Abstract

For the first time, electrospinning has been used to recycle polyacrylonitrile terpolymer (PAN) waste following the solid-phase N-methylmorpholine-N-oxide (NMMO) process from PAN solutions in DMSO into nonwoven materials. The morphology of the obtained material has been studied. The material derived from secondary raw materials was compared to the material from the original PAN using IR spectroscopy, X-ray diffraction, scanning electron microscopy, and atomic force microscopy. It has been demonstrated that the chemical changes of PAN that occur during NMMO processing do not interfere with nonwoven material manufacture. Spun PAN nonwovens with different histories have similar morphology. It has been shown that the elastic modulus of ultrafine fibers depends on the history of PAN. Single monofilaments produced from initial PAN have a threefold greater elastic modulus than fibers spun from NMMO-recycled polymer. The revealed structure and properties of PAN fibers allow them to be considered as filter materials, as well as precursors of carbon nonwoven fabrics.

1. Introduction

Fiber-forming copolymers of polyacrylonitrile (PAN) play an essential role in modern industry due to their unique characteristics and wide range of applications [1]. Polyacrylonitrile is widely used in the textile industry. Almost all wool-like products on the market include polyacrylonitrile or its copolymers [2]. This is owing to the fact that PAN fibers have qualities similar to genuine wool: they are soft, warm, wear-resistant, and keep their form even after several washings [3]. PAN materials may be used to filter liquids and gases due to their high mechanical strength, resistance to acids and alkalis, many organic solvents, and temperatures of up to 130 °C [4,5]. The second key area of application of PAN fibers is their conversion into carbon fibers (CFs) [6]. CF has exceptional strength [7], lightness, and resistance to chemical and temperature effects (especially in an inert atmosphere), so it is used in the form of carbon composites as structural materials in almost every industry, particularly in aerospace, defense, and electricity [8]. The process of extracting hydrocarbons from PAN consists of sequential heat treatment in an oxidizing environment at temperatures typically not exceeding 300 °C, followed by single- or multi-stage heating in an inert atmosphere, including a carbonization stage, and, in the case of multi-stage heating, precarbonization and graphitization [7,9,10].

Polyacrylonitrile is produced by spinning solutions containing aprotic solvents such as dimethylformamide (DMF), dimethyl sulfoxide (DMSO), dimethylacetamide (DMA), and aqueous sodium thiocyanate solutions [11,12,13,14]. Fiber spinning from DMF and DMSO is the most extensively used technology in industry due to its reduced toxicity [15]. Furthermore, the dissolving rate of PAN is greater in DMF than in DMSO, resulting in PAN solutions that are less prone to gelation at different temperatures than PAN solutions in DMF [16]. Recently, the possibility of employing a novel solvent for PAN, N-methylmorpholine-N-oxide (NMMO), was demonstrated. On this basis, it is feasible to create not only highly concentrated solutions containing up to 45% polymer by weight, but also to perform chemical changes in PAN by altering the temperature–time regime of dissolution and aging of the polymer [17]. Although this solvent is rarely utilized in industry to produce PAN spinning solutions, it is a multiton solvent since it is one of the few direct solvents for cellulose [18]. In addition to its non-toxicity, regeneration procedures for this solvent have been devised to achieve 99% or higher [19].

Wet spinning, in which the spinneret is submerged in a coagulant, and dry-jet wet spinning, in which the solution jets created at the spinneret’s exit pass through an air gap and then enter a bath containing a coagulant, are the two primary ways of producing PAN fibers from solutions [20]. Wet and dry-jet wet spinning methods of PAN fibers require precise and reproducible solution parameters (concentration), which is difficult to achieve by evaporation. Changing the concentration causes the solution’s coagulation to change [21] when it comes into contact with a non-solvent (precipitant), as well as deterioration of the formation of a gel fiber capable of spinneret and orientation drawing, during which the solvent is removed and a solid fiber is formed. Changes in mass-exchange activities in the precipitation bath influence the structure and morphology of future fibers [22]. Furthermore, the color of PAN treated with NMMO ranges from gold to brown, depending on the degree of co-treatment with cellulose in NMMO. This is due to partial intramolecular cyclization, which results in the production of chromophore groups [23].

Using the NMMO features as a solvent for both cellulose and PAN, we previously created cellulose/PAN solutions in NMMO, examined the rheology and dissolution kinetics, and proved the feasibility of constructing comparable systems to obtain composite fibers with unique properties [23,24,25]. Such composite fibers may be further treated to separate unique cellulose microfibrils of infinite length [26,27], which can be employed in a variety of applications, particularly as filtering materials due to their developed surface. In the initial stage of cellulose microfibril production, composite fibers are created utilizing a dry-jet wet spinning process from joint cellulose/PAN solutions in NMMO. In the second stage, PAN is removed by running the mixed fibers through DMSO-based washing solutions. The processing of diluted PAN solutions obtained during the cellulose microfibril production process is governed not only by economic feasibility, but also by a modern responsible approach to ecology that seeks to reduce anthropogenic influence on ecosystems [28]. The concentration of PAN solutions in DMSO created by washing composite fibers ranges from a few tenths of a percent to 1%, with additional concentration occurring by evaporation at lower pressure. The distilled pure DMSO may be reused in washing baths, and the resultant concentrated PAN solution can be utilized to produce fiber.

The above-mentioned characteristics of the PAN produced during processing may be leveled using the electrospinning method with the output of nonwoven materials. Electrospinning is a considerably simpler approach that does not require expensive equipment, is more readily scaled, and produces ultra-thin fibers from polymer solutions using electrostatic forces [29]. This approach is actively utilized to develop materials with distinguishing characteristics such as high specific surface area, porosity, and flexibility. High voltage generates an electrostatic field that forms fibers. The distance between the capillary and collector influences the diameter and shape of the fibers [30,31]. It was shown that during electrospinning from PAN solutions in high-boiling solvents such as DMAA and DMSO, a mechanotropic gelation mechanism is realized with phase separation and solvent migration on the fiber surface [32]. Nonwoven materials constructed of PAN (due to their chemical structure) are a promising class of materials that, due to their unique features, are commonly utilized as universal filter materials [33]. Nonwoven PAN material may be converted into carbon felt due to the high carbon yield during PAN carbonization, as well as the retention of fibrousness during the pyrolysis and carbonization processes. In addition to filtering applications and widening the range of operation in harsh environments, the resultant non-woven materials have improved stability in an oxidizing atmosphere at increased temperatures and may be utilized as a heat-insulating material [34,35].

The processing of PAN into nonwoven material allows for the elimination of a number of limits, which must be followed in order to generate high-strength CF from stretched PAN fibers acquired using traditional procedures. The most important conditions are the consistency of the polymer composition [36,37] (to avoid disruption of the processes for the selected temperature–time modes of oxidative stabilization and carbonization of fibers) and the material’s reduced ash content (absence of salts and metal oxides), which, if not met, significantly reduces the performance characteristics of the final materials. It was previously discovered that PAN in NMMO solutions can undergo chemical transformations, including partial intramolecular cyclization, which, on the one hand, opens up new possibilities for processing PAN into carbon fiber, but also imposes additional constraints in the form of parameter control accuracy during joint processing of cellulose and PAN through NMMO solutions. The cyclic use of the solvent in polymer manufacturing causes progressive contamination, including a rise in the ash content of the final product. We do not rule out the possibility that future refinement of the parameters for the combined processing of cellulose and PAN, as well as the removal of the latter, would allow PAN to be processed directly into precursors of high-quality carbon fiber, including using traditional techniques.

Many diverse chemical reactions occur during the combined processing of PAN and cellulose using NMMO solutions, particularly due to the large variation in chemical makeup. The abundance of different factors requires a fundamental scientific approach to the description of the observed transformations. Until now, no research has been published on the feasibility of converting PAN exposed to NMMO into fibrous materials. The goal of this work is to investigate the feasibility of reusing PAN subjected to NMMO in the presence of cellulose.

2. Materials and Methods

The polymer utilized in the investigation was the commercial copolymer AN316020 manufactured by the Good Fellow company (Huntingdon, UK). The average number and average molecular weights were 50 and 85 kg/mol, respectively. The monomer composition of PAN was acrylonitrile (93.9%), methyl acrylate (5.8%), and sulfonate/sulfate terminal groups (0.3%). DMSO 99.5% (EKOS-1, Moscow, Russia) was used as a direct solvent. PAN/cellulose composite fibers were obtained using the method described [25,26]

2.1. Preparation of Spinning Solution from Regenerated PAN

To evaluate the PAN concentration in the DMSO solution after selective removal of cellulose from PAN/cellulose composite fibers (containing 60–80% PAN), 10 mL of the solution was centrifuged at 10,000× g for 5 min, then the supernatant was put into a flat glass dish and evaporated on a hotplate at 90 °C to a constant weight. The resultant film was weighed on a scale, and the initial concentration of the solution was estimated.

To make a spinning solution, a known concentration of PAN solution was filtered through a 50 micron metal mesh and evaporated to around 20% using a rotary evaporator. The viscosity was then measured by taking a piece of the solution. Further concentration of the solution was stopped when its viscosity exceeded 1 Pa·s.

2.2. Preparation of Comparison Solution

To prepare a 10% PAN solution, a precisely weighed quantity of the polymer was dissolved in DMSO with continuous stirring at 70 °C. The quality of the dopes was evaluated using an optical microscope (microscopy “Boetius”, VEB Kombinat Nadema, Ruhla, former GDR).

2.3. Rheology

The rotating rheometer HAAKE MARS 60 (Thermo Fisher Scientific, Karlsruhe, Germany) was used to test all of the spinning solutions under study. The experimental results were acquired utilizing the “cone–plate” geometry of the measuring unit with diameters of 20 and 60 mm and an angle of 1 degree between the conical and plate surfaces. For solvents and extremely low-viscosity solutions, the biconic measuring unit was set at 60 mm with a 1-degree angle between the conical and plate surfaces. Throughout the experiment, a protective cup was inserted to prevent moisture absorption from the air. Furthermore, the sides of the measuring unit were coated with a polydimethylsiloxane liquid, which inhibits solvent evaporation and contact with humid air.

2.4. Electrospinning

Electrospinning was performed on the precipitator surface (water and soda). First, a model solution of the original polymer was prepared. The regenerated PAN solution was then concentrated in DMSO.

To produce nonwoven materials based on PAN, the following conditions were used: voltage—18 kV, spinning solution concentration 23.6% by weight, needle diameter—0.5 mm. Air gap from the end of the needle to the surface of the precipitant—2.5 cm (total 5.5 cm). Precipitant—0.5% aqueous soda solution. Feed rate 26.7 μL/min (400 μL in 15 min).

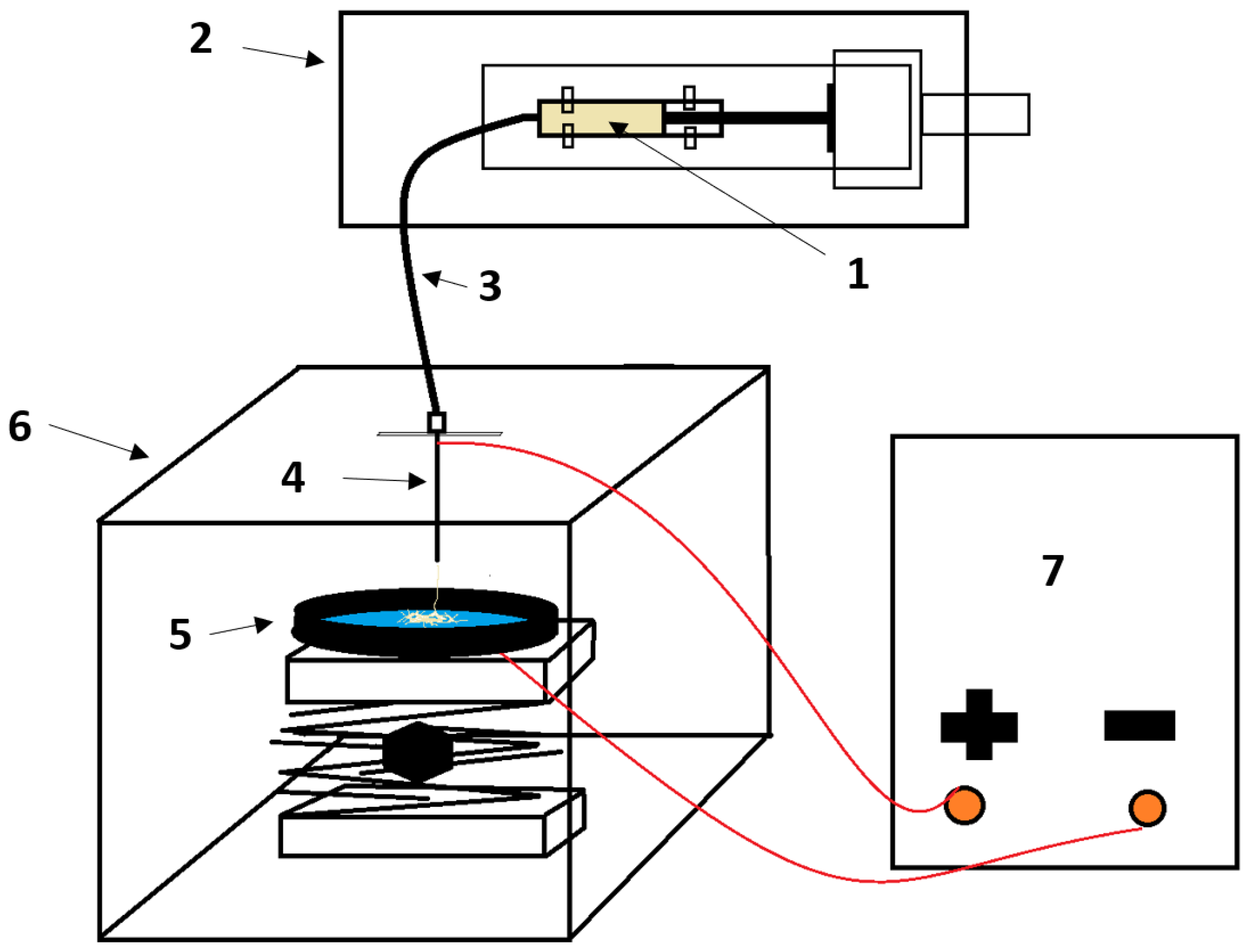

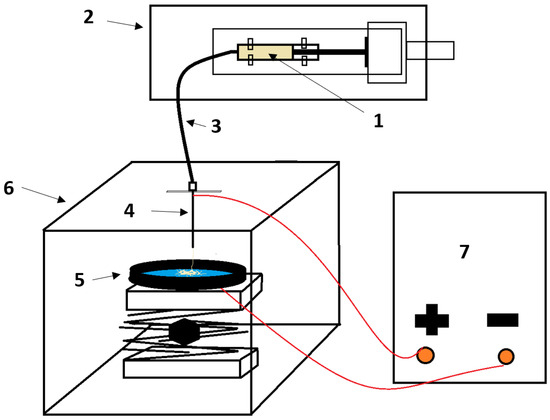

Figure 1 depicts the basic diagram of the spinning equipment.

Figure 1.

1—Syringe with PAN solution, 2—single-channel syringe dispenser SinoMDT CN-50C6 with a feed rate from 0.1 to 1500 mL/h, 3—connecting tube, 4—steel needle, 5—precipitation bath, 6—protective box, 7—voltage source Plazon IVNR-50/1 (+/−) (output voltage up to 50 kV and load current up to 1 mA, Moscow, Russia).

2.5. IR Study

The IR spectra of the samples were recorded using a HYPERION-2000 IR microscope and an IFS-66 v/s Bruker IR Fourier spectrometer (crystal–Ge, scan. 50, resolution 2 cm−1, range 4000–600 cm−1).

2.6. X-Ray Diffraction

X-ray diffraction (XRD) analysis was performed using a powder diffractometer Rigaku MiniFlex 600 (CuKα radiation) in the range of detection angles 2θ = 8–35°.

2.7. Scanning Electron Microscopy

The surface morphology of nonwovens was studied by low-voltage scanning electron microscopy (SEM) on an FEI Scios microscope (Waltham, MA, USA) at an accelerating voltage of less than 1 kV in secondary electron mode.

2.8. Atomic Force Microscopy

The morphology of the samples was studied by atomic force microscopy in the intermittent contact mode using the NTEGRA Prima device (NT-MDT Spectrum Instruments, Zelenograd, Russia) using HA_FM silicon cantilevers (LLC “Kapella”, Moscow, Russia). AFM studies of the surface of the samples were carried out under controlled conditions of the measuring complex “TRACKPORE ROOM-05”, purity class 5 ISO (100), with humidity maintained at 40 ± 1% and temperature at 22 ± 0.05 ° C. The mechanical properties of the samples were studied by atomic force spectroscopy (AFS) [38]. For each sample, 15 force curves were measured, from which curves of the dependence of force on the indentation depth were obtained. The dependencies were averaged and approximated by the Hertz model (1) for a hemisphere, and the average Young’s modulus E was determined. In addition, the maximum and minimum Young’s modulus E were calculated for each sample:

where R—the radius of the cantilever needle tip m, E—Young’s modulus Pa, Δh—the depth of indentation of the tip into the surface of the sample m, and F—the force at which indentation occurs N.

3. Results

3.1. IR Spectroscopy

PAN undergoes chemical changes in the NMMO solution, the depth of which is determined by both exposure duration and temperature, as previously explained. The processes that occur might also cause a reduction in the viscosity of the solution. When producing mixed solutions, the limiting issue is cellulose dissolution [39], which may result in a deeper level of chemical changes of PAN than when preparing PAN solutions in NMMO.

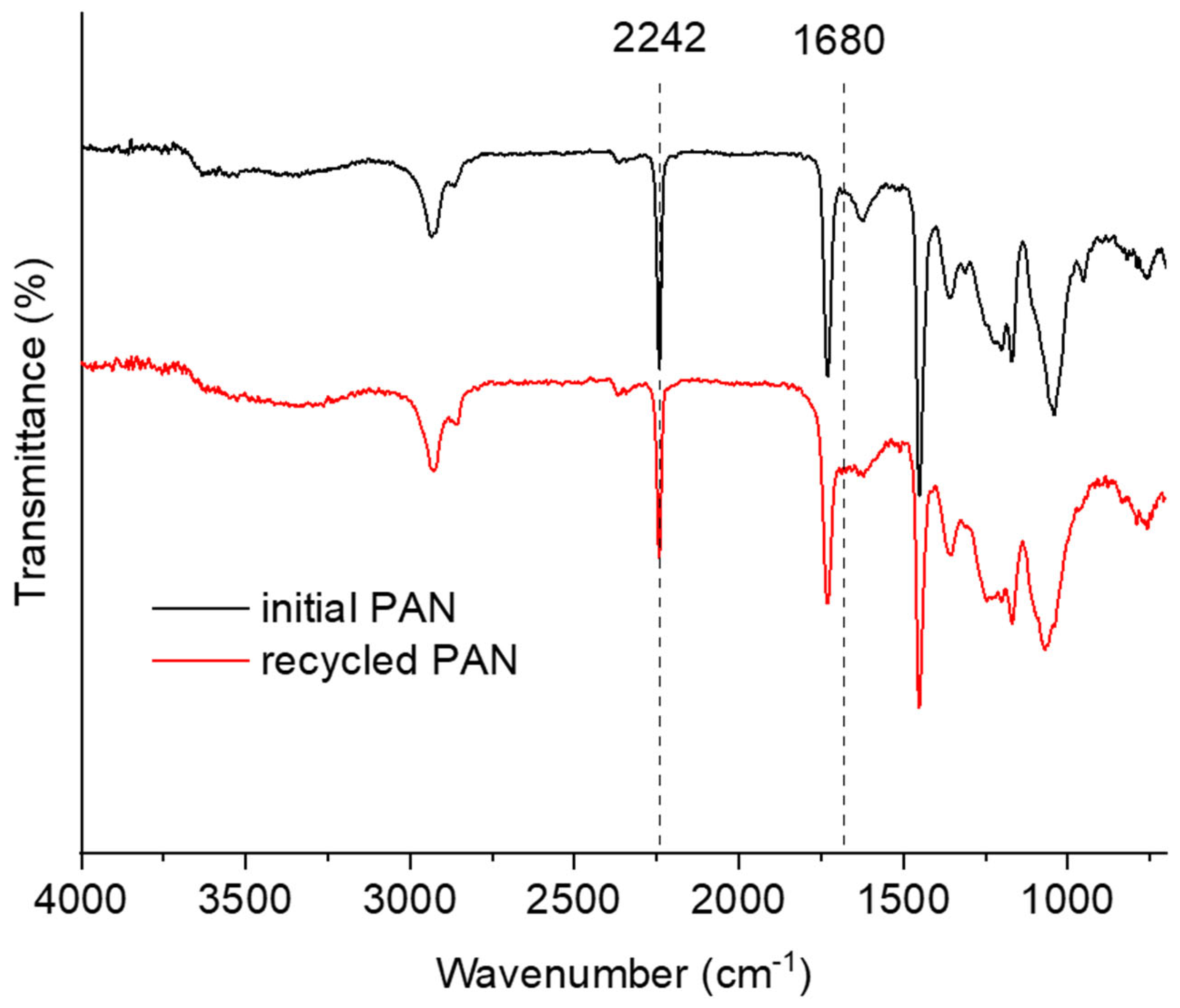

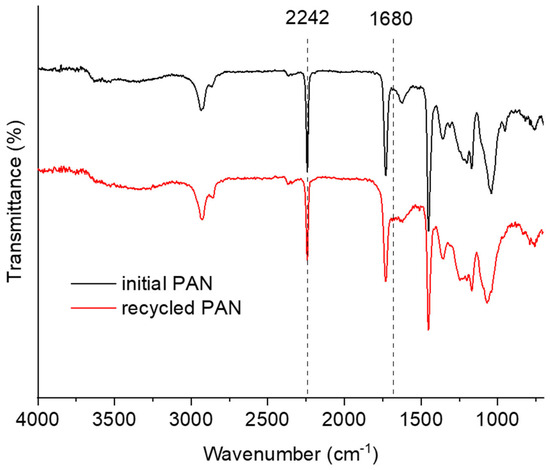

To determine the depth of PAN transformation in joint cellulose/PAN solutions in NMMO, IR spectra of nonwoven materials were obtained, as shown in Figure 2. The spectral intensities are normalized to the line of deformation vibrations δCHH, observed at 1452 cm−1.

Figure 2.

IR spectra of PAN nonwoven samples. Black—original PAN, red—recycled PAN.

The spectra shown in the figure are similar in nature, but upon closer examination several differences can be identified. For the sample of nonwoven material of recycled PAN, a decrease in the intensity of the band at 2242 cm−1 associated with the stretching vibrations of the nitrile group by 17% is observed compared to the original polymer. This may be due to both the processes of hydrolysis of the nitrile group with the formation of amides and amines, and the formation of conjugated and polyconjugated structures due to the activation of intramolecular cyclization processes in the NMMO solution. In the case of the latter, the splitting of the band at 2242 cm−1 should occur with the appearance of absorption at 2200 cm−1, as well as an increase in the absorption of C=N at 1590–1580 cm−1, which is not observed. At the same time, a significant increase in absorption at 1690–1630 cm−1 is observed, which may be associated with the hydrolysis of the nitrile bond with the formation of amides and imines, which is also visually manifested by the appearance of a golden color in the sample.

3.2. Scanning Electron Microscopy

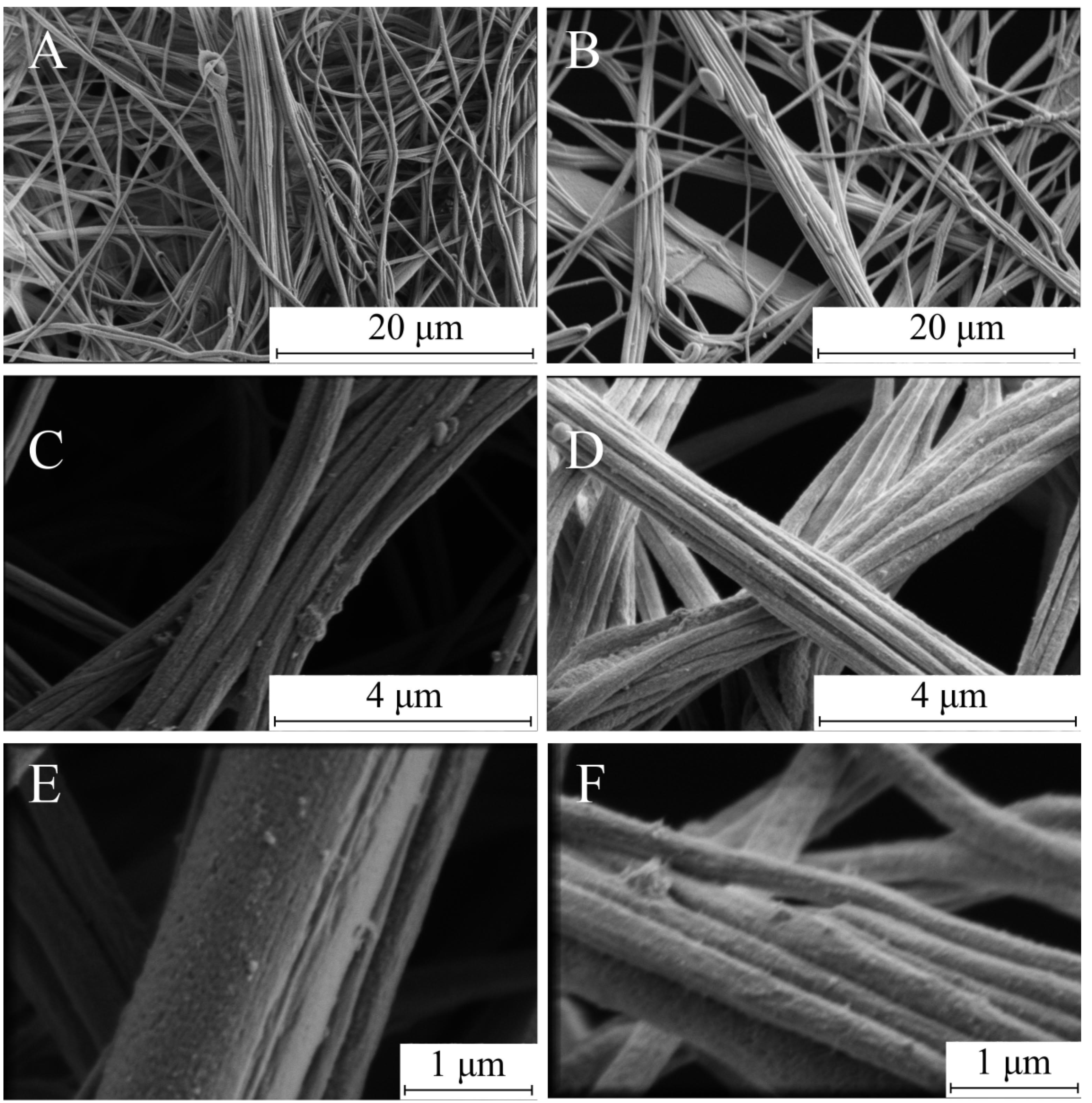

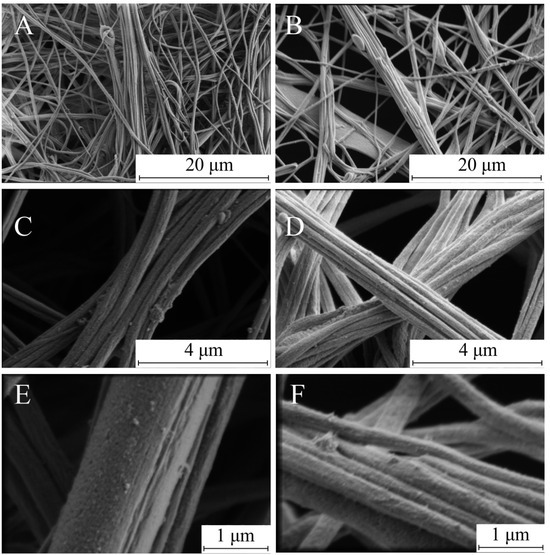

Nonwovens need detailed knowledge on the structure of the mesh of individual ultrafine fibers. Electron microscopy allows for the visualization of network interlacing frequency. Photographs of the obtained nonwoven materials are shown in Figure 3.

Figure 3.

(A,C,E)—Nonwoven material from recycled PAN, (B,D,F)—nonwoven material from initial PAN.

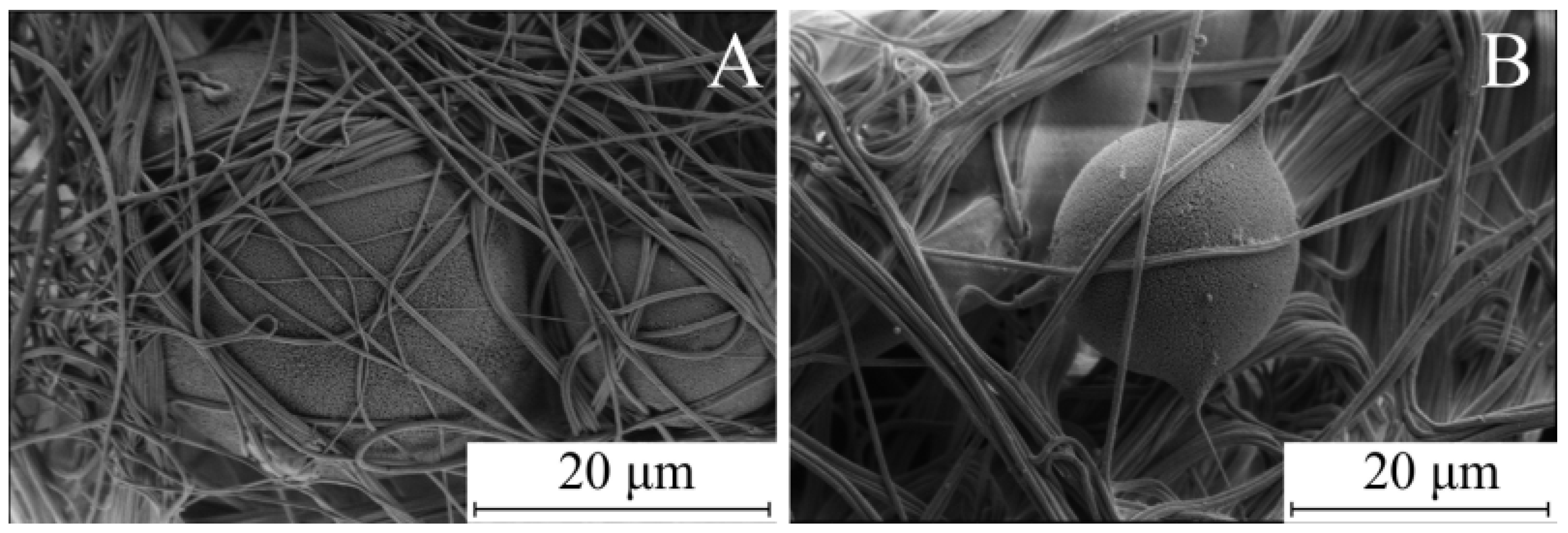

Nonwoven materials are made up of submicron-sized fibrils that are interwoven into bundles that are randomly distributed across the plane. The generated network of physical interlocks between individual fibers ensures the material’s unity and visible strength properties during deformation. The microfibers’ surface is not smooth, which, along with the development of novel functional groups, might be useful not only as filtering materials, but also for modulating surface polarity. There is no fundamental difference in the morphology of nonwoven materials. The beaded structures found in micrographs are consistent with traditional Plateau–Rayleigh instability (Figure 4). Most bead-free microfibers range in diameter from a few tens to 200 nm. Ellipsoidal formations on a drop cause the average diameter of the droplets to increase, reaching 250–300 nm. A detailed investigation of the surface morphology of microfibers with varied histories at high magnifications allows us to hypothesize about the rigid precipitation of spinning solutions, which results in the construction of a core–shell cross-section structure similar to typical fibers (Figure 3). Microphotographs of fiber surfaces reveal that morphology is consistent independent of PAN history. The surface pattern is comparable to PAN fiber samples generated using the wet technique [40]. Small-sized craters and burrs can be seen on the surface, which could suggest hard precipitation of solutions by water. As a result of this precipitation, vacuoles (voids) are formed in the fiber volume and might partially collapse after drying. Surface flaws are more visible on microbead surfaces (Figure 4).

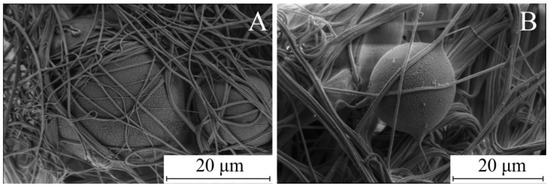

Figure 4.

Photo of the microbeads: nonwoven material from recycled PAN (A), nonwoven material from initial PAN (B).

The literature does not provide a clear solution to the subject of microbeads’ effect on the functional qualities of nonwoven materials. Their quantity may be regulated by adjusting the spinning conditions and the viscoelastic properties of the spinning solution. In our perspective, the minimal number of microbeads in both samples implies that identical processes occur during electrospinning.

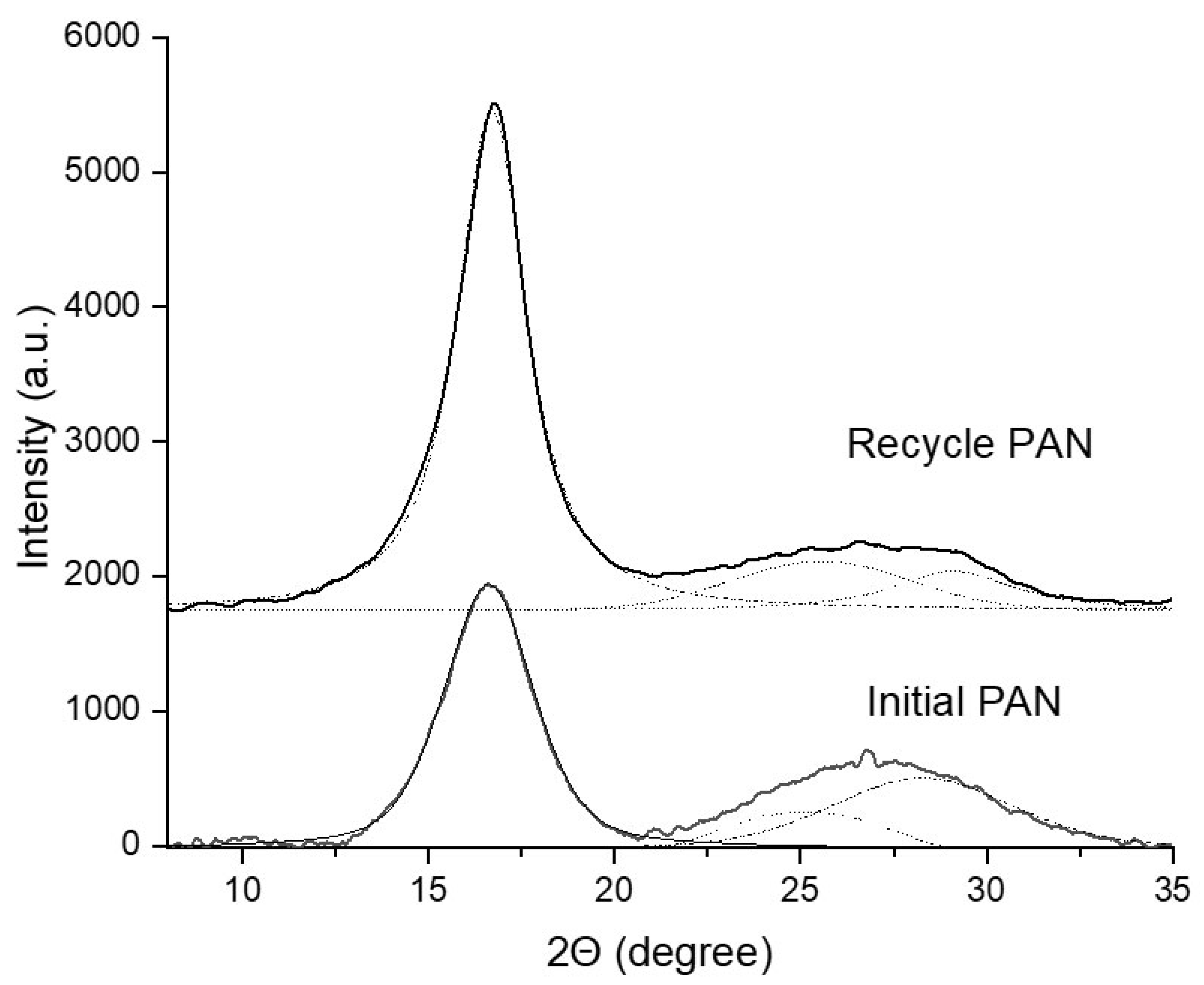

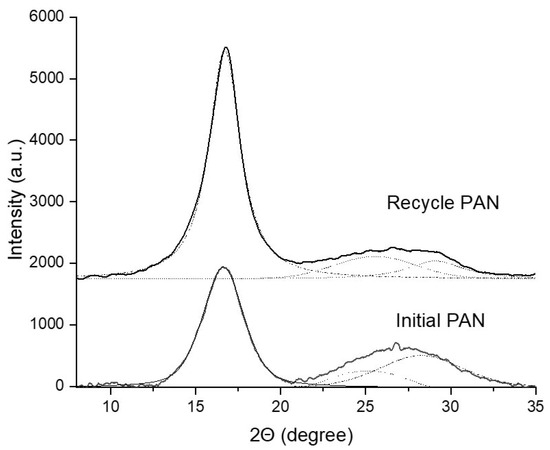

3.3. X-Ray Diffraction

X-ray diffraction was used to study nonwoven materials produced by electrospinning recycled PAN and the original polymer (Figure 5). The diffraction patterns reveal three crystalline reflections (1~17, 2~25–26, 3~29 degrees) in the 2Θ angle range of 8–35 degrees. A disorganized amorphous phase does not exhibit diffuse scattering. Peaks 1 and 3 correspond to crystallographic planes 100 and 101, respectively, while peak 2 (according to the authors of Ref. [41]) represents the ordered phase and is generated by rotational disorder in the parallel packing of rod-shaped chains. The absence of the amorphous phase makes it impossible to calculate the degree of crystallinity. Nevertheless, the diffraction patterns show a redistribution of the intensities of the reflections caused by a change in the ratio of the ordered and orientationally disordered phases, for the assessment of which one can use Formula (2):

Figure 5.

Diffraction patterns of nonwoven material samples.

The values calculated by this formula are 78 and 91 for recycled and original PAN, respectively. In addition, for nonwoven material made from recycled PAN, a shift in the reflex maxima is observed from 16.6, 25.1, and 29.3° to 16.8, 25.5, and 29.1°, which is most likely due to a partial change in the chemical composition of the polymer, since the morphology of the compared materials is almost identical (Figure 3).

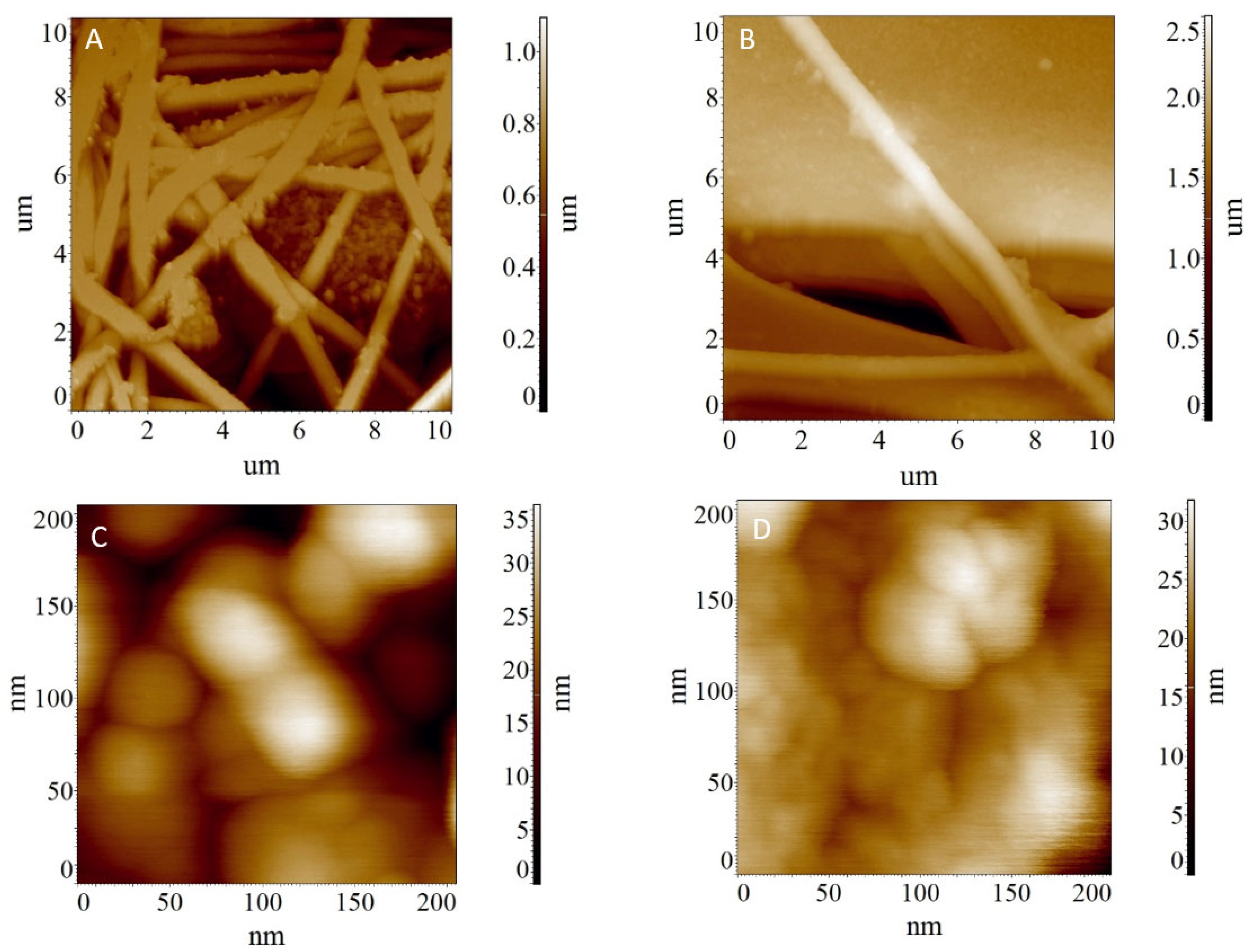

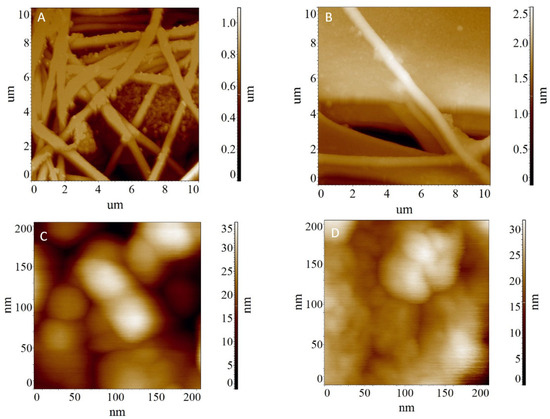

3.4. Atomic Force Microscopy

The surface relief of the nonwoven material sample composed of recycled PAN is a network of fibers with widths of 700–1000 nm at the base and 500–600 nm at half-height, with fiber thickness ranging from 300 to 500 nm (Figure 6A). The surface relief of the nonwoven material sample produced from original PAN is fibers with a width of 600–800 nm at the base and 500–600 nm at half-height, respectively, with fiber thickness ranging from 200 to 400 nm (Figure 6B). The fiber length of the analyzed samples greatly surpasses the maximum allowable scanning area of 20 μm.

Figure 6.

Surface relief of nonwoven fibers from recycled (A,C) and initial (B,D) PAN obtained by atomic force spectroscopy.

Analysis of the surface images of smaller sizes showed that the surface of the fiber samples has a globular structure consisting of round and elongated particles with a width of 30 nm to 100 nm and a length of 30 nm to 150 nm, with smaller particles predominating for the nonwoven material sample made from the original PAN (Figure 6C,D).

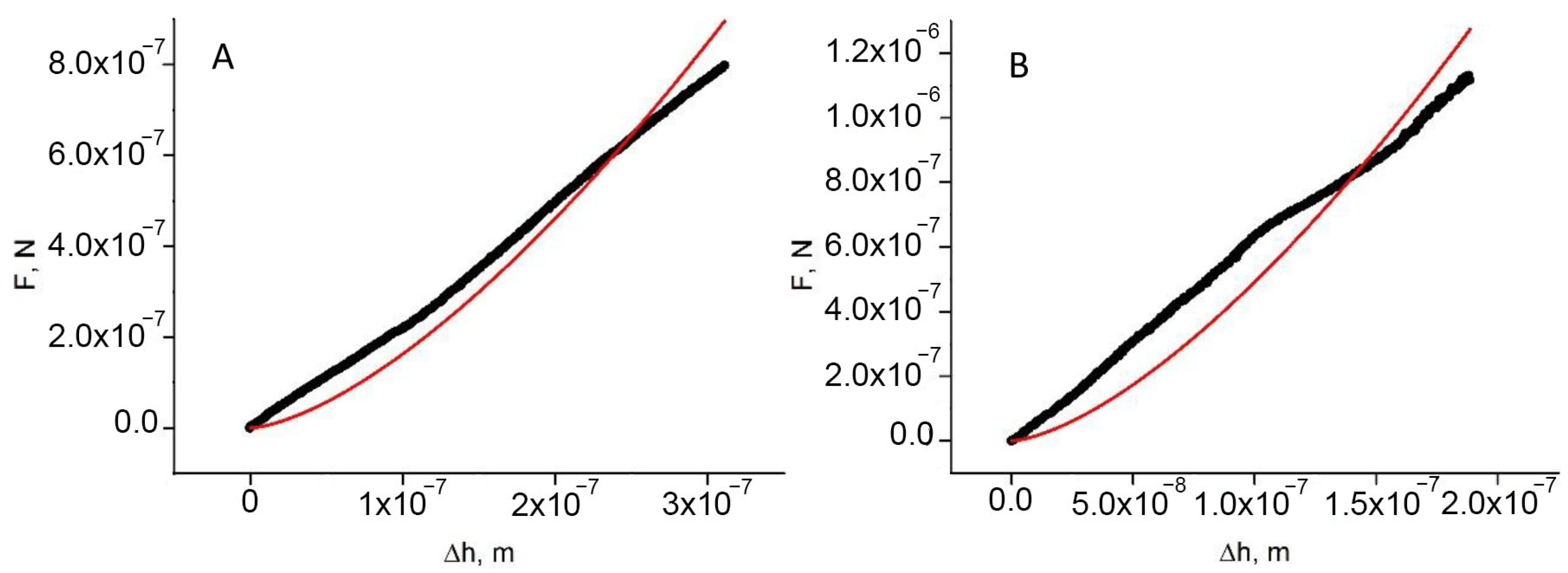

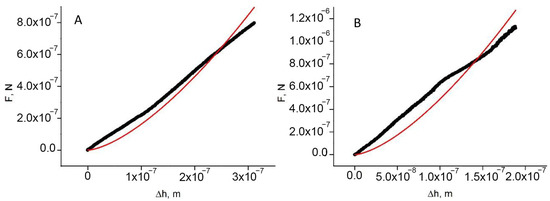

The mechanical properties of the samples were studied using atomic force spectroscopy (AFS) (Figure 7).

Figure 7.

Averaged dependences of the force acting on the sample on the depth of penetration of the tip under the surface of the samples (black—experimental dependence, red—approximation by the Hertz model) of recycled (A) and original (B) PAN obtained by atomic force spectroscopy.

The analysis of the results showed that the average Young’s modulus for the fibers of the nonwoven material made of the original PAN is 116.4 MPa (the maximum and minimum values of the Young’s modulus were 168.2 and 90.7 MPa, respectively), which is three times higher than for the sample made of waste PAN—38.7 MPa (the maximum and minimum values of the Young’s modulus were 63 and 13.6 MPa, respectively). These differences can be associated with both partial chemical transformation of the polymer and with the difference in the concentrations of the solutions being formed (the concentration of the waste PAN sample is ≈2.4 times higher). The data obtained indicate that the sample made of recycled PAN is less uniform in its mechanical characteristics at different points on the surface. In Ref. [42], for fibers formed from PAN solutions (Mw=100,000 g/mol) in DMF by electrospinning, the average values of the elastic modulus are 91–95 MPa. The described values are close to those found in the current work for the original PAN and significantly exceed those for the processed PAN.

The revealed mechanical properties and structural features of nonwoven materials based on the initial and regenerated PAN allow the latter to be considered in the future as a precursor of carbon materials. Unlike nonwoven samples based on the initial PAN, chemical transformations (cyclization) are observed for the regenerated one, which will subsequently facilitate the thermal processing of such nonwoven materials. As a result, opportunities open up for obtaining paper-like carbon materials, which are extremely in demand for creating ultracapacitors or electrical double-layer capacitors.

4. Conclusions

For the first time, the possibility of recycling PAN waste after polymer treatment in an NMMO solution into nonwoven materials has been demonstrated. Chemical transformation of PAN during its stay in an NMMO solution has virtually no effect on the morphology of the resulting materials, provided that they are formed from DMSO solutions of close viscosity, in contrast to mechanical characteristics, where a three-fold decrease in the average value of the Young’s modulus is observed compared to a sample made from the original PAN. At the same time, this chemical transformation affects the crystalline structure of the polymer, which can significantly affect further orientational drawing of the polymer and is the subject of further research. Chemical transformation can also have a positive effect on changing the polarity of the material (impact on the hydrophilic–lipophilic properties), improving the tribological and filtration properties, which, together with the submicron diameter of the resulting fibers, as well as the developed surface, can serve as a basis for applying various catalysts. Despite the lack of evidence of intramolecular cyclization for the object under consideration, in general, with an increase in the intensity of processing, as well as the use of a PAN containing itaconic acid, it can be achieved, which opens up prospects for obtaining new carbon nonwoven materials. The resulting carbon nonwoven materials can be considered carbon paper, which can be used as a current collector or electrode material in supercapacitors (also known as ultracapacitors or electric double-layer capacitors).

Author Contributions

Writing—original draft, Y.V.G.; writing—review and editing, Y.V.G., I.S.M., D.N.K., N.A.A., R.V.G. and S.V.K.; methodology, Y.V.G. and I.S.M.; investigation, Y.V.G., I.S.M., D.N.K., N.A.A., S.A.L. and S.V.K.; supervision, I.S.M.; conceptualization, Y.V.G. and I.S.M.; data curation, D.N.K. and R.V.G.; formal analysis, R.V.G. and S.A.L. All authors have read and agreed to the published version of the manuscript.

Funding

Part of the structure characterization of this work was carried out within the state assignment of the NRC “Kurchatov Institute” using the equipment from the Shared Research Center’s “structural diagnostics of materials” of the Kurchatov Complex Crystallography and Photonics NRC “Kurchatov Institute” under the support of the Ministry of Science and Higher Education of the Russian Federation and within the State Program of the A.V. Topchiev Institute of Petrochemical Synthesis.

Data Availability Statement

Data are contained within the article and available upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Adegbola, T.A.; Agboola, O.; Fayomi, O.S.I. Review of Polyacrylonitrile Blends and Application in Manufacturing Technology: Recycling and Environmental Impact. Results Eng. 2020, 7, 100144. [Google Scholar] [CrossRef]

- Geller, B.E. Status and Prospects for Development of Polyacrylonitrile Fibre Production. Fibre Chem. 2002, 34, 151–161. [Google Scholar] [CrossRef]

- Zuo, C.; Guo, Y.; Jiang, L.; Yu, D.; Chen, X.; Ren, Y.; Liu, X. Fabrication of Durable Flame Retardant PAN Fibers through Bio-Based Ammonium Phytate Surface Modification and Highly Efficient Thermal Oxidation. Eur. Polym. J. 2023, 196, 112304. [Google Scholar] [CrossRef]

- Brandrup, J.; Immergut, E.H.; Grulke, E.A. (Eds.) Polymer Handbook, 4th ed.; Wiley: New York, NY, USA, 1999. [Google Scholar]

- Vatanpour, V.; Pasaoglu, M.E.; Kose-Mutlu, B.; Koyuncu, I. Polyacrylonitrile in the Preparation of Separation Membranes: A Review. Ind. Eng. Chem. Res. 2023, 62, 6537–6558. [Google Scholar] [CrossRef]

- Newcomb, B.A. Processing, Structure, and Properties of Carbon Fibers. Compos.—A Appl. Sci. Manuf. 2016, 91, 262–282. [Google Scholar] [CrossRef]

- Jang, D.; Lee, M.E.; Choi, J.; Cho, S.Y.; Lee, S. Strategies for the Production of PAN-Based Carbon Fibers with High Tensile Strength. Carbon. 2022, 186, 644–677. [Google Scholar] [CrossRef]

- Holmes, M. Global Carbon Fibre Market Remains on Upward Trend. FRP 2014, 58, 38–45. [Google Scholar] [CrossRef]

- Tse-Hao, K.; Tzy-Chin, D.; Jeng-An, P.; Ming-Fong, L. The Characterization of PAN-Based Carbon Fibers Developed by Two-Stage Continuous Carbonization. Carbon 1993, 31, 765–771. [Google Scholar] [CrossRef]

- Gupta, A.; Harrison, I.R. New Aspects in the Oxidative Stabilization of PAN-Based Carbon Fibers. Carbon 1996, 34, 1427–1445. [Google Scholar] [CrossRef]

- Hattori, M.; Yamazaki, H.; Saito, M.; Hisatani, K.; Okajima, K. NMR Study on the Dissolved State of Polyacrylonitrile in Various Solvents. Polym. J. 1996, 28, 594–600. [Google Scholar] [CrossRef]

- Samimi-Sohrforozani, E.; Azimi, S.; Abolhasani, A.; Malekian, S.; Arbab, S.; Zendehdel, M.; Abolhasani, M.M.; Yaghoobi Nia, N. Development of Porous Polyacrylonitrile Composite Fibers: New Precursor Fibers with High Thermal Stability. Electron. Mater. 2021, 2, 454–465. [Google Scholar] [CrossRef]

- Ahn, H.; Wee, J.-H.; Kim, Y.M.; Yu, W.-R.; Yeo, S.-Y. Microstructure and Mechanical Properties of Polyacrylonitrile Precursor Fiber with Dry and Wet Drawing Process. Polymers 2021, 13, 1613. [Google Scholar] [CrossRef]

- Cai, J.Y.; McDonnell, J.; Brackley, C.; O’Brien, L.; Church, J.S.; Millington, K.; Smith, S.; Phair-Sorensen, N. Polyacrylonitrile-Based Precursors and Carbon Fibers Derived from Advanced RAFT Technology and Conventional Methods—The 1st Comparative Study. Mater. Today Commun. 2016, 9, 22–29. [Google Scholar] [CrossRef]

- Skvortsov, I.Y.; Kuzin, M.S.; Vashchenko, A.F.; Toms, R.V.; Varfolomeeva, L.A.; Chernikova, E.V.; Shambilova, G.K.; Kulichikhin, V.G. Fiber Spinning of Polyacrylonitrile Terpolymers Containing Acrylic Acid and Alkyl Acrylates. Fibers 2023, 11, 65. [Google Scholar] [CrossRef]

- Eom, Y.; Kim, B.C. Solubility parameter-based analysis of polyacrylonitrile solutions in N, N-dimethyl formamide and dimethyl sulfoxide. Polymer 2014, 55, 2570–2577. [Google Scholar] [CrossRef]

- Golova, L.K.; Bondarenko, G.N.; Makarov, I.S.; Kuznetsova, L.K.; Vinogradov, M.I.; Kulichikhin, V.G. Peculiarities of Dissolving Polyacrylonitrile Copolymer Containing Methylsulfo Groups in N-Methylmorpholine-N-Oxide. Polym. Sci. Ser. A 2020, 62, 597–606. [Google Scholar] [CrossRef]

- Golova, L.K. Processing of Cellulose via Highly Concentrated “Solid Solutions”. Fibre Chem. 1996, 28, 5–16. [Google Scholar] [CrossRef]

- Guo, Y.; Cai, J.; Sun, T.; Xing, L.; Cheng, C.; Chi, K.; Xu, J.; Li, T. The Purification Process and Side Reactions in the N-Methylmorpholine-N-Oxide (NMMO) Recovery System. Cellulose 2021, 28, 7609–7617. [Google Scholar] [CrossRef]

- Gao, B.; Wang, M. Multistep Structure Evolution during the Coagulation of PAN/DMSO Solution Studied by in-Situ FTIR Spectroscopy. Polymer 2023, 283, 126221. [Google Scholar] [CrossRef]

- Skvortsov, I.Y.; Chernikova, E.V.; Kulichikhin, V.G.; Varfolomeeva, L.A.; Kuzin, M.S.; Toms, R.V.; Prokopov, N.I. The Effect of the Synthetic Procedure of Acrylonitrile–Acrylic Acid Copolymers on Rheological Properties of Solutions and Features of Fiber Spinning. Materials 2020, 13, 3454. [Google Scholar] [CrossRef]

- Skvortsov, I.Y.; Kulichikhin, V.G.; Ponomarev, I.I.; Varfolomeeva, L.A.; Kuzin, M.S.; Razorenov, D.Y.; Skupov, K.M. Some Specifics of Defect-Free Poly-(o-Aminophenylene) Naphthoylenimide Fibers Preparation by Wet Spinning. Materials 2022, 15, 808. [Google Scholar] [CrossRef]

- Kulichikhin, V.; Golova, L.; Makarov, I.; Bondarenko, G.; Makarova, V.; Ilyin, S.; Skvortsov, I.; Berkovich, A. Solutions of Acrylonitrile Copolymers in N-Methylmorpholine-N-Oxide: Structure, Properties, Fiber Spinning. Eur. Polym. J. 2017, 92, 326–337. [Google Scholar] [CrossRef]

- Kulichikhin, V.G.; Golova, L.K.; Makarov, I.S.; Bondarenko, G.N.; Berkovich, A.K.; Ilyin, S.O. Cellulose–Co-Polyacrylonitrile Blends: Properties of Combined Solutions in N-Metylmorpholine-N-Oxide and the Formation and Thermolysis of Composite Fibers. Polym. Sci. Ser. C 2016, 58, 74–84. [Google Scholar] [CrossRef]

- Golova, L.K.; Makarov, I.S.; Vinogradov, M.I.; Kuznetsova, L.K.; Kulichikhin, V.G. Morphological Features and Rheological Properties of Combined Cellulose and Polyacrylonitrile Solutions in N-Methylmorpholine-N-Oxide. Polym. Sci. Ser. A 2018, 60, 796–804. [Google Scholar] [CrossRef]

- Makarov, I.; Vinogradov, M.; Golubev, Y.; Palchikova, E.; Kulanchikov, Y.; Grishin, T. Development of Cellulose Microfibers from Mixed Solutions of PAN-Cellulose in N-Methylmorpholine-N-Oxide. Polymers 2024, 16, 1869. [Google Scholar] [CrossRef] [PubMed]

- Makarov, I.; Palchikova, E.; Vinogradov, M.; Golubev, Y.; Legkov, S.; Gromovykh, P.; Makarov, G.; Arkharova, N.; Karimov, D.; Gainutdinov, R. Characterization of Structure and Morphology of Cellulose Lyocell Microfibers Extracted from PAN Matrix. Polysaccharides 2025, 6, 10. [Google Scholar] [CrossRef]

- Chure, G.; Banks, R.A.; Flamholz, A.I.; Sarai, N.S.; Kamb, M.; Lopez-Gomez, I.; Bar-On, Y.; Milo, R.; Phillips, R. Anthroponumbers.Org: A Quantitative Database of Human Impacts on Planet Earth. Patterns 2022, 3, 100552. [Google Scholar] [CrossRef]

- Shao, S.; Ma, T.; Fernando, G.F. Electro-Spinning of Highly-Aligned Polyacrylonitrile Nano-Fibres with Continuous Spooling. Sci. Rep. 2021, 11, 21713. [Google Scholar] [CrossRef] [PubMed]

- Ahmadi Bonakdar, M.; Rodrigue, D. Electrospinning: Processes, Structures, and Materials. Macromol 2024, 4, 58–103. [Google Scholar] [CrossRef]

- Xue, J.; Wu, T.; Dai, Y.; Xia, Y. Electrospinning and Electrospun Nanofibers: Methods, Materials, and Applications. Chem. Rev. 2019, 119, 5298–5415. [Google Scholar] [CrossRef]

- Kotomin, S.; Malkin, A.; Skvortsov, I. Electrospinning and Mechanotropic Phenomena in Polymer Solutions. Macromol. Symp. 2020, 389, 1900091. [Google Scholar] [CrossRef]

- Nataraj, S.K.; Yang, K.S.; Aminabhavi, T.M. Polyacrylonitrile-Based Nanofibers—A State-of-the-Art Review. Prog. Polym. Sci. 2012, 37, 487–513. [Google Scholar] [CrossRef]

- Wang, T.; Chen, Z.; Gong, W.; Xu, F.; Song, X.; He, X.; Fan, M. Electrospun Carbon Nanofibers and Their Applications in Several Areas. ACS Omega 2023, 8, 22316–22330. [Google Scholar] [CrossRef] [PubMed]

- Mokhova, E.; Gordienko, M.; Menshutina, N.; Serkina, K.; Avetissov, I. Obtaining Polyacrylonitrile Carbon Nanofibers by Electrospinning for Their Application as Flame-Retardant Materials. Polymers 2025, 17, 1255. [Google Scholar] [CrossRef]

- Moskowitz, J.D.; Jacobs, W.; Tucker, A.; Astrove, M.; Harmon, B. Thermo-Oxidative Stabilization of Polyacrylonitrile-Based Copolymers with Guanidinium Itaconate. Polym. Degrad. Stab. 2020, 178, 109198. [Google Scholar] [CrossRef]

- Moskowitz, J.D.; Wiggins, J.S. Thermo-Oxidative Stabilization of Polyacrylonitrile and Its Copolymers: Effect of Molecular Weight, Dispersity, and Polymerization Pathway. Polym. Degrad. Stab. 2016, 125, 76–86. [Google Scholar] [CrossRef]

- Kalinin, A.S. Methods of atomic force microscopy for non-destructive analysis of electromechanical properties of nanostructures. Dissertation 2017, 104. [Google Scholar]

- Palchikova, E.E.; Makarov, I.S.; Vinogradov, M.I.; Golova, L.K.; Shambilova, G.K.; Kulichikhin, V.G. Kinetics of Dissolution of Polyacrylonitrile in N-Methylmorpholine-N-Oxide in the Absence and Presence of Cellulose. Polym. Sci. Ser. B 2021, 63, 833–842. [Google Scholar] [CrossRef]

- Li, J.; Yu, Y.; Li, H.; Liu, Y. Polyacrylonitrile Based Carbon Fibers: Spinning Technology Dependent Precursor Fiber Structure and Its Successive Transformation. J. Appl. Polym. Sci. 2021, 138, 50988. [Google Scholar] [CrossRef]

- Liu, X.D.; Ruland, W. X-Ray Studies on the Structure of Polyacrylonitrile Fibers. Macromolecules 1993, 26, 3030–3036. [Google Scholar] [CrossRef]

- Ahmadi, Z.; Ravandi, S.A.H.; Haghighat, F.; Dabirian, F. Enhancement of the Mechanical Properties of PAN Nanofiber/Carbon Nanotube Composite Mats Produced via Needleless Electrospinning System. Fibers Polym. 2020, 21, 1200–1211. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).