Photosensitive Yb-Doped Germanophosphosilicate Artificial Rayleigh Fibers as a Base of Random Lasers

Abstract

:1. Introduction

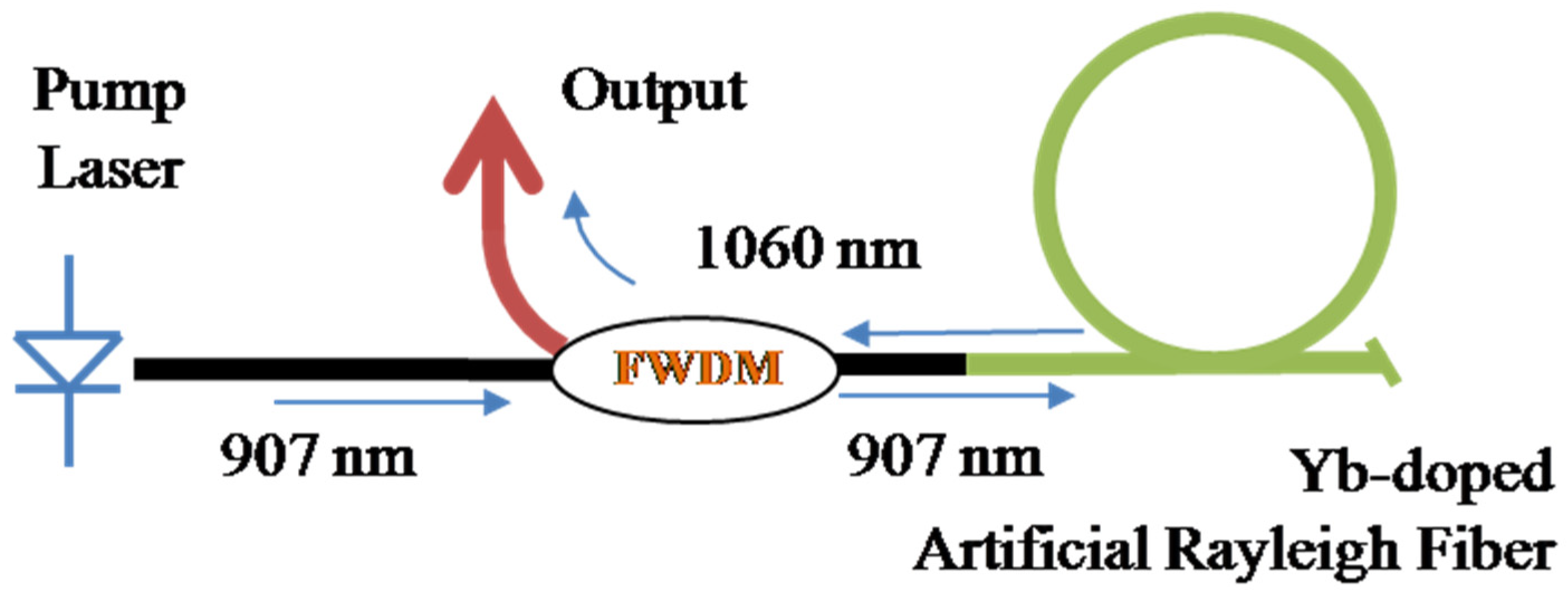

2. Materials and Methods

3. Results

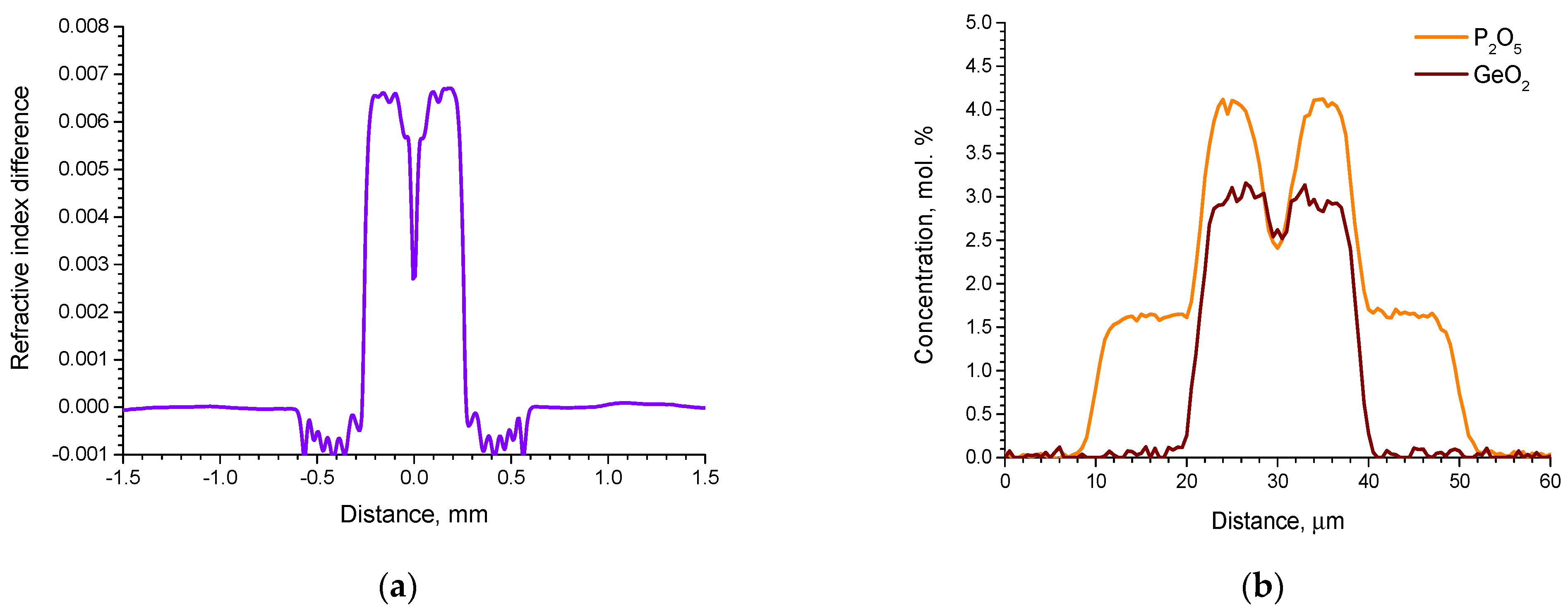

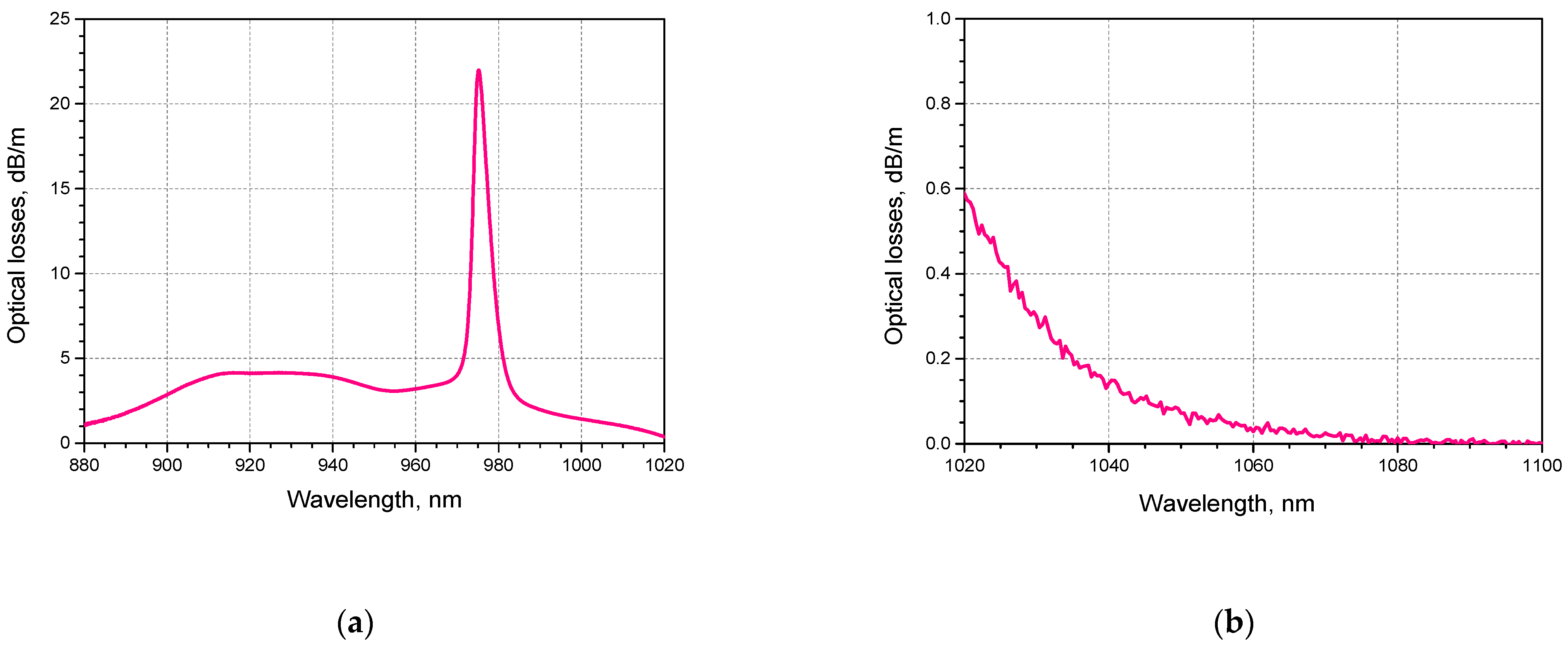

3.1. Optical and Material Properties of the Developed Active Fiber

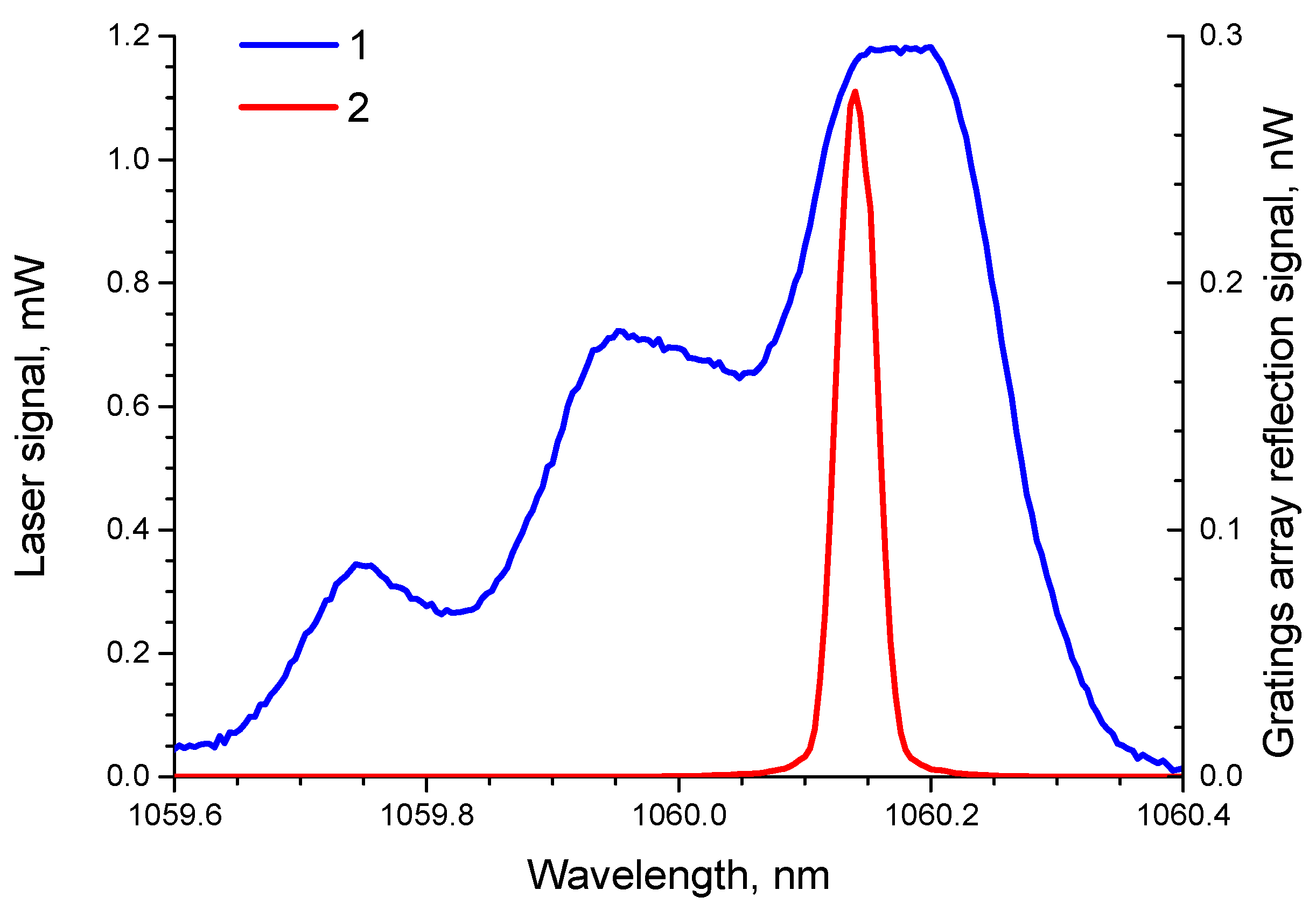

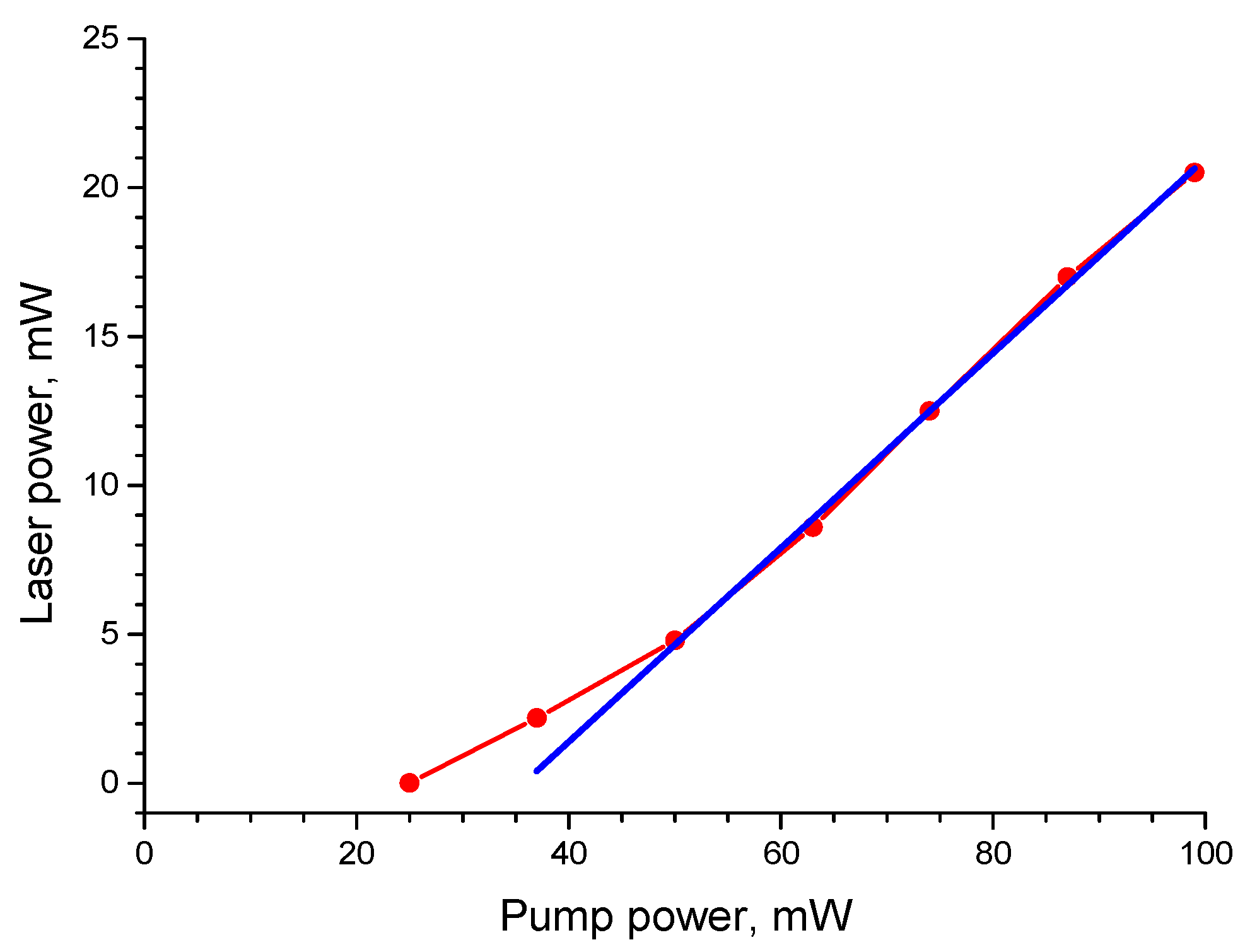

3.2. Random FBG Fiber Laser Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Barmenkov, Y.O.; Zalvidea, D.; Torres-Peiró, S.; Cruz, J.L.; Andrés, M.V. Effective length of short Fabry-Perot cavity formed by uniform fiber Bragg gratings. Opt. Express 2006, 14, 6394–6399. [Google Scholar] [CrossRef] [PubMed]

- Mo, S.; Xu, S.; Huang, X.; Zhang, W.; Feng, Z.; Chen, D.; Yang, T.; Yang, Z. A 1014 nm linearly polarized low noise narrow-linewidth single-frequency fiber laser. Opt. Express 2013, 21, 12419–12423. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Zhao, Q.; Feng, Z.; Peng, M.; Yang, Z.; Xu, S. 1120 nm kHz-linewidth single-polarization single-frequency Yb-doped phosphate fiber laser. Opt. Express 2016, 24, 29794–29799. [Google Scholar] [CrossRef] [PubMed]

- Fu, S.; Shi, W.; Feng, Y.; Zhang, L.; Yang, Z.; Xu, S.; Zhu, X.; Norwood, R.A.; Peyghambarian, N. Review of recent progress on single-frequency fiber lasers. J. Opt. Soc. Am. B 2017, 34, A49–A62. [Google Scholar] [CrossRef]

- Kir’yanov, A.V.; Barmenkov, Y.O. Self-Q-switched Ytterbium-doped all-fiber laser. Laser Phys. Lett. 2006, 3, 498–502. [Google Scholar] [CrossRef]

- Smirnov, A.M.; Bazakutsa, A.P.; Chamorovskiy, Y.K.; Nechepurenko, I.A.; Dorofeenko, A.V.; Butov, O.V. Thermal switching of lasing regimes in heavily doped Er3+ fiber lasers. ACS Photonics 2018, 5, 5038–5046. [Google Scholar] [CrossRef] [Green Version]

- Fotiadi, A.A. Random lasers: An incoherent fibre laser. Nat. Photonics 2010, 4, 204–205. [Google Scholar] [CrossRef]

- Popov, S.M.; Butov, O.V.; Chamorovskiy, Y.K.; Isaev, V.A.; Kolosovskiy, A.O.; Voloshin, V.V.; Vorob’ev, I.L.; Vyatkin, M.Y.; Mégret, P.; Odnoblyudov, M.; et al. Brillouin lasing in single-mode tapered optical fiber with inscribed fiber Bragg grating array. Results Phys. 2018, 9, 625–627. [Google Scholar] [CrossRef]

- Popov, S.M.; Butov, O.V.; Bazakutsa, A.P.; Vyatkin, M.Y.; Chamorovskii, Y.K.; Fotiadi, A.A. Random lasing in a short Er-doped artificial Rayleigh fiber. Results Phys. 2020, 16, 102868. [Google Scholar] [CrossRef]

- Lobach, I.A.; Drobyshev, R.V.; Fotiadi, A.A.; Podivilov, E.V.; Kablukov, S.I.; Babin, S.A. Open-cavity fiber laser with distributed feedback based on externally or self-induced dynamic gratings. Opt. Lett. 2017, 42, 4207–4210. [Google Scholar] [CrossRef]

- Lipatov, D.S.; Guryanov, A.N.; Yashkov, M.V.; Bubnov, M.M.; Likhachev, M.E. Fabrication of Yb2O3-Al2O3-P2O5-SiO2 opticalfibers with a perfect step-index profile by the MCVD process. Inorg. Mater. 2018, 54, 276–282. [Google Scholar] [CrossRef]

- Khudyakov, M.M.; Lobanov, A.S.; Lipatov, D.S.; Abramov, A.N.; Vechkanov, N.N.; Guryanov, A.N.; Melkumov, M.M.; Bobkov, K.K.; Aleshkina, S.S.; Kochergina, T.A.; et al. Single-mode large-mode-area Er–Yb fibers with core based on phosphorosilicate glass highly doped with fluorine. Laser Phys. Lett. 2019, 16, 025105. [Google Scholar] [CrossRef]

- Lipatov, D.S.; Lobanov, A.S.; Guryanov, A.N.; Umnikov, A.A.; Abramov, A.N.; Khudyakov, M.M.; Likhachev, M.E.; Morozov, O.G. Fabrication and characterization of Er/Yb co-doped fluorophosphosilicate glass core optical fibers. Fibers 2021, 9, 15. [Google Scholar] [CrossRef]

- Zaitsev, I.A.; Butov, O.V.; Voloshin, V.V.; Vorob’ev, I.L.; Vyatkin, M.Y.; Kolosovskii, A.O.; Popov, S.M.; Chamorovskii, Y.K. Optical Fiber with Distributed Bragg-Type Reflector. J. Commun. Technol. Electron. 2016, 61, 639–645. [Google Scholar] [CrossRef]

- Popov, S.M.; Butov, O.V.; Kolosovskii, A.O.; Voloshin, V.V.; Vorob’ev, I.L.; Isaev, V.A.; Vyatkin, M.Y.; Fotiadi, A.A.; Chamorovsky, Y.K. Optical fibres and fibre tapers with an array of Bragg gratings. Quantum Electron. 2019, 49, 1127–1131. [Google Scholar] [CrossRef]

- Singh, N.; Jain, S.C.; Aggarwal, A.K.; Bajpai, R.P. Fibre Bragg grating using phase mask technology. J. Sci. Ind. Res. 2005, 64, 108–115. [Google Scholar]

- Soller, B.J.; Gifford, D.K.; Wolfe, M.S.; Froggatt, M.E. High resolution optical frequency domain reflectometry for characterization of components and assemblies. Opt. Express 2005, 13, 666–674. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Butov, O.V.; Rybaltovsky, A.A.; Bazakutsa, A.P.; Golant, K.M.; Vyatkin, M.Y.; Popov, S.M.; Chamorovsky, Y.K. 1030 nm Yb3+ distributed feedback short cavity silica-based fiber laser. J. Opt. Soc. Am. B 2017, 34, A43–A47. [Google Scholar] [CrossRef]

- Bubnov, M.M.; Dianov, E.M.; Egorova, O.N.; Semjonov, S.L.; Guryanov, A.N.; Khopin, V.F.; DeLiso, E.M. Fabrication and investigation of single-mode highly phosphorus-doped fibers for Raman lasers. SPIE Proc. 2000, 4083, 12–22. [Google Scholar]

- Smirnov, A.M.; Butov, O.V. All-fiber heavily ytterbium-doped, passively mode-locked laser with the 456 MHz repetition rate. Opt. Lett. 2019, 44, 5065–5068. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rybaltovsky, A.; Popov, S.; Lipatov, D.; Umnikov, A.; Abramov, A.; Morozov, O.; Ryakhovskiy, D.; Voloshin, V.; Kolosovskii, A.; Vorob’ev, I.; et al. Photosensitive Yb-Doped Germanophosphosilicate Artificial Rayleigh Fibers as a Base of Random Lasers. Fibers 2021, 9, 53. https://doi.org/10.3390/fib9090053

Rybaltovsky A, Popov S, Lipatov D, Umnikov A, Abramov A, Morozov O, Ryakhovskiy D, Voloshin V, Kolosovskii A, Vorob’ev I, et al. Photosensitive Yb-Doped Germanophosphosilicate Artificial Rayleigh Fibers as a Base of Random Lasers. Fibers. 2021; 9(9):53. https://doi.org/10.3390/fib9090053

Chicago/Turabian StyleRybaltovsky, Andrey, Sergei Popov, Denis Lipatov, Andrey Umnikov, Alexey Abramov, Oleg Morozov, Dmitry Ryakhovskiy, Viktor Voloshin, Alexander Kolosovskii, Igor Vorob’ev, and et al. 2021. "Photosensitive Yb-Doped Germanophosphosilicate Artificial Rayleigh Fibers as a Base of Random Lasers" Fibers 9, no. 9: 53. https://doi.org/10.3390/fib9090053

APA StyleRybaltovsky, A., Popov, S., Lipatov, D., Umnikov, A., Abramov, A., Morozov, O., Ryakhovskiy, D., Voloshin, V., Kolosovskii, A., Vorob’ev, I., Butov, O., & Chamorovskiy, Y. (2021). Photosensitive Yb-Doped Germanophosphosilicate Artificial Rayleigh Fibers as a Base of Random Lasers. Fibers, 9(9), 53. https://doi.org/10.3390/fib9090053