Abstract

Even in the epoch of the 4th Industrial Revolution, technologies are introducing human–machine/technology interactions that must be appropriately managed to prevent or reduce avoidable human errors. In recent years, power plants have started examining ways to manage human errors attributable to maintenance, thereby improving performance, safety, and well-being. Maintenance management requires the integration of human factors engineering (HFE) principles with maintenance practices to handle the issue of human errors. When adopting human factors engineering interventions to enhance maintenance, power plants must demonstrate the capacity for change to ensure effective management of change and realize the intervention’s benefits. The main focus in power plants is usually on the technical side of change, with less emphasis on human factors. This study aimed to develop and trial a model for determining the capacity for change to aid HFE adoption in electric power systems maintenance. A quantitative and cross-sectional survey was conducted with maintenance personnel working in South African power plants. The results showed that management commitment, knowledge, and employee involvement are associated with the capacity for change in the maintenance of power plants. This study extends previous studies on the capacity for change when adopting unconventional interventions in maintenance such as HFE principles.

1. Introduction

The purpose of Human Factors Engineering (HFE) is to probe the links connecting human and technical systems with the view of improving productivity (effectiveness and efficiency), quality, safety, and job satisfaction, thereby minimizing human errors [1]. Since HFE became a concept of scientific exploration, the development of models that amalgamate human factors principles with maintenance practices has increased. The use of HFE offered benefits such as enhanced quality, improved system performance, reduced destruction to plants, and decreased errors, costs, and outages [2].

In power plants, there is less attention paid to HFE in maintenance [3,4], despite the development and application of HFE initiatives in maintenance leading to various benefits [5]. A number of equipment failure examinations in power systems focus on the technical root and finding methods to address them, whereas there are inadequate studies addressing the sources of breakdowns emanating from human errors [3]. This is concerning since human errors are part of the factors that have a negative effect on the electricity networks’ reliability [3,6], and they have imposed heavy costs on industry [7]. The problem is that, there is inadequate number of applied methods intended for the reliability of power systems that incorporate human factors (HF), particularly power networks for industrial and commercial use [6]. “The next step in the evolution of maintenance management is a maintenance performance measurement that includes human factors” [7].

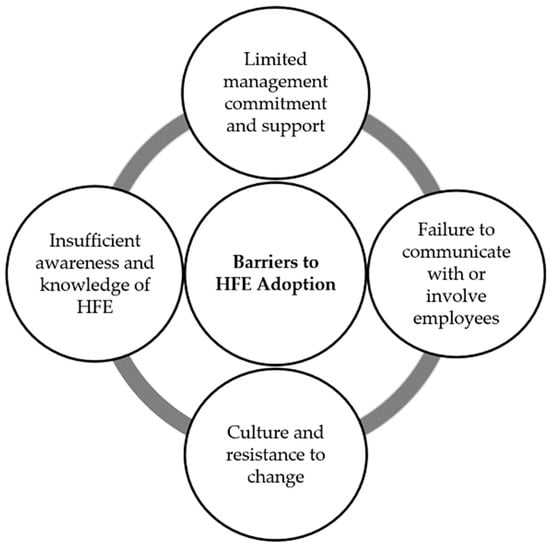

Now, the introduction of new technology and other maintenance interventions including HFE causes changes that affect the maintenance process and the entire plant [8]. HFE adoption can be hindered by barriers such as the ones shown in Figure 1.

Figure 1.

Barriers to HFE adoption.

Among the barriers to HFE adoption, culture and resistance to change are nearly related to the overall objective of the paper since the proposed model is aimed at evaluating the current culture to determine if it supports or impedes change.

Organizations must demonstrate the capacity for change to successfully introduce changes into a system [9].

To achieve this aim, this study developed the following objectives:

- To identify and analyze the factors that determine the capacity for change prior to the adoption of HFE;

- To develop a model for assessing the capacity for change in the maintenance of power plants;

- To trial and confirm the factors associated with the capacity for change through a survey conducted with participants from South African power plants.

This study has three contributions. First, it created and proposed a model for determining the capacity for change in the maintenance of power plants, especially the human aspect of change. It instigated a debate and discussion about human factors in the maintenance and change research domain. Lastly, it provides the maintenance practitioners with a tool for assessing the capacity for change in maintenance prior to the adoption of HFE interventions.

2. Literature Review

2.1. Adoption of HFE in Power Plant Maintenance

In this study, the adoption of HFE in maintenance is viewed as using, integrating, or applying HFE principles in maintenance practices to enhance performance and well-being and reduce errors. For example, in a power plant setting, a human error reduction plan was developed after identifying, quantifying, and grading the consequences of human errors and prioritizing root causes [3,4]. The adoption of this HFE plan showed a positive change in factors associated with human reliability in power plant maintenance [3]. In another study, the outputs of an HFE simplified approach adopted in a nuclear power plant enabled the enhancement of the strategy for the technical system, improvement of safety value, and monitoring of change [10]. Ensuring the usefulness and reliability of HFE initiatives and methods adopted to enhance human–system relationships requires the enhancement of knowledge and enlightenment on modern power systems and their interrelations with human factors [4]. A proposition was made to monitor the expertise (skills level), and commitment alongside system performance [7]. Adopting a systematic approach, which takes poor training, education, culture, and quality management, helps avoid operational errors in power enterprises [11]. The use of historical information and current practices in the operation of power systems can aid the establishment and adoption of an intervention for recording and computing the impact of power systems’ operational traits integrated with human factor needs to decrease gravitating errors [12]. Most of these HFE initiatives focused on analyzing, quantifying, and predicting human error and human behavior concerning the maintenance and operation of power plants. They lack focus on managing human–machine relationships and addressing change associated with using HFE techniques.

2.2. Overview of the Capacity for Change

The term change capacity or capacity for change refers to the level to which elements of an organization and change process promote or impede change [13]. It serves as the basis for effective management of change. Change management is needed to create a linkage connecting interventions and results, and is basically related to people and their shared duty of converting change into an organization’s successful outcomes [14]. It is an essential aspect of change—the people. It helps adopters of an intervention to integrate and align people, processes, activities, culture, and strategic objectives to support change [15]. Change management should ensure that there is effective implementation of change and that there are no misalignments in efforts. The state of affairs in an organization can contribute to or reduce its change capacity [13]. Leaders who motivate others properly communicate and provide emotional support, which has a great impact on change outcomes [16]. The capacity to implement specific changes includes factors such as leadership commitment and support, intervention-specific skills and knowledge, and relationships and networks [17]. The capacity for change involves the ability to communicate change, effective management of change and stakeholders, sufficient involvement of those affected by change, seeking feedback, alignment, and coordination, and fair management practices [16]. It enables organizations to change effectively and efficiently [9].

2.3. Change Management in HFE Adoption

In human factors engineering, change management forms part of the systemic performance-shaping factors [18]. One study revealed that HFE principles were welcomed but the initiation of changes was viewed as a separate issue [19]. Examining the adequacy of change management is a crucial aspect when adopting an intervention, since through this process one can determine whether power plants can properly or cannot properly manage change. If they cannot adequately manage change in their current maintenance practices, it would be highly difficult to support change that will be introduced by interventions such as HFE. The study that focused on maintenance human factors in the maintenance of transmission systems revealed that the expertise and motivation of employees, supervision, workload, and feedback were the crucial factors of HFE performance [7]. The commitment of top management and the influence of management over organizational culture were classified as key to the application of HFE [20]. Managers should better communicate with relevant stakeholders when introducing HFE. Proper communication mediums and sufficient keeping of records are classified as great necessities for the climate of collaboration among groups during the change or implementation phase [21,22]. There was a common inability to change specifically in instances where practitioners thought there would be additional duties [19]. Another critical aspect required for the successful use of HFE is special expertise and knowledge [19]. Therefore, power plants intending to change and incorporate HFE need proper management of knowledge, competencies, communication, employee involvement, and management commitment.

2.4. Change Models

The longstanding model is Kurt Lewin’s “unfreeze, change, and re-freeze” model, which focuses on how knowledge, employee involvement, and leadership styles affect change implementation and organizational change process [23]. Kurt Lewin’s Model has been criticized due to time, simplistic representation, and purpose; however, after careful analysis of the model and criticisms, it showed that the model does not provide a simplistic view but a simplistic representation, and it does not lack a psychological characteristic but it provides a clear comprehension of human temperament and behavior [23]. Employee involvement in a change model aims to maximize employees’ inputs during the decision-making process since the organization’s decisions affect their performance and well-being [24]. The other constituent of the change model is the knowledge required to facilitate change. This knowledge can be acquired through training and knowledge sharing from external and internal sources [23]. The capacity for change is demonstrated by middle managers when they transform the top management’s direction/goal into action [9]. This change model has general steps but must be adopted cautiously for specific situations. There are various change models, such as Luecke’s Seven Steps, Kanter’s Ten Commandments, Kotter’s Eight-stage Process [25], and the ADKAR change model [26]. The factors of Kanter’s Model that are relevant to this study are the need for change, support of a strong leader role, sponsorship, creating enabling structures, and communicating and involving people honestly [27].

Furthermore, factors from Kotter’s Model are the development of partnerships, communication, and supporting new approaches. The key factors extracted from Luecke’s Model are commitment, leadership, and monitoring and adjusting/improving strategies. Lastly, the ones based on the ADKAR model are awareness, knowledge, and ability [26]. These models are processual and not descriptive [25]; hence, only factors associated with the descriptive approach and in line with the developed HFE theory were shortlisted.

3. Conceptual Model and Hypotheses

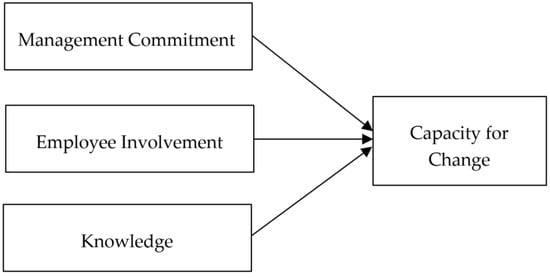

The review and analysis of the literature unearthed the aspects of a change process that can promote or impede change in an organization. The factors that are associated with the capacity for change when adopting HFE in maintenance were also analyzed. The current literature revealed that, even though there are a number of change models, each is unique and cannot be applied in all situations. Thus, change models were identified and discussed, and the factors that are relevant to this study were synthesized to form a specific conceptual model for determining the capacity for change, as shown in Figure 2.

Figure 2.

Conceptual model for determining the capacity for change.

The following subsections describe the constructs and propose the hypotheses of this study.

3.1. Management Commitment

Management commitment is about the willingness to give support and direction during the transition stage and provide necessary resources. Management commitment plays a major role in the incorporation of HFE into a system [20,22]. Mentioning that HFE is part of the company’s goal, providing sufficient resources, and setting clear duties and responsibilities promotes the successful transition to a system that incorporates HFE principles [20]. Senior management should also be committed to providing necessary training to enable the achievement of HFE outcomes [28]. The visibility of top management in displaying their commitment to maintenance policies and procedures is key to change management in maintenance, health, and safety [8]. There is a small chance for a successful culture change in maintenance when there is a lack of support and strategies administered by senior management [7]. Organizational commitment is positively correlated with the capacity for change [29]. Hence, this study proposed the following hypothesis:

H1.

Management commitment is positively associated with the capacity for change.

3.2. Employee Involvement

Employee involvement maximizes the inputs of members when making decisions that have an effect on performance and well-being [24]. To successfully adopt an intervention, it is important to involve workers at early stages, since engaged workers tend to support efforts aimed at realizing the outcomes of an intervention. HFE implementation and development are dependent on the promotion of awareness, involvement, participation, and adequate communication in all hierarchies of the organization [20]. Lack of involvement of maintenance workers and poor communication inhibits the company’s continuous development [8]. Employee involvement is positively correlated with the capacity for change [29]. Thus, the following hypothesis was proposed:

H2.

Employee involvement is positively associated with the capacity for change.

3.3. Knowledge

HFE adoption requires a holistic approach that integrates HFE expertise and knowledge with technical and practical knowledge [24]. For example, understanding and knowledge of their interactions with human factors ensures that adopted HFE initiatives are useful and reliable [4]. Providing adequate training, support needed for new activities, and adequate performance feedback assist workers in building their confidence and coping with the anxiety associated with changes [8]. On the other hand, inadequate awareness, insufficient knowledge, and lack of comprehension of HFE by management that is responsible for decisions have a negative impact on the application of HFE [30,31]. Thus, training should be provided to workers to enhance their technical and soft skills, supervisors to improve management skills, and top managers to advance their leadership skills that would support proper change management.

Training, knowledge sharing, and skills development provide workers with essential technical and business knowledge and competencies to properly navigate the changes [15]. HFE principles were accepted, but making changes was challenging due to knowledge limited to a few individuals [19]. Thus, the study suggests the following hypothesis:

H3.

Knowledge is positively associated with the capacity for change.

4. Methodology

This study adopted a deductive and quantitative approach, purposive sampling, and cross-sectional time horizon. The purposive study was adopted on the basis that there are no limitations in terms of the sample size as long as sufficient data to make informed decisions is obtained [32]. The study analyzed and interpreted the results of descriptive statistics, exploratory factor analysis, hypotheses testing through regression analysis, and confirmatory factor analysis using structural equation modeling.

4.1. Data Collection

4.1.1. Sample and Data Collection

The data was collected from the technical participants (plant managers, managers, engineers, technicians, planners, and others) working in various power plants around South Africa. About 137 participants working in various power plants were approached to solicit perspectives on the current practices within power plants with regard to the capacity for change or ability to adopt change. The participants were reached through emails and LinkedIn messaging. These participants were selected on the criteria that they are either involved on a daily or case-by-case basis in the maintenance of power plants so as to provide reasonable information on power plant practices. Those who did not fit the criteria were eliminated to ensure sound results.

4.1.2. Demographic Traits

The target population was people working as power plant and senior managers, section managers, engineers, supervisors, technicians, advisors, planners, and specialists. These participants were involved in different sections of the power plant, namely various power plants, the entire power plant, turbine, generator, transformers, boiler and auxiliaries, electrical/control and instrumentation, civil and support, and generation/distribution/systems. Their power experience was classified into years ˂ 5, 6 ≤ years ≤ 10, and years > 10. They were also asked to provide their understanding of HFE knowledge.

4.2. Instrument Development and Testing

The questionnaire was adapted from the thesis in which the constructs and items were created using the information from the previous studies [33]. The five-point Likert scale with cutoff verges of 1 ‘strongly disagree’ and 5 ‘strongly agree’ was adopted to measure the constructs comprised of multiple items. Four constructs, namely management commitment, employee involvement, knowledge, and capacity for change were measured in this study. They were selected on the basis that they were found to be better explaining the human side of change when using HFE [15,20,22]. Furthermore, these factors were strongly represented in change models, specifically the capacity or ability to change, and they could provide a descriptive approach, as opposed to some factors of change models ADKAR, Kotter, and Kenter, processual approach [24,25]. Table 1 below presents the constructs, and items of the measuring instrument as well as the sources used to formulate them.

Table 1.

Measurement constructs and items [33].

The constructs and items or questions were carefully crafted by the researchers based on the information from the sources referenced in Table 1. The questions that address new interventions or initiatives were asked using “would” on the basis that major interventions are not carried out on a regular basis. Thus, perceptions may be influenced by the historical experience more than the current practices [13]. It was completed for clarity, rather than theoretical purposes. The pre-test of the questionnaire was conducted using ten participants of the target population. They were asked to make comments on the clarity of instructions and questions, and time to answer questions. Generally, the respondents had no concerns; thus, there we no substantial changes made to the questions.

4.3. Data Analysis Techniques

The Statistical Package for the Social Sciences (SPSS) version 26 and AMOS-26 helped with the statistical evaluation of data. The SPSS was beneficial to descriptive statistics, exploratory factor analysis, and testing statistical assumptions, whereas AMOS was used for confirmatory factors analysis and structural equation modeling. The SPSS was used for the evaluation of the internal consistency and reliability through Cronbach’s Alpha (α), and instrument validity through the varimax-rotated matrix of the Exploratory Factor Analysis. The data was also investigated for issues by examining the key statistical assumptions such as multicollinearity, outliers, normality, homoscedasticity, and linearity. Thereafter, factor loadings were transferred to AMOS to do structural equation modeling (SEM). The SEM followed the maximum probability perspective to test the validity and establish the significant paths of the hypothesized model. Each item of the measuring instrument was assessed for composite reliability (CR), average variance extracted (AVE), validity, and model fit. Thereafter, standardized regression was performed to test the association or significant paths in the hypothesized model.

5. Results and Discussion

5.1. Descriptive Statistics of Sample

About 137 participants were approached for participation, but 70 returned fully completed and usable questionnaires. Therefore, a 51% response rate was achieved, which is slightly above the common response rates of 40% (average) and 50% (good) when emails are used for data collection [33]. Since the value of the Kaiser–Meyer–Olkin (KMO) was 0.879, higher than the proposed minimum of 0.5 and correlation coefficient ρ (Sig.) < 0.05 for Bartlett’s Test, the sample size was deemed sufficient to proceed with the exploratory factors analysis [34]. The participants were selected on the criteria that they are either involved on a daily or case-by-case basis in the maintenance of power plants to provide reasonable information on power plant practices.

5.2. Descriptive Statistics of Demographic Traits

The descriptive statistics reflecting the demographic attributes of the participants are presented in Table 2. Power plant managers, senior managers, section managers, and engineers, which is a group that is responsible for scope changes and initiation of interventions with key perceptions about power plants counted for a major proportion (61.43%) of respondents. A larger component (54%) of participants had been working in electric power systems for more than 10 years, followed by 29%, which constituted those with experience from 6 to 10 years. Thus, the participants could provide sound feedback about organizational practices that have an effect on power plant maintenance.

Table 2.

Demographic characteristics of respondents.

5.3. Testing of Reliability and Validity

Table 3 shows the results of the reliability and exploratory factor analysis results. The values of Cronbach’s Alpha (α) ranged from 0.820 and 0.930, exceeding the minimum margin of 0.7 [35]. The factors with eigenvalues of 1 and above were maintained in the model because they account for a significant proportion of variation [36]. These factors had a cumulative variance of 75.491%, higher than the threshold of 50% [35]. The values of factor loadings obtained through a varimax-rotated matrix ranged from 0.632 to 0.912 greater than the lower limit of 0.6 [37]. The factors were already assigned with names based on the literature and the items were all loaded on the proposed factors. Thus, the measuring instrument was deemed consistent and reliable. As a standard norm, the factor loadings of the dependent variable (CC) presented in Table 3 were performed separately from its drivers.

Table 3.

Outcomes of reliability and validity testing.

The Kaiser–Meyer–Olkin (KMO) values were 0.864 and the correlation coefficient (ρ) was < 0.001 and was higher than the value of 0.6, which is suggested as an acceptable minimum.

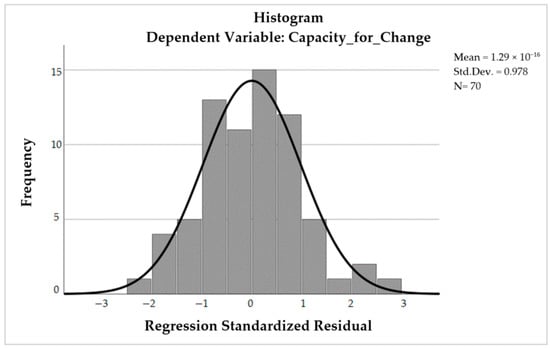

5.4. Results of Statistical Assumptions Testing

The key statistical assumptions were met. For example, the periphery of the scores was in the center of the histogram in the normal distribution curve and symmetric about the mean, as shown in Figure 3.

Figure 3.

Normal distribution curve.

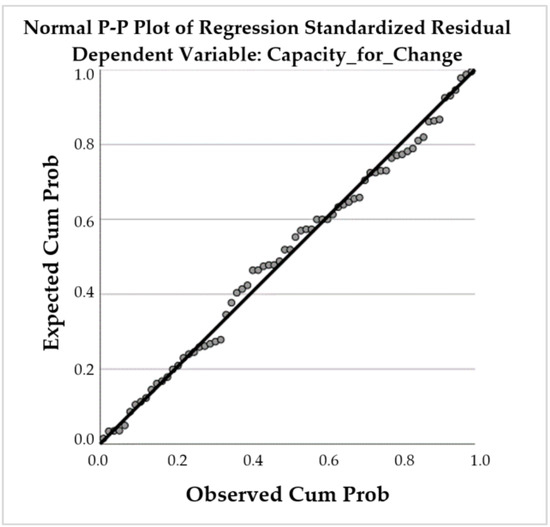

The scatters of residuals on the normal P-P plot were reasonable on a straight line; therefore, mean scores were normally distributed as presented in Figure 4.

Figure 4.

Normal P-P plot of regression standardized residual.

Furthermore, multicollinearity assumption was also achieved since tolerances were above 0.1 and variance inflation factors (VIF) were below 10. Lastly, homoscedasticity and linearity assumptions were also met since the scatterplot exhibited in Figure 5 demonstrated a fairly random cloud of dots. It was fairly acceptable because residuals were below 3.3 and above −3.3 [38].

Figure 5.

Scatterplot of regression standardized residual and predicted value.

5.5. Structural Equation Modeling

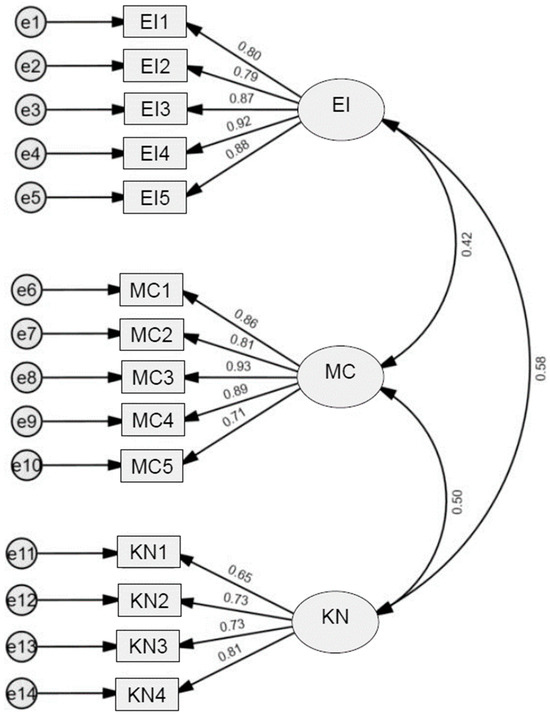

Figure 6 presents the results of confirmatory factor analysis (CFA) based on structural equation modeling (SEM).

Figure 6.

Factor loadings of confirmatory factor analysis.

All factor loadings were higher than the minimum margin of 0.5, hence, demonstrating the model’s validity and reliability [35]. The results of the model fit measurements, namely Chi-square (CMin), degrees of freedom (Df), Comparative Fit Index (CFI), Root Mean Square Error of Approximation (RMSEA), and Close Fit (PClose) are shown in Table 4 below.

Table 4.

Model fit measures.

The value of CMin/Df was 1.846, the CFI was 0.913, meaning that the model fit was good, the RMSEA was 0.111 and the PClose was 0.01, indicating a poor model fit [39]. The results of the measurement of the model fit are presented in Table 4. The framework’s validity and reliability were further tested by determining the composite reliability (CR) as well as the average variance extracted (AVE). Table 5 below presents the results of the model validity analysis. The model validity and reliability were substantiated because the CR values ranged between 0.821 and 0.930 and AVE values from 0.535 to 0.728, above the minimum margins of 0.7 and 0.5, respectively [35].

Table 5.

Validity analysis.

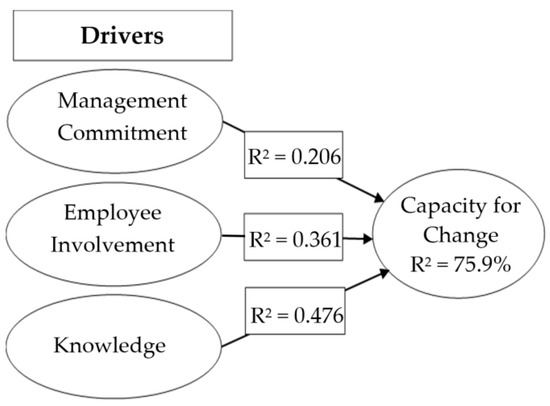

Figure 7 presents the structural equation model of the drivers of change when adopting HFE.

Figure 7.

Results of factors influencing the capacity for change in HFE adoption.

The R-squared (R2) coefficient of 0.759 for variance was obtained meaning that 75.9% of the variance in the capacity for change was explained by the combination of all these significant independent variables.

The results of the hypothesized model generated through the structural equation modeling are presented in Table 6 below.

Table 6.

Regression results.

The standardized regression results show that management commitment (R2 = 0. 206, ρ ˂ 0.05), employee involvement (R2 = 0. 361, ρ ˂ 0.001), and knowledge (R2 = 0.476, ρ ˂ 0.001) are positive and significant; therefore, hypothesis H1, H2 and H3 were supported. This means that management commitment was viewed by participants as a driver of change during the adoption of intervention in power plants, specifically HFE. Participants also believed that employee involvement could influence the capacity for change to support the adoption of HFE. Lastly, respondents felt that knowledge is also key to the capacity for change during the incorporation of HFE in South African electric power systems maintenance.

These findings when it comes to the influence of management commitment to organizational change during HFE adoption are in agreement with the suggestions of the existing studies [18], findings related to employee involvement during transition are also supported by the existing literature [20,21]. Also, the results of knowledge in association with the capacity for change when adopting HFE are consistent with the propositions found in previous scholarly writings and reports [7,18]. Therefore, to appropriately incorporate HFE in maintenance, power plants must assess the management commitment, employee involvement, and knowledge for the capacity to support the change that HFE would bring into the organization’s processes, systems, and practices. They must capitalize on their strengths while addressing barriers and improving their limitations. The tool proposed in this study should be able to assist them in measuring the capacity for change in their power plants, prior to and during the adoption of HFE [19].

6. Conclusions

This study examined the factors that influence the capacity for change at the amalgamation of HFE principles, specifically in the maintenance of electric power systems. Through the literature, it was discovered that power plants normally focus their efforts on the technical side of change and give less attention to the human side of an intervention, leading to failure to realize the benefits of the initiative. Then, this study aimed to create and trial a model for determining the capacity for change prior to the adoption of HFE in the maintenance of power plants. The model was found to be fit for explaining the capacity for change in power plant maintenance. This study revealed that the key drivers of capacity for change specifically the human side of change are management commitment, employee involvement, and knowledge. These multiple-item variables were all positively and significantly associated with the capacity for change. It should be noted that the model was testing the association rather than the cause–effect relationship.

This study contributed knowledge to the academic research domain on the capacity for change, especially in light of the adoption of interventions, specifically HFE in maintenance. It made contributions through new findings obtained from the empirical test of the model. It provided insights into the factors that influence the capacity for change, especially within power plant maintenance. Thus, it has created an agenda for further discussions and debate. It also provided important insights and a tool for practical application, which is a general guide to understanding power plant practices that can enable or impede change or successful adoption of interventions. It also adds to the efforts to influence power plants to consider the use of HFE models to enhance maintenance. Even though this study made contributions to identifying and shortlisting key factors influencing the capacity for change in power plants, it had some limitations such as the context and time horizon. So, the focus of the future studies could be:

- To add other geographical contexts and diverse industrial settings to enhance the generalizability of results;

- To use the longitudinal time horizon to establish the causation more clearly, since this study was cross-sectional in nature to infer the hypotheses or determine the association rather than proving the hypotheses.

It would also be interesting to see the determination of the actual capacity for change when adopting HFE and the subsequent impact on the productivity of maintenance in power plants.

Author Contributions

M.N.: literature review, methodology, data collection, analysis, and writing and editing; K.G.: guidance, editing, feedback, and project administration; P.M.M.: guidance, editing, review, and feedback. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to [confidentiality and ethics]. The participants only consented to the publication of aggregated data, and confidential care of data.

Acknowledgments

The authors express their gratitude to the Executive Leadership Group of the University of Johannesburg for the support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ahmed, H. Human Systems Integration of Agricultural Machinery in Developing Economy Countries: Sudan as a Case Study. Ph.D. Thesis, Colorado State University, Fort Collins, CO, USA, 2022. [Google Scholar]

- Leva, M.C.; Naghdali, F.; Alunni, C.C. Human factors engineering in system design: A roadmap for improvement. Procedia CIRP 2015, 38, 94–99. [Google Scholar] [CrossRef][Green Version]

- Tavakoli, M.; Nafar, M. Estimating and ranking the impact of human error roots on power grid maintenance group based on a combination of mathematical expectation, Shannon entropy, and TOPSIS. Qual. Reliab. Eng. Int. 2021, 37, 3673–3692. [Google Scholar] [CrossRef]

- Torres, E.S.; Celeita, D.; Ramos, G. State of the art of human factors analysis applied to industrial and commercial power systems. In Proceedings of the 2018 2nd IEEE International Conference on Power Electronics, Intelligent Control and Energy Systems (ICPEICES), Delhi, India, 2–24 October 2018; pp. 33–38. [Google Scholar] [CrossRef]

- Shanmugam, A.; Robert, T.P. Ranking of aircraft maintenance organization based on human factor performance. Comput. Ind. Eng. 2015, 88, 410–416. [Google Scholar] [CrossRef]

- Martsri, A.; Yodpijit, N.; Jongprasithporn, M.; Junsupasen, S. Energy, Economic and Environmental (3E) Analysis for Sustainable Development: A Case Study of a 9.9 MW Biomass Power Plant in Thailand. Appl. Sci. Eng. Prog. 2021, 14, 378–386. [Google Scholar] [CrossRef]

- Peach, R.; Ellis, H.; Visser, J.K. A Maintenance Performance Measurement Framework that Includes Maintenance Human Factors: A Case Study from The Electricity Transmission Industry. S. Afr. J. Ind. Eng. 2016, 27, 177–189. [Google Scholar] [CrossRef]

- Health and Safety Executive. Improving Maintenance a Guide to Reducing Human Error; Health and Safety Executive Books: Soho, London, UK, 2000. [Google Scholar]

- Sukoco, B.M.; Adna, B.E.; Musthofa, Z.; Nasution, R.A.; Ratmawati, D. Middle Managers’ Cognitive Styles, Capacity for Change, and Organizational Performance. SAGE Open 2022, 12. [Google Scholar] [CrossRef]

- Bona, G.D.; Falcone, D.; Forcina, A.; Silvestri, L. Systematic human reliability analysis (SHRA): A new approach to evaluate human error probability (HEP) in a nuclear plant. Int. J. Math. Eng. Manag. Sci. 2021, 6, 345–362. [Google Scholar]

- Liu, J.; Guan, Y.; Qu, X.; Wang, J. Research on Human Factors Reliability of Electric Power Enterprises Based on HFCRA Model. SHS Web Conf. 2023, 169, 01001. [Google Scholar] [CrossRef]

- Wang, Z.; Rahnamay-Naeini, M.; Abreu, J.M.; Shuvro, R.A.; Das, P.; Mammoli, A.A.; Ghani, N.; Hayat, M.M. Impacts of operators’ behavior on reliability of power grids during cascading failures. IEEE Trans. Power Syst. 2018, 33, 6013–6024. [Google Scholar] [CrossRef]

- Mladenova, I. Relation between Organizational Capacity for Change and Readiness for Change. Adm. Sci. 2022, 12, 135. [Google Scholar] [CrossRef]

- Gravenhorst, K.M.B.; Werkman, R.A.; Boonstra, J.J. The change capacity of organisations: General assessment and five configurations. Appl. Psychol. 2003, 52, 83–105. [Google Scholar] [CrossRef]

- Hiatt, J.M.; Creasey, T. Change Management: The People Side of Change; An Introduction to Change Management from the Editors of the Change Management Learning Center; Prosci Learning Center Publications: Fort Collins, CO, USA, 2012; Available online: https://www.sahrd.com/storage/app/public/240/Change-Management.pdf (accessed on 25 August 2022).

- Hayes, J. The Theory and Practice of Change Management, 4th ed.; Palgrave Macmillan: London, UK, 2014. [Google Scholar]

- Capacity Building Center for States. Change and Implementation in Practice: Readiness Brief; Children’s Bureau, Administration for Children and Families, U.S. Department of Health and Human Services: Washington, DC, USA, 2018. [Google Scholar]

- National Offshore Petroleum Safety and Environmental Management Authority. Human Error Risk Reduction to ALARP; Nopsema: Perth, Australia, 2015. Available online: https://www.nopsema.gov.au/sites/default/files/documents/2021–03/A424182.pdf (accessed on 4 February 2021).

- Timmons, S.; Baxendale, B.; Buttery, A.; Miles, G.; Roe, B.; Browes, S. Implementing human factors in clinical practice. Emerg. Med. J. 2015, 32, 368–372. [Google Scholar] [CrossRef]

- McCafferty, D.B.; Baker, C.C.; McSweeney, K.P.; Holdsworth, R. Effective Integration of Human Factors into HSE Management Systems. In Proceedings of the 2nd International Workshop on Human Factors in Offshore Operations ’02, Huston, TX, USA, 8–10 April 2002; United States Department of Transportation--Publications & Papers 36. Available online: https://digitalcommons.unl.edu/usdot/36?utm_source=digitalcommons.unl.edu%2Fusdot%2F36&utm_medium=PDF&utm_campaign=PDFCoverPages (accessed on 13 July 2022).

- Nkosi, M.S. A Study into the Effect of Human Error on Substandard Maintenance Performance, and the Formulation of a Complete Solution Based on the Experience of Successful Maintenance Organisations. Master’s Thesis, University of Johannesburg, Johannesburg, South Africa, 2014. [Google Scholar]

- Pinder, A. Literature Review: Barriers to the Application of Ergonomics/Human Factors in Engineering Design; Health and Safety Executive: Bootle, UK, 2015. [Google Scholar]

- Burnes, B. The origins of Lewin’s three-step model of change. J. Appl. Behav. Sci. 2020, 56, 32–59. [Google Scholar] [CrossRef]

- Ahmed, H.; Ahmed, M. Human Systems Integration: A Review of Concepts, Applications, Challenges, and Benefits. J. Econ. Sustain. Dev. 2023, 14, 30–39. [Google Scholar] [CrossRef]

- Errida, A.; Lotfi, B. The determinants of organizational change management success: Literature review and case study. Int. J. Eng. Bus. Manag. 2021, 13, 18479790211016273. [Google Scholar] [CrossRef]

- Sistare, S.C. Overcoming Resistance through Organizational Change Models and Leadership Strategies; Charleston Southern University: North Charleston, SC, USA, 2022. [Google Scholar]

- Yang, N.H.; Bertassini, A.C.; Mendes, J.A.; Gerolamo, M.C. The ‘3CE2CE’Framework—Change Management Towards a Circular Economy: Opportunities for Agribusiness. Circ. Econ. Sustain. 2021, 1, 697–718. [Google Scholar] [CrossRef]

- Carthey, J. Implementing Human Factors in Healthcare. How to Guide—Taking Further Steps; Clinical Human Factors Group: Baltimore, MD, USA, 2013; Volume 2, pp. 1–59. [Google Scholar]

- Mangundjaya, W.L. The role of employee engagement on the commitment to change (During large-scale organizational change in Indonesia). Int. J. Multidiscip. Thought 2014, 4, 375–384. [Google Scholar]

- Ala-Laurinaho, A.; Launis, M. Humans in Machinery Investments—Collaborative Development of Company-Specific Design Practices and Tools. In Proceedings of the International Symposium on Design Process & Human Factors Integration, Nice, France, 1–3 March 2006; INRS: Quebec, Canada, 2006; p. 6. [Google Scholar]

- Goodman, J.; Dong, H.; Langdon, P.M.; Clarkson, P.J. Industry’s Response to Inclusive Design: A Survey of Current Awareness and Perceptions. In Contemporary Ergonomics 2006: Proceedings of the International Conference on Contemporary Ergonomics (CE2006), Cambridge, UK, 4–6 April 2006; Bust, P.D., Ed.; Taylor & Francis: London, UK, 2006; pp. 368–372. [Google Scholar]

- Vecchio, Y.; De Rosa, M.; Pauselli, G.; Masi, M.; Adinolfi, F. The leading role of perception: The FACOPA model to comprehend innovation adoption. Agric. Food Econ. 2022, 10, 5. [Google Scholar] [CrossRef]

- Nkosi, M.S. Determining the Readiness to Implement Human Factors Engineering in Maintenance: A Special Case of Power Plants. PhD. Thesis, University of Johannesburg, Johannesburg, South Africa, 2020. [Google Scholar]

- Saldivar, M.G. A Primer on Survey Response Rate; Florida State University, Learning Systems Institute: Tallahassee, FL, USA, 2012. [Google Scholar]

- Hair Jr, J.F.; Hult, G.T.M.; Ringle, C.M.; Sarstedt, M.; Danks, N.P.; Ray, S. Partial Least Squares Structural Equation Modeling (PLS-SEM) Using R: A Workbook; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Wiid, J.; Diggines, C. Marketing Research; Juta and Company Ltd.: Cape Town, South Africa, 2015. [Google Scholar]

- Kline, R.B. Principles and Practice of Structural Equation Modeling, 2nd ed.; Guilford: New York, NY, USA, 2005. [Google Scholar]

- Pallant, J. A Step by Step Guide to Data Analysis Using SPSS; McGraw-Hill Education: Berkshire, UK, 2010. [Google Scholar]

- Gaskin, J.; Lim, J. Model Fit Measures, Amos Plugin, 2022, Gaskination’s StatWiki. 2022. Available online: https://statwiki.gaskination.com/index.php?title=Main_Page (accessed on 4 February 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).