Kinetics of Cellulose Deposition in Developing Cotton Fibers Studied by Thermogravimetric Analysis

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

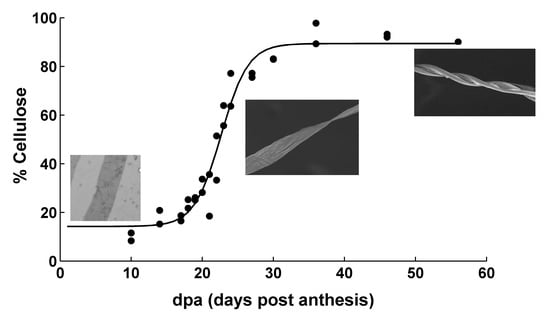

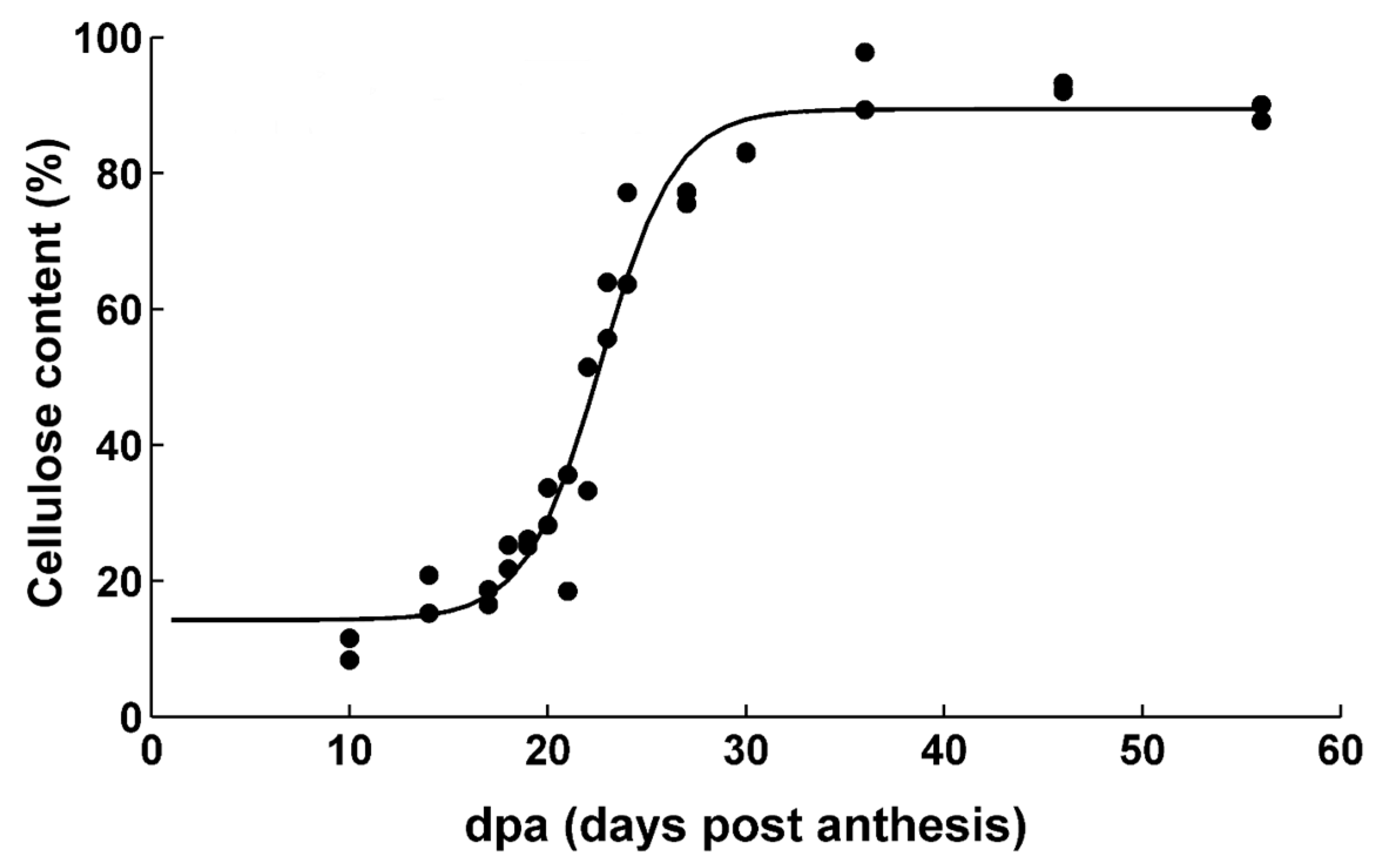

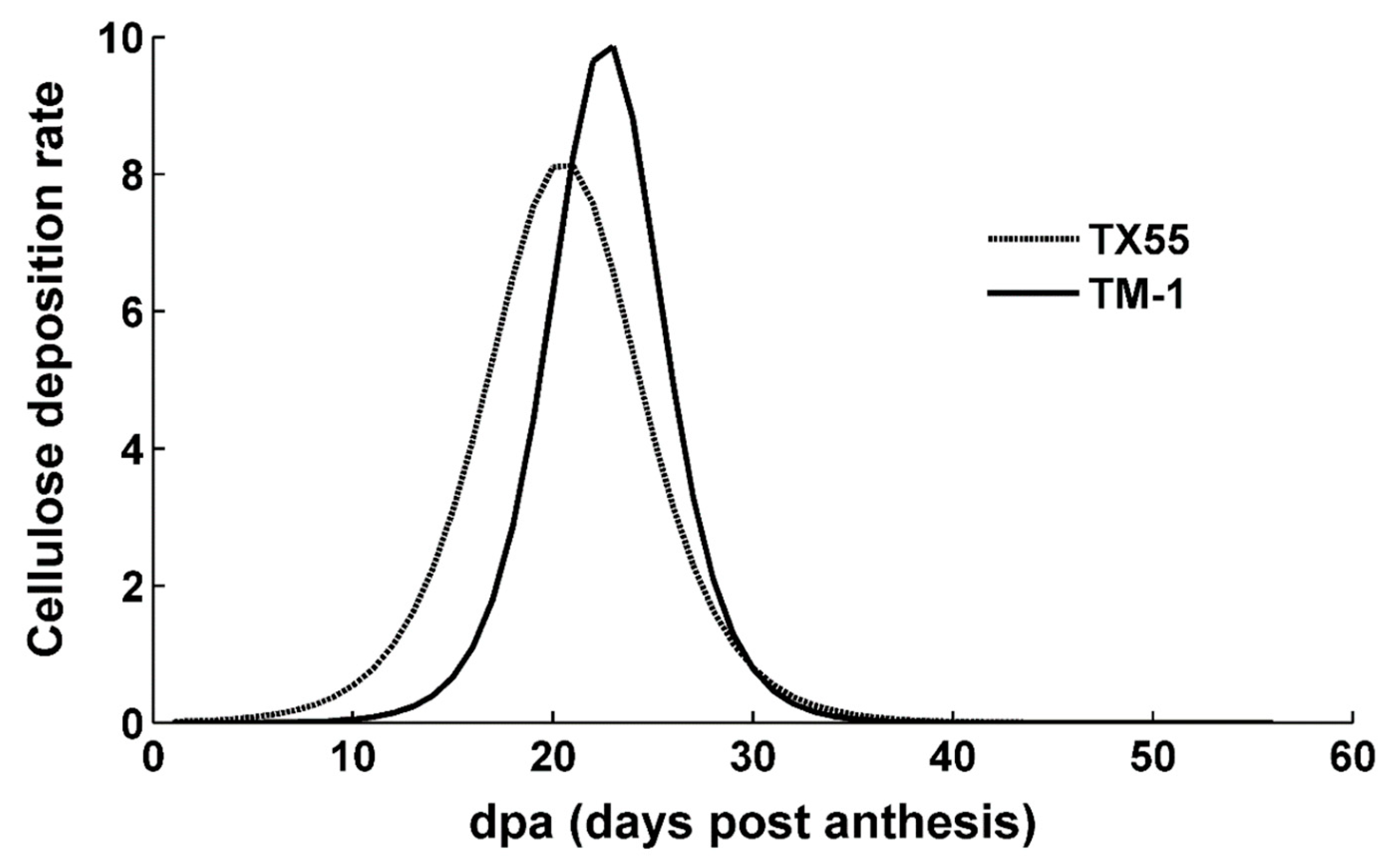

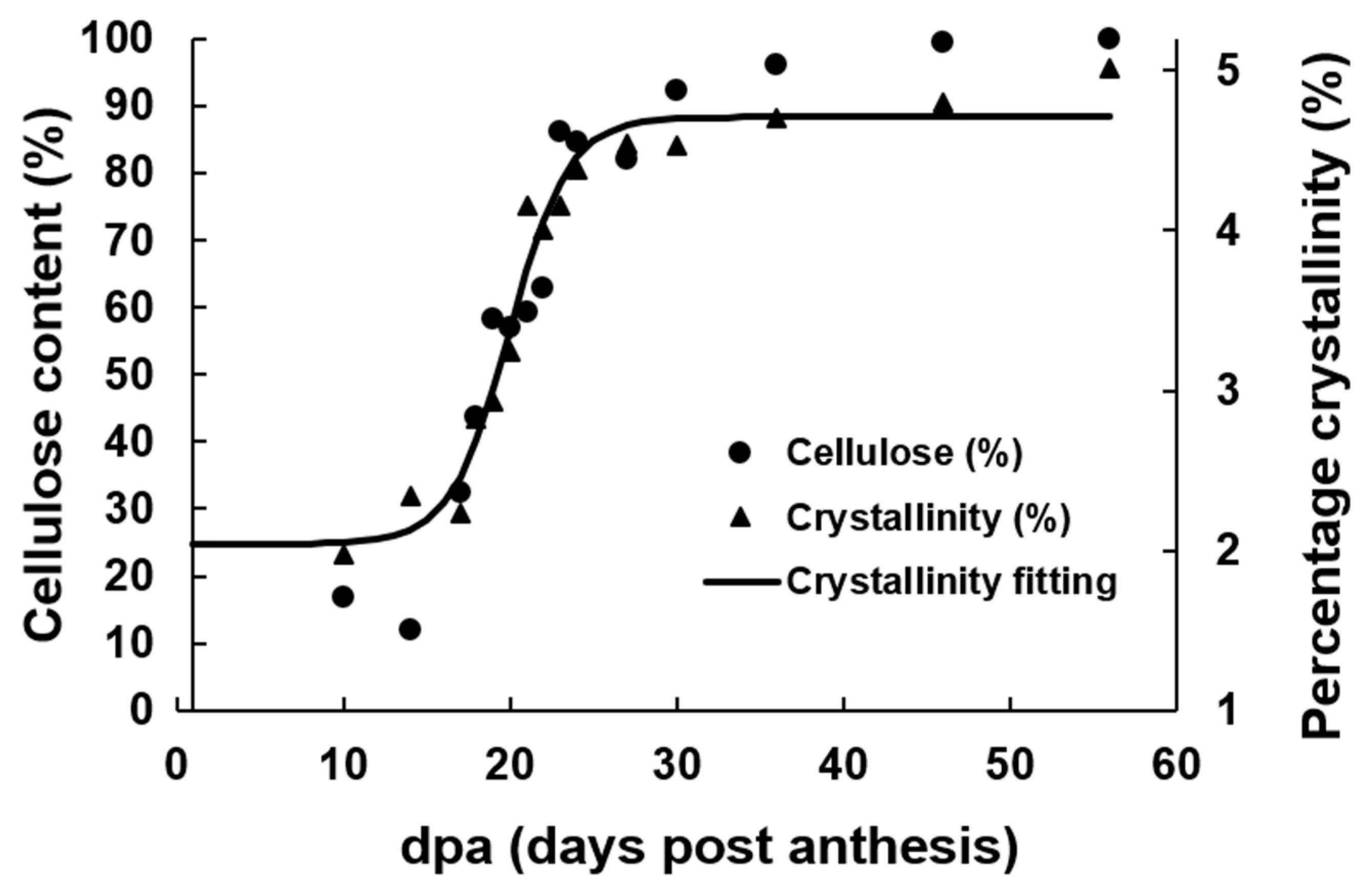

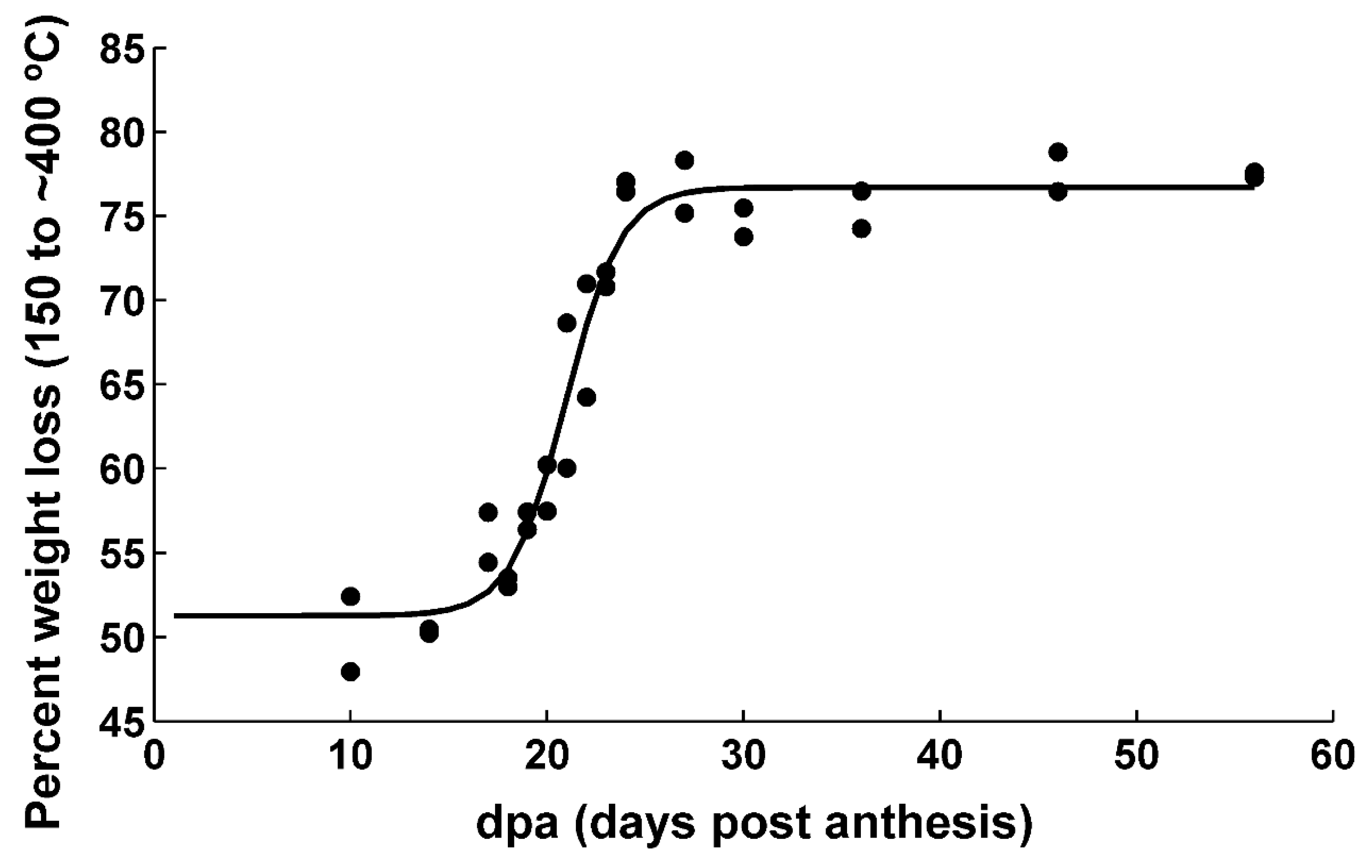

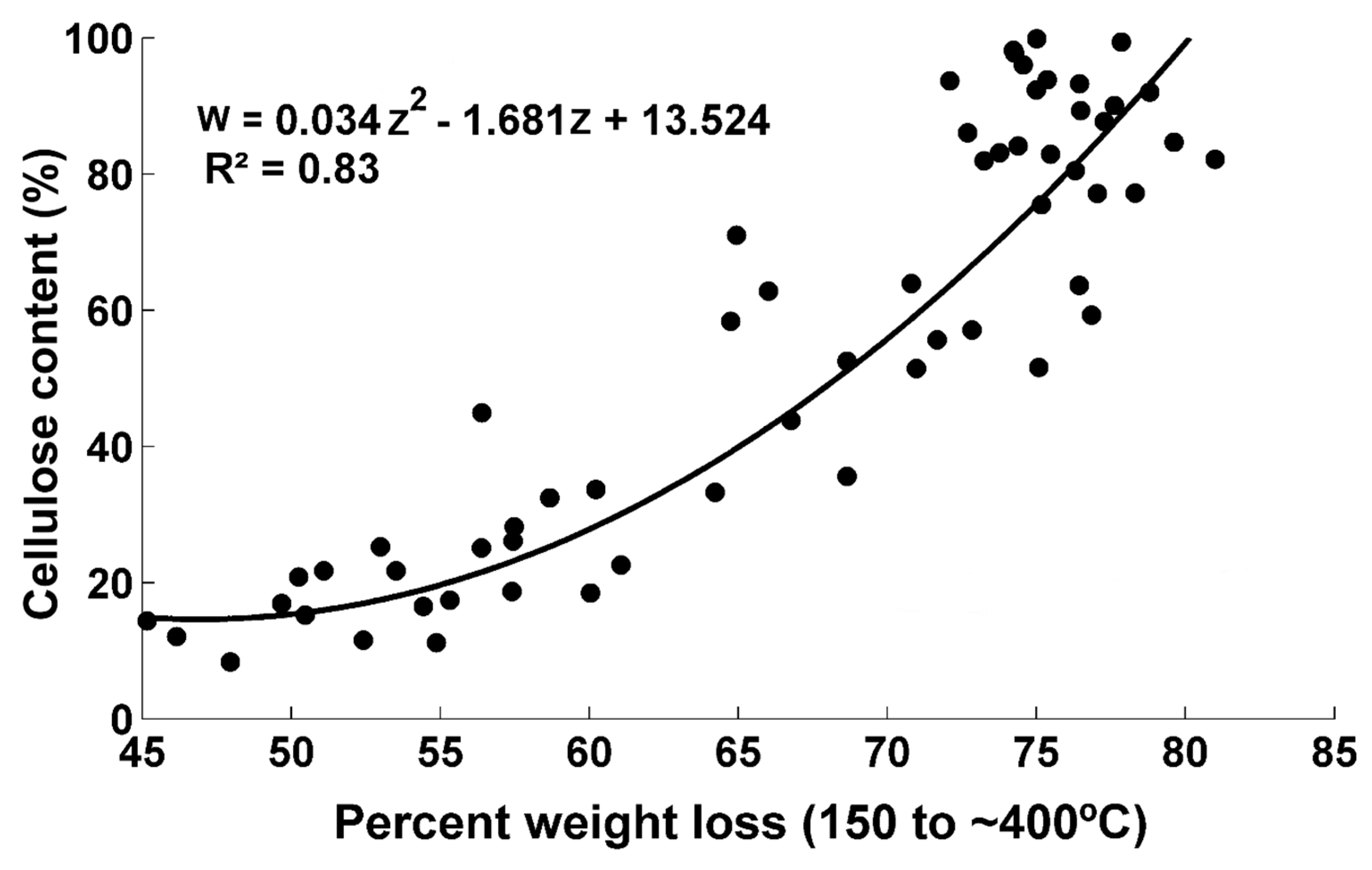

3.1. Cellulose Content

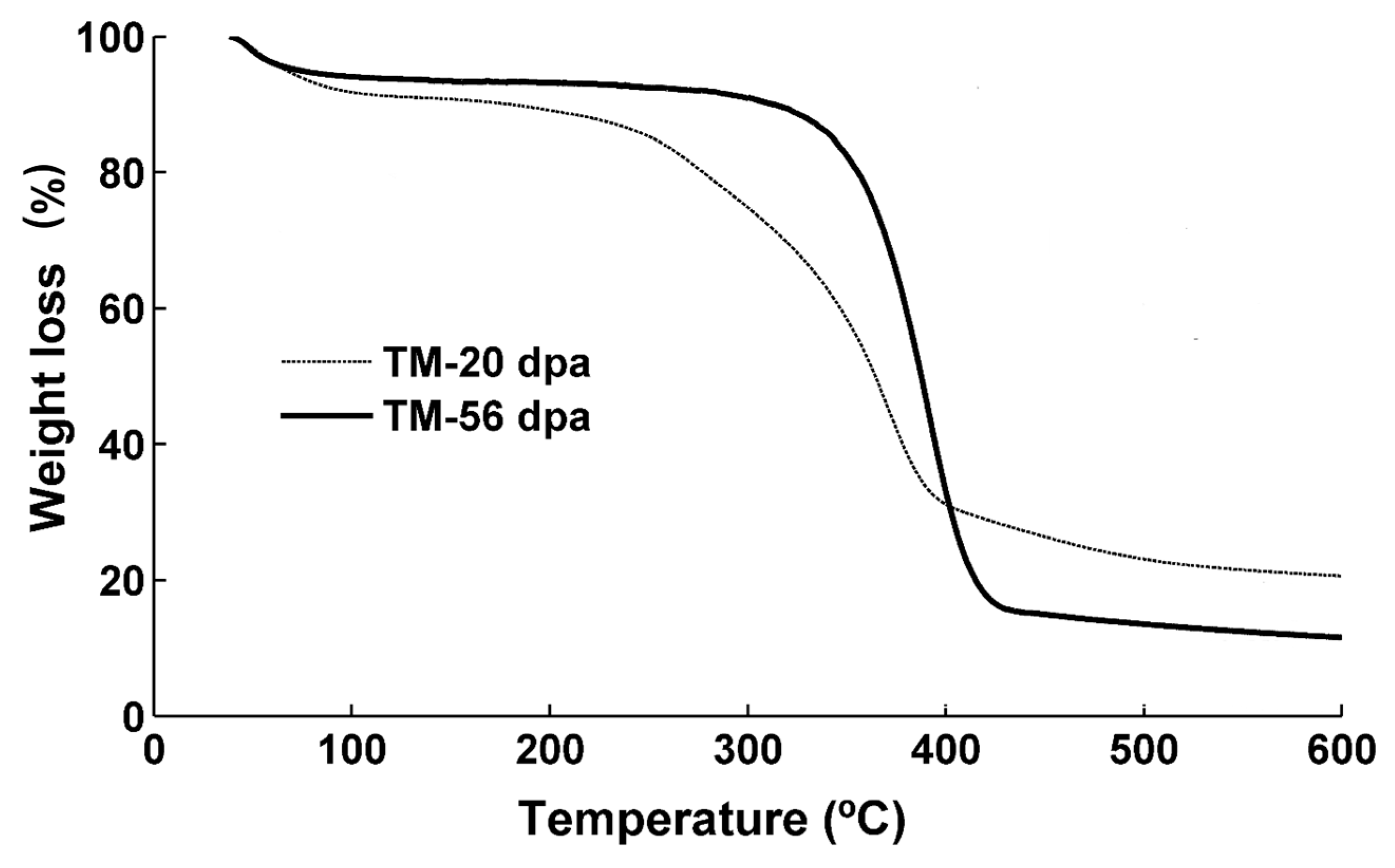

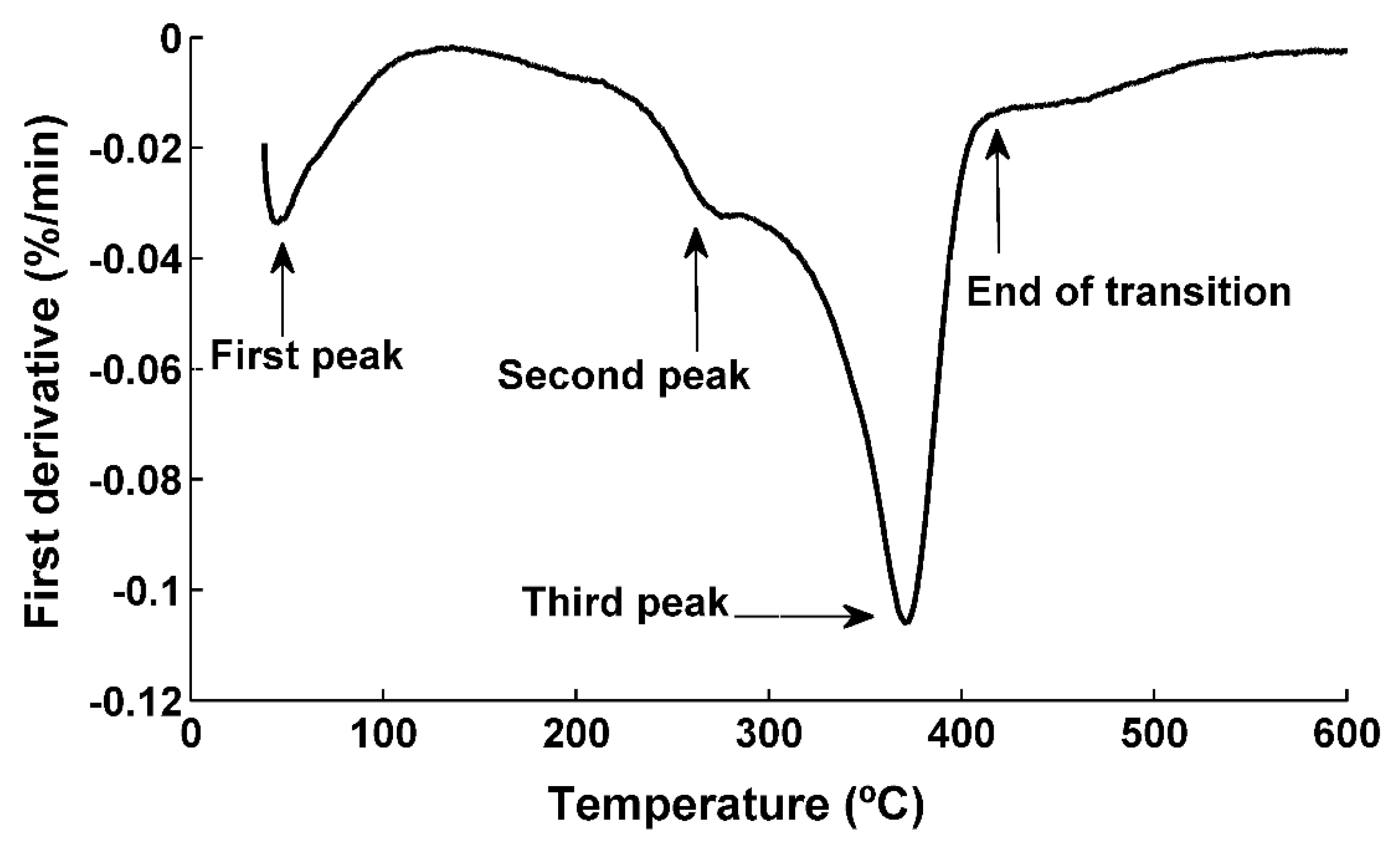

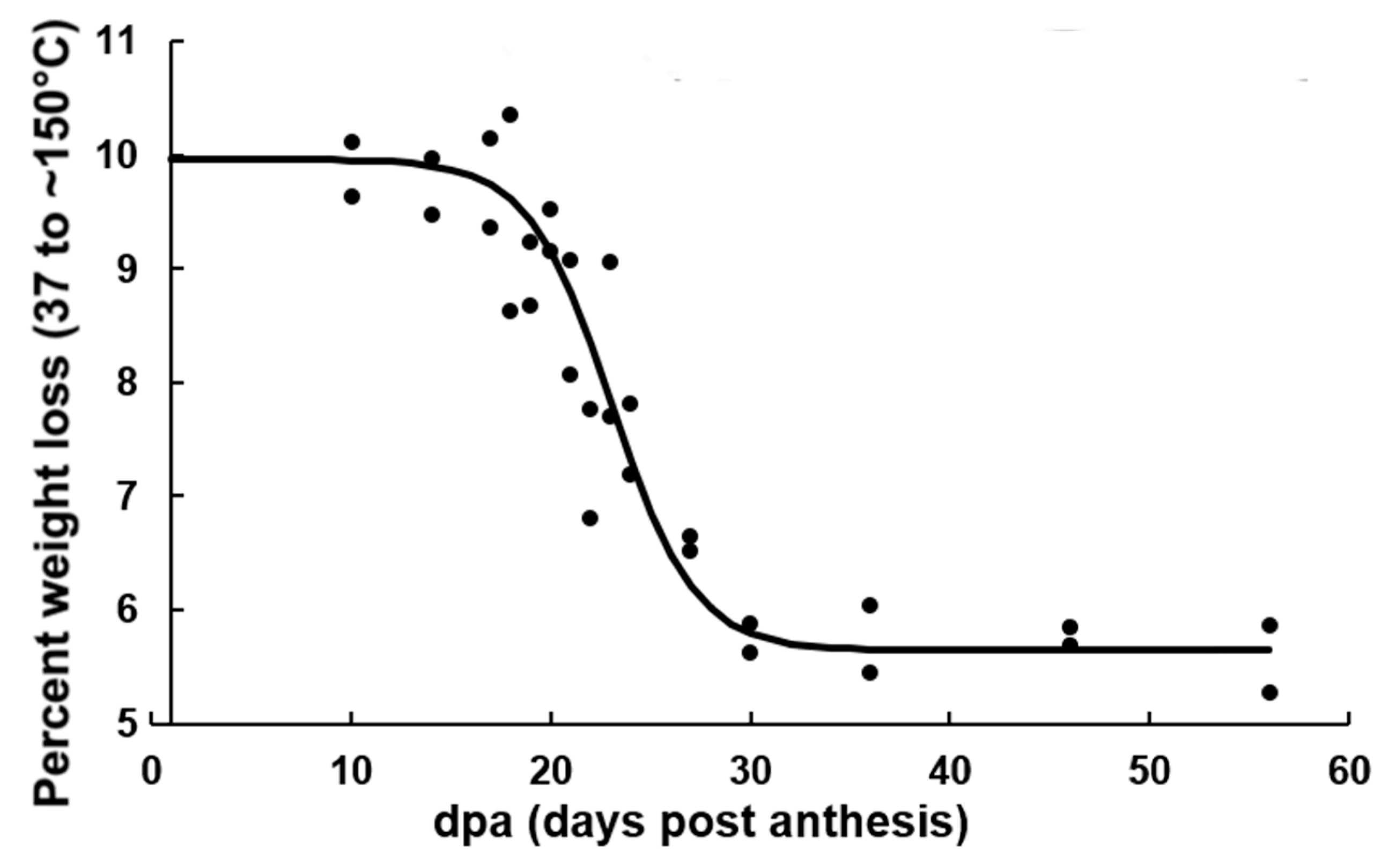

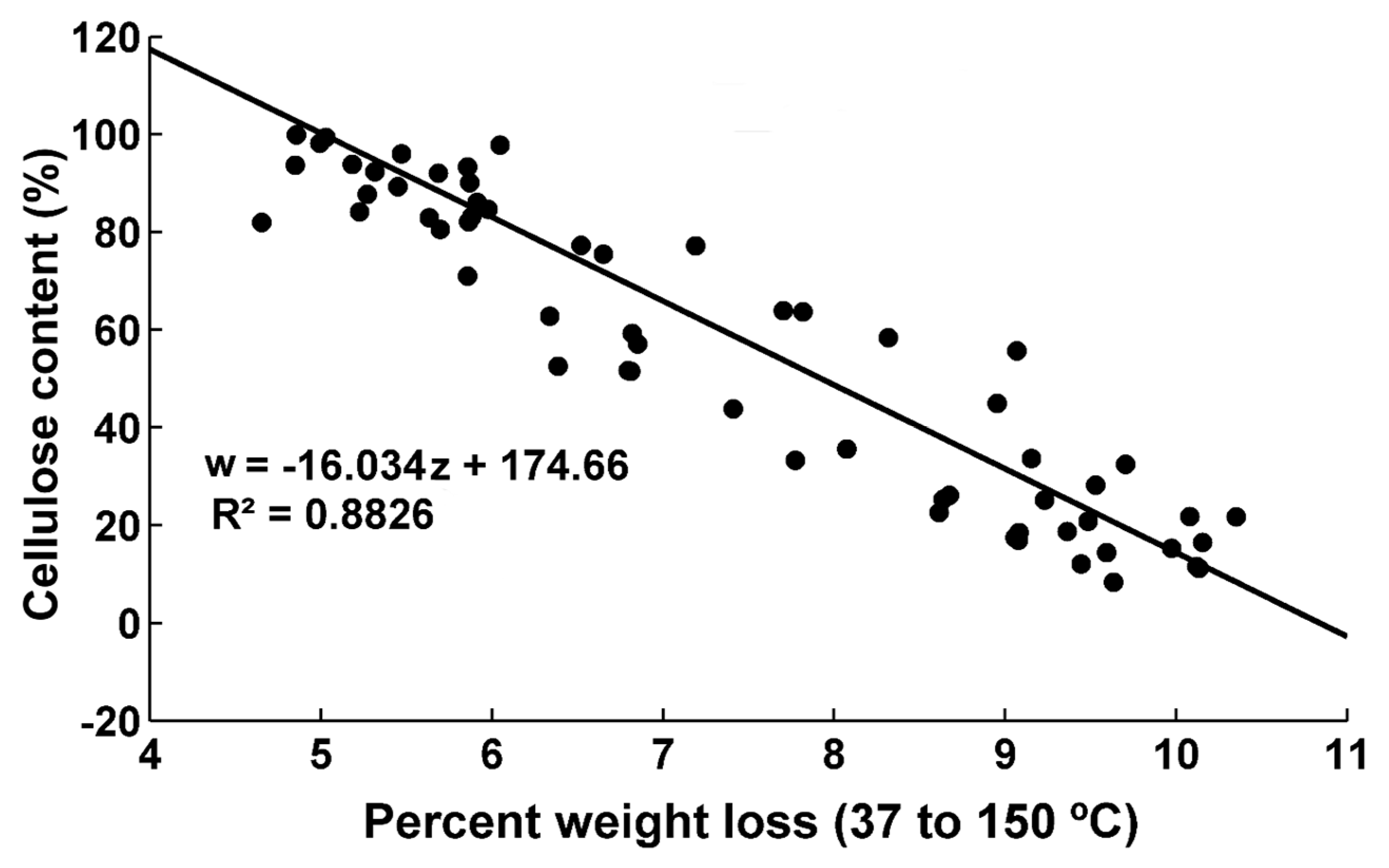

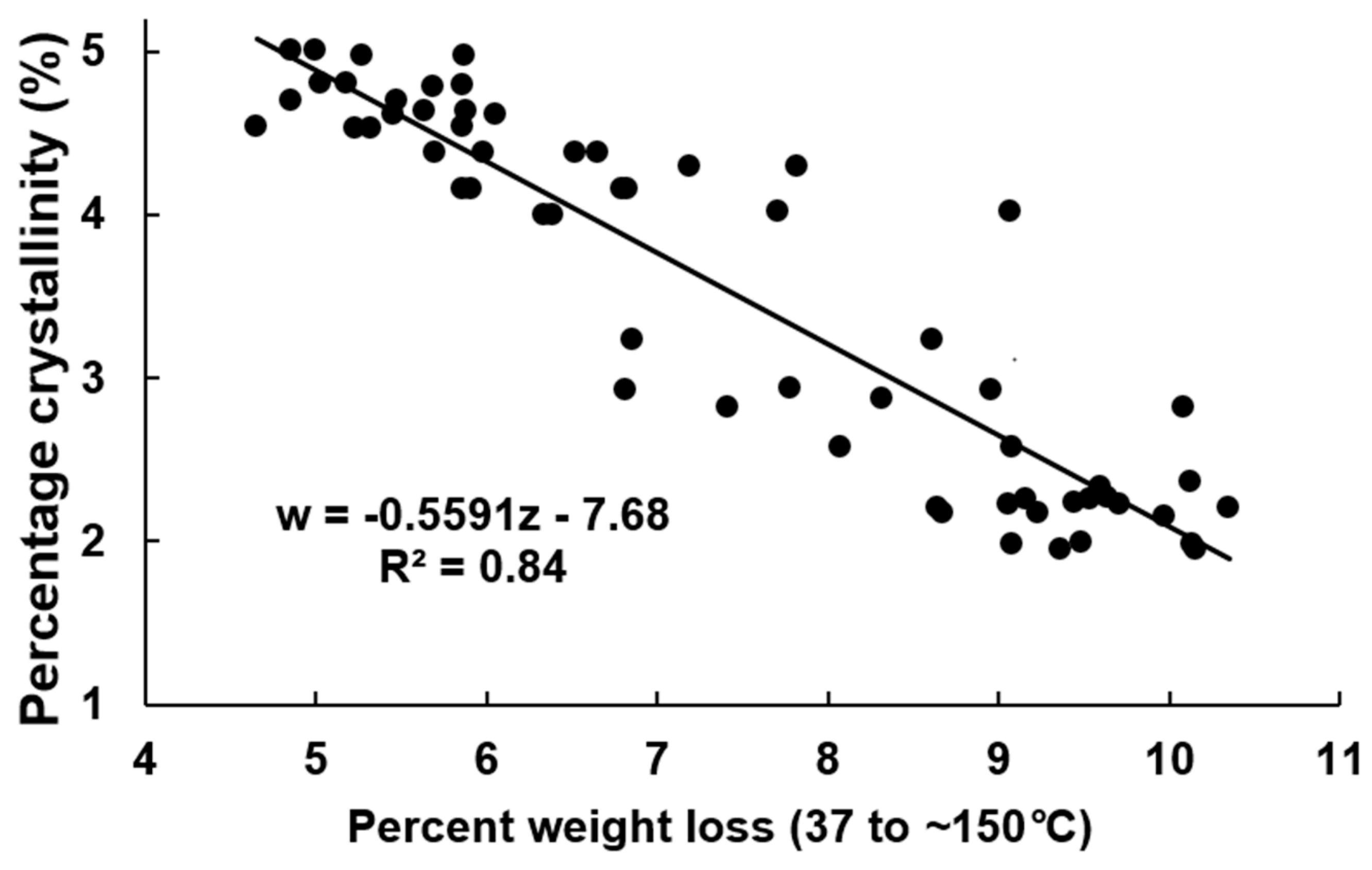

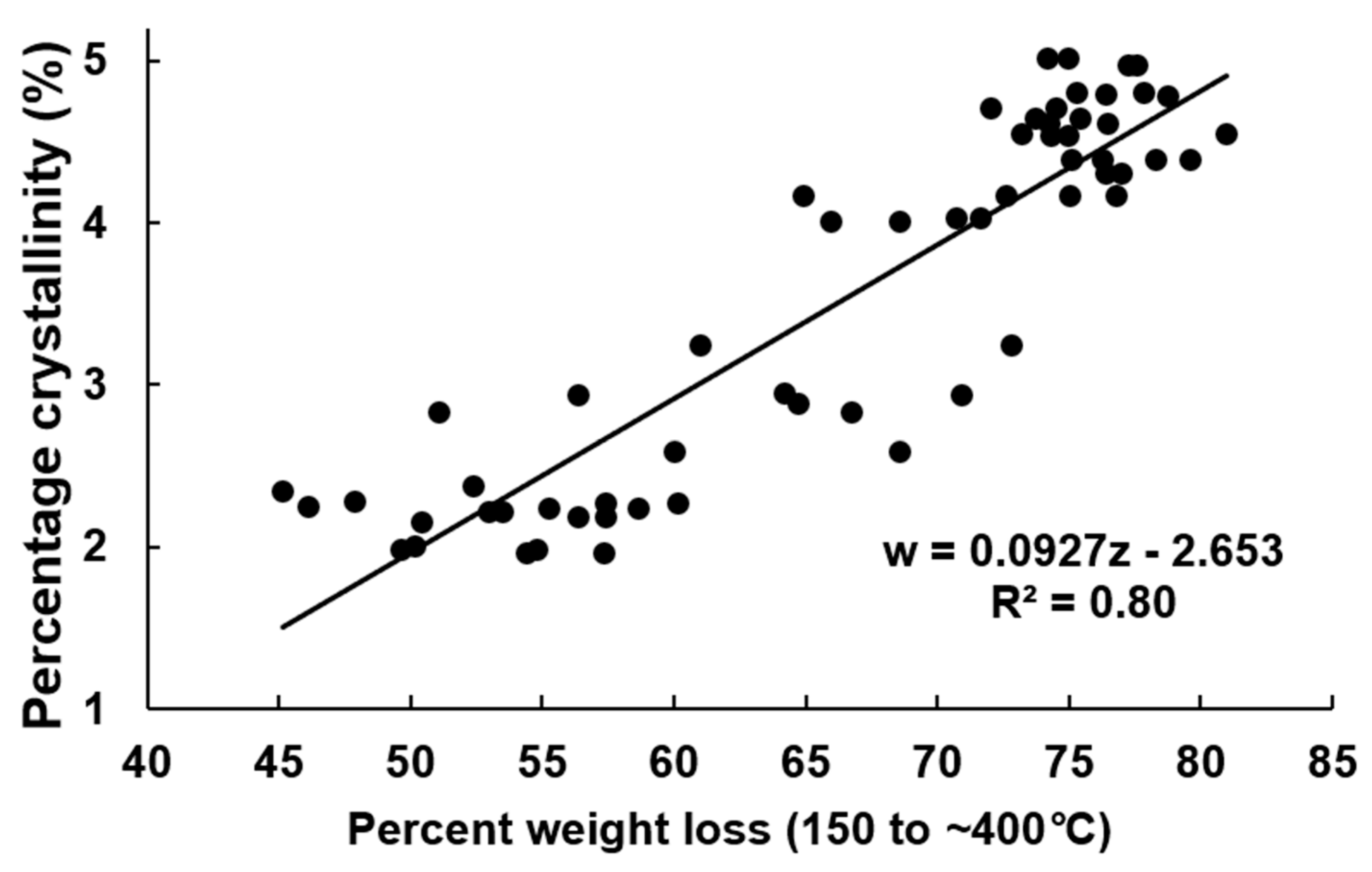

3.2. Thermogravimetric Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Basra, A. Cotton Fibers: Developmental Biology, Quality Improvement, and Textile Processing; Food Products Press; The Haworth Press: Binghamton, NY, USA, 1999. [Google Scholar]

- Hsieh, Y.L. Chapter 6: Structural Development of Cotton Fibers and Linkages to Fiber Quality. In Cotton Fibers: Developmental Biology, Quality Improvement, and Textile Processing; Basra, A., Ed.; Food Products Press; The Haworth Press: Binghamton, NY, USA, 1999; pp. 137–166. [Google Scholar]

- Xu, Y.; Li, H.B.; Zhu, Y.X. Molecular Biological and Biochemical Studies Reveal New Pathways Important for Cotton Fiber Development. J. Integr. Plant Biol. 2007, 49, 69–74. [Google Scholar] [CrossRef]

- Abidi, N.; Hequet, E.; Cabrales, L.; Gannaway, J.; Wilkins, T.; Wells, L.W. Evaluating cell wall structure and composition of developing cotton fibers using Fourier transform infrared spectroscopy and thermogravimetric analysis. J. Appl. Polym. Sci. 2008, 107, 476–486. [Google Scholar] [CrossRef]

- Haigler, C.H. Physiological and Anatomical Factors Determining Fiber Structure and Utility. In Physiology of Cotton; Stewart, J.M., Oosterhuis, D.M., Heitholt, J.J., Mauney, J.R., Eds.; Springer: Dordrecht, The Netherlands, 2010. [Google Scholar]

- Heyn, A.N.J. The microcrystalline structure of cellulose in cell walls of cotton, ramie, and jute fibers as revealed by negative staining of sections. J. Cell Biol. 1966, 29, 181–197. [Google Scholar] [CrossRef] [PubMed]

- Muhlethaler, K. Ultrastructure and Formation of Plant Cell Walls. Annu. Rev. Plant Physiol. 1967, 18, 1–24. [Google Scholar] [CrossRef]

- Paralikar, K.M. Electron diffraction studies of cotton fibers from bolls during early stages of development. J. Polym. Sci. Part C Polym. Lett. 1986, 24, 419–421. [Google Scholar] [CrossRef]

- Hu, X.P.; Hsieh, Y.L. Crystalline structure of developing cotton fibers. J. Polym. Sci. Part B Polym. Phys. 1996, 34, 1451–1459. [Google Scholar] [CrossRef]

- Hsieh, Y.L.; Hu, X.P.; Nguyen, A. Strength and Crystalline Structure of Developing Acala Cotton. Text. Res. J. 1997, 67, 529–536. [Google Scholar] [CrossRef]

- Mihranyan, A.; Llagostera, A.P.; Karmhag, R.; Strømme, M.; Ek, R. Moisture sorption by cellulose powders of varying crystallinity. Int. J. Pharm. 2004, 269, 433–442. [Google Scholar] [CrossRef]

- Ling, Z.; Wang, T.; Makarem, M.; Cintrón, M.S.; Cheng, H.N.; Kang, X.; Bacher, M.; Potthast, A.; Rosenau, T.; King, H.; et al. Effects of ball milling on the structure of cotton cellulose. Cellulose 2019, 26, 305–328. [Google Scholar] [CrossRef]

- Avolio, R.; Bonadies, I.; Capitani, D.; Errico, M.E.; Gentile, G.; Avella, M. A multitechnique approach to assess the effect of ball milling on cellulose. Carbohydr. Polym. 2012, 87, 265–273. [Google Scholar] [CrossRef]

- Huwyler, H.R.; Franz, G.; Meier, H. Changes in the composition of cotton fibre cell walls during development. Planta 1979, 146, 635–642. [Google Scholar] [CrossRef] [PubMed]

- Timpa, J.D.; Triplett, B.A. Analysis of cell-wall polymers during cotton fiber development. Planta 1993, 189, 101–108. [Google Scholar] [CrossRef]

- Hoson, T.; Tokumoto, H.; Wakabayashi, K.; Kamisaka, S. Changes in the Sugar Composition and Molecular Mass Distribution of Matrix Polysaccharides during Cotton Fiber Development. Plant Cell Physiol. 2002, 43, 411–418. [Google Scholar]

- Thomasson, J.A.; Manickavasagam, S.; Mengüç, M.P. Cotton fiber quality characterization with light scattering and fourier transform infrared techniques. Appl. Spectrosc. 2009, 63, 321–330. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y. Recent Progress in Fourier Transform Infrared (FTIR) Spectroscopy Study of Compositional, Structural and Physical Attributes of Developmental Cotton Fibers. Materials 2013, 6, 299–313. [Google Scholar] [CrossRef] [PubMed]

- Abidi, N.; Cabrales, L.; Hequet, E. Fourier transform infrared spectroscopic approach to the study of the secondary cell wall development in cotton fiber. Cellulose 2010, 17, 309–320. [Google Scholar] [CrossRef]

- Abidi, N.; Hequet, E.; Cabrales, L. Changes in sugar composition and cellulose content during the secondary cell wall biogenesis in cotton fibers. Cellulose 2010, 17, 153–160. [Google Scholar] [CrossRef]

- Ball, R.; McIntosh, A.C.; Brindley, J. The role of char-forming processes in the thermal decomposition of cellulose. Phys. Chem. Chem. Phys. 1999, 1, 5035–5043. [Google Scholar] [CrossRef]

- Cabrales, L.; Abidi, N. On the thermal degradation of cellulose in cotton fibers. J. Therm. Anal. Calorim. 2010, 102, 485–491. [Google Scholar] [CrossRef]

- Price, D.M.; Hourston, D.J.; Dumont, F. Thermogravimetry of Polymers. In Encyclopedia of Analytical Chemistry; Meyers, R.A., Ed.; John Wiley & Sons: Hoboken, NJ, USA, 2000; pp. 8094–8105. [Google Scholar]

- Abidi, N.; Hequet, E.; Ethridge, D. Thermogravimetric analysis of cotton fibers: Relationships with maturity and fineness. J. Appl. Polym. Sci. 2007, 103, 3476–3482. [Google Scholar] [CrossRef]

- Schultz, T.P.; McGinnis, G.D.; Bertran, M.S. Estimation of Cellulose Crystallinity Using Fourier Transform-Infrared Spectroscopy and Dynamic Thermogravimetry. J. Wood Chem. Technol. 1985, 5, 543–557. [Google Scholar] [CrossRef]

- Lengowski, E.C.; Magalhães, W.L.E.; Nisgoski, S.; De Muniz, G.I.B.; Satyanarayana, K.G.; Lazzarotto, M. New and improved method of investigation using thermal tools for characterization of cellulose from eucalypts pulp. Thermochim. Acta 2016, 638, 44–51. [Google Scholar] [CrossRef]

- Abidi, N.; Cabrales, L.; Hequet, E. Thermogravimetric analysis of developing cotton fibers. Thermochim. Acta 2010, 498, 27–32. [Google Scholar] [CrossRef]

- Vyazovkin, S.; Wight, C.A. Isothermal and non-isothermal kinetics of thermally stimulated reactions of solids. Int. Rev. Phys. Chem. 1998, 17, 407–433. [Google Scholar] [CrossRef]

- Vyazovkin, S.; Wight, C.A. Kinetics in Solids. Annu. Rev. Phys. Chem. 1997, 48, 125–149. [Google Scholar] [CrossRef] [PubMed]

- Abidi, N.; Cabrales, L.; Haigler, C.H. Changes in the cell wall and cellulose content of developing cotton fibers investigated by FTIR spectroscopy. Carbohydr. Polym. 2014, 100, 9–16. [Google Scholar] [CrossRef] [PubMed]

- Updegraff, D.M. Semimicro determination of cellulose inbiological materials. Anal. Biochem. 1969, 32, 420–424. [Google Scholar] [CrossRef]

- Viles, F.J.; Silverman, L. Determination of Starch and Cellulose with Anthrone. Anal. Chem. 1949, 21, 950–953. [Google Scholar] [CrossRef]

- Yin, X.; Goudriaan, J.A.; Lantinga, E.; Vos, J.; Spiertz, H.J. A flexible sigmoid function of determinate growth. Ann. Bot. 2003, 91, 361–371. [Google Scholar] [CrossRef]

- Wang, Y.; Shu, H.; Chen, B.; McGiffen, M.E.; Zhang, W.; Xu, N.; Zhou, Z. The rate of cellulose increase is highly related to cotton fibre strength and is significantly determined by its genetic background and boll period temperature. Plant Growth Regul. 2009, 57, 203–209. [Google Scholar] [CrossRef]

- Abidi, N.; Manike, M. X-ray diffraction and FTIR investigations of cellulose deposition during cotton fiber development. Text. Res. J. 2018, 88, 719–730. [Google Scholar] [CrossRef]

- Wang, Z.; McDonald, A.G.; Westerhof, R.J.; Kersten, S.R.; Cuba-Torres, C.M.; Ha, S.; Pecha, B.; Garcia-Perez, M. Effect of cellulose crystallinity on the formation of a liquid intermediate and on product distribution during pyrolysis. J. Anal. Appl. Pyrolysis 2013, 100, 56–66. [Google Scholar] [CrossRef]

- Poletto, M.; Pistor, V.; Santana, R.M.C.; Zattera, A.J. Materials produced from plant biomass: Part II: Evaluation of crystallinity and degradation kinetics of cellulose. Mater. Res. 2012, 15, 421–427. [Google Scholar] [CrossRef]

- Hideno, A. Comparison of the Thermal Degradation Properties of Crystalline and Amorphous Cellulose, as well as Treated Lignocellulosic Biomass. Bioresources 2016, 11, 6309–6319. [Google Scholar] [CrossRef]

- Das, K.; Ray, D.; Bandyopadhyay, N.R.; Sengupta, S. Study of the Properties of Microcrystalline Cellulose Particles from Different Renewable Resources by XRD, FTIR, Nanoindentation, TGA and SEM. J. Polym. Environ. 2010, 18, 355–363. [Google Scholar] [CrossRef]

- Kim, U.-J.; Eom, S.H.; Wada, M. Thermal decomposition of native cellulose: Influence on crystallite size. Polym. Degrad. Stab. 2010, 95, 778–781. [Google Scholar] [CrossRef]

- Poletto, M.; Zattera, A.J.; Forte, M.M.; Santana, R.M. Thermal decomposition of wood: Influence of wood components and cellulose crystallite size. Bioresour. Technol. 2012, 109, 148–153. [Google Scholar] [CrossRef] [PubMed]

| Genotype | ||

|---|---|---|

| TM-1 | TX55 | |

| Coefficient a Confidence Interval | [66.67, 83.59] | [68.94, 100.75] |

| Coefficient b Confidence Interval | [21.99, 23.33] | [19.30, 21.77] |

| Coefficient c Confidence Interval | [1.22, 2.55] | [1.47, 3.70] |

| Coefficient d Confidence Interval | [7.99, 20.44] | [−3.07, 23.30] |

| Coefficients | |||||

|---|---|---|---|---|---|

| Graph | a | b | c | d | R2 |

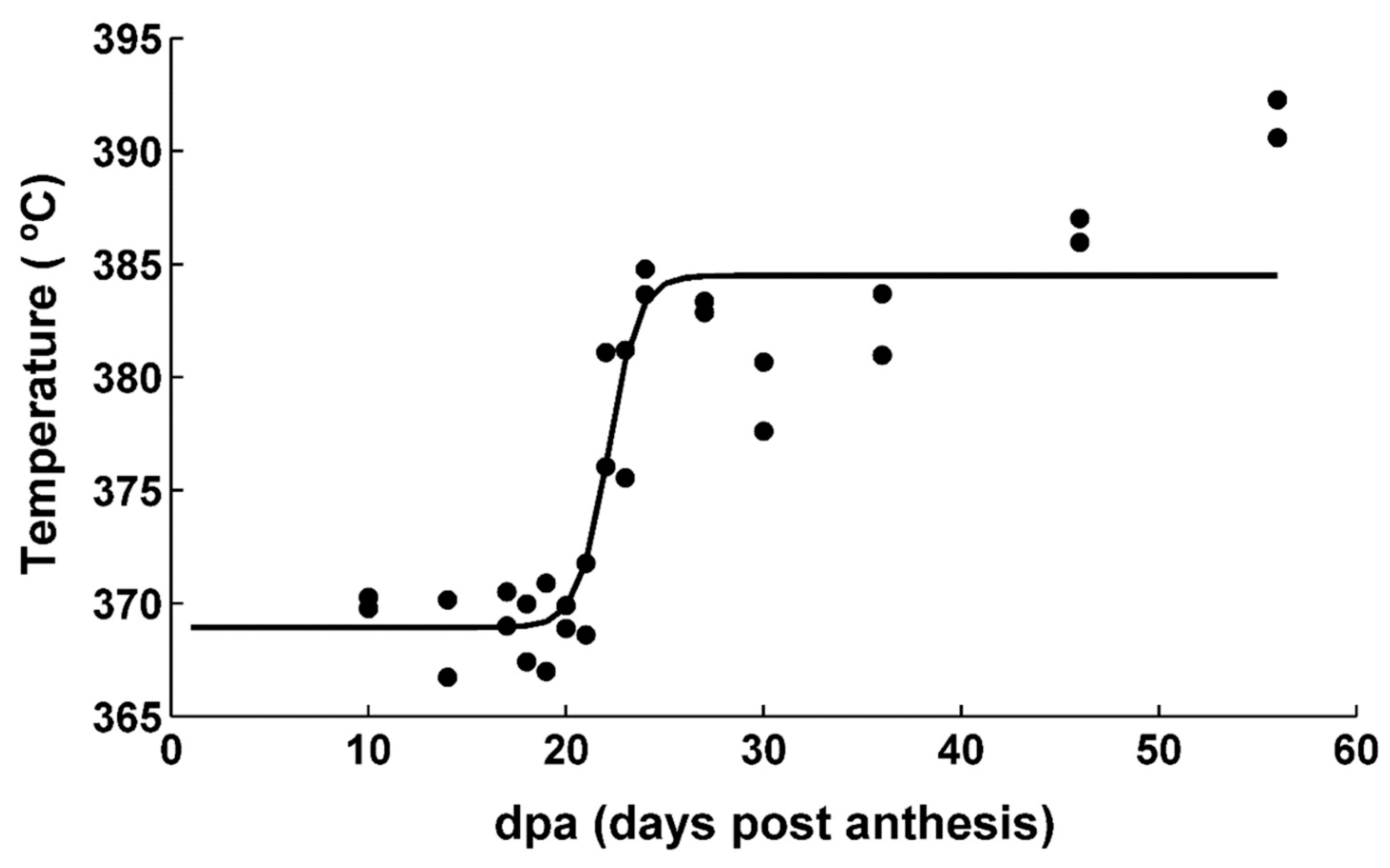

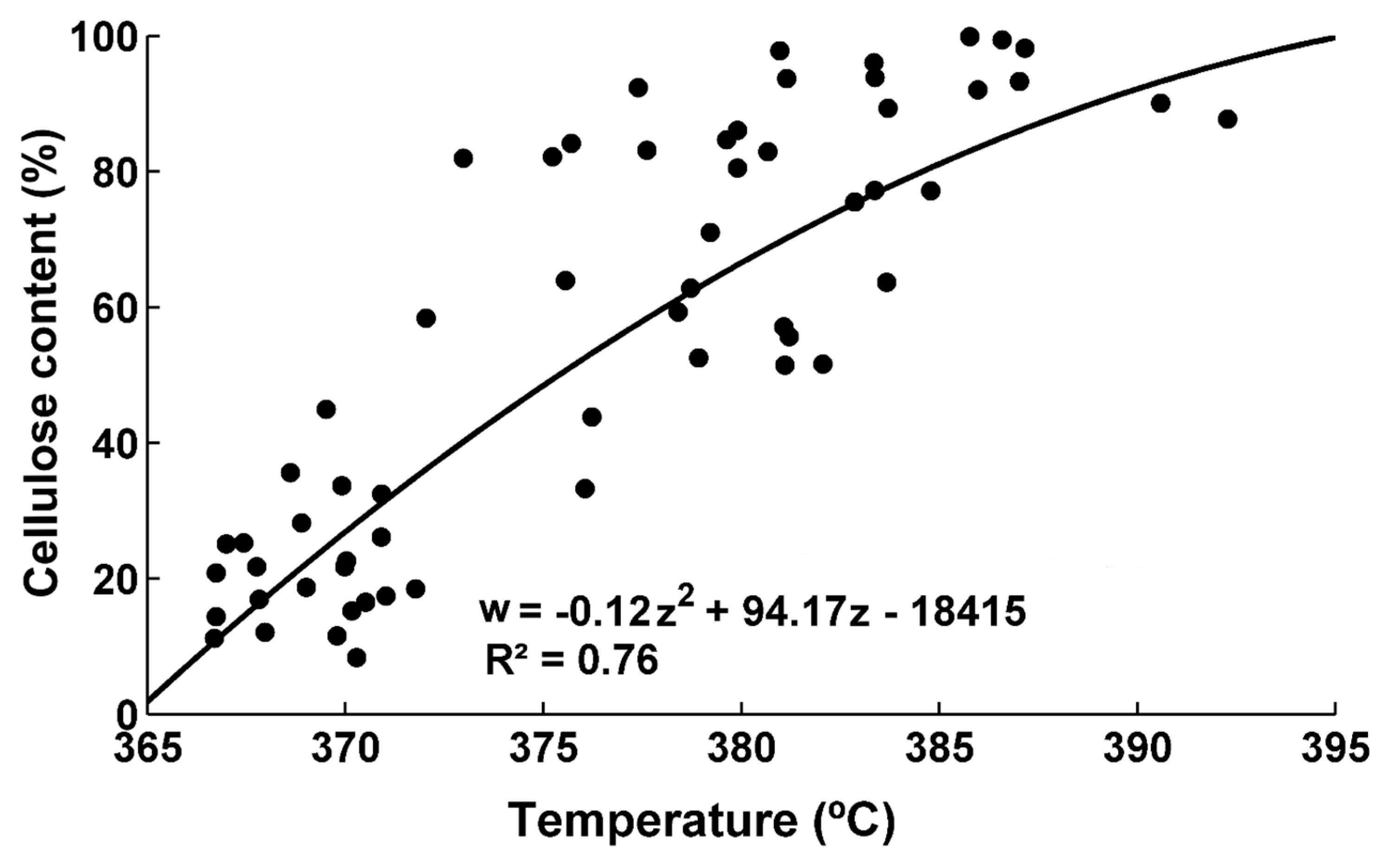

| Cellulose % TM-1 (Figure 1) | 75.17 | 22.66 | 1.89 | 14.22 | 0.91 |

| Crystallinity TX55 (Figure 4) | −2.67 | 19.99 | −1.78 | 4.71 | 0.95 |

| WL 37–150 °C TM-1 (Figure 6) | 4.31 | 23.04 | −2.07 | 5.65 | 0.89 |

| WL 150–400 °C TM-1 (Figure 9) | 25.43 | 20.96 | 1.4 | 51.27 | 0.94 |

| Peak 300–400 °C TM-1 (Figure 12) | 15.55 (14.17 *) | 22.13 (21.92 *) | 0.76 (0.62 *) | 368.94 (368.99 *) | 0.82 (0.87 *) |

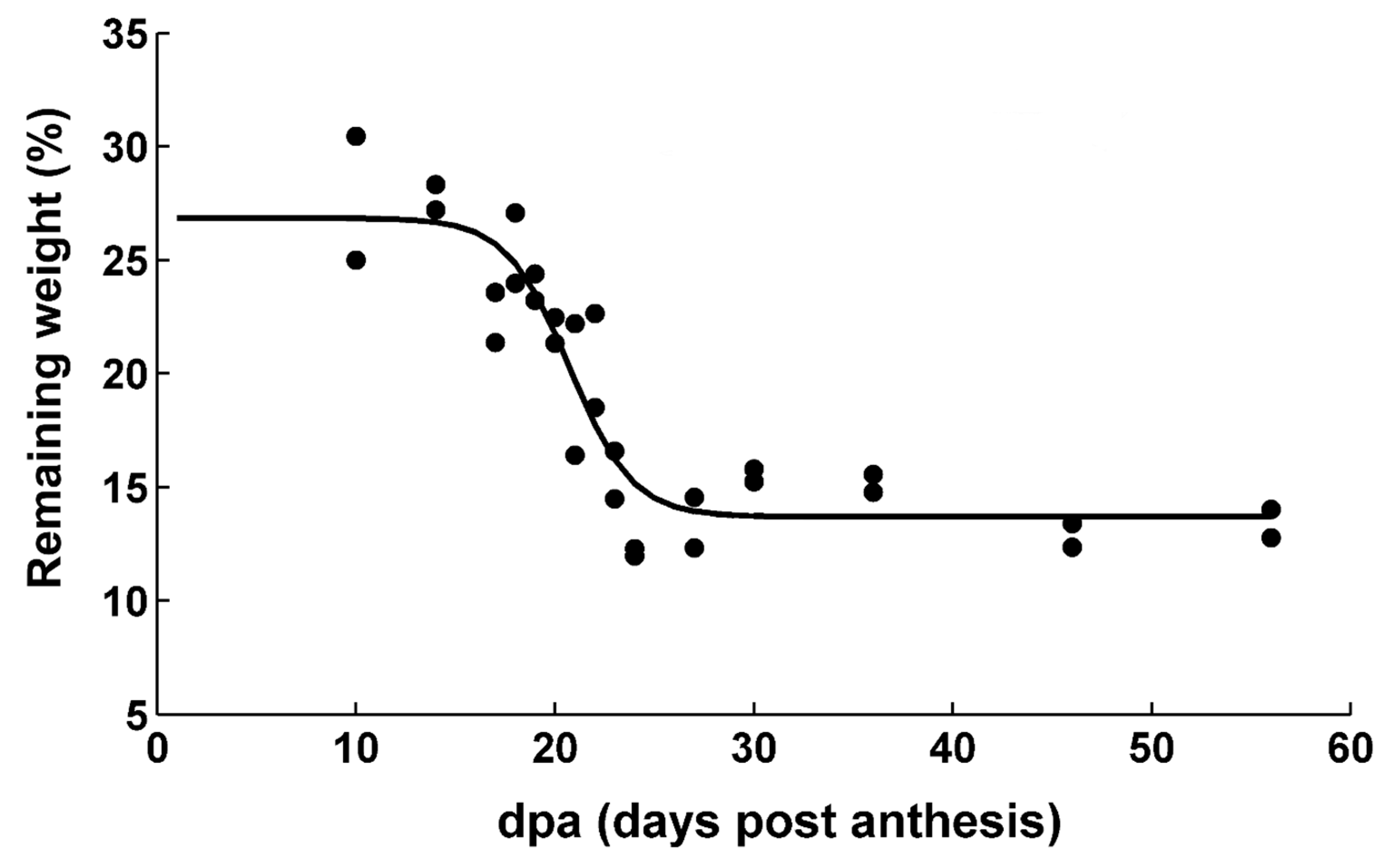

| Remaining % TM-1 (Figure 14) | 13.15 | 20.72 | −1.58 | 13.69 | 0.84 |

| Cellulose % TX55 (Figure S2) | 84.85 | 20.53 | 2.59 | 10.66 | 0.95 |

| Crystallinity TM-1 (Figure S3) | −2.51 | 22.42 | −0.75 | 4.67 | 0.97 |

| WL 37–150 °C TX55 (Figure S4) | 4.48 | 20.47 | −1.53 | 5.15 | 0.91 |

| WL 150–400 °C TX55 (Figure S6) | 26.02 | 18.81 | 1.51 | 49.03 | 0.79 |

| Peak 300–400 °C TX55 (Figure S8) | 14.03 (12.85 *) | 19.25 (19.30 *) | 1.73 (1.26 *) | 367.03 (367.66 *) | 0.67 (0.76 *) |

| Remaining % TX55 (Figure S10) | 12.69 | 18.62 | −1.57 | 16.05 | 0.53 |

| Graph | Coefficient b Confidence Interval |

|---|---|

| Cellulose % TM-1 (Figure 1) | [21.59, 24.50] |

| Crystallinity TX55 (Figure 4) | [19.08, 20.91] |

| WL 37–150 °C TM-1 (Figure 6) | [21.59, 24.50] |

| WL 150–400 °C TM-1 (Figure 9) | [20.39, 21.54] |

| Peak 300–400 °C TM-1 (Figure 12) | [21.36, 22.90] [21.34, 22.50] * |

| Remaining % TM-1 (Figure 14) | [19.58, 21.87] |

| Cellulose % TX55 (Figure S2) | [19.30, 21.77] |

| Crystallinity TM-1 (Figure S3) | [22.03, 22.81] |

| WL 37–150 °C TX55 (Figure S4) | [19.67, 21.27] |

| WL 150–400 °C TX55 (Figure S6) | [17.54, 20.08] |

| Peak 300–400 °C TX55 (Figure S8) | [17.15, 21.34] [17.65, 20.95] * |

| Remaining % TX55 (Figure S10) | [16.34, 20.91] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cabrales, L.; Abidi, N. Kinetics of Cellulose Deposition in Developing Cotton Fibers Studied by Thermogravimetric Analysis. Fibers 2019, 7, 78. https://doi.org/10.3390/fib7090078

Cabrales L, Abidi N. Kinetics of Cellulose Deposition in Developing Cotton Fibers Studied by Thermogravimetric Analysis. Fibers. 2019; 7(9):78. https://doi.org/10.3390/fib7090078

Chicago/Turabian StyleCabrales, Luis, and Noureddine Abidi. 2019. "Kinetics of Cellulose Deposition in Developing Cotton Fibers Studied by Thermogravimetric Analysis" Fibers 7, no. 9: 78. https://doi.org/10.3390/fib7090078

APA StyleCabrales, L., & Abidi, N. (2019). Kinetics of Cellulose Deposition in Developing Cotton Fibers Studied by Thermogravimetric Analysis. Fibers, 7(9), 78. https://doi.org/10.3390/fib7090078