Abstract

With huge varieties of fabrics, the first challenge for any performance evaluation is to categorize the vast types of the products into fewer, more homogeneous and akin groups. Classification or sorting is arguably the first step of any scientific investigation, and comparison of product quality is meaningful only when conducted within a group of comparable products. A new criterion termed fabric linear density λ is first proposed in this paper so that fabrics can in general be divided into four groups. The derivation and validation of this parameter are provided. The importance of fabric drape is almost self-evident, but there are still no effective ways to easily measure this fabric attribute. A few existing instruments, notably the Cusick Drapemeter, suffer from low repeatability and low sensitivity and are hence not widely or frequently used. It is demonstrated in this study that, by using the PhabrOmeter, along with the fabric linear density λ, a much more efficient alternative for fabric drape test can be achieved. By actually testing 40 various fabrics, the principle, procedure and results of this method is presented in this paper.

1. Introduction

Visual attributes of textile fabrics represent a sub-group of sensory properties, perceived particularly by the visual sense of consumers. Such visual qualities include fabric drape, surface state and luster, and, by logical extension, the fabric wrinkle recovery, fabric surface retention and stain resistance, i.e., all fabric appearance related esthetic characteristics. We call them fabric attributes to differentiate from the term fabric properties such as the fabric weight and fabric strength, for the latter are much simpler to describe, with definitions widely accepted and measurement methods well established.

The importance of such fabric sensory attributes is indisputable. It is hard to imagine a consumer would buy a textile product without first looking at them. Therefore, it can be stated that the success of any new fiber, new finish or new textile product is largely dependent on the acceptance of its sensory traits [1,2,3]. In this paper, we focus on measurement of fabric drape as one of the sensory attributes.

Fabric drape refers to the fabric shape or profile when held at the center/edge, such as used for curtains, or as a tablecloth or a skirt covering an object, often termed in the latter cases as the fabric formability, and is resulted from fabric’s response towards gravity due to its own weight [2,3].

The current approaches in evaluating all such attributes including drape are still quite primitive, and largely rely on human sensory judgment, which in many cases is not readily reproducible and repeatable, lagging far behind the need for fast product development from the industry, and for short product turn over time in the apparel market.

It is interesting to note that the major fabric sensory attributes, namely hand, drape and wrinkle recovery, are interconnected and governed by the same group of mechanical properties [1,4], thus implying a collective approach for measurement, i.e., because of this close interconnectivity, it is possible that the same instrument properly configured can measure all such fabric attributes.

Although there has been a long history of research and many attempts have been made to develop instrumental means to measure such fabric attributes, the resultant methods are not effective enough to meet the industrial requirements [5,6,7,8]. Pierce [1], for instance, proposed several simple methods including the “cantilever” and “loop” sample shapes to measure the bending resistance as “… strictly a measure of the draping quality of a fabric”. Such approaches are reflected in several existing American Association of Textile Chemists and Colorists (AATCC) and American Society of Testing and Materials (ASTM) standard tests. However Chu et al. later pointed out that “two-dimensional distortion tests are incapable of differentiating between drape and paperiness, i.e., it is possible to select a piece of paper and a piece of fabric both of which have the same bending properties, yet it is doubtful that the paper will drape as well as the cloth” [2]. Hearle et al. provided a comprehensive review of existing research on the subject [9], and a very thorough study of fabric drape was done by Cusick [3].

Then, there was a detailed review article in 1987 by Jacob and Subramaniam on the literature of fabric drape [10]. For instance, multiple regression analysis was used to determine whether certain deformation properties (stiffness, shear, and extensibility) and structural characteristics (fabric weight, thickness, and density) can serve as reliable predictors of the drape of knitted fabrics [11]. Several studies focused on static and dynamic drape of fabrics [12,13,14]. There are also reported investigations on the draping behaviors of multi-layer textiles using digital image processing [15,16]. As expected, the challenging question of theoretical modeling of fabric drape phenomena has attracted much interest [17,18,19,20,21,22,23,24,25,26,27,28,29,30,31].

Fabric drape has been considered to be primarily determined not only by its bending but also its shear resistance, and in that order [3,9]. We also know that it is the shear properties that differentiate between a piece of paper and fabric.

The search and exploration for a better instrument for fabric drape test continues today, but very few commercial products are available, including notably the Fabric Drape Tester (better known as the Cusick Drapemeter [3] or Chu method [2]), by tracing the shadow of a draped fabric on paper. However, this test suffers from several shortcomings [32,33,34] and thus has not been widely used by, for instance, the U.S. industry. It is a bit surprising that there is not even a U.S. standard for fabric drape test, a grave gap urgently required to fill. For anyone who has the experience of using the Cusick Drapemeter, several problems become immediately clear:

- Poor reproducibility, i.e., multiple tests of the same sample often do not yield reasonably close results, and Chu thus recommended for more test replicas: “Five in each direction, warp and filling, is a reasonable number” [2]. Knowing fabrics are anisotropic, one may argue why not in other directions?

- Low sensitivity—only significant difference in fabric drape can be detected [34].

- It has a slow and cumbersome test process [35].

- Many fabrics tend to curl and twist when cut into specimens, which further affects the reproducibility, and even the physical meaning of the test results [4].

- A large size sample size is required: 30 cm in diameter [36]. If five each are required in both warp and filling directions, that is too much fabric to ask for in many cases.

Although there have been variations [32,33,37,38] of the Cusick Drapemeter, attempting to eliminate or alleviate some of the problems in the original design, none of them seems to have improved to such degree that a commercial model has been widely accepted by industrial users. Imaging analysis has been [15,39,40,41,42] applied to the test, but it can only improve the analysis of the results and can do little in dealing the problems intrinsic in the test principles.

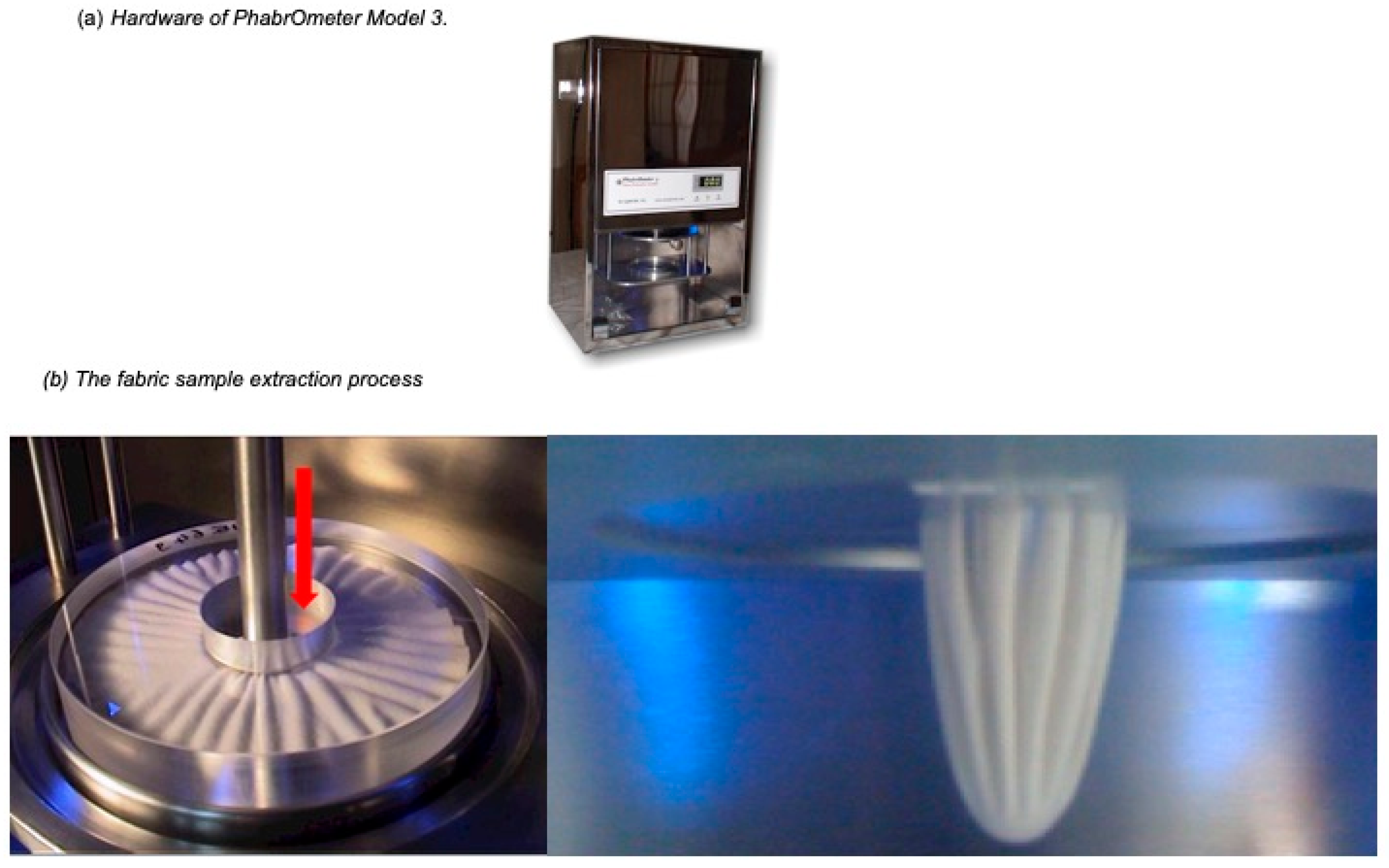

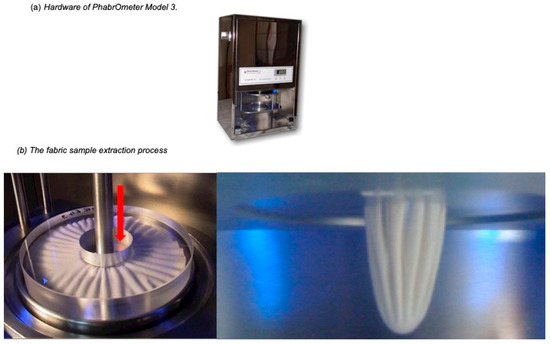

The Japanese Kawabata’s fabric hand system (better known as the Japanese KES system) is probably among the very few attempted to address the overall relationships between fabric sensory attributes and mechanical properties [43]. Then, there is a result by Pan and his coworkers from 1983 [4,44,45], when a new instrument called PhabrOmeter fabric test system [46] was developed and commercialized for evaluating sensory attributes of various types of fibrous sheets, as shown in Figure 1. Unlike the Japanese KES system, no attempt is made to separately measure individual fabric properties (such as bending, compression, tensile and surface properties) deemed to be associated with fabric sensory attributes. Instead, this instrument is based on the previously proposed fabric extraction method [4] with some critical improvements to generate comprehensive test results [4,44,45]. Then, a computer algorithm will derive a series of parameters including a Relative Hand Value, the fabric Softness, Smoothness, Stiffness, etc. PhabrOmeter has been commercialized by Nu Cybertek Inc. in Davis CA [46] and some successful applications have been reported [47,48]. In addition, an AATCC standard test method for the PhabrOmeter, AATCC TM202, has been devised to guide the users [49].

Figure 1.

PhabrOmeter Model 3 Fabric Evaluation System: (a) hardware of PhabrOmeter Model 3; and (b) the fabric sample extraction process.

It has long been established that fabric hand is closely related to its drapeability [1,50]. Given the fact that, during an extraction process on the PhabrOmeter, the fabric sample is going through a forced drape with complex yet low stress state, as in Figure 1b, it is only logical to examine the potential for PhabrOmeter to be applied to fabric drape measurement. An added feature of using PhabrOmeter for fabric drape test is that, as the sample is cut into circular shape and extracted by a force exerted at the sample center, it thus “isotropicizes” the measurement process and eliminates the sample directional effect—a problem severely plaguing the results of the Cusick Drapemeter [35].

2. A New Criterion for Fabric Classification

Before proceeding any further, one major issue has to be settled. With huge varieties of fabrics, the first challenge for any quality evaluation scheme is to categorize the products into fewer, and more homogeneous groups if a general test method is to be applicable to all fabric types. Classification or sorting is arguably the first step of any scientific investigation, and comparison of product quality is meaningful only when conducted within a group of comparable products.

There is no formally established fabric classification scheme, and some parameters including weave types, fabric weight and thickness have often been used expediently in categorizing fabrics [32,51]. The Japanese Kawabata’s KES system approached this problem by first choosing fabrics for the same applications, and then grouping them based on the fabric weight to yield four major groups including the fabrics for Men’s winter and summer suits, as well as Women’s medium-thickness and thin dress [43].

The PhabrOmeter has been applied to cover much wider range of products, including textile fabrics and paper tissues so that more general and representative schemes have to be established. Here are the rules we used to establish general parameters, by which all products can be classified into groups that both make sense and are easy to use:

- As the most fundamental parameters in determining fabric performance, both fabric weight and thickness should be included in the resultant parameters.

- In developing PhabrOmeter, it is known that, in the fabric extraction process, the fabric compaction density in the nozzle in Figure 1b is the key factor [52,53] in generating the test results. Increasing either fabric weight or thickness will lead to an increased fabric compaction density, i.e., both fabric weight and thickness affect the resultant parameter in the same trend.

- Structural differences (weaves, fiber types, etc.) can be specified afterwards within each resultant group, if necessary.

According to Rule 1, the actual fabric volumetric density ρ (weight/volume) becomes the first logical candidate:

where W is the fabric weight (weight/area) and T is the fabric thickness (length). However, use of ρ would violate the second rule, i.e., both fabric weight and thickness have to influence the result in the same trend. Alternatively, we define a new parameter λ

In this case, changing either fabric weight or thickness will alter the λ value in the same trend, thus satisfying both rules. λ has the unit of (weight/length) and is expediently termed linear density. Table 1 provides the normal possible ranges for the three quantities W, T and λ, covering most commercial fibrous sheet products.

Table 1.

The possible ranges of fabric parameters *.

Although λ value is a linear function of either W or T, it is still questionable to classify all products by evenly dividing the λ value, as there is no proof that λ value is evenly distributed over the entire scope. It is conceivable that, over the possible fabric ranges, there are fewer extremes or exceptions; in other words, a normal distribution of λ would be a more acceptable assumption. The division shown in Table 2 is the grouping result based on this consideration, currently used in the PhabrOmeter.

Table 2.

Different major fabric groups based on possible λ values [46].

Again, as it is less meaningful to compare samples from different groups, all data processing, calculations, transformations and comparisons should be conducted within each major group. Of course, fabric classification is a hugely complex issue and the groups shown in Table 2 are just general yet useful results. It may be practiced to further classify products in the same major group into subgroups if deemed necessary.

For this project, 40 fabrics of various types were collected from Cotton Inc. (Raleigh, NC, USA). Based on their λ values, the 40 fabrics were found to span all four major groups (S = 2), (L = 27), (M = 10) and (H = 1), as listed in Table 3:

Table 3.

Groups for collected fabrics.

3. Samples and Test Methods

Of the 40 fabrics in Table 4, the drape for 38, with the Cusick drape data using the imaging approach of Option B in the widely recognized international standard ISO 9073-9:2008, are provided, while the drape data for Samples #9 and #10 are not available. Our textile testing lab at University of California Davis (UCD) conducted the following experiments on all 40 fabrics including: fabric thickness (ASTM D1777) and fabric weight (ASTM D3776). We also tested all 40 fabrics using Cusick method in following steps:

Table 4.

Specs of the fabric samples.

- Option A in ISO 9073-9:2008 was followed, using 30 cm specimen diameter.

- Three specimens for each fabric were tested on each side (face and back), thus six data points were obtained for one fabric.

- For each of the six readings from a given fabric, a drape coefficient value D was calculated as

Note that, in ISO 9073-9:2008 Option A, the area equaling to the center-plate was not included in the calculation since we only weighed the paper ring without the center-circle part. Therefore, when the specimen is very limp (the shadow area is very small), the drape coefficient could be very small (theoretically down to 0%). Thus, to be consistent with Option B used by Cotton Inc., we also rectified the UCD data by making mt equal to the weight of a paper of circular shape with the same diameter to the outer diameter of the paper ring (i.e., adding the weight of the center-part of the paper ring) in the calculation, so that all our Cusick data were increased, with a minimum for Sample #33 from 20.7% to 38.8%.

In addition, according to ISO 9073-9:2008 standard, different diameters should be adopted for certain types of fabric to make the test consistent with the real condition. However, the document also states that “Results obtained on test specimens of different diameters are not directly comparable, in all cases, tests also need to be carried out on a 30 cm diameter test specimen, regardless of the drape coefficient”. Thus, all UCD Cusick data were obtained using 30 cm specimen diameter only.

4. Measurement by PhabrOmeter

The fabric extraction method used in PhabrOmeter simulates the related fabric behaviors and closely imitates the testing processes—during a test, the fabric sample is actually going through a forced drape under complex stresses. It is therefore proposed here to use the PhabrOmeter as a tool to measure the fabric drape. To save space and avoid repetition, a more detailed theoretical background on the principle can be found in [4,9]. The high repeatability, sensitivity and fast test speed of PhabrOmeter provide high potential in evaluating the fabric drape in a much more consistent way to replace some of the existing but less effective test methods.

Samples were cut into the circular shape of 100 cm2 area using a standard cutter and mounted onto a secure sample holder in PhabrOmeter. Once ready to operate the instrument, the computer will prompt for both fabric weight and thickness so that the linear density λ value for this sample is calculated. Accordingly, the sample is assigned to the corresponding density group in Table 3 for subsequent testing and analysis. The user has the option to input other specifications for the sample so that finer grouping, if needed, can be done easily in the computer.

Among several outputs after the sample is tested, the fabric drape coefficient will be displayed or saved into a data file. For details on testing operation and data generation, the user can refer to the PhabrOmeter user manual [46].

5. Data Analysis

Once done with actual measurements, we obtained the following kinds of data related to drape (Table 5):

Table 5.

Correlations between the parameters.

- Fabric linear density λ values calculated from Equation (2);

- Cusick data DrapeCB based on Option B in ISO 9073-9:2008 by Cotton Inc;

- Cusick data DrapeUA based on Option A in ISO 9073-9:2008 by UCD;

- DrapeUAB UCD Cusick Option A data rectified to Option B; and

- PhabrOmeter drape data DrapePh by UCD;

A series of analysis listed below was conducted to explore the important information, implication and relationships of the fabrics tested regarding the fabric drape behaviors.

5.1. λ as a Fabric SAMPLE Classifier

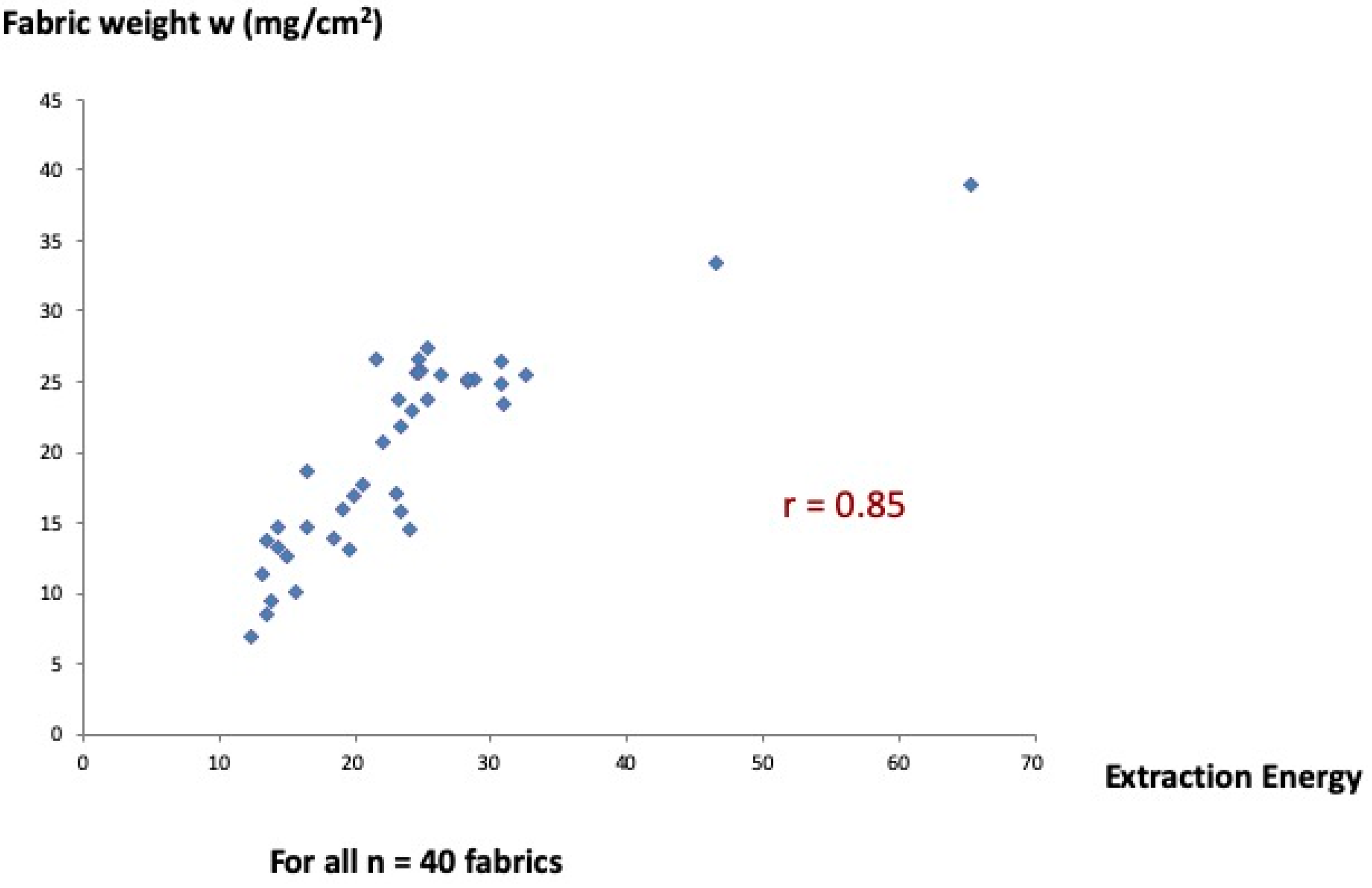

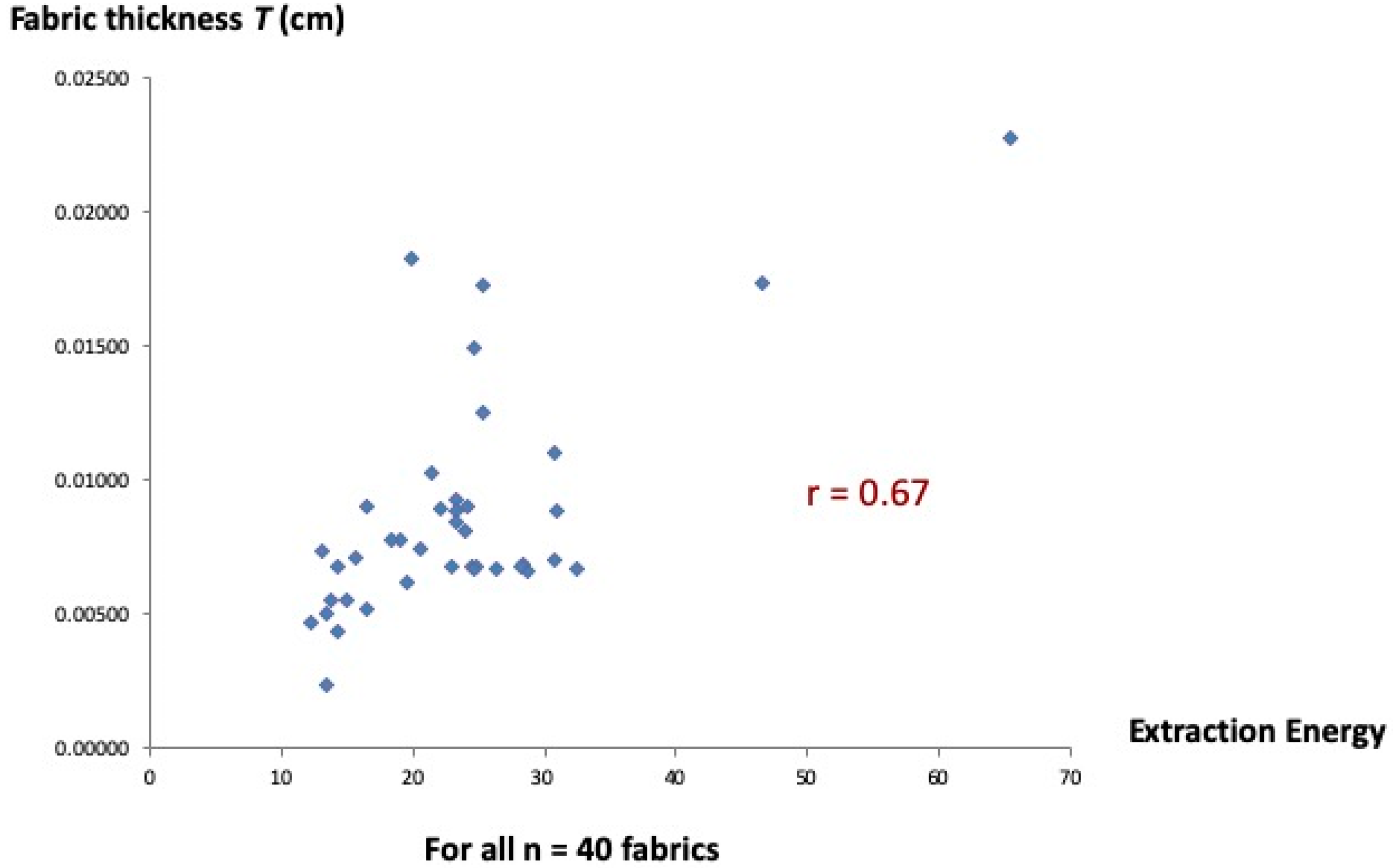

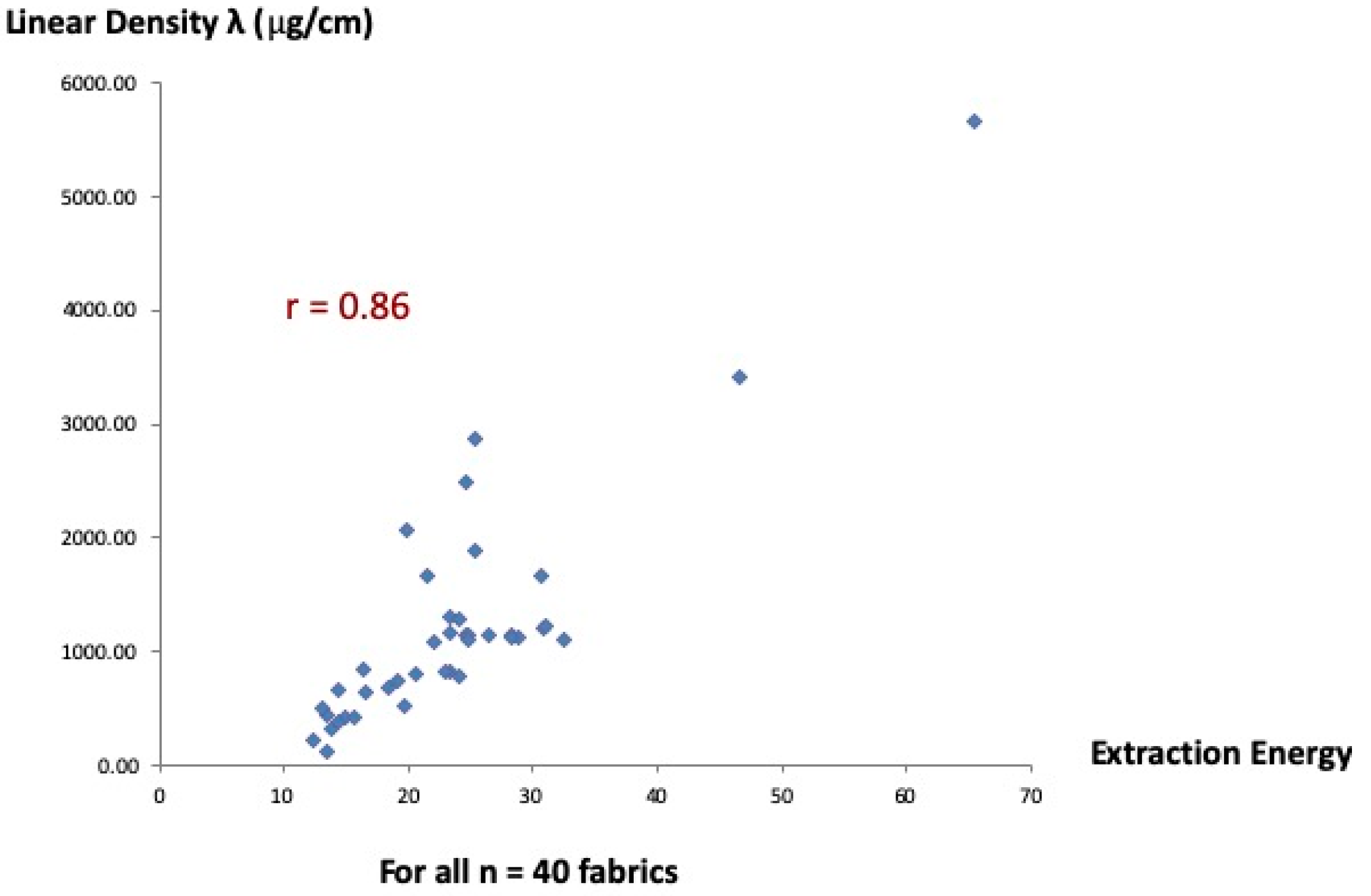

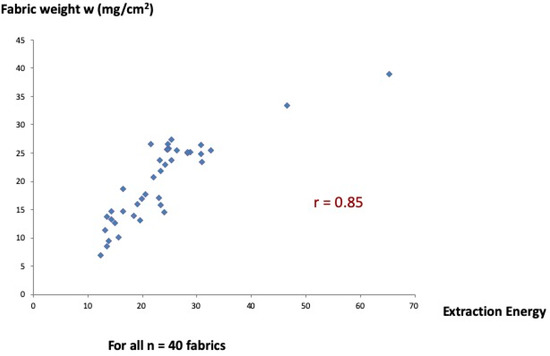

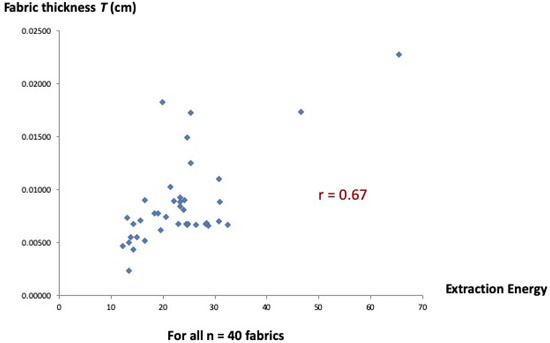

As shown above, λ is the fabric classifier currently adopted by PhabrOmeter, and was studied here to further confirm its effectiveness. Along with the fabric λ value, we provided the area under the extraction curve (energy) as a representation of the energy required to extract the sample through the testing ring and calculated by PhabrOmeter in Table 5. Figure 2 shows the connection between fabric weight W and the energy, and Figure 3 between fabric thickness T and energy, for all 40 fabrics. It is clear in both figures that increasing either fabric weight or thickness will increase the fabric compaction density during extraction, thus the extraction energy, i.e., both exert the same trend to the result. The fabric linear density λ, which, as shown in Figure 4, presented a correlation r = 0.86 with the extraction energy, higher than either fabric weight or thickness yet incorporating both, is a more comprehensive fabric describer.

Figure 2.

Fabric weight vs. extraction energy.

Figure 3.

Fabric thickness vs. extraction energy.

Figure 4.

Linear density λ vs. extraction energy.

It may help further explore the validity of this linear density acting as the primary factor in representing fabric properties, by analyzing the connection between the linear density λ and other fabric parameters provided in Table 6, where DrapePh and DrapeUA are the UCD fabric drape coefficients measured by PhabrOmeter and Cusick methods, respectively; Energy is the fabric extraction energy and RHV is the relative fabric hand value when #26 (RHV = 0) was chosen as the reference [46]. It may be noted in the table that:

Table 6.

Correlations between key parameters.

- DrapePh, DrapeUA and RHV are highly correlated with each other.

- Extraction energy only correlates significantly with the linear density.

Here are some possible explanations. The extraction energy and linear density, both being more intrinsic material properties in describing the fabric extraction process, are thus well connected with each other, and less related to the other three, whereas DrapePh, DrapeUA and RHV are more extrinsic properties, and each is highly correlated with the other two.

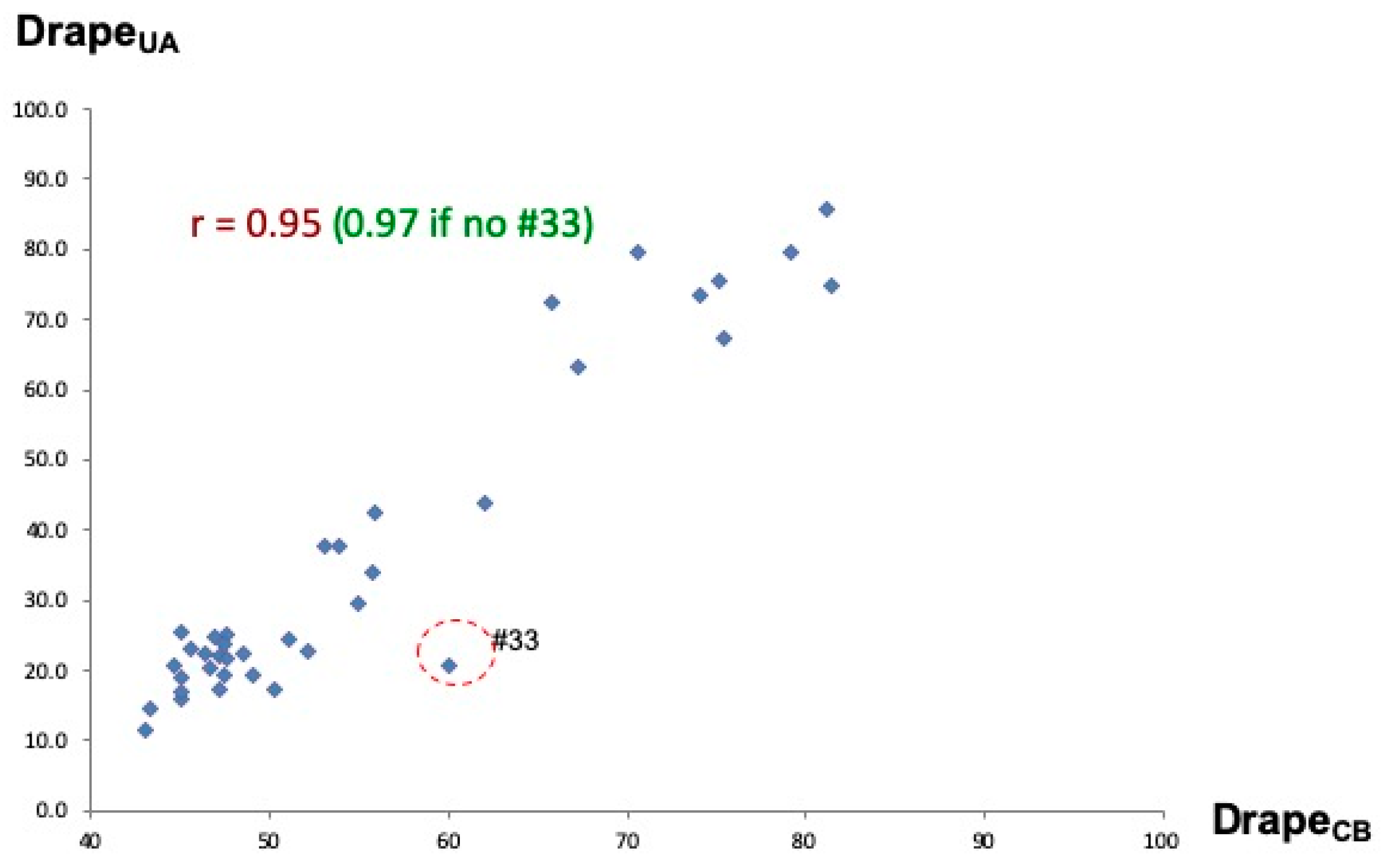

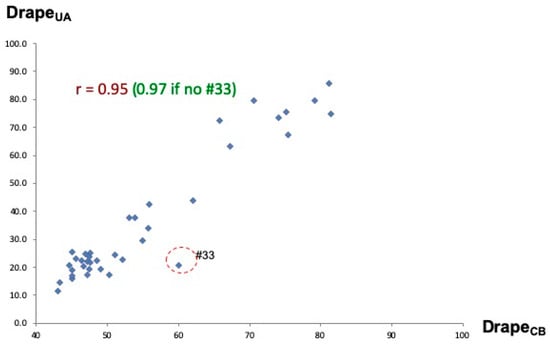

5.2. Comparison of Drape Data

When comparing with the Cusick drape data from Cotton Inc., drape data are not available for Samples #9 and #10, thus only n = 38 samples were involved. Figure 5 presents the results between the Cusick drape data from Cotton Inc. versus from UCD. A very good agreement is exhibited with a correlation as high as r = 0.95. This suggests that data from both Options A and B, ISO 9073-9:2008, used by UCD and Cotton Inc., respectively, are consistent. The outlier, #33, is a single knit Inlay that appeared to have yielded an irregular drape data, either too high (for Cotton Inc.) or too low (for UCD).

Figure 5.

Cusick drape Data vs. UCD and Cotton (n = 38) (data not available for Samples #9 and #10).

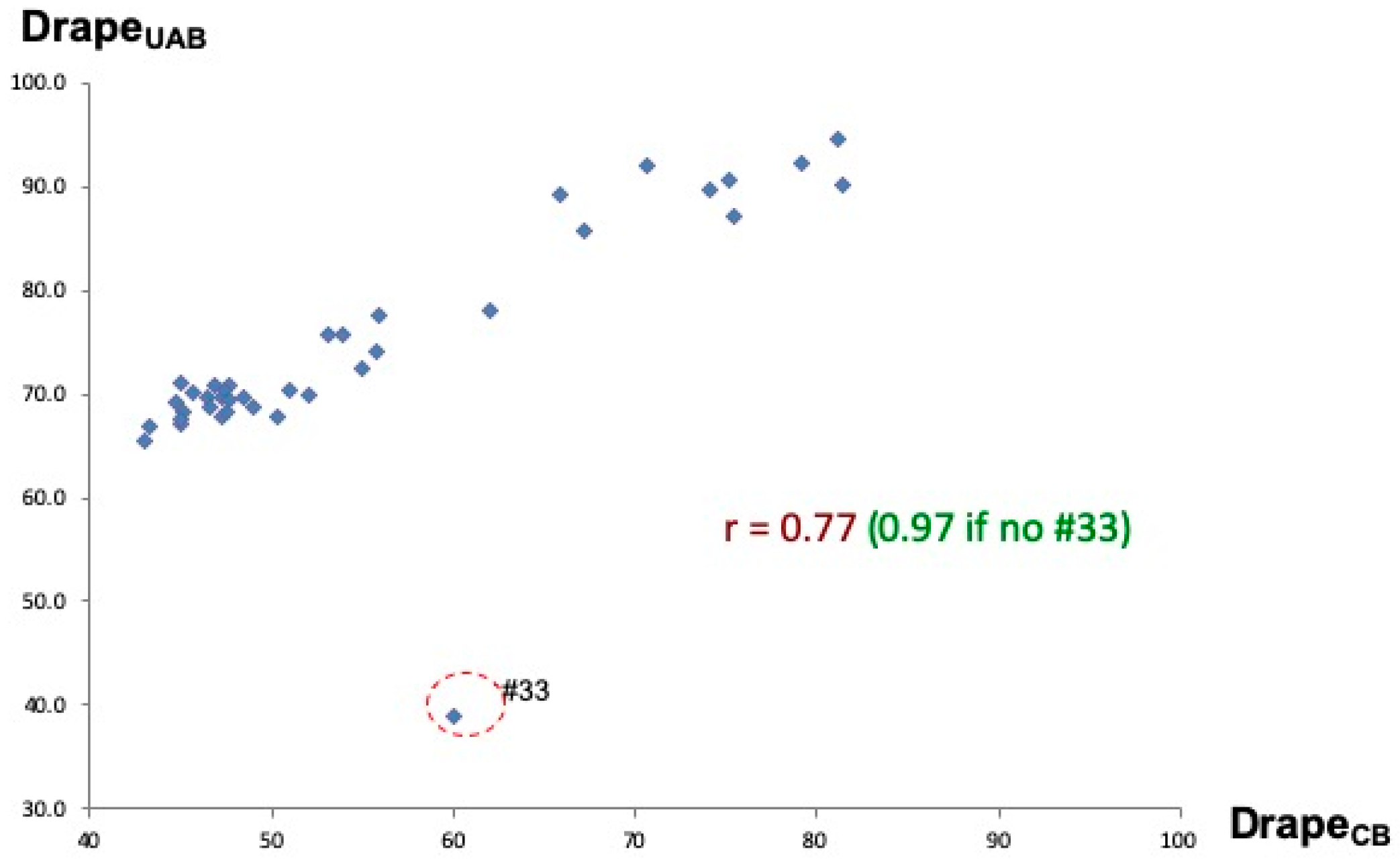

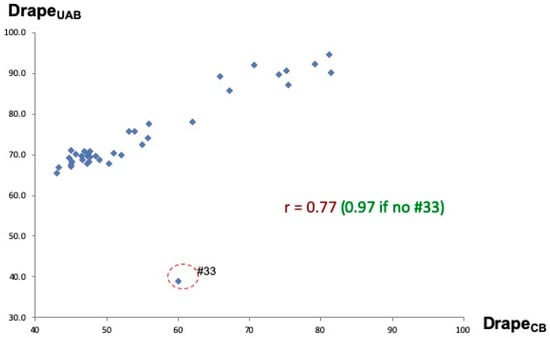

Figure 6 is the same plot as Figure 5, except the rectified UCD drape data are used. A very decent linear relation between the two groups of data is again shown, if excluding #33. If fact, the existence of #33 led to a big drop of correlation from r = 0.97 to r = 0.77. Overall, these data suggest that both Cotton Inc. and UCD Cusick data are consistent, and data rectification does not seem to yield noticeable improvement. Thus, despite the problems with the Cusick test method discussed above, these data can serve as a reference when in comparison with PhabrOmeter drape data for at least the 40 fabrics given.

Figure 6.

Cusick drape Data vs. Rectified UCD and Cotton (n = 38) (data not available for Samples #9 and #10).

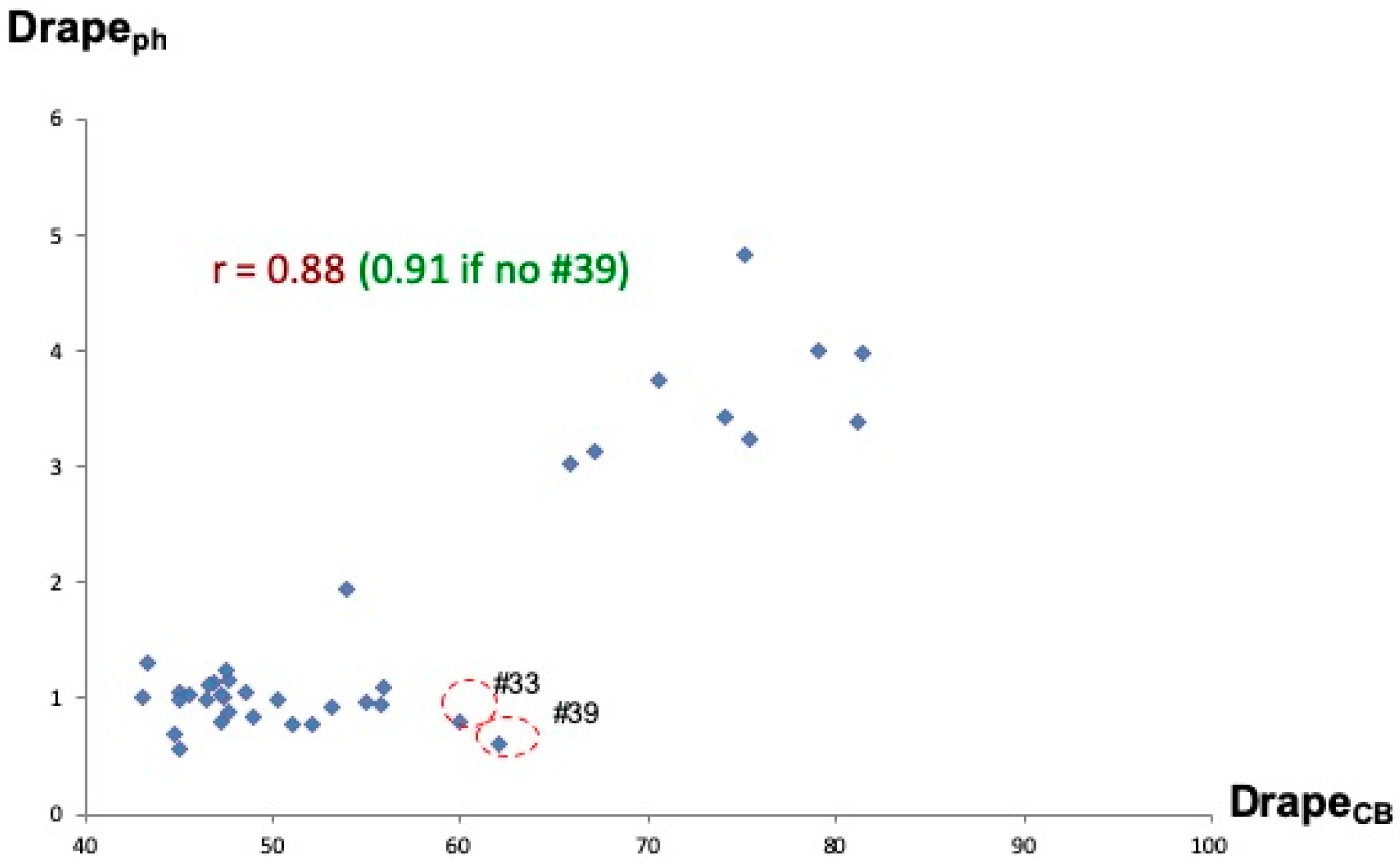

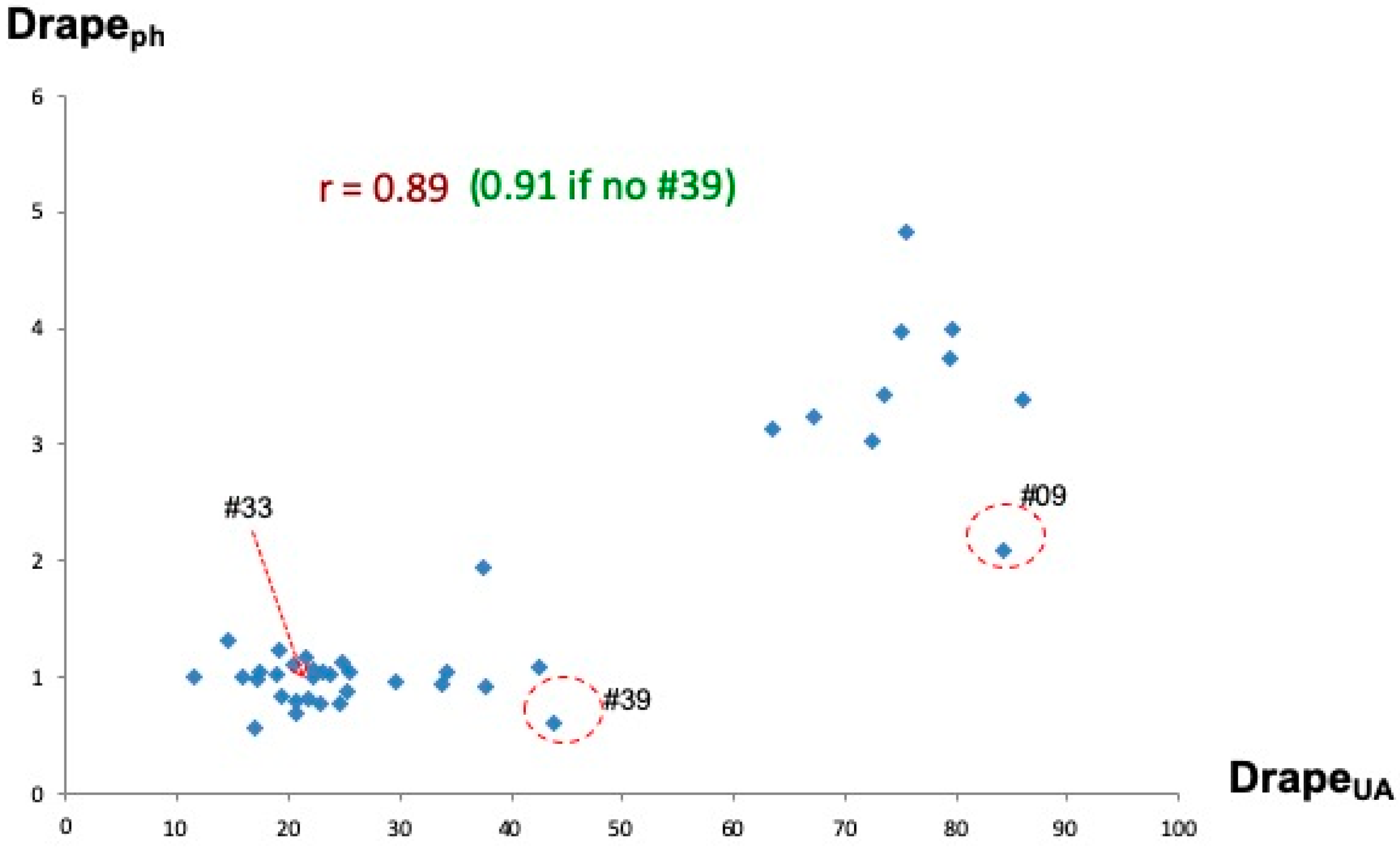

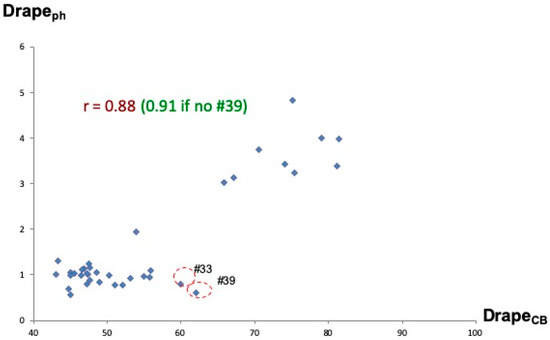

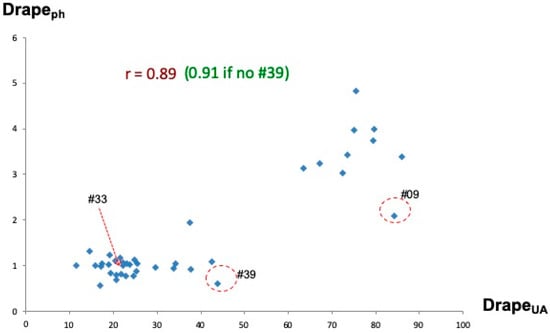

Figure 7 uses the drape data DrapePh by the PhabrOmeter method against the Cusick drape data for the 38 fabrics from Cotton Inc. DrapeCB. Again, a high correlation r = 0.88 (r = 0.91 if excluding #39) exists between the two groups of data, indicating that the PhabrOmeter drape data represent the fabric drape performance just as well as the Cusick drape data. A similar conclusion can be drawn from the results in Figure 8, where the PhabrOmeter data DrapePh are plotted against the UCD Cusick drape data DrapeUA for all n = 40 fabrics with r = 0.89 (r = 0.91 if excluding #39).

Figure 7.

PhabrOmeter Drape and Cotton Cusick data (n = 38) (sata not available for Aamples #9 and #10).

Figure 8.

PhabrOmeter Drape and UCD Cusick (n = 40).

In discussing the outliers, it is noted that, according to the figures, in addition to #33 and #39, #9 in Figure 8 may also be problematic. As shown in Table 5, #9 is a 100% cotton twill, but careful examination found that there seems to be some coating or special finish on its surface to render it more rigid than Samples #1–#8, otherwise identical fabrics of 100% cotton twill. As there is no Cusick data for #9 from Cotton Inc., #9 only appears once in Figure 8 where all 40 fabrics were involved, and thus there is insufficient information to further examine #9. Sample #33 is a single knit Inlay fabric and Sample #39 is 100% polyester, very loose twill. Both are highly stretchy fabrics. Note that fabric curl, a tough problem in Cusick method, is no longer a concern in conducting PhabrOmeter test.

5.3. Factors Influencing Fabric Drape Measurement

Thus far, we have concluded that Cusick drape data following either Option A or Option B in ISO 9073-9:2008 are consistent; in addition, PhabrOmeter has been demonstrated to measure fabric drape properties effectively. For certain products, different sample size was recommended in Cusick test, and the fabric curl is also a tough problem in Cusick. Neither is a concern for PhabrOmeter. There are still other factors, as presented below.

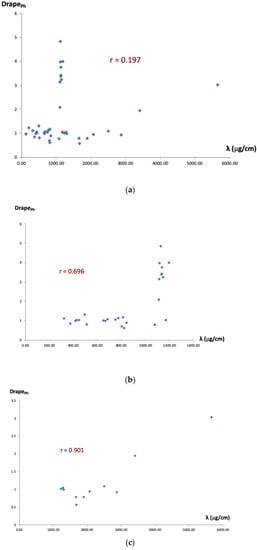

5.3.1. The Grouping Effect

One of the remaining issues is whether we should use all 40 fabrics as a single group to test/compare fabric drape behavior or divide them into subgroups for more thorough examination. As expected, if we divide all fabrics into more similar and thus smaller groups, there would be higher agreement between the test results, which, on the other hand, will increase the complicity of the entire test and analysis process—a compromise is therefore desirable. We used three groups classified by fabric linear density discussed above in Table 3 to study such grouping influence:

- All (40 fabrics) were used in one group, and then split into Group 2 (27 light fabrics only) and Group 3 (11 Medium and heavy fabrics).

- Two fabrics (#26 and #38) in the Super light Group, and #31 in Heavy Group were eliminated from comparison.

- We used PhabrOmeter to test the drape data to explore the grouping effect associated with linear density λ.

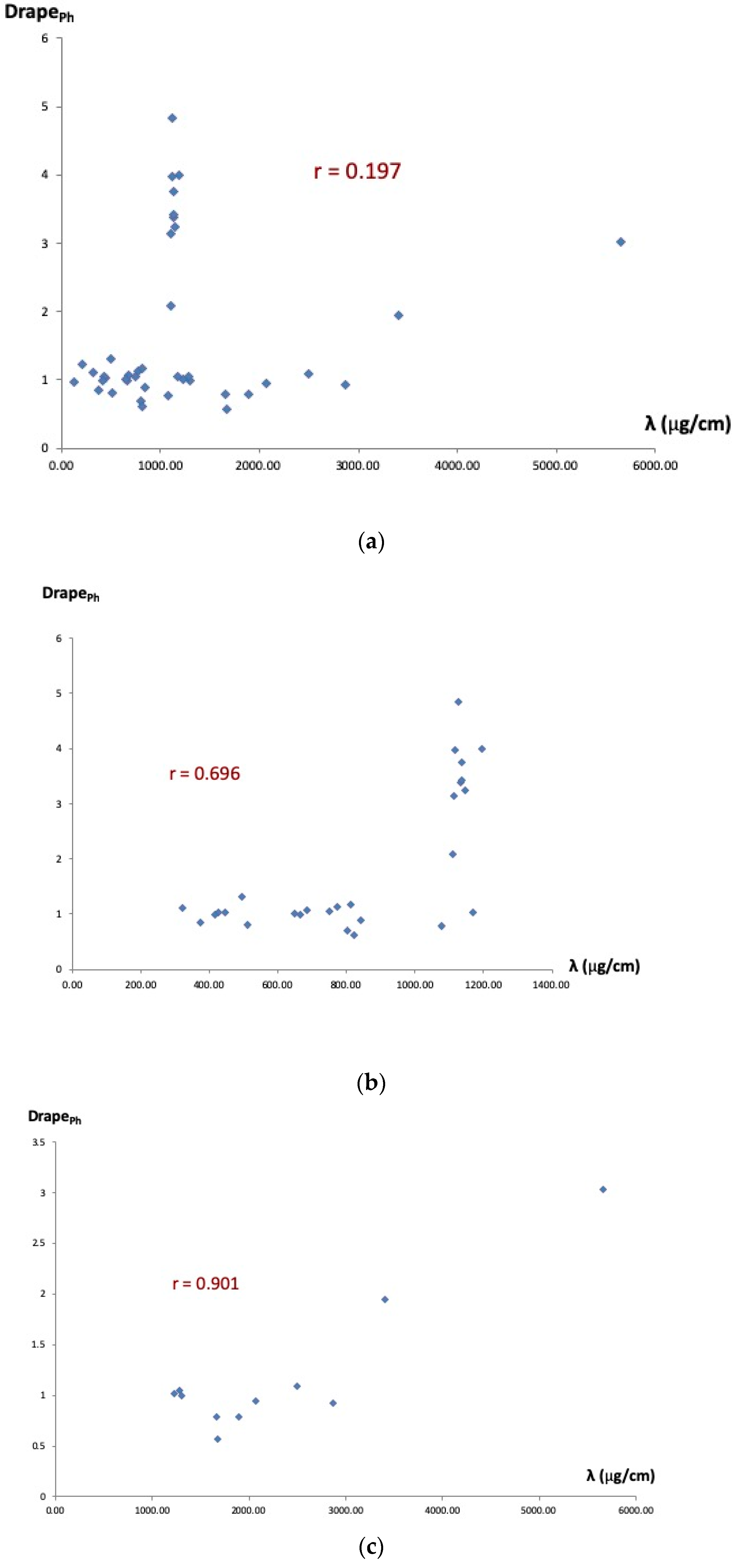

The comparison between drape data DrapePh and fabric linear density when all 40 fabrics forming a single group is provided in Figure 9a. A disappointing correlation of r = 0.197 suggests that it is not a good idea to put fabrics of different types into one group to compare their drape behaviors. Once divided into smaller groups based on the fabric linear density λ, Group 2 (27 light fabrics only) shows an increased r value to 0.696 in Figure 9b, and further to 0.901 for Group 3 (11 Medium and heavy fabrics) in Figure 9c. That is, grouping fabrics based on linear density indeed improves performance comparability.

Figure 9.

(a) PhabrOmeter Drape and UCD Linear Density (n = 40); (b) PhabrOmeter Drape data and Linear Density (Light weight only n = 27); and (c) PhabrOmeter Drape and Linear Density (Medium weight only, n = 11).

5.3.2. Construction Type Effect

An often-used grouping criterion is the fabric construction types, i.e., woven, knits or nonwoven. There are only two construction types out of the 40 fabrics: 13 wovens and 27 knits. We again used correlation analysis to examine if construction-based grouping improves the results. Note that, as this grouping based on construction mixed the different fabric linear density λ values into the same group, we had to use the Cusick drape data DrapeUA in comparison.

First, if all 40 fabrics formed a single group, the correlation between the drape data measured using Cusick and PhabrOmeter methods (see Figure 8) is r = 0.89. If we divide them into woven and knit groups, however, this correlation turned out to be r = 0.819 for the woven group, and r = 0.785 for the knit group. That is, grouping fabrics based on construction type does not seem to improve the consistency.

5.3.3. Effect of Fiber Types

Another general grouping scheme is based on fiber types. This way, the 40 fabrics present three categories—15 of pure cotton, 19 of cotton blend, and 6 of manufactured fibers (five polyester and one1 rayon). Again, comparing their drape data measured by Cusick and PhabrOmeter methods, the resultant correlations are: r = 0.838 within the pure cotton group; r = 0.554 for the cotton blend group; and r = 0.545 for the synthetic group. In other words, grouping based on fiber type does not seem to be a very useful option here either.

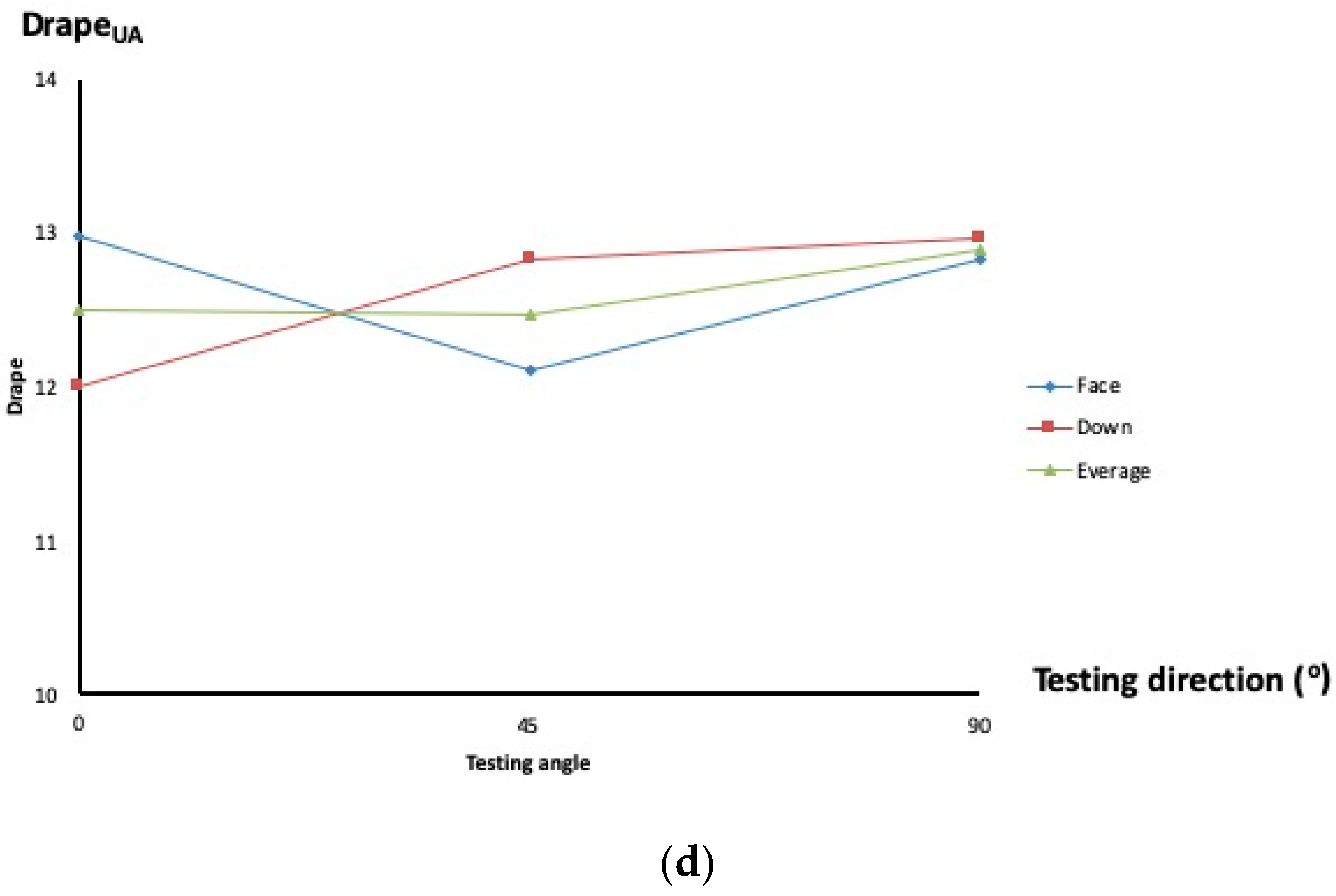

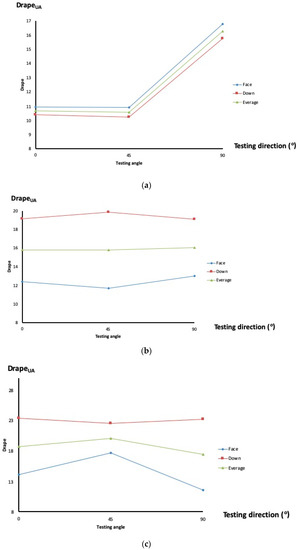

5.3.4. Side and Direction Effects

Next, we conducted studies to look into some extremely loose, limp and stretchy fabrics for which existing test results often appear irregular. There are several factors that may contribute to such test errors and we tackled the problems of testing direction and sample side, which appeared to be more influential. There are fabrics that tend to exhibit different behaviors when tested at different directions, called material anisotropy, although, by cutting specimens into circular shape when using PhabrOmeter, we have more or less “isotropicized” the specimen and thus alleviated the problem. Here are the steps followed:

- Select 18 loosest, limpest and stretchiest fabrics out of the 40 fabric set.

- Follow Option A in ISO 9073-9:2008 for Cusick drape test, as directionality is not a concern for PhabrOmeter.

- Test by aligning the sample in three different directions: at 0°, 45°, and 90° between warp and the instrument width directions.

- Test both face and back sides.

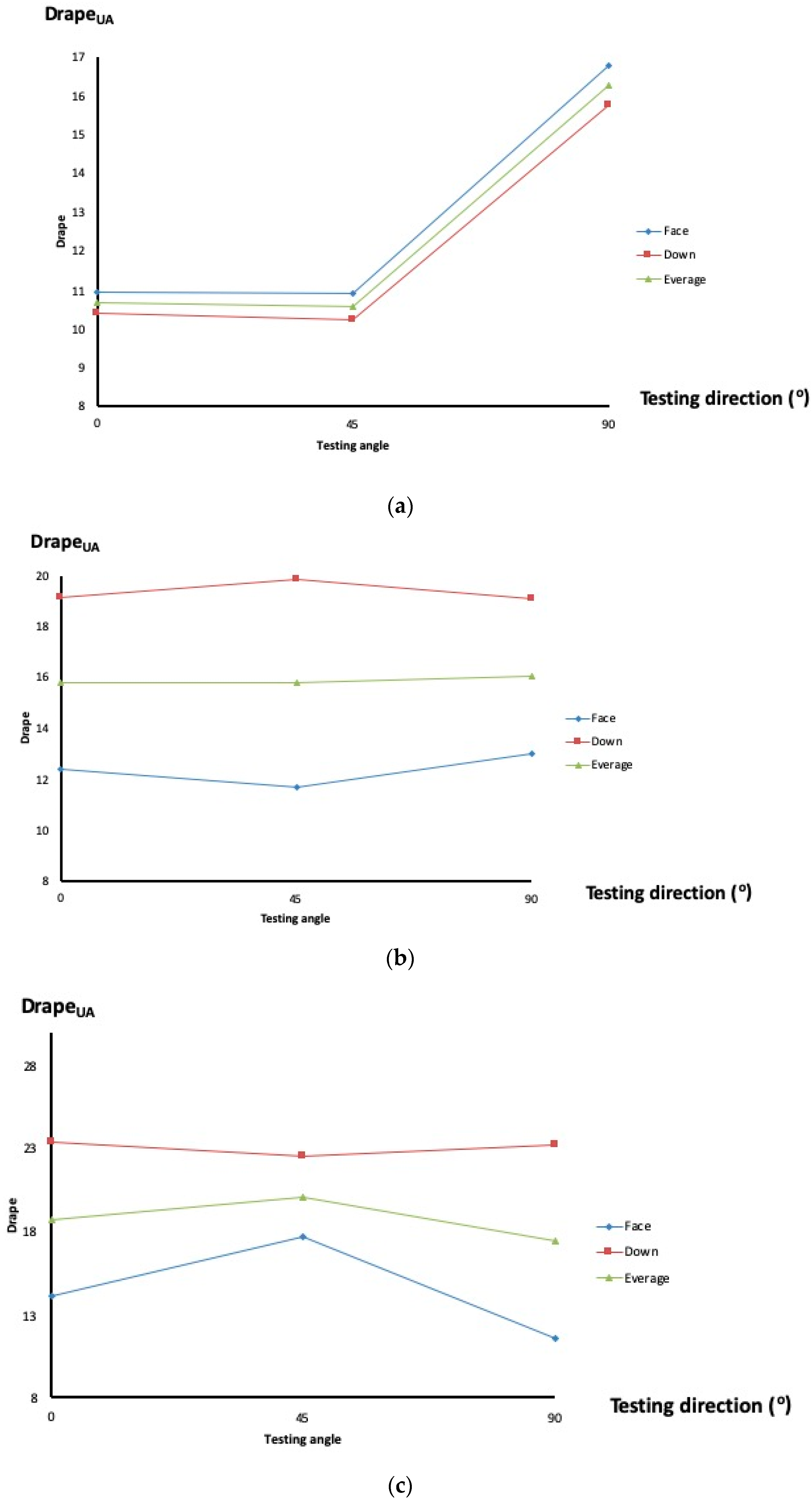

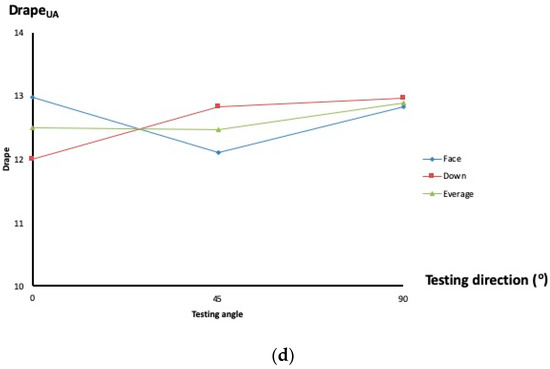

It is clear from the data that both testing direction and specimen side can impact testing results. For instance, in Figure 10a for Sample #36, a 100% polyester jersey with alternating S and Z twist in yarns, the tested average drape coefficients are 10.66 (0°) and 16.26 (90°), differing by more than 50%. However, this same sample shows a moderate variation between face and back sides, with highest difference at 90° of 16.774 (face) and 15.754 (back). On the other hand, in Figure 10b for Sample #23, a 37% cotton/63% acetate, plated jersey, it produced negligible direction effect but significant side effect. Overall, Sample #30 in Figure 10c generated the highest direction related error, and Sample #29 in Figure 10d the highest side error.

Figure 10.

(a) Directional and side effects for Sample #36; (b) directional and side effects for Sample #23; (c) directional and side effects for Sample #30; and (d) directional and side effects for Sample #29.

However, throughout our testing, it is Sample #33 that constantly displayed a peculiar drape behavior. In the original data from our first around of Cusick drape test, it resulted in a value of 20.6. However, in our second around of testing in examining the directional effect, the values for the three testing directions (0°, 45°, and 90°) are 35.4, 34.54 and 33.61 respectively, exhibiting large discrepancy between two testing times. After carefully checking our test procedures, we affirmed that all the data are reliable. By examining the fabric itself, we found a few possible causes:

- Being a single knit Inlay, #33 is a highly unstable structure. If not handled or even stored with extra caution during the whole process, inadvertent alternation of the fabric structure would lead to testing variations.

- Sample #33 has an extremely high (1852.4%) fabric stretch. It is thus hard to determine if there is any residual deformation left in a sample from previous stressing, resulting in changes in properties.

- Sample #33 also shows a very significant curl, known to cause testing error using Cusick method.

6. Conclusions

The fabric linear density λ defined in this paper is an intrinsic fabric parameter by definition, which reflects the influence of both fabric weight and thickness on fabric extraction using PhabrOmeter is related closely to a series of fabric properties, and is easy to calculate. Our results demonstrate that grouping fabrics based on this linear density indeed improves performance comparability. With the validation presented in this study, other major parameters including fabric weave and fiber type do not show any conflicts with or supersede over the fabric linear density λ. We hence recommend that it be used more widely as a primary fabric classifier.

Regarding fabric drape test using Cusick Drapemeter (ISO 9073-9:2008), our data confirm that both Option A, and Option B are consistent. This study further demonstrated that using PhabrOmeter to measure fabric drape properties is a more reliable and effective approach—it is quick, sensitive and with high repeatability [4,9]. In addition, it has the additional characteristics:

- cutting specimens into circular shape and being extracted during test by a force exerted at the sample center actually “isotropicize” the measurement process to reduce the variation caused by fabric directionality or anisotropies;

- as the samples are forced to drape, different sample sizes recommended in Cusick test are no longer necessary; and

- fabric curl, a tough problem in Cusick method, is no longer a concern for PhabrOmeter when the sample is actively compressed during test.

On the other hand, this approach will not be sensitive if fabric directionality or curling is of interest to be studied, which unfortunately is not handled well using Cusick approach either.

Before conducting drape test, the test face should be identified and recorded to maintain consistence. Face/back sides can lead to significantly different results.

Comparing the drape behaviors of different fabric types is not appropriate, and dividing them into more homogeneous groups, e.g., using fabric linear density λ, can make such comparison more meaningful. Logically, once in the same group defined by fabric linear density λ, further grouping based on fabric structure and fiber types can be done, if necessary. Our results here show, however, such further division does not result in further improvement.

Author Contributions

Conceptualization, N.P.; methodology, N.P. and J.X.; validation, J.X. and C.L.; investigation, J.X. and C.L.; formal analysis, N.P., J.X. and C.L.; resources, N.P.; data curation, N.P.; writing—original draft preparation, N.P.; writing—review and editing, N.P.; visualization, N.P.; supervision, N.P.; project administration, N.P.; and funding acquisition, N.P.

Funding

This research was partially funded by US NIFA, grant number CA-D*-TXC-6426-RR and CA-D*-TXC-7694-H.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Peirce, F.T. The handle of cloth as a measurable quantity. J. Text. Inst. 1930, 21, T377–T416. [Google Scholar] [CrossRef]

- Chu, C.C.; Cummings, C.L.; Teixeira, N.A. Mechanics of elastic performance of textile materials part V: A study of the factors affecting the drape of fabrics-the development of a drape meter. Text. Res. J. 1950, 20, 539–548. [Google Scholar] [CrossRef]

- Cusick, G.E. Measurement of fabric drape. J. Text. Inst. 1968, 59, 253. [Google Scholar] [CrossRef]

- Pan, N. Quantification and evaluation of human tactile sense towards fabrics. Int. J. Des. Nat. 2006, 1, 48–60. [Google Scholar]

- Easson, M.; Edwards, J.; Mao, N.; Carr, C.; Marshall, D.; Qu, J.; Graves, E.; Reynolds, M.; Villalpando, A.; Condon, B. Structure/Function Analysis of Nonwoven Cotton Topsheet Fabrics: Multi-Fiber Blending Effects on Fluid Handling and Fabric Handle Mechanics. Materials 2018, 11, 2077. [Google Scholar] [CrossRef] [PubMed]

- Kan, C.W.; Lau, T.C. Use of Softener in Home Laundering of Cotton Fabric-Hand Feel Value Measurement by PhabrOmeter. Fibers Polym. 2018, 19, 2203–2207. [Google Scholar] [CrossRef]

- De Pascalis, F.; Nacucchi, M. Relationship between the anisotropy tensor calculated through global and object measurements in high-resolution X-ray tomography on cellular and composite materials. J. Microsc. 2019, 273, 65–80. [Google Scholar] [CrossRef]

- Tadesse, M.G.; Harpa, R.; Chen, Y.; Wang, L.; Nierstrasz, V.; Loghin, C. Assessing the comfort of functional fabrics for smart clothing using subjective evaluation. J. Ind. Text. 2019, 48, 1310–1326. [Google Scholar] [CrossRef]

- Hearle, J.W.S.; Grosberg, P.; Backer, S. Structural Mechanics of Yarns and Fabrics; Wiley-Interscience: New York, NY, USA, 1969. [Google Scholar]

- Jacob, M.; Subramaniam, V. A review of the literature on drape and pilling properties of textile fabrics. Colourage 1987, 34, 21–22. [Google Scholar]

- Gaucher, M.L.; King, M.W.; Johnston, B. Predicting the drape coefficient of knitted fabrics. Text. Res. J. 1983, 53, 297–303. [Google Scholar] [CrossRef]

- Stylios, G.K.; Zhu, R. The characterisation of the static and dynamic drape of fabrics. J. Text. Inst. 1997, 88, 465–475. [Google Scholar] [CrossRef]

- Postle, J.R.; Postle, R. The dynamics of fabric drape. Text. Res. J. 1999, 69, 623–629. [Google Scholar] [CrossRef]

- Matsudaira, M. Study on static and dynamic drape coefficients of fabrics. Sen-I Gakkaishi 2003, 59, P306–P310. [Google Scholar] [CrossRef]

- Taha, I.; Abdin, Y.; Ebeid, S. Analysis of the Draping Behaviour of Multi-Layer Textiles using Digital Image Processing. Polym. Polym. Compos. 2012, 20, 837–843. [Google Scholar] [CrossRef]

- Döbrich, O.; Gereke, T.; Cherif, C.; Krzywinski, S. Analysis and finite element simulation of the draping process of multilayer knit structures and the effects of a localized fixation. Adv. Compos. Mater. 2013, 22, 175–189. [Google Scholar] [CrossRef]

- Fischer, P.; Krzywinski, S.; Rodel, H.; Schenk, A.; Ulbricht, V. Simulating the drape behavior of fabrics. Text. Res. J. 1999, 69, 331–334. [Google Scholar] [CrossRef]

- Dias, J.M.S.; Gamito, M.N.; Rebordao, J.M. A discretized linear elastic model for cloth buckling and drape. Text. Res. J. 2000, 70, 285–297. [Google Scholar] [CrossRef]

- Hu, J.L.; Chen, S.F.; Teng, J.G. Numerical drape behavior of circular fabric sheets over circular pedestals. Text. Res. J. 2000, 70, 593–603. [Google Scholar]

- Bruniaux, P.; Vasseur, C. Modeling and identifying the parameters of a fabric drape model. Text. Res. J. 2001, 71, 336–342. [Google Scholar] [CrossRef]

- Fan, J.; Newton, E.; Au, R.; Chan, S.C.F. Predicting garment drape with a fuzzy-neural network. Text. Res. J. 2001, 71, 605–608. [Google Scholar] [CrossRef]

- Fare, N.; Maitre, E. Existence of solutions for a woven fabric drape model. Comptes Rendus De L Acad. Des Sci. Serie I-Math. 2001, 333, 967–972. [Google Scholar]

- Hofstee, J.; van Keulen, F. 3-D geometric modeling of a draped woven fabric. Compos. Struct. 2001, 54, 179–195. [Google Scholar] [CrossRef]

- Lo, W.M.; Hu, J.L.; Li, L.K. Modeling a fabric drape profile. Text. Res. J. 2002, 72, 454–463. [Google Scholar] [CrossRef]

- Bruniaux, P.; Ghith, A.; Vasseur, C. Modeling and parametric study of a fabric drape. Adv. Complex Syst. 2003, 6, 457–476. [Google Scholar] [CrossRef]

- Termonia, Y. Lattice model for the drape and bending properties of nonwoven fabrics. Text. Res. J. 2003, 73, 74–78. [Google Scholar] [CrossRef]

- Sirtautas, J.; Pickett, A.K.; Lepicier, P. A mesoscopic model for coupled drape-infusion simulation of biaxial Non-Crimp Fabric. Compos. Part B-Eng. 2013, 47, 48–57. [Google Scholar] [CrossRef]

- Chen, B.J.; Govindaraj, M. A physically-based model of fabric drape using flexible shell theory. Text. Res. J. 1995, 65, 324–330. [Google Scholar] [CrossRef]

- Stump, D.M.; Fraser, W.B. A simplified model of fabric drape based on ring theory. Text. Res. J. 1996, 66, 506–514. [Google Scholar] [CrossRef]

- Chen, M.X.; Sun, Q.P.; Yuen, M.F. Simulation of fabric drape using a thin plate element with finite rotation. Acta Mech. Sin. 1998, 14, 239–247. [Google Scholar]

- Dhande, S.G.; Rao, P.V.M.; Tavakkoli, S.; Moore, C.L. Geometric Modeling of Draped Fabric Surfaces. In Graphics, Design and Visualization; Mudur, S.P., Pattanaik, S.N., Eds.; Elsevier: Amsterdam, The Netherlands, 1993; pp. 349–356. [Google Scholar]

- Al-Gaadi, B.; Goktepe, F.; Halasz, M. A new method in fabric drape measurement and analysis of the drape formation process. Text. Res. J. 2012, 82, 502–512. [Google Scholar] [CrossRef]

- Mizutani, C.; Amano, T.; Sakaguchi, Y. A new apparatus for the study of fabric drape. Text. Res. J. 2005, 75, 81–87. [Google Scholar] [CrossRef]

- Sun, M.N. A new tester and method for measuring fabric stiffness and drape. Text. Res. J. 2008, 78, 761–770. [Google Scholar] [CrossRef]

- Jacob, M.; Subramanniam, V. Assessment of drape of uniform fabrics. Colourage 1990, 37, 21–22. [Google Scholar]

- Szabo, L.; Halasz, M. Examination of dependence of drape coefficient on the samples size. Tekstil 2008, 57, 439–447. [Google Scholar]

- Tamas, P.; Gersak, J.; Halasz, M. Sylvie((R)) 3D drape tester-New system for measuring fabric drape. Tekstil 2006, 55, 497–502. [Google Scholar]

- Farajikhah, S.; Madanipour, K.; Saharkhiz, S.; Latifi, M. Shadow Moire Aided 3-D Reconstruction of Fabric Drape. Fibers Polym. 2012, 13, 928–935. [Google Scholar] [CrossRef]

- Jeong, Y.J. A study of fabric-drape behaviour with image analysis part I: Measurement, characterisation, and instability. J. Text. Inst. 1998, 89, 59–69. [Google Scholar] [CrossRef]

- Kown, E.S.; Yoon, S.Y.; Sul, I.H.; Kim, S.; Park, C.K. A Quantitative Fabric Drape Evaluation System Using Image-Processing Technology, Part 2: Effect of Fabric Properties on Drape Parameters. J. Test. Eval. 2010, 38, 263–270. [Google Scholar]

- Park, C.K.; Kim, S.; Yu, W.R. Quantitative fabric drape evaluation system using image processing technology (Part 1: Measurement system and geometric model). J. Test. Eval. 2004, 32, 131–137. [Google Scholar] [CrossRef]

- Willems, A.; Lomov, S.V.; Verpoest, I.; Vandepitte, D. Drape-ability characterization of textile composite reinforcements using digital image correlation. Opt. Lasers Eng. 2009, 47, 343–351. [Google Scholar] [CrossRef]

- Kawabata, S. The Standardization and Analysis of Handle Evaluation, 2nd ed.; The Textile Machinery Society of Japan: Osaka, Japan, 1980. [Google Scholar]

- Pan, N.; Yen, K.C.; Zhao, S.J.; Yang, S.R. A new approach to the objective evaluation of fabric handle from mechanical-properties. Text. Res. J. 1988, 58, 438–444. [Google Scholar] [CrossRef]

- Pan, N.; Yen, K.C. Physical interpretations of curves obtained through the fabric extraction process for handle measurement. Text. Res. J. 1992, 62, 279–290. [Google Scholar] [CrossRef]

- Nu Cybertek, Inc. PhabrOmeter. 2014. Available online: http://www.nucybertek.com (accessed on 23 July 2019).

- Wang, H.; Mahar, T.J.; Pan, N.; Postle, R. Objective handle evaluation of next-to-skin fabrics knitted from merino wool. In Proceedings of the 86th Textile Institute World Conference, Hong kong, China, 18–21 November 2008; Volume 3. [Google Scholar]

- Mahar, T.J.; Wang, H. Measuring fabric handle to define luxury: An overview of handle specification in next-to-skin knitted fabrics from Merino wool. Anim. Prod. Sci. 2010, 50, 1082–1088. [Google Scholar] [CrossRef]

- AATCC. Test Method 202–2012, Relative Hand Value of Textiles: Instrumental Method; AATCC: Raleigh, NC, USA, 2012. [Google Scholar]

- Kim, J.O.; Slaten, B.L. Objective evaluation of fabric hand-Part I: Relationships of fabric hand by the extraction method and related physical and surface properties. Text. Res. J. 1999, 69, 59–67. [Google Scholar] [CrossRef]

- Bassett, R.J.; Postle, R.; Pan, N. Experimental methods for measuring fabric mechanical properties: A review and analysis. Textile Res. J. 1999, 69, 866–875. [Google Scholar] [CrossRef]

- Alley, V.L., Jr. Revised Theory for the Quantitative Analysis of Fabric Hand. J. Eng. Ind. 1980, 102, 25–31. [Google Scholar] [CrossRef]

- Behery, H.M. Comparison of Fabric Hand Assessment in the United States and Japan. Textile Res. J. 1986, 56, 227–240. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).