Optimized Planning and Evaluation of Dental Implant Fatigue Testing: A Specific Software Application

Simple Summary

Abstract

1. Introduction

2. General Considerations: Load, Fatigue, S-N Curves

3. Previous and Current ISO Standard: Comparative Analysis

4. ProFatigue Software

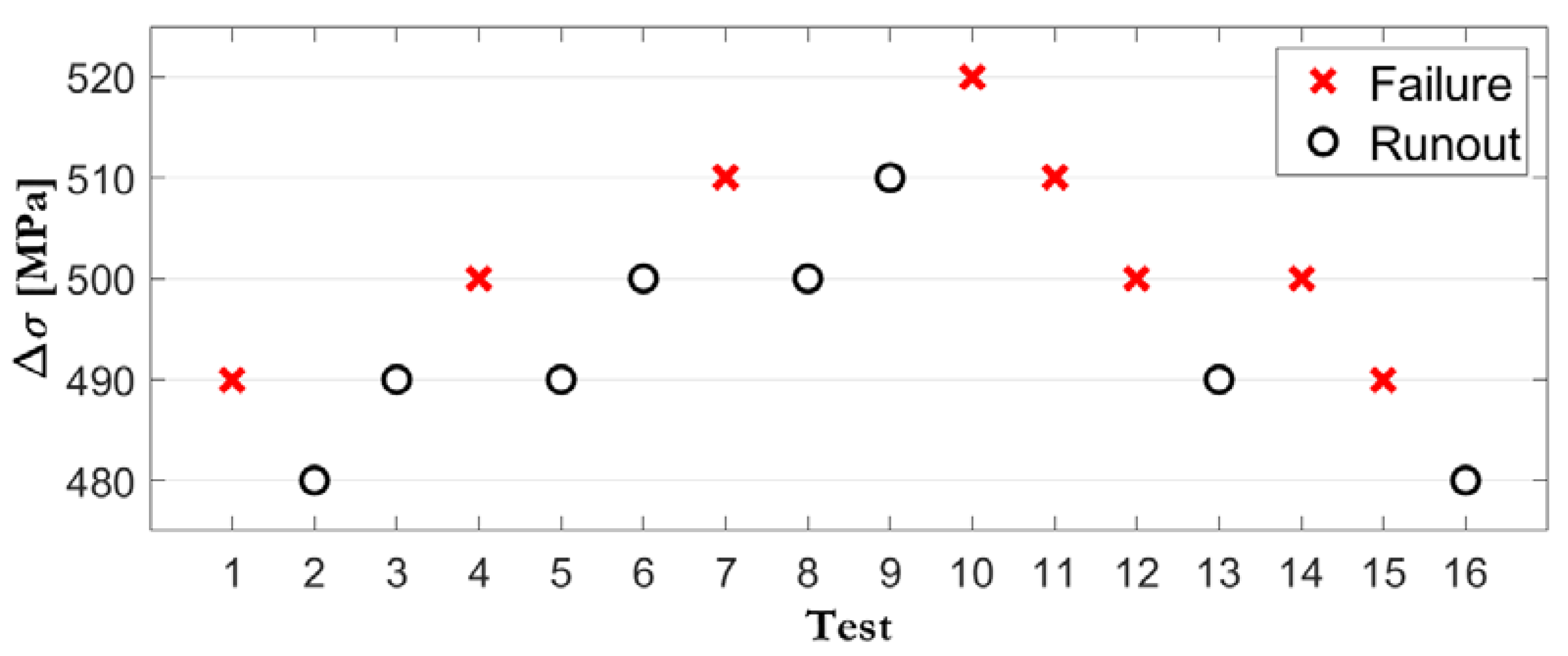

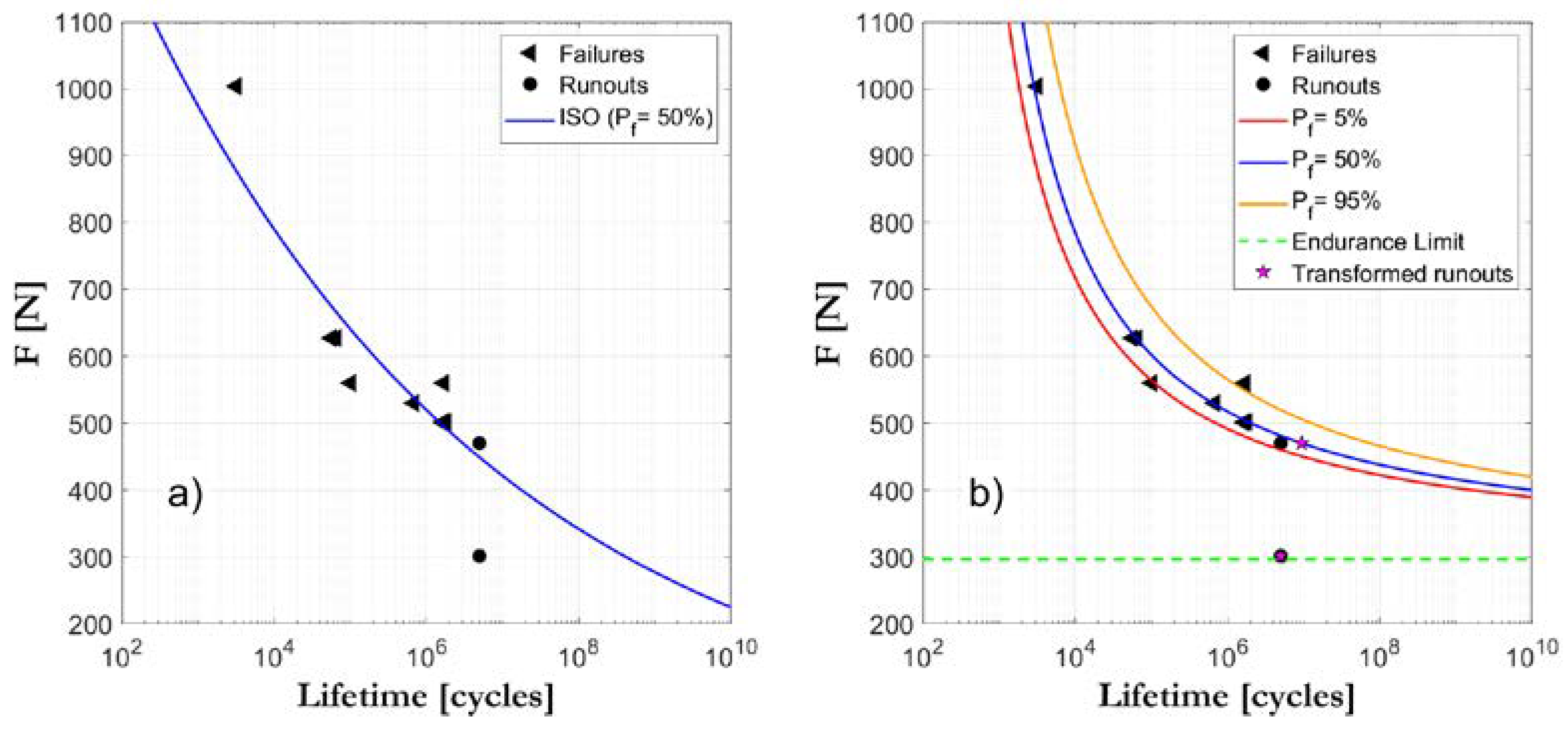

- The possibility of an optimized test planning campaign, which results in a reduction in the total number of tests required and its rationalization, by avoiding the undesirable outcome of run-outs, or at least reducing them to an acceptable number. Thus, the S-N field is determined by a number of tests not previously stated, and in any case, far fewer than those currently required by the ISO standard for the same level of confidence. Furthermore, given the normalization property that sustains the model, it is unnecessary to repeat the tests under the same load range, with any negative consequences for the completion of the statistical analysis (see Part 2). This contrasts with the alternative procedures to determine the S-N field presented by the current ISO standard, which require numerous tests for the same load range.

- The complete S-N field is reduced to a simple distribution function of the normalized variable, V, which is deduced as the combined expression of both stress range and number of cycles, through the expression V = log(N/N0) log(Δσ/Δσ0), where N0 is the number of limit cycles and Δσ0 is the endurance limit for a theoretically infinite fatigue limit. This normalization allows the optimized planning of the testing campaign, in addition to the combined evaluation of different levels of test results as belonging to a single homogeneous group. This increases the reliability of the deduced model, and ultimately, it allows for the detection of possible bias in the joint distribution, thanks to the non-randomness of the results obtained from the different tested load levels, which would point out an anomalous behavior, that may be worthy of further study.

- The possibility of a simple calculation of the number of cycles for a given particular stress range and probability, or conversely, of the stress range for a predetermined number of cycles and probability, is a direct consequence of the S-N field analytic expression. This paragraph is directly related to paragraph 1, regarding its application as a means of support for fatigue program planning.

5. Conclusions

- The current ISO standard suffers from a number of limitations due to the inadequate selection of the probabilistic model recommended in the planning of the experimental program and the insufficient evaluation of the results obtained. This implies higher costs because of the large number of specimens tested and the long test duration, which should be avoided as much as possible.

- ProFatigue’s advanced statistical model optimizes these factors, making it an innovative and valuable tool that could be adapted for use in fatigue programs within the field of dentistry implant research.

- Correct implementation of the ProFatigue software makes it possible to improve the test programming procedure by reducing the number of tests and the total duration of the experimental design, while simultaneously guaranteeing reliability in the material characterization. Its efficacy and efficiency are supported by its long-standing use when applied to a wide range of experimental fatigue programs for different materials.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pjetursson, B.E.; Asgeirsson, A.G.; Zwahlen, M.; Sailer, I. Improvements in implant dentistry over the last decade: Comparison of survival and complication rates in older and newer publications. Int. J. Oral Maxillofac. Implant. 2014, 29, 308–324. [Google Scholar] [CrossRef] [PubMed]

- Hu, M.L.; Lin, H.; Zhang, Y.D.; Han, J.M. Comparison of technical, biological, and esthetic parameters of ceramic and metal-ceramic implant-supported fixed dental prostheses: A systematic review and meta-analysis. J. Prosthet. Dent. 2020, 124, 26–35. [Google Scholar] [CrossRef] [PubMed]

- Gaddale, R.; Mishra, S.K.; Chowdhary, R. Complications of screw- and cement-retained implant-supported full-arch restorations: A systematic review and meta-analysis. Int. J. Oral Implantol. 2020, 13, 11–40. [Google Scholar]

- Frost, H.M. Bone ‘‘mass’’ and the ‘‘mechanostat’’: A proposal. Anat. Rec. 1987, 219, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Frost, H.M. A 2003 update of bone physiology and Wolff’s law for clinicians. Angle Orthod. 2004, 74, 3–15. [Google Scholar]

- Chang, Y.; Tambe, A.A.; Maeda, Y.; Wada, M.; Gonda, T. Finite element analysis of dental implants with validation: To what extent can we expect the model to predict biological phenomena? A literature review and proposal for classification of a validation process. Int. J. Implant. Dent. 2018, 4, 7. [Google Scholar] [CrossRef]

- Pesqueira, A.A.; Goiato, M.C.; Filho, H.G.; Monteiro, D.R.; Santos, D.M.D.; Haddad, M.F.; Pellizzer, E.P. Use of stress analysis methods to evaluate the biomechanics of oral rehabilitation with implants. J. Oral Implantol. 2014, 40, 217–228. [Google Scholar] [CrossRef]

- Ey-Chmielewska, H.; Chruściel-Nogalska, M.; Frączak, B. Photogrammetry and Its Potential Application in Medical Science on the Basis of Selected Literature. Adv. Clin. Exp. Med. 2015, 24, 737–741. [Google Scholar] [CrossRef]

- Bonfante, E.A.; Coelho, P.G. A Critical Perspective on Mechanical Testing of Implants and Prostheses. Adv. Dent. Res. 2016, 28, 18–27. [Google Scholar] [CrossRef]

- Kelly, J.R.; Cesar, P.F.; Scherrer, S.S.; Della Bona, A.; van Noort, R.; Tholey, M.; Vichi, A.; Lohbauer, U. ADM guidance-ceramics: Fatigue principles and testing. Dent. Mater. 2017, 33, 1192–1204. [Google Scholar] [CrossRef]

- Smith, B.G.N.; Wright, P.S.; Brown, D. The Clinical Handling of Dental Materials; Wright: Oxford, UK, 1994; pp. 1–13. ISBN 978-0723610038. [Google Scholar]

- Macchi, R.L. Materiales Dentales; Médica Panamericana: Buenos Aires, Argentina, 2007; pp. 391–397. ISBN 9789500615839. [Google Scholar]

- Anusavice, K.J.; Shen, C.; Rawls, H.R. Philipps’ Science of Dental Materials; Elsevier Saunders: St. Louis, MO, USA, 2013; pp. 48–68. ISBN 9781437724189. [Google Scholar]

- Llobell, A.; Nicholls, J.I.; Kois, J.C.; Daly, C.H. Fatigue life of porcelain repair systems. Int. J. Prosthodont. 1992, 5, 205–213. [Google Scholar]

- Wiskott, H.W.; Nicholls, J.I.; Belser, U.C. Fatigue resistance of soldered joints: A methodological study. Dent. Mater. 1994, 10, 215–220. [Google Scholar] [CrossRef]

- Balfour, A.; O’Brien, G.R. Comparative study of antirotational single tooth abutments. J. Prosthet. Dent. 1995, 73, 36–43. [Google Scholar] [CrossRef]

- Huang, H.M.; Tsai, C.M.; Chang, C.C.; Lin, C.T.; Lee, S.Y. Evaluation of loading conditions on fatigue-failed implants by fracture surface analysis. Int. J. Oral. Maxillofac. Implants. 2005, 20, 854–859. [Google Scholar] [PubMed]

- Gehrke, P.; Dhom, G.; Brunner, J.; Wolf, D.; Degidi, M.; Piattelli, A. Zirconium implant abutments: Fracture strength and influence of cyclic loading on retaining-screw loosening. Quintessence Int. 2006, 37, 19–26. [Google Scholar]

- Seetoh, Y.L.; Tan, K.B.; Chua, E.K.; Quek, H.C.; Nicholls, J.I. Load fatigue performance of conical implant-abutment connections. Int. J. Oral Maxillofac. Implant. 2011, 26, 797–806. [Google Scholar]

- Marchetti, E.; Ratta, S.; Mummolo, S.; Tecco, S.; Pecci, R.; Bedini, R.; Marzo, G. Mechanical Reliability Evaluation of an Oral Implant-Abutment System According to UNI EN ISO 14801 Fatigue Test Protocol. Implant. Dent. 2016, 25, 613–618. [Google Scholar] [CrossRef] [PubMed]

- ASM International. Fatigue and Fracture. In ASM Handbook; ASM International: Materials Park, OH, USA, 1996; Volume 19, ISBN 978-0-87170-385-9. [Google Scholar]

- Castillo, E.; Ramos, A.; Koller, R.; López-Aenlle, M.; Fernández-Canteli, A. A critical comparison of two models for assessment of fatigue data. Int. J. Fatigue 2008, 30, 45–57. [Google Scholar] [CrossRef]

- Dixon, W.J.; Mood, A.M. A Method for Obtaining and Analyzing Sensitivity Data. J. Am. Stat. Assoc. 1948, 43, 109–126. [Google Scholar] [CrossRef]

- Little, R.E.; Jebe, E.H. Statistical Design of Fatigue Experiments; Applied Science Publishers: London, UK, 1975; ISBN 978-0470541159. [Google Scholar]

- Bruce, R.D. An up-and-down procedure for acute toxicity testing. Fundam. Appl. Toxicol. 1985, 5, 151–157. [Google Scholar] [CrossRef]

- Choi, S.C. Interval estimation of the LD50 based on an up-and-down experiment. Biometrics 1990, 46, 485–492. [Google Scholar] [CrossRef] [PubMed]

- Dixon, W.J. Design and Analysis of Quantal Dose–Response Experiments (with Emphasis on Staircase Designs); Dixon Statistical Associates: Los Angeles, CA, USA, 1991. [Google Scholar]

- Lipnick, R.L.; Cotruvo, J.A.; Hill, R.N.; Bruce, R.D.; Stitzel, K.A.; Walker, A.P.; Chu, I.; Goddard, M.; Segal, L.; Springer, J.A.; et al. Comparison of the up-and-down, conventional LD50 and fixed dose acute toxicity procedures. Food Chem. Toxicol. 1995, 33, 223–231. [Google Scholar] [CrossRef]

- Vagerö, M.; Sundberg, R. The distribution of the maximum likelihood estimator in up-and-down experiments for quantal dose–response data. J. Biopharm. Stat. 1999, 9, 499–519. [Google Scholar] [CrossRef] [PubMed]

- Coray, R.; Zeltner, M.; Özcan, M. Fracture strength of implant abutments after fatigue testing: A systematic review and a meta-analysis. J. Mech. Behav. Biomed. Mater. 2016, 62, 333–346. [Google Scholar] [CrossRef]

- Rojo, R.; Prados-Privado, M.; Reinoso, A.; Prados-Frutos, J. Evaluation of Fatigue Behavior in Dental Implants from In Vitro Clinical Tests: A Systematic Review. Metals 2018, 8, 313. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 14801: Dentistry—Implants—Dynamic Fatigue Test for Endosseous Dental Implants; ISO: Geneve, Switzerland, 2016. [Google Scholar]

- Canullo, L.; Coelho, P.G.; Bonfante, E.A. Mechanical testing of thin-walled zirconia abutments. J. Appl. Oral Sci. 2013, 21, 20–24. [Google Scholar] [CrossRef]

- Marchetti, E.; Ratta, S.; Mummolo, S.; Tecco, S.; Pecci, R.; Bedini, R.; Marzo, G. Evaluation of an endosseous oral implant system according to UNI EN ISO 14801 Fatigue Test Protocol. Implant. Dent. 2014, 23, 665–671. [Google Scholar] [CrossRef]

- Park, J.M.; Baek, C.H.; Heo, S.J.; Kim, S.K.; Koak, J.Y.; Kim, S.K.; Belser, U.C. An in vitro evaluation of the loosening of different interchangeable abutments in internal-connection-type implants. Int. J. Oral Maxillofac. Implant. 2017, 32, 350–355. [Google Scholar] [CrossRef]

- Spies, B.C.; Nold, J.; Vach, K.; Kohal, R.J. Two-piece zirconia oral implants withstand masticatory loads: An investigation in the artificial mouth. J. Mech. Behav. Biomed. Mater. 2016, 53, 1–10. [Google Scholar] [CrossRef]

- Joda, T.; Voumard, B.; Zysset, P.K.; Brägger, U.; Ferrari, M. Ultimate force and stiffness of 2-piece zirconium dioxide implants with screw-retained monolithic lithium disilicate reconstructions. J. Prosthodont. Res. 2018, 62, 258–263. [Google Scholar] [CrossRef]

- Choi, J.W.; Choi, K.H.; Chae, H.J.; Chae, S.K.; Bae, E.B.; Lee, J.J.; Lee, S.H.; Jeong, C.M.; Huh, J.B. Load-Bearing Capacity and Retention of Newly Developed Micro-Locking Implant Prosthetic System: An In Vitro Pilot Study. Materials 2018, 11, 564. [Google Scholar] [CrossRef] [PubMed]

- University of Cantabria. ProFatigue, User Guide. Available online: https://meteo.unican.es/temp/castie/Profatigue.html (accessed on 1 September 2014).

- Fernández-Canteli, A.; Przybilla, C.; Nogal, M.; López-Aenlle, M.; Castillo, E. ProFatigue: A software program for probabilistic assessment of experimental fatigue data sets. Procedia Eng. 2014, 74, 236–241. [Google Scholar] [CrossRef]

- Castillo, E.; Fernández-Canteli, A. A Unified Statistical Methodology for Modeling Fatigue Damage, 1st ed.; Springer: Dordrecht, The Netherlands, 2009; ISBN 978-1-4020-9181-0. [Google Scholar]

- Pascual, F.J.; Przybilla, C.; Gracia-Villa, L.; Puértolas, J.A.; Fernández-Canteli, A. Probabilistic assessment of fatigue initiation data on highly crosslinked ultra high molecular weight polyethylenes. J. Mech. Behav. Biomed. Mater. 2012, 15, 190–198. [Google Scholar] [CrossRef]

- Castillo, E.; Muñiz-Calvente, M.; Fernández-Canteli, A.; Blasón, S. Fatigue assessment strategy using Bayesian techniques. Materials 2019, 12, 3239. [Google Scholar] [CrossRef] [PubMed]

- Blasón, S.; Fernández-Canteli, A.; Rodríguez, C.; Castillo, E. Retroextrapolation of crack growth curves using phenomenological models based on cumulative distribution functions of the generalized extreme value family. Int. J. Fatigue 2020, 141, 105897. [Google Scholar] [CrossRef]

- Kim, Y.J.; You, H.; Kim, S.J.; Yun, G.J. Effects of porosity on the fatigue life of polyamide 12 considering crack initiation and propagation. Adv. Compos. Mater. 2020, 29, 399–421. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-González, M.; Blasón-González, S.; García-García, I.; Lamela-Rey, M.J.; Fernández-Canteli, A.; Álvarez-Arenal, Á. Optimized Planning and Evaluation of Dental Implant Fatigue Testing: A Specific Software Application. Biology 2020, 9, 372. https://doi.org/10.3390/biology9110372

García-González M, Blasón-González S, García-García I, Lamela-Rey MJ, Fernández-Canteli A, Álvarez-Arenal Á. Optimized Planning and Evaluation of Dental Implant Fatigue Testing: A Specific Software Application. Biology. 2020; 9(11):372. https://doi.org/10.3390/biology9110372

Chicago/Turabian StyleGarcía-González, Marta, Sergio Blasón-González, Ismael García-García, María Jesús Lamela-Rey, Alfonso Fernández-Canteli, and Ángel Álvarez-Arenal. 2020. "Optimized Planning and Evaluation of Dental Implant Fatigue Testing: A Specific Software Application" Biology 9, no. 11: 372. https://doi.org/10.3390/biology9110372

APA StyleGarcía-González, M., Blasón-González, S., García-García, I., Lamela-Rey, M. J., Fernández-Canteli, A., & Álvarez-Arenal, Á. (2020). Optimized Planning and Evaluation of Dental Implant Fatigue Testing: A Specific Software Application. Biology, 9(11), 372. https://doi.org/10.3390/biology9110372