Impact Resistance of Functionally Layered Two-Stage Fibrous Concrete

Abstract

1. Introduction

1.1. Literature Review

1.2. Impact Test Methods and Modifications

- It enables the development of fractures in any direction, making the first visible crack more challenging to identify.

- Although concrete is a composite mixture, the concentrated force may hit a soft mortar area or a solid grain of coarse aggregate. As a result, findings may not correctly represent the impact strength of material.

2. Significance of Research

3. Experimental Program

3.1. Raw Materials

- Portland Pozzolana Cement, obtained from Dalmia cement, was used to make FLTSFC. It met the requirements of (Bureau of Indian Standard (BIS), Manak Bhawan, Old Delhi, 1991) [38].

- Conforming to the specifications of IS 383 (2016) [39], natural river sand was utilized as the fine aggregate. The specific gravity of 2.65 and a fineness modulus of 2.41 of used aggregate, as specified by the standard ASTM:C939-10 (2010) [40]. The fine aggregate particle size was less than 2.36 mm, so that the grout enters the fibre skeleton and aggregates via gravity.

- Crushed granite gravel with a particle size of 12.5 mm is used to make coarse aggregate, according to IS 383 (2016) [39]. Water absorption was 0.56%, the specific gravity was 2.69, and the apparent bulk density was 1700 kg/m3 for coarse aggregate.

- The flowable cement grout was made possible by the employment of Tech Mix 640 high-range super plasticizing ingredient, with a dose ranging from 0.35% to 0.45% of cement weight, to satisfy the efflux time of the grout. The mixing combination of materials is shown in Table 1.

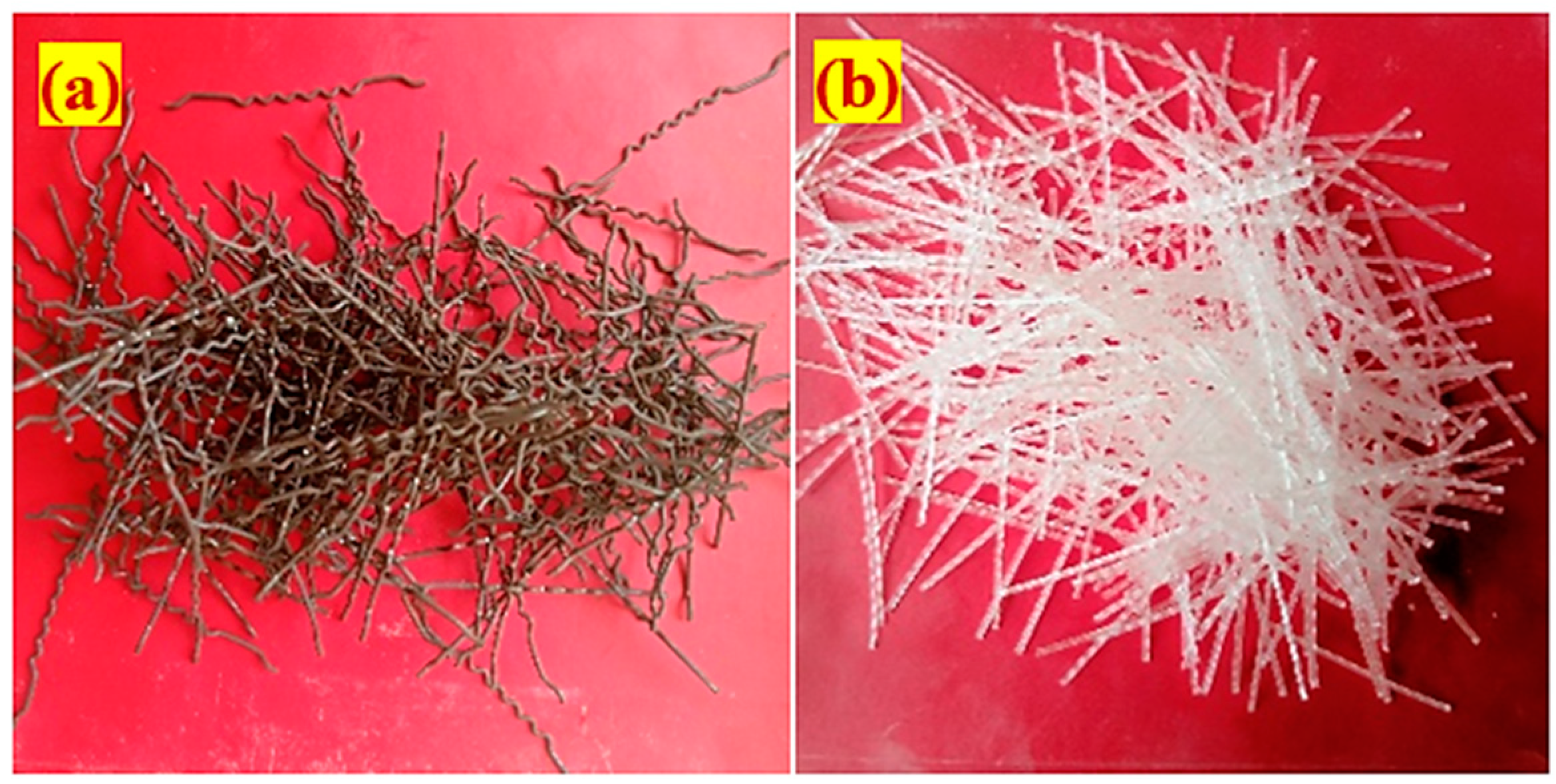

- The tensile strength of composite was improved by adding two distinct fibres. A polypropylene fibre (PF) with a tensile strength of 500 MPa, a length of 45 mm, and a diameter of 0.8 mm was used. Steel fibre (SF) with a diameter of 1 mm, length of 50 mm, and strength of 1150 MPa was used. The appearance of two distinct fibres utilized in this research is shown in Figure 3. The average dosage of fibre was restricted to 2.4% owing to low-density fibre utilisation (PF). The dose of PF above 2.4% removes the additionally aggregates placed into the formwork. The idea of two-stage fibrous concrete was updated as slurry infiltrated fibrous concrete (SIFCON). This study focuses solely on impact performance of functionally graded two-stage fibrous concrete beams. To prevent creating SIFCON, an average fibre dose is restricted to 2.4% in this research.

3.2. Mixing Composition

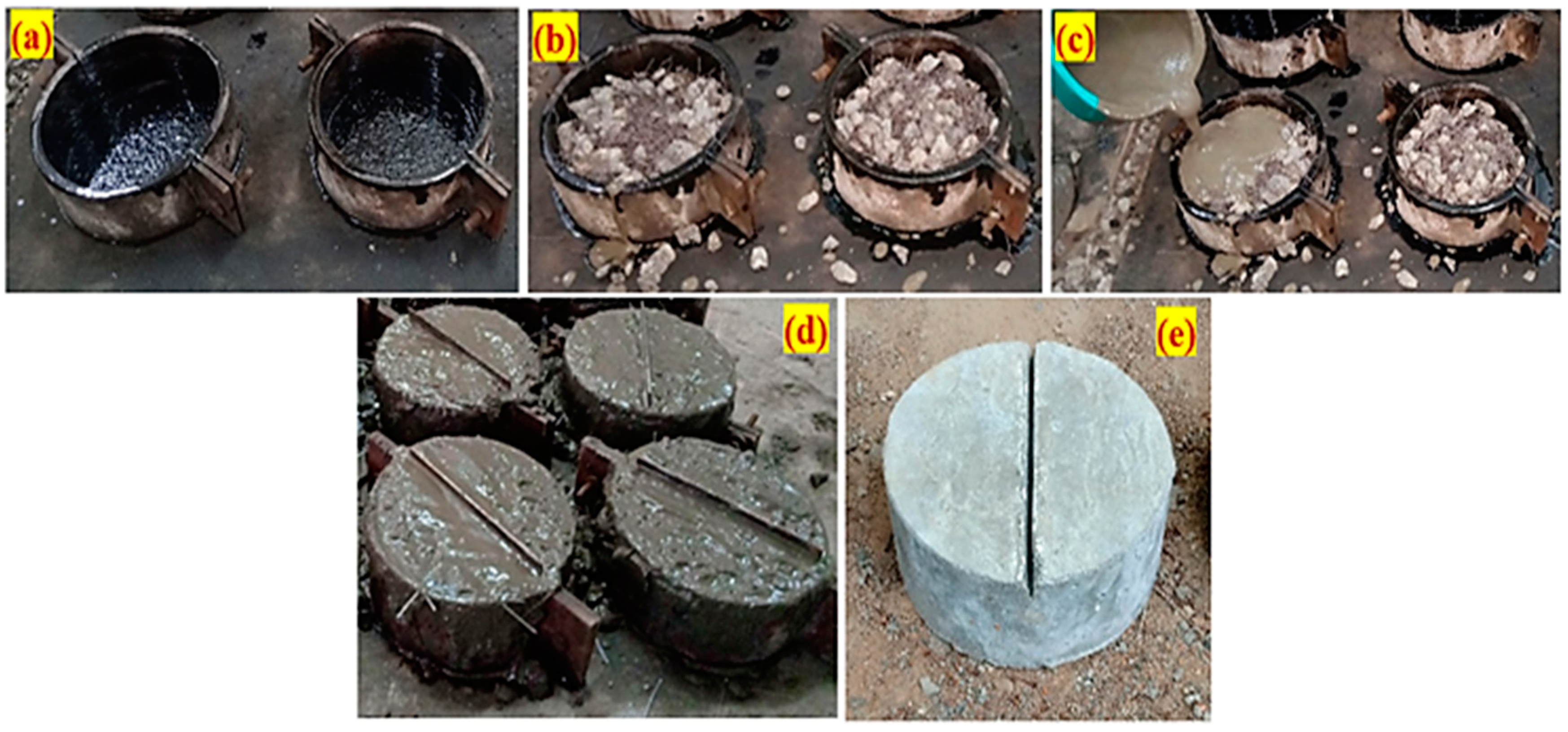

3.3. Specimen Preparation

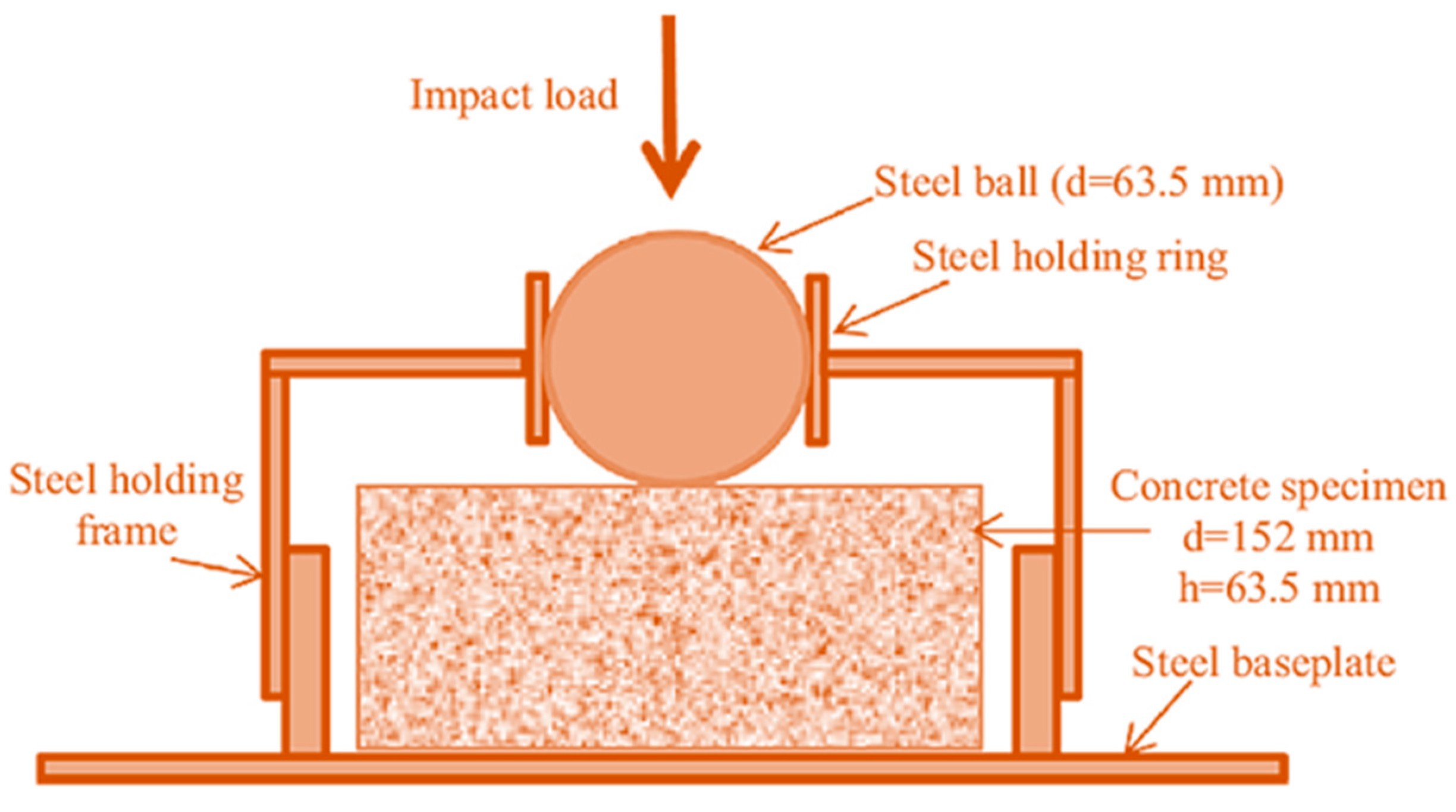

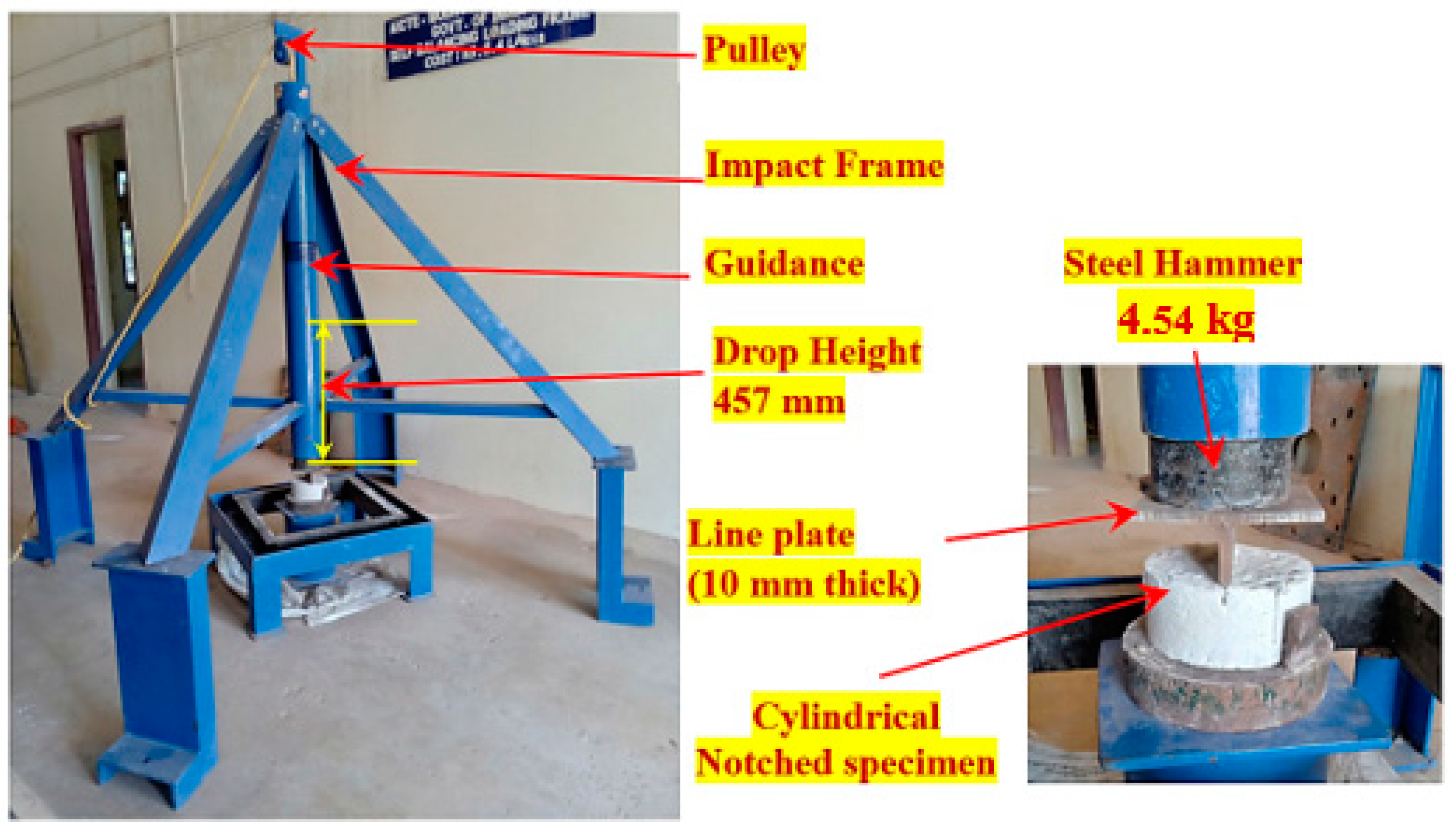

3.4. Drop-Mass Impact Testing Device

4. Results and Discussion

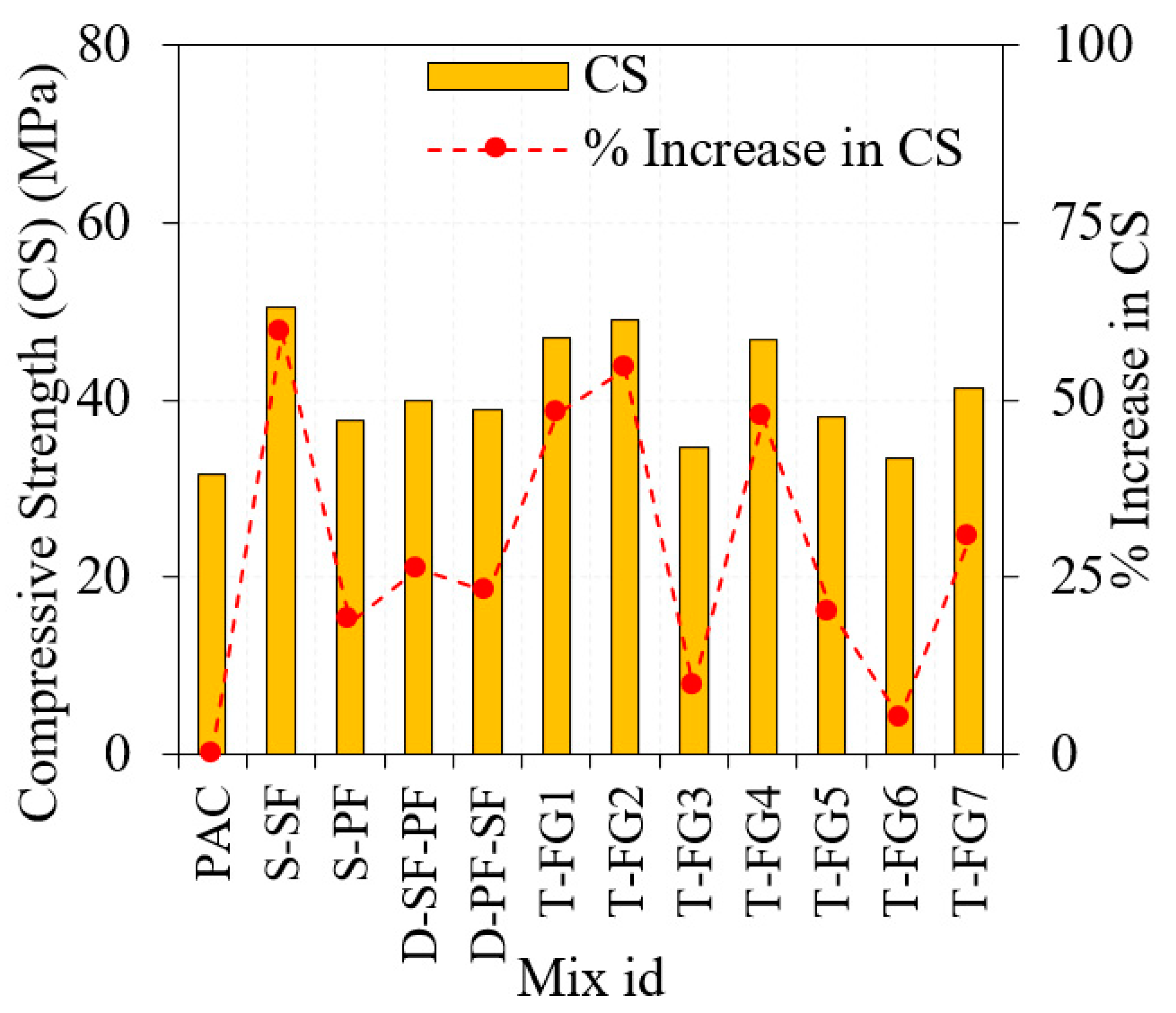

4.1. Compressive Strength of FLTSFC

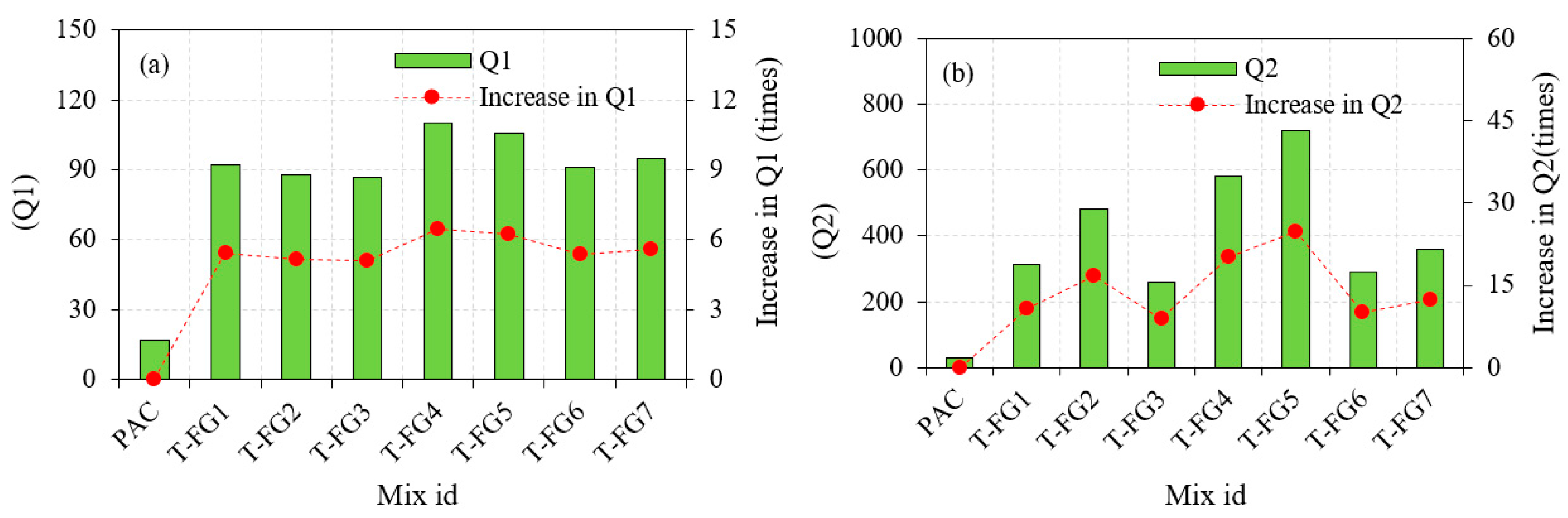

4.2. Impact Test Results

4.2.1. Effect of Single-Layered Concrete

- The S-SF specimen exhibited a Q1 value around 101 and Q2 around 536. These observed values were 5.94 and 18.48 times larger than PAC specimens, respectively.

- The S-PF specimen exhibited a Q1 value of 60 and Q2 of 152. Values obtained from this specimen were 3.53 and 5.24 times higher than those from the PAC specimen, respectively.

- S-SF specimen showed improved Q1 and Q2 values by about 1.68 and 3.7 times, respectively, with respect to the S-PF specimen.

4.2.2. Effect of Double-Layered FLTSFC

- The recorded values were 92 and 299, corresponding to Q1 and Q2 for the D-SF-PF specimen. With respect to PAC specimen, the recorded Q1 value improved by 5.41 times and Q2 by 10.31 times.

- The Q1 and Q2 of the D-PF-SF specimens recorded were 89 and 296, respectively. These values were 5.24 times higher in Q1 and 10 times higher in Q2.

4.2.3. Effect of Three-Layer FLTSFC

- For T-FG1 specimen, the recorded Q1 value was 92 and Q2 was 313. These two values were improved by 5.41 and 10.79 times higher with respect to PAC specimen.

- T-FG2 specimen exhibited an impact strength of 88 and 483 corresponding to Q1 and Q2, respectively. In comparison with PAC specimen, the recorded values were 5.18 and 16.65 times higher.

- For T-FG3 specimen, the recorded Q1 value was 87 and Q2 value was 260. These two impact strength values were enhanced by 5.12 and 8.96 times, respectively.

- The T-FG4 specimen displayed a Q1 value of 110 and Q2 value of 583. These values were improved by about 6.47 and 20.10 times, respectively.

- The T-FG5 specimen has the maximum Q1 and Q2 values ever recorded, with the highest being 106 and 720, respectively. When compared to PAC, the values were improved by 24 and 24.82 times, respectively.

- For the T-FG6 specimen, the recorded Q1 and Q2 values were 91 and 292, respectively. There was an increase in the values observed by 5.35 and 10.07 times, respectively.

- In the case of the T-FG7 specimen, the Q1 and Q2 values were 95 and 360, respectively. The numbers were multiplied by 5.59 and 12.41 times, respectively.

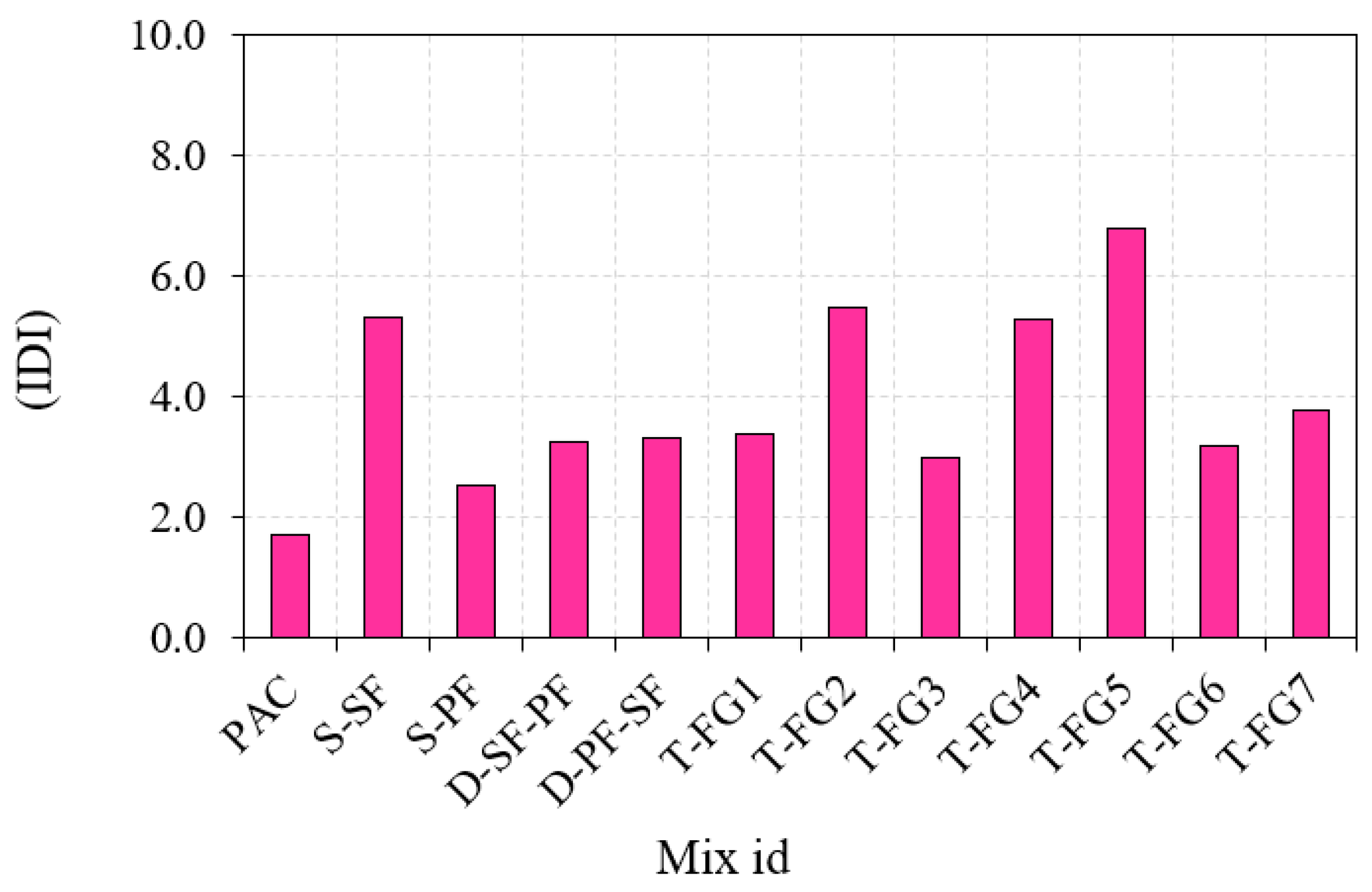

4.2.4. Ductility Index (IDI) of FLTSFC

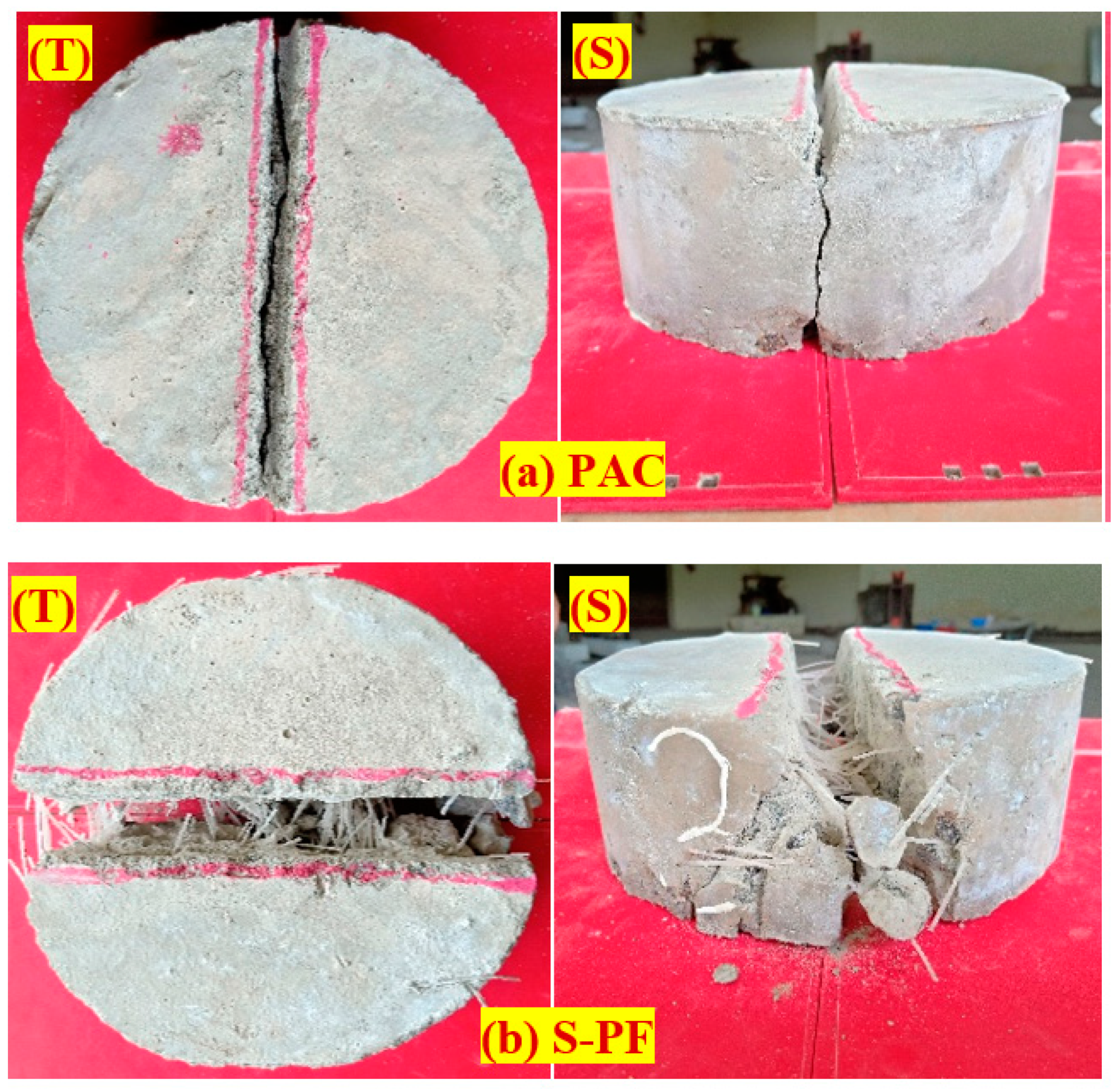

4.2.5. Failure Pattern

4.2.6. The Results of the ACI and the Modified Technique Impact Tests

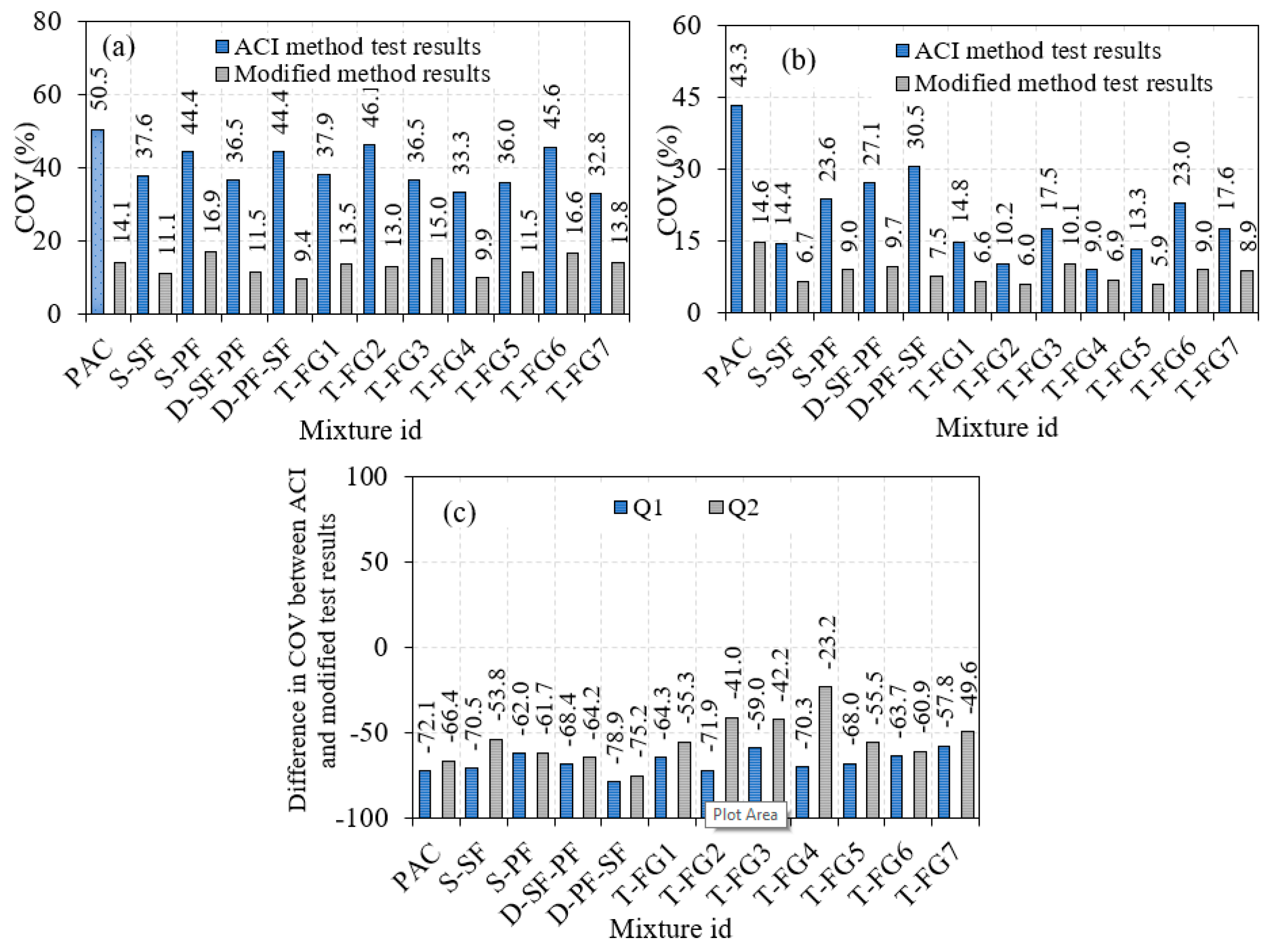

4.2.7. Coefficient of Variance (COV) Comparison

5. Conclusions

- The S-SF specimen had the highest compressive strength, which increased by 59.6% compared to the PAC specimen. The T-FG2 specimen had the second largest compressive strength increase, with 2.8% SF at the topmost and bottom layers, and 1.6% SF at the intermediate layer, resulting in the second highest compressive strength gain overall. The single-layered specimens exhibited higher compressive strength than the three-layered FLTSFC. The contribution of SF in increasing strength is considerably higher than PF, irrespective of the fibre scheme or number of layers.

- When compared to PAC, the reported Q1 values for the S-SF and S-PF specimens were raised by 5.94 and 5.23 times, respectively. Likewise, the recorded Q2 values increased by about 10.31 and 10.21 times, respectively. This phenomenon is due to the addition of fibres, which increased the matrix’s tensile strength by delivering high tensile stress absorption over cracks via crack bridging.

- Due to the obvious matrix reinforcing impact of fibres, the T-FG group of specimens showed higher Q1 and Q2 records than the PAC specimen, as was anticipated. In Q1 and Q2, significant increases was recorded by about 6.47 and 20.10 times for T-FG4 and 6.4 and 23.2 times for TFG-5, respectively. The top and bottom layers of higher SF dosage receive greater impact stresses due to direct contact with the drop weight and the supporting base plate. Moreover, SF’s crimped and hooked-end structure improved bond strength, including its significantly higher tensile strength than PF.

- The index ductility values of all fibre specimens ranged between 2.53 and 6.79, indicating a greater resistance after cracking. A properly controlled cracking pattern was obtained via the use of notched specimens and transmission plates. The fractures in the notch specimens were initiated and proliferated mostly along the borders of the notches. In contrast, there were many randomly distributed cracks in the samples evaluated according to the ACI 544-2R technique. This regulated activity would simplify the identification of criteria for the acceptance or rejection of results of test specimens according to their cracking pattern, which leads to a reduction in the dispersion of results.

- Compared to the ACI-544 method, the modified impact results were superior. The computed COV values for all twelve mixtures were decreased by 57.8–78.9% in Q1 and by 23.2–75.2% in Q2 compared with the ACI test method. Therefore, the proposed suggestion for the impact test could improve the reliability of results, make them easy to conduct, and contribute to new materials science.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FLTSFC | Functionally Layered Two-stage Fibrous Concrete |

| FRC | Fibre Reinforced Concrete |

| TSFC | Two-Stage Fibrous Concrete |

| FGC | Functionally Graded Concrete |

| FLFC | Functionally Layered Fibrous concrete |

| PF | Polypropylene Fibre |

| SF | Steel fibre |

| SIFCON | Slurry Infiltrated Fibrous Concrete |

| SP | Superplasticizer |

| Q1 | First crack impact number |

| Q2 | Failure impact number |

| SD | Standard deviation |

| COV | Coefficient of variation |

References

- Abid, S.R.; Ali, S.H.; Murali, G.; Al-Gasham, T.S. A simple suggested approach to reduce the testing time of concrete surface abrasion using ASTM C1138. Case Stud. Constr. Mater. 2021, 15, e00685. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Amran, M.; Fediuk, R.; Vatin, N.; Karelina, M. Combined effect of multi-walled carbon nanotubes, steel fibre and glass fibre mesh on novel two-stage expanded clay aggregate concrete against impact loading. Crystals 2021, 11, 720. [Google Scholar] [CrossRef]

- Abid, S.R.; Abdul-Hussein, M.L.; Ayoob, N.S.; Ali, S.H.; Kadhum, A.L. Repeated drop-weight impact tests on self-compacting concrete reinforced with micro-steel fiber. Heliyon 2020, 6, e03198. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Abdelgader, H.S.; Amran, Y.H.M.; Shekarchi, M.; Wilde, K. Repeated Projectile Impact Tests on Multi-Layered Fibrous Cementitious Composites. Int. J. Civ. Eng. 2021, 19, 635–651. [Google Scholar] [CrossRef]

- Mohan, K.S.R.; Diviyabharrathi, K.B.; Murali, G. Research on the Development of High Impact Resistant Preplaced Aggregate Fibrous Concrete by the Inclusion of Coarse Aggregates Coated with Asphalt. Arab. J. Sci. Eng. 2021. [Google Scholar] [CrossRef]

- Al-ameri, R.A.; Abid, S.R.; Murali, G.; Ali, S.H.; Özakça, M. Residual repeated impact strength of concrete exposed to elevated temperatures. Crystals 2021, 11, 941. [Google Scholar] [CrossRef]

- Murali, G.; Santhi, A.S.; Mohan Ganesh, G. Empirical relationship between the impact energy and compressive strength for fiber reinforced concrete. J. Sci. Ind. Res. 2014, 73, 469–473. [Google Scholar]

- Murali, G.; Santhi, A.S.; Ganesh, G.M. Impact resistance and strength reliability of fiber-reinforced concrete in bending under drop weight impact load. Int. J. Technol. 2014, 5, 111–120. [Google Scholar] [CrossRef]

- Murali, G.; Santhi, A.S.; Mohan Ganesh, G. Effect of crimped and hooked end steel fibres on the impact resistance of concrete. J. Appl. Sci. Eng. 2014, 17, 259–266. [Google Scholar] [CrossRef]

- Jabir, H.A.; Abid, S.R.; Murali, G.; Ali, S.H.; Klyuev, S.; Fediuk, R.; Vatin, N.; Promakhov, V.; Vasilev, Y. Experimental tests and reliability analysis of the cracking impact resistance of uhpfrc. Fibers 2020, 8, 74. [Google Scholar] [CrossRef]

- Mohamed, N.; Soliman, A.M.; Nehdi, M.L. Full-scale pipes using dry-cast steel fibre-reinforced concrete. Constr. Build. Mater. 2014, 72, 411–422. [Google Scholar] [CrossRef]

- Şahin, Y.; Köksal, F. The influences of matrix and steel fibre tensile strengths on the fracture energy of high-strength concrete. Constr. Build. Mater. 2011, 25, 1801–1806. [Google Scholar] [CrossRef]

- Nataraja, M.C.; Dhang, N.; Gupta, A.P. Statistical variations in impact resistance of steel fiber-reinforced concrete subjected to drop weight test. Cem. Concr. Res. 1999, 29, 989–995. [Google Scholar] [CrossRef]

- Deifalla, A.F.; Zapris, A.G.; Chalioris, C.E. Multivariable regression strength model for steel fiber-reinforced concrete beams under torsion. Materials 2021, 14, 3889. [Google Scholar] [CrossRef]

- Zanuy, C.; Ulzurrun, G.S.D. Impact resisting mechanisms of shear-critical reinforced concrete beams strengthened with high-performance FRC. Appl. Sci. 2020, 10, 3154. [Google Scholar] [CrossRef]

- Kazemi, M.T.; Golsorkhtabar, H.; Beygi, M.H.A.; Gholamitabar, M. Fracture properties of steel fiber reinforced high strength concrete using work of fracture and size effect methods. Constr. Build. Mater. 2017, 142, 482–489. [Google Scholar] [CrossRef]

- Guo, Y.C.; Zhang, J.H.; Chen, G.M.; Xie, Z.H. Compressive behaviour of concrete structures incorporating recycled concrete aggregates, rubber crumb and reinforced with steel fibre, subjected to elevated temperatures. J. Clean. Prod. 2014, 72, 193–203. [Google Scholar] [CrossRef]

- Murali, G.; Vinodha, E. Experimental and Analytical Study of Impact Failure Strength of Steel Hybrid Fibre Reinforced Concrete Subjected to Freezing and Thawing Cycles. Arab. J. Sci. Eng. 2018, 43, 5487–5497. [Google Scholar] [CrossRef]

- Murali, G.; Asrani, N.P.; Ramkumar, V.R.; Siva, A.; Haridharan, M.K. Impact Resistance and Strength Reliability of Novel Two-Stage Fibre-Reinforced Concrete. Arab. J. Sci. Eng. 2019, 44, 4477–4490. [Google Scholar] [CrossRef]

- Ramkumar, V.R.; Murali, G.; Asrani, N.P.; Karthikeyan, K. Development of a novel low carbon cementitious two stage layered fibrous concrete with superior impact strength. J. Build. Eng. 2019, 25, 100841. [Google Scholar] [CrossRef]

- Murali, G.; Poka, L.; Parthiban, K.; Haridharan, M.K.; Siva, A. Impact Response of Novel Fibre-Reinforced Grouted Aggregate Rubberized Concrete. Arab. J. Sci. Eng. 2019, 44, 8451–8463. [Google Scholar] [CrossRef]

- Abirami, T.; Murali, G.; Saravana Raja Mohan, K.; Salaimanimagudam, M.P.; Nagaveni, P.; Bhargavi, P. Multi-layered two stage fibrous composites against low-velocity falling mass and projectile impact. Constr. Build. Mater. 2020, 248, 118631. [Google Scholar] [CrossRef]

- Murali, G.; Ramprasad, K. A feasibility of enhancing the impact strength of novel layered two stage fibrous concrete slabs. Eng. Struct. 2018, 175, 41–49. [Google Scholar] [CrossRef]

- Torelli, G.; Fernández, M.G.; Lees, J.M. Functionally graded concrete: Design objectives, production techniques and analysis methods for layered and continuously graded elements. Constr. Build. Mater. 2020, 242, 118040. [Google Scholar] [CrossRef]

- Sridhar, R.; Prasad, D.R. Damage assessment of functionally graded reinforced concrete beams using hybrid fiber engineered cementitious composites. Structures 2019, 20, 832–847. [Google Scholar] [CrossRef]

- Moghadam, A.S.; Omidinasab, F. Assessment of hybrid FRSC cementitious composite with emphasis on flexural performance of functionally graded slabs. Constr. Build. Mater. 2020, 250, 118904. [Google Scholar] [CrossRef]

- Prasad, N.; Murali, G. Exploring the impact performance of functionally-graded preplaced aggregate concrete incorporating steel and polypropylene fibres. J. Build. Eng. 2021, 35, 102077. [Google Scholar] [CrossRef]

- ACI 544-2R Measurement of Properties of Fiber Reinforced Concrete. Publ. SP Am. Concr. Inst. 1984, 89, 433–439.

- Murali, G.; Karthikeyan, K.; Ramkumar, V.R. Reliability analysis of impact failure energy of fibre reinforced concrete using Weibull distribution. J. Appl. Sci. Eng. 2018, 21, 163–170. [Google Scholar] [CrossRef]

- Murali, G.; Santhi, A.S.; Mohan Ganesh, G. Impact resistance and strength reliability of fiber reinforced concrete using two parameter weibull distribution. J. Eng. Appl. Sci. 2014, 9, 554–559. [Google Scholar]

- Murali, G.; Gayathri, R.; Ramkumar, V.R.; Karthikeyan, K. Two statistical scrutinize of impact strength and strength reliability of steel Fibre-Reinforced Concrete. KSCE J. Civ. Eng. 2018, 22, 257–269. [Google Scholar] [CrossRef]

- Murali, G.; Chandana, V. Weibull reliability analysis of impact resistance on self-compacting concrete reinforced with recycled CFRP pieces. Rev. Rom. Mater. Rom. J. Mater. 2017, 47, 196–203. [Google Scholar]

- Gunasekaran, M.; Thangavel, M.; Nemichandran, N.K.; Ravikumar, I.; Glarance, H.J.; Kothandapani, K. Impact response and strength reliability of green high performance fibre reinforced concrete subjected to freeze-thaw cycles in NaCl solution. Medziagotyra 2017, 23, 384–388. [Google Scholar] [CrossRef][Green Version]

- Gunasekaran, M.; Kothandapani, K.; Kanthamani, M.K.H. Statistical scrutiny of variations in impact strength of green high performance fibre reinforced concrete subjected to drop weight test. Rev. Rom. Mater. Rom. J. Mater. 2018, 48, 214–221. [Google Scholar]

- Haridharan, M.K.; Matheswaran, S.; Murali, G.; Abid, S.R.; Fediuk, R.; Mugahed Amran, Y.H.; Abdelgader, H.S. Impact response of two-layered grouted aggregate fibrous concrete composite under falling mass impact. Constr. Build. Mater. 2020, 263, 120628. [Google Scholar] [CrossRef]

- Prasad, N.; Murali, G.; Vatin, N. Modified falling mass impact test performance on functionally graded two stage aggregate fibrous concrete. Materials 2021, 14, 5833. [Google Scholar] [CrossRef]

- Badr, A.; Ashour, A.F. Modified ACI drop-weight impact test for concrete. ACI Mater. J. 2005, 102, 249–255. [Google Scholar] [CrossRef]

- IS 1489(Part 1): 2015 Portland Pozzolana Cement-Specification; IS 1489 (Part 1) (Third rev.); Bureau of Indian Standards: New Delhi, India, 2015.

- IS 383 Is 383: 2016 Annex-a; Bureau of Indian Standards: New Delhi, India, 2016; pp. 1–14.

- Astm:C939-10 Standard Test Method for Flow of Grout for Preplaced-Aggregate Concrete (Flow Cone Method). ASTM Int. 2010, 4, 9–11. [CrossRef]

- IS 516:2014 Method of Tests for Strength of Concrete; IS 516—1959 (Reaffirmed 2004); Bureau of Indian Standards: New Delhi, India, 2004.

- Nili, M.; Afroughsabet, V. The effects of silica fume and polypropylene fibers on the impact resistance and mechanical properties of concrete. Constr. Build. Mater. 2010, 24, 927–933. [Google Scholar] [CrossRef]

- Yildirim, S.T.; Ekinci, C.E.; Findik, F. Properties of Hybrid Fiber Reinforced Concrete under Repeated Impact Loads. Russ. J. Nondestruct. Test. 2010, 46, 538–546. [Google Scholar] [CrossRef]

- Prasad, N.; Murali, G.; Fediuk, R.; Vatin, N.; Karelina, M. Response of novel functionally-graded prepacked aggregate fibrous concrete against low velocity repeated projectile impacts. Materials 2021, 14, 280. [Google Scholar] [CrossRef]

- Nia, A.A.; Hedayatian, M.; Nili, M.; Sabet, V.A. An experimental and numerical study on how steel and polypropylene fi bers affect the impact resistance in fi ber-reinforced concrete. Int. J. Impact Eng. 2012, 46, 62–73. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A. The impact resistance and mechanical properties of the reinforced self-compacting concrete incorporating recycled CFRP fi ber with different lengths and dosages. Compos. Part B 2017, 112, 74–92. [Google Scholar] [CrossRef]

- Rithanyaa, R.; Murali, G.; Salaimanimagudam, M.P.; Fediuk, R.; Abdelgader, H.S.; Siva, A. Impact response of novel layered two stage fibrous composite slabs with different support type. Structures 2021, 29, 1–13. [Google Scholar] [CrossRef]

- Murali, G.; Abid, S.R.; Karthikeyan, K.; Haridharan, M.K.; Amran, M.; Siva, A. Low-velocity impact response of novel prepacked expanded clay aggregate fibrous concrete produced with carbon nano tube, glass fiber mesh and steel fiber. Constr. Build. Mater. 2021, 284, 122749. [Google Scholar] [CrossRef]

- Li, Q.; Zhao, X.; Xu, S.; Leung, C.K.Y.; Wang, B. Multiple Impact Resistance of Hybrid Fiber Ultrahigh Toughness Cementitious Composites with Different Degrees of Initial Damage. J. Mater. Civ. Eng. 2019, 31, 04018368. [Google Scholar] [CrossRef]

- Fu, Q.; Niu, D.; Li, D.; Wang, Y.; Zhang, J.; Huang, D. Impact characterization and modelling of basalt–polypropylene fibre-reinforced concrete containing mineral admixtures. Cem. Concr. Compos. 2018, 93, 246–259. [Google Scholar] [CrossRef]

- Ghernouti, Y.; Rabehi, B.; Bouziani, T.; Ghezraoui, H.; Makhloufi, A. Fresh and hardened properties of self-compacting concrete containing plastic bag waste fibers (WFSCC). Constr. Build. Mater. 2015, 82, 89–100. [Google Scholar] [CrossRef]

- Mastali, M.; Ghasemi Naghibdehi, M.; Naghipour, M.; Rabiee, S.M. Experimental assessment of functionally graded reinforced concrete (FGRC) slabs under drop weight and projectile impacts. Constr. Build. Mater. 2015, 95, 296–311. [Google Scholar] [CrossRef]

- Ramkumar, V.R.; Komarasamy, C.; Gunasekaran, M. Impact resistance of fibre reinforced concrete containing lime sludge based composite cements. J. Struct. Eng. 2018, 44, 649–662. [Google Scholar]

- Asrani, N.P.; Murali, G.; Parthiban, K.; Surya, K.; Prakash, A.; Rathika, K.; Chandru, U. A feasibility of enhancing the impact resistance of hybrid fibrous geopolymer composites: Experiments and modelling. Constr. Build. Mater. 2019, 203, 56–68. [Google Scholar] [CrossRef]

- Mo, K.H.; Yap, S.P.; Alengaram, U.J.; Jumaat, M.Z.; Bu, C.H. Impact resistance of hybrid fibre-reinforced oil palm shell concrete. Constr. Build. Mater. 2014, 50, 499–507. [Google Scholar] [CrossRef]

- Manohar, T.; Suribabu, C.R.; Murali, G.; Salaimanimagudam, M.P. A novel steel-PAFRC composite fender for bridge pier protection under low velocity vessel impacts. Structures 2020, 26, 765–777. [Google Scholar] [CrossRef]

- Salaimanimagudam, M.P.; Suribabu, C.R.; Murali, G.; Abid, S.R. Impact response of hammerhead pier fibrous concrete beams designed with topology optimization. Period. Polytech. Civ. Eng. 2020, 64, 1244–1258. [Google Scholar] [CrossRef]

- Abirami, T.; Loganaganandan, M.; Murali, G.; Fediuk, R.; Vickhram Sreekrishna, R.; Vignesh, T.; Januppriya, G.; Karthikeyan, K. Experimental research on impact response of novel steel fibrous concretes under falling mass impact. Constr. Build. Mater. 2019, 222, 447–457. [Google Scholar] [CrossRef]

- Ramakrishnan, K.; Depak, S.R.; Hariharan, K.R.; Abid, S.R.; Murali, G.; Cecchin, D.; Fediuk, R.; Mugahed Amran, Y.H.; Abdelgader, H.S.; Khatib, J.M. Standard and modified falling mass impact tests on preplaced aggregate fibrous concrete and slurry infiltrated fibrous concrete. Constr. Build. Mater. 2021, 298, 123857. [Google Scholar] [CrossRef]

- Abid, S.R.; Abdul Hussein, M.L.; Ali, S.H.; Kazem, A.F. Suggested modified testing techniques to the ACI 544-R repeated drop-weight impact test. Constr. Build. Mater. 2020, 244, 118321. [Google Scholar] [CrossRef]

- Prasad, N.; Murali, G. Research on flexure and impact performance of functionally-graded two-stage fibrous concrete beams of different sizes. Constr. Build. Mater. 2021, 288, 123138. [Google Scholar] [CrossRef]

- Elistratkin, M.Y.; Lesovik, V.S.; Zagorodnjuk, L.H.; Pospelova, E.A.; Shatalova, S.V. New point of view on materials development. IOP Conf. Ser. Mater. Sci. Eng. 2018, 327, 32020. [Google Scholar] [CrossRef]

- Klyuyev, S.V.; Guryanov, Y.V. External reinforcing of fiber concrete constructions by carbon fiber tapes. Mag. Civ. Eng. 2013, 36, 21–26. [Google Scholar] [CrossRef]

- Begich, Y.E.; Klyuev, S.V.; Jos, V.A.; Cherkashin, A.V. Fine-grained concrete with various types of fibers. Mag. Civ. Eng. 2020, 97. [Google Scholar] [CrossRef]

- Klyuyev, A.V.; Sopin, D.M.; Netrebenko, A.V.; Kazlitin, S.A. Heavy loaded floors based on fine-grained fiber concrete. Mag. Civ. Eng. 2013, 38, 7–14. [Google Scholar] [CrossRef]

- Klyuev, S.V.; Bratanovskiy, S.N.; Trukhanov, S.V.; Manukyan, H.A. Strengthening of concrete structures with composite based on carbon fiber. J. Comput. Theor. Nanosci. 2019, 16, 2810–2814. [Google Scholar] [CrossRef]

- Lesovik, R.V.; Klyuyev, S.V.; Klyuyev, A.V.; Tolbatov, A.A.; Durachenko, A.V. The Development of textile fine-grained fiber concrete using technogenic raw materials. Res. J. Appl. Sci. 2015, 10, 701–706. [Google Scholar]

- Lesovik, R.V.; Klyuyev, S.V.; Klyuyev, A.V.; Netrebenko, A.V.; Durachenko, A.V. High-strength fiber-reinforced concrete containing technogenic raw materials and composite binders with use of nanodispersed powder. Res. J. Appl. Sci. 2014, 9, 1153–1157. [Google Scholar]

| Mix Id | c/s | w/c | First Layer’s Fibre Dosage (%) | Second Layer’s Fibre Dosage (%) | Third Layer’s Fibre Dosage (%) | SP (%) | |||

|---|---|---|---|---|---|---|---|---|---|

| SF | PF | SF | PF | SF | PF | ||||

| PAC | 1.0 | 0.45 | 0 | 0.35 | |||||

| S-SF | SF (2.4) | 0.45 | |||||||

| S-PF | PF (2.4) | ||||||||

| D-SF-PF | SF (2.4) | PF (2.4) | |||||||

| D-PF-SF | PF (2.4) | SF (2.4) | |||||||

| T-FG1 | SF (1.2) | PF (1.2) | SF (1.2) | PF (1.2) | SF (1.2) | PF (1.2) | |||

| T-FG2 | SF (2.8) | - | SF (1.6) | - | SF (2.8) | - | |||

| T-FG3 | - | PF (2.8) | - | PF (1.6) | - | PF (2.8) | |||

| T-FG4 | SF (1.4) | PF (1.4) | SF (0.8) | PF (0.8) | SF (1.4) | PF (1.4) | |||

| T-FG5 | SF (3.6) | - | - | - | SF (3.6) | - | |||

| T-FG6 | - | PF (3.6) | - | - | - | PF (3.6) | |||

| T-FG7 | SF (1.8) | PF (1.8) | - | - | SF (1.8) | PF (1.8) | |||

| Mix ID | Compressive Strength (Mpa) | Mean | SD | COV (%) | ||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | ||||

| PAC | 32.18 | 29.09 | 33.85 | 31.71 | 2.42 | 7.62 |

| S-SF | 48.9 | 52.3 | 50.5 | 50.57 | 1.70 | 3.36 |

| S-PF | 34.19 | 41.18 | 37.51 | 37.63 | 3.50 | 9.29 |

| D-SF-PF | 39.49 | 41.84 | 38.64 | 39.99 | 1.66 | 4.14 |

| D-PF-SF | 39.92 | 35.74 | 41.38 | 39.01 | 2.93 | 7.50 |

| T-FG1 | 44.15 | 46.92 | 49.75 | 46.94 | 2.80 | 5.97 |

| T-FG2 | 48.05 | 49.58 | 49.27 | 48.97 | 0.81 | 1.65 |

| T-FG3 | 32.52 | 36.88 | 34.74 | 34.71 | 2.18 | 6.28 |

| T-FG4 | 45.71 | 45.79 | 48.92 | 46.81 | 1.83 | 3.91 |

| T-FG5 | 34.81 | 38.23 | 41.32 | 38.12 | 3.26 | 8.54 |

| T-FG6 | 34.44 | 32.26 | 33.41 | 33.37 | 1.09 | 3.27 |

| T-FG7 | 42.71 | 38.32 | 43.13 | 41.39 | 2.66 | 6.44 |

| Mix ID | PAC | S-SF | S-PF | D-SF-PF | D-PF-SF | T-FG1 | T-FG2 | T-FG3 | T-FG4 | T-FG5 | T-FG6 | T-FG7 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Q1 | 23 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | Q1 | Q2 | |

| 1 | 13 | 24 | 85 | 482 | 46 | 131 | 75 | 260 | 76 | 265 | 74 | 281 | 71 | 436 | 62 | 224 | 94 | 526 | 89 | 656 | 71 | 251 | 76 | 315 |

| 2 | 14 | 24 | 86 | 487 | 47 | 133 | 78 | 262 | 78 | 269 | 76 | 286 | 73 | 438 | 65 | 226 | 95 | 530 | 90 | 663 | 72 | 255 | 78 | 316 |

| 3 | 14 | 25 | 88 | 490 | 49 | 136 | 80 | 265 | 80 | 271 | 79 | 292 | 77 | 442 | 74 | 230 | 97 | 534 | 92 | 671 | 74 | 259 | 81 | 324 |

| 4 | 15 | 26 | 92 | 495 | 50 | 139 | 82 | 266 | 81 | 275 | 81 | 295 | 78 | 456 | 77 | 234 | 100 | 541 | 93 | 673 | 76 | 268 | 83 | 332 |

| 5 | 15 | 26 | 94 | 506 | 52 | 142 | 85 | 271 | 84 | 280 | 82 | 301 | 80 | 472 | 81 | 241 | 102 | 555 | 96 | 687 | 80 | 274 | 86 | 339 |

| 6 | 16 | 27 | 95 | 524 | 53 | 146 | 86 | 282 | 85 | 282 | 83 | 307 | 82 | 476 | 86 | 249 | 105 | 563 | 99 | 695 | 85 | 280 | 87 | 345 |

| 7 | 16 | 27 | 97 | 531 | 55 | 151 | 91 | 294 | 87 | 287 | 89 | 309 | 85 | 481 | 88 | 253 | 106 | 571 | 107 | 718 | 86 | 285 | 91 | 352 |

| 8 | 17 | 28 | 103 | 546 | 59 | 155 | 93 | 303 | 88 | 296 | 94 | 311 | 87 | 486 | 89 | 260 | 109 | 587 | 109 | 727 | 90 | 296 | 96 | 354 |

| 9 | 17 | 29 | 105 | 559 | 61 | 159 | 94 | 315 | 90 | 299 | 95 | 315 | 90 | 493 | 92 | 266 | 111 | 595 | 111 | 738 | 91 | 302 | 100 | 367 |

| 10 | 18 | 29 | 110 | 560 | 65 | 160 | 96 | 316 | 92 | 305 | 99 | 319 | 93 | 499 | 93 | 270 | 115 | 603 | 113 | 743 | 95 | 309 | 103 | 379 |

| 11 | 18 | 30 | 111 | 563 | 67 | 161 | 98 | 319 | 95 | 311 | 101 | 324 | 95 | 503 | 95 | 275 | 117 | 617 | 115 | 755 | 101 | 314 | 105 | 384 |

| 12 | 19 | 32 | 114 | 567 | 69 | 165 | 100 | 324 | 96 | 316 | 104 | 328 | 96 | 507 | 98 | 282 | 120 | 626 | 117 | 762 | 106 | 319 | 107 | 389 |

| 13 | 19 | 33 | 115 | 571 | 72 | 166 | 104 | 331 | 98 | 321 | 107 | 333 | 100 | 512 | 100 | 289 | 123 | 620 | 119 | 768 | 110 | 320 | 110 | 398 |

| 14 | 20 | 36 | 116 | 576 | 73 | 170 | 106 | 337 | 101 | 326 | 109 | 347 | 105 | 517 | 102 | 295 | 124 | 638 | 121 | 772 | 112 | 322 | 112 | 403 |

| 15 | 21 | 38 | 118 | 580 | 75 | 172 | 109 | 338 | 102 | 334 | 110 | 350 | 108 | 525 | 105 | 307 | 126 | 640 | 125 | 774 | 115 | 325 | 116 | 409 |

| Mean | 17 | 29 | 101 | 536 | 60 | 152 | 92 | 299 | 89 | 296 | 92 | 313 | 88 | 483 | 87 | 260 | 110 | 583 | 106 | 720 | 91 | 292 | 95 | 360 |

| SD | 2.4 | 4.2 | 11.2 | 35.7 | 10.1 | 13.8 | 10.6 | 29.0 | 8.3 | 22.3 | 12.5 | 20.8 | 11.4 | 29.2 | 13.0 | 26.3 | 10.9 | 40.3 | 12.2 | 42.7 | 15.1 | 26.2 | 13.2 | 32.0 |

| COV % | 14.1 | 14.6 | 11.1 | 6.7 | 16.9 | 9.0 | 11.5 | 9.7 | 9.4 | 7.5 | 13.5 | 6.6 | 13.0 | 6.0 | 15.0 | 10.1 | 9.9 | 6.9 | 11.5 | 5.9 | 16.6 | 9.0 | 13.8 | 8.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murali, G.; Prasad, N.; Klyuev, S.; Fediuk, R.; Abid, S.R.; Amran, M.; Vatin, N. Impact Resistance of Functionally Layered Two-Stage Fibrous Concrete. Fibers 2021, 9, 88. https://doi.org/10.3390/fib9120088

Murali G, Prasad N, Klyuev S, Fediuk R, Abid SR, Amran M, Vatin N. Impact Resistance of Functionally Layered Two-Stage Fibrous Concrete. Fibers. 2021; 9(12):88. https://doi.org/10.3390/fib9120088

Chicago/Turabian StyleMurali, Gunasekaran, Nandhu Prasad, Sergey Klyuev, Roman Fediuk, Sallal R. Abid, Mugahed Amran, and Nikolai Vatin. 2021. "Impact Resistance of Functionally Layered Two-Stage Fibrous Concrete" Fibers 9, no. 12: 88. https://doi.org/10.3390/fib9120088

APA StyleMurali, G., Prasad, N., Klyuev, S., Fediuk, R., Abid, S. R., Amran, M., & Vatin, N. (2021). Impact Resistance of Functionally Layered Two-Stage Fibrous Concrete. Fibers, 9(12), 88. https://doi.org/10.3390/fib9120088