1. Introduction

As carbon dioxide emissions rise year by year, countries around the world have agreed to reduce greenhouse gases. Green development is the fundamental way to achieve advanced production, livable life and beautiful ecology, as well as the key to achieve carbon peak and carbon neutrality [

1]. At present, China is in a special period of “dual carbon” goals, the implementation of innovation-driven development strategy and “Made in China 2025” to drive economic development. The manufacturing industry is the main support of the real economy and the engine of the high-quality development of China’s real economy [

2]. However, at present, the gap between China’s regional economic development continues to expand; a manufacturing industry appearing “big but not strong” situation. Resource exhaustion, environmental deterioration and other problems are becoming increasingly serious. The adjustment of economic structure and transformation and upgrading of the manufacturing industry are imminent [

3]. The green development of the manufacturing industry has formed a consensus, which is also the need of its high-quality development [

4]. Under the background of carbon peak and carbon neutral, low-carbon and energy-saving are the general trends of manufacturing upgrading and transformation and also the inevitable result of the high-quality development of the manufacturing industry [

5]. How to achieve green and low-carbon development while reducing costs and increasing efficiency in the manufacturing industry has become the focus of enterprises’ survival and competition. “Green + intelligent” is an important link to enhance the competitiveness of digital green manufacturing enterprises [

6]. Digital technology empowerment is the key point to accelerate the greening and intellectualization of the manufacturing industry [

7].

At present, digital technology is widely permeated in production and life, and the digital economy is booming. Digital industrialization and industrial digitization are accelerating. The deep integration of the digital economy and real economy has become an important path to promote the green and high-quality development of the manufacturing production mode [

8]. On the one hand, the digital economy can effectively not only improve the production process and improve the efficiency of equipment operation, but also improve the accuracy of production process management. Production efficiency and energy saving and emission reduction are improved through intelligent collaborative management [

9]. On the other hand, the digital economy can effectively optimize the pattern of resource allocation. Digital infrastructure in the industrial Internet, big data, artificial intelligence and other fields can realize the integration and sharing of various resource elements in different industries and enterprises. Resource allocation efficiency helps to be further enhanced through digital technology [

10]. In addition, the core production factor of the digital economy is data. Data have the characteristics of high efficiency, cleanliness, low cost and replicability [

11]. Therefore, the traditional industrial structure and ecosystem can be optimized only when data elements are well utilized to accelerate the deep integration of the digital economy and real economy.

The continuous emergence of digital technology innovation has accelerated the digital transformation and upgrading of the traditional manufacturing industry and the quality improvement and upgrading of the modern manufacturing industry [

12]. Traditional manufacturing is gradually shifting to digital manufacturing. Data as a new production factor and other factors into the manufacturing industry chain. Data elements not only improve the industry integration efficiency of the whole industry chain, but also improve the efficiency of resource allocation among traditional elements such as labor, capital, technology and land [

13,

14]. At this point, traditional manufacturing gradually moves to an intelligent manufacturing transformation. Digital technology enables the whole process of traditional manufacturing and breaks down the spatial barrier between industries. Digital technology not only improves the cooperation efficiency between manufacturing and producer services, but also accelerates the rise of strategic emerging industries, such as the information industry and advanced equipment manufacturing [

15]. Some possible problems are predicted in advance by manufacturing enterprises through real-time aggregation analysis of massive data. The production process continues to be optimized, and the supply quality of manufacturing products is comprehensively improved [

16]. Digital technology intelligent scenarios are widely used in manufacturing. The application value of digital technology is mainly reflected in the reduction in manufacturing cost, the optimization of the production process and organizational form. With the wide application of digital technology, many new industries, new forms of business and new models have been created. Digital technology has brought many benefits to enterprises, including the maximum benefit with the smallest cost, and the economic benefit of enterprises has been significantly improved [

17]. Digital technology has brought many benefits to the government and society, including green manufacturing, green supply and green payment. Although reducing environmental pollution, digital technology can not only reduce resource consumption, but also increase social benefits [

18]. Manufacturing sustainability has been significantly enhanced through digital technology.

Over the past decade, digital technologies such as big data, cloud computing, artificial intelligence and the Internet of Things have flourished. The research on the application of digital technology in various fields has been warmly welcomed by the academic world and the industry. The problem of digital innovation has been widely concerning researchers. At present, the connotation, denotation and implementation framework of digital innovation are widely discussed in academic circles. Theoretical derivation and case analysis are the main research methods.

In terms of the connotation of digital innovation, scholars mainly expound its connotation from two perspectives: process and result. Some scholars believed that the process performance of enterprise innovation can be improved by digital resources, and other scholars believed that existing non-digital products and services are endowed with new attributes through digital resources [

19,

20,

21,

22]. With the integration of these two perspectives, the connotation of digital innovation should break through the shackles of process and result perspectives. How digital innovation is realized should be discussed comprehensively from a theoretical perspective [

23].

In terms of the epitaxial aspect of digital innovation, the characteristics of digital innovation mainly include convergence (fuzzy boundary and low importance) [

24] and self-growth (continuous improvement and change) [

25]. According to the realization mode, digital innovation can be divided into digital product innovation, digital process innovation, digital organization innovation and digital business model innovation [

26,

27,

28]. Digital product innovation is the combination of new products or services containing digital technologies, namely information, computing, communication and connectivity technologies, or supported by such digital technologies [

29]. Digital process innovation is the application of digital technology to improve or even reconstruct the original innovation process framework [

30]. Digital organizational innovation means that digital technology changes the form or governance structure of an organization [

31]. Digital business model innovation is the embedding of digital technology that changes the original business model [

32]. Digital infrastructure is the basic support for realizing digital innovation, as well as the digital technology, organizational structure and related service facilities that support the operation of an enterprise or industry [

33]. Formally, digital infrastructure refers to shared, unbounded, heterogeneous and open systems. Based on digital infrastructure, the multi-agent cooperative digital platform has gradually become the center of innovation activities of many enterprises due to its flexibility, openness and availability [

34]. Existing research on multi-agent cooperation digital platforms mainly include technology management perspective, industrial organization perspective and strategic management perspective [

35,

36]. Although these studies adopt different research perspectives, they are generally similar to those on digital infrastructure, including the construction, evolution and governance of multi-agent cooperative digital platforms.

As for the realization of digital innovation, the representative frameworks are those of Desouza et al. (2009) [

37] and Kohli & Melville (2019) [

38]. The framework shows that the realization of digital innovation needs to go through three stages: digital innovation initiation, digital innovation development and digital innovation application. The start-up process of digital innovation is the process by which enterprises identify digital innovation opportunities and prepare for digital innovation. Developing digital strategy, structuring digital resources, enhancing digital innovation capacity and constructing digital innovation-oriented culture is an important step for organizations to launch digital innovation [

38,

39,

40]. Digital innovation development is a process in which an enterprise develops an innovative idea generated at the start-up stage into a digital innovation that can be applied. Digital innovation development process is a dynamic interactive process that emphasizes design logic, open innovation, situational integration and continuous iteration [

41]. Digital innovation application is the application process of developing digital innovation, which involves a series of complex organizational changes [

38]. The application process of digital innovation requires organizations to continuously redefine value networks and carry out organizational structure changes [

42]. In addition, many scholars believed that the realization of digital innovation is mainly reflected in operational efficiency and organizational performance. On the one hand, the advantages of digital technology itself can greatly improve operational efficiency through the optimization of products, processes, organizations and business models. On the other hand, digital innovation can help enterprises improve organizational performance. Digital product innovation creates new value for customers and improves the dynamic capability of enterprises [

8,

18,

21]. Moreover, it also changes the original way of enterprise value acquisition and value creation.

In terms of green innovation, the research on green innovation in the manufacturing industry involves the relevant factors affecting green innovation and the evaluation of green innovation. In terms of relevant factors, Karakaya et al. (2014) believed that one of the important elements of the industrial green progress is to combine technological innovation with ecological protection, namely green innovation [

43]. Weber et al. (2014) argued that green innovation should aim at producing significant environmental benefits rather than reducing the environmental burden [

44]. Fernando et al. (2019) proposed that service innovation capability plays a mediating role in the relationship between sustainable organizational performance and environmental innovation [

45]. Xie et al. (2019) found that both green process innovation and green product innovation can improve the financial performance of enterprises [

46]. Fujii & Managi (2019) found that sustainable green patent publications increased due to increased efficiency, increased share of R&D spending and economic growth [

47]. In terms of relevant evaluation, Lin et al. (2018) believed that the overall efficiency of green innovation in the manufacturing industry is low, declining first, then rising and then declining [

48]. Lee & Choi (2019) believed that innovation effect leads the environmental productivity of South Korea’s manufacturing industry [

49]. Nie & Qi (2019) measured the two-stage green innovation efficiency of industrial enterprises under resource and environment constraints [

50]. Yin et al. (2020) studied the impact of environmental regulation and government R&D funding on green innovation [

51]. Yin et al. (2021) measured four dimensions of regional green innovation input capacity, green innovation output capacity, green innovation environment capacity and green diffusion input capacity [

52].

The high-quality manufacturing industry based on green innovation mainly has the characteristics of strong innovation ability, high resource allocation efficiency, high product quality, high economic benefits and good ecological and environmental benefits [

51,

52]. Scholars conducted in-depth research on this topic from the following five aspects. As for the connotation research of high-quality development of manufacturing industry, Yu (2020) believed that high-quality development of manufacturing industry refers to the realization of high-level sustainable development with low input of production factors, high efficiency of resource allocation, strong strength of quality improvement, excellent ecological environment quality and good economic and social benefits in the whole process of production, manufacturing and sales [

53]. As for the research on the evaluation system of the high-quality development of the manufacturing industry, Jiang et al. (2019) constructed an evaluation index system of the high-quality development of the manufacturing industry from six aspects: economic benefit, technological innovation, green development, quality brand, integration of industrialization and industrialization and high-end development [

54]. Research on the high-quality development of the manufacturing industry in different regions mainly includes macro, medium and micro perspective. Deng et al. (2020) believed that the Internet plays a significant role in promoting the development of the manufacturing industry, and different manufacturing industries have different degrees of influence [

55]. Pei et al. (2019) believed that brand’s synergistic technological progress can promote the high-quality development of China’s manufacturing industry [

56]. Ren (2019) proposed six strategies to promote the high-quality development of China’s manufacturing industry from a strategic perspective [

57]. Chen (2020) focused on the quality reform strategy and put forward a path to promote the manufacturing quality reform [

58]. In addition, Sturgeon (2021) analyzed the influence of the digital economy level on the optimization and upgrading of the manufacturing industrial structure [

59]. Liu et al. (2022) analyzed the mechanism and path of the high-quality development of the manufacturing industry in the digital economy [

60]. A large number of theoretical achievements on economic growth and the quality of economic growth provide enlightenment for the research on the high-quality development of the manufacturing industry.

In addition, some scholars have studied the impact of the Internet, Internet+, Internet of Things, big data and other information technologies on industrial innovation and development. For example, Munín-Doce et al., (2020) pointed out that intelligent products developed by “Internet+” have been widely applied in industrial production [

61]. Li & Zhang (2021) believed that big data can enable enterprises to achieve outstanding performance beyond their competitors [

62]. Sundarakani et al. (2021) analyzed the instrumental application of big data resources and technologies to promote the formation of the “big data” industrial chain from a three-dimensional perspective [

63]. Matarazzo et al. (2021) believed that using big data can help enterprises reshape the value creation process in their business models [

64]. Fang et al. (2022) believed that “Internet+” can promote high-quality industrial development through the transmission mechanism of green development [

65].

To sum up, existing studies focus on green innovation evaluation and the high-quality development of the manufacturing industry. There are very few pieces of research on the convergence of green innovation and digital innovation. There is a dearth of research on the effective integration of green and numbers. The related index systems and evaluation methods of digital green innovation in the manufacturing industry have been systematically explained. There is a lack of research on macro policies and micro countermeasures based on improving the development level of regional digital green innovation. Therefore, the development path of digital green innovation in the manufacturing industry will be analyzed in this study. The evaluation index system of digital green innovation level will be constructed. In theory, the research perspective and method of the digital green innovation evaluation will be established in this study. In practice, the policy guidance and practical guidance of digital technology to accelerate the green and intelligent manufacturing industry will also be put forward.

The rest of the structure of this study is as follows. The theoretical mechanism of digital green innovation in the manufacturing industry is analyzed, and its level evaluation system is established in

Section 2. In

Section 3, the evaluation model of the digital green innovation level is established. The empirical results and discussion are presented in

Section 4.

Section 5 summarizes the conclusion, enlightenment and future research direction.

5. Conclusions and Implication

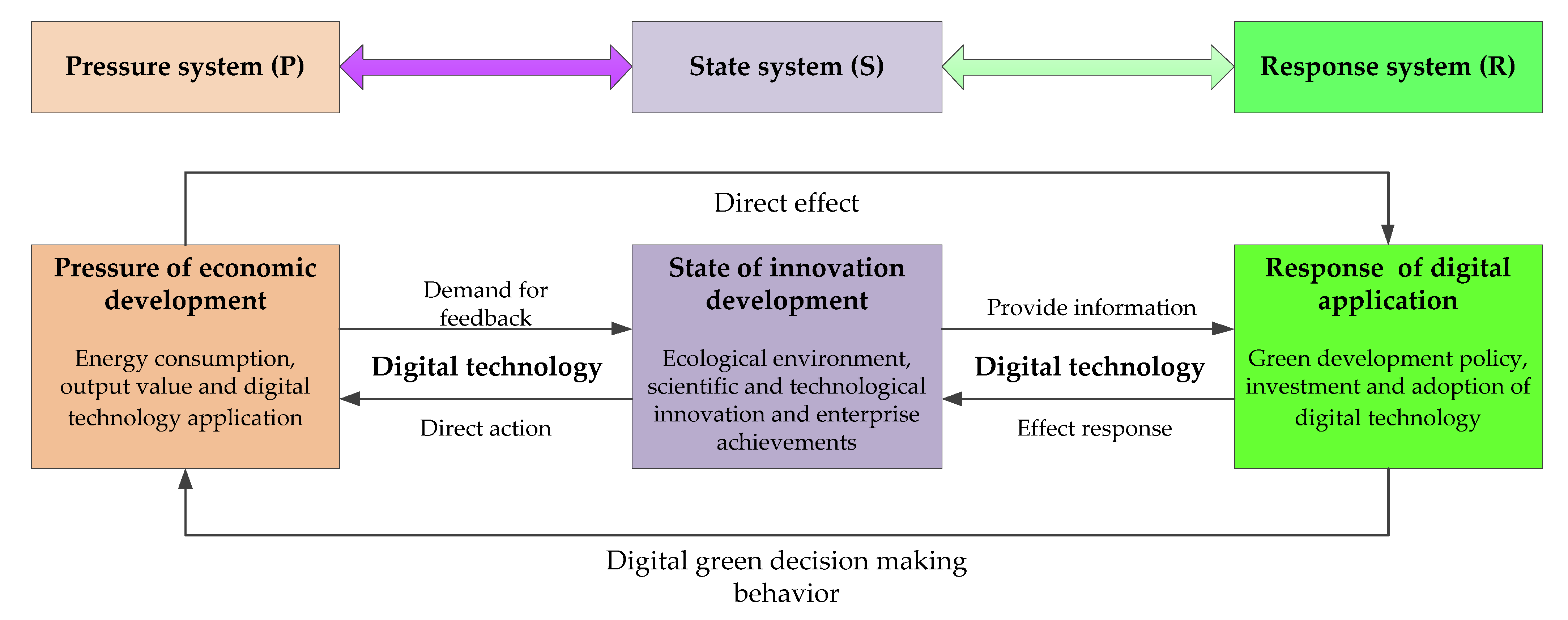

The development of intelligent and green manufacturing driven by digital innovation has become an important strategic support to promote high-quality economic development. The development capability and level of digital green innovation play an important role in promoting the high-quality development of the manufacturing industry. With the background of resource constraint tightening, ecological environment degradation and digital technology development, resource environment and digital technology are incorporated into manufacturing innovation systems to measure the quality of the digital green innovation in the manufacturing industry. In this study, the evaluation index system of the digital green innovation level in the manufacturing industry was constructed based on the PSR model framework. The 21 districts, cities and counties under the jurisdiction of Baoding city were selected as the research object to carry out quantitative evaluation and comprehensive comparative analysis. On this basis, specific policies and suggestions were put forward to comprehensively improve the development of the digital green innovation in Baoding’s manufacturing industry.

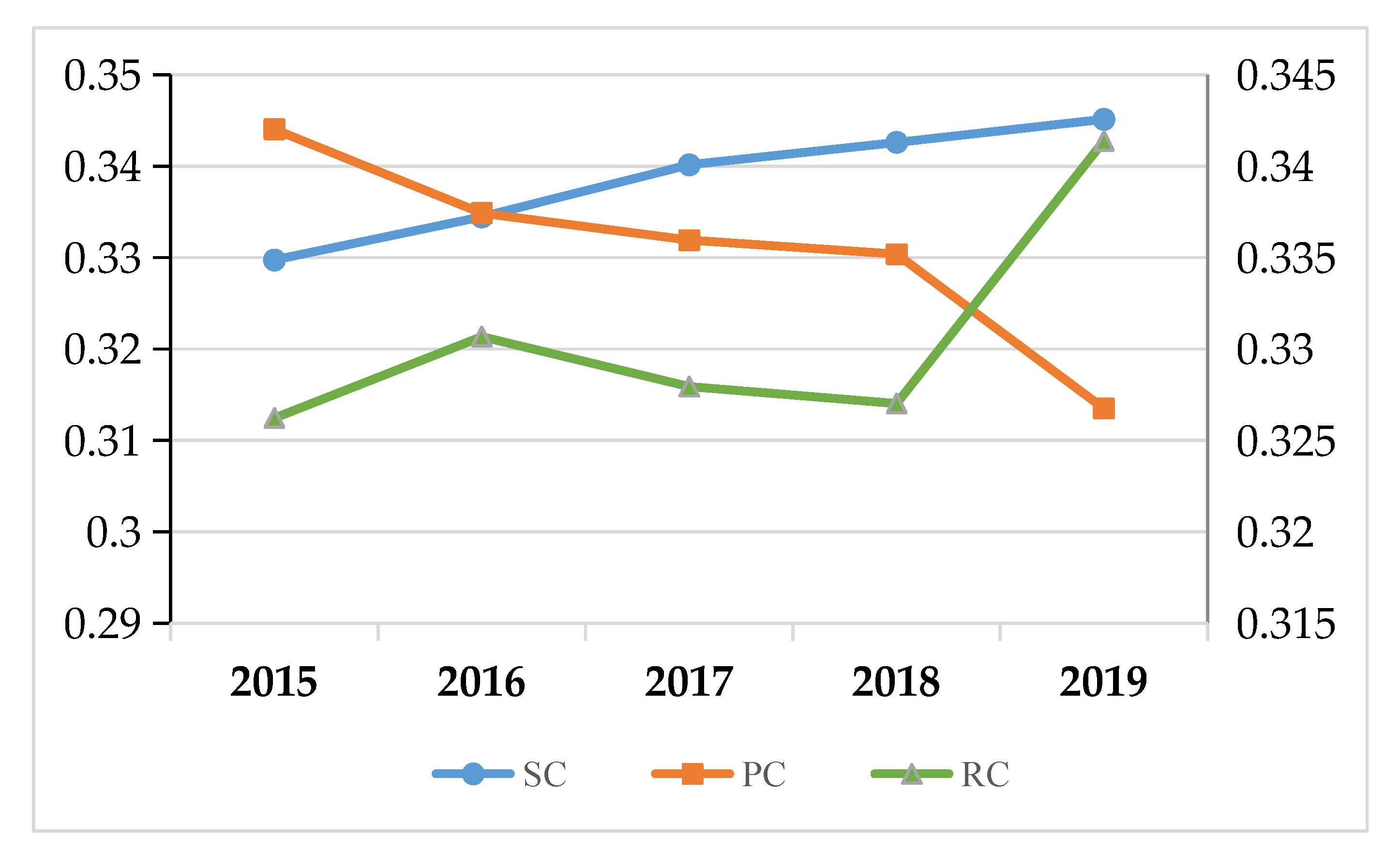

The results of this study are as follows. (i) The measurement system of the development level of the digital green innovation in the manufacturing industry includes pressure system (P), state system (S) and response system. This system can be widely applied to research on the development level of the digital green innovation in the manufacturing industry. (ii) From 2015 to 2019, the comprehensive index of the development level of the digital green innovation in the manufacturing industry generally showed a trend of fluctuating rise. Each region has an overall low and unbalanced phenomenon, but also there is a certain gap. However, the gap decreased from 0.1320 to 0.1187, showing a gradually narrowing trend. (iii) Compared with other regions, the composite index of the regions with better ecological environments in the east and more developed economies in the north is generally higher. State parameters are higher than pressure and response parameters in most areas. Compared with other regions, the composite index of the western and southern regions was lower. The parameters of pressure, state and response are basically coordinated. In the future, local governments should strengthen the indicators of the development status index of the digital green innovation in the manufacturing industry. (iv) The application degree of digital technology such as artificial intelligence, the emission intensity of waste water/exhaust gas of output value of one hundred million yuan, and the expenditure intensity of digital technology such as artificial intelligence adopted by enterprises are the key influencing factors of the digital green innovation in the manufacturing industry.

The academic contribution of this study are as follows. In this study, the measurement system of the digital green innovation level in the manufacturing industry based on the PSR model was proposed. The pressure system is based on economic and social development, supplemented by energy consumption, output value and digital technology application. The state system is represented by the state of innovation and development, supplemented by indicators such as ecological environment, scientific and technological innovation enterprises and achievements. The response system focuses on the application effect of innovation and development, supplemented by indicators of green development-related policies, investment and adoption of digital technologies. The whole process of the digital green innovation in the manufacturing industry needs to be revealed in a circular perspective corresponding to PSR. This cycle is a two-way interactive relationship among the dynamic mechanism, collaborative mechanism and safeguard mechanism of digital green innovation. The dynamic mechanism involves the application degree of digital technology, energy consumption structure and regional economic level. The collaborative mechanism should not only achieve high-level development at the technical level, but also take into account environmental regulation at the institutional level. Manufacturing enterprises must deal with the reasonable conversion between economic value, social value and ecological value in the safeguard mechanism.

The practical implications of this study are as follows. Advanced manufacturing should be vigorously developed to promote the transformation and upgrading of traditional industries. Innovation ecology should be optimized to build a digital green innovation system with enterprises as the main body and the market as the guidance and the deep integration of enterprises, universities and research institutes. Digital industrialization and industry digitization should be promoted by government support. The digitalization level of key manufacturing industries should be greatly enhanced to achieve comprehensive index improvement. This study verifies that the established evaluation index system and evaluation model of the digital green innovation development in the manufacturing industry are very scientific and reasonable and have practical application value.

Although this study achieves this goal, there is still room for improvement in the evaluation index system and evaluation methods. In terms of the evaluation index system, the digital transformation and globalization trend of the manufacturing industry have not been fully included in the evaluation index. Digital transformation not only emphasizes the application degree of digital technology, but also emphasizes the improvement of enterprise’s digital transformation performance. Therefore, performance related indicators brought by digital technology can be integrated into the evaluation index system in future research. At the same time, manufacturing globalization risk control should also be fully considered in the process of digital green innovation. In terms of evaluation methods, the evaluation method considering the order of pros and cons in this study is suitable for regional comparative evaluation. The evaluation of manufacturing digital green innovation based on time and space can be characterized by the kernel density function and spatial econometric model. In addition, artificial intelligence techniques such as data mining and fuzzy mathematics [

82] can also be integrated into evaluation methods.