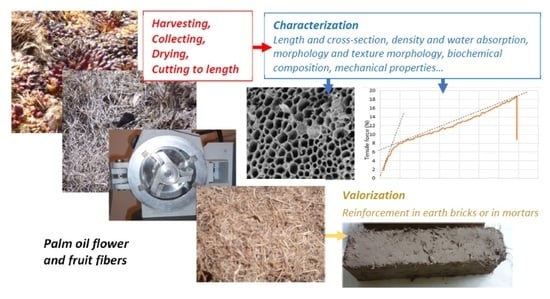

Properties of Mexican Tropical Palm Oil Flower and Fruit Fibers for Their Prospective Use in Eco-Friendly Construction Material

Abstract

1. Introduction

2. Materials and Methods

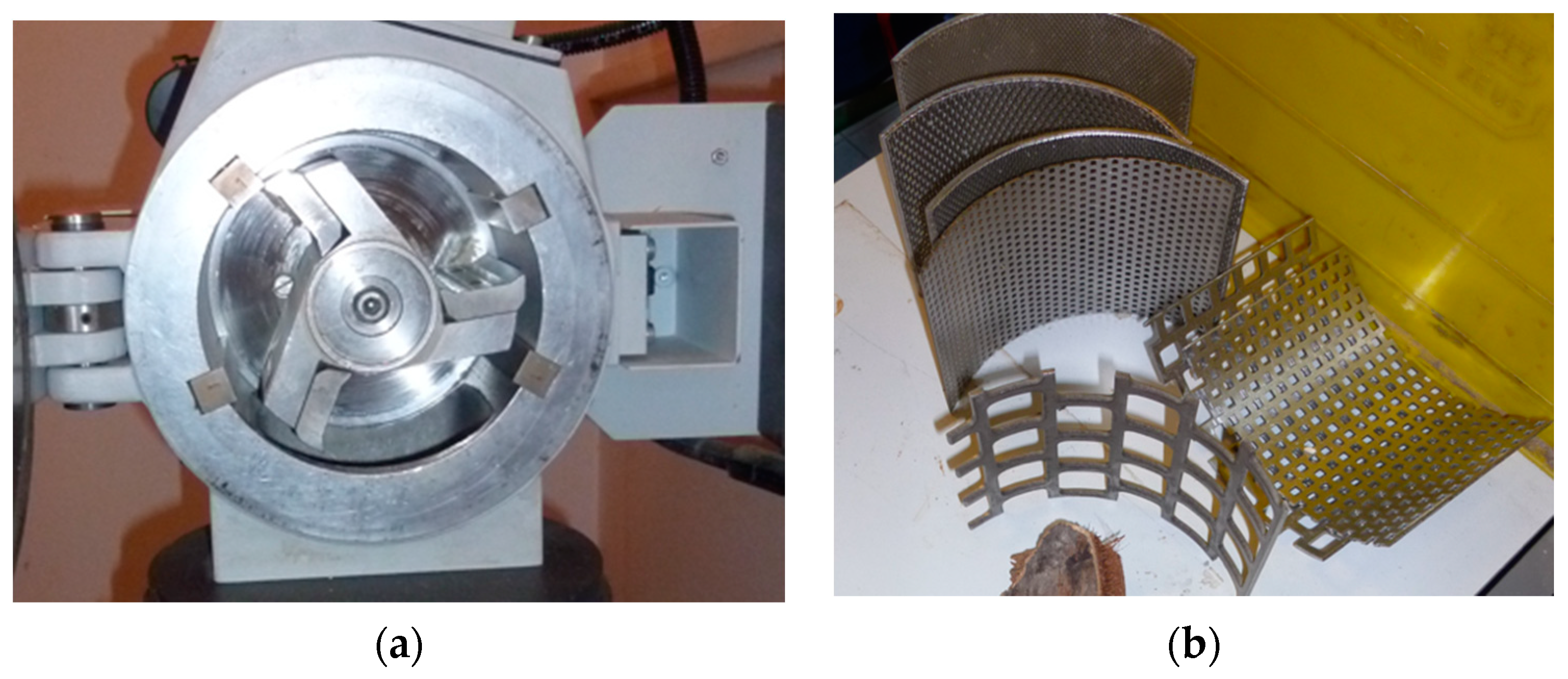

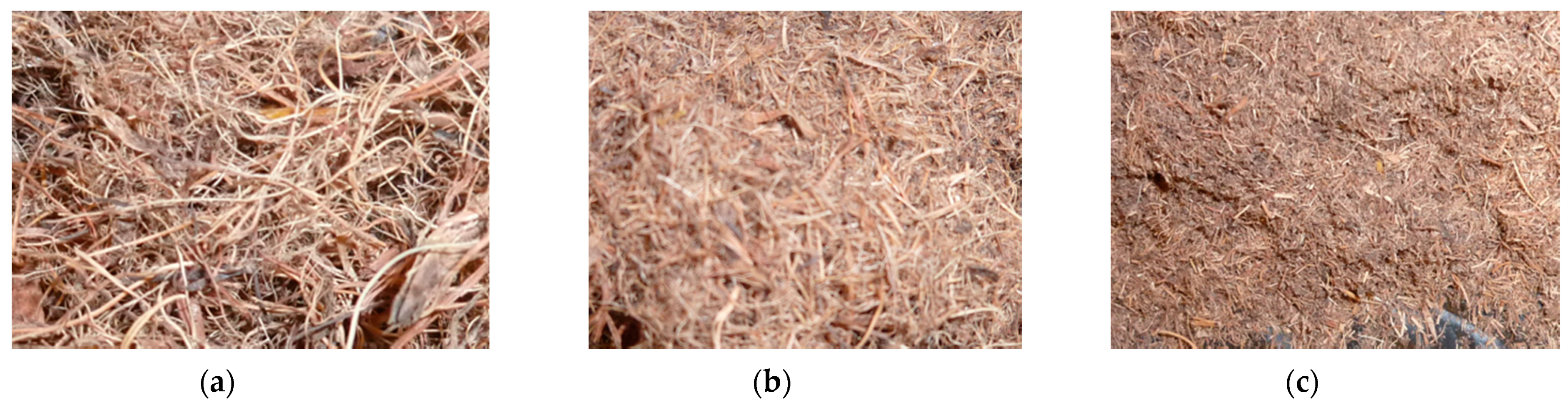

2.1. Palm Oil Fibers Preparation

2.2. Physical, Chemical and Thermal Properties of Fibers

2.3. Mechanical Properties of Fibers

3. Results and Discussion

3.1. Analysis of Fibers Physical Characteristics

3.1.1. Length Distribution of Fibers

3.1.2. Cross-Section of Fibers

3.1.3. Water Absorption of Fibers

3.1.4. Density of Fibers

3.1.5. Morphology of Palm Oil Fibers

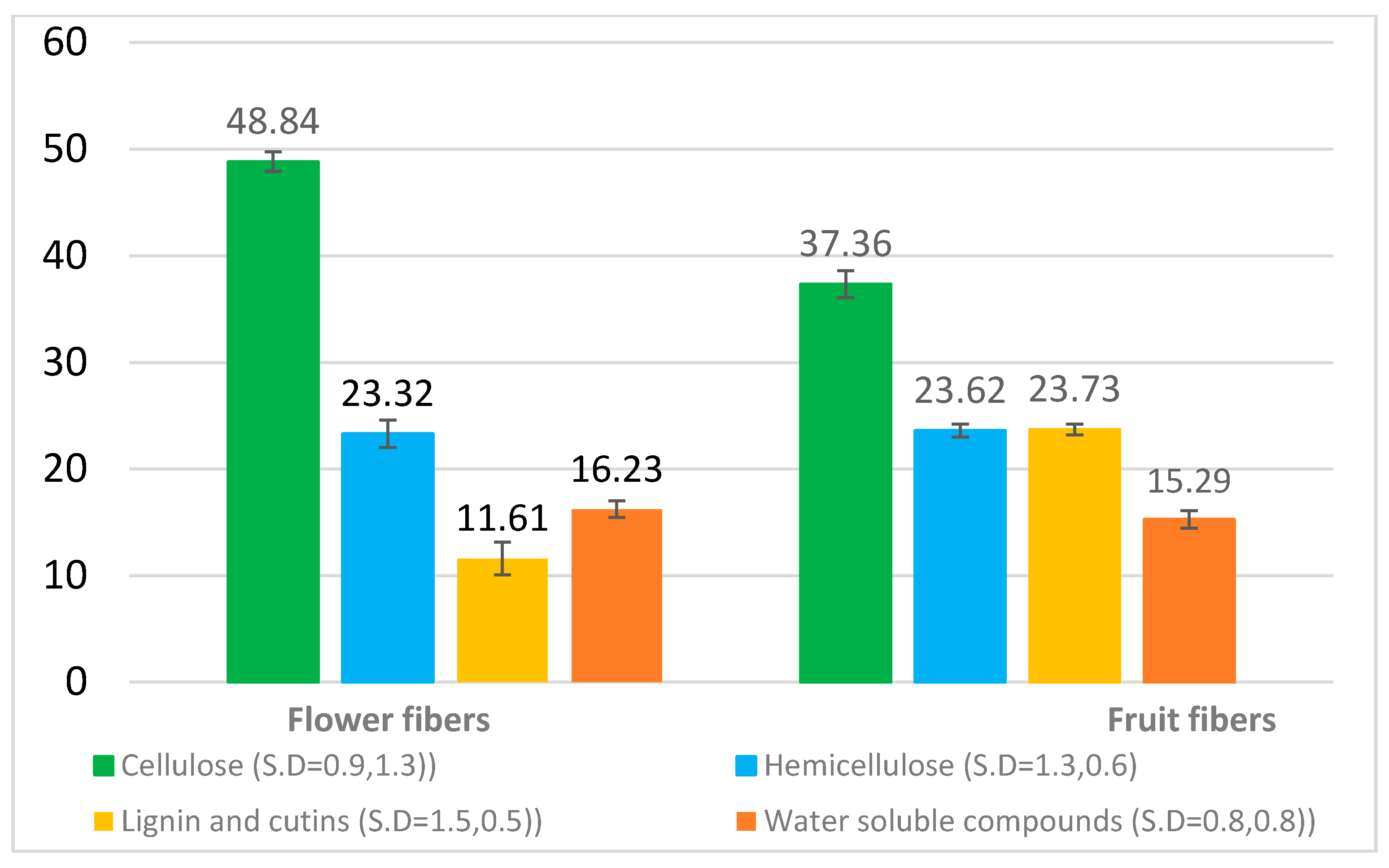

3.2. Chemical Characteristics Analysis

Chemical Composition of Fibers

3.3. Analysis of Fibers Thermal Characteristics

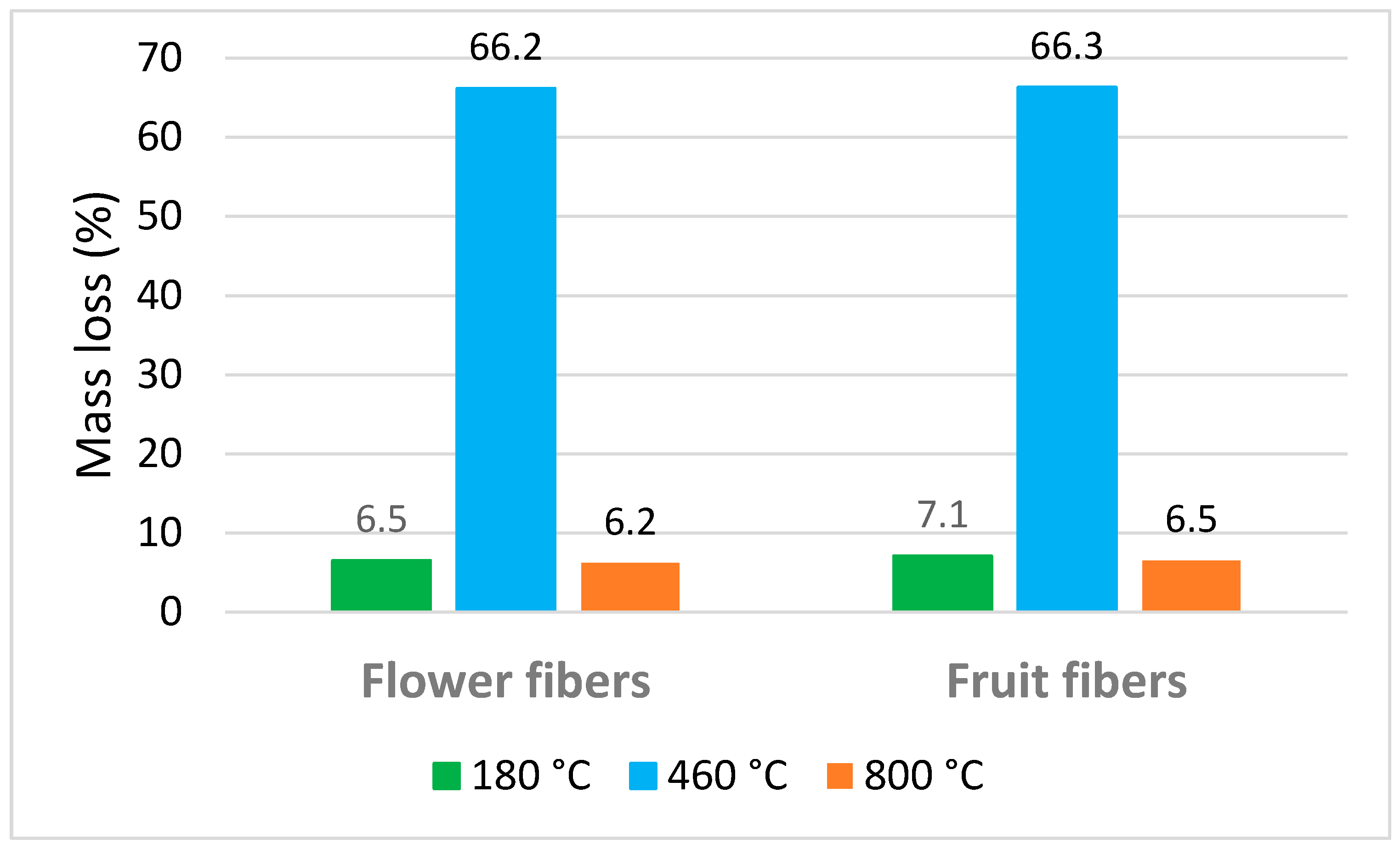

3.3.1. Thermogravimetric Analysis

3.3.2. Thermal Properties of Fibers

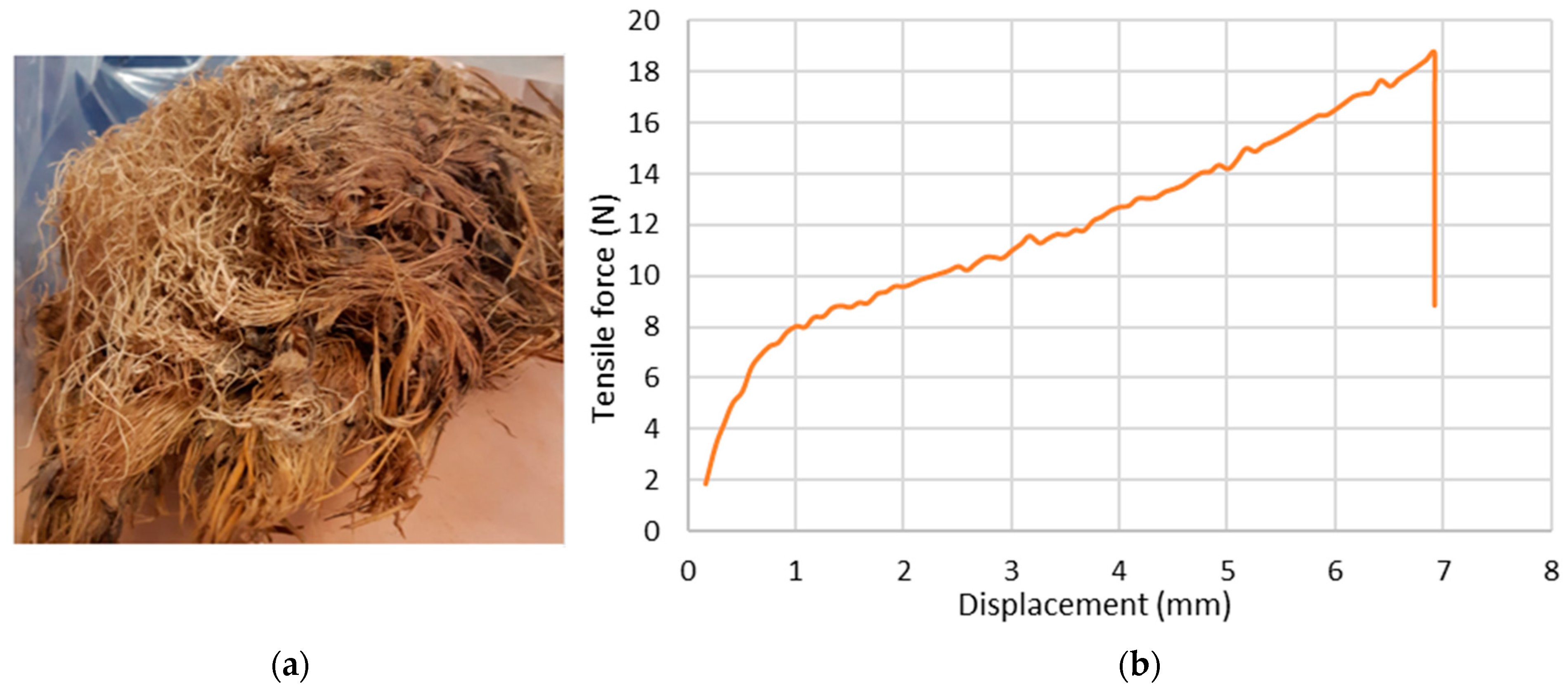

3.4. Analysis of Fibers Mechanical Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dungani, R.; Aditiawati, P.; Aprilia, S.; Yuniarti, K.; Karliati, T.; Suwandhi, I.; Sumardi, I. Biomaterial from Oil Palm Waste: Properties, Characterization and Applications. Palm Oil 2018, 32. [Google Scholar] [CrossRef]

- Sumathi, S.; Chai, S.; Mohamed, A.R. Utilization of oil palm as a source of renewable energy in Malaysia. Renew. Sustain. Energy Rev. 2008, 12, 2404–2421. [Google Scholar] [CrossRef]

- Hasamudin, W.; Soom, R.M. Road-Making Using Oil Palm Fiber (BIT5); Malaysian Palm Oil Board Information Series; Malaysian Palm Oil Board, Ministry of Primary Industries, Malaysia: Kuala Lumpur, Malaysia, 2002; Volume 171, 4p, ISSN 1511-7871. [Google Scholar]

- Liew, W.L.; Muda, K.; Kassim, M.A.; Affam, A.C.; Loh, S.K. Agro-industrial waste sustainable management—A potential source of economic benefits to palm oil mills in malaysia. J. Urban. Environ. Eng. 2017, 11, 108–118. [Google Scholar] [CrossRef]

- Alhijazi, M.; Zeeshan, Q.; Safaei, B.; Asmael, M.; Qin, Z. Recent Developments in Palm Fibers Composites: A Review. J. Polym. Environ. 2020, 28, 3029–3054. [Google Scholar] [CrossRef]

- Kicińska-Jakubowska, A.; Bogacz, E.; Zimniewska, M. Review of Natural Fibers. Part I—Vegetable Fibers. J. Nat. Fibers 2012, 9, 150–167. [Google Scholar] [CrossRef]

- El Azhary, K.; Chihab, Y.; Mansour, M.; Laaroussi, N.; Garoum, M. Energy Efficiency and Thermal Properties of the Composite Material Clay-straw. Energy Procedia 2017, 141, 160–164. [Google Scholar] [CrossRef]

- Hakkoum, S.; Kriker, A.; Mekhermeche, A. Thermal characteristics of Model houses Manufactured by date palm fiber reinforced earth bricks in desert regions of Ouargla Algeria. Energy Procedia 2017, 119, 662–669. [Google Scholar] [CrossRef]

- Purnomo, H.; Priadi, D.; Lumingkewas, H.R.; Lumingkewas, R.H. Strength Improvement of Early Age Unfired Soil Lime Bricks. Adv. Mater. Res. 2013, 689, 299–303. [Google Scholar] [CrossRef]

- Danso, H. Use of Agricultural Waste Fibres as Enhancement of Soil Blocks for Low-Cost Housing in Ghana. Ph.D. Thesis, University of Portsmouth, Portsmouth, NH, USA, 2015; 258p. [Google Scholar]

- ASTM D7357–07. Standard Specification for Cellulose Fibers for Fiber-Reinforced Concrete; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Hussain, M.; Levacher, D.; Leblanc, N.; Zmamou, H.; Djeran Maigre, I.; Razakamanantsoa, A. Influence of palm oil fibers length variation on mechanical properties of reinforced crude bricks. In Proceedings of the 4th International Conference on Bio-Based Building Materials ICBBM 2021, Barcelona, Spain, 16–18 June 2021; pp. 628–633. [Google Scholar]

- Fang, T.W.; Malaysia, M.U.S.; Asyikin, N.S.S.N.; Shawkataly, A.K.H.P.; Kassim, M.H.M.; Syakir, M. Water Absorption and Thickness Swelling of Oil Palm Empty Fruit Bunch (OPEFB) and Seaweed Composite for Soil Erosion Mitigation. J. Phys. Sci. 2017, 28, 1–17. [Google Scholar] [CrossRef]

- Ismail, S.; Yaacob, Z. Properties of laterite brick reinforced with oil palm empty fruit bunch fibres. Pertanika J. Sci. Technol. 2011, 19, 33–43. [Google Scholar]

- Karina, M.; Onggo, H.; Abdullah, A.D.; Syampurwadi, A. Effect of Oil Palm Empty Fruit Bunch Fiber on the Physical and Mechanical Properties of Fiber Glass Reinforced Polyester Resin. J. Biol. Sci. 2007, 8, 101–106. [Google Scholar] [CrossRef]

- Bledzki, A. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Defoirdt, N.; Biswas, S.; De Vriese, L.; Tran, L.Q.N.; Van Acker, J.; Ahsan, Q.; Gorbatikh, L.; Van Vuure, A.; Verpoest, I. Assessment of the tensile properties of coir, bamboo and jute fibre. Compos. Part A Appl. Sci. Manuf. 2010, 41, 588–595. [Google Scholar] [CrossRef]

- Levacher, D.; Saouti, L. Determination of Some Physical and Mechanical Properties of Mexican Natural Fibers, ANR-CONACYT: VAL-USES Project 2018–2020, Task 4: Characteristics, Future Uses and Valorization of Sediments 2020. Available online: https://imu.universite-lyon.fr/international/mexique/depot-du-projet-anr-conacyt-val-uses/ (accessed on 22 October 2021).

- Khennache, M.; Mahieu, A.; Ragoubi, M.; Taibi, S.; Poilane, C.; Leblanc, N. Physicochemical and Mechanical Performances of Technical Flax Fibers and Biobased Composite Material: Effects of Flax Transformation Process. J. Renew. Mater. 2019, 7, 821–838. [Google Scholar] [CrossRef]

- Fidelis, M.E.A.; Pereira, T.V.C.; Gomes, O.D.F.M.; Silva, F.D.A.; Filho, R.D.T. The effect of fiber morphology on the tensile strength of natural fibers. J. Mater. Res. Technol. 2013, 2, 149–157. [Google Scholar] [CrossRef]

- Ramlee, N.A.; Jawaid, M.; Zainudin, E.S.; Yamani, S.A.K. Tensile, physical and morphological properties of oil palm empty fruit bunch/sugarcane bagasse fibre reinforced phenolic hybrid composites. J. Mater. Res. Technol. 2019, 8, 3466–3474. [Google Scholar] [CrossRef]

- Barrera, I.; Allieri, M.A.; Estupiñan, L.; Martínez, T.; Aburto, J. Technical and economical evaluation of bioethanol production from lignocellulosic residues in Mexico: Case of sugarcane and blue agave bagasses. Chem. Eng. Res. Des. 2016, 107, 91–101. [Google Scholar] [CrossRef]

- Bhatnagar, R.; Gupta, G.; Yadav, S. A review on composition and properties of banana fibers. Int. J. Sci. Eng. Res. 2015, 6, 49–52. [Google Scholar]

- Chaib, H.; Kriker, A.; Mekhermeche, A. Thermal Study of Earth Bricks Reinforced by Date palm Fibers. Energy Procedia 2015, 74, 919–925. [Google Scholar] [CrossRef]

- Rao, P.R.; Ramakrishna, G. Experimental Investigation on Mechanical Properties of Oil Palm Empty Fruit Bunch Fiber Reinforced Cement Mortar. Mater. Today Proc. 2021, 46, 471–477. [Google Scholar] [CrossRef]

- Salih, M.M.; Imbabi, M.S.; Osofero, A.I. Mechanical properties of fibre-reinforced mud bricks. In Proceedings of the 2nd Conference Civil Engineering, Khartoum, Sudan, 3–5 December 2018; 8pAvailable online: https://www.researchgate.net/publication/329786369 (accessed on 28 June 2021).

- Bui, H.; Sebaibi, N.; Boutouil, M.; Levacher, D. Determination and Review of Physical and Mechanical Properties of Raw and Treated Coconut Fibers for Their Recycling in Construction Materials. Fibers 2020, 8, 37. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Degradation mechanisms of natural fiber in the matrix of cement composites. Cem. Concr. Res. 2015, 73, 1–16. [Google Scholar] [CrossRef]

- Subramanian, G.K.M.; Balasubramanian, M.; Kumar, A.A.J. A Review on the Mechanical Properties of Natural Fiber Reinforced Compressed Earth Blocks. J. Nat. Fibers 2021, 1–15. [Google Scholar] [CrossRef]

- Bui, H.; Boutouil, M.; Sebaibi, N.; Levacher, D. Effect of coconut fibres content on the mechanical properties of mortars. In Proceedings of the 3rd International Conference on Bio-Based Building Materials, Belfast, UK, 26–28 June 2019. [Google Scholar]

- Salih, M.M.; Osofero, A.I.; Imbabi, M.S. Critical review of recent development in fiber reinforced adobe bricks for sustainable construction. Front. Struct. Civ. Eng. 2020, 14, 839–854. [Google Scholar] [CrossRef]

- Mostafa, M.; Uddin, N. Effect of Banana Fibers on the Compressive and Flexural Strength of Compressed Earth Blocks. Buildings 2015, 5, 282–296. [Google Scholar] [CrossRef]

- Bergström, S.G.; Gram, H.-E. Durability of alkali-sensitive fibres in concrete. Int. J. Cem. Compos. Light. Concr. 1984, 6, 75–80. [Google Scholar] [CrossRef]

- Campos, A.; Neto, A.S.; Rodrigues, V.; Luchesi, B.; Mattoso, L.; Marconcini, J. Effect of raw and chemically treated oil palm mesocarp fibers on thermoplastic cassava starch properties. Ind. Crop. Prod. 2018, 124, 149–154. [Google Scholar] [CrossRef]

- Then, Y.Y.; Ibrahim, N.A.; Zainuddin, N.; Hidayah, A.; Wan Yunus, W.M.Z.; Chieng, B.W. Static mechanical, interfacial, and water absorption behaviors of alkali treated oil palm mesocarp fiber reinforced poly (butylene succinate). BioResources 2015, 10, 123–136. [Google Scholar] [CrossRef]

- USDA. United States Department of Agriculture, Foreign Agricultural Service 2021. Available online: https://ipad.fas.usda.gov/cropexplorer/cropview/commodityView.aspx?startrow=1&cropid=4243000&sel_year=2021&rankby=Production (accessed on 28 June 2021).

- Van Soest, P.J.; Robertson, J.B. Analysis of Forages and Fibrous Foods, a Laboratory Manual for Animal Science 1985; Cornell University: Ithaca, NY, USA, 1985; 202p. [Google Scholar]

- Sreekala, M.S.; Kumaran, M.G.; Thomas, S. Oil palm fibers: Morphology, chemical composition, surface modification, and mechanical properties. J. Appl. Polym. Sci. 1997, 66, 821–835. [Google Scholar] [CrossRef]

- Xu, J.; Yao, J.; Zeng, C.; Zhang, L.; Xu, N. Preparation of binderless honeycomb silicalite-1 monolith by using bundled palm fibers as template. J. Porous Mater. 2009, 17, 329–334. [Google Scholar] [CrossRef]

- ASTM C1557-03. Standard Test Methods for Tensile Strength and Young’s Modulus of Fibers; American Society for Testing and Analysis: West Conshohocken, PA, USA, 2003. [Google Scholar]

- Petroudy, S.D. Physical and mechanical properties of natural fibers. In Advanced High Strength Natural Fibre Composites in Construction; Elsevier BV: Amsterdam, The Netherlands, 2017; pp. 59–83. [Google Scholar]

- Indran, S.; Raj, R.E. Characterization of new natural cellulosic fiber from Cissus quadrangularis stem. Carbohydr. Polym. 2015, 117, 392–399. [Google Scholar] [CrossRef] [PubMed]

| Grid Size | Average Length (mm) | Maximum Length (mm) |

|---|---|---|

| 2 cm | 9.48 | 24.05 |

| 3 cm | 11.5 | 32.96 |

| Method | POFL Area (mm2) | POFR Area (mm2) |

|---|---|---|

| Microscopic analysis | 0.070 | 0.027 |

| Fiber Type | Water Absorption (%) |

|---|---|

| Palm oil flower POFL | 235 |

| Palm oil fruit POFR | 258 |

| Fiber Type | Measured Density (g/cm3) | Literature Density (g/cm3) | References |

|---|---|---|---|

| Palm oil flower POFL | 1.37 | 1.15−1.40 | Fang et al., 2017 Karina et al., 2008 |

| Palm oil fruit POFR | 1.36 |

| Reference | Type of Fiber | Cellulose (%) | Hemicellulose (%) | Lignin (%) | Ash (%) |

|---|---|---|---|---|---|

| [13] | OPEFB | 59 | 2.1 | 25 | 3.2 |

| [20] | OPEFB | 49.44 | 23.19 | 12.56 | - |

| [36] | OPEFB | 65 | - | 19 | 2 |

| Type of Fiber | Thermal Conductivity (W/mK) | Thermal Resistivity (m2K/W) |

|---|---|---|

| POFL fiber | 0.058 | 0.80 |

| POFR fiber | 0.055 | 0.84 |

| Type of Fiber | σmax. (MPa) | σmin. (MPa) | σaverage (MPa) | Et1 (GPa) | Et2 (GPa) |

|---|---|---|---|---|---|

| POFL | 181.33 | 31.72 | 104.33 | 1.3 | 0.38 |

| POFR | 117.64 | 49.09 | 85.00 | 3 | 0.72 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, M.; Levacher, D.; Leblanc, N.; Zmamou, H.; Djeran-Maigre, I.; Razakamanantsoa, A.; Saouti, L. Properties of Mexican Tropical Palm Oil Flower and Fruit Fibers for Their Prospective Use in Eco-Friendly Construction Material. Fibers 2021, 9, 63. https://doi.org/10.3390/fib9110063

Hussain M, Levacher D, Leblanc N, Zmamou H, Djeran-Maigre I, Razakamanantsoa A, Saouti L. Properties of Mexican Tropical Palm Oil Flower and Fruit Fibers for Their Prospective Use in Eco-Friendly Construction Material. Fibers. 2021; 9(11):63. https://doi.org/10.3390/fib9110063

Chicago/Turabian StyleHussain, Mazhar, Daniel Levacher, Nathalie Leblanc, Hafida Zmamou, Irini Djeran-Maigre, Andry Razakamanantsoa, and Léo Saouti. 2021. "Properties of Mexican Tropical Palm Oil Flower and Fruit Fibers for Their Prospective Use in Eco-Friendly Construction Material" Fibers 9, no. 11: 63. https://doi.org/10.3390/fib9110063

APA StyleHussain, M., Levacher, D., Leblanc, N., Zmamou, H., Djeran-Maigre, I., Razakamanantsoa, A., & Saouti, L. (2021). Properties of Mexican Tropical Palm Oil Flower and Fruit Fibers for Their Prospective Use in Eco-Friendly Construction Material. Fibers, 9(11), 63. https://doi.org/10.3390/fib9110063