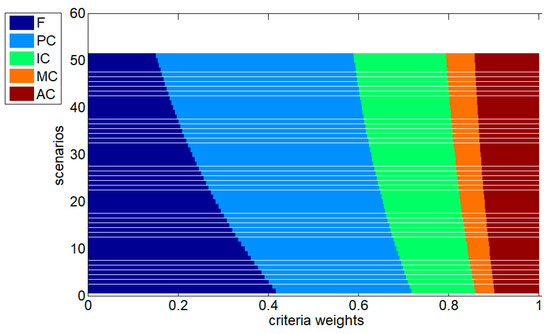

In this section, the performance of the proposed approach was evaluated according to the weights of the most important criterion. In this study, certainty-based reusable sample selection and correction (CRSSC) criterion was determined as the most important criterion, with a weight of . In the first scenario analysis, the value of the CRSSC criterion was reduced by , and the values of the remaining criteria were adjusted proportionally according to the recommendations of [90,91]. The change of the values of the weight coefficients CRSSC and SSSC in the interval and was simulated through 50 scenarios. The vectors of CRSSC criterion coefficients are depicted in Figure 3. After creating 50 coefficient vectors, the effects of these values on alternative rankings were analyzed. The change of alternatives according to the Q values is shown in Figure 4.

Figure 3.

The change of CRSSC criterion weights in 50 scenarios.

Figure 4.

Ranking results of the first scenario analysis.

According to the scenario analysis results, it was concluded that the first supplier (S8) keeps its order in 38 out of 50 scenarios. For interval , the best supplier (S8) is losing its place and S3 took the first rank. After this interval, S8 and S3 exchanged their places. One of the main reasons for these changes is that the weight of the criterion is noticeably increased and the criterion becomes dominant at about 28% of the weight. The S1 supplier ranks last in all 50 scenarios.

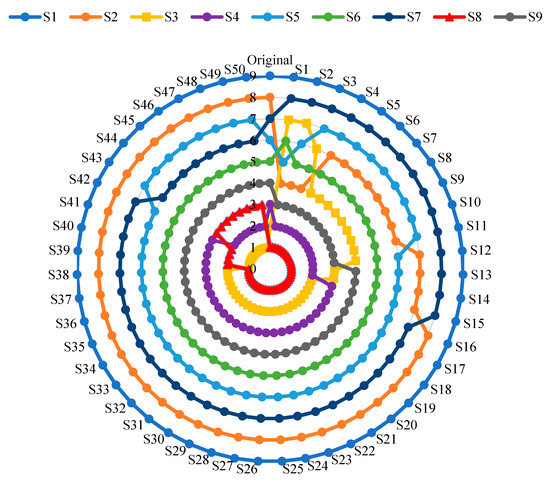

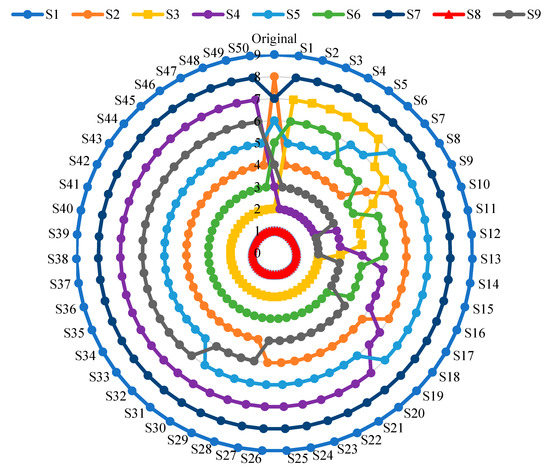

In the second 50 scenarios, the different weights for the most important sub-criterion in are analyzed. The weight of flexibility that is the highest influence in criterion was decreased by as seen in Figure 5, and a new set of weight coefficients was generated from the interval . From the results given in Figure 6, it is concluded that the best supplier in the current result (S8) is the dominant one that captures first place in all rankings.

Figure 5.

The change of flexibility criterion weights in 50 scenarios.

Figure 6.

Ranking results of second scenario analysis.

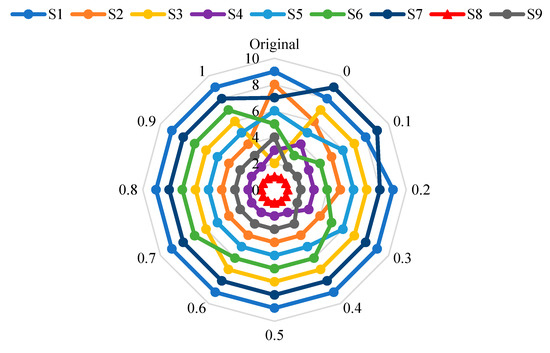

5.2. Influence of Parameter on the Ranking Results

In the VIKOR method, the value of is generally accepted as 0.5. However, can take any value in the interval 0–1. To prove the validity and robustness of the obtained sequences, sensitivity analysis was performed for the parameter. Based on various values from 0 to 1, values were calculated. Figure 7 shows the ranking order results. As can be seen in Figure 7, the ranking of the best supplier is not affected at all by the value. However, when takes values from 0 to 0.3, supplier S4 leaves its second rank to S9. Supplier S9, which was the third supplier, is not affected by at values larger than 0.4. This result indicates that the evaluation results obtained from the proposed PFVIKOR model are robust and reliable.

Figure 7.

The effect of changing the parameter in ranking results.

5.3. Comparative Analysis Based on Different MCDM Methods

A comparative analysis was carried out by the Technique for Order Preference by Similarity to Ideal Solution (TOPSIS) and Combinative distance-based assessment (CODAS) methods under Pythagorean fuzzy environment. The reasons for selecting these methods for comparison are first to integrate with PFAHP method, and secondly, to allocate PFNs for evaluation of suppliers. A Kendall’s tau-b correlation was conducted to specify the relationship between obtained ranking results amongst methods. There was a strong, positive correlation between the rankings, which was statistically significant ( for the result of TOPSIS and ( for the result of CODAS. According to the obtained results, the S8 and S4 suppliers were the best alternatives in both methods. However, the rank of the third alternative is changed. The S1 alternative is the worst alternative of all three methods, as it is ranked last. S8 is the best supplier for all employed fuzzy methods when the ranking results derived from the Pythagorean fuzzy approaches were evaluated. Additionally, the ranking performance of S4 has not changed, although it has been noted that the ranking performances of the other alternatives have slightly changed. The superiority of alternative S4 was verified through the use of all multi-criteria methods. Given that there is a very high similarity coefficient between the ranking results of the proposed approach and those of the established MCDM frameworks, the obtained findings demonstrate that the suggested model is stable and consistent at a satisfactory level.

6. Conclusions, Policy, and Limitations of the Study

With the transition to the new normal, the disruptions are expected to improve, but the impact of COVID-19 on the economy and businesses will continue. Although there is no proven method or tool for addressing supply chain disruptions during the COVID-19 crisis, this study proposed a new approach to RSS.

The main contributions of this study to RSS are thus included: creating a detailed and comprehensive set of resilience criteria sub-criteria, choosing the most suitable supplier using the PFAHP-PFVIKOR hybrid method, and proposing detailed theoretical and managerial inferences. With the COVID-19 period, the literature was comprehensively analyzed in order to address the need for durability emphasized in supply chain management in the selection of suppliers, and applicable durability criteria was determined in line with expert opinions. Subsequently, a new hybrid MCDM approach was proposed with the aim of ensuring robustness in supplier selection problems. In the present study, the PFAHP-PFVIKOR hybrid method was employed to cope with uncertainty in the decision-making process.

In many studies strategic criteria such as quality, cost, and delivery are found to be the most important criteria in supplier selection, however, the COVID-19 outbreak process has changed the opinion of decision-makers, and the most important criterion in the present study was found to be CRSSC. Therefore, this study revealed that flexibility is the most important criterion to improve the operations of the supply chain for RSS. Next to flexibility is process capabilities, while quality (Q) and cost (C) are found as the first and second in the category of influential criteria for strategic supplier selection criteria, respectively. To verify the robustness of the results from the study, two different sensitivity analyses and comparative analyses were performed, and the obtained results were confirmed to be robust.

6.1. Policy Implications

The proposed PFAHP-PFVIKOR approach enables decision-makers to better reflect the subjectivity and uncertainty that exists in the evaluation process, as it includes PFNs in the decision-making process. PFNs give decision-makers more flexibility in expressing uncertain, imprecise, and inconsistent information. From this point of view, in order to increase the flexibility of decision-makers in the evaluation process, AHP and VIKOR methods have been integrated under PFSs.

The established list of RSS can help decision-makers by acting as a checklist in unexpected situations such as the COVID-19 outbreak. This study provides new contributions to the existing knowledge by taking into account the RSS criteria (two main criteria namely traditional and critical) and determining the list of corresponding criteria and sub-criteria through a nominal group technique. This study revealed that flexibility is the most important criterion to improve the operations of the supply chain for RSS. Supply chain networks can be strengthened with not only flexibility but also with other resilience capabilities. For example, facility fortification, safety stock, and direct-to-store deliveries can be used to reduce the impact of disruptions. Facility fortification can lower the total cost of operation and also meet more demand in the post-disruption phase. Additionally, inventory sharing can provide flexibility in dealing with disruptions [63]. According to KPMG global automotive executive survey (2020), international cooperation is needed on issues such as controlling global demand decline and managing digital demand. For instance, Procter & Gamble (P&G), the global consumer goods giant, used digital tools to reposition their inventory, thereby avoiding disruptions and financial losses in Hurricane Irma in 2017.

In the context of RSS, the study highlights flexibility as the most crucial factor for enhancing supply chain operations. Hiring suppliers should be prioritized based on a supplier’s capacity for quick adaptation and response to changing conditions. This can include flexible supply schedules, flexible production processes, and quick reactions. Decision-makers should concentrate on increasing various resilience characteristics inside their supply chain networks, in addition to flexibility. Facility fortification can lessen the effects of disruptions and enhance overall operating effectiveness. Holding excess inventory on hand can serve as a cushion during disruptions. Direct-to-store deliveries can also be used to get around clogged distribution routes and keep the flow of merchandise constant.

Lastly, digital tools should be used by companies to enhance supply chain management and reduce disruptions. In addition, fostering international cooperation is also essential for controlling the reduction in global demand and addressing issues with digital demand. While focusing on resilience capabilities, decision-makers should also assess the total cost of operation. Overall, the results highlight how flexibility and the use of digital technologies are important to enhancing supply chain resilience. Organizations may improve their supply chains and better manage unforeseen interruptions by putting these management and policy implications into practice, which will ultimately enhance their operational performance and customer satisfaction.

6.2. Limitations of the Study

Although this study proposed a novel MCDM methodology, it still has some limitations in the following aspects.

The data collection: The experts expressed their judgments on criteria and alternatives in different periods because of the various restrictions and initial confusion during the COVID-19 outbreak process. Thus, the interview with experts took a much longer time than in normal circumstances.

The current study is limited to a company in the automotive industry solely. Therefore, similarities and differences in the results can be examined and compared by analyzing different companies, although the approach can also be applied in various industries such as chemistry, machinery, and electronics.

The determined criteria and sub-criteria were narrowed according to the experts’ judgments. Therefore, they may be company-specific in nature, and other resilient criteria have not been specified.

Lastly, supplier evaluations and rankings have been handled by various MCDM methods within a Pythagorean environment.

Therefore, for future studies, different extensions of fuzzy sets such as interval type-2, spherical, hesitant, and picture sets can be considered to deal with the specificity in the decision-making process. In addition, future studies can also be expanded by considering various evaluation criteria and sub-criteria. Moreover, methods such as DEMATEL, MACBETH, and ANP may also be useful in analyzing the relationships between criteria under different fuzzy sets. Overall, the proposed model in this study may be useful in other real-world applications.

Author Contributions

Conceptualization, A.Ç.; Methodology, A.Ç.; Formal analysis, A.Ç.; Resources, S.T.O.; Writing—original draft, S.T.O.; Writing—review & editing, A.A.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The utilized data are publicly available in an online database as mentioned in the text.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mehrjerdi, Y.Z.; Shafiee, M. A resilient and sustainable closed-loop supply chain using multiple sourcing and information sharing strategies. J. Clean. Prod. 2020, 289, 125141. [Google Scholar] [CrossRef]

- Hanna, D.; Huang, Y. The Impact of SARS on Asian Economies. Asian Econ. Pap. 2004, 3, 102–112. [Google Scholar] [CrossRef]

- Lee, A.H.I. A fuzzy supplier selection model with the consideration of benefits, opportunities, costs and risks. Expert Syst. Appl. 2009, 36, 2879–2893. [Google Scholar] [CrossRef]

- Hillman, M.; Keltz, H. Managing Risk in the Supply Chain: A Quantitative Study; AMR Research: Boston, MA, USA, 2007. [Google Scholar]

- Goel, R.K.; Saunoris, J.W.; Goel, S.S. Supply chain performance and economic growth: The impact of COVID-19 disruptions. J. Policy Model. 2021, 43, 298–316. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, R.; Panchal, R.; Tiwari, M.K. Impact of COVID-19 on logistics systems and disruptions in food supply chain. Int. J. Prod. Res. 2021, 59, 1993–2008. [Google Scholar] [CrossRef]

- Han, S.-L.; Sung, H.-S.; Shim, H.-S. Antecedents and performance outcomes of flexibility in industrial customer–supplier relationships. J. Bus. Res. 2014, 67, 2115–2122. [Google Scholar] [CrossRef]

- Wagner, S.M.; Grosse-Ruyken, P.T.; Erhun, F. Determinants of sourcing flexibility and its impact on performance. Int. J. Prod. Econ. 2018, 205, 329–341. [Google Scholar] [CrossRef]

- Gosling, J.; Purvis, L.; Naim, M.M. Supply chain flexibility as a determinant of supplier selection. Int. J. Prod. Econ. 2010, 128, 11–21. [Google Scholar] [CrossRef]

- Pamucar, D.; Yazdani, M.; Obradovic, R.; Kumar, A.; Torres-Jiménez, M. A novel fuzzy hybrid neutrosophic decision-making approach for the resilient supplier selection problem. Int. J. Intell. Syst. 2020, 35, 1934–1986. [Google Scholar] [CrossRef]

- Peck, H. Drivers of supply chain vulnerability: An integrated framework. Int. J. Phys. Distrib. Logist. Manag. 2005, 35, 210–232. [Google Scholar] [CrossRef]

- Memon, M.S.; Lee, Y.H.; Mari, S.I. Group multi-criteria supplier selection using combined grey systems theory and uncertainty theory. Expert Syst. Appl. 2015, 42, 7951–7959. [Google Scholar] [CrossRef]

- Qin, J.; Liu, X.; Pedrycz, W. An extended TODIM multi-criteria group decision making method for green supplier selection in interval type-2 fuzzy environment. Eur. J. Oper. Res. 2017, 258, 626–638. [Google Scholar] [CrossRef]

- Gupta, S.; Soni, U.; Kumar, G. Green supplier selection using multi-criterion decision making under fuzzy environment: A case study in automotive industry. Comput. Ind. Eng. 2019, 136, 663–680. [Google Scholar] [CrossRef]

- Çalık, A. A novel Pythagorean fuzzy AHP and fuzzy TOPSIS methodology for green supplier selection in the Industry 4.0 era. Soft Comput. 2020, 25, 2253–2265. [Google Scholar] [CrossRef]

- Rani, P.; Mishra, A.R.; Pardasani, K.R.; Mardani, A.; Liao, H.; Streimikiene, D. A novel VIKOR approach based on entropy and divergence measures of Pythagorean fuzzy sets to evaluate renewable energy technologies in India. J. Clean. Prod. 2019, 238, 117936. [Google Scholar] [CrossRef]

- Ozdemir, Y.; Gul, M. Measuring development levels of NUTS-2 regions in Turkey based on capabilities approach and multi-criteria decision-making. Comput. Ind. Eng. 2019, 128, 150–169. [Google Scholar] [CrossRef]

- Statista. Number of Cars Sold Worldwide between 2010 and 2021; Statista: Hamburg, Germany, 2020. [Google Scholar]

- Deloitte. Understanding COVID-19′s Impact on the Automotive Sector; Deloitte: Boston, MA, USA, 2020. [Google Scholar]

- Fallahpour, A.; Udoncy Olugu, E.; Nurmaya Musa, S.; Yew Wong, K.; Noori, S. A decision support model for sustainable supplier selection in sustainable supply chain management. Comput. Ind. Eng. 2017, 105, 391–410. [Google Scholar] [CrossRef]

- Shishodia, A.; Verma, P.; Dixit, V. Supplier evaluation for resilient project driven supply chain. Comput. Ind. Eng. 2019, 129, 465–478. [Google Scholar] [CrossRef]

- Mohammed, A. Towards ‘gresilient’ supply chain management: A quantitative study. Resources 2020, 155, 104641. [Google Scholar] [CrossRef]

- Davoudabadi, R.; Mousavi, S.M.; Sharifi, E. An integrated weighting and ranking model based on entropy, DEA and PCA considering two aggregation approaches for resilient supplier selection problem. J. Comput. Sci. 2020, 40, 101074. [Google Scholar] [CrossRef]

- Pramanik, D.; Mondal, S.C.; Haldar, A. Resilient supplier selection to mitigate uncertainty: Soft-computing approach. J. Model. Manag. 2020, 15, 1339–1361. [Google Scholar] [CrossRef]

- Fallahpour, A.; Nayeri, S.; Sheikhalishahi, M.; Wong, K.Y.; Tian, G.; Fathollahi-Fard, A.M. A hyper-hybrid fuzzy decision-making framework for the sustainable-resilient supplier selection problem: A case study of Malaysian Palm oil industry. Environ. Sci. Pollut. Res. 2021. ahead of print. [Google Scholar] [CrossRef]

- Sahebjamnia, N. Resilient supplier selection and order allocation under uncertainty. Sci. Iran. 2020, 27, 411–426. [Google Scholar] [CrossRef]

- Sureeyatanapas, P.; Waleekhajornlert, N.; Arunyanart, S.; Niyamosoth, T. Resilient Supplier Selection in Electronic Components Procurement: An Integration of Evidence Theory and Rule-Based Transformation into TOPSIS to Tackle Uncertain and Incomplete Information. Symmetry 2020, 12, 1109. [Google Scholar] [CrossRef]

- Hosseini, S.; Khaled, A.A. A Hybrid Ensemble and AHP Approach for Resilient Supplier Selection. J. Intell. Manuf. 2019, 30, 207–228. [Google Scholar] [CrossRef]

- Haldar, A.; Ray, A.; Banerjee, D.; Ghosh, S. Resilient supplier selection under a fuzzy environment. Int. J. Manag. Sci. Eng. Manag. 2014, 9, 147–156. [Google Scholar] [CrossRef]

- Valipour Parkouhi, S.; Safaei Ghadikolaei, A. A resilience approach for supplier selection: Using Fuzzy Analytic Network Process and grey VIKOR techniques. J. Clean. Prod. 2017, 161, 431–451. [Google Scholar] [CrossRef]

- Wang, T.-K.; Zhang, Q.; Chong, H.-Y.; Wang, X. Integrated Supplier Selection Framework in a Resilient Construction Supply Chain: An Approach via Analytic Hierarchy Process (AHP) and Grey Relational Analysis (GRA). Sustainability 2017, 9, 289. [Google Scholar] [CrossRef]

- Valipour Parkouhi, S.; Safaei Ghadikolaei, A.; Fallah Lajimi, H. Resilient supplier selection and segmentation in grey environment. J. Clean. Prod. 2019, 207, 1123–1137. [Google Scholar] [CrossRef]

- Davoudabadi, R.; Mousavi, S.M.; Mohagheghi, V.; Vahdani, B. Resilient Supplier Selection Through Introducing a New Interval-Valued Intuitionistic Fuzzy Evaluation and Decision-Making Framework. Arab. J. Sci. Eng. 2019, 44, 7351–7360. [Google Scholar] [CrossRef]

- Haldar, A.; Ray, A.; Banerjee, D.; Ghosh, S. A hybrid MCDM model for resilient supplier selection. Int. J. Manag. Sci. Eng. Manag. 2012, 7, 284–292. [Google Scholar] [CrossRef]

- Sahu, A.K.; Datta, S.; Mahapatra, S.S. Evaluation and selection of resilient suppliers in fuzzy environment. Benchmarking Int. J. 2016, 23, 651–673. [Google Scholar] [CrossRef]

- Pramanik, D.; Haldar, A.; Mondal, S.C.; Naskar, S.K.; Ray, A. Resilient supplier selection using AHP-TOPSIS-QFD under a fuzzy environment. Int. J. Manag. Sci. Eng. Manag. 2017, 12, 45–54. [Google Scholar] [CrossRef]

- Ilbahar, E.; Karaşan, A.; Cebi, S.; Kahraman, C. A novel approach to risk assessment for occupational health and safety using Pythagorean fuzzy AHP & fuzzy inference system. Saf. Sci. 2018, 103, 124–136. [Google Scholar] [CrossRef]

- Gul, M. Application of Pythagorean fuzzy AHP and VIKOR methods in occupational health and safety risk assessment: The case of a gun and rifle barrel external surface oxidation and colouring unit. Int. J. Occup. Saf. Ergon. 2018, 26, 705–718. [Google Scholar] [CrossRef]

- Gul, M.; Ak, M.F. A comparative outline for quantifying risk ratings in occupational health and safety risk assessment. J. Clean. Prod. 2018, 196, 653–664. [Google Scholar] [CrossRef]

- Cui, F.-B.; You, X.-Y.; Shi, H.; Liu, H.-C. Optimal Siting of Electric Vehicle Charging Stations Using Pythagorean Fuzzy VIKOR Approach. Math. Probl. Eng. 2018, 2018, 9262067. [Google Scholar] [CrossRef]

- Büyüközkan, G.; Göçer, F. A Novel Approach Integrating AHP and COPRAS Under Pythagorean Fuzzy Sets for Digital Supply Chain Partner Selection. IEEE Trans. Eng. Manag. 2019, 68, 1486–1503. [Google Scholar] [CrossRef]

- Karasan, A.; Ilbahar, E.; Kahraman, C. A novel pythagorean fuzzy AHP and its application to landfill site selection problem. Soft Comput. 2019, 23, 10953–10968. [Google Scholar] [CrossRef]

- Mete, S. Assessing occupational risks in pipeline construction using FMEA-based AHP-MOORA integrated approach under Pythagorean fuzzy environment. Hum. Ecol. Risk Assess. Int. J. 2019, 25, 1645–1660. [Google Scholar] [CrossRef]

- Liang, D.; Zhang, Y.; Xu, Z.; Jamaldeen, A. Pythagorean fuzzy VIKOR approaches based on TODIM for evaluating internet banking website quality of Ghanaian banking industry. Appl. Soft Comput. 2019, 78, 583–594. [Google Scholar] [CrossRef]

- Mete, S.; Serin, F.; Oz, N.E.; Gul, M. A decision-support system based on Pythagorean fuzzy VIKOR for occupational risk assessment of a natural gas pipeline construction. J. Nat. Gas Sci. Eng. 2019, 71, 102979. [Google Scholar] [CrossRef]

- Gul, M.; Ak, M.F.; Guneri, A.F. Pythagorean fuzzy VIKOR-based approach for safety risk assessment in mine industry. J. Saf. Res. 2019, 69, 135–153. [Google Scholar] [CrossRef] [PubMed]

- Yucesan, M.; Kahraman, G. Risk evaluation and prevention in hydropower plant operations: A model based on Pythagorean fuzzy AHP. Energy Policy 2019, 126, 343–351. [Google Scholar] [CrossRef]

- Shete, P.C.; Ansari, Z.N.; Kant, R. A Pythagorean fuzzy AHP approach and its application to evaluate the enablers of sustainable supply chain innovation. Sustain. Prod. Consum. 2020, 23, 77–93. [Google Scholar] [CrossRef]

- Tepe, S.; Kaya, İ. A fuzzy-based risk assessment model for evaluations of hazards with a real-case study. Hum. Ecol. Risk Assess. Int. J. 2020, 26, 512–537. [Google Scholar] [CrossRef]

- Wang, L.; Li, W.; Li, H. Decision-making for ecological landslide prevention in tropical rainforests. Nat. Hazards 2020, 103, 985–1008. [Google Scholar] [CrossRef]

- Yucesan, M.; Gul, M. Hospital service quality evaluation: An integrated model based on Pythagorean fuzzy AHP and fuzzy TOPSIS. Soft Comput. 2020, 24, 3237–3255. [Google Scholar] [CrossRef]

- Sarkar, B.; Biswas, A. Pythagorean fuzzy AHP-TOPSIS integrated approach for transportation management through a new distance measure. Soft Comput. 2021, 25, 4073–4089. [Google Scholar] [CrossRef]

- Ayyildiz, E.; Taskin Gumus, A. Interval-valued Pythagorean fuzzy AHP method-based supply chain performance evaluation by a new extension of SCOR model: SCOR 4.0. Complex Intell. Syst. 2021, 7, 559–576. [Google Scholar] [CrossRef]

- Ayyildiz, E.; Taskin Gumus, A. Pythagorean fuzzy AHP based risk assessment methodology for hazardous material transportation: An application in Istanbul. Environ. Sci. Pollut. Res. 2021, 28, 35798–35810. [Google Scholar] [CrossRef]

- Bakioglu, G.; Atahan, A.O. AHP integrated TOPSIS and VIKOR methods with Pythagorean fuzzy sets to prioritize risks in self-driving vehicles. Appl. Soft Comput. 2021, 99, 106948. [Google Scholar] [CrossRef]

- Ayyildiz, E.; Taskin, A. A novel spherical fuzzy AHP-VIKOR methodology to determine serving petrol station selection during COVID-19 lockdown: A pilot study for İstanbul. Socio-Econ. Plan. Sci. 2022, 83, 101345. [Google Scholar] [CrossRef]

- Awasthi, A.; Govindan, K.; Gold, S. Multi-tier sustainable global supplier selection using a fuzzy AHP-VIKOR based approach. Int. J. Prod. Econ. 2018, 195, 106–117. [Google Scholar] [CrossRef]

- Hemmati, A.; Stålhane, M.; Hvattum, L.M.; Andersson, H. An effective heuristic for solving a combined cargo and inventory routing problem in tramp shipping. Comput. Oper. Res. 2015, 64, 274–282. [Google Scholar] [CrossRef]

- Ibishukcu, O.; Datar, A. Maintaining Power Relations in Supply Chain; Jönköping University: Jönköping, Sweden, 2016. [Google Scholar]

- Milovanovic, G.; Milovanovic, S.; Spasic, T. The role of contemporary web technologies in supply chain management. Ekonomika 2016, 62, 43–58. [Google Scholar] [CrossRef]

- Welker, G.A.; de Vries, J. Formalisation of the Ordering Process; University of Groningen: Groningen, The Netherlands, 2002. [Google Scholar]

- Chen, X.; Wan, N.; Wang, X. Flexibility and coordination in a supply chain with bidirectional option contracts and service requirement. Int. J. Prod. Econ. 2017, 193, 183–192. [Google Scholar] [CrossRef]

- Alikhani, R.; Torabi, S.A.; Altay, N. Retail supply chain network design with concurrent resilience capabilities. Int. J. Prod. Econ. 2021, 234, 108042. [Google Scholar] [CrossRef]

- Ivanov, D. Revealing interfaces of supply chain resilience and sustainability: A simulation study. Int. J. Prod. Res. 2018, 56, 3507–3523. [Google Scholar] [CrossRef]

- Salehi Sadghiani, N.; Torabi, S.A.; Sahebjamnia, N. Retail supply chain network design under operational and disruption risks. Transp. Res. Part E Logist. Transp. Rev. 2015, 75, 95–114. [Google Scholar] [CrossRef]

- Manello, A.; Calabrese, G. The influence of reputation on supplier selection: An empirical study of the European automotive industry. J. Purch. Supply Manag. 2019, 25, 69–77. [Google Scholar] [CrossRef]

- Scholten, K.; Schilder, S. The role of collaboration in supply chain resilience. Supply Chain. Manag. Int. J. 2015, 20, 471–484. [Google Scholar] [CrossRef]

- Gunasekaran, A.; Subramanian, N.; Rahman, S. Supply chain resilience: Role of complexities and strategies. Int. J. Prod. Res. 2015, 53, 6809–6819. [Google Scholar] [CrossRef]

- Sabouhi, F.; Pishvaee, M.S.; Jabalameli, M.S. Resilient supply chain design under operational and disruption risks considering quantity discount: A case study of pharmaceutical supply chain. Comput. Ind. Eng. 2018, 126, 657–672. [Google Scholar] [CrossRef]

- Adobor, H. Supply chain resilience: A multi-level framework. Int. J. Logist. Res. Appl. 2019, 22, 533–556. [Google Scholar] [CrossRef]

- Ageron, B.; Bentahar, O.; Gunasekaran, A. Digital supply chain: Challenges and future directions. Supply Chain. Forum Int. J. 2020, 21, 133–138. [Google Scholar] [CrossRef]

- Ghadge, A.; Kara, M.E.; Moradlou, H.; Goswami, M. The impact of Industry 4.0 implementation on supply chains. J. Manuf. Technol. Manag. 2020, 31, 669–686. [Google Scholar] [CrossRef]

- Irfan, M.; Wang, M.; Akhtar, N. Enabling supply chain agility through process integration and supply flexibility. Asia Pac. J. Mark. Logist. 2019. [Google Scholar] [CrossRef]

- Lin, C.-T.; Chiu, H.; Chu, P.-Y. Agility index in the supply chain. Int. J. Prod. Econ. 2006, 100, 285–299. [Google Scholar] [CrossRef]

- Wu, K.-J.; Tseng, M.-L.; Chiu, A.S.F.; Lim, M.K. Achieving competitive advantage through supply chain agility under uncertainty: A novel multi-criteria decision-making structure. Int. J. Prod. Econ. 2017, 190, 96–107. [Google Scholar] [CrossRef]

- Agarwal, A.; Shankar, R.; Tiwari, M.K. Modeling agility of supply chain. Ind. Mark. Manag. 2007, 36, 443–457. [Google Scholar] [CrossRef]

- Chan, A.T.L.; Ngai, E.W.T.; Moon, K.K.L. The effects of strategic and manufacturing flexibilities and supply chain agility on firm performance in the fashion industry. Eur. J. Oper. Res. 2017, 259, 486–499. [Google Scholar] [CrossRef]

- Yang, J. Supply chain agility: Securing performance for Chinese manufacturers. Int. J. Prod. Econ. 2014, 150, 104–113. [Google Scholar] [CrossRef]

- Ijadi Maghsoodi, A.; Kavian, A.; Khalilzadeh, M.; Brauers, W.K.M. CLUS-MCDA: A novel framework based on cluster analysis and multiple criteria decision theory in a supplier selection problem. Comput. Ind. Eng. 2018, 118, 409–422. [Google Scholar] [CrossRef]

- Kannan, D.; Govindan, K.; Rajendran, S. Fuzzy Axiomatic Design approach based green supplier selection: A case study from Singapore. J. Clean. Prod. 2015, 96, 194–208. [Google Scholar] [CrossRef]

- Mina, H.; Kannan, D.; Gholami-Zanjani, S.M.; Biuki, M. Transition towards circular supplier selection in petrochemical industry: A hybrid approach to achieve sustainable development goals. J. Clean. Prod. 2021, 286, 125273. [Google Scholar] [CrossRef]

- Inemek, A.; Tuna, O. Global supplier selection strategies and implications for supplier performance: Turkish suppliers’ perception. Int. J. Logist. Res. Appl. 2009, 12, 381–406. [Google Scholar] [CrossRef]

- Jain, N.; Singh, A.R. Sustainable supplier selection under must-be criteria through Fuzzy inference system. J. Clean. Prod. 2020, 248, 119275. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, S.; Yao, J.; Li, Y.; Yang, S. Socially responsible supplier selection and sustainable supply chain development: A combined approach of total interpretive structural modeling and fuzzy analytic network process. Bus. Strategy Environ. 2018, 27, 1708–1719. [Google Scholar] [CrossRef]

- Lamba, K.; Singh, S.P. Dynamic supplier selection and lot-sizing problem considering carbon emissions in a big data environment. Technol. Forecast. Soc. Chang. 2019, 144, 573–584. [Google Scholar] [CrossRef]

- Roy, S.A.; Ali, S.M.; Kabir, G.; Enayet, R.; Suhi, S.A.; Haque, T.; Hasan, R. A framework for sustainable supplier selection with transportation criteria. Int. J. Sustain. Eng. 2020, 13, 77–92. [Google Scholar] [CrossRef]

- Feng, J.; Gong, Z. Integrated linguistic entropy weight method and multi-objective programming model for supplier selection and order allocation in a circular economy: A case study. J. Clean. Prod. 2020, 277, 122597. [Google Scholar] [CrossRef]

- Hosseini, S.; Morshedlou, N.; Ivanov, D.; Sarder, M.D.; Barker, K.; Khaled, A.A. Resilient supplier selection and optimal order allocation under disruption risks. Int. J. Prod. Econ. 2019, 213, 124–137. [Google Scholar] [CrossRef]

- Peng, X.; Yang, Y. Fundamental Properties of Interval-Valued Pythagorean Fuzzy Aggregation Operators. Int. J. Intell. Syst. 2016, 31, 444–487. [Google Scholar] [CrossRef]

- Keshavarz Ghorabaee, M.; Amiri, M.; Zavadskas, E.K.; Turskis, Z.; Antucheviciene, J. A new multi-criteria model based on interval type-2 fuzzy sets and EDAS method for supplier evaluation and order allocation with environmental considerations. Comput. Ind. Eng. 2017, 112, 156–174. [Google Scholar] [CrossRef]

- Pamucar, D.; Yazdani, M.; Montero-Simo, M.J.; Araque-Padilla, R.A.; Mohammed, A. Multi-criteria decision analysis towards robust service quality measurement. Expert Syst. Appl. 2021, 170, 114508. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).