The Development, Coupling Degree, and Value-Added Capability of the Digital Economy and Manufacturing Industry in China

Abstract

1. Introduction

2. Literature Review

3. Theory and Methods

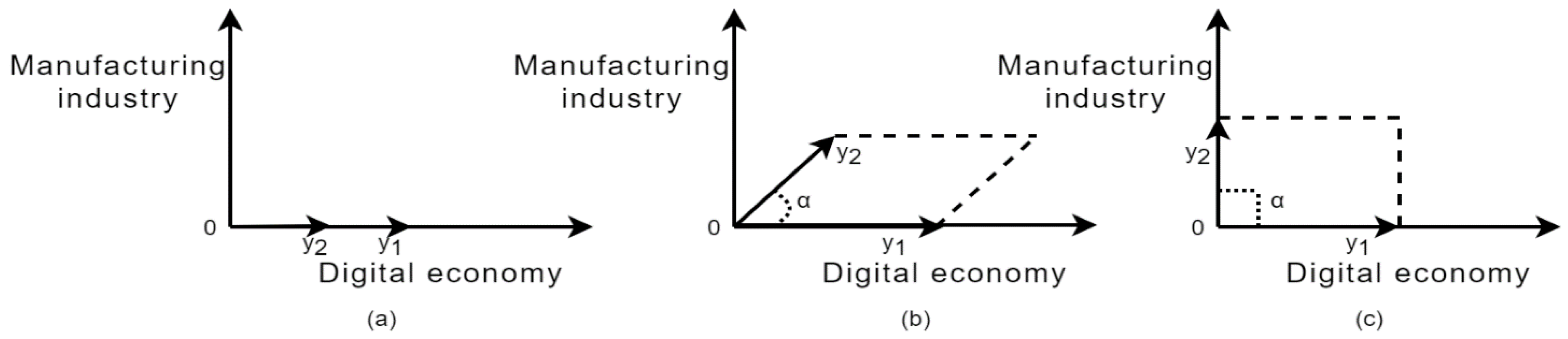

3.1. Theoretical Foundations of Interaction between the Digital Economy and Manufacturing System

3.1.1. The Coupling Mechanism between Digital Technology and Manufactured Products

3.1.2. Coupling Mechanism between Digital Technology and Manufacturers

3.1.3. The Coupling Mechanism between the Digital Economy and Manufacturing Industry

3.2. Methods

3.3. Index System

4. Results

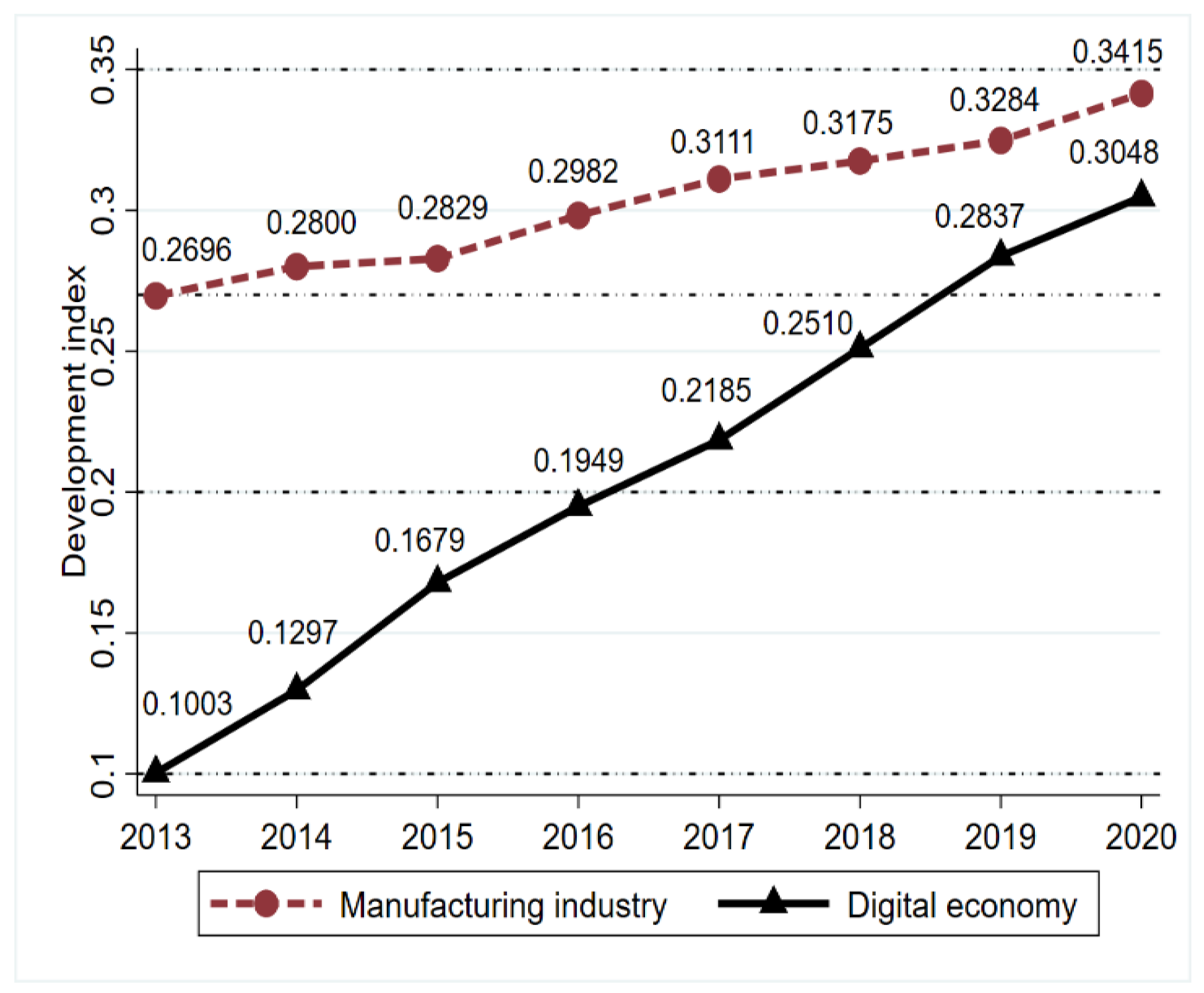

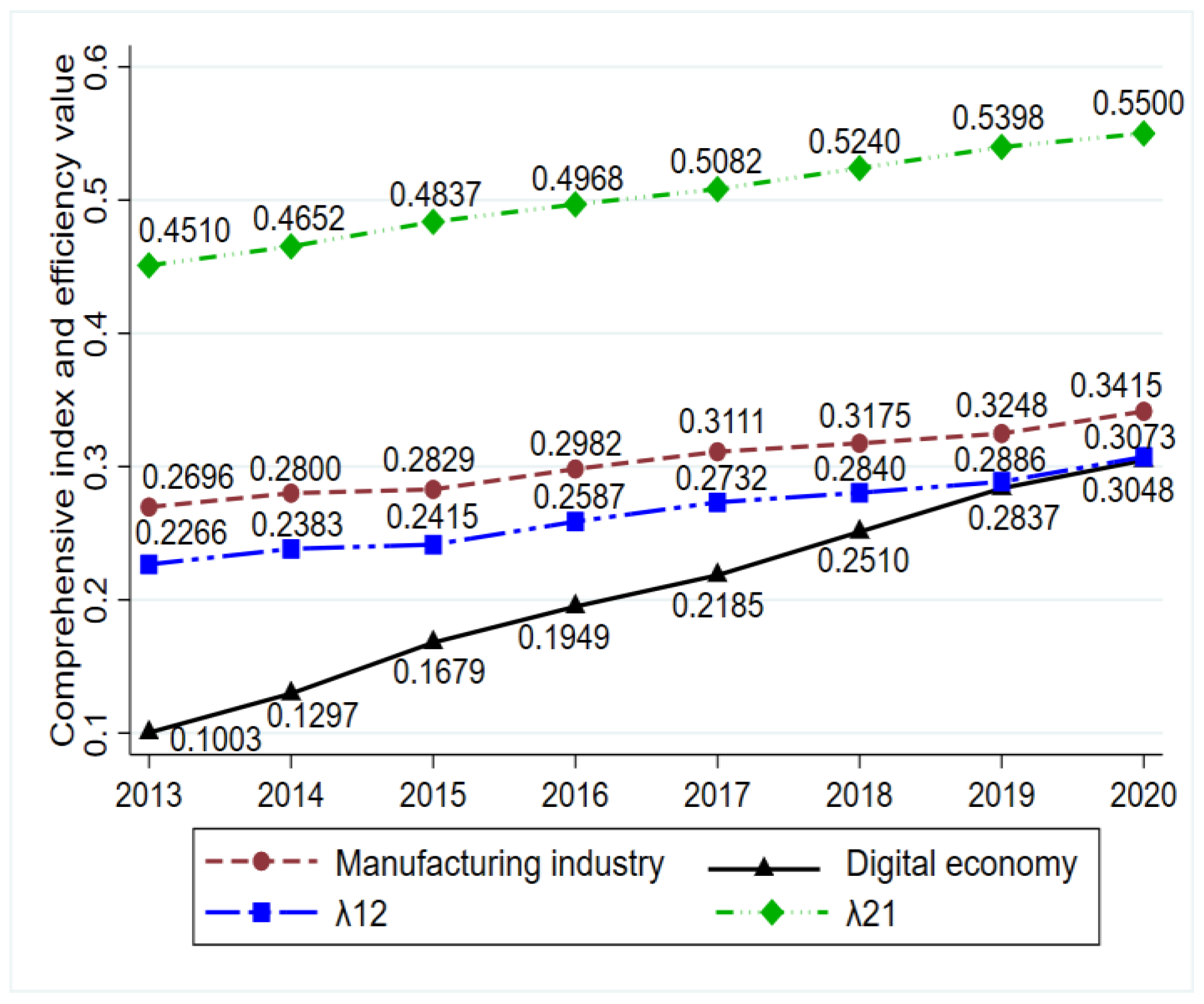

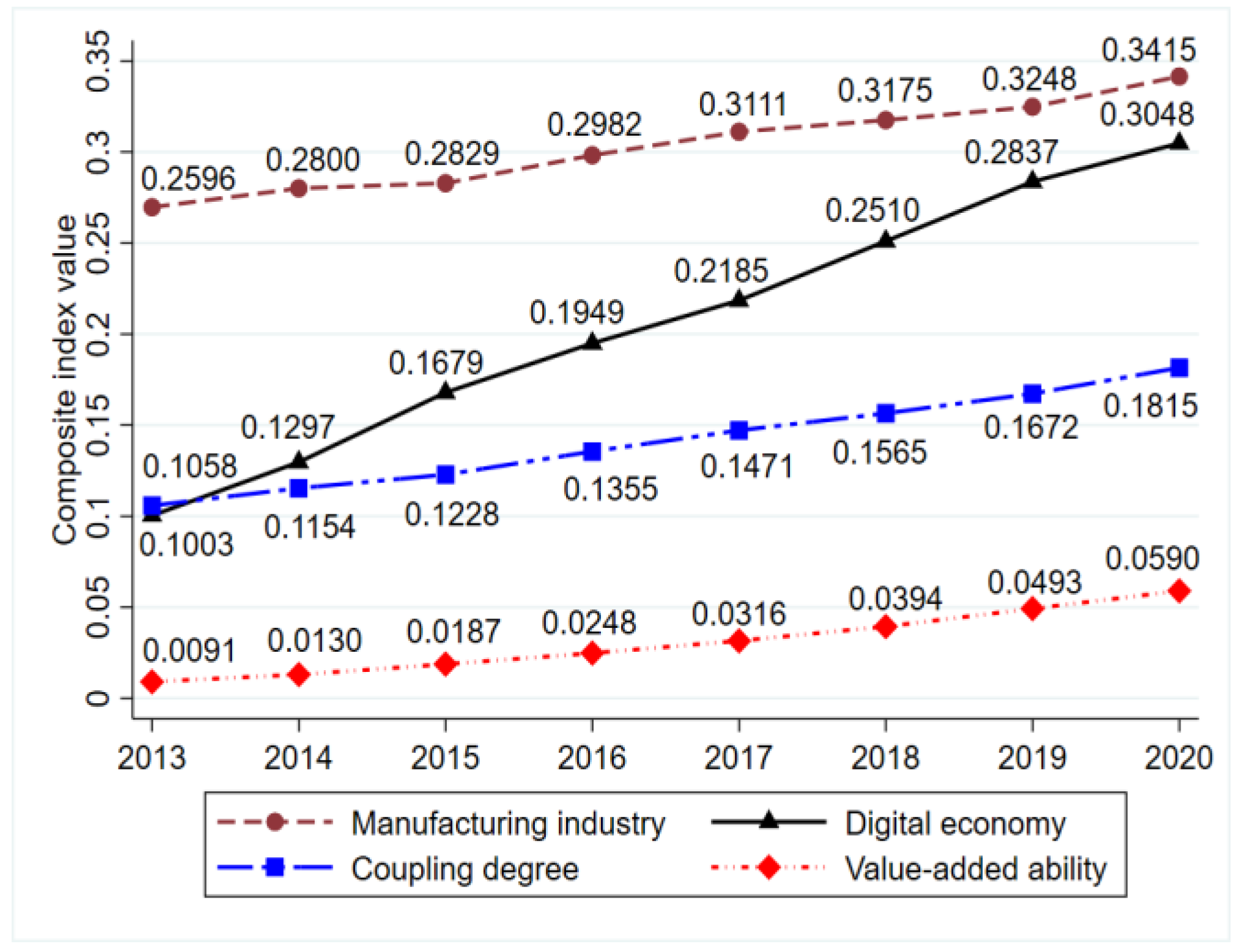

4.1. Comprehensive Index of Economy and Manufacturing Industry Development

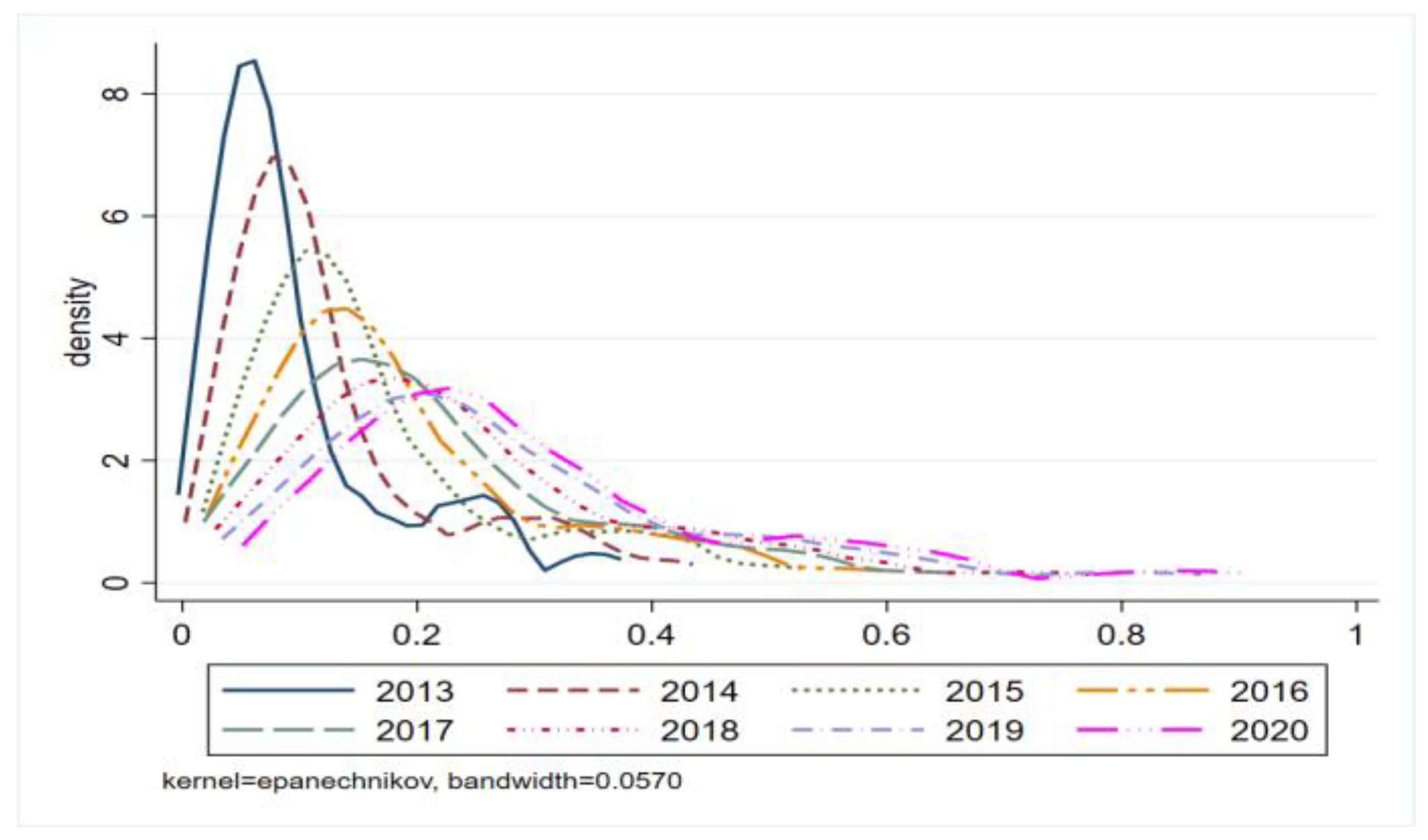

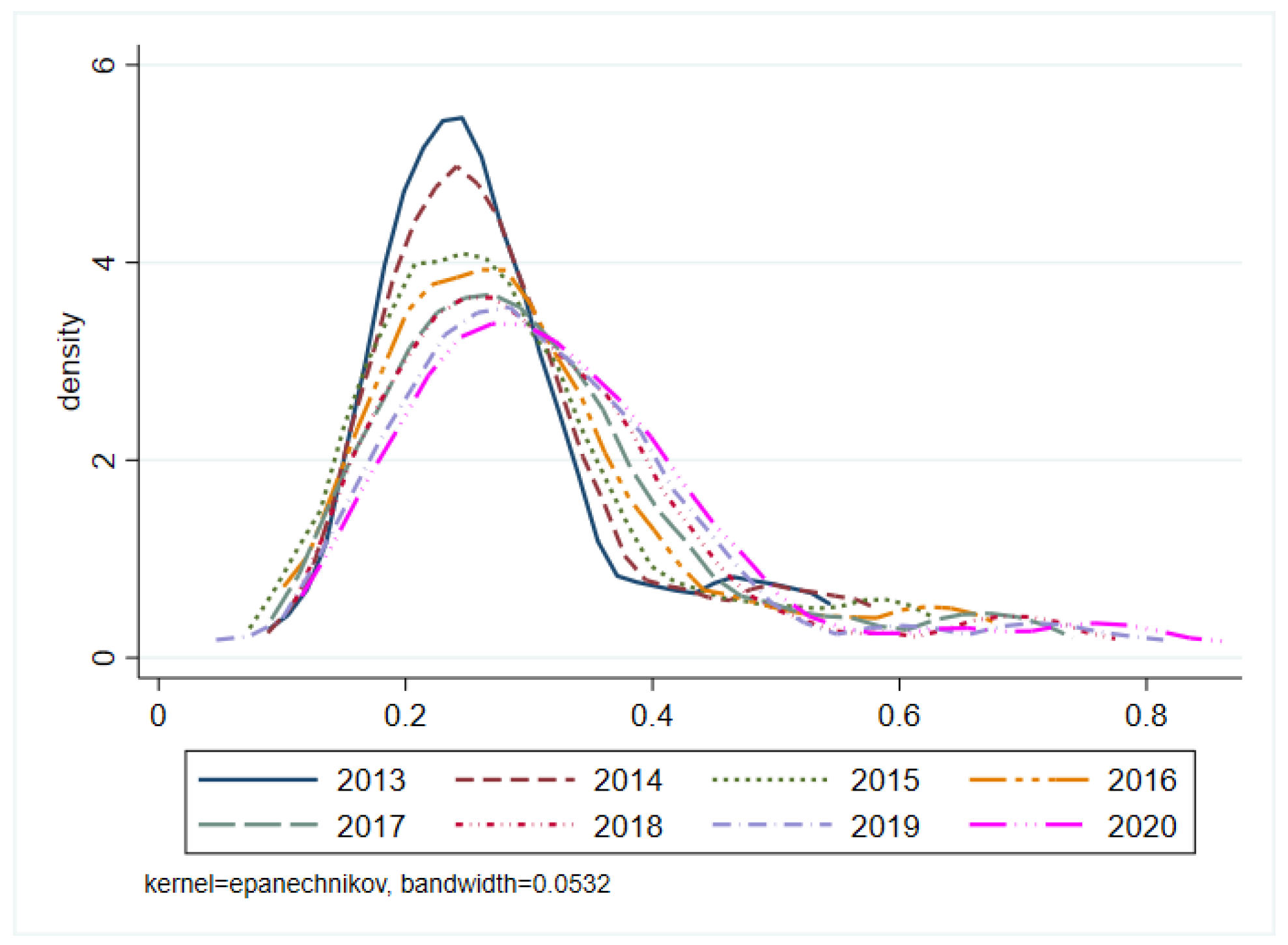

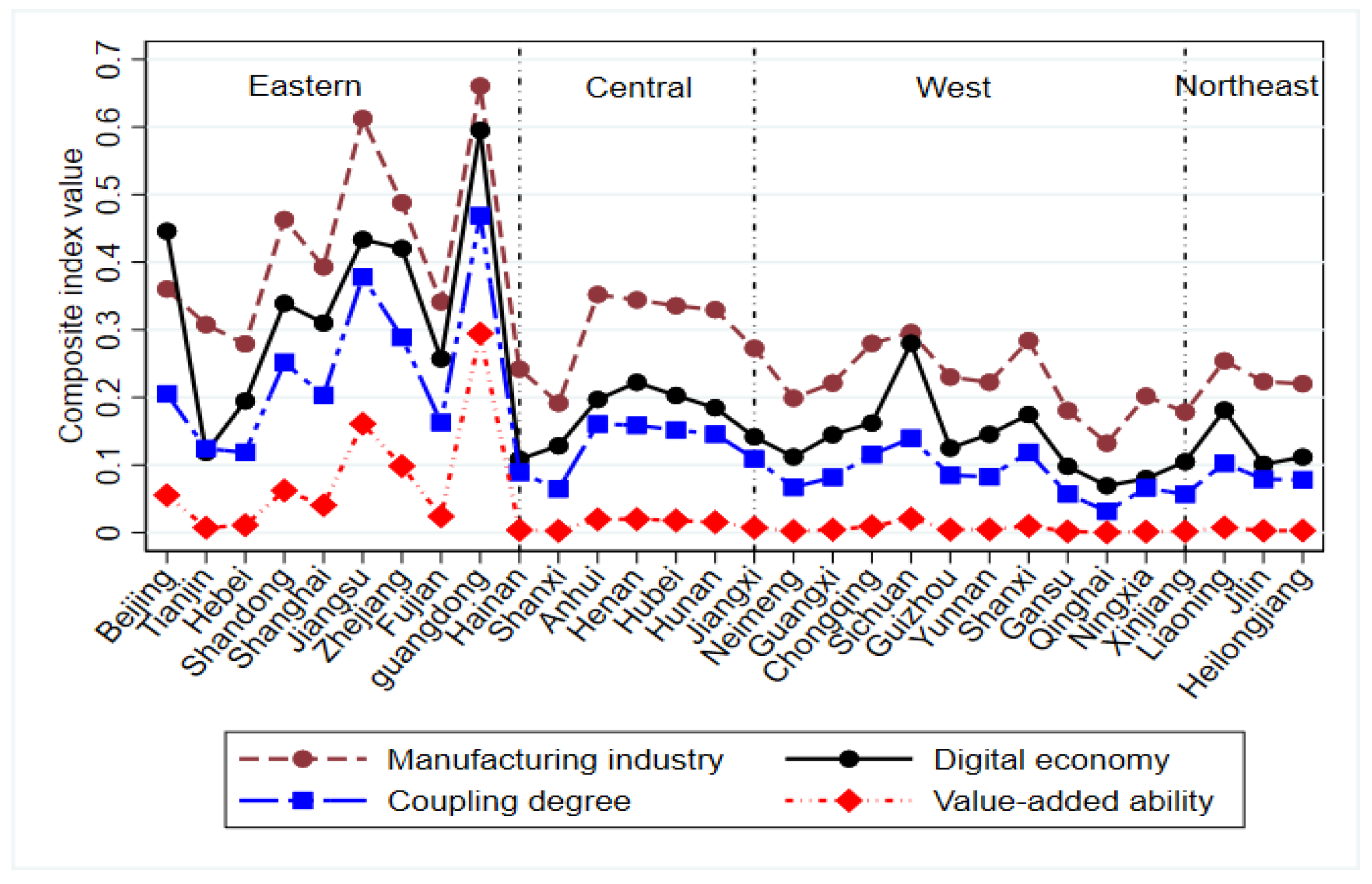

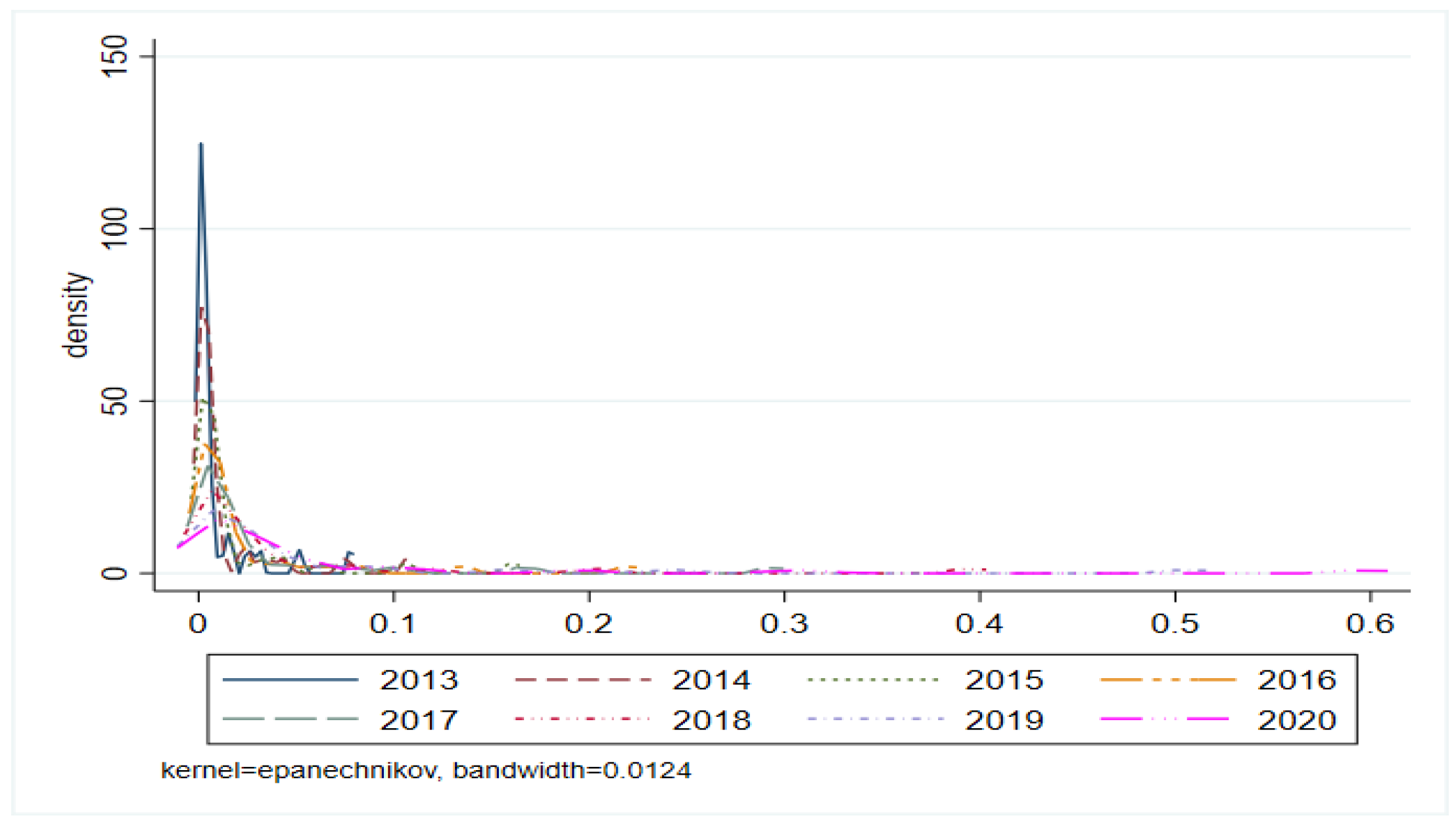

4.2. Visual Analysis of the Comprehensive Development Index

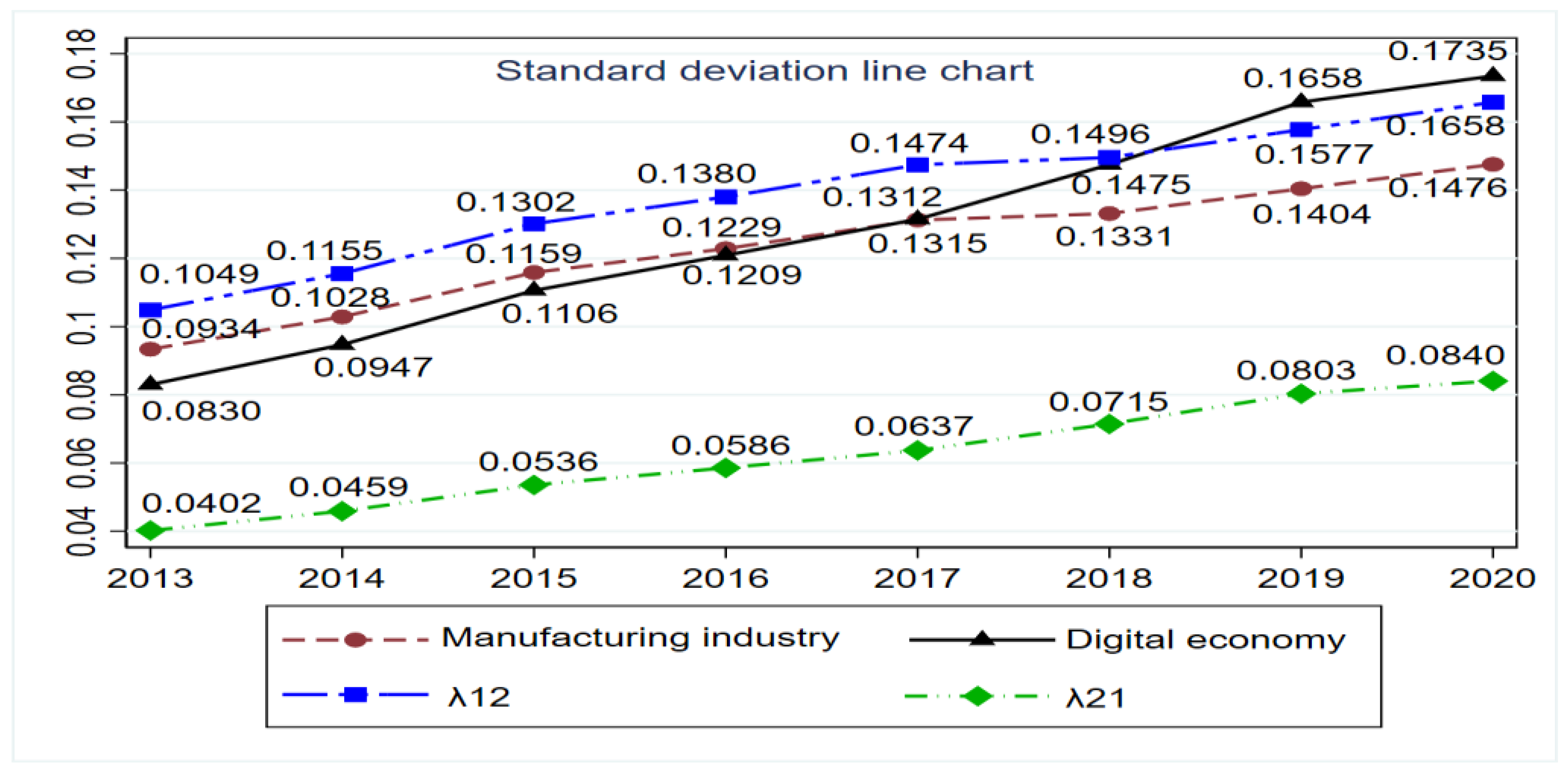

4.3. Promotion Efficiency between the Digital Economy and Manufacturing Industry Development

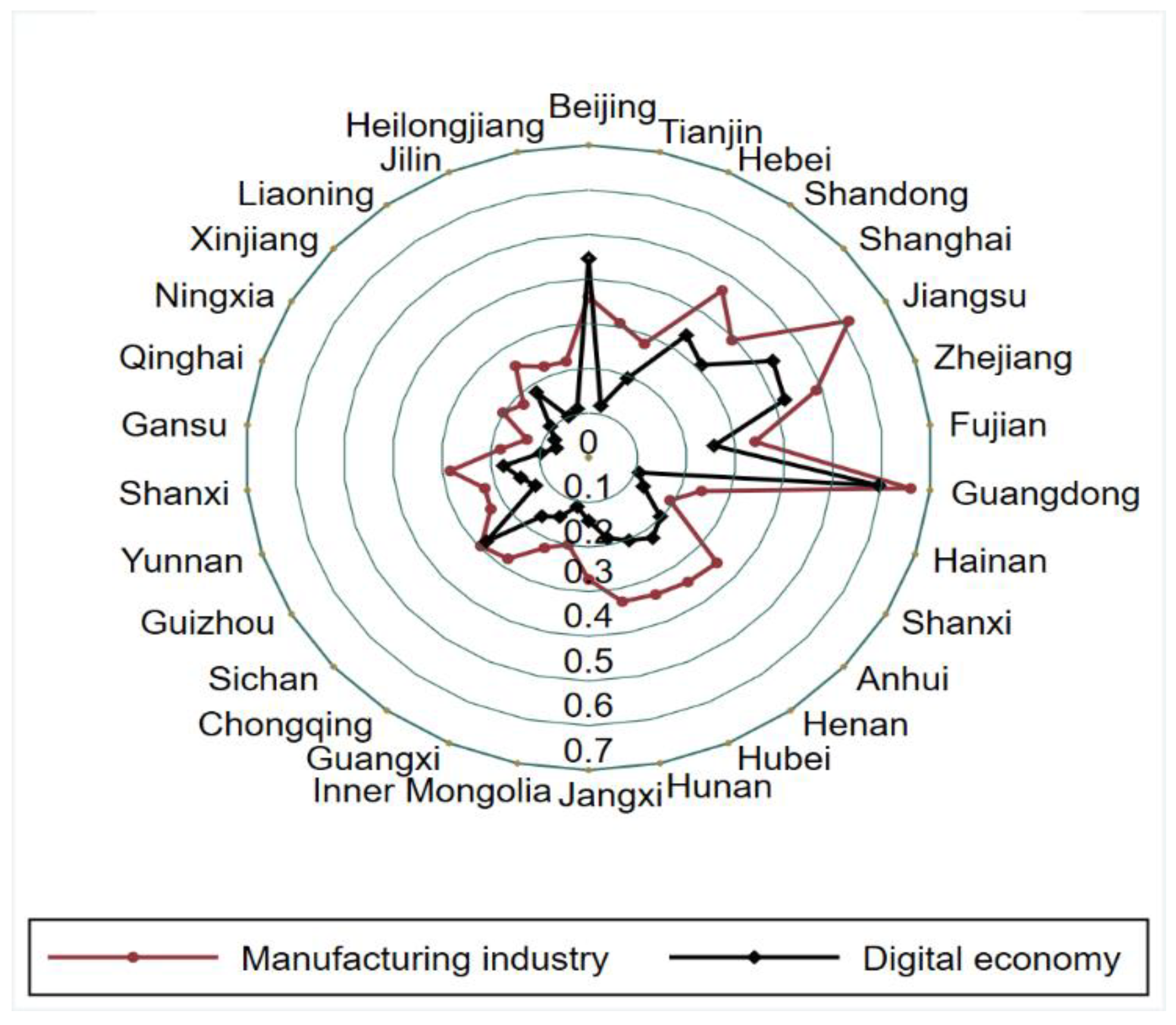

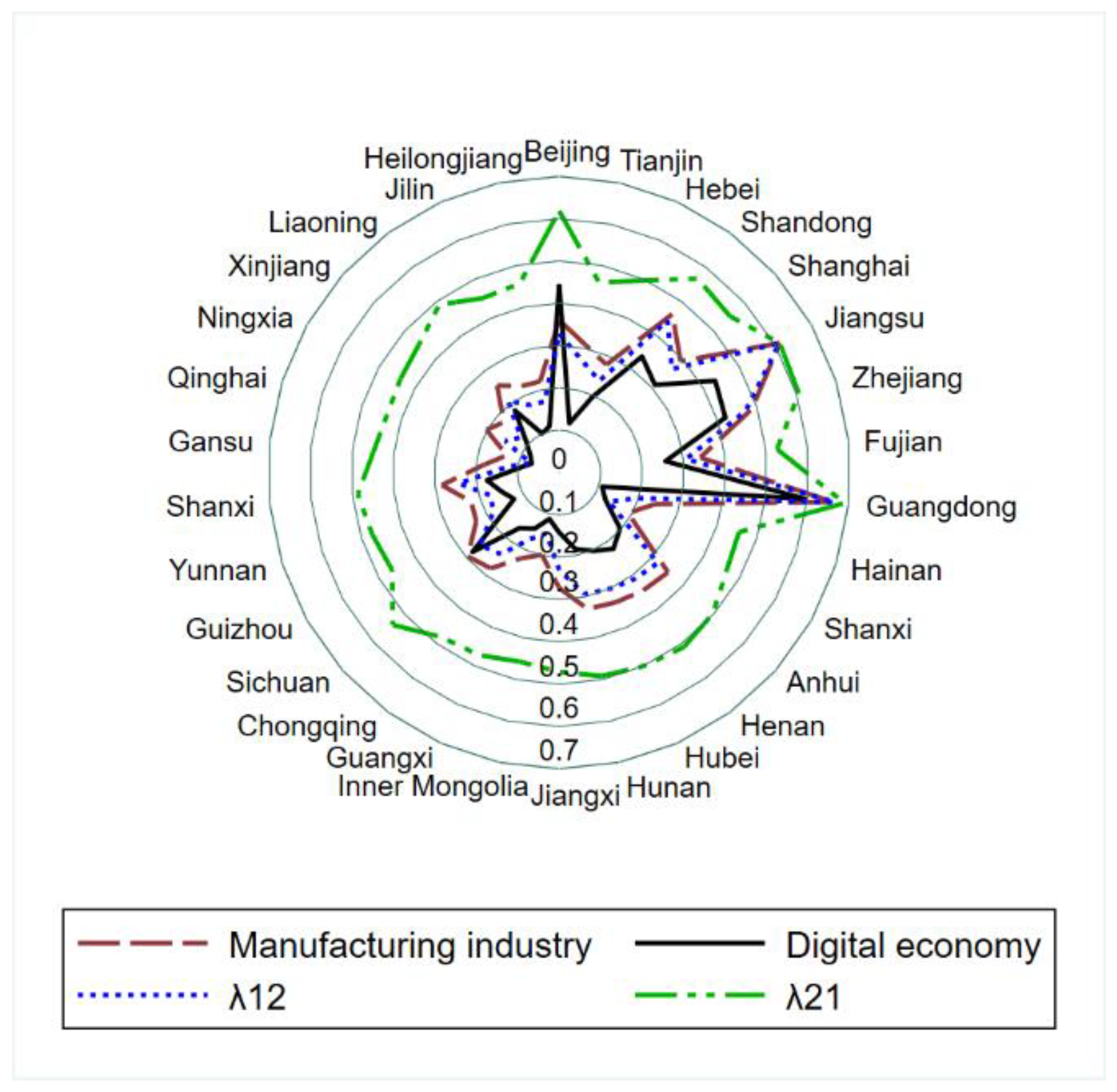

4.4. Visual Analysis of the Promoting Effect

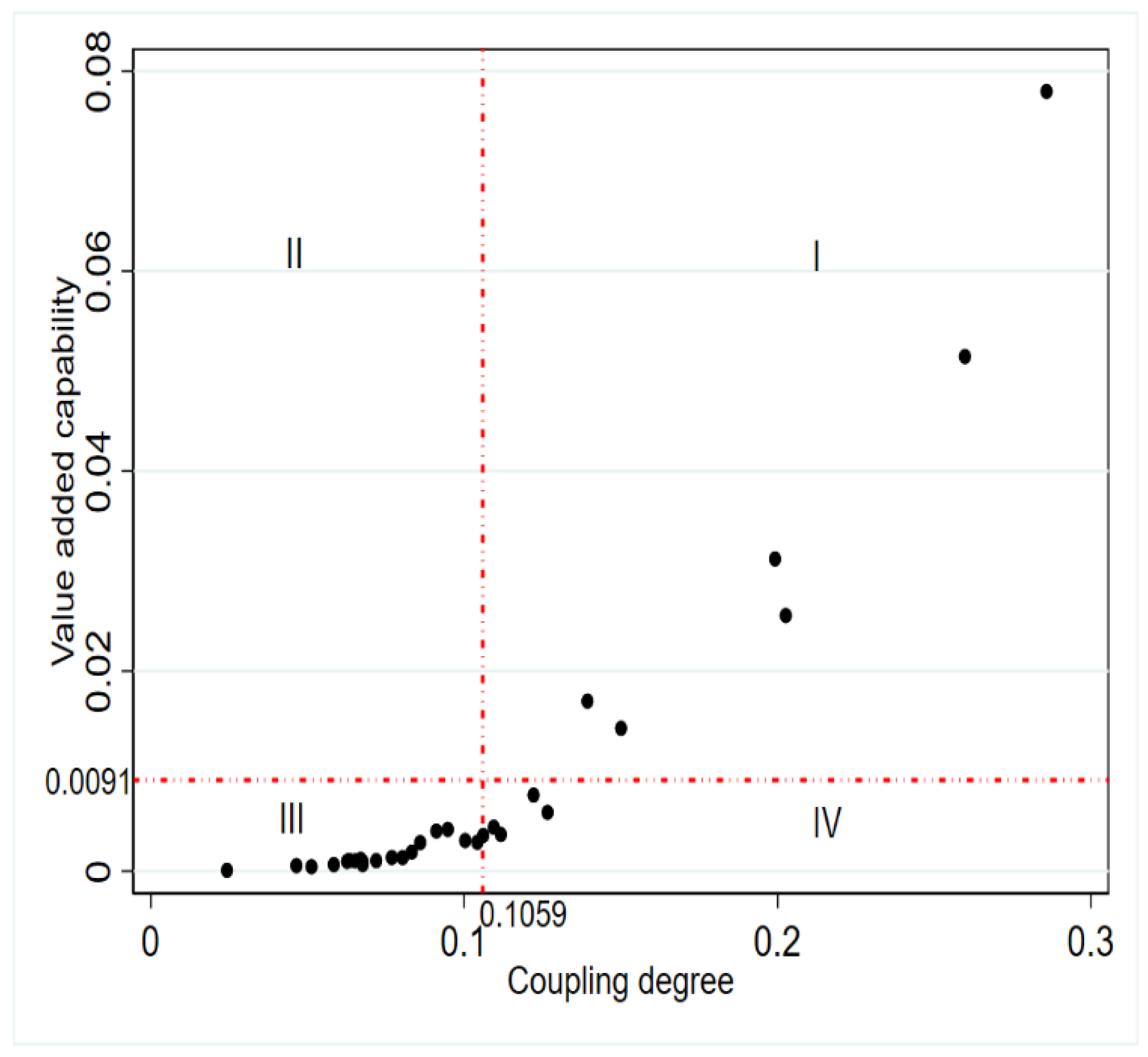

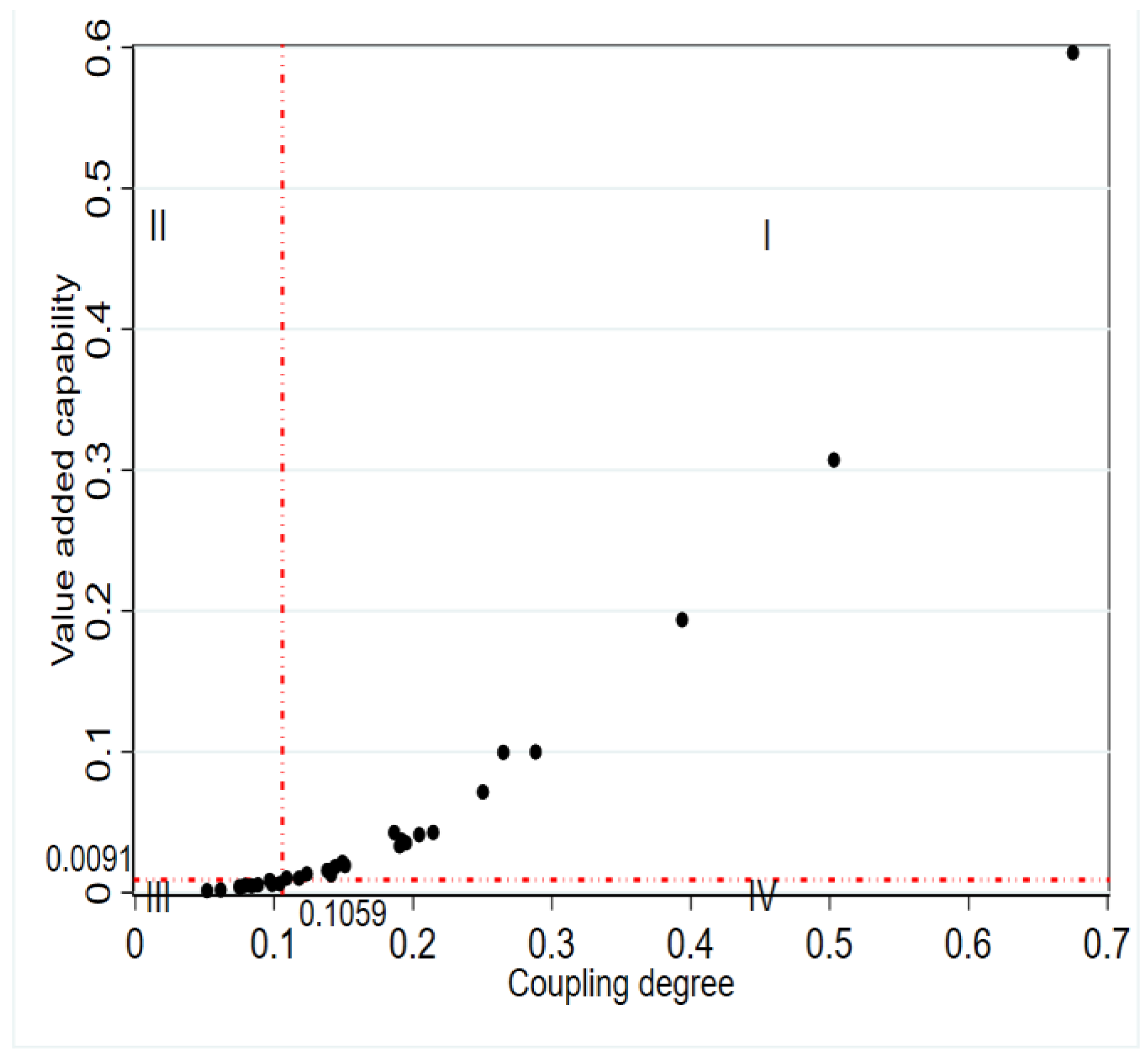

4.5. Coupling Degree and Value-Added Ability between the Digital Economy and the Manufacturing Industry

4.6. Visual Analysis of the Coupling Degree and the Value-Added Ability

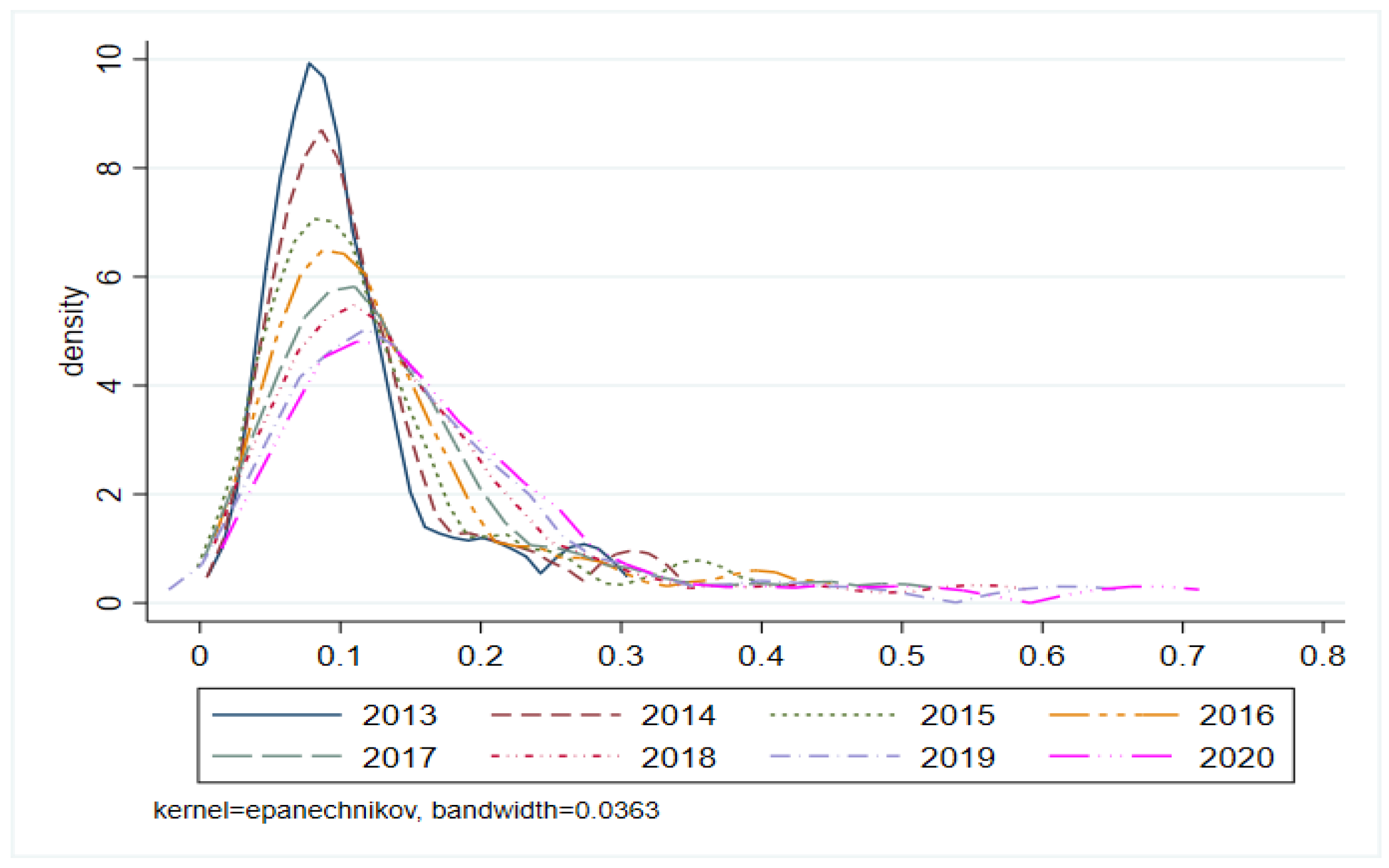

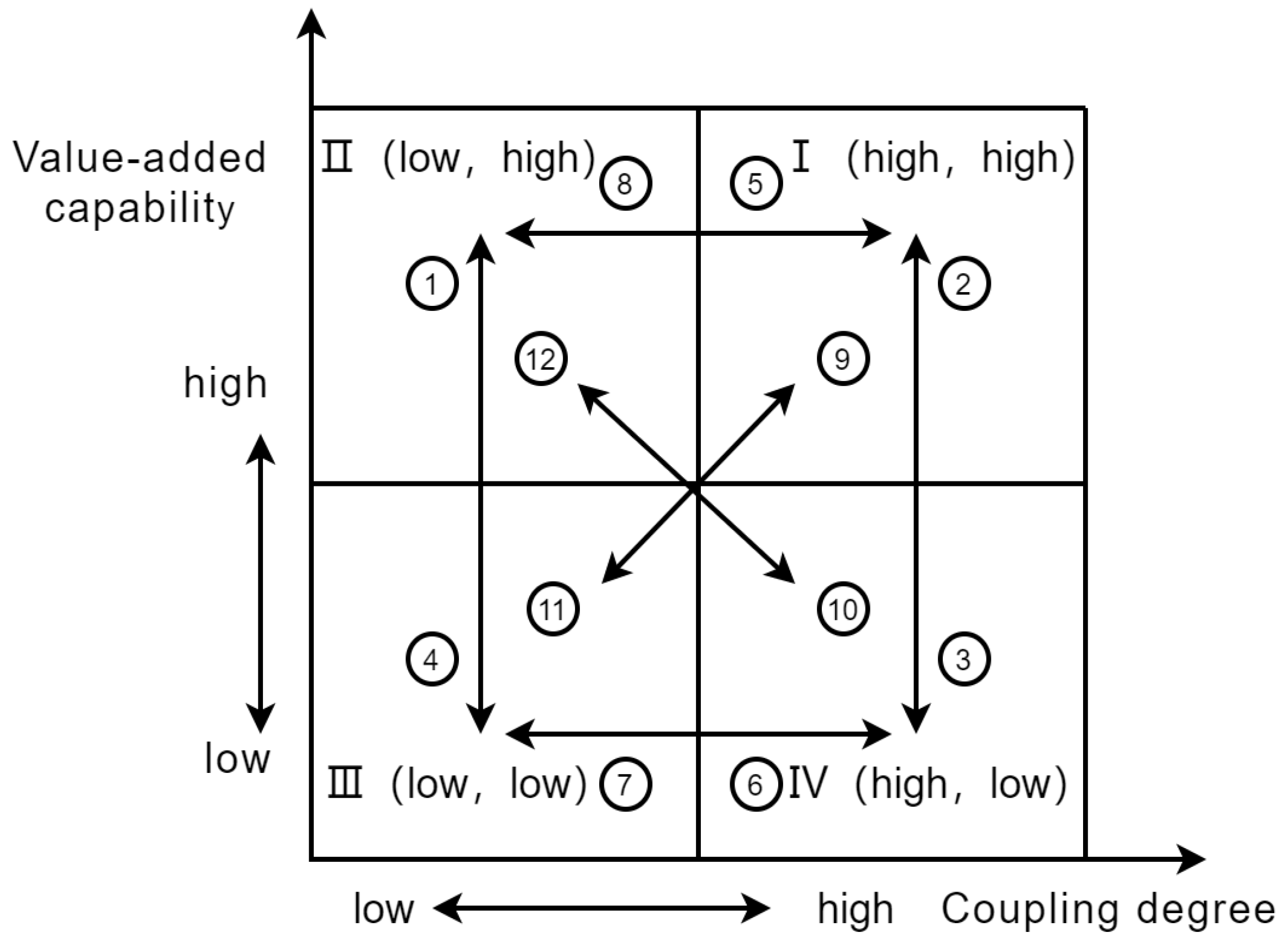

4.7. Analysis of the Evolution Pattern of the Coupling Degree and the Value-Added Capability of the Digital Economy and Manufacturing Industry System

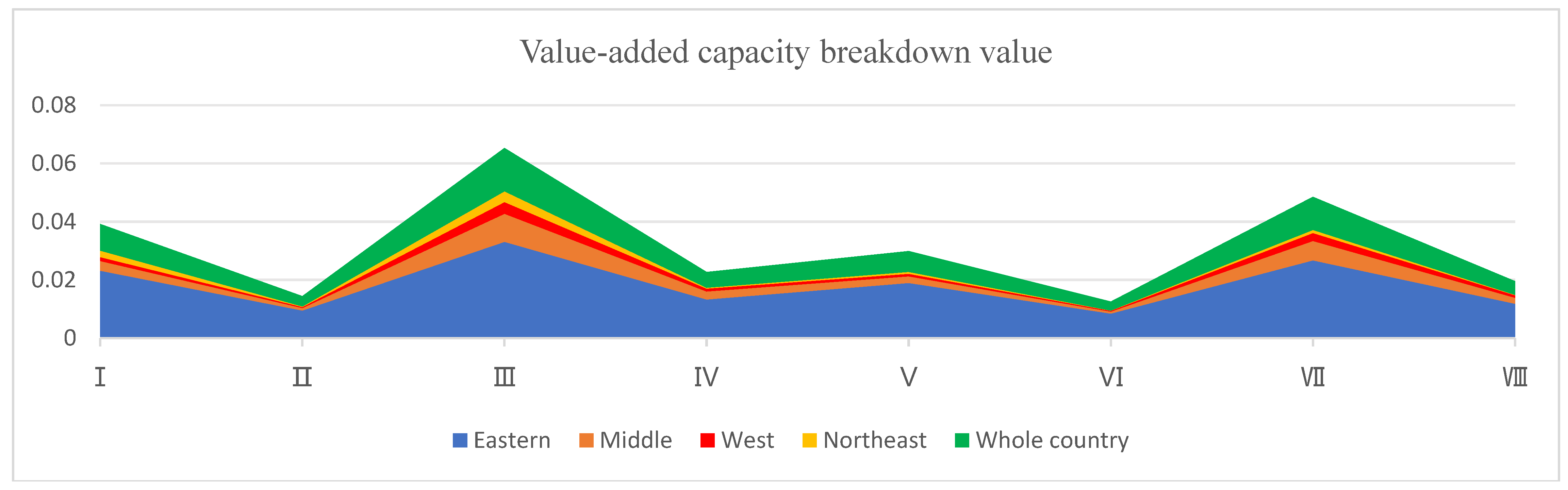

4.8. The Decomposition of the Value-Added Capability of the Digital Economy and the Manufacturing Industry

5. Discussion and Implications

5.1. Discussion

5.2. Implications

5.3. Limitations and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

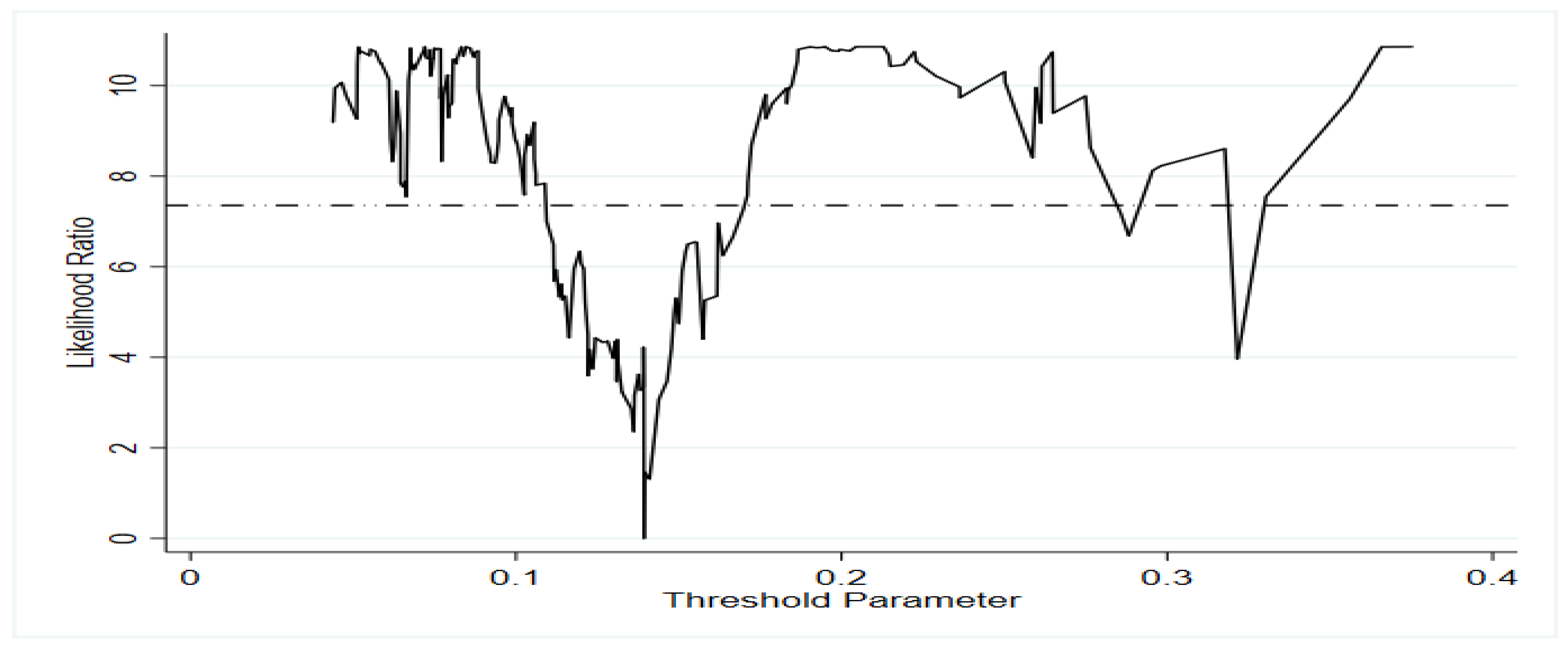

Panel Threshold Model Regression Test

- (1)

- Explained variable:

- (2)

- Explanatory variable and threshold variable:

- (3)

- Control variables:

| Explained Variables: The Digital Economy and the Value-Added Capability of the Manufacturing System (val) | ||||||

|---|---|---|---|---|---|---|

| Threshold value | F-statistic | p value | Threshold interval | Threshold interval regression coefficient | p value of interval regression | Interval sample size |

| 0.1393 | 63.72 *** | 0.000 | 0.909 *** | 0.000 | 159 | |

| 0.839 *** | 0.000 | 71 | ||||

| 0.956 *** | 0.000 | 10 | ||||

References

- China Academy of Information and Communication Research. Global Digital Economy White Paper—A New Dawn of Recovery under the Impact of the Epidemic (2021). China Academy of Information and Communication Research. 2021. Available online: http://www.caict.ac.cn/kxyj/qwfb/bps/202108/P020210913403798893557.pdf (accessed on 7 January 2023).

- Hui, N.; Yang, X. Digital economy drive and high-quality development of China’s manufacturing industry. J. Shaanxi Norm. Univ. 2022, 51, 133–147. [Google Scholar]

- Jiao, Y. Digital economy-enabled manufacturing transformation: From value reshaping to value creation. Economist 2020, 6, 87–94. [Google Scholar]

- Kılıçaslan, Y.; Töngür, Ü. ICT and employment generation: Evidence from Turkish manufacturing. Appl. Econ. Lett. 2019, 26, 1053–1057. [Google Scholar] [CrossRef]

- Rasel, F. ICT and global sourcing–evidence for German manufacturing and service firms. Econ. Innov. New Technol. 2017, 26, 634–660. [Google Scholar] [CrossRef]

- Kılıçaslan, Y.; Sickles, R.C.; Atay Kayış, A.A.; Gurel, Y.U. Impact of ICT on the productivity of the firm: Evidence from Turkish manufacturing. J. Prod. Anal. 2017, 47, 277–289. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, S.; Liu, Y.; Si, S.B. A big data analytics architecture for cleaner manufacturing and maintenance processes of complex products. J. Clean Prod. 2017, 142, 626–641. [Google Scholar] [CrossRef]

- Wamba, S.F.; Akter, S.; Edwards, A.; Chopin, G.; Gnanzou, D. How ‘big data’ can make big impact: Findings from a systematic review and a longitudinal case study. Int. J. Prod. Econ. 2015, 165, 234–246. [Google Scholar] [CrossRef]

- Sharma, R.; Mithas, S.; Kankanhalli, A. Transforming decision-making processes: A research agenda for understanding the impact of business analytics on organisations. Eur. J. Inf. Syst. 2014, 23, 433–441. [Google Scholar] [CrossRef]

- Liu, J.J.; Zhang, Z.Y.; Ayangbah, F. The impact of industrial internet on high quality development of the manufacturing industry. Cogent Econ. Financ. 2022, 10, 2135723. [Google Scholar]

- Shan, S.Q.; Wen, X.; Wei, Y.G.; Wang, Z.J.; Chen, Y. Intelligent manufacturing in industry 4.0: A case study of Sany heavy industry. Syst. Res. Behav. Sci. 2020, 37, 679–690. [Google Scholar] [CrossRef]

- Zhou, R.R.; Tang, D.C.; Da, D.; Chen, W.Y.; Kong, L.; Boamah, V. Research on China’s Manufacturing Industry Moving towards the Middle and High-End of the GVC Driven by Digital Economy. Sustainability 2022, 14, 7717. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, X.; Mao, F. The synergy degree measurement and transformation path of China’s traditional manufacturing industry enabled by digital economy. Math. Biosci. Eng. 2022, 19, 5738–5753. [Google Scholar] [PubMed]

- Xie, K.; Xiao, J.H.; Zhou, X.B.; Wu, J.P. The quality of industrialization and informatization integration in China: Theory and empirical evidence. Econ. Res. 2012, 47, 4–16+30. [Google Scholar]

- Wang, K.; Li, L.Y. An empirical study on the impact of "Internet+" on the development of China’s manufacturing industry. Quant. Econ. Tech. Econ. Res. 2018, 35, 3–20. [Google Scholar]

- Shi, Y.P. Integrated development of digital economy and manufacturing industry: Paths and suggestions. People’s Forum Acad. Front. 2021, 6, 34–39. [Google Scholar]

- Huang, Z.L.; Qin, S.Y.; Zhang, Y.H. How the digital economy drives the upgrading of manufacturing industry. Econ. Manag. 2022, 44, 80–97. [Google Scholar]

- Zheng, Q.J.; Jiang, W.M. Research on digital transformation of manufacturing enterprises under the perspective of digital economy. Jiangsu. Soc. Sci. 2022, 10, 137–149+244. [Google Scholar]

- Jia, J.F.; Zhao, R.N.; Liu, W.P. A study on the grouping of transformation and upgrading of manufacturing state-owned enterprises in the digital economy. Res. Dev. Manag. 2022, 34, 13–26. [Google Scholar]

- Li, C.F.; Li, D.D.; Zhou, C. The mechanism of the transformation and upgrading of manufacturing industry driven by digital economy. Bus. Res. 2020, 2, 73–82. [Google Scholar]

- He, X.H.; Ping, Q.Y.; Hu, W.F. Does digital technology promote the sustainable development of the marine equipment manufacturing industry in China. Mar. Pol. 2022, 136, 104868. [Google Scholar] [CrossRef]

- Qi, Q.L.; Tao, F. Digital twin and big data towards smart manufacturing and industry 4.0: 360 degree comparison. IEEE Access. 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.L.; Wang, L.H.; Nee, A.Y.C. Digital twins and cyber–physical systems toward smart manufacturing and industry 4.0: Correlation and comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Yin, S.; Zhang, N.; Ullah, K.; Gao, S. Enhancing Digital Innovation for the Sustainable Transformation of Manufacturing Industry: A Pressure-State-Response System Framework to Perceptions of Digital Green Innovation and Its Performance for Green and Intelligent Manufacturing. Systems 2022, 10, 72. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, T.; Li, H.Y.; Zhang, H. Dynamic spillover capacity of R&D and digital investments in China’s manufacturing industry under long-term technological progress based on the industry chain perspective. Technol. Soc. 2022, 71, 102129. [Google Scholar]

- Guo, L.; Xu, L. The Effects of Digital Transformation on Firm Performance: Evidence from China’s Manufacturing Sector. Sustainability 2021, 13, 12844. [Google Scholar] [CrossRef]

- Lv, M.Y.; Ma, L.Y. Analysis of provincial big data and manufacturing industry integration measurement in China--based on Chinese provincial panel data from 2013–2018. Technol. Econ. 2022, 41, 88–100. [Google Scholar]

- Wu, X.T.; Zhang, Q.Y. Measuring the integration of digital economy industry and manufacturing industry based on input-output perspective. China. Circ. Econ. 2021, 35, 89–98. [Google Scholar]

- Wang, S.J.; Kong, W.; Ren, L.; Zhi, D.D.; Dai, B.T. Misconceptions and corrections of domestic coupled coordination models. J. Nat. Resour. 2021, 36, 793–810. [Google Scholar]

- Leng, J.W.; Wang, D.W.; Shen, W.M.; Li, X.Y.; Liu, Q.; Chen, X. Digital twins-based smart manufacturing system design in Industry 4.0: A review. J. Manuf. Syst. 2021, 60, 119–137. [Google Scholar] [CrossRef]

- Lee, J.; Azamfar, M.; Bagheri, B. A unified digital twin framework for shop floor design in industry 4.0 manufacturing systems. Manuf. Lett. 2021, 27, 87–91. [Google Scholar] [CrossRef]

- Kurfess, T.R.; Saldana, C.; Saleeby, K.; Dezfouli, M.P. A review of modern communication technologies for digital manufacturing processes in industry 4.0. J. Manuf. Sci. Eng. Trans. ASME. 2020, 142. [Google Scholar] [CrossRef]

- Young, A.A. Increasing returns and economic progress. Econ. J. 1928, 38, 527–542. [Google Scholar] [CrossRef]

- Yang, H.X.; Jiao, Y.; Chen, Q.J. Dualization and endogenous economic growth. Econ Manag. 2016, 38, 1–9. [Google Scholar]

- Kumbhakar, S.C. Production frontiers, panel data, and time-varying technical inefficiency. J. Econom. 1990, 46, 201–211. [Google Scholar] [CrossRef]

- Zhou, X.; Li, K.W.; Li, Q. An analysis on technical efficiency in post-reform China. China Econ. Rev. 2011, 22, 357–372. [Google Scholar] [CrossRef]

- Liu, J.; Yang, Y.J.; Zhang, S.F. Study on the measurement and drivers of China’s digital economy. Shanghai. Econ. Res. 2020, 6, 81–96. [Google Scholar]

- Wang, J.; Zhu, J.; Luo, Q. The development level and evolution measurement of China’s digital economy. Quant. Econ. Tech. Econ. Res. 2021, 38, 26–42. [Google Scholar]

- Wan, X.Y.; Luo, Y.Q. Measurement of development level of digital economy and its influence on total factor productivity. Reform. 2022, 335, 101–118. [Google Scholar]

- Wang, J.J.; She, G.J. Digital measure and regional economic development level more in China. China. Circ. Econ. 2021, 35, 3–17. [Google Scholar]

- Sheng, B.; Liu, Y.Y. Research on measurement and spatial differentiation of China’s digital economy development index. Nanjing. Soc. Sci. 2022, 411, 43–54. [Google Scholar]

- Xu, X.C.; Zhang, M.H. Measurement and research on the scale of China’s digital economy-based on the perspective of international comparison. China Ind. Econ. 2020, 386, 23–41. [Google Scholar]

- Jiao, Y. Regional differences and dynamic evolution of high-quality digital economy in China. Econ. Syst. Reform. 2021, 231, 34–40. [Google Scholar]

- Jin, C.Y.; Xu, A.T.; Qiu, K.Y. Measurement and spatial correlation of provincial digital economy in China. Statist. Inf. Forum. 2022, 37, 11–21. [Google Scholar]

- Guo, H.; Quan, Q.H. Integrated development of digital economy and real economy: Measurement evaluation and realization path. Econ. Rev. 2022, 444, 72–82. [Google Scholar]

- Jiang, X.G.; He, J.B.; Fang, L. Measurement of high quality development level, regional difference and improvement path of manufacturing industry. Shanghai. Econ. Res. 2019, 370, 70–78. [Google Scholar]

- Qu, L.; Wang, L.; Ji, H.Y. Analysis on the high quality development of China’s regional manufacturing Industry. Quant. Econ. Tech. Econ. Res. 2021, 38, 45–61. [Google Scholar]

- Zhang, L.; Zhu, N. Research on high quality Development evaluation of manufacturing industry in Central China based on entropy method. J. Xiangtan Univ. 2022, 46, 46–51. [Google Scholar]

- Zhang, A.Q.; Zhang, H.C. Analysis of high quality development level of manufacturing industry under the background of digital transformation. Sci. Tech. Manag. Res. 2021, 41, 68–75. [Google Scholar]

- Wang, M.J.; Yu, D.H. Regional difference measurement, dynamic evolution and source decomposition of high quality development in manufacturing industry. Stat. Decis. 2022, 38, 5–9. [Google Scholar]

- Xu, B.; Nie, Y.X. Research on Construction and evaluation of high quality development index system of manufacturing industry. Res. Tech. Econ. Manag. 2021, 302, 119–123. [Google Scholar]

- Wang, F.; Shi, X. Study on measurement and influencing factors of high quality development level of China’s manufacturing industry. China Soft Sci. 2022, 374, 22–31. [Google Scholar]

- Luo, X.B.; Huang, L. Measurement and inter-provincial comparison of high-quality transformation and upgrading of China’s manufacturing industry: Based on the perspective of “Four Modernizations”. Econ Probl. 2020, 496, 43–52. [Google Scholar]

- Guo, F.; Wang, J.Y.; Wang, F.; Kong, T.; Zhang, X.; Cheng, Z.Y. Measuring the development of digital inclusive finance in China: Index compilation and spatial characteristics. Economics 2020, 19, 1401–1418. [Google Scholar]

- Hansen, B.E. Sample splitting and threshold estimation. Econometrica 2000, 68, 575–603. [Google Scholar] [CrossRef]

| Index | Variable | Unit | Data Source | Reference | |

|---|---|---|---|---|---|

| Digital Economy | Digital Economy Infrastructure | Length of optical cable line | km | China Statistical Yearbook | [37,38,39,40,41] |

| Number of mobile phone base stations | 10,000 stations | ||||

| Mobile phone penetration rate | phones/100 people | ||||

| Number of domain names per thousand people | 10,000 names | ||||

| Number of broadband access ports | 10,000 ports | ||||

| Number of broadband access users | 10,000 users | ||||

| Number of ICT employees | 10,000 employees | ||||

| Industry Digitization | Electronic business sales | RMB 100,000,000 | Statistical Yearbook of China Electronic Information Industry China Statistical Yearbook | [37,38,42,43] | |

| Online retail sales | RMB 100,000,000 | ||||

| Number of enterprises offering APP | enterprise | ||||

| Number of computers used in enterprises | computer | ||||

| Number of enterprises with e-commerce transactions | enterprise | ||||

| Number of enterprises with e-commerce transactions/total number of enterprises | % | ||||

| Digital financial inclusion index | / | Peking University Digital Finance Index | [44] | ||

| Digital Industrialization | Total telecom business | RMB 100,000,000 | China Statistical Yearbook | [37,45,46] | |

| Software business revenue | RMB 10,000 | ||||

| Software product revenue | RMB 10,000 | ||||

| Manufacturing Industry | Economic Returns | Industrial added value | RMB 100,000,000 | China Industrial Statistics Yearbook China Statistical Yearbook | [27,47,48,49,50] |

| Main business revenue | RMB 100,000,000 | ||||

| Total operating profits | RMB 100,000,000 | ||||

| Total operating profits/main business revenue | % | ||||

| Manufacturers liabilities/manufacturers assets | % | ||||

| Innovative Development | R&D expenditure of the manufacturing industry | RMB | China Stock Market and Accounting Research Database (CSMAR) China Statistical Yearbook | [27,47,48,51,52,53] | |

| R&D expenditure of the manufacturing industry/main business revenue | % | ||||

| Full-time equivalent of R&D personnel | person/year | ||||

| Number of valid invention patents | patents | ||||

| Number of valid invention patents/R&D expenditure of the manufacturing industry | patents/RMB 10,000 | ||||

| Number of valid invention patents/FTE of R&D personnel | patent/person/year | ||||

| Sales revenue of new products | RMB 10,000 | ||||

| Number of legal entities in manufacturing industry | entity | ||||

| Number of listed manufacturing enterprises | enterprise | ||||

| Green Development | Total industrial energy consumption/industrial added value | tons/RMB | According to China Energy Statistical Yearbook | [47,48,54] | |

| Comprehensive utilization of industrial solid waste/output of industrial solid waste | % | China Statistical Yearbook | |||

| Total investment in industrial pollution control /GDP | % | ||||

| Regions | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | Annual Mean | Average Annual Growth Rate (%) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Eastern | Beijing | 0.2586 | 0.3287 | 0.3938 | 0.4278 | 0.4705 | 0.5115 | 0.5713 | 0.6053 | 0.4459 | 13.1264 |

| Tianjin | 0.0629 | 0.0803 | 0.1028 | 0.1114 | 0.1182 | 0.1366 | 0.1610 | 0.1778 | 0.1189 | 16.2881 | |

| Hebei | 0.0885 | 0.1103 | 0.1459 | 0.1850 | 0.2119 | 0.2425 | 0.2742 | 0.2986 | 0.1946 | 19.2371 | |

| Shandong | 0.1887 | 0.2179 | 0.2638 | 0.3211 | 0.3556 | 0.4258 | 0.4546 | 0.4855 | 0.3391 | 14.6152 | |

| Shanghai | 0.1795 | 0.2314 | 0.2753 | 0.2941 | 0.3168 | 0.3491 | 0.4023 | 0.4311 | 0.3100 | 13.5752 | |

| Jiangsu | 0.2557 | 0.3078 | 0.3748 | 0.4054 | 0.4465 | 0.5026 | 0.5663 | 0.6092 | 0.4335 | 13.3228 | |

| Zhejiang | 0.2494 | 0.2916 | 0.3676 | 0.4107 | 0.4410 | 0.4824 | 0.5479 | 0.5725 | 0.4204 | 12.7917 | |

| Fujian | 0.1327 | 0.1622 | 0.2060 | 0.2496 | 0.2999 | 0.3247 | 0.3471 | 0.3345 | 0.2571 | 14.5842 | |

| Guangdong | 0.3506 | 0.4053 | 0.4880 | 0.5503 | 0.6069 | 0.7095 | 0.8026 | 0.8459 | 0.5949 | 13.4972 | |

| Hainan | 0.0416 | 0.0717 | 0.1002 | 0.1139 | 0.1196 | 0.1297 | 0.1432 | 0.1472 | 0.1084 | 21.7755 | |

| Mean | 0.1808 | 0.2207 | 0.2718 | 0.3069 | 0.3387 | 0.3814 | 0.4271 | 0.4508 | 0.3223 | 14.0909 | |

| Central | Shanxi | 0.0546 | 0.0765 | 0.1016 | 0.1208 | 0.1364 | 0.1623 | 0.1775 | 0.1980 | 0.1285 | 20.6621 |

| Anhui | 0.0712 | 0.1091 | 0.1543 | 0.1786 | 0.2061 | 0.2491 | 0.2940 | 0.3139 | 0.1970 | 24.4948 | |

| Henan | 0.0931 | 0.1248 | 0.1716 | 0.2139 | 0.2399 | 0.2776 | 0.3154 | 0.3417 | 0.2223 | 20.8607 | |

| Hubei | 0.0897 | 0.1196 | 0.1665 | 0.1965 | 0.2111 | 0.2468 | 0.2870 | 0.3054 | 0.2028 | 19.6581 | |

| Hunan | 0.0763 | 0.1039 | 0.1350 | 0.1681 | 0.1947 | 0.2314 | 0.2698 | 0.2978 | 0.1846 | 21.7529 | |

| Jiangxi | 0.0459 | 0.0685 | 0.1098 | 0.1166 | 0.1516 | 0.1849 | 0.2168 | 0.2399 | 0.1417 | 27.9447 | |

| Mean | 0.0718 | 0.1004 | 0.1398 | 0.1658 | 0.1900 | 0.2253 | 0.2601 | 0.2828 | 0.1795 | 22.1460 | |

| Western | Inner Mongolia | 0.0540 | 0.0666 | 0.0851 | 0.1046 | 0.1240 | 0.1358 | 0.1552 | 0.1717 | 0.1121 | 18.1436 |

| Guangxi | 0.0494 | 0.0770 | 0.1047 | 0.1307 | 0.1486 | 0.1812 | 0.2186 | 0.2488 | 0.1449 | 26.6809 | |

| Chongqing | 0.0612 | 0.0897 | 0.1232 | 0.1524 | 0.1767 | 0.2065 | 0.2336 | 0.2536 | 0.1621 | 23.1588 | |

| Sichuan | 0.1152 | 0.1560 | 0.2180 | 0.2653 | 0.3007 | 0.3487 | 0.3998 | 0.4378 | 0.2802 | 21.4747 | |

| Guizhou | 0.0376 | 0.0580 | 0.0920 | 0.1211 | 0.1382 | 0.1629 | 0.1880 | 0.2023 | 0.1250 | 28.5020 | |

| Yunnan | 0.0506 | 0.0752 | 0.1105 | 0.1375 | 0.1517 | 0.1825 | 0.2152 | 0.2403 | 0.1455 | 25.7435 | |

| Shanxi | 0.0719 | 0.1000 | 0.1318 | 0.1677 | 0.1893 | 0.2181 | 0.2507 | 0.2672 | 0.1746 | 21.1062 | |

| Gansu | 0.0313 | 0.0486 | 0.0758 | 0.0939 | 0.1056 | 0.1269 | 0.1438 | 0.1583 | 0.0980 | 27.3070 | |

| Qinghai | 0.0199 | 0.0321 | 0.0560 | 0.0685 | 0.0782 | 0.0923 | 0.0990 | 0.1084 | 0.0693 | 29.5754 | |

| Ningxia | 0.0296 | 0.0512 | 0.0689 | 0.0805 | 0.0889 | 0.1029 | 0.1057 | 0.1116 | 0.0799 | 22.6950 | |

| Xinjiang | 0.0463 | 0.0602 | 0.0818 | 0.0933 | 0.1058 | 0.1352 | 0.1495 | 0.1672 | 0.1049 | 20.5090 | |

| Mean | 0.0515 | 0.0741 | 0.1043 | 0.1287 | 0.1462 | 0.1721 | 0.1963 | 0.2152 | 0.1361 | 23.2909 | |

| Northeast | Liaoning | 0.1114 | 0.1343 | 0.1636 | 0.1710 | 0.1876 | 0.2052 | 0.2306 | 0.2470 | 0.1813 | 12.2108 |

| Jilin | 0.0427 | 0.0603 | 0.0800 | 0.0956 | 0.1109 | 0.1309 | 0.1365 | 0.1512 | 0.1010 | 20.3534 | |

| Heilongjiang | 0.0498 | 0.0715 | 0.0891 | 0.1021 | 0.1209 | 0.1351 | 0.1536 | 0.1730 | 0.1119 | 19.8946 | |

| Mean | 0.0680 | 0.0887 | 0.1109 | 0.1229 | 0.1398 | 0.1571 | 0.1735 | 0.1904 | 0.1314 | 16.0851 | |

| Whole Country | Mean | 0.1003 | 0.1297 | 0.1679 | 0.1949 | 0.2185 | 0.2510 | 0.2837 | 0.3048 | 0.2064 | 17.4706 |

| Region | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | Annual Mean | Average Annual Growth Rate (%) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Eastern | Beijing | 0.3029 | 0.3174 | 0.3428 | 0.3521 | 0.3715 | 0.3814 | 0.4070 | 0.4070 | 0.3603 | 4.3413 |

| Tianjin | 0.2821 | 0.2941 | 0.3033 | 0.3098 | 0.3156 | 0.3197 | 0.3127 | 0.3248 | 0.3078 | 2.0538 | |

| Hebei | 0.2397 | 0.2571 | 0.2625 | 0.2762 | 0.2871 | 0.3014 | 0.2993 | 0.3106 | 0.2792 | 3.7978 | |

| Shandong | 0.4331 | 0.4588 | 0.4646 | 0.4847 | 0.4961 | 0.4551 | 0.4418 | 0.4703 | 0.4631 | 1.3058 | |

| Shanghai | 0.3408 | 0.3639 | 0.3748 | 0.3938 | 0.4089 | 0.4091 | 0.4202 | 0.4324 | 0.3930 | 3.4776 | |

| Jiangsu | 0.5073 | 0.5449 | 0.5715 | 0.6118 | 0.6389 | 0.6542 | 0.6599 | 0.7098 | 0.6123 | 4.9432 | |

| Zhejiang | 0.4067 | 0.4319 | 0.4514 | 0.4749 | 0.4988 | 0.5126 | 0.5426 | 0.5835 | 0.4878 | 5.3010 | |

| Fujian | 0.3008 | 0.3109 | 0.3148 | 0.3325 | 0.3462 | 0.3599 | 0.3753 | 0.3902 | 0.3413 | 3.7945 | |

| Guangdong | 0.5125 | 0.5460 | 0.5913 | 0.6391 | 0.6943 | 0.7286 | 0.7642 | 0.8078 | 0.6605 | 6.7266 | |

| Hainan | 0.2104 | 0.2246 | 0.2275 | 0.2555 | 0.2664 | 0.2334 | 0.2543 | 0.2630 | 0.2419 | 3.5146 | |

| Mean | 0.3536 | 0.3750 | 0.3905 | 0.4130 | 0.4324 | 0.4356 | 0.4477 | 0.4700 | 0.4147 | 4.1633 | |

| Central | Shanxi | 0.1992 | 0.1799 | 0.1622 | 0.1666 | 0.1981 | 0.2078 | 0.2082 | 0.2091 | 0.1914 | 1.0877 |

| Anhui | 0.2955 | 0.3067 | 0.3219 | 0.3500 | 0.3689 | 0.3796 | 0.3824 | 0.4123 | 0.3522 | 4.9047 | |

| Henan | 0.3197 | 0.3355 | 0.3403 | 0.3458 | 0.3538 | 0.3391 | 0.3513 | 0.3683 | 0.3442 | 2.0835 | |

| Hubei | 0.2864 | 0.3023 | 0.3091 | 0.3298 | 0.3373 | 0.3618 | 0.3748 | 0.3833 | 0.3356 | 4.2709 | |

| Hunan | 0.2828 | 0.2924 | 0.3118 | 0.3171 | 0.3405 | 0.3478 | 0.3662 | 0.3778 | 0.3296 | 4.2444 | |

| Jiangxi | 0.2364 | 0.2485 | 0.2606 | 0.2685 | 0.2811 | 0.2865 | 0.2958 | 0.3050 | 0.2728 | 3.7127 | |

| Mean | 0.2700 | 0.2776 | 0.2843 | 0.2963 | 0.3133 | 0.3204 | 0.3298 | 0.3426 | 0.3043 | 3.4668 | |

| Western | Inner Mongolia | 0.2071 | 0.2043 | 0.1852 | 0.1877 | 0.1985 | 0.1965 | 0.2068 | 0.2051 | 0.1989 | −0.0264 |

| Guangxi | 0.2042 | 0.2053 | 0.2173 | 0.2240 | 0.2315 | 0.2262 | 0.2295 | 0.2327 | 0.2213 | 1.9113 | |

| Chongqing | 0.2394 | 0.2520 | 0.2602 | 0.2662 | 0.2915 | 0.3002 | 0.3057 | 0.3239 | 0.2799 | 4.4425 | |

| Sichuan | 0.2449 | 0.2646 | 0.2717 | 0.2873 | 0.3079 | 0.3204 | 0.3318 | 0.3379 | 0.2958 | 4.7279 | |

| Guizhou | 0.1915 | 0.2050 | 0.2157 | 0.2210 | 0.2344 | 0.2420 | 0.2541 | 0.2775 | 0.2301 | 5.4630 | |

| Yunnan | 0.1984 | 0.2017 | 0.2110 | 0.2144 | 0.2207 | 0.2260 | 0.2522 | 0.2547 | 0.2224 | 3.6871 | |

| Shanxi | 0.2721 | 0.2678 | 0.2637 | 0.2731 | 0.2841 | 0.2964 | 0.3050 | 0.3087 | 0.2839 | 1.8465 | |

| Gansu | 0.1772 | 0.1755 | 0.1567 | 0.1708 | 0.1759 | 0.1834 | 0.1975 | 0.2087 | 0.1807 | 2.5622 | |

| Qinghai | 0.1204 | 0.1239 | 0.1109 | 0.1436 | 0.1375 | 0.1563 | 0.0961 | 0.1690 | 0.1322 | 9.8098 | |

| Ningxia | 0.2123 | 0.2217 | 0.1837 | 0.2278 | 0.1919 | 0.1949 | 0.1945 | 0.1878 | 0.2018 | −0.9360 | |

| Xinjiang | 0.1652 | 0.1749 | 0.1488 | 0.1468 | 0.1696 | 0.1963 | 0.2033 | 0.2222 | 0.1784 | 4.8202 | |

| Mean | 0.2030 | 0.2088 | 0.2023 | 0.2148 | 0.2221 | 0.2308 | 0.2342 | 0.2480 | 0.2205 | 2.9435 | |

| Northeast | Liaoning | 0.2527 | 0.2481 | 0.2239 | 0.2396 | 0.2584 | 0.2670 | 0.2642 | 0.2786 | 0.2541 | 1.5734 |

| Jilin | 0.2192 | 0.2164 | 0.2144 | 0.2204 | 0.2113 | 0.2256 | 0.2288 | 0.2521 | 0.2235 | 2.1197 | |

| Heilongjiang | 0.2284 | 0.2250 | 0.2120 | 0.2148 | 0.2172 | 0.2158 | 0.2185 | 0.2298 | 0.2202 | 0.1357 | |

| Mean | 0.2334 | 0.2298 | 0.2168 | 0.2249 | 0.2290 | 0.2361 | 0.2371 | 0.2535 | 0.2326 | 1.2572 | |

| Whole Country | Mean | 0.2696 | 0.2800 | 0.2829 | 0.2982 | 0.3111 | 0.3175 | 0.3248 | 0.3415 | 0.3032 | 3.4465 |

| Region | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | Annual Mean | |

|---|---|---|---|---|---|---|---|---|---|---|

| Eastern | Beijing | 0.2640 | 0.2803 | 0.3088 | 0.3192 | 0.3411 | 0.3521 | 0.3809 | 0.3809 | 0.3284 |

| Tianjin | 0.2407 | 0.2541 | 0.2645 | 0.2718 | 0.2783 | 0.2828 | 0.2749 | 0.2886 | 0.2695 | |

| Hebei | 0.1930 | 0.2126 | 0.2186 | 0.2340 | 0.2462 | 0.2623 | 0.2599 | 0.2726 | 0.2374 | |

| Shandong | 0.4102 | 0.4391 | 0.4456 | 0.4682 | 0.4810 | 0.4350 | 0.4200 | 0.4520 | 0.4439 | |

| Shanghai | 0.3066 | 0.3325 | 0.3447 | 0.3661 | 0.3830 | 0.3833 | 0.3957 | 0.4094 | 0.3652 | |

| Jiangsu | 0.4935 | 0.5359 | 0.5657 | 0.6110 | 0.6414 | 0.6586 | 0.6650 | 0.7211 | 0.6115 | |

| Zhejiang | 0.3806 | 0.4089 | 0.4308 | 0.4572 | 0.4840 | 0.4995 | 0.5333 | 0.5792 | 0.4717 | |

| Fujian | 0.2616 | 0.2730 | 0.2773 | 0.2972 | 0.3126 | 0.3280 | 0.3453 | 0.3621 | 0.3071 | |

| Guangdong | 0.4994 | 0.5370 | 0.5880 | 0.6417 | 0.7037 | 0.7422 | 0.7822 | 0.8312 | 0.6657 | |

| Hainan | 0.1601 | 0.1760 | 0.1792 | 0.2108 | 0.2229 | 0.1859 | 0.2094 | 0.2192 | 0.1954 | |

| Mean | 0.3210 | 0.3449 | 0.3623 | 0.3877 | 0.4094 | 0.4130 | 0.4267 | 0.4516 | 0.3896 | |

| Central | Shanxi | 0.1475 | 0.1258 | 0.1059 | 0.1108 | 0.1463 | 0.1572 | 0.1576 | 0.1586 | 0.1387 |

| Anhui | 0.2556 | 0.2682 | 0.2854 | 0.3168 | 0.3382 | 0.3502 | 0.3533 | 0.3869 | 0.3193 | |

| Henan | 0.2828 | 0.3006 | 0.3060 | 0.3122 | 0.3211 | 0.3046 | 0.3184 | 0.3374 | 0.3104 | |

| Hubei | 0.2454 | 0.2633 | 0.2710 | 0.2942 | 0.3026 | 0.3301 | 0.3448 | 0.3542 | 0.3007 | |

| Hunan | 0.2414 | 0.2522 | 0.2739 | 0.2799 | 0.3062 | 0.3144 | 0.3351 | 0.3481 | 0.2939 | |

| Jiangxi | 0.1892 | 0.2028 | 0.2164 | 0.2253 | 0.2394 | 0.2455 | 0.2560 | 0.2663 | 0.2301 | |

| Mean | 0.2270 | 0.2355 | 0.2431 | 0.2565 | 0.2756 | 0.2837 | 0.2942 | 0.3086 | 0.2655 | |

| Western | Inner Mongolia | 0.1563 | 0.1532 | 0.1318 | 0.1346 | 0.1467 | 0.1444 | 0.1561 | 0.1541 | 0.1472 |

| Guangxi | 0.1531 | 0.1544 | 0.1678 | 0.1753 | 0.1838 | 0.1779 | 0.1815 | 0.1851 | 0.1724 | |

| Chongqing | 0.1927 | 0.2067 | 0.2160 | 0.2228 | 0.2511 | 0.2610 | 0.2671 | 0.2875 | 0.2381 | |

| Sichuan | 0.1988 | 0.2209 | 0.2289 | 0.2464 | 0.2696 | 0.2836 | 0.2964 | 0.3033 | 0.2560 | |

| Guizhou | 0.1388 | 0.1539 | 0.1660 | 0.1720 | 0.1870 | 0.1955 | 0.2092 | 0.2354 | 0.1822 | |

| Yunnan | 0.1466 | 0.1503 | 0.1607 | 0.1645 | 0.1717 | 0.1776 | 0.2070 | 0.2099 | 0.1736 | |

| Shanxi | 0.2294 | 0.2245 | 0.2200 | 0.2306 | 0.2428 | 0.2567 | 0.2663 | 0.2705 | 0.2426 | |

| Gansu | 0.1228 | 0.1209 | 0.0997 | 0.1155 | 0.1213 | 0.1297 | 0.1456 | 0.1582 | 0.1267 | |

| Qinghai | 0.0590 | 0.0629 | 0.0483 | 0.0850 | 0.0782 | 0.0992 | 0.0317 | 0.1136 | 0.0722 | |

| Ningxia | 0.1622 | 0.1727 | 0.1300 | 0.1796 | 0.1393 | 0.1427 | 0.1422 | 0.1346 | 0.1504 | |

| Xinjiang | 0.1093 | 0.1201 | 0.0909 | 0.0886 | 0.1142 | 0.1442 | 0.1521 | 0.1733 | 0.1241 | |

| Mean | 0.1517 | 0.1582 | 0.1509 | 0.1650 | 0.1732 | 0.1830 | 0.1868 | 0.2023 | 0.1714 | |

| Northeast | Liaoning | 0.2076 | 0.2024 | 0.1752 | 0.1929 | 0.2140 | 0.2236 | 0.2204 | 0.2366 | 0.2091 |

| Jilin | 0.1700 | 0.1668 | 0.1646 | 0.1712 | 0.1611 | 0.1771 | 0.1807 | 0.2069 | 0.1748 | |

| Heilongjiang | 0.1803 | 0.1765 | 0.1619 | 0.1651 | 0.1677 | 0.1661 | 0.1691 | 0.1818 | 0.1711 | |

| Mean | 0.1860 | 0.1819 | 0.1672 | 0.1764 | 0.1809 | 0.1890 | 0.1901 | 0.2084 | 0.1850 | |

| Whole Country | Mean | 0.2266 | 0.2383 | 0.2415 | 0.2587 | 0.2732 | 0.2804 | 0.2886 | 0.3073 | 0.2643 |

| Region | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | Annual Mean | |

|---|---|---|---|---|---|---|---|---|---|---|

| Eastern | Beijing | 0.5277 | 0.5616 | 0.5931 | 0.6096 | 0.6303 | 0.6502 | 0.6791 | 0.6956 | 0.6184 |

| Tianjin | 0.4329 | 0.4413 | 0.4522 | 0.4564 | 0.4597 | 0.4686 | 0.4804 | 0.4885 | 0.4600 | |

| Hebei | 0.4453 | 0.4558 | 0.4731 | 0.4920 | 0.5050 | 0.5199 | 0.5352 | 0.5470 | 0.4967 | |

| Shandong | 0.4938 | 0.5080 | 0.5302 | 0.5579 | 0.5747 | 0.6087 | 0.6226 | 0.6376 | 0.5667 | |

| Shanghai | 0.4894 | 0.5145 | 0.5358 | 0.5449 | 0.5559 | 0.5715 | 0.5973 | 0.6112 | 0.5525 | |

| Jiangsu | 0.5263 | 0.5515 | 0.5840 | 0.5988 | 0.6187 | 0.6459 | 0.6767 | 0.6975 | 0.6124 | |

| Zhejiang | 0.5232 | 0.5437 | 0.5805 | 0.6014 | 0.6160 | 0.6361 | 0.6678 | 0.6798 | 0.6061 | |

| Fujian | 0.4667 | 0.4810 | 0.5022 | 0.5233 | 0.5477 | 0.5597 | 0.5705 | 0.5644 | 0.5269 | |

| Guangdong | 0.5722 | 0.5988 | 0.6388 | 0.6690 | 0.6964 | 0.7461 | 0.7912 | 0.8122 | 0.6906 | |

| Hainan | 0.4225 | 0.4371 | 0.4509 | 0.4576 | 0.4603 | 0.4652 | 0.4718 | 0.4737 | 0.4549 | |

| Mean | 0.4900 | 0.5093 | 0.5341 | 0.5511 | 0.5665 | 0.5872 | 0.6093 | 0.6208 | 0.5585 | |

| Central | Shanxi | 0.4289 | 0.4395 | 0.4516 | 0.4609 | 0.4685 | 0.4810 | 0.4884 | 0.4983 | 0.4646 |

| Anhui | 0.4369 | 0.4552 | 0.4771 | 0.4889 | 0.5022 | 0.5231 | 0.5448 | 0.5544 | 0.4978 | |

| Henan | 0.4475 | 0.4628 | 0.4855 | 0.5060 | 0.5186 | 0.5369 | 0.5552 | 0.5679 | 0.5101 | |

| Hubei | 0.4459 | 0.4603 | 0.4831 | 0.4976 | 0.5047 | 0.5220 | 0.5414 | 0.5503 | 0.5007 | |

| Hunan | 0.4393 | 0.4527 | 0.4678 | 0.4838 | 0.4967 | 0.5145 | 0.5331 | 0.5467 | 0.4918 | |

| Jiangxi | 0.4246 | 0.4356 | 0.4556 | 0.4589 | 0.4758 | 0.4920 | 0.5074 | 0.5186 | 0.4711 | |

| Mean | 0.4372 | 0.4510 | 0.4701 | 0.4827 | 0.4944 | 0.5116 | 0.5284 | 0.5394 | 0.4893 | |

| Western | Inner Mongolia | 0.4286 | 0.4347 | 0.4436 | 0.4531 | 0.4625 | 0.4682 | 0.4776 | 0.4856 | 0.4567 |

| Guangxi | 0.4263 | 0.4397 | 0.4531 | 0.4657 | 0.4744 | 0.4902 | 0.5083 | 0.5229 | 0.4726 | |

| Chongqing | 0.4320 | 0.4458 | 0.4621 | 0.4762 | 0.4880 | 0.5024 | 0.5156 | 0.5253 | 0.4809 | |

| Sichuan | 0.4582 | 0.4779 | 0.5080 | 0.5309 | 0.5480 | 0.5713 | 0.5961 | 0.6145 | 0.5381 | |

| Guizhou | 0.4206 | 0.4305 | 0.4469 | 0.4610 | 0.4693 | 0.4813 | 0.4935 | 0.5004 | 0.4629 | |

| Yunnan | 0.4269 | 0.4388 | 0.4559 | 0.4690 | 0.4759 | 0.4908 | 0.5067 | 0.5188 | 0.4729 | |

| Shanxi | 0.4372 | 0.4508 | 0.4662 | 0.4837 | 0.4941 | 0.5081 | 0.5239 | 0.5318 | 0.4870 | |

| Gansu | 0.4175 | 0.4260 | 0.4391 | 0.4479 | 0.4536 | 0.4639 | 0.4721 | 0.4791 | 0.4499 | |

| Qinghai | 0.4120 | 0.4180 | 0.4295 | 0.4356 | 0.4403 | 0.4471 | 0.4504 | 0.4549 | 0.4360 | |

| Ningxia | 0.4167 | 0.4272 | 0.4358 | 0.4414 | 0.4455 | 0.4522 | 0.4536 | 0.4564 | 0.4411 | |

| Xinjiang | 0.4248 | 0.4316 | 0.4420 | 0.4476 | 0.4537 | 0.4679 | 0.4748 | 0.4834 | 0.4532 | |

| Mean | 0.4274 | 0.4383 | 0.4529 | 0.4647 | 0.4732 | 0.4858 | 0.4975 | 0.5066 | 0.4683 | |

| Northeast | Liaoning | 0.4564 | 0.4675 | 0.4816 | 0.4852 | 0.4933 | 0.5018 | 0.5141 | 0.5220 | 0.4902 |

| Jilin | 0.4231 | 0.4316 | 0.4411 | 0.4487 | 0.4561 | 0.4658 | 0.4685 | 0.4757 | 0.4513 | |

| Heilongjiang | 0.4265 | 0.4370 | 0.4456 | 0.4519 | 0.4610 | 0.4678 | 0.4768 | 0.4862 | 0.4566 | |

| Mean | 0.4353 | 0.4454 | 0.4561 | 0.4619 | 0.4701 | 0.4785 | 0.4865 | 0.4946 | 0.4661 | |

| Whole Country | Mean | 0.4510 | 0.4652 | 0.4837 | 0.4968 | 0.5082 | 0.5240 | 0.5398 | 0.5500 | 0.5024 |

| Region | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | Annual Mean | Average Annual Growth Rate (%) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Eastern | Beijing | 0.1393 | 0.1574 | 0.1832 | 0.1946 | 0.2150 | 0.2290 | 0.2587 | 0.2650 | 0.2053 | 9.7133 |

| Tianjin | 0.1042 | 0.1121 | 0.1196 | 0.1240 | 0.1279 | 0.1325 | 0.1321 | 0.1410 | 0.1242 | 4.4507 | |

| Hebei | 0.0859 | 0.0969 | 0.1034 | 0.1151 | 0.1243 | 0.1364 | 0.1391 | 0.1491 | 0.1188 | 8.2394 | |

| Shandong | 0.2026 | 0.2230 | 0.2363 | 0.2612 | 0.2764 | 0.2648 | 0.2615 | 0.2882 | 0.2517 | 5.3119 | |

| Shanghai | 0.1500 | 0.1711 | 0.1847 | 0.1995 | 0.2129 | 0.2190 | 0.2363 | 0.2503 | 0.2030 | 7.6278 | |

| Jiangsu | 0.2597 | 0.2955 | 0.3304 | 0.3659 | 0.3968 | 0.4254 | 0.4500 | 0.5030 | 0.3783 | 9.9334 | |

| Zhejiang | 0.1991 | 0.2223 | 0.2501 | 0.2749 | 0.2982 | 0.3178 | 0.3561 | 0.3937 | 0.2890 | 10.2451 | |

| Fujian | 0.1221 | 0.1313 | 0.1392 | 0.1555 | 0.1712 | 0.1836 | 0.1970 | 0.2044 | 0.1630 | 7.6623 | |

| Guangdong | 0.2858 | 0.3215 | 0.3756 | 0.4293 | 0.4900 | 0.5538 | 0.6189 | 0.6751 | 0.4687 | 13.0893 | |

| Hainan | 0.0676 | 0.0769 | 0.0808 | 0.0964 | 0.1026 | 0.0865 | 0.0988 | 0.1038 | 0.0892 | 6.8767 | |

| Mean | 0.1616 | 0.1808 | 0.2003 | 0.2216 | 0.2415 | 0.2549 | 0.2749 | 0.2974 | 0.2291 | 9.1170 | |

| Central | Shanxi | 0.0633 | 0.0553 | 0.0478 | 0.0511 | 0.0685 | 0.0756 | 0.0770 | 0.0790 | 0.0647 | 4.2373 |

| Anhui | 0.1117 | 0.1221 | 0.1362 | 0.1549 | 0.1698 | 0.1832 | 0.1925 | 0.2145 | 0.1606 | 9.8031 | |

| Henan | 0.1266 | 0.1391 | 0.1486 | 0.1580 | 0.1665 | 0.1635 | 0.1768 | 0.1916 | 0.1588 | 6.1648 | |

| Hubei | 0.1094 | 0.1212 | 0.1309 | 0.1464 | 0.1527 | 0.1723 | 0.1867 | 0.1950 | 0.1518 | 8.6484 | |

| Hunan | 0.1061 | 0.1142 | 0.1281 | 0.1354 | 0.1521 | 0.1618 | 0.1786 | 0.1903 | 0.1458 | 8.7417 | |

| Jiangxi | 0.0803 | 0.0884 | 0.0986 | 0.1034 | 0.1139 | 0.1208 | 0.1299 | 0.1381 | 0.1092 | 8.0714 | |

| Mean | 0.0996 | 0.1067 | 0.1150 | 0.1249 | 0.1373 | 0.1462 | 0.1569 | 0.1681 | 0.1318 | 7.7747 | |

| Western | Inner Mongolia | 0.0670 | 0.0666 | 0.0585 | 0.0610 | 0.0679 | 0.0676 | 0.0745 | 0.0748 | 0.0672 | 1.8665 |

| Guangxi | 0.0653 | 0.0679 | 0.0760 | 0.0817 | 0.0872 | 0.0872 | 0.0923 | 0.0968 | 0.0818 | 5.8471 | |

| Chongqing | 0.0833 | 0.0922 | 0.0998 | 0.1061 | 0.1226 | 0.1311 | 0.1377 | 0.1510 | 0.1155 | 8.9279 | |

| Sichuan | 0.0911 | 0.1056 | 0.1163 | 0.1308 | 0.1477 | 0.1621 | 0.1767 | 0.1864 | 0.1396 | 10.8125 | |

| Guizhou | 0.0584 | 0.0663 | 0.0742 | 0.0793 | 0.0878 | 0.0941 | 0.1032 | 0.1178 | 0.0851 | 10.5788 | |

| Yunnan | 0.0626 | 0.0660 | 0.0733 | 0.0772 | 0.0817 | 0.0872 | 0.1049 | 0.1089 | 0.0827 | 8.3537 | |

| Shanxi | 0.1003 | 0.1012 | 0.1026 | 0.1115 | 0.1200 | 0.1304 | 0.1395 | 0.1439 | 0.1187 | 5.3403 | |

| Gansu | 0.0513 | 0.0515 | 0.0438 | 0.0517 | 0.0550 | 0.0602 | 0.0687 | 0.0758 | 0.0572 | 6.2624 | |

| Qinghai | 0.0243 | 0.0263 | 0.0207 | 0.0370 | 0.0344 | 0.0444 | 0.0143 | 0.0517 | 0.0316 | 40.2981 | |

| Ningxia | 0.0676 | 0.0738 | 0.0567 | 0.0793 | 0.0621 | 0.0645 | 0.0645 | 0.0615 | 0.0662 | 0.4808 | |

| Xinjiang | 0.0465 | 0.0518 | 0.0402 | 0.0397 | 0.0518 | 0.0675 | 0.0722 | 0.0838 | 0.0567 | 10.2447 | |

| Mean | 0.0652 | 0.0699 | 0.0693 | 0.0778 | 0.0835 | 0.0906 | 0.0953 | 0.1048 | 0.0820 | 7.0736 | |

| Northeast | Liaoning | 0.0948 | 0.0946 | 0.0844 | 0.0936 | 0.1056 | 0.1122 | 0.1133 | 0.1235 | 0.1027 | 4.1489 |

| Jilin | 0.0719 | 0.0720 | 0.0726 | 0.0768 | 0.0735 | 0.0825 | 0.0847 | 0.0984 | 0.0790 | 4.7953 | |

| Heilongjiang | 0.0769 | 0.0771 | 0.0721 | 0.0746 | 0.0773 | 0.0777 | 0.0806 | 0.0884 | 0.0781 | 2.1124 | |

| Mean | 0.0812 | 0.0812 | 0.0764 | 0.0817 | 0.0854 | 0.0908 | 0.0929 | 0.1034 | 0.0866 | 3.6533 | |

| Whole Country | Mean | 0.1058 | 0.1154 | 0.1228 | 0.1355 | 0.1471 | 0.1565 | 0.1672 | 0.1815 | 0.1415 | 8.0196 |

| Region | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | Annual Mean | Annual Average Growth Rate (%) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Eastern | Beijing | 0.0170 | 0.0255 | 0.0383 | 0.0453 | 0.0579 | 0.0687 | 0.0919 | 0.0996 | 0.0555 | 29.5763 |

| Tianjin | 0.0029 | 0.0041 | 0.0058 | 0.0067 | 0.0074 | 0.0090 | 0.0104 | 0.0127 | 0.0074 | 24.0574 | |

| Hebei | 0.0029 | 0.0043 | 0.0062 | 0.0092 | 0.0118 | 0.0155 | 0.0178 | 0.0215 | 0.0111 | 34.0701 | |

| Shandong | 0.0256 | 0.0343 | 0.0444 | 0.0621 | 0.0742 | 0.0783 | 0.0802 | 0.0999 | 0.0624 | 22.2075 | |

| Shanghai | 0.0143 | 0.0224 | 0.0295 | 0.0357 | 0.0425 | 0.0482 | 0.0613 | 0.0714 | 0.0407 | 26.5166 | |

| Jiangsu | 0.0515 | 0.0751 | 0.1062 | 0.1348 | 0.1665 | 0.2038 | 0.2427 | 0.3072 | 0.1610 | 29.4070 | |

| Zhejiang | 0.0312 | 0.0431 | 0.0635 | 0.0816 | 0.0993 | 0.1184 | 0.1578 | 0.1937 | 0.0986 | 30.1214 | |

| Fujian | 0.0076 | 0.0103 | 0.0141 | 0.0201 | 0.0276 | 0.0332 | 0.0397 | 0.0412 | 0.0242 | 27.9577 | |

| Guangdong | 0.0780 | 0.1071 | 0.1606 | 0.2196 | 0.2932 | 0.3951 | 0.5067 | 0.5963 | 0.2946 | 34.0373 | |

| Hainan | 0.0009 | 0.0019 | 0.0029 | 0.0044 | 0.0051 | 0.0041 | 0.0056 | 0.0063 | 0.0039 | 36.5114 | |

| Mean | 0.0232 | 0.0328 | 0.0472 | 0.0620 | 0.0786 | 0.0974 | 0.1214 | 0.1450 | 0.0759 | 30.2143 | |

| Central | Shanxi | 0.0011 | 0.0012 | 0.0012 | 0.0016 | 0.0029 | 0.0040 | 0.0045 | 0.0051 | 0.0027 | 26.9698 |

| Anhui | 0.0037 | 0.0064 | 0.0105 | 0.0151 | 0.0200 | 0.0268 | 0.0335 | 0.0428 | 0.0198 | 43.0553 | |

| Henan | 0.0059 | 0.0091 | 0.0135 | 0.0182 | 0.0219 | 0.0239 | 0.0304 | 0.0373 | 0.0200 | 31.0419 | |

| Hubei | 0.0044 | 0.0068 | 0.0105 | 0.0148 | 0.0169 | 0.0239 | 0.0311 | 0.0353 | 0.0180 | 35.6026 | |

| Hunan | 0.0036 | 0.0054 | 0.0084 | 0.0113 | 0.0157 | 0.0202 | 0.0274 | 0.0331 | 0.0156 | 37.8873 | |

| Jiangxi | 0.0014 | 0.0024 | 0.0044 | 0.0051 | 0.0076 | 0.0100 | 0.0130 | 0.0157 | 0.0074 | 43.9047 | |

| Mean | 0.0033 | 0.0052 | 0.0081 | 0.0110 | 0.0142 | 0.0181 | 0.0233 | 0.0282 | 0.0139 | 36.3228 | |

| Western | Inner Mongolia | 0.0012 | 0.0014 | 0.0014 | 0.0019 | 0.0026 | 0.0028 | 0.0038 | 0.0041 | 0.0024 | 20.3920 |

| Guangxi | 0.0010 | 0.0017 | 0.0027 | 0.0037 | 0.0047 | 0.0056 | 0.0072 | 0.0088 | 0.0044 | 36.7767 | |

| Chongqing | 0.0019 | 0.0033 | 0.0050 | 0.0067 | 0.0099 | 0.0127 | 0.0153 | 0.0193 | 0.0093 | 40.0713 | |

| Sichuan | 0.0040 | 0.0068 | 0.0108 | 0.0156 | 0.0213 | 0.0281 | 0.0363 | 0.0427 | 0.0207 | 41.0827 | |

| Guizhou | 0.0007 | 0.0012 | 0.0023 | 0.0033 | 0.0045 | 0.0058 | 0.0077 | 0.0103 | 0.0045 | 49.9238 | |

| Yunnan | 0.0010 | 0.0016 | 0.0027 | 0.0036 | 0.0043 | 0.0056 | 0.0089 | 0.0104 | 0.0048 | 41.3774 | |

| Shanxi | 0.0031 | 0.0042 | 0.0056 | 0.0080 | 0.0101 | 0.0131 | 0.0166 | 0.0185 | 0.0099 | 29.5872 | |

| Gansu | 0.0004 | 0.0007 | 0.0008 | 0.0013 | 0.0016 | 0.0022 | 0.0031 | 0.0039 | 0.0018 | 37.1991 | |

| Qinghai | 0.0001 | 0.0002 | 0.0002 | 0.0006 | 0.0006 | 0.0010 | 0.0002 | 0.0015 | 0.0005 | 125.5512 | |

| Ningxia | 0.0007 | 0.0013 | 0.0011 | 0.0023 | 0.0017 | 0.0020 | 0.0021 | 0.0020 | 0.0016 | 25.6983 | |

| Xinjiang | 0.0006 | 0.0009 | 0.0008 | 0.0009 | 0.0015 | 0.0028 | 0.0034 | 0.0049 | 0.0020 | 40.2755 | |

| Mean | 0.0013 | 0.0021 | 0.0030 | 0.0043 | 0.0057 | 0.0074 | 0.0095 | 0.0115 | 0.0056 | 36.6039 | |

| Northeast | Liaoning | 0.0042 | 0.0049 | 0.0048 | 0.0060 | 0.0080 | 0.0096 | 0.0108 | 0.0133 | 0.0077 | 18.4197 |

| Jilin | 0.0011 | 0.0015 | 0.0020 | 0.0025 | 0.0027 | 0.0038 | 0.0041 | 0.0059 | 0.0029 | 28.6105 | |

| Heilongjiang | 0.0014 | 0.0019 | 0.0021 | 0.0026 | 0.0032 | 0.0036 | 0.0042 | 0.0055 | 0.0031 | 22.3570 | |

| Mean | 0.0022 | 0.0028 | 0.0030 | 0.0037 | 0.0046 | 0.0057 | 0.0064 | 0.0082 | 0.0046 | 20.9368 | |

| Whole Country | Mean | 0.0091 | 0.0130 | 0.0187 | 0.0248 | 0.0316 | 0.0394 | 0.0493 | 0.0590 | 0.0306 | 30.8970 |

| Region Type | Coupling Degree | Value-Added Capability |

|---|---|---|

| Developed | Guangdong (0.4687), Jiangsu (0.3783), Zhejiang (0.2890), Shandong (0.2517) | Guangdong (0.2946), Jiangsu (0.1610), Zhejiang (0.0986), Shandong (0.0624) |

| Moderately Developed | Beijing (0.2053), Shanghai (0.2030), Fujian (0.1630), Anhui (0.1606), Henan (0.1588), Hubei (0.1518), Hunan (0.1458) | Beijing (0.0555), Shanghai (0.0407) |

| Moderately Underdeveloped | Sichuan (0.1396), Tianjin (0.1242), Hebei (0.1188), Shaanxi (0.1187), Chongqing (0.1155) | Fujian (0.0242) |

| Underdeveloped | Jiangxi (0.1092), Liaoning (0.1027), Hainan (0.0892), Guizhou (0.0851), Yunnan (0.0827), Guangxi (0.0818), Jilin (0.0790), Heilongjiang (0.0781), Inner Mongolia (0.0672), Ningxia (0.0662), Shanxi (0.0647), Gansu (0.0572), Xinjiang (0.0567), Qinghai (0.0316) | Sichuan (0.0207), Henan (0.0200), Anhui (0.0198), Hubei (0.0180), Hunan (0.0156), Hebei (0.0111), Shaanxi (0.0099), Chongqing (0.0093), Liaoning (0.0077), Jiangxi (0.0074), Tianjin (0.0074), Yunnan (0.0048), Guizhou (0.0045), Guangxi (0.0044), Hainan (0.0039), Heilongjiang (0.0031), Jilin (0.0029), Shanxi (0.0027), Inner Mongolia (0.0024), Xinjiang (0.0020), Gansu (0.0018), Ningxia (0.0016), Qinghai (0.0005) |

| Type | Type I | Type II | Type III | Type IV |

| Description | Original value-added capability | Value-added effect driven by manufacturing industry development on basis of coupling degree of both systems and digital economy in the base period. | Value-added effect driven by digital economy development on basis of coupling degree of both systems and manufacturing industry in the base period. | Value-added effect driven by interactive influence of digital economy and manufacturing industry on basis of coupling degree of both systems in the base period. |

| Type | Type V | Type VI | Type VII | Type VIII |

| Description | Value-added effect driven by coupling degree of both systemson basis of digital economy and manufacturing industry in the base period. | Value-added effect driven by manufacturing industry development and coupling degree of two systems on basis of digital economy in the base period. | Value-added effect driven by digital economy and coupling degree of both systems on basis of manufacturing industry in the base period. | Value-added effect driven by coupling degree of both systems and interactive influence of digital economy and manufacturing industry. |

| Region | Values of Decomposed Value-Added Capability | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Type | Type I | Type Ⅱ | Type III | Type IV | Type V | Type VI | Type VII | Type VIII | |

| Eastern | Beijing | 0.0170 | 0.0058 | 0.0228 | 0.0078 | 0.0147 | 0.0050 | 0.0197 | 0.0068 |

| Tianjin | 0.0029 | 0.0004 | 0.0053 | 0.0008 | 0.0010 | 0.0002 | 0.0018 | 0.0003 | |

| Hebei | 0.0029 | 0.0008 | 0.0068 | 0.0020 | 0.0021 | 0.0006 | 0.0049 | 0.0015 | |

| Shandong | 0.0256 | 0.0022 | 0.0402 | 0.0035 | 0.0102 | 0.0009 | 0.0160 | 0.0014 | |

| Shanghai | 0.0143 | 0.0038 | 0.0200 | 0.0054 | 0.0092 | 0.0025 | 0.0128 | 0.0034 | |

| Jiangsu | 0.0515 | 0.0206 | 0.0711 | 0.0284 | 0.0407 | 0.0162 | 0.0562 | 0.0225 | |

| Zhejiang | 0.0312 | 0.0136 | 0.0404 | 0.0176 | 0.0276 | 0.0120 | 0.0358 | 0.0155 | |

| Fujian | 0.0076 | 0.0023 | 0.0116 | 0.0034 | 0.0050 | 0.0015 | 0.0076 | 0.0023 | |

| Guangdong | 0.0780 | 0.0449 | 0.1102 | 0.0635 | 0.0788 | 0.0454 | 0.1114 | 0.0642 | |

| Hainan | 0.0009 | 0.0002 | 0.0024 | 0.0006 | 0.0005 | 0.0001 | 0.0013 | 0.0003 | |

| mean | 0.0232 | 0.0095 | 0.0331 | 0.0133 | 0.0190 | 0.0084 | 0.0267 | 0.0118 | |

| Central | Shanxi | 0.0011 | 0.0001 | 0.0028 | 0.0001 | 0.0003 | 0.0000 | 0.0007 | 0.0000 |

| Anhui | 0.0037 | 0.0015 | 0.0125 | 0.0049 | 0.0033 | 0.0013 | 0.0112 | 0.0044 | |

| Henan | 0.0059 | 0.0009 | 0.0157 | 0.0024 | 0.0029 | 0.0004 | 0.0079 | 0.0012 | |

| Hubei | 0.0044 | 0.0015 | 0.0106 | 0.0036 | 0.0034 | 0.0011 | 0.0081 | 0.0027 | |

| Hunan | 0.0036 | 0.0012 | 0.0104 | 0.0035 | 0.0028 | 0.0009 | 0.0081 | 0.0027 | |

| Jiangxi | 0.0014 | 0.0004 | 0.0058 | 0.0017 | 0.0010 | 0.0003 | 0.0041 | 0.0012 | |

| mean | 0.0033 | 0.0009 | 0.0096 | 0.0027 | 0.0023 | 0.0007 | 0.0067 | 0.0020 | |

| Western | Inner Mongolia | 0.0012 | 0.0000 | 0.0026 | 0.0000 | 0.0001 | 0.0000 | 0.0003 | 0.0000 |

| Guangxi | 0.0010 | 0.0001 | 0.0042 | 0.0006 | 0.0005 | 0.0001 | 0.0020 | 0.0003 | |

| Chongqing | 0.0019 | 0.0007 | 0.0060 | 0.0021 | 0.0015 | 0.0005 | 0.0048 | 0.0017 | |

| Sichuan | 0.0040 | 0.0015 | 0.0113 | 0.0043 | 0.0041 | 0.0016 | 0.0115 | 0.0044 | |

| Guizhou | 0.0007 | 0.0003 | 0.0029 | 0.0013 | 0.0007 | 0.0003 | 0.0029 | 0.0013 | |

| Yunnan | 0.0010 | 0.0003 | 0.0037 | 0.0010 | 0.0007 | 0.0002 | 0.0027 | 0.0008 | |

| Shanxi | 0.0031 | 0.0004 | 0.0083 | 0.0011 | 0.0013 | 0.0002 | 0.0036 | 0.0005 | |

| Gansu | 0.0004 | 0.0001 | 0.0018 | 0.0003 | 0.0002 | 0.0000 | 0.0009 | 0.0002 | |

| Qinghai | 0.0001 | 0.0000 | 0.0004 | 0.0002 | 0.0001 | 0.0000 | 0.0005 | 0.0002 | |

| Ningxia | 0.0007 | −0.0001 | 0.0018 | −0.0002 | −0.0001 | 0.0000 | −0.0002 | 0.0000 | |

| Xinjiang | 0.0006 | 0.0002 | 0.0015 | 0.0005 | 0.0004 | 0.0002 | 0.0012 | 0.0004 | |

| Mean | 0.0013 | 0.0003 | 0.0040 | 0.0010 | 0.0009 | 0.0003 | 0.0027 | 0.0009 | |

| Northeast | Liaoning | 0.0042 | 0.0004 | 0.0051 | 0.0005 | 0.0013 | 0.0001 | 0.0015 | 0.0002 |

| Jilin | 0.0011 | 0.0002 | 0.0027 | 0.0004 | 0.0004 | 0.0001 | 0.0010 | 0.0001 | |

| Heilongjiang | 0.0014 | 0.0000 | 0.0034 | 0.0000 | 0.0002 | 0.0000 | 0.0005 | 0.0000 | |

| Mean | 0.0022 | 0.0002 | 0.0037 | 0.0003 | 0.0006 | 0.0001 | 0.0010 | 0.0001 | |

| Whole Country | Mean | 0.0091 | 0.0035 | 0.0148 | 0.0054 | 0.0072 | 0.0031 | 0.0114 | 0.0047 |

| Region | Percentages of the Values of Decomposed Value-Added Capability (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Type | Type I | Type Ⅱ | Type III | Type IV | Type V | Type VI | Type VII | Type VIII | |

| Eastern | Beijing | 17.08 | 5.87 | 22.88 | 7.86 | 14.73 | 5.06 | 19.74 | 6.78 |

| Tianjin | 22.80 | 3.45 | 41.61 | 6.30 | 7.95 | 1.20 | 14.50 | 2.19 | |

| Hebei | 13.27 | 3.92 | 31.49 | 9.31 | 9.62 | 2.84 | 22.81 | 6.74 | |

| Shandong | 25.59 | 2.20 | 40.27 | 3.46 | 10.19 | 0.88 | 16.03 | 1.38 | |

| Shanghai | 20.01 | 5.37 | 28.04 | 7.53 | 12.82 | 3.44 | 17.96 | 4.83 | |

| Jiangsu | 16.75 | 6.69 | 23.16 | 9.25 | 13.24 | 5.29 | 18.31 | 7.31 | |

| Zhejiang | 16.12 | 7.01 | 20.88 | 9.08 | 14.25 | 6.19 | 18.46 | 8.02 | |

| Fujian | 18.48 | 5.49 | 28.09 | 8.35 | 12.11 | 3.60 | 18.41 | 5.47 | |

| Guangdong | 13.07 | 7.54 | 18.47 | 10.65 | 13.21 | 7.62 | 18.67 | 10.76 | |

| Hainan | 14.76 | 3.69 | 37.48 | 9.37 | 7.84 | 1.96 | 19.91 | 4.98 | |

| Mean | 15.99 | 6.53 | 22.81 | 9.17 | 13.08 | 5.82 | 18.45 | 8.14 | |

| Central | Shanxi | 21.06 | 1.04 | 55.29 | 2.73 | 5.22 | 0.26 | 13.71 | 0.68 |

| Anhui | 8.58 | 3.39 | 29.25 | 11.57 | 7.67 | 3.03 | 26.16 | 10.34 | |

| Henan | 15.76 | 2.39 | 42.07 | 6.39 | 7.90 | 1.20 | 21.08 | 3.20 | |

| Hubei | 12.46 | 4.22 | 29.93 | 10.13 | 9.50 | 3.22 | 22.83 | 7.73 | |

| Hunan | 10.79 | 3.63 | 31.36 | 10.53 | 8.38 | 2.81 | 24.33 | 8.17 | |

| Jiangxi | 8.67 | 2.52 | 36.64 | 10.64 | 6.16 | 1.79 | 26.02 | 7.56 | |

| Mean | 11.79 | 3.24 | 34.10 | 9.57 | 8.03 | 2.42 | 23.60 | 7.25 | |

| Western | Inner Mongolia | 28.45 | −0.27 | 61.96 | −0.58 | 3.32 | −0.03 | 7.23 | −0.07 |

| Guangxi | 11.76 | 1.64 | 47.52 | 6.64 | 5.65 | 0.79 | 22.82 | 3.19 | |

| Chongqing | 9.90 | 3.49 | 31.13 | 10.97 | 7.94 | 2.80 | 24.97 | 8.80 | |

| Sichuan | 9.42 | 3.58 | 26.39 | 10.02 | 9.64 | 3.66 | 27.02 | 10.26 | |

| Guizhou | 6.38 | 2.86 | 27.97 | 12.56 | 6.43 | 2.89 | 28.22 | 12.67 | |

| Yunnan | 9.47 | 2.69 | 35.47 | 10.06 | 6.95 | 1.97 | 26.02 | 7.38 | |

| Shanxi | 16.61 | 2.24 | 45.08 | 6.07 | 7.12 | 0.96 | 19.32 | 2.60 | |

| Gansu | 11.35 | 2.02 | 46.15 | 8.21 | 5.41 | 0.96 | 21.99 | 3.91 | |

| Qinghai | 6.15 | 2.48 | 27.40 | 11.05 | 6.91 | 2.79 | 30.79 | 12.42 | |

| Ningxia | 33.01 | −3.81 | 91.28 | −10.54 | −2.98 | 0.34 | −8.25 | 0.95 | |

| Xinjiang | 11.44 | 3.94 | 29.87 | 10.29 | 9.16 | 3.15 | 23.90 | 8.24 | |

| Mean | 11.56 | 2.81 | 35.14 | 8.86 | 7.66 | 2.45 | 23.86 | 7.65 | |

| Northeast | Liaoning | 31.47 | 3.22 | 38.30 | 3.91 | 9.45 | 0.97 | 11.51 | 1.18 |

| Jilin | 17.96 | 2.69 | 45.70 | 6.85 | 6.57 | 0.99 | 16.73 | 2.51 | |

| Heilongjiang | 24.93 | 0.15 | 61.61 | 0.37 | 3.71 | 0.02 | 9.16 | 0.05 | |

| Mean | 26.79 | 2.41 | 45.27 | 3.82 | 7.48 | 0.76 | 12.23 | 1.24 | |

| Whole Country | Mean | 15.42 | 5.89 | 25.09 | 9.11 | 12.13 | 5.19 | 19.24 | 7.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, R.; Fang, Y.; Zhao, X. The Development, Coupling Degree, and Value-Added Capability of the Digital Economy and Manufacturing Industry in China. Systems 2023, 11, 52. https://doi.org/10.3390/systems11020052

Su R, Fang Y, Zhao X. The Development, Coupling Degree, and Value-Added Capability of the Digital Economy and Manufacturing Industry in China. Systems. 2023; 11(2):52. https://doi.org/10.3390/systems11020052

Chicago/Turabian StyleSu, Rengang, Yinhai Fang, and Xianglian Zhao. 2023. "The Development, Coupling Degree, and Value-Added Capability of the Digital Economy and Manufacturing Industry in China" Systems 11, no. 2: 52. https://doi.org/10.3390/systems11020052

APA StyleSu, R., Fang, Y., & Zhao, X. (2023). The Development, Coupling Degree, and Value-Added Capability of the Digital Economy and Manufacturing Industry in China. Systems, 11(2), 52. https://doi.org/10.3390/systems11020052