Abstract

Virtual manufacturing (VM) technology emerged in the 1980s as a revolutionary strategy to optimize and streamline the entire product/service manufacturing lifecycle. However, over the years, its popularity appears to have waned. Further, the advent of the fourth industrial revolution (4IR) or Industry 4.0 brings with it other integrated digital technologies, including the Internet of Things (IoT), Blockchain, and digital twin (DT), among others. DT offers functions like VM plus other benefits, including intelligent manufacturing, to revolutionize future manufacturing operations activities and predictive capability using real-time data. This paper employs bibliographic metadata from publications indexed on SCOPUS to evaluate the recent trends in VM research and develop predictive models to forecast VM’s future trajectory and relevance in 4IR. The results of the bibliometric evaluation of VM-related scientific literature publications show a rapidly declining research productivity and highlight an exponential decline from the mid-2000s. This period of VM publication decline coincides with the advent of 4IR and DT technology, which are trending. The results of the predictive analytics using the quadratic regression model created in this study to forecast the future relevance of VM in the 4IR era suggest that VM publications show a similar conclusion. VM research output increased until 2009 and then started decreasing exponentially. The quadratic model implies an exponential decrease in yearly VM publications. Future works can evaluate DT and VM research trends from the last two decades.

1. Introduction

Virtual manufacturing (VM) technology emerged in the 1980s as a revolutionary manufacturing strategy to transform conventional production and operations [1,2]. VM is a comprehensive, synthetic digital manufacturing environment that enhances all levels of decision and control of a manufacturing system [3,4,5]. The growing demand for greater productivity, lower production costs, and better product quality in the fiercely competitive global market was the primary impetus for the VM initiative [4,5]. In VM, sophisticated computer-based models, simulations, and data-driven analytics are created to optimize and streamline the entire product/service lifecycle by incorporating components of computer-aided design (CAD), computer-aided manufacturing (CAM), and simulation [5,6,7]. Various functions are then performed to boost efficiency, sustainability, and innovation in the manufacturing industry, from original product design and prototyping to process optimization, resource planning, and quality assurance [8].

Additionally, VM encourages continual improvement by offering insightful information about the production process, allowing businesses to quickly adjust to market needs and keep a competitive advantage [8,9]. VM is anticipated to play an increasingly important role in determining the future of manufacturing and industry as fourth industrial revolution (4IR) technologies continue to develop [10]. Hence, VM offers significant benefits for product and service manufacturing throughout the entire product/service lifecycle [10,11]. The benefits include design and prototyping through visualization with the ability to refine techniques before committing to physical production [11]. A VM environment proffers process optimization through simulations and modeling with the ability to analyze different scenarios, identify bottlenecks, and fine-tune parameters to maximize efficiency, reduce waste, and improve overall productivity [12,13]. Thus, VM aids in the planning and management of resources effectively.

The emergence of 4IR brought with it a set of integrated technologies capable of revolutionizing the manufacturing industry and other sectors of the economy. As mentioned earlier, these integrated technologies cut across several fields, including computer technology and telecommunications, such as the Internet of Things, big data, virtual reality, simulation, and DT [10,14]. As technology evolves rapidly, 4IR will continue to impact different manufacturing areas in the coming years. 4IR, or Industry 4.0 (as it is also known), is characterized by the convergence of digital, physical, and biomedical technologies, transforming various industries and aspects of society [14]. Its key features include the widespread use of the Internet, popularly called the Internet of Things (IoT), connecting mobile devices for seamless communication and data exchange, and the integration of sensors and intelligent devices into various objects and machines to collect, share, and analyze data to enable automation, pattern recognition, and prediction capabilities [15,16,17]. Other characteristics of 4IR include advanced robotics and automation technologies that transform industries by enhancing productivity and efficiency, 3D printing technology that enables the creation of complex and customized objects, and augmented reality (AR) and virtual reality (VR) that provide immersive and interactive experiences [7,15,16,17]. Embracing and harnessing its potential while addressing its challenges is essential for ensuring a sustainable and inclusive future.

However, VM’s popularity appears to have waned with the advent of 4IR or Industry 4.0 in the mid-2000s, especially regarding VM’s research productivity. This study undertakes a bibliometric analysis of VM research in the past three decades and develops predictive models to forecast the future relevance of VM in the 4IR era. Specifically, this study addresses the following three research objectives:

- Evaluate the bibliometric performance of VM-related scientific literature production (SCP) from 1983 to 2023 (RO1);

- Examine the thematic evolution of VM publications over the past four decades (RO2);

- Predict the future research productivity and relevance of VM technology in 4IR (RO3).

RO1 involves an analysis of annual SCP and trends and citation impacts over the period covered in this study. RO2 examines the evolution of research themes and topics in VM technology research. For RO3, this paper employs predictive regression analysis models using the same bibliographic metadata from SCOPUS-indexed publications to forecast the future trajectory of VM research productivity and relevance in the era of 4IR.

The rest of the present paper is organized as follows: Section 2 presents the literature framework relating to VM, DT, and 4IR. Section 3 addresses the materials and methods, including the bibliometric analysis framework, data collection processes and procedures, and analysis techniques. Section 4 presents and discusses the results. The final part, Section 5, concludes the paper and identifies the potential future research areas.

2. Theoretical Background

2.1. Virtual Manufacturing (VM) Technology

VM involves creating a digital or computer-based environment that mimics an actual system and simulating the different aspects of manufacturing operations and processes to optimize and improve efficiency, quality, and productivity before actual physical production occurs [2,5,6]. It entails the use of virtual reality or augmented reality and simulation technologies to model and evaluate the different components of manufacturing activities and processes, incorporating product design, digital prototyping, and production processes. VM also helps to ensure efficient resource utilization and quality control in manufacturing. Furthermore, VM helps to accelerate time to market by identifying and addressing potential issues virtually before they become costly problems in the physical world [4].

The development of VM came into existence following the emergence of allied manufacturing technologies, including CAD, CAM, simulation, and virtual reality (VR) [6,18]. Thus, VM integrates these technologies to present a virtual environment that enhances optimal product development. CAD and CAM are fundamental tools used to create detailed digital models of products, services, components, and manufacturing processes. CAD systems use mathematical and geometrical representations to describe the physical aspects of products or systems. CAM generates instructions for computers and robots to develop products. Generally, CAM converts CAD models into machine-specific and understandable code, allowing for automation and precision in the manufacturing process [6]. Mathematical models and simulations are utilized to analyze, predict, and correct the behavior of manufacturing processes by identifying potential issues, optimizing parameters, and evaluating different scenarios without the cost of building a physical prototype [18,19,20,21,22,23]. Today, these benefits of VM in simulating manufacturing processes are also possible in a digital twin (DT) setting, one of the advanced technologies under 4IR [24]. 4IR is discussed in further detail in the section below.

2.2. Fourth Industrial Revolution and Associated Technologies

The dramatic advances in computing power (hardware and software), Internet connectivity, and advanced communication technologies have led to the evolution of 4IR and associated technologies, including DT. A DT is a virtual replica of a physical manufacturing system. This virtual environment captures the manufacturing complex from design to behavior and real-time performance. Real-time monitoring, analysis, recommendation, and the physical system’s optimization are made possible using data collected from the virtual counterpart [24]. Interaction in the virtual environment of the DT is possible through virtual reality (VR) and augmented reality (AR) technologies. VR and AR enable virtual walks and work through manufacturing facilities with training simulations and visualization [14,20,23,24,25].

4IR is powered by various advances in mathematics and its applications in engineering, artificial intelligence (AI), data science, and other emerging fields using developments in computer science technologies [26,27]. Unlike the previous industrial revolution, 4IR is characterized by the convergence of data, intellectual discoveries, and technological advances rather than material discoveries [28]. This leads to transformative changes across industries and society. Information technology (IT) and the Internet of Things (IoT) comprise the reliable foundation on which 4IR lies. The rapid advancement of information technology, including the Internet, cloud computing, and the proliferation of connected devices, has enabled seamless communication, data sharing, and real-time connectivity between people, machines, and systems anywhere [29]. The natural consequence is the IoT. The analytic pillar of 4IR that fuels its running is data collection through sensors and smart devices implanted into objects and machines exchanging data. This interconnectedness and collection of data allow for intelligent data-driven decision making, automation, and optimization in various manufacturing sectors. The vast amounts of data (big data) collected require advanced analysis due to their volume, generation velocity, and variety. Machine learning and artificial intelligence models enable organizations to derive valuable insights from these data and make data-driven decisions [10,17].

It appears that the period of the advent of DT and the hype that followed it corresponds with the decline in VM research, hence the rationale for this study.

3. Methodology

3.1. Database Survey and Data Collection

The data used in this study were obtained from surveying the SCOPUS bibliographic database. Publications on VM are indexed on several bibliographic databases, including SCOPUS and Web of Science (WoS), the two most popular citation databases regarding quality and coverage [30]. We opted for SCOPUS because it holds more sources and published documents on VM than WoS.

The SCOPUS research citation database offers options for users to search and retrieve data using a set of ”query string” or search criteria based on predefined keywords. The researchers developed the query (Table 1). The final data collection occurred on 31 July 2023. The survey generated 13,735 published records, which went through further filtering and screening. The user interface offers data filtering mechanisms before data extraction. Over 185 non-research documents (such as errata, editorials, notes, and letters to the editor) were filtered out (Table 1).

Table 1.

Literature survey and data collection process: Search and retrieval, filtering, screening, and selection criteria of the published documents.

Further data filtering and screening on SCOPUS helped to remove 11,970 irrelevant records using subquery, which involved developing SQL queries within the initial output [30]. Thus, 11,970 publications that addressed general manufacturing rather than VM were discarded, leaving 1220 relevant publications of interest.

The filtered data were collected as a text file and exported to the chosen citation software (the R-based Bibliometrix application was used in this study and is described in Section 3.2.1) for processing and analysis [31]. Table 1 presents the search, filtering, screening, and selection criteria for the published documents.

3.2. Data Analysis Techniques

The analysis of data in this study involved two main aspects. First, we performed bibliometric performance analysis of VM-related scientific literature production during the period covered in this study; second, we developed predictive models to forecast VM’s future trajectory and relevance in 4IR. Both analytics techniques (Section 3.2.1 and Section 3.2.2) utilized the metadata from the published documents retrieved from the SCOPUS research database (Table 1).

3.2.1. Bibliometric Analysis

Our bibliometric performance analysis employed quantitative techniques to evaluate publication trends and citation impact analysis and map the thematic evolution of the VM literature [31,32]. In carrying out the bibliometric performance analysis, this study utilized the R-based Bibliometrix, a freely available open-source software application embedded in the R-Studio environment [33,34].

3.2.2. Regression Analysis

This part of the study employed descriptive analysis to explain the data used and various cross-sectional regression research designs to forecast VM’s publication trend. The dependent variable was the number of total published articles. We used different transformations of the years of publication of VM papers. These included the log transformation and the squared transformation. Descriptive statistics presented the summary of the distribution of the independent variable (year). In this section, we describe our development of a predictive model used to forecast the future trajectory of VM given the availability of DT technology, which performs similar functions. The data featured in this part of the analysis were processed, transformed, analyzed, and presented using Microsoft Excel software and the R-based statistical package [35].

Linear regression models were developed to analyze the annual publication (tp) trend as the dependent variable. There were two linear independent variables (year and other transformation and normalization of years of publication). Since this study aimed to forecast publication trends, the total number of publications (Y) was chosen as the dependent variable. In contrast, the year of publication and/or transformations of the year of publication variables were the independent variables (X). In general, the linear regression models had the form of Equation (1):

where is the dependent variable (number of total publications, tp), “” is a vector of the predictors or independent variables, “p” is the number of predictors, “α” is the intercept, “” represents the regression coefficients to be estimated, “” is the standard error of estimate assumed to be normally distributed, and n is the sample size. The predictions can be obtained using Equation (2).

where the hats represent the estimated value. Replacing the values of the predictor variables returns the fitted or predicted values of . To forecast the future total publications, we used the same fitted value of future years. However, we distinguished between the ex ante and ex post forecasts. Ex -ante forecasts used only the parameters obtained using available past and present data and information. For example, ex ante forecasts for future years of annual publications used the parameters obtained using only the observations obtained from SCOPUS discussed in Section 3.1. Although we obtained data for the period 1983 to 2023, we used whole-year data from 1990 to 2022 for the predictive analysis for two reasons: first, the annual publications (tp) for the period (1983–1989) were near zero; second, the 2023 data comprised a half year (January to 31 July 2023). The ex post forecasts were made using an updated model of new forecast observations.

In R software, multiple linear regression can be implemented using the “lm()” function [5]. The estimation result output provides, in addition to the estimated parameter coefficients with their confidence measures, the adjusted and residual standard error. Three linear models and one quadratic model were used in this study (Table 2).

Table 2.

Formulated regression models.

The performance of the six models SLR1, SLR2, SLR3, SLR4, and QR in predicting the total number of published VM articles was assessed using several measures including the residual standard error, R-squared, and adjusted R-squared.

4. Analysis of Results and Discussion

4.1. Summary of Results

The data came from publications retrieved from SCOPUS covering the period from 1983 to 2023 (31 July). As explained earlier, the 1220 screened and selected documents were downloaded as metadata in text format and exported to ”Bibliometrix”, an R-based software application, Microsoft Excel, and R-statistics for analyses and visualization. The documents were published in 559 sources and authored/co-authored by 2735 researchers. Table 3 presents a data summary.

Table 3.

Summary of metadata of VM-related scientific literature publications.

4.2. Performance Bibliometric Analysis

This section presents a performance bibliometric evaluation relating to the scientific literature publication trend and the citation impact analysis, which helps to address the first research objective (RO1).

4.2.1. Scientific Literature Production Trend

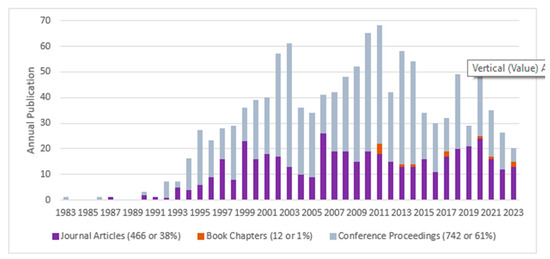

The first part of the performance bibliometric analysis examines the publication trend of VM literature production covering the investigated period (1983–2023). The time frame signals the evolution of VM up until the present. The metadata extracted from the published documents consisted of journal articles (466 or 38%), conference proceedings (742 or 61%), and book chapters (12 or 1%). Thus, most published documents were conference proceedings. The trend spanned nearly all years comprising the four decades of VM research with few exceptions, which occurred in 1993, 2006, 2017, and 2019 (Figure 1). The annual scientific literature production (SCP) was moderate, with an SCP growth rate of 7.78% (Table 3) and a yearly average of 30, the highest number of publications occurring in 2011, with a total of 68 publications, namely 18 journal articles, 4 book chapters, and 46 conference proceedings (Figure 2). The trend also shows that VM’s SCP maximum occurred a decade ago when 4IR started gaining momentum [36]. After this year, the annual total publications on VM declined continuously until the present (Figure 1).

Figure 1.

Scientific Literature publications on VM for 1983–2023.

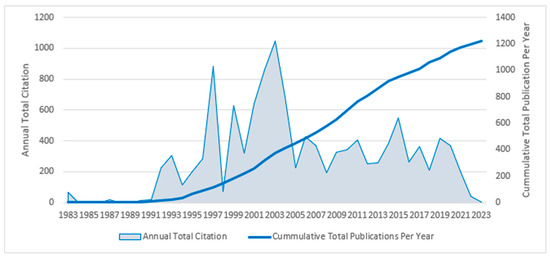

Figure 2.

Annual literature publications and document citations per year of VM literature (1983–2023). The number of publications for 2023 is as of 31 July.

4.2.2. Citation Impact Analysis of Publications

The summary of the bibliometric analysis results shows an average number of citations of 9.82 per document and a total of 11,977 over the forty years of VM research (Table 3). The result was generated using the R-based Bibliometrix application. Figure 2 shows the relationship between total publications and annual citations. The results show that VM publications earned the highest single-year citation impact of 1049 in 2003 while achieving the highest yearly publication count of 61 with a cumulative total of 377 publications, the highest indices since VM’s inception. Thus, 2003 remains the most impactful year regarding earned citations throughout VM research history to date.

Despite subsequent increases in the cumulative total of annual publications each year, the citation impact of VM literature nosedived significantly in 2004 and by 45% in 2019. However, the years following the evolution of 4IR [36] saw some signs of weak recovery between 2010 and 2012 and a momentary upward movement in 2015; publications’ citation impact grew weaker, returning to the equivalent of that of VM’s early years (e.g., 1998 level) when VM technology evolved (Figure 2). Considering that the decline in VM’s relevance coincides with the evolution of Industry 4.0, one can speculate that the development of DT technology, which coincides with 4IR (Industry 4.0) and performs similar functions, accounts for the decline in VM’s relevance.

4.2.3. Citation Structure of VM Literature

This section also analyzes the citation structure of VM publications. Table 4 presents the citation structure of VM literature. The results show that about 67.1% (819) of published documents earned one or more citations, while 32.9% received none. The 401 non-cited publications spanned four decades, including those with long citable years published in the 1990s and recent ones published between 2020–2023.

Table 4.

Citation structure of VM publications.

Further, about 46.89% of the cited publications earned between 1 and 10 citations, while 15.66% of documents received more than 10 but less than 51. Less than 5% earned 51 or more citations. Most VM literature was cited in the earlier years of VM’s launch (Figure 2; Table 4), especially between 1991 and 2003, while the later years experienced a continuous decline in earned citations from 2004 to the present. Further analysis showed that about 32.9% (401) of the publications received no citations. The table below shows the complete classification and citation structure.

The number of citations reported above is based on SCOPUS bibliographic data. The Google Scholar (scholar.google.com) citation count can be more than records on SCOPUS. For example, [37] earned 409 citations as of July 31, 2023, based on SCOPUS data, but over 700 citations on Google Scholar.

4.2.4. Document Citation Impact Analysis

The results of the citation structure showed that 819 (67.1%) of the 1220 publications surveyed in this study earned at least one citation in the past 40 years (1983–2023). The results generated from the R-based Bibliometrix application [33] highlight the top 15 most cited publications, areas of focus, total citations (TC), average citations per year, and normalized TC. The top fifteen publications earned at least 100 citations (TC ≥ 100). Further analysis showed that all published documents were journal articles except for one conference paper. The top cited areas of research focus in VM include “virtual reality,” “manufacturing processes,” “intelligent manufacturing,” “virtual prototyping,” “manufacturing simulation,” “computer-aided concurrent design,” and “additive manufacturing processes” [19,20,21,22,23,37,38]. Table 5 displays the complete list.

Table 5.

Most cited publications and themes.

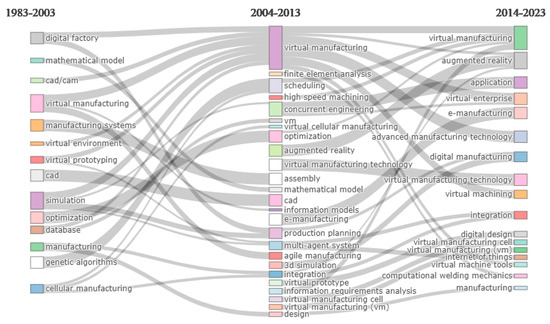

4.3. Thematic Evolution of Virtual Manufacturing Literature (1983–2023)

The second research objective (RO2) examines the evolution of VM research themes over the past forty years. The purpose is to identify the transformation in research focus during the period. Text analytics of author keywords and science mapping using the R-based Bibliometrix application highlight the trending themes in each segmented period (Figure 3).

Figure 3.

Thematic evolution of virtual manufacturing (1983 to 2023).

The trend analysis highlights the origin and evolution of dominant VM research themes in three strata (1983–2003; 2004–2013; 2014–2023). The first segment covers the initial twenty years (1983–2003) of VM research. During this period, the total number of VM publications was 377, hence the rationale for grouping the first two decades. The next decade (2004–2013) accumulated 486 publications, and 2014–2023 had 357 publications per the cumulative total publication trend (Figure 2).

Some of the vital research themes in the first segment other than VM include “cellular manufacturing [45,46],” “digital factory [47],” “simulation [3,45],” “manufacturing systems [3,45],” “virtual machine tools [48],” “CAD/CAM [6,11],” and “virtual prototyping [47].” In addition to the themes covered in the first segment, new themes addressed in the second period include “3D simulation [49,50,51],” “production planning [43,52],” “augmented reality [53],” and “e-manufacturing [54].” Some new themes evolved in the third segment, including “virtual enterprise [55,56],” “digital design [57],” and “digital manufacturing [58].” The result shows the growth and continuous addition of new VM research terminologies that point to new digital technologies toward improving product and service manufacturing.

VM plays a significant role in 4IR by leveraging innovative and advanced digital technologies capable of transforming manufacturing processes [2,8]. As shown in Figure 3, during 2014–2023, which corresponds to the period of 4IR, we witnessed emerging concepts such as e-manufacturing, virtual machinery, and virtual enterprise [55,56]. E-manufacturing (electronic manufacturing) uses advanced digital technologies to optimize and streamline manufacturing processes. It integrates information technology, automation, data analytics, and connectivity to enhance manufacturing operations’ efficiency, flexibility, and productivity [54]. These digital technologies have revolutionized the manufacturing industry by improving efficiency, reducing waste, and enabling greater agility in response to changing market demands and other conditions. It empowers manufacturers to produce high-quality products at a lower cost while adapting to evolving technologies and customer preferences.

Virtual machinery simulates and mimics physical machinery, processes, or systems in a virtual or digital environment [41]. It involves using computer software and models to replicate real-world machinery’s behavior, functionality, and characteristics without the need for physical hardware. Overall, virtual machinery is a valuable tool in modern engineering and industry, allowing for the efficient development, operation, and maintenance of complex machinery and systems in a digital environment [41,55].

A virtual enterprise, also known as a virtual organization or networked enterprise, is a business model or organizational structure in which various geographically dispersed and independent entities collaborate and work together to achieve common goals, such as the delivery of products or services [55,59]. Usually, advanced information and communication technologies, including wireless networks, are tools that enhance business interconnectedness in a globalized world. Business objectives include leveraging technology and collaboration to lower costs and create value costs [56,59]. The use of these technologies has increased since the 4IR era and accelerated during the global health pandemic when virtual technologies became more pervasive [59,60].

4.4. Predictive Analysis of Future Trajectory of Virtual Manufacturing

4.4.1. Regression Analysis

This section attempts to predict the future trajectory of VM research productivity, which helps to address the third research objective (RO3).

Table 6 presents descriptive statistics of the selected VM publications. The average number of publications obtained is 36, with a standard deviation of 17 and a variance of 299. Hence, there is a significant variation in the total number of yearly VM publications, with a minimum of 1 and a maximum of 68 a year. The discrepancy between the mean and the variance suggests that the Poisson regression (PR) model is not the best fit since the mean and the variance are unequal. The minimum annual number of publications occurred in 1990, while the maximum was recorded in 2012. Since then, the number of VM publications has continued to decrease (Figure 1 and Figure 2).

Table 6.

Descriptive statistics of the number of VM publications.

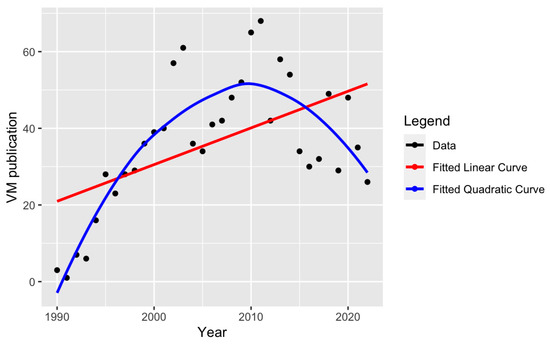

Figure 4 shows the scatter plot of the number of VM publications as a function of the year of publication. In addition, to evaluate the trend, a linear curve (in red) and a quadratic curve (in blue) have been added to the scatter plot. Visually, the quadratic curve fits the data best. This is analyzed further in Section 4.4.2.

Figure 4.

Scatter plot and fitted linear and quadratic curves to yearly VM publications.

4.4.2. Predictive Models

This section presents the computational results of the regression analysis methodology. The results are obtained from statistical computation in R to produce parameter coefficients and slope, including and RSE, as well as the performance of prediction models. The predictive models are utilized to forecast VM’s future publication trajectory.

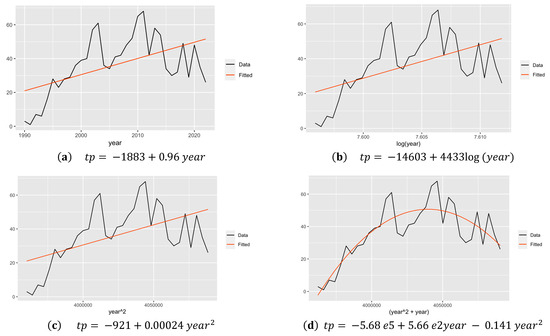

This study used five predictive models to describe the relationship between the passing years and the number of VM publications. Table 7 highlights the estimated coefficients in the equation and the predictive models. The p-values of all the models are statistically significant (p < 0.005). This ascertains that all the year of publication are significant in describing the number of publications. However, the models’ and adjusted , which indicate that the percentage of variability in the number of VM publications explained by the year of publication, vary substantially with the quadratic regression model, explaining a staggering 72% of the variation. Also, the fitted curves of the models shown in Figure 5a–d show that only the quadratic model has a good fit. These results showed that the number of VM publications increased from 1990 to 2012 and, since then, has started decreasing substantially. For the QR, the number of VM publications is significantly and highly influenced by the year of publication. In this regard, the quadratic model is used to forecast the future number of VM publications.

Table 7.

Model estimations and test scores.

Figure 5.

(a–d) Fitted model curves forecasting (using quadratic regression model).

The quadratic regression model is used to produce the equation of the parabola that best fits the dataset. The model obtained is given below.

The least-squares estimates of the quadratic model are tabulated in Table 8. As observed in the table, all the coefficients are significant with 99% confidence. As expected, the quadratic term contributes negatively while the linear term contributes positively. The ANOVA table in Table 9 shows that the model is significant with a critical F value of 41.23, greater than the significant F value of 2.4652 × 10−9.

Table 8.

Coefficient estimates, test score, and confidence interval of the Quadratic model (QR).

Table 9.

Quadratic model’s ANOVA Table.

Even though quadratic regression is a type of multiple linear regression, the individual coefficients have no direct underlying prediction power since there is a strong correlation between and (correlation = 0.9999978). Hence, the whole fitted regression is used as a predictor. The multiple values obtained show that the whole model explains 86% of the variation in the total number of publications and the adjusted of 72%.

The regression analysis performed in this paper aims to predict the future research productivity and relevance of the VM in 4IR. As a proxy, we used the number of VM publications in the context that increasing research productivity (the number of published documents) implies increased relevance. Predictive analytics using regression models have been used primarily to explain the supposed relationship between predictor variables and an outcome variable. However, in addition to the goal to understand and explain the relationship, with the availability of massive data, regression is now widely used to predict outcomes; thus, we use it as a predictive model. In this case, the item of interest is represented by fitted values rather than the estimated coefficient. A helpful metric that explains and measures the usefulness of the model is . Of the five models we ran, the quadratic model (QR) has the highest and, therefore, explains and predicts the relations between the future and the number of publications better. The quadratic model used to forecast the future number of publications shows that with a unit increase in time (one year), there is a unit change in the number of publications. This model captures the nonlinear relationships between the number of publications and time, as seen in Figure 4. Table 4 shows that both the coefficients of the linear and quadratic terms are significant at 99%.

The overall relationship between the number of VM publications and the year is quadratic and well captured by the quadratic regression model and associated curve (Figure 5a–d). The large standard deviation is due to the highly volatile data observed. It is worth noting that because of the relatively lengthy period of one year, this prediction is impacted by scalability. However, we point out that there is an exponential decrease in the production of VM papers in the literature, indicating the potential of VM concepts now being captured in the DT literature.

The decline in VM research productivity and relevance corresponds to the introduction of DT, a 4IR technology and framework more potent in capturing the complexities of the real-world manufacturing environment. DT creates a more accurate and realistic representation of processes, allowing for better analysis and decision making. Moreover, because DT enables real-time monitoring of physical systems and processes by integrating sensors and data from the physical world with their digital counterparts, this capability allows for better control, optimization, and responsiveness in manufacturing operations. Also, DT can predict when equipment or machinery is likely to fail based on real-time data and historical patterns.

The decline in VM research will have academic and industry-level impacts on the field of manufacturing in several ways. First, academia can benefit by exploring opportunities for interdisciplinary research in DT and 4IR and developing new academic programs leading to discoveries and collaboration with industry. Further, this development can lead to new curricula and courses related to the new manufacturing paradigm.

5. Conclusions

This study has examined a performance bibliometric analysis of VM and predicted its future research productivity and impact in the 4IR era amidst the hype and popularity of DT technology, which is currently trending and tends to perform similar functions as VM. The results reveal the growth and impacts of VM in the early years (1983–2009). However, in the subsequent years following the advent of DT, a replica technology like VM that was introduced alongside 4IR (Industry 4.0) around 2010 [36], coincides with the drastic and continuous decline in VM research productivity and impacts.

Further, the quadratic regression model provided valuable insights into the relationship between the year and the number of VM publications. The decreasing trend and the potential nonlinear behavior have been captured by considering both linear and quadratic terms. A comparative graphical representation of the various linear models and the quadratic regression curve further clarified the need for the quadratic component to explain the curvature in the relationship, demonstrating how the model effectively predicts the continuous decline in VM research and relevance in the 4IR era. It implies that DT now captures VM concepts; thus, VM faces the danger of becoming an irrelevant technology in Industry 4.0. It is essential to acknowledge the limitations of the quadratic regression model. While it captures nonlinear patterns, it might not be the best fit as more data will require new models. However, the quadratic regression model has proven to be valuable in uncovering the complex matters studied in this paper. Its ability to account for nonlinear effects enriches our understanding of data, offering a comprehensive perspective beyond traditional linear models.

This paper provides several guiding points to the VM research community and DT and 4IR or Industry 4.0 practitioners. Technological trends and developments in 4IR are evolving, while emerging technologies like DT significantly enhance manufacturing operations. Therefore, we call for openness and adaptation to newer technologies. There is a need for long-term strategic planning or decision making towards achieving business strategies. Companies must stay current with technological shifts to remain relevant and competitive in the globalized world.

Decision makers in the industry should consider investing in new manufacturing technology research and implementation of virtual enterprise technologies as a strategic imperative [55,61]. As new technologies rely heavily on data integration and IoT devices, organizations should prioritize data security and implement robust cybersecurity measures to protect sensitive information [62,63]. Both academia and industry should encourage interdisciplinary collaboration to fully realize the potential of integrative technologies across multiple disciplines in engineering, data science, AI, and business to drive innovation [8,61]. Companies can continue to leverage technology to enhance sustainability by optimizing resource usage, reducing energy consumption, and minimizing waste to meet environmental goals [64,65].

We aim to provoke intellectual discourse on restructuring and repositioning VM technology to remain relevant in the 4IR era. Future studies intend to undertake a comparative analysis of DT and VM performance bibliometric analyses.

Author Contributions

Y.M.K. and I.J.A. contributed equally to the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not Applicable.

Data Availability Statement

Third party proprietary data. Authors are not permitted to share data.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Savastano, M.; Amendola, C.; Bellini, F.; D’Ascenzo, F. Contextual impacts on industrial processes brought by the digital transformation of manufacturing: A systematic review. Sustainability 2019, 11, 891. [Google Scholar]

- Radharamanan, R. Virtual manufacturing: An emerging technology. In Proceedings of the 2002 American Society for Engineering Education Annual Conference & Exposition, Montreal, ON, Canada, 16–19 June 2002. [Google Scholar]

- Iwata, K.; Onosato, M.; Teramoto, K.; Osaki, S. Virtual manufacturing systems as advanced information infrastructure for integrating manufacturing resources and activities. CIRP Ann. 1997, 46, 335–338. [Google Scholar] [CrossRef]

- Graf, M.; Härtel, S.; Binotsch, C.; Awiszus, B. Virtual Manufacturing as Tool for Material and Process Developments and Optimizations. J. Mech. Eng. 2018, 4, 33–59. [Google Scholar]

- Cheng TC, E.; Choy, P.W.; Wong, S.W. Virtual Manufacturing: Critical Capabilities and Their Organizational Performance Implications. IEEE Eng. Manag. Rev. 2022, 50, 103–114. [Google Scholar] [CrossRef]

- Lim, K.T.; El-Mounayri, H. CAD/CAM-based geometric modeling simulation for virtual manufacturing. In Proceedings of the Electrical Insulation Conference and Electrical Manufacturing and Coil Winding Conference (Cat. No. 99CH37035), Cincinnati, OH, USA, 28 October 1999; pp. 547–551. [Google Scholar]

- Akpan, I.J.; Shanker, M. The confirmed realities and myths about the benefits and costs of 3D visualization and virtual reality in discrete event modeling and simulation: A descriptive meta-analysis of evidence from research and practice. Comput. Ind. Eng. 2017, 112, 197–211. [Google Scholar]

- Souza, M.C.F.; Sacco, M.; Porto, A.J.V. Virtual manufacturing as a way for the factory of the future. J. Intell. Manuf. 2006, 17, 725–735. [Google Scholar]

- Westkämper, E.; von Briel, R. Continuous improvement and participative factory planning by computer systems. CIRP Ann. 2001, 50, 347–352. [Google Scholar] [CrossRef]

- Kumar, K.; Zindani, D.; Davim, J.P. Industry 4.0: Developments towards the Fourth Industrial Revolution; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Yuan, Q.K.; Luo, S.M.; Tang, W.Y. A collaborative design frame based on virtual prototypes and virtual manufacturing. In Proceedings of the 11th IEEE International Conference on Computer-Aided Design and Computer Graphics, Huangshan City, China, 19–21 August 2009; pp. 568–571. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, Z.Q.; Huang, P.L.; Ai, X.; Deng, J.X. Simulation Diagnosis for the Bottleneck of Production Lines and Its Application. Mater. Sci. Forum 2004, 471, 563–567. [Google Scholar] [CrossRef]

- Akpan, I.J.; Brooks, R.J. Experimental evaluation of user performance on two-dimensional and three-dimensional perspective displays in discrete-event simulation. Decis. Support Syst. 2014, 64, 14–30. [Google Scholar]

- Li, X.; Wang, L.; Zhu, C.; Liu, Z. Framework for manufacturing-tasks semantic modelling and manufacturing-resource recommendation for digital twin shop-floor. J. Manuf. Syst. 2021, 58, 281–292. [Google Scholar]

- Gilchrist, A. Introducing Industry 4.0. In Industry 4.0; Apress: Berkeley, CA, USA, 2016. [Google Scholar] [CrossRef]

- Azarian, M.; Yu, H.; Solvang, W.D. Integrating additive manufacturing into a virtual Industry 4.0 factory. In Advanced Manufacturing and Automation; Springer: Singapore, 2021; Volume X10, pp. 587–594. [Google Scholar]

- Lind, A.; Elango, V.; Hanson, L.; Högberg, D.; Lämkull, D.; Mårtensson, P.; Syberfeldt, A. Virtual-Simulation-Based Multi-Objective Optimization of an Assembly Station in a Battery Production Factory. Systems 2023, 11, 395. [Google Scholar]

- Onosato, M.; Iwata, K. Development of a virtual manufacturing system by integrating product models and factory models. CIRP Ann. 1993, 42, 475–478. [Google Scholar]

- Wang, G.G. Definition review of virtual prototyping. J. Comput. Inf. Sci. Eng. 2002, 2, 232–236. [Google Scholar] [CrossRef]

- Mujber, T.S.; Szecsi, T.; Hashmi, M.S. Virtual reality applications in manufacturing process simulation. J. Mater. Process. Technol. 2004, 155, 1834–1838. [Google Scholar] [CrossRef]

- Williams, J.R.; Pentland, A.P. Superquadrics and modal dynamics for discrete elements in interactive design. Eng. Comput. 1992, 9, 115–127. [Google Scholar] [CrossRef]

- Choi, S.; Jung, K.; Noh, S.D. Virtual reality applications in manufacturing industries: Past research, present findings, and future directions. Concurr. Eng. 2015, 23, 40–63. [Google Scholar]

- Maturana, F.; Shen, W.; Norrie, D.H. MetaMorph: An adaptive agent-based architecture for intelligent manufacturing. Int. J. Prod. Res. 1999, 37, 2159–2173. [Google Scholar] [CrossRef]

- Alexopoulos, K.; Nikolakis, N.; Chryssolouris, G. Digital twin-driven supervised machine learning for the development of artificial intelligence applications in manufacturing. Int. J. Comput. Integr. Manuf. 2020, 33, 429–439. [Google Scholar] [CrossRef]

- Wei, X.; Wu, H.; Yang, Z.; Han, C.; Xu, B. Simulation of manufacturing scenarios’ ambidexterity green technological innovation driven by inter-firm social networks: Based on a multi-objective model. Systems 2023, 11, 39. [Google Scholar]

- Bühler, M.M.; Jelinek, T.; Nübel, K. Training and preparing tomorrow’s workforce for the fourth industrial revolution. Educ. Sci. 2022, 12, 782. [Google Scholar]

- Oladele, J.I.; Ndlovu, M.; Ayanwale, M.A. Computer Adaptive-Based Learning and Assessment for Enhancing STEM Education in Africa: A Fourth Industrial Revolution Possibility. In Mathematics Education in Africa: The Fourth Industrial Revolution; Springer International Publishing: Cham, Switzerland, 2022; pp. 131–144. [Google Scholar]

- Frederico, G.F. From supply chain 4.0 to supply chain 5.0: Findings from a systematic literature review and research directions. Logistics 2021, 5, 49. [Google Scholar] [CrossRef]

- Munirathinam, S. Industry 4.0: Industrial internet of things (IIOT). Adv. Comput. 2020, 117, 129–164. [Google Scholar]

- Jacso, P. As We May Search—Comparison of Major Features of the Web of Science, Scopus, and Google Scholar Citation-Based and Citation-Enhanced Databases. Curr. Sci. 2005, 89, 1537–1547. [Google Scholar]

- Akpan, I.J.; Akpan, A.A. Multiple criteria analysis of the popularity and growth of research and practice of visual analytics, and a forecast of the future trajectory. Int. Trans. Oper. Res. 2021, 28, 2275–2298. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar]

- Aria, M.; Cuccurullo, C. Bibliometrix: An R-tool for comprehensive science mapping analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Cobo, M.J.; López-Herrera, A.G.; Herrera-Viedma, E.; Herrera, F. Science mapping software tools: Review, analysis, and cooperative study among tools. J. Am. Soc. Inf. Sci. Technol. 2011, 62, 1382–1402. [Google Scholar] [CrossRef]

- Rossiter, D.G. Introduction to the R Project for Statistical Computing for use at ITC. Int. Inst. Geo-Inf. Sci. Earth Obs. (ITC) Enschede (NL) 2012, 3, 3–6. [Google Scholar]

- Datta, P.M. The Road to 4IR (4th Industrial Revolution). In Global Technology Management 4.0; Palgrave Macmillan: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Jayaram, S.; Connacher, H.I.; Lyons, K.W. Virtual assembly using virtual reality techniques. Comput.-Aided Des. 1997, 29, 575–584. [Google Scholar] [CrossRef]

- Paul, R.; Anand, S.; Gerner, F. Effect of thermal deformation on part errors in metal powder based additive manufacturing processes. J. Manuf. Sci. Eng. 2014, 136, 031009. [Google Scholar] [CrossRef]

- Burdea, G.C. Invited review: The synergy between virtual reality and robotics. IEEE Trans. Robot. Autom. 1999, 15, 400–410. [Google Scholar] [CrossRef]

- Cho, H.; Jung, M.; Kim, M. Enabling technologies of agile manufacturing and its related activities in Korea. Comput. Ind. Eng. 1996, 30, 323–334. [Google Scholar] [CrossRef]

- Kadir, A.A.; Xu, X.; Hämmerle, E. Virtual machine tools and virtual machining—A technological review. Robot. Comput.-Integr. Manuf. 2011, 27, 494–508. [Google Scholar] [CrossRef]

- Rogers, G.G.; Bottaci, L. Modular production systems: A new manufacturing paradigm. J. Intell. Manuf. 1997, 8, 147–156. [Google Scholar] [CrossRef]

- Karageorgos, A.; Mehandjiev, N.; Weichhart, G.; Hämmerle, A. Agent-based optimisation of logistics and production planning. Eng. Appl. Artif. Intell. 2003, 16, 335–348. [Google Scholar] [CrossRef]

- Lämkull, D.; Hanson, L.; Örtengren, R. A comparative study of digital human modelling simulation results and their outcomes in reality: A case study within manual assembly of automobiles. Int. J. Ind. Ergon. 2009, 39, 428–441. [Google Scholar] [CrossRef]

- Mak, K.L.; Wang, X.X. Production scheduling and cell formation for virtual cellular manufacturing systems. Int. J. Adv. Manuf. Technol. 2002, 20, 144–152. [Google Scholar] [CrossRef]

- Kannan, V.R. A simulation analysis of the impact of family configuration on virtual cellular manufacturing. Prod. Plan. Control 1997, 8, 14–24. [Google Scholar] [CrossRef]

- da Silva, G.C.; Kaminski, P.C. Application of digital factory concepts to optimise and integrate inventories in automotive pre-assembly areas. Int. J. Comput. Integr. Manuf. 2015, 28, 607–615. [Google Scholar] [CrossRef]

- Li, Z.F.; Xu, J. Virtual manufacturing technology and application over tooling machines. Adv. Mater. Res. 2012, 588, 1748–1750. [Google Scholar] [CrossRef]

- Akpan, I.J.; Brooks, R.J. Users’ perceptions of the relative costs and benefits of 2D and 3D visual displays in discrete-event simulation. Simulation 2012, 88, 464–480. [Google Scholar] [CrossRef]

- Qin, S.F.; Harrison, R.; West, A.A.; Wright, D.K. Development of a novel 3D simulation modelling system for distributed manufacturing. Comput. Ind. 2004, 54, 69–81. [Google Scholar] [CrossRef]

- Shen, Z.; Shah, J.J.; Davidson, J.K. A complete variation algorithm for slot and tab features for 3D simulation-based tolerance analysis. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Long Beach, CA, USA, 24–28 September 2005; Volume 4739, pp. 587–597. [Google Scholar]

- Tu, Y. Production planning and control in a virtual one-of-a-kind production company. Comput. Ind. 1997, 34, 271–283. [Google Scholar] [CrossRef]

- Novak-Marcincin, J.; Novakova-Marcincinova, L. Application of augmented reality technologies in virtual manufacturing. Acad. J. Manuf. Eng. 2013, 11, 48–51. [Google Scholar]

- Nyanga, L.; Van der Merwe, A.F.; Matope, S.; Dewa, M.T. A web-based manufacturability agent framework for an E-manufacturing system. Procedia CIRP 2015, 28, 167–172. [Google Scholar] [CrossRef][Green Version]

- Wen, X.L. Research on the destructive Leadership in Virtual Enterprises. Adv. Mater. Res. 2013, 712, 3199–3202. [Google Scholar] [CrossRef]

- Wang, H. Research on the resource sharing among hierarchically distributed virtual enterprises based on grid system. Open Cybern. Syst. J. 2014, 8, 385–392. [Google Scholar] [CrossRef]

- Yang, J.; Kim, E.; Hur, M.; Cho, S.; Han, M.; Seo, I. Knowledge extraction and visualization of digital design process. Expert Syst. Appl. 2018, 92, 206–215. [Google Scholar] [CrossRef]

- Lambiase, F.; Lambiase, A. An integrated approach to the analysis of automotive assembly activities using digital manufacturing tools. Int. J. Internet Manuf. Serv. 2008, 1, 160–175. [Google Scholar] [CrossRef]

- Akpan, I.J.; Effiom, L.; Akpanobong, A.C. Towards developing a knowledge base for small business survival techniques during COVID-19 and sustainable growth strategies for the post-pandemic era. J. Small Bus. Entrep. 2023, 1–23. [Google Scholar] [CrossRef]

- Anthony Jnr, B. A developed distributed ledger technology architectural layer framework for decentralized governance implementation in virtual enterprise. Inf. Syst. e-Bus. Manag. 2023, 21, 437–470. [Google Scholar] [CrossRef]

- Popescu, G.H.; Valaskova, K.; Majerova, J. Real-Time Sensor Networks, Advanced Robotics, and Product Decision-Making Information Systems in Data-driven Sustainable Smart Manufacturing. Econ. Manag. Financ. Mark. 2020, 15, 29–38. [Google Scholar] [CrossRef]

- Fosch-Villaronga, E.; Mahler, T. Cybersecurity, safety and robots: Strengthening the link between cybersecurity and safety in the context of care robots. Comput. Law Secur. Rev. 2021, 41, 105528. [Google Scholar] [CrossRef]

- Nica, E.; Janoskova, K.; Kovacova, M. Smart Connected Sensors, Industrial Big Data, and Real-Time Process Monitoring in Cyber-Physical System-based Manufacturing. J. Self-Gov. Manag. Econ. 2020, 8, 29–38. [Google Scholar] [CrossRef]

- Jogunola, O.; Morley, C.; Akpan, I.J.; Tsado, Y.; Adebisi, B.; Yao, L. Energy consumption in commercial buildings in a post-covid-19 world. IEEE Eng. Manag. Rev. 2022, 50, 54–64. [Google Scholar] [CrossRef]

- Bi, Z. Revisiting system paradigms from the viewpoint of manufacturing sustainability. Sustainability 2011, 3, 1323–1340. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).