1. Introduction

The escalating environmental impact of petroleum-based materials has intensified the search for sustainable alternatives in engineering applications. Natural lignocellulosic fibers (NLFs) have emerged as attractive reinforcements for polymer matrices owing to their renewability, biodegradability, low cost, and wide availability [

1,

2,

3,

4]. Their industrial relevance is evidenced by applications in the automotive [

5,

6,

7], construction [

8,

9], and textile sectors [

10], among others [

11,

12,

13,

14].

Several NLFs, including hemp [

15,

16,

17,

18], bamboo [

19,

20,

21], jute [

22,

23,

24], sisal [

25,

26,

27], flax [

28,

29,

30,

31], coconut [

32], and curaua [

33,

34], exhibit mechanical properties that rival synthetic fibers. For instance, curaua fibers present tensile strengths of up to 3000 MPa at low density, yielding a higher specific strength than carbon, aramid, or E-glass fibers [

35]. Such performance underscores the potential of NLFs as eco-friendly reinforcements for structural composites.

Within this context, kenaf (

Hibiscus cannabinus L.) has gained attention due to its global cultivation, favorable mechanical performance, and increasing use in composite materials [

36]. Kenaf fibers have been incorporated into a variety of polymer matrices, including epoxy [

37,

38,

39], polypropylene [

40,

41,

42,

43], HDPE [

44,

45,

46,

47], polystyrene [

48,

49,

50], PLA [

51,

52,

53,

54], PVC [

55,

56,

57], and polyester [

58,

59,

60,

61]. In epoxy systems, however, studies remain comparatively limited. While early reviews [

36] reported no examples of kenaf/epoxy composites, subsequent research has primarily focused on thermal properties [

62] and flexural or fatigue behavior [

63,

64,

65,

66,

67], with fewer studies addressing tensile or impact performance [

68,

69,

70].

Despite these efforts, important gaps remain. For example, Bakar et al. [

63] reported Izod impact results for kenaf/epoxy composites that were comparable to neat epoxy, whereas Mutasher et al. [

64] observed higher values. Rassmann et al. [

65] and Mahjoub et al. [

67] emphasized tensile strength, while more recent studies [

68,

69,

70] explored alkali treatment effects and dynamic behavior. Nevertheless, comprehensive evaluation of toughness—particularly absorbed energy under tensile loading—remains scarce.

To address these gaps, the present study investigates, for the first time, the tensile and dynamic (Izod impact) toughness of epoxy composites reinforced with 10, 20, and 30 vol% of untreated kenaf fibers. The research scope included (i) the characterization of individual fiber properties, (ii) the fabrication and testing of composite specimens under standardized tensile and impact conditions, and (iii) the analysis of the relationship between fiber content, fracture mechanisms, and toughness. These objectives were defined to establish a comprehensive understanding of kenaf fiber as reinforcement in epoxy matrices and to provide a foundation for future structural applications.

2. Materials and Methods

Kenaf fibers were supplied by Tapete São Carlos Ltd.a. (São Paulo, Brazil). They were extracted from the herbaceous plant

Hibiscus cannabinus (Malvaceae family) [

71], then manually separated, washed by immersion in water for 24 h, cut into 150 mm lengths, and oven-dried at 70 °C for 24 h. No chemical treatment was applied to the fibers.

The polymeric matrix consisted of a commercial epoxy resin, diglycidyl ether of bisphenol A (DGEBA), cured with triethylenetetramine (TETA) at a stoichiometric ratio of 13 phr. Both resin and hardener were produced by Dow Chemical (São Paulo, Brazil) and distributed by Resinpoxy Ltd.a. (Rio de Janeiro, Brazil).

2.1. Kenaf Fiber Characterization

2.1.1. Diameter Measurement

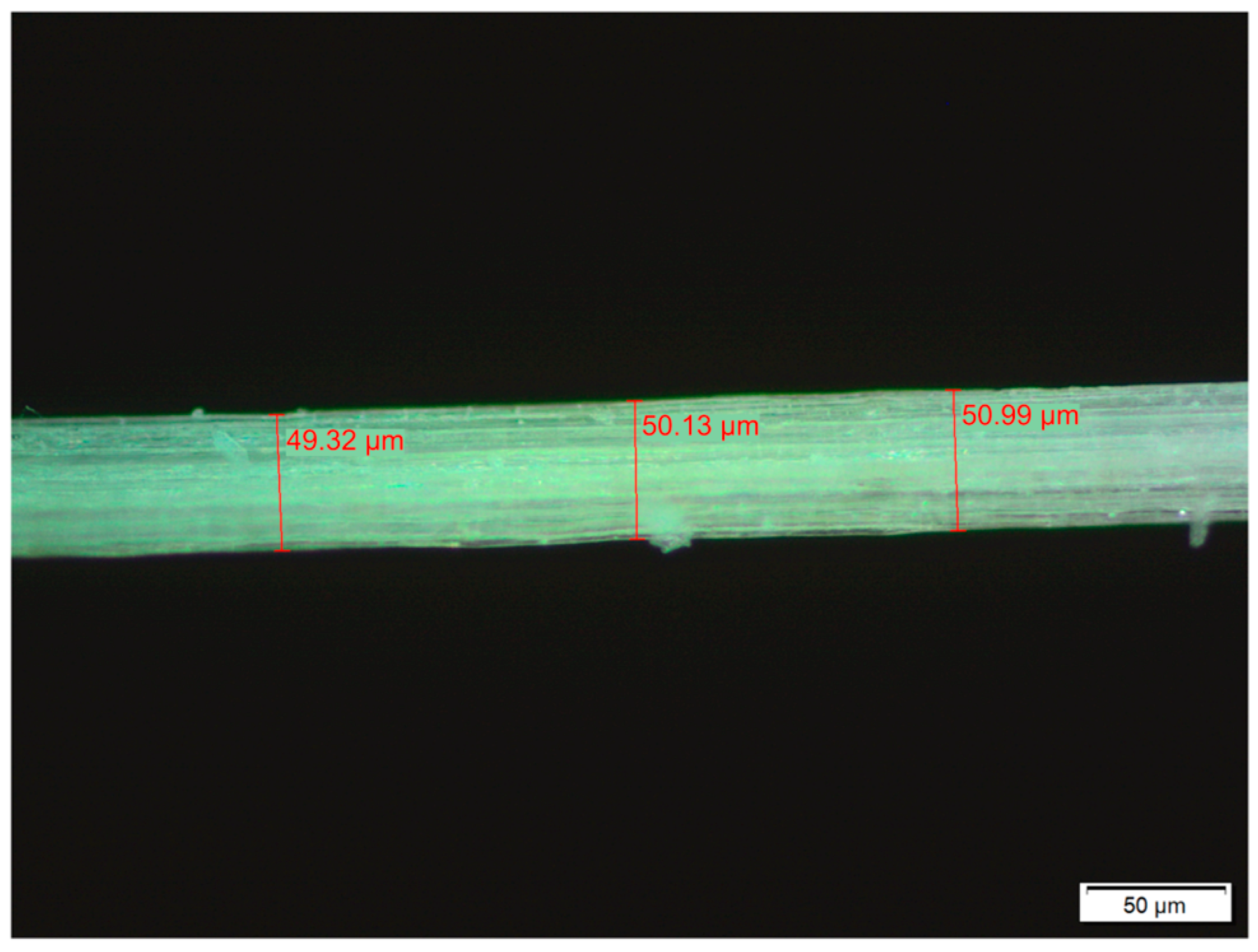

The experiment included a detailed analysis of fiber dimensions, encompassing both cross-sectional diameter and length, performed using light microscopy. A total of 100 fibers were individually measured at three distinct positions and two orientations (0° and 90°). Each fiber was subsequently weighed on an electronic balance (AG-200, Sipcam Nichino Brasil, São Paulo, Brazil) with a precision of 0.0001 g. Dimensional measurements were obtained using an optical microscope (BX53M, Olympus, Center Valley, PA, USA).

The diameters of the 100 pre-selected fibers were measured and categorized into six classes, enabling the determination of the diameter distribution and the average diameter of the as-received kenaf fibers. Representative micrographs were also acquired to illustrate the measurement procedure.

Figure 1 presents a typical example of an individual fiber measured at three points along its length, highlighting the dimensional heterogeneity characteristic of natural lignocellulosic fibers.

2.1.2. Fiber Tensile Tests

Tensile tests of kenaf fibers were carried out in accordance with ASTM D3822 [

72] using a universal testing machine (Instron 3365, Instron, Norwood, MA, USA) equipped with a 10 kN load cell, providing ±0.5% accuracy for both load and strain measurements. The crosshead speed was set at 0.4 mm/min.

Based on material availability, an equal number of fibers from each dimensional group were tested. Specifically, five fibers from each of the six groups were selected, each with a gauge length of 40 mm. The results were statistically analyzed to obtain mean values and standard deviations, and further evaluated at a 95% confidence level.

2.2. Composites Processing

Composite plates containing 10, 20, and 30 vol% kenaf fibers were fabricated using a steel mold with internal dimensions of 150 × 120 × 12 mm. Fibers were manually aligned along the mold length to promote unidirectional orientation before resin impregnation, after which the epoxy–hardener mixture was poured at the previously calculated fiber/resin ratio. Although no quantitative orientation distribution analysis was performed, care was taken to minimize misalignment during fabrication. The reproducibility of mechanical results across specimens indicates consistent fiber orientation. Fiber density was determined using the geometric linear density method, by weighing approximately 100 fibers and measuring their diameters and lengths under an optical microscope.

The average fiber density was calculated as 1.53 g/cm

3, while the epoxy resin density was reported as 1.11 g/cm

3 [

73,

74]. The curing process was carried out under a constant pressure of 5 tons at room temperature (≈25 °C) for 24 h, without additional thermal post-curing, in line with standard practices for DGEBA/TETA systems, which achieved complete curing at ambient conditions through stoichiometric hardener addition. The void content, measured by the Archimedes method, was below 5%.

Table 1 summarizes the nomenclature adopted for the analyzed samples.

Two types of plates were produced to prepare specimens for mechanical testing: thin plates (150 × 120 × 2 mm) for tensile tests in accordance with ASTM D3039 [

75], and thick plates (150 × 120 × 10 mm) for Izod impact tests in accordance with ASTM D256 [

76]. This procedure ensured that the final specimen dimensions complied with the respective standard requirements.

No chemical treatment was applied to the fibers, as the purpose of this study was to assess the intrinsic contribution of raw kenaf fibers to the tensile and impact toughness of epoxy composites. Although surface treatments were often employed to enhance fiber–matrix interfacial adhesion, they may also introduce additional variables that complicate direct comparison with untreated fibers. Therefore, the use of raw fibers was intentionally chosen to isolate their natural reinforcing effect.

2.2.1. Composites Characterization

Composite Tensile Tests

Tensile tests of the kenaf fiber-reinforced epoxy composites were conducted in accordance with ASTM D3039 [

75]. Specimens were extracted from composite plates measuring 150 × 120 × 2 mm and containing 0, 10, 20, or 30 vol% fibers. Seven specimens were prepared for each group. Testing was performed on an Instron 5582 universal machine at a crosshead speed of 2 mm/min. The measured properties included the tensile strength, elastic modulus, elongation at break, and toughness, with the latter determined from the area under the stress–strain curve.

Stress–strain curves were recorded directly from the testing machine without compliance correction. This approach was justified by the relatively large specimen dimensions compared with the machine stiffness, which minimized compliance effects. Furthermore, since all groups were tested under identical conditions, any residual compliance equally influenced the specimens, thereby preserved the validity of comparisons between neat epoxy and kenaf fiber composites.

Izod Impact Tests

Izod impact tests were conducted in accordance with ASTM D256 [

76]. Specimens were cut from the composite plates to dimensions of 63.5 × 12.7 × 10 mm, yielding 10 specimens per group. Notches with a depth of 2.54 mm and an angle of 45 ± 1° were introduced using a manual broaching machine (IME, Rio de Janeiro, Brazil). The tests were performed on a PANTEC XC-50 pendulum impact tester (PANTEC, Campos do Goytacazes, Brazil) equipped with a 22 J hammer.

Scanning Electron Microscopy (SEM)

The fracture surfaces of the kenaf fiber-reinforced epoxy composites were examined using a scanning electron microscope (SEM, Quanta FEG 250, FEI, Hillsboro, OR, USA). Observations were carried out with a secondary electron detector at an accelerating voltage of 10 kV and magnifications ranging from 240× to 1600×. To improve conductivity and image quality, the samples were gold-coated using a Leica ACE 600 sputter coater (Leica Microsystems, Wetzlar, Germany).

Statistical Analysis

The mechanical results were statistically analyzed using analysis of variance (ANOVA) to evaluate significant differences among the mean values at a 95% confidence level. Post hoc comparisons were performed using Tukey’s test, also known as the honestly significant difference (HSD), calculated as follows:

where

q is the tabulated HSD constant for a 5% significance level, EMS is the error mean square obtained from ANOVA, and r is the number of replicates per treatment [

77].

3. Results and Discussions

3.1. Kenaf Fiber Properties

The six diameter intervals obtained for the kenaf fibers and their respective frequencies are summarized in

Table 2. The first four intervals exhibited the highest frequencies, with the most common diameter being 0.058 mm.

From the measurements of 100 fibers, the average diameter corresponding to the most frequent interval (0.058 mm) was consistent with the value reported by Ramesh [

72], approximately 0.067 mm. Owing to their heterogeneous structure, NLFs naturally exhibit diameter variations along the length of individual fibers [

34].

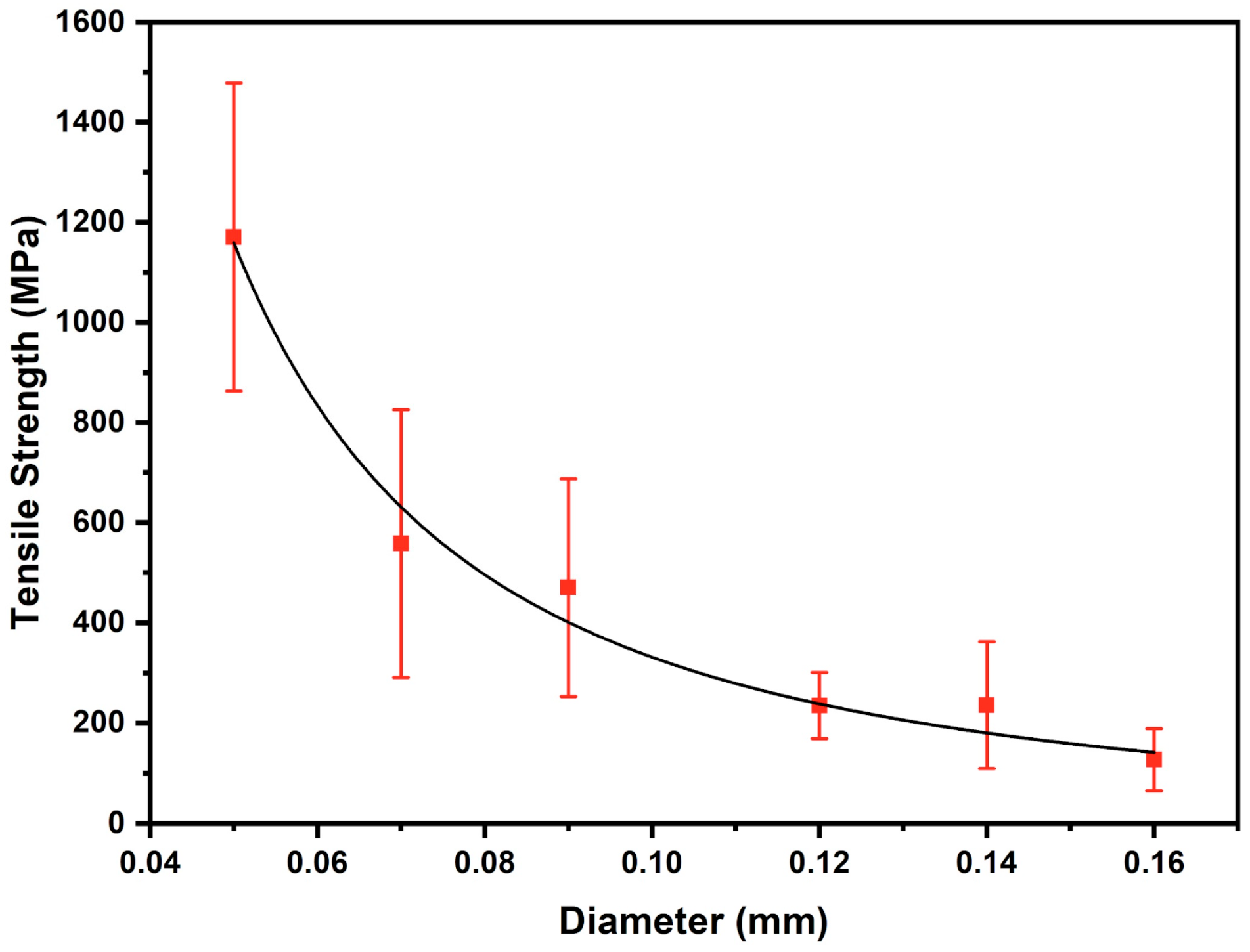

Figure 2 presents representative stress–strain curves for single kenaf fibers corresponding to each of the six diameter intervals listed in

Table 2. These curves reveal an initial linear elastic response followed by abrupt rupture, a characteristic feature of brittle fracture. As observed in

Figure 2, an increase in fiber diameter generally correlates with reduced tensile strength and decreased elongation at break.

Table 3 presents the average and standard deviation of tensile strength and absorbed energy for single kenaf fibers across the diameter intervals defined in

Table 2.

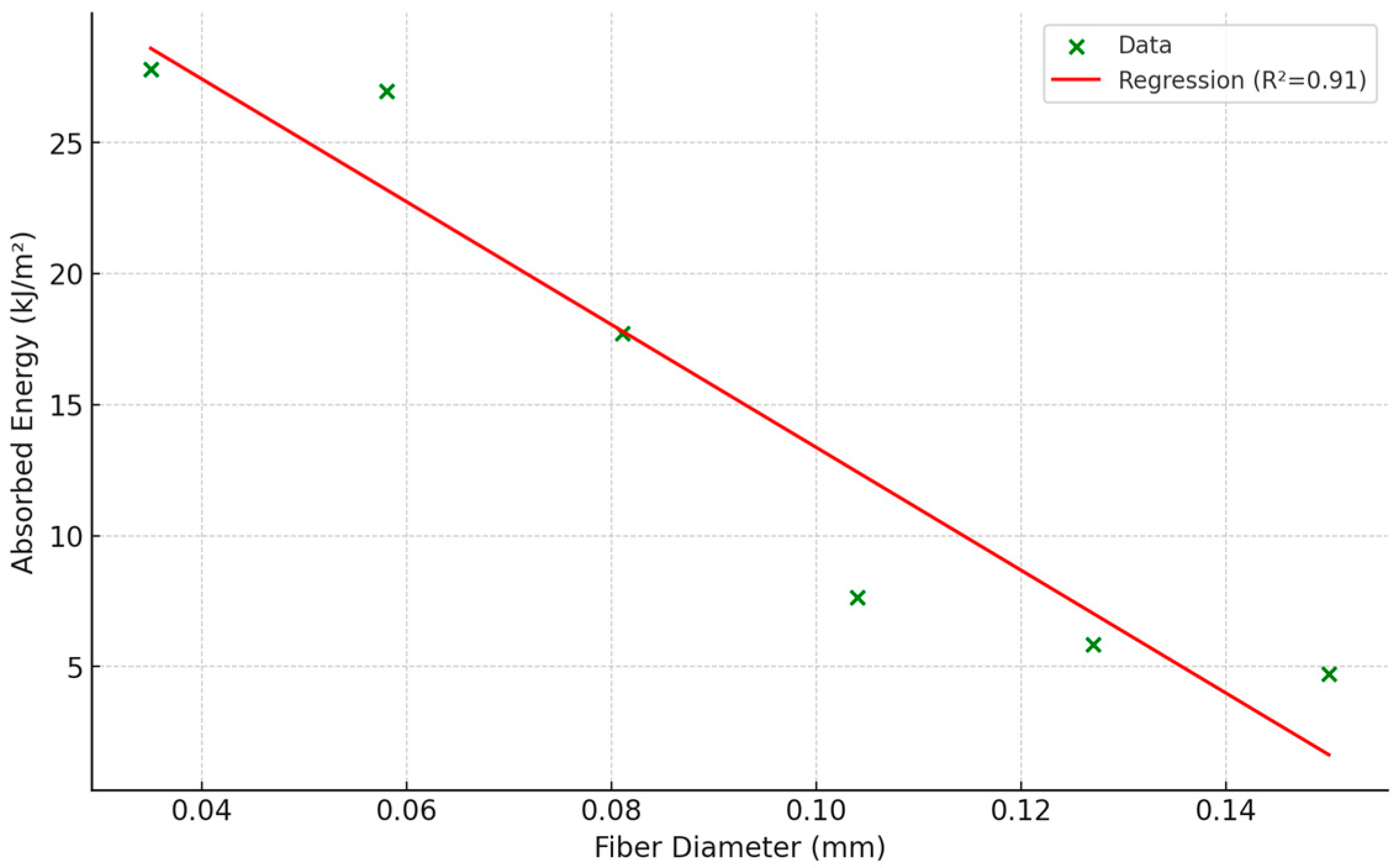

To quantify the relationship between fiber diameter and mechanical performance, statistical analyses were conducted. Pearson’s correlation revealed strong and significant negative relationships between fiber diameter and tensile strength (r = −0.90,

p = 0.014), as well as between fiber diameter and absorbed energy (r = −0.96,

p = 0.003). Linear regression further confirmed these results, with coefficients of determination of R

2 = 0.82 for tensile strength and R

2 = 0.91 for absorbed energy. These findings, illustrated in

Figure 3 and

Figure 4, demonstrate that thinner kenaf fibers consistently exhibit superior tensile properties, supporting the hypothesis that defect density increases with fiber thickness.

Both tensile strength and absorbed energy were higher in the fibers of the smallest diameter range compared to those of larger diameters, as shown in

Table 3. Increasing fiber diameter resulted in a substantial reduction in both properties. This behavior is attributed to the greater defect density present in thicker fibers, which impairs mechanical resistance [

34]. Notably, the absorbed energy values in

Table 3 indicate that thinner kenaf fibers exhibit relatively high tensile toughness, a result not previously reported for brittle NLFs.

Based on the absorbed energy data in

Table 3, ANOVA was performed to verify the statistical reliability of the mean values, particularly in light of the relatively high standard deviations observed for the smaller diameter intervals. The corresponding analysis of variance is presented in

Table 4.

The absorbed energy results of single kenaf fibers were found to be statistically different, as the calculated F value exceeded the tabulated critical F. To further identify differences among the groups, Tukey’s test was applied. With an HSD value of 21.29, the results presented in

Table 5 revealed significant differences among the diameter intervals.

3.2. Composite Tensile Properties

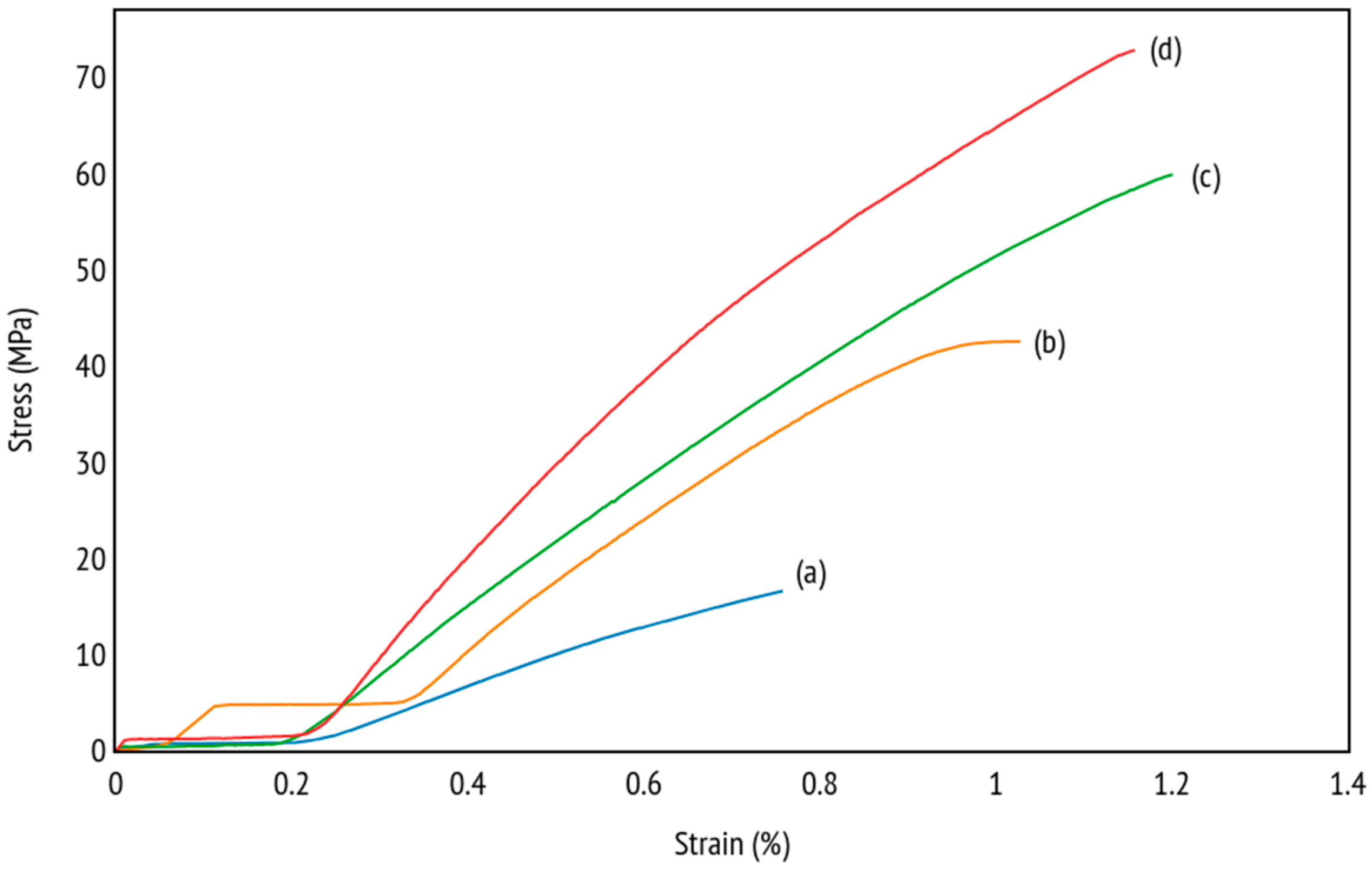

Figure 5 presents representative tensile stress–strain curves for neat epoxy and epoxy composites reinforced with 10, 20, and 30 vol% kenaf fibers.

The average mechanical properties obtained from the seven tensile specimens in each group are summarized in

Table 6.

A slight increase in tensile properties was observed between neat epoxy and the 10 vol% kenaf composite. By contrast, a significant improvement was found between 10 and 20 vol% fiber content, even considering the standard deviations. This suggests the existence of a threshold fiber content (between 10 and 20 vol%) required to achieve more effective reinforcement in epoxy composites. Such behavior is not commonly observed in epoxy composites reinforced with other NLFs, which often exhibit reduced tensile properties at a low fiber content, as reported for hemp [

18] and caranan fibers [

78].

Table 6 also indicates that the tensile properties of composites with 20 and 30 vol% kenaf fibers are statistically similar. This can be attributed to the reduced fiber–matrix adhesion at higher fiber contents [

79], which hinders effective stress transfer. For example, Krishna and Kanny [

69] reported a tensile strength of 16 ± 1 MPa for an epoxy composite with 41 wt% kenaf fibers, which is significantly lower than the present result of 60.23 ± 7.33 MPa for 37 wt% (30 vol%).

Comparisons with other studies further highlight the variability of results. Mahjoub et al. [

67], without statistical analysis, reported higher values of tensile strength, the modulus, and elongation at break than those in

Table 6. Conversely, Mutasher et al. [

64] reported a tensile strength of only 27.72 MPa for an epoxy composite with 24 wt% kenaf fibers, which is markedly lower than the present results. These discrepancies underscore the inherent variability of NLFs [

34], even within the same fiber type.

Within the scope of this work, the tensile toughness results in

Table 6 warrant particular attention. Since no fiber selection was performed during composite fabrication, the mean absorbed energy of single kenaf fibers (

Table 3) must be considered. By accounting for the frequency distribution of fiber diameters (

Table 2), the overall contribution was estimated as follows:

When this average absorbed energy of single fibers is added to the neat epoxy tensile toughness of 4.23 ± 1.57 kJ/m

2, the resulting values closely match those of EK20 and EK30 composites in

Table 6. This quantitatively demonstrates the contribution of kenaf fibers to the tensile toughness of epoxy composites.

3.3. Statistical Analysis of Tensile Toughness

ANOVA was performed on the tensile toughness values (area under the stress–strain curve) presented in

Table 6 to verify the presence of statistically significant differences. The results are summarized in

Table 7.

The analysis indicated that the tensile toughness values of the kenaf fiber composites were significantly different, as the calculated F exceeded the critical F value. To further identify differences among the groups, Tukey’s test was applied. With an HSD value of 16.96, the results shown in

Table 8 confirm significant differences among the composites.

Specifically, no statistical difference was observed between EPOXY and EK10, as their toughness values were below the HSD threshold. In contrast, EK20 and EK30 displayed statistically similar performance but with significantly higher toughness than both EPOXY and EK10.

3.4. Tensile Fracture Mechanism

Figure 6 presents representative SEM micrographs of the fracture surfaces of neat epoxy and kenaf fiber/epoxy composites.

In

Figure 6a, the neat epoxy exhibits characteristic river markings that are typical of brittle fracture, consistent with its low toughness and elongation values reported in

Table 6. For the EK10 composite (

Figure 6b), limited fiber pullout is observed together with interlaminar cracks. These defects, attributed to reduced fiber–matrix adhesion and the presence of occasional voids or impurities, account for the only modest improvement in mechanical properties relative to neat epoxy.

At higher fiber fractions, EK20 (

Figure 6c) displays a greater density of pulled-out fibers, whereas EK30 (

Figure 6d) reveals a combination of fiber fracture and pullout. The reduced prevalence of interfacial cracks in EK20 and EK30 correlates with the higher tensile strength, elastic modulus, and toughness values in

Table 6. Notably, the increased proportion of fiber fracture relative to pullout indicates more efficient stress transfer across the fiber–matrix interface, consistent with the improved load-bearing capacity of these composites.

3.5. Dynamic Izod Impact Toughness

Figure 7 presents the macroscopic appearance of typical impact-tested kenaf fiber/epoxy composite specimens. Notably, the 30 vol% specimens (EK30) shown in

Figure 7c did not fracture into two separate parts.

According to ASTM D256 [

76], such specimens cannot be statistically considered; however, their partial failure strongly indicates a higher energy absorption capacity. This observation is consistent with the fact that incomplete fracture requires greater impact energy for failure.

Table 9 summarizes the absorbed energy values obtained in the Izod impact tests.

For validation, it is relevant to note that the DGEBA/TETA epoxy manufacturer reports a typical Izod impact strength of approximately 2.0 kJ/m2 for neat epoxy, which agrees with the 1.8 kJ/m2 measured in the present study, confirming the reliability of the experimental procedure.

A clear trend of increasing absorbed energy with higher fiber content is evident in

Table 9, consistent with reports on other, less widely investigated NLF composites [

80,

81,

82]. The effect of incorporating 30 vol% kenaf fibers was particularly remarkable, resulting in an energy absorption that was more than 20 times greater than that of neat epoxy.

Figure 8 graphically compares the tensile and Izod impact toughness values obtained in this study. It is worth emphasizing that, on average, the tensile toughness of kenaf fiber/epoxy composites exceeded their corresponding Izod impact toughness. Such results, reported here for the first time in NLF-reinforced polymer composites, highlight the relevance of these materials for applications where mechanical energy absorption is critical.

3.6. Statistical Analysis of Izod Impact Toughness

ANOVA was performed on the dynamic toughness (absorbed energy) values obtained from the Izod impact test (

Table 9) to assess the presence of statistically significant differences. The ANOVA results are presented in

Table 10.

The analysis confirmed that the impact toughness values of the kenaf fiber/epoxy composites were statistically significant, as the calculated F exceeded the critical F value. To further discriminate among groups, Tukey’s test was applied. With an HSD value of 2.30, the results in

Table 11 indicate significant differences among all composites.

Examination of the intervals revealed that all groups differed significantly, as the variation in mean toughness values exceeded the HSD threshold. Notably, EK30 exhibited the most pronounced difference, confirming its superior energy absorption capacity.

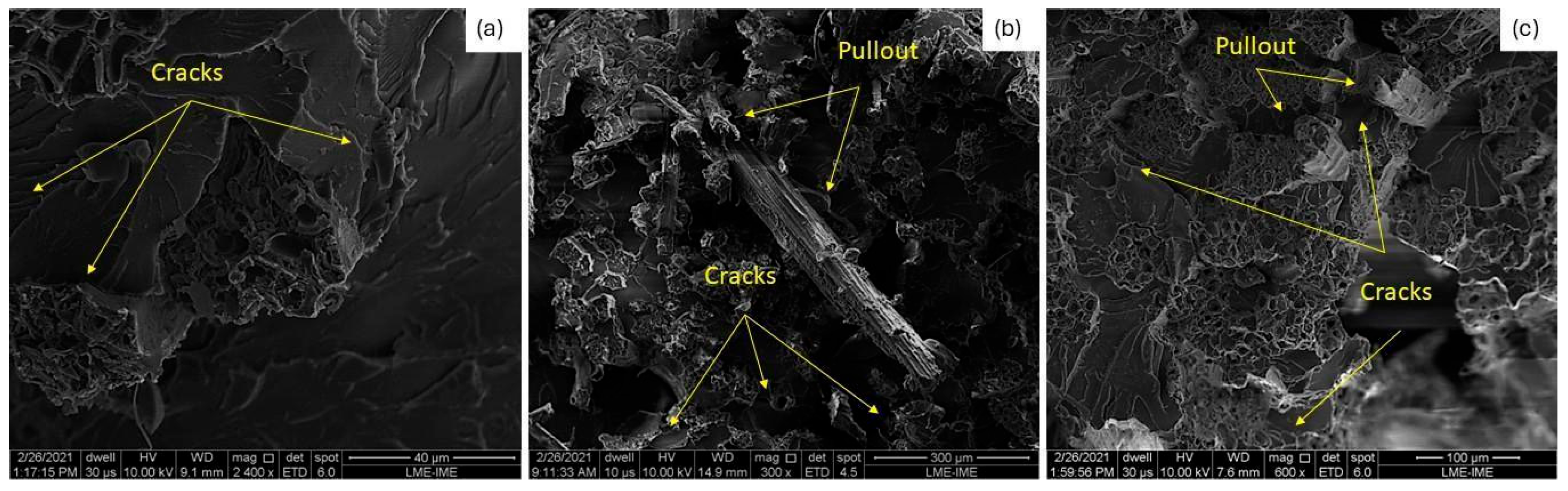

3.7. Izod Impact Fracture Mechanism

Figure 9 shows SEM fractographs of kenaf fiber/epoxy composites after Izod impact testing. All samples, including neat epoxy, exhibit river markings that are characteristic of brittle thermosets.

For EK10 (

Figure 9a), relatively few fibers are fractured, with most being cleanly detached from the matrix, consistent with the limited energy absorption reported in

Table 9. With increasing fiber content, EK20 and EK30 (

Figure 9b,c) display larger fracture surface areas, more extensive fiber breakage, and pronounced interfacial decohesion. This morphology accounts for the higher absorbed impact energy in these composites, as crack propagation along the fiber/matrix interface generates additional fracture surfaces that dissipate energy.

In comparison with tensile loading, distinct fracture mechanisms are evident. Under tensile conditions (

Figure 6), fiber pullout played a major role in energy dissipation, enhancing toughness. In contrast, under impact loading (

Figure 9), interfacial decohesion dominates, leading to matrix cracking that limits efficient stress transfer. This explains why the relative increase in impact resistance is less pronounced than the gain in tensile toughness.

Overall, the SEM observations provide a consistent microstructural rationale for the mechanical behavior: higher fiber content promotes fiber fracture and the formation of larger crack surfaces, correlating with the improvements in strength, modulus, and energy absorption reported in

Table 6.

4. Final Remarks

This study provides the first direct comparison between the tensile and dynamic (Izod impact) toughness of kenaf fiber/epoxy composites with fiber contents up to 30 vol%. The results demonstrate a consistent increase in absorbed energy with increasing fiber fraction, particularly from 10 to 20 vol%, within statistical significance. This behavior highlights the reinforcing effect of kenaf fibers on energy dissipation. Furthermore, tensile toughness values were systematically higher than impact toughness, indicating distinct dominant fracture mechanisms: fiber pullout under quasi-static loading versus interfacial cracking under dynamic loading.

These findings have important implications for the design of structural components. The superior tensile toughness compared with impact toughness suggests that kenaf/epoxy composites may perform more efficiently under quasi-static loads than under high strain-rate conditions. For instance, panels or components subjected to long-term tensile stresses or controlled deformation could benefit from the enhanced tensile toughness, whereas applications exposed to sudden impacts may require hybridization with other fibers (e.g., aramid or glass) to compensate for the relatively lower impact toughness. Understanding this balance is therefore crucial for optimizing the use of natural fiber composites in automotive, construction, and protective structures.

5. Conclusions

Single kenaf fibers exhibited an average absorbed energy of 28.33 kJ/m2, with thinner fibers demonstrating superior toughness.

Epoxy composites reinforced with 10, 20, and 30 vol% kenaf fibers showed significantly higher tensile and impact toughness than neat epoxy.

Toughness increased with fiber content, with the best performance achieved at 20 and 30 vol%.

The higher tensile toughness compared with impact toughness is explained by distinct fracture mechanisms: fiber pullout under tensile loading and fiber/matrix interfacial cracking under impact loading.

Author Contributions

Conceptualization, methodology and investigation, T.T.d.S.; formal analysis and data curation, T.T.d.S., P.H.P.M.d.S., M.P.R., N.T.S., L.d.M.N.; software, P.H.P.M.d.S. and M.P.R.; writing—original draft preparation, T.T.d.S., M.P.R., P.H.P.M.d.S. and L.d.M.N.; writing—review and editing, L.F.C.N. and S.N.M.; supervision, L.F.C.N.; project administration, S.N.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research work is supported by the Brazilian Agency CAPES (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior), Protocol #001. The author Pedro Henrique Poubel Mendonça da Silveira thanks to the Carlos Chagas Filho Foundation for Research Support of the State of Rio de Janeiro (FAPERJ) (Grant number E-26/202.081/2025). And, the APC was funded by Fibers.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, Z.; Cai, S.; Li, Y.; Wang, Z.; Long, Y.; Yu, T.; Shen, Y. High performances of plant fiber-reinforced composites—A new insight from hierarchical microstructures. Compos. Sci. Technol. 2020, 194, 108151. [Google Scholar] [CrossRef]

- Sanjay, M.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Kannan, G.; Thangaraju, R. Recent progress on natural lignocellulosic fiber reinforced polymer composites: A review. J. Nat. Fibers 2022, 19, 7100–7131. [Google Scholar] [CrossRef]

- Fantuzzi, N.; Bacciocchi, M.; Benedetti, D.; Agnelli, J. The use of sustainable composites for the manufacturing of electric cars. Compos. Part C Open Access 2021, 4, 100096. [Google Scholar] [CrossRef]

- Yusof, N.; Sapuan, S.; Sultan, M.; Jawaid, M. Materials selection of “green” natural fibers in polymer composite automotive crash box using DMAIC approach in Six Sigma method. J. Eng. Fibers Fabr. 2020, 15, 1558925020920773. [Google Scholar] [CrossRef]

- Koronis, G.; Silva, A.; Fontul, M. Green composites: A review of adequate materials for automotive applications. Compos. Part B Eng. 2013, 44, 120–127. [Google Scholar] [CrossRef]

- Silva, G.; Kim, S.; Aguilar, R.; Nakamatsu, J. Natural fibers as reinforcement additives for geopolymers–A review of potential eco-friendly applications to the construction industry. Sustain. Mater. Technol. 2020, 23, e00132. [Google Scholar] [CrossRef]

- Hussain, M.; Levacher, D.; Leblanc, N.; Zmamou, H.; Maigre, I.D.; Razakamanantsoa, A. Influence of palm oil fibers length variation on mechanical properties of reinforced crude bricks. Constr. Technol. Archit. 2022, 1, 707–714. [Google Scholar]

- Dong, Z.; Li, N.; Chu, T.; Ding, J.; Zhang, J.; Dong, A. High-Quality Natural Fibers from Cotton Stalk Bark via Limited Alkali Penetration and Simultaneous Accelerated Temperature Rise. Materials 2022, 15, 422. [Google Scholar] [CrossRef]

- Dweib, M.; Hu, B.; O’donnell, A.; Shenton, H.; Wool, R. All natural composite sandwich beams for structural applications. Compos. Struct. 2004, 63, 147–157. [Google Scholar] [CrossRef]

- Hassan, N.A.A.; Ahmad, S.; Chen, R.S.; Natarajan, V.D. Synergistically Enhanced Mechanical, Combustion and Acoustic Properties of Biopolymer Composite Foams Reinforcement by Kenaf Fibre. Compos. Part A Appl. Sci. Manuf. 2022, 155, 106826. [Google Scholar] [CrossRef]

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural fibre composites and their applications: A review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef]

- Sanjay, M.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Pruncu, C.I.; Khan, A. A comprehensive review of techniques for natural fibers as reinforcement in composites: Preparation, processing and characterization. Carbohydr. Polym. 2019, 207, 108–121. [Google Scholar] [CrossRef]

- da Silveira, P.H.P.; Ribeiro, M.P.; Silva, T.T.; Lima, A.M.; Lemos, M.F.; Oliveira, A.G.; Nascimento, L.F.C.; Gomes, A.V.; Monteiro, S.N. Effect of Alkaline Treatment and Graphene Oxide Coating on Thermal and Chemical Properties of Hemp (Cannabis Sativa L.) Fibers. J. Nat. Fibers 2022, 19, 12168–12181. [Google Scholar] [CrossRef]

- Vinod, A.; Tengsuthiwat, J.; Gowda, Y.; Vijay, R.; Sanjay, M.; Siengchin, S.; Dhakal, H.N. Jute/Hemp bio-epoxy hybrid bio-composites: Influence of stacking sequence on adhesion of fiber-matrix. Int. J. Adhes. Adhes. 2022, 113, 103050. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Sain, M. Thermal Properties of Hemp Fiber-Based Hybrid Composites. In Natural Fiber-Reinforced Composites: Thermal Properties and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2022; pp. 183–200. [Google Scholar]

- Ribeiro, M.P.; de Mendonça Neuba, L.; da Silveira, P.H.P.M.; da Luz, F.S.; da Silva Figueiredo, A.B.H.; Monteiro, S.N.; Moreira, M.O. Mechanical, thermal and ballistic performance of epoxy composites reinforced with Cannabis sativa hemp fabric. J. Mater. Res. Technol. 2021, 12, 221–233. [Google Scholar] [CrossRef]

- Jawaid, M.; Chee, S.S.; Asim, M.; Saba, N.; Kalia, S. Sustainable kenaf/bamboo fibers/clay hybrid nanocomposites: Properties, environmental aspects and applications. J. Clean. Prod. 2022, 330, 129938. [Google Scholar] [CrossRef]

- Sun, B.; Zheng, L.; Li, P.; Sheng, G.; Li, X.; Zuo, Y. Enhance of strengthening phase and chemical bonding in bamboo scrap/magnesium oxychloride composites by sodium silicate. Mater. Lett. 2022, 308, 131275. [Google Scholar] [CrossRef]

- Hemath, M.; Hemath, B.V.; Govindarajulu, H.K.; Rangappa, S.M.; Siengchin, S.; Sundaram, S.N. Effect of CNT Fillers on Thermal Properties of the Bamboo Fiber-Based Hybrid Composites. In Natural Fiber-Reinforced Composites: Thermal Properties and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2022; pp. 255–272. [Google Scholar]

- Hasan, M.; Saifullah, A.; Dhakal, H.N.; Khandaker, S.; Sarker, F. Improved mechanical performances of unidirectional jute fibre composites developed with new fibre architectures. RSC Adv. 2021, 11, 23010–23022. [Google Scholar] [CrossRef] [PubMed]

- Chaturvedi, R.; Pappu, A.; Tyagi, P.; Patidar, R.; Khan, A.; Mishra, A.; Gupta, M.K.; Thakur, V.K. Next-generation high-performance sustainable hybrid composite materials from silica-rich granite waste particulates and jute textile fibres in epoxy resin. Ind. Crops Prod. 2022, 177, 114527. [Google Scholar] [CrossRef]

- Chinta, V.S.; Reddy, P.R.; Prasad, K.E. The effect of stacking sequence on the tensile properties of jute fibre reinforced hybrid composite material for axial flow fan blades: An experimental and finite element investigation. Mater. Today Proc. 2022, 59, 747–755. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Puttegowda, M.; Mavinkere Rangappa, S.; Siengchin, S. Influence of nanofillers on biodegradable composites: A comprehensive review. Polym. Compos. 2021, 42, 5691–5711. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Ungtrakul, T.; Chandrasekar, M.; Senthil Muthu Kumar, T.; Rajini, N.; Siengchin, S.; Pulikkalparambil, H.; Parameswaranpillai, J.; Ayrilmis, N. Performance of sisal/hemp bio-based epoxy composites under accelerated weathering. J. Polym. Environ. 2021, 29, 624–636. [Google Scholar] [CrossRef]

- Siva, R.; Kesavaram, B.; Martin, J.J.; Mathiselvan, G.; Navas, K.B.; Sangeetha, M. Mechanical behavior of sisal and banana fiber reinforced hybrid epoxy composites. Mater. Today Proc. 2021, 44, 3692–3696. [Google Scholar] [CrossRef]

- Pantaloni, D.; Rudolph, A.L.; Shah, D.U.; Baley, C.; Bourmaud, A. Interfacial and mechanical characterisation of biodegradable polymer-flax fibre composites. Compos. Sci. Technol. 2021, 201, 108529. [Google Scholar] [CrossRef]

- Javanshour, F.; Ramakrishnan, K.; Layek, R.; Laurikainen, P.; Prapavesis, A.; Kanerva, M.; Kallio, P.; Van Vuure, A.; Sarlin, E. Effect of graphene oxide surface treatment on the interfacial adhesion and the tensile performance of flax epoxy composites. Compos. Part A Appl. Sci. Manuf. 2021, 142, 106270. [Google Scholar] [CrossRef]

- Barouni, A.; Lupton, C.; Jiang, C.; Saifullah, A.; Giasin, K.; Zhang, Z.; Dhakal, H.N. Investigation into the fatigue properties of flax fibre epoxy composites and hybrid composites based on flax and glass fibres. Compos. Struct. 2022, 281, 115046. [Google Scholar] [CrossRef]

- Giuliani, P.M.; Giannini, O.; Panciroli, R. Characterizing flax fiber reinforced bio-composites under monotonic and cyclic tensile loading. Compos. Struct. 2022, 280, 114803. [Google Scholar] [CrossRef]

- Asasutjarit, C.; Hirunlabh, J.; Khedari, J.; Charoenvai, S.; Zeghmati, B.; Shin, U.C. Development of coconut coir-based lightweight cement board. Constr. Build. Mater. 2007, 21, 277–288. [Google Scholar] [CrossRef]

- Satyanarayana, K.; Guimarães, J.; Wypych, F. Studies on lignocellulosic fibers of Brazil. Part I: Source, production, morphology, properties and applications. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1694–1709. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Lopes, F.P.D.; Barbosa, A.P.; Bevitori, A.B.; Silva, I.L.A.D.; Costa, L.L.D. Natural lignocellulosic fibers as engineering materials—An overview. Metall. Mater. Trans. A 2011, 42, 2963–2974. [Google Scholar] [CrossRef]

- Meints, P.D.; Smith, C. Kenaf seed storage duration on germination, emergence, and yield. Ind. Crops Prod. 2003, 17, 9–14. [Google Scholar] [CrossRef]

- Akil, H.; Omar, M.; Mazuki, A.M.; Safiee, S.; Ishak, Z.M.; Bakar, A.A. Kenaf fiber reinforced composites: A review. Mater. Des. 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Waghmare, P.M.; Bedmutha, P.G.; Sollapur, S.B. Investigation of effect of hybridization and layering patterns on mechanical properties of banana and kenaf fibers reinforced epoxy biocomposite. Mater. Today Proc. 2021, 46, 3220–3224. [Google Scholar] [CrossRef]

- Jaafar, C.A.; Zainol, I.; Ishak, N.; Ilyas, R.; Sapuan, S. Effects of the liquid natural rubber (LNR) on mechanical properties and microstructure of epoxy/silica/kenaf hybrid composite for potential automotive applications. J. Mater. Res. Technol. 2021, 12, 1026–1038. [Google Scholar] [CrossRef]

- Sathiamurthi, P.; KS, K.V.; Sathishkumar, T.; Arunkumar, S.; Anaamalaai, A. Fiber extraction and mechanical properties of Agave Americana/Kenaf fiber reinforced hybrid epoxy composite. Mater. Today Proc. 2021, 46, 8594–8601. [Google Scholar]

- Akhtar, M.N.; Sulong, A.B.; Radzi, M.F.; Ismail, N.; Raza, M.; Muhamad, N.; Khan, M.A. Influence of alkaline treatment and fiber loading on the physical and mechanical properties of kenaf/polypropylene composites for variety of applications. Prog. Nat. Sci. Mater. Int. 2016, 26, 657–664. [Google Scholar] [CrossRef]

- Arjmandi, R.; Ismail, A.; Hassan, A.; Bakar, A.A. Effects of ammonium polyphosphate content on mechanical, thermal and flammability properties of kenaf/polypropylene and rice husk/polypropylene composites. Constr. Build. Mater. 2017, 152, 484–493. [Google Scholar] [CrossRef]

- Othman, M.H. Renewable agricultural fibers as reinforcing fillers in plastics: Mechanical properties of kenaf fiber-polypropylene composites. Encycl. Renew. Sustain. Mater. 2020, 5, 231–241. [Google Scholar]

- Saad, F.; Salim, N.; Roslan, R. Physical and mechanical properties of kenaf/seaweed reinforced polypropylene composite. Mater. Today Proc. 2022, 51, 1372–1375. [Google Scholar] [CrossRef]

- Verma, R.; Shukla, M. Characterization of mechanical properties of short kenaf fiber-HDPE green composites. Mater. Today Proc. 2018, 5, 3257–3264. [Google Scholar] [CrossRef]

- Singh, M.K.; Zafar, S. Wettability, absorption and degradation behavior of microwave-assisted compression molded kenaf/HDPE composite tank under various environments. Polym. Degrad. Stab. 2021, 185, 109500. [Google Scholar] [CrossRef]

- Pundhir, N.; Zafar, S.; Pathak, H. Performance evaluation of HDPE/MWCNT and HDPE/kenaf composites. J. Thermoplast. Compos. Mater. 2021, 34, 1315–1333. [Google Scholar] [CrossRef]

- Tewari, R.; Singh, M.K.; Zafar, S.; Powar, S. Parametric optimization of laser drilling of microwave-processed kenaf/HDPE composite. Polym. Polym. Compos. 2021, 29, 176–187. [Google Scholar] [CrossRef]

- Xu, Y.; Kawata, S.; Hosoi, K.; Kawai, T.; Kuroda, S. Thermomechanical properties of the silanized-kenaf/polystyrene composites. Express Polym. Lett. 2009, 3, 657–664. [Google Scholar] [CrossRef]

- Moustafa, H.; El-Wakil, A.E.A.A.; Nour, M.T.; Youssef, A.M. Kenaf fibre treatment and its impact on the static, dynamic, hydrophobicity and barrier properties of sustainable polystyrene biocomposites. RSC Adv. 2020, 10, 29296–29305. [Google Scholar] [CrossRef]

- Zi Mun, C.; Kwong, K.Z.; Lee, F.W.; Lim, J.H. Mechanical, sound and thermal properties of recycled expanded polystyrene concrete reinforced with 0.5% to 5.5% kenaf fibre. Eur. J. Environ. Civ. Eng. 2021, 26, 7345–7358. [Google Scholar] [CrossRef]

- Ramesh, P.; Prasad, B.D.; Narayana, K. Influence of montmorillonite clay content on thermal, mechanical, water absorption and biodegradability properties of treated kenaf fiber/PLA-hybrid biocomposites. Silicon 2021, 13, 109–118. [Google Scholar] [CrossRef]

- Azlin, M.; Sapuan, S.; Zuhri, M.; Zainudin, E. Effect of Stacking Sequence and Fiber Content on Mechanical and Morphological Properties of Woven Kenaf/Polyester Fiber Reinforced Polylactic Acid (PLA) Hybrid Laminated Composites. J. Mater. Res. Technol. 2021, 16, 1190–1201. [Google Scholar] [CrossRef]

- Manral, A.; Bajpai, P.K. Effect of non-acidic chemical treatment of kenaf fiber on physico mechanical properties of PLA based composites. J. Nat. Fibers 2021, 19, 5709–5727. [Google Scholar] [CrossRef]

- Shahar, F.S.; Sultan, M.T.H.; Safri, S.N.A.; Jawaid, M.; Talib, A.R.A.; Basri, A.A.; Shah, A.U.M. Fatigue and impact properties of 3D printed PLA reinforced with kenaf particles. J. Mater. Res. Technol. 2022, 16, 461–470. [Google Scholar] [CrossRef]

- El-Shekeil, Y.; Sapuan, S.; Jawaid, M.; Al-Shuja’a, O. Influence of fiber content on mechanical, morphological and thermal properties of kenaf fibers reinforced poly (vinyl chloride)/thermoplastic polyurethane poly-blend composites. Mater. Des. 2014, 58, 130–135. [Google Scholar] [CrossRef]

- Bakar, N.A.; Chee, C.Y.; Abdullah, L.C.; Ratnam, C.T.; Ibrahim, N.A. Thermal and dynamic-mechanical properties of grafted kenaf filled poly (vinyl chloride)/ethylene vinyl acetate composites. Mater. Des. 2015, 65, 204–211. [Google Scholar] [CrossRef]

- Abdul Majid, R.; Ismail, H.; Taib, R.M. Sodium dodecyl sulfate (SDS) as a filler treatment: Effects on mechanical, morphological and swelling properties of poly (vinyl chloride)(PVC)/epoxidized natural rubber (ENR)/kenaf core powder composites. Mater. Res. Innov. 2016, 20, 504–511. [Google Scholar] [CrossRef]

- Nimanpure, S.; Hashmi, S.; Kumar, R.; Bhargaw, H.; Kumar, R.; Nair, P.; Naik, A. Mechanical, electrical, and thermal analysis of sisal fibril/kenaf fiber hybrid polyester composites. Polym. Compos. 2019, 40, 664–676. [Google Scholar] [CrossRef]

- Arjmandi, R.; Yıldırım, I.; Hatton, F.; Hassan, A.; Jefferies, C.; Mohamad, Z.; Othman, N. Kenaf fibers reinforced unsaturated polyester composites: A review. J. Eng. Fibers Fabr. 2021, 16, 15589250211040184. [Google Scholar] [CrossRef]

- SaravanaKumar, M.; Kumar, S.S.; Babu, B.S.; Chakravarthy, C.N. Influence of fiber loading on mechanical characterization of pineapple leaf and kenaf fibers reinforced polyester composites. Mater. Today Proc. 2021, 46, 439–444. [Google Scholar] [CrossRef]

- Ornaghi, H.L.; Neves, R.M.; Monticeli, F.M.; Thomas, S. Modeling of dynamic mechanical curves of kenaf/polyester composites using surface response methodology. J. Appl. Polym. Sci. 2022, 139, 52078. [Google Scholar] [CrossRef]

- Silva, T.T.d.; Silveira, P.H.P.M.d.; Ribeiro, M.P.; Lemos, M.F.; da Silva, A.P.; Monteiro, S.N.; Nascimento, L.F.C. Thermal and chemical characterization of kenaf fiber (Hibiscus cannabinus) reinforced epoxy matrix composites. Polymers 2021, 13, 2016. [Google Scholar] [CrossRef]

- Bakar, A.; Ahmad, S.; Kuntjoro, W. The mechanical properties of treated and untreated kenaf fibre reinforced epoxy composite. J. Biobased Mater. Bioenergy 2010, 4, 159–163. [Google Scholar] [CrossRef]

- Mutasher, S.A.; Poh, A.; Than, A.M.; Law, J. The effect of alkali treatment mechanical properties of kenaf fiber epoxy composite. Key Eng. Mater. 2011, 471, 191–196. [Google Scholar] [CrossRef]

- Rassmann, S.; Paskaramoorthy, R.; Reid, R. Effect of resin system on the mechanical properties and water absorption of kenaf fibre reinforced laminates. Mater. Des. 2011, 32, 1399–1406. [Google Scholar] [CrossRef]

- Abdullah, A.H.; Alias, S.K.; Jenal, N.; Abdan, K.; Ali, A. Fatigue behavior of kenaf fibre reinforced epoxy composites. Eng. J. 2012, 16, 105–114. [Google Scholar] [CrossRef]

- Mahjoub, R.; Yatim, J.M.; Sam, A.R.M.; Raftari, M. Characteristics of continuous unidirectional kenaf fiber reinforced epoxy composites. Mater. Des. 2014, 64, 640–649. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Valenza, A. The effect of alkaline treatment on mechanical properties of kenaf fibers and their epoxy composites. Compos. Part B Eng. 2015, 68, 14–21. [Google Scholar] [CrossRef]

- Krishna, K.V.; Kanny, K. The effect of treatment on kenaf fiber using green approach and their reinforced epoxy composites. Compos. Part B Eng. 2016, 104, 111–117. [Google Scholar] [CrossRef]

- da Silva, T.T.; Silveira, P.H.P.M.d.; Figueiredo, A.B.H.d.S.; Monteiro, S.N.; Ribeiro, M.P.; Neuba, L.d.M.; Simonassi, N.T.; Garcia Filho, F.d.C.; Nascimento, L.F.C. Dynamic mechanical analysis and ballistic performance of kenaf fiber-reinforced epoxy composites. Polymers 2022, 14, 3629. [Google Scholar] [CrossRef]

- Ramesh, M. Kenaf (Hibiscus cannabinus L.) fibre based bio-materials: A review on processing and properties. Prog. Mater. Sci. 2016, 78, 1–92. [Google Scholar] [CrossRef]

- ASTM D3822; Tensile Properties of Textile Fibers. American Society for Testing Materials: West Conshohocken, PA, USA, 2020.

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering: An Introduction, 10th ed.; Wiley: New York, NY, USA, 2020. [Google Scholar]

- de Mendonça Neuba, L.; Pereira Junio, R.F.; Ribeiro, M.P.; Souza, A.T.; de Sousa Lima, E.; Garcia Filho, F.d.C.; Figueiredo, A.B.H.d.S.; Braga, F.d.O.; Azevedo, A.R.G.d.; Monteiro, S.N. Promising mechanical, thermal, and ballistic properties of novel epoxy composites reinforced with Cyperus malaccensis sedge fiber. Polymers 2020, 12, 1776. [Google Scholar] [CrossRef]

- ASTM D3039; Tensile Test on Composites. American Society for Testing Materials: West Conshohocken, PA, USA, 2017.

- ASTM D256; Notched Izod Impact Test on Plastics. American Society for Testing Materials: West Conshohocken, PA, USA, 2006.

- Nanda, A.; Mohapatra, B.B.; Mahapatra, A.; Abiresh Prasad Kumar Mahapatra, A.; Mahapatra, A. Multiple comparison test by Tukey’s honestly significant difference (HSD): Do the confident level control type I error. Int. J. Appl. Math. Stat. 2021, 6, 59–65. [Google Scholar] [CrossRef]

- Souza, A.T.; Pereira Junio, R.F.; Neuba, L.d.M.; Candido, V.S.; da Silva, A.C.R.; de Azevedo, A.R.G.; Monteiro, S.N.; Nascimento, L.F.C. Caranan fiber from Mauritiella armata palm tree as novel reinforcement for epoxy composites. Polymers 2020, 12, 2037. [Google Scholar] [CrossRef] [PubMed]

- Marzuki, N.H.; Wahit, M.U.; Arsad, A.; Othman, N.; Yusoff, N.I.S.M. The effect of kenaf loading on the mechanical properties of kenaf-reinforced recycled poly(ethylene terephthalate)/recycled poly(propylene) (rPET/rPP) composite. Mater. Today Proc. 2021, 39, 959–964. [Google Scholar] [CrossRef]

- Reis, R.H.; Garcia Filho, F.C.; Nunes, L.F.; Candido, V.S.; Silva, A.C.; Monteiro, S.N. Impact resistance of epoxy composites reinforced with Amazon guaruman fiber: A brief report. Polymers 2021, 13, 2264. [Google Scholar] [CrossRef]

- Junio, R.F.P.; Nascimento, L.F.C.; Neuba, L.d.M.; Souza, A.T.; Moura, J.V.B.; Garcia Filho, F.d.C.; Monteiro, S.N. Copernicia prunifera leaf fiber: A promising new reinforcement for epoxy composites. Polymers 2020, 12, 2090. [Google Scholar] [CrossRef]

- da Cunha, J.d.S.C.; Nascimento, L.F.C.; da Luz, F.S.; Monteiro, S.N.; Lemos, M.F.; da Silva, C.G.; Simonassi, N.T. Physical and mechanical characterization of titica vine (Heteropsis flexuosa) incorporated epoxy matrix composites. Polymers 2021, 13, 4079. [Google Scholar] [CrossRef]

Figure 1.

Optical microscopy image of a kenaf fiber with diameter measurements at different positions along its length.

Figure 1.

Optical microscopy image of a kenaf fiber with diameter measurements at different positions along its length.

Figure 2.

Relationship between kenaf fiber diameter and tensile strength.

Figure 2.

Relationship between kenaf fiber diameter and tensile strength.

Figure 3.

Correlation between fiber diameter and tensile strength.

Figure 3.

Correlation between fiber diameter and tensile strength.

Figure 4.

Correlation between fiber diameter and absorbed energy.

Figure 4.

Correlation between fiber diameter and absorbed energy.

Figure 5.

Examples of stress–strain curves of (a) neat epoxy; (b) 10 vol% kenaf fiber composite; (c) 20 vol% kenaf fiber composite; and (d) 30 vol% kenaf fiber composite.

Figure 5.

Examples of stress–strain curves of (a) neat epoxy; (b) 10 vol% kenaf fiber composite; (c) 20 vol% kenaf fiber composite; and (d) 30 vol% kenaf fiber composite.

Figure 6.

SEM images of the fractured surfaces of tensile test specimens: (a) EPOXY; (b) EK10; (c) EK20; (d) EK30.

Figure 6.

SEM images of the fractured surfaces of tensile test specimens: (a) EPOXY; (b) EK10; (c) EK20; (d) EK30.

Figure 7.

Typical macroscopic aspect of the fractured specimens: (a) EK10; (b) EK20; (c) EK30.

Figure 7.

Typical macroscopic aspect of the fractured specimens: (a) EK10; (b) EK20; (c) EK30.

Figure 8.

Tensile and Izod impact absorbed energies as a function of the fiber fraction for the neat epoxy resin and kenaf fiber-reinforced composites.

Figure 8.

Tensile and Izod impact absorbed energies as a function of the fiber fraction for the neat epoxy resin and kenaf fiber-reinforced composites.

Figure 9.

SEM fractographs of typical Izod impact specimens: (a) EK10; (b) EK20; (c) EK30.

Figure 9.

SEM fractographs of typical Izod impact specimens: (a) EK10; (b) EK20; (c) EK30.

Table 1.

Nomenclature of the composites used in this study.

Table 1.

Nomenclature of the composites used in this study.

| Nomenclature | Composition |

|---|

| EPOXY | Neat Epoxy |

| EK10 | 10 vol% kenaf fiber |

| EK20 | 20 vol% kenaf fiber |

| EK30 | 30 vol% kenaf fiber |

Table 2.

Different kenaf fiber dimension ranges.

Table 2.

Different kenaf fiber dimension ranges.

| Interval | Diameter Interval (mm) | Mean Diameter (mm) | Frequency (%) |

|---|

| 1 | 0.024–0.047 | 0.035 | 23 |

| 2 | 0.047–0.069 | 0.058 | 38 |

| 3 | 0.069–0.092 | 0.081 | 24 |

| 4 | 0.092–0.115 | 0.104 | 10 |

| 5 | 0.115–0.138 | 0.127 | 4 |

| 6 | 0.138–0.161 | 0.150 | 1 |

Table 3.

Tensile strength of different diameter intervals of kenaf fibers.

Table 3.

Tensile strength of different diameter intervals of kenaf fibers.

| Interval | Diameter Interval (mm) | Tensile Strength (MPa) | Absorbed Energy (kJ/m2) |

|---|

| 1 | 0.024–0.047 | 1170.00 ± 332.10 | 27.79 ± 12.57 |

| 2 | 0.047–0.069 | 568.90 ± 281.90 | 26.95 ± 11.59 |

| 3 | 0.069–0.092 | 488.10 ± 268.10 | 17.73 ± 4.95 |

| 4 | 0.092–0.115 | 236.00 ± 75.08 | 7.66 ± 1.30 |

| 5 | 0.115–0.138 | 249.40 ± 159.20 | 5.84 ± 4.62 |

| 6 | 0.138–0.161 | 130.90 ± 69.46 | 4.73 ± 1.69 |

Table 4.

ANOVA for the absorbed energy results in

Table 4 for single kenaf fibers.

Table 4.

ANOVA for the absorbed energy results in

Table 4 for single kenaf fibers.

| Source of Variation | DF | SSq | AQ | Fcalculated | F |

|---|

| Treatment | 3 | 10,215.07 | 3405.02 | 27.11 | 3.24 |

| Residue | 16 | 2009.85 | 125.62 | | |

| Total | 19 | 12,224.92 | | | |

Table 5.

Tukey’s test for the absorbed energy results in

Table 3 for single kenaf fibers.

Table 5.

Tukey’s test for the absorbed energy results in

Table 3 for single kenaf fibers.

| Interval | 1 | 2 | 3 | 4 | 5 | 6 |

|---|

| 1 | 0.00 | 6.59 | 13.74 | 19.78 | 18.78 | 23.07 |

| 2 | 6.59 | 0.00 | 7.15 | 13.19 | 12.18 | 16.47 |

| 3 | 13.74 | 7.15 | 0.00 | 6.04 | 5.04 | 9.33 |

| 4 | 19.78 | 13.19 | 6.04 | 0.00 | 1.00 | 3.28 |

| 5 | 18.78 | 12.18 | 5.04 | 1.00 | 0.00 | 4.29 |

| 6 | 23.07 | 16.47 | 9.33 | 3.28 | 4.29 | 0.00 |

Table 6.

Values for the tensile strength, modulus of elasticity, elongation at break, and tensile toughness of the composites.

Table 6.

Values for the tensile strength, modulus of elasticity, elongation at break, and tensile toughness of the composites.

| Sample | Tensile Strength (MPa) | Elastic Modulus (GPa) | Elongation at Break (%) | Tensile Toughness (kJ/m2) |

|---|

| EPOXY | 7.92 ± 2.5 | 0.28 ± 0.32 | 0.32 ± 0.07 | 4.23 ± 1.57 |

| EK10 | 11.86 ± 9.42 | 0.33 ± 0.21 | 0.36 ± 0.16 | 9.36 ± 7.69 |

| EK20 | 61.13 ± 7.96 | 3.21 ± 0.53 | 2.00 ± 0.22 | 49.36 ± 12.12 |

| EK30 | 60.23 ± 7.73 | 3.17 ± 0.95 | 1.77 ± 0.32 | 52.30 ± 16.47 |

Table 7.

ANOVA for the tensile toughness results of the kenaf fibers/epoxy composite.

Table 7.

ANOVA for the tensile toughness results of the kenaf fibers/epoxy composite.

| Source of Variation | DF | SSq | AQ | Fcalculated | F |

|---|

| Treatment | 3 | 11,739.32 | 3913.10 | 32.62 | 3.10 |

| Residue | 20 | 2399.08 | 119.95 | | |

| Total | 23 | 14,138.40 | | | |

Table 8.

Tukey’s test for tensile toughness results of the kenaf fibers/epoxy composites.

Table 8.

Tukey’s test for tensile toughness results of the kenaf fibers/epoxy composites.

| Samples | EPOXY | EK10 | EK20 | EK30 |

|---|

| EPOXY | 0.00 | 5.13 | 45.13 | 48.07 |

| EK10 | 5.13 | 0.00 | 40.00 | 42.94 |

| EK20 | 45.13 | 40.00 | 0.00 | 2.94 |

| EK30 | 48.07 | 42.94 | 2.94 | 0.00 |

Table 9.

Energy absorbed by Izod impact test samples.

Table 9.

Energy absorbed by Izod impact test samples.

| Dynamic Izod Absorbed Energy (kJ/m2) |

|---|

| EPOXY | EK10 | EK20 | EK30 |

|---|

| 1.8 ± 0.02 | 5.6 ± 0.7 | 23.9 ± 2.7 | 38.8 ± 3.8 |

Table 10.

ANOVA for the impact toughness results of the kenaf fibers/epoxy composite.

Table 10.

ANOVA for the impact toughness results of the kenaf fibers/epoxy composite.

| Source of Variation | DF | SSq | AQ | Fcalculated | F |

|---|

| Treatment | 3 | 3857.79 | 1285.93 | 949.73 | 3.01 |

| Residue | 24 | 32.49 | 1.35 | | |

| Total | 27 | 3890.29 | | | |

Table 11.

Tukey’s test for impact toughness results of the kenaf fibers/epoxy composites.

Table 11.

Tukey’s test for impact toughness results of the kenaf fibers/epoxy composites.

| Samples | EPOXY | EK10 | EK20 | EK30 |

|---|

| EPOXY | 0.00 | 3.09 | 17.51 | 29.27 |

| EK10 | 3.09 | 0.00 | 14.42 | 26.18 |

| EK20 | 17.51 | 14.42 | 0.00 | 11.76 |

| EK30 | 29.27 | 26.18 | 11.76 | 0.00 |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).