Effect of Screw Configuration on the Recyclability of Natural Fiber-Based Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Blends Formulated for This Study

2.3. Hot Melt Extrusion Conditions

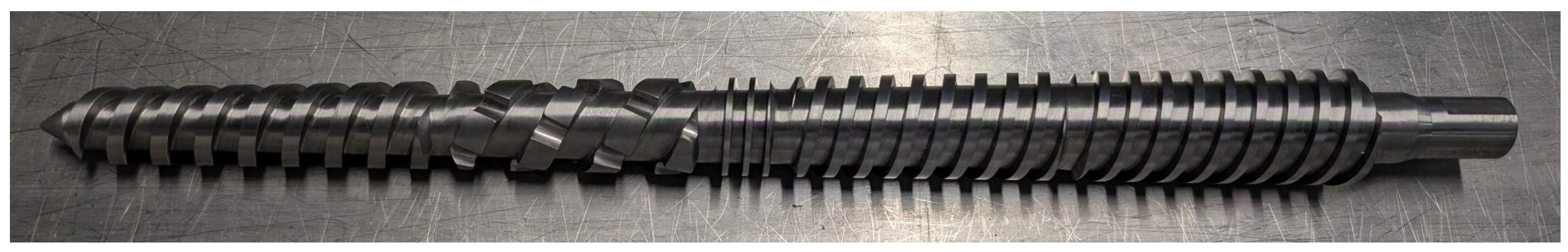

2.3.1. Material Compounding

2.3.2. Mechanical Recycling via PTSE

2.3.3. Mechanical Recycling via CTSE

2.4. Micro Injection Molding

2.5. Mechanical Analysis

2.5.1. Tensile Testing

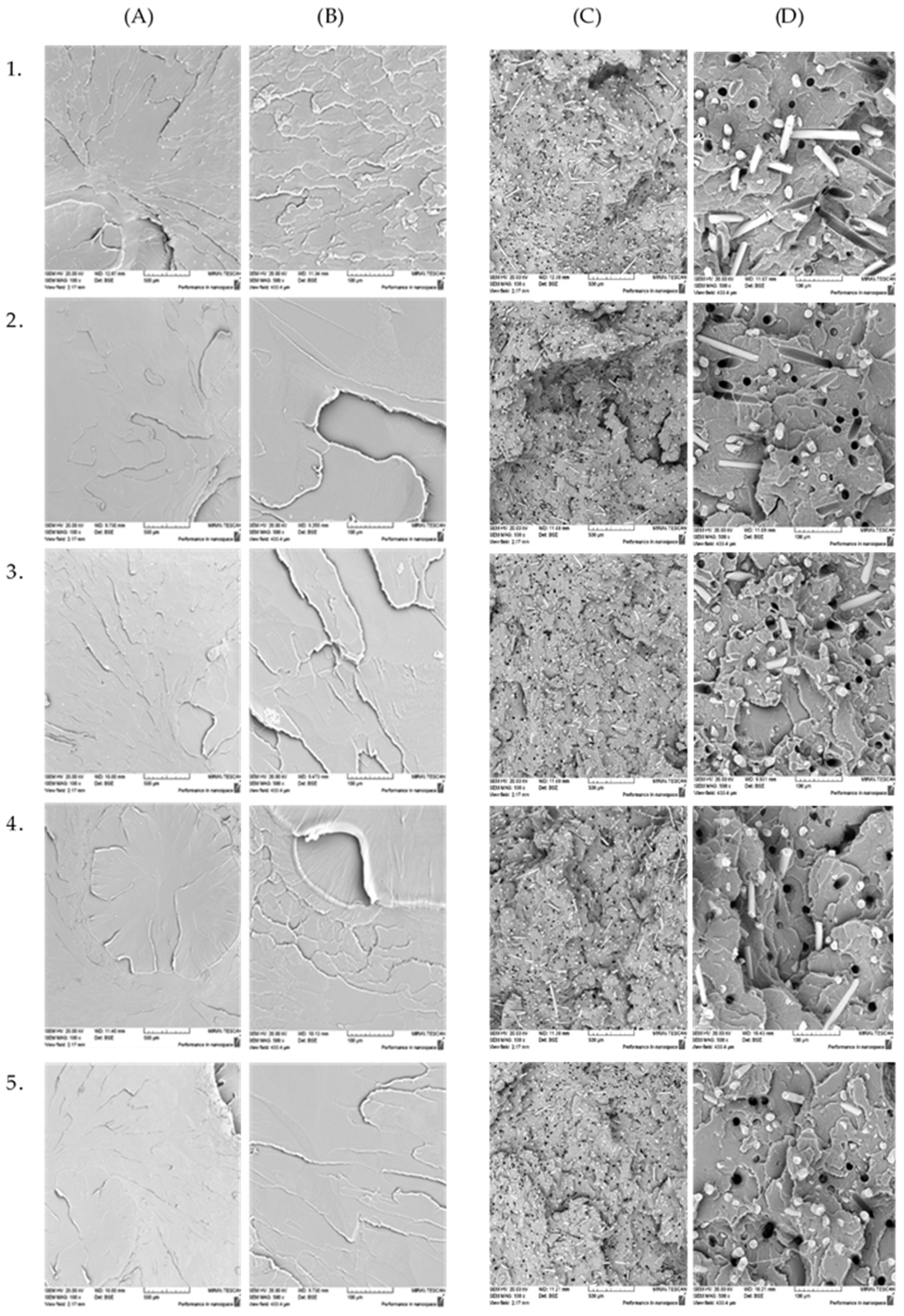

2.5.2. Fracture Surface Morphology

2.5.3. Shore D Hardness

2.6. Thermal Analysis

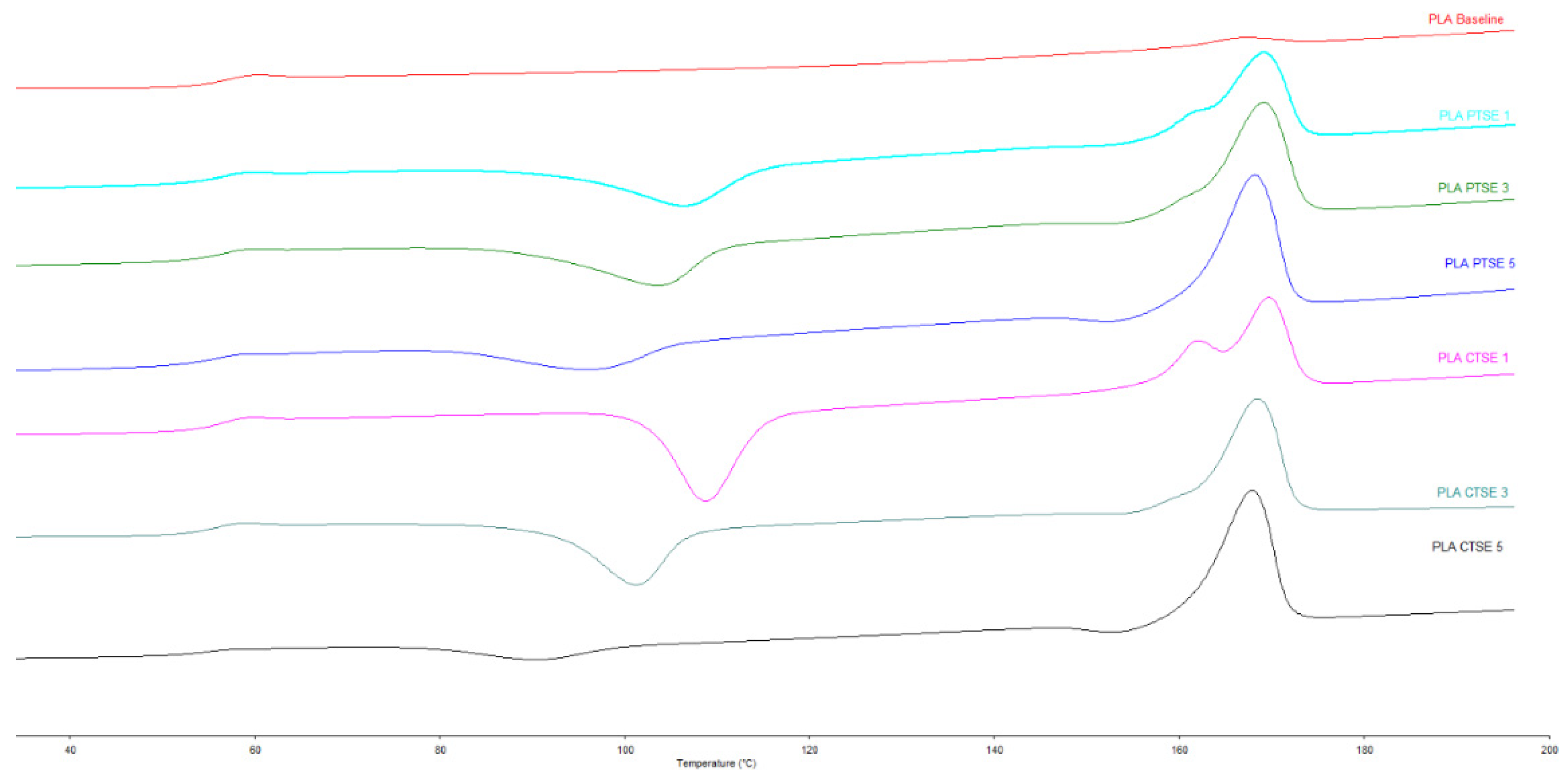

2.6.1. Differential Scanning Calorimetry

2.6.2. Gel Permeation Chromatography

3. Results & Discussion

3.1. Tensile Properties

3.2. Fracture Surface Morphology

3.3. Shore D Hardness

3.4. Thermal Characterization

3.5. Molecular Weight

3.6. Limitations of Current Study

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- OECD. Global Plastics Outlook: Economic Drivers, Environmental Impacts and Policy Options; Organisation for Economic Cooperation and Development: Paris, France, 2022. [Google Scholar]

- Wojnowska-Baryła, I.; Bernat, K.; Zaborowska, M. Plastic Waste Degradation in Landfill Conditions: The Problem with Microplastics, and Their Direct and Indirect Environmental Effects. Int. J. Environ. Res. Public Health 2022, 19, 13223. [Google Scholar] [CrossRef]

- Taipale, S.J.; Vesamäki, J.; Kautonen, P.; Kukkonen, J.V.K.; Biasi, C.; Nissinen, R.; Tiirola, M. Biodegradation of microplastic in freshwaters: A long-lasting process affected by the lake microbiome. Environ. Microbiol. 2023, 25, 2669–2680. [Google Scholar] [CrossRef] [PubMed]

- Chamas, A.; Moon, H.; Zheng, J.; Qiu, Y.; Tabassum, T.; Jang, J.H.; Abu-Omar, M.; Scott, S.L.; Suh, S. Degradation Rates of Plastics in the Environment. ACS Sustain. Chem. Eng. 2020, 8, 3494–3511. [Google Scholar] [CrossRef]

- Derraik, J.G.B. The pollution of the marine environment by plastic debris: A review. Mar. Pollut. Bull. 2002, 44, 842–852. [Google Scholar] [CrossRef] [PubMed]

- Thevenon, F.; Carroll, C.; Sousa, J. (Eds.) Plastic Debris in the Ocean: The Characterization of Marine Plastics and Their Environmental Impacts, Situation Analysis Report; International Union for Conservation of Nature: Gland, Switzerland, 2015. [Google Scholar] [CrossRef]

- Woods, J.S.; Verones, F.; Jolliet, O.; Vázquez-Rowe, I.; Boulay, A.-M. A framework for the assessment of marine litter impacts in life cycle impact assessment. Ecol. Indic. 2021, 129, 107918. [Google Scholar] [CrossRef]

- Kühn, S.; van Franeker, J.A. Quantitative overview of marine debris ingested by marine megafauna. Mar. Pollut. Bull. 2020, 151, 110858. [Google Scholar] [CrossRef]

- Pinto da Costa, J.; Rocha-Santos, T.; Duarte, A.C. The Environmental Impacts of Plastics and Micro-Plastics Use, Waste and Pollution: EU and National Measures; European Parliament: Strasbourg, France, 2020. [Google Scholar]

- Maris, J.; Bourdon, S.; Brossard, J.-M.; Cauret, L.; Fontaine, L.; Montembault, V. Mechanical recycling: Compatibilization of mixed thermoplastic wastes. Polym. Degrad. Stab. 2018, 147, 245–266. [Google Scholar] [CrossRef]

- ASTM D7209-06; Standard Guide for Waste Reduction, Resource Recovery, and Use of Recycled Polymeric Materials and Products 2015. ASTM: West Conshohocken, PA, USA, 2015.

- ISO 15270:2008; Plastics—Guidelines for the Recovery and Recycling of Plastics Waste. ISO: Geneva, Switzerland, 2008.

- Schyns, Z.O.G.; Shaver, M.P. Mechanical Recycling of Packaging Plastics: A Review. Macromol. Rapid Commun. 2021, 42, 2000415. [Google Scholar] [CrossRef]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef]

- Plastics Europe. Chemical Recycling • Plastics Europe. 2022. Available online: https://plasticseurope.org/sustainability/circularity/recycling/chemical-recycling/ (accessed on 8 July 2023).

- McKeown, P.; Jones, M.D. The Chemical Recycling of PLA: A Review. Sustain. Chem. 2020, 1, 1–22. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

- Shen, L.; Worrell, E. Chapter 31—Plastic recycling. In Handbook of Recycling, 2nd ed.; Meskers, C., Worrell, E., Reuter, M.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; pp. 497–510. [Google Scholar] [CrossRef]

- Zheng, J.; Arifuzzaman, M.; Tang, X.; Chelsea Chen, X.; Saito, T. Recent development of end-of-life strategies for plastic in industry and academia: Bridging their gap for future deployment. Mater. Horiz. 2023, 10, 1608–1624. [Google Scholar] [CrossRef] [PubMed]

- EcoEnclose. Post Consumer vs. Post Industrial Recycled Content. 2021. Available online: https://www.ecoenclose.com/blog/post-consumer-vs-post-industrial-recycled-content/ (accessed on 8 July 2023).

- Grabiel, T.; Gammage, T.; Perry, C.; Dixon, C. Achieving sustainable production and consumption of virgin plastic polymers. Front. Mar. Sci. 2022, 9, 981439. [Google Scholar] [CrossRef]

- Department of the Environment, Climate and Communications Waste Action Plan for a Circular Economy. 2020. Available online: https://www.gov.ie/en/publication/4221c-waste-action-plan-for-a-circular-economy/ (accessed on 8 July 2023).

- Baranwal, J.; Barse, B.; Fais, A.; Delogu, G.L.; Kumar, A. Biopolymer: A Sustainable Material for Food and Medical Applications. Polymers 2022, 14, 983. [Google Scholar] [CrossRef] [PubMed]

- Abhilash, M.; Thomas, D. 15—Biopolymers for Biocomposites and Chemical Sensor Applications. In Biopolymer Composites in Electronics; Sadasivuni, K.K., Ponnamma, D., Kim, J., Cabibihan, J.-J., AlMaadeed, M.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 405–435. [Google Scholar] [CrossRef]

- Flury, M.; Narayan, R. Biodegradable plastic as an integral part of the solution to plastic waste pollution of the environment. Curr. Opin. Green. Sustain. Chem. 2021, 30, 100490. [Google Scholar] [CrossRef]

- Atiwesh, G.; Mikhael, A.; Parrish, C.C.; Banoub, J.; Le, T.-A.T. Environmental impact of bioplastic use: A review. Heliyon 2021, 7, e07918. [Google Scholar] [CrossRef]

- Kumar, R.; Verma, A.; Shome, A.; Sinha, R.; Sinha, S.; Jha, P.K.; Kumar, R.; Kumar, P.; Shubham; Das, S.; et al. Impacts of Plastic Pollution on Ecosystem Services, Sustainable Development Goals, and Need to Focus on Circular Economy and Policy Interventions. Sustainability 2021, 13, 9963. [Google Scholar] [CrossRef]

- Moshood, T.D.; Nawanir, G.; Mahmud, F.; Mohamad, F.; Ahmad, M.H.; AbdulGhani, A. Biodegradable plastic applications towards sustainability: A recent innovations in the green product. Clean. Eng. Technol. 2022, 6, 100404. [Google Scholar] [CrossRef]

- Alassali, A.; Picuno, C.; Chong, Z.K.; Guo, J.; Maletz, R.; Kuchta, K. Towards Higher Quality of Recycled Plastics: Limitations from the Material’s Perspective. Sustainability 2021, 13, 13266. [Google Scholar] [CrossRef]

- Kearney; Walberer, A.; Prabhakar, R.; Rowe, E. Bioplastics Have Shown Promise, but Are They Truly a Sustainable Packaging Solution? 2023. Available online: https://www.kearney.com/service/sustainability/article/bioplastics-have-shown-promise-but-are-they-truly-a-sustainable-packaging-solution (accessed on 8 July 2023).

- Rosenboom, J.-G.; Langer, R.; Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef]

- Hidalgo-Carvajal, D.; Muñoz, Á.H.; Garrido-González, J.J.; Carrasco-Gallego, R.; Alcázar Montero, V. Recycled PLA for 3D Printing: A Comparison of Recycled PLA Filaments from Waste of Different Origins after Repeated Cycles of Extrusion. Polymers 2023, 15, 3651. [Google Scholar] [CrossRef]

- Taib, N.-A.A.B.; Rahman, M.R.; Huda, D.; Kuok, K.K.; Hamdan, S.; Bakri, M.K.B.; Julaihi, M.R.M.B.; Khan, A. A review on poly lactic acid (PLA) as a biodegradable polymer. Polym. Bull. 2023, 80, 1179–1213. [Google Scholar] [CrossRef]

- Armentano, I.; Bitinis, N.; Fortunati, E.; Mattioli, S.; Rescignano, N.; Verdejo, R.; Lopez-Manchado, M.A.; Kenny, J.M. Multifunctional nanostructured PLA materials for packaging and tissue engineering. Prog. Polym. Sci. 2013, 38, 1720–1747. [Google Scholar] [CrossRef]

- Mistry, A.N.; Kachenchart, B.; Pinyakong, O.; Assavalapsakul, W.; Jitpraphai, S.M.; Somwangthanaroj, A.; Luepromchai, E. Bioaugmentation with a defined bacterial consortium: A key to degrade high molecular weight polylactic acid during traditional composting. Bioresour. Technol. 2023, 367, 128237. [Google Scholar] [CrossRef] [PubMed]

- Maitz, M.F. Applications of synthetic polymers in clinical medicine. Biosurface Biotribology 2015, 1, 161–176. [Google Scholar] [CrossRef]

- Moreno, E.; Beltrán, F.R.; Arrieta, M.P.; Gaspar, G.; Muneta, L.M.; Carrasco-Gallego, R.; Yáñez, S.; Hidalgo-Carvajal, D.; Orden, M.U.d.l.; Urreaga, J.M. Technical Evaluation of Mechanical Recycling of PLA 3D Printing Wastes. Proceedings 2020, 69, 19. [Google Scholar] [CrossRef]

- Beltrán, F.R.; Arrieta, M.P.; Moreno, E.; Gaspar, G.; Muneta, L.M.; Carrasco-Gallego, R.; Yáñez, S.; Hidalgo-Carvajal, D.; de la Orden, M.U.; Martínez Urreaga, J. Evaluation of the Technical Viability of Distributed Mechanical Recycling of PLA 3D Printing Wastes. Polymers 2021, 13, 1247. [Google Scholar] [CrossRef]

- Ramos-Hernández, T.; Robledo-Ortíz, J.R.; González-López, M.E.; del Campo, A.S.M.; González-Núñez, R.; Rodrigue, D.; Pérez Fonseca, A.A. Mechanical recycling of PLA: Effect of weathering, extrusion cycles, and chain extender. J. Appl. Polym. Sci. 2023, 140, e53759. [Google Scholar] [CrossRef]

- Wilczyński, K.; Wilczyński, K.J.; Buziak, K. Modeling and Experimental Studies on Polymer Melting and Flow in Injection Molding. Polymers 2022, 14, 2106. [Google Scholar] [CrossRef]

- Milisavljevi, J.; Đorđević, M. Tensile testing for different types of polymers. In Proceedings of the 29th Danubia—Adria Symposium on Advances in Experimental Mechanics, Belgrade, Serbia, 26–29 September 2012. [Google Scholar]

- Biopdi. Mardoqueu Tensile Testing. 2019. Available online: https://biopdi.com/tensile-testing/ (accessed on 23 July 2023).

- MatWeb Shore Durometer Hardness Testing of Rubber and Plastics. 2023. Available online: https://www.matweb.com/reference/shore-hardness.aspx (accessed on 29 July 2023).

- Oksiuta, Z.; Jalbrzykowski, M.; Mystkowska, J.; Romanczuk, E.; Osiecki, T. Mechanical and Thermal Properties of Polylactide (PLA) Composites Modified with Mg, Fe, and Polyethylene (PE) Additives. Polymers 2020, 12, 2939. [Google Scholar] [CrossRef]

- Shamsuyeva, M.; Endres, H.-J. Plastics in the context of the circular economy and sustainable plastics recycling: Comprehensive review on research development, standardization and market. Compos. Part C 2021, 6, 100168. [Google Scholar] [CrossRef]

- Hummel, S.; Obermeier, K.; Zier, K.; Krommes, S.; Schemme, M.; Karlinger, P. Analysis of Mechanical Properties Related to Fiber Length of Closed-Loop-Recycled Offcuts of a Thermoplastic Fiber Composites (Organo Sheets). Materials 2022, 15, 3872. [Google Scholar] [CrossRef] [PubMed]

- Finnerty, J.; Rowe, S.; Howard, T.; Connolly, S.; Doran, C.; Devine, D.M.; Gately, N.M.; Chyzna, V.; Portela, A.; Bezerra, G.S.N.; et al. Effect of Mechanical Recycling on the Mechanical Properties of PLA-Based Natural Fiber-Reinforced Composites. J. Compos. Sci. 2023, 7, 141. [Google Scholar] [CrossRef]

- MohammadKarimi, S.; Neitzel, B.; Lang, M.; Puch, F. Investigation of the Fiber Length and the Mechanical Properties of Waste Recycled from Continuous Glass Fiber-Reinforced Polypropylene. Recycling 2023, 8, 82. [Google Scholar] [CrossRef]

- Graupner, N.; Albrecht, K.; Ziegmann, G.; Enzler, H.; Muessig, J. Influence of reprocessing on fibre length distribution, tensile strength and impact strength of injection moulded cellulose fibre-reinforced polylactide (PLA) composites. Express Polym. Lett. 2016, 10, 647–663. [Google Scholar] [CrossRef]

- Thomson, C.I.; Lowe, R.M.; Ragauskas, A.J. Imaging cellulose fibre interfaces with fluorescence microscopy and resonance energy transfer. Carbohydr. Polym. 2007, 69, 799–804. [Google Scholar] [CrossRef]

- Billmeyer, F.W. Textbook of Polymer Science; John Wiley & Sons: Hoboken, NJ, USA, 1984. [Google Scholar]

- Da Costa, H.M.; Ramos, V.D.; de Oliveira, M.G. Degradation of polypropylene (PP) during multiple extrusions: Thermal analysis, mechanical properties and analysis of variance. Polym. Test. 2007, 26, 676–684. [Google Scholar] [CrossRef]

- Pillin, I.; Montrelay, N.; Bourmaud, A.; Grohens, Y. Effect of thermo-mechanical cycles on the physico-chemical properties of poly(lactic acid). Polym. Degrad. Stab. 2008, 93, 321–328. [Google Scholar] [CrossRef]

- Fazelinejad, S.; Åkesson, D.; Skrifvars, M. Repeated Mechanical Recycling of Polylactic Acid Filled with Chalk. Prog. Rubber Plast. Recycl. Technol. 2016, 33, 1–16. [Google Scholar] [CrossRef]

- Badia, J.D.; Strömberg, E.; Karlsson, S.; Ribes-Greus, A. Material valorisation of amorphous polylactide. Influence of thermo-mechanical degradation on the morphology, segmental dynamics, thermal and mechanical performance. Polym. Degrad. Stab. 2012, 97, 670–678. [Google Scholar] [CrossRef]

- Żenkiewicz, M.; Richert, J.; Rytlewski, P.; Moraczewski, K.; Stepczyńska, M.; Karasiewicz, T. Characterisation of multi-extruded poly(lactic acid). Polym. Test. 2009, 28, 412–418. [Google Scholar] [CrossRef]

- Yarahmadi, N.; Jakubowicz, I.; Enebro, J. Polylactic acid and its blends with petroleum-based resins: Effects of reprocessing and recycling on properties. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Le Duigou, A.; Pillin, I.; Bourmaud, A.; Davies, P.; Baley, C. Effect of recycling on mechanical behaviour of biocompostable flax/poly(l-lactide) composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1471–1478. [Google Scholar] [CrossRef]

- Agüero, A.; Morcillo, M.d.C.; Quiles-Carrillo, L.; Balart, R.; Boronat, T.; Lascano, D.; Torres-Giner, S.; Fenollar, O. Study of the Influence of the Reprocessing Cycles on the Final Properties of Polylactide Pieces Obtained by Injection Molding. Polymers 2019, 11, 1908. [Google Scholar] [CrossRef] [PubMed]

- Kuciel, S.; Mazur, K.; Hebda, M. The Infuence of Wood and Basalt Fibres on Mechanical, Thermal and Hydrothermal Properties of PLA Composites. J. Polym. Environ. 2020, 28, 1204–1215. [Google Scholar] [CrossRef]

- Persico, L.; Giacalone, G.; Cristalli, B.; Tufano, C.; Saccorotti, E.; Casalone, P.; Mattiazzo, G. Recycling Process of a Basalt Fiber-Epoxy Laminate by Solvolysis: Mechanical and Optical Tests. Fibers 2022, 10, 55. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Puttegowda, M.; Mavinkere Rangappa, S.; Siengchin, S. Accelerated weathering of sustainable and micro-filler Basalt reinforced polymer biocomposites: Physical, mechanical, thermal, wettability, and water absorption studies. J. Build. Eng. 2023, 80, 108040. [Google Scholar] [CrossRef]

- Graupner, N.; Müssig, J. A comparison of the mechanical characteristics of kenaf and lyocell fibre reinforced poly(lactic acid) (PLA) and poly(3-hydroxybutyrate) (PHB) composites. Compos. Part A Appl. Sci. Manuf. 2011, 42, 2010–2019. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Singh, M.; Preet, P. On compressive and morphological features of 3D printed almond skin powder reinforced PLA matrix. Mater. Res. Express 2020, 7, 025311. [Google Scholar] [CrossRef]

- Qi, H.J.; Joyce, K.; Boyce, M.C. Durometer Hardness and the Stress-Strain Behavior of Elastomeric Materials. Rubber Chem. Technol. 2003, 76, 419–435. [Google Scholar] [CrossRef]

- Carrasco, F.; Santana Pérez, O.; Maspoch, M.L. Kinetics of the Thermal Degradation of Poly(lactic acid) and Polyamide Bioblends. Polymers 2021, 13, 3996. [Google Scholar] [CrossRef]

- Effect of Thermal Degradation on Polymer Thermal Properties—TA Instruments. Available online: https://www.tainstruments.com/applications-notes/effect-of-thermal-degradation-on-polymer-thermal-properties/ (accessed on 16 February 2024).

- Niaounakis, M. Chapter 2—Properties. In Biopolymers: Processing and Products; Elsevier: Amsterdam, The Netherlands, 2015; pp. 79–116. [Google Scholar] [CrossRef]

- Rojas-Gonzáles, A.F.; Carrero-Mantilla, J.I. Thermal degradation kinetic of polylactic acid in multiple extrusions. Ing. Univ. 2015, 19, 189–206. [Google Scholar]

- Parallel Twin Screw Extruder VS. Conical Twin Screw Extruder—KAILIDA EXTRUSION 2023. Available online: https://www.kailidaextrusion.com/parallel-twin-screw-extruder-vs-conical-twin-screw-extruder/ (accessed on 17 February 2024).

- Wypych, G. Handbook of Nucleating Agents; Elsevier: Amsterdam, The Netherlands, 2021. [Google Scholar]

- Ying, Z.; Wu, D.; Zhang, M.; Qiu, Y. Polylactide/basalt fiber composites with tailorable mechanical properties: Effect of surface treatment of fibers and annealing. Compos. Struct. 2017, 176, 1020–1027. [Google Scholar] [CrossRef]

- Beltrán, F.R.; Infante, C.; De La Orden, M.U.; Martínez Urreaga, J. Mechanical recycling of poly(lactic acid): Evaluation of a chain extender and a peroxide as additives for upgrading the recycled plastic. J. Clean. Prod. 2019, 219, 46–56. [Google Scholar] [CrossRef]

- Lee, D.; Lee, Y.; Kim, I.; Hwang, K.; Kim, N. Thermal and Mechanical Degradation of Recycled Polylactic Acid Filaments for Three-Dimensional Printing Applications. Polymers 2022, 14, 5385. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Barczewski, M.; Skórczewska, K.; Matykiewicz, D. Correlation between Processing Parameters and Degradation of Different Polylactide Grades during Twin-Screw Extrusion. Polymers 2020, 12, 1333. [Google Scholar] [CrossRef]

| ASTM D7209-06 Standard Definitions [11] | Equivalent ISO 15270 Standard Definitions [12] | Other Equivalent Terms |

|---|---|---|

| Primary recycling | Mechanical recycling | Re-extrusion, re-use, closed-loop recycling |

| Secondary recycling | Mechanical recycling | Downgrading |

| Tertiary recycling | Chemical recycling | Feedstock recycling |

| Quaternary recycling | Energy recovery | Valorisation |

| Physical Properties | ||

|---|---|---|

| Ingeo 4032D | ASTM Method | |

| Specific Gravity | 1.24 | D792 |

| MFR, g/10 min (210 °C, 2.16 kg) | 7 | D1238 |

| Melt Density (g/cc) | 1.08 at 230 °C | - |

| Mechanical Properties | ||

| Tensile Strength @ Break, psi (MPa) | 7700 (53) | D882 |

| Tensile Yield Strength, psi (MPa) | 8700 (60) | D882 |

| Tensile Modulus, kpsi (GPa) | 500 (3.5) | D882 |

| Tensile Elongation, % | 6.0 | D882 |

| Notched Izod Impact, ft-lb/in (J/m) | 0.3 (16) | D256 |

| Melting Point(°C) | 155–170 | - |

| Sample Name | PLA (wt.%) | BF (wt.%) |

|---|---|---|

| PLA100 | 100 | - |

| PLA80BF20 | 80 | 20 |

| Heating Zone | Barrell Temperatures (°C) |

|---|---|

| Zone 1 | 150 |

| Zone 2 | 160 |

| Zone 3 | 170 |

| Zone 4 | 180 |

| Zone 5 | 190 |

| Die | 200 |

| Screw speed (RPM) | 150 |

| Parameter | Virgin PLA | PLA-Based Composites |

|---|---|---|

| Temperature | 190 °C—plasticising 180 °C—chamber 170 °C—nozzle | 180 °C—plasticising 170 °C—chamber 170 °C—nozzle |

| Piston diameter | 14 mm | 14 mm |

| Shot size | 42 mm | 39 mm |

| Cooling time | 30 s | 23 s |

| 1st injection pressure | 55 bar | 60 bar |

| 2nd injection pressure | 50 bar | 50 bar |

| 1st injection pressure time | 3.5 s | 3.5 s |

| 2nd injection pressure time | 4.0 s | 3.0 s |

| Decompression | 2 mm | 2 mm |

| Max. Load (N) | σ (n = 5) | δ (MPa) | σ (n = 5) | Ε (MPa) | σ (n = 5) | ε (%) | σ (n = 5) | |

|---|---|---|---|---|---|---|---|---|

| PLA100 | 828.6 | 12.9 | 72.8 | 1.1 | 1483.5 | 49.1 | 9.7 | 2.4 |

| PLA100 PTSE 1 | 801.6 | 9.5 | 70.4 | 0.8 | 1514.5 | 22.8 | 12.8 | 1.7 |

| PLA100 PTSE 5 | 795.8 | 25.2 | 69.9 | 2.2 | 1491.7 | 36.6 | 10.9 | 3.1 |

| PLA100 CTSE 1 | 826 | 18.7 | 72.6 | 1.6 | 1510.8 | 51.6 | 12.5 | 1.0 |

| PLA100 CTSE 5 | 770.1 | 17.8 | 67.6 | 1.6 | 1458.2 | 33.3 | 8.3 | 0.8 |

| PLA80BF20 | 922.0 | 45.5 | 81.0 | 4.0 | 1714.8 | 96.1 | 6.7 | 0.5 |

| PLA80BF20PTSE 1 | 901.9 | 17.3 | 79.2 | 1.5 | 1772.5 | 106.0 | 7.1 | 0.8 |

| PLA80BF20PTSE 5 | 758.3 | 7.4 | 66.6 | 0.7 | 1621.8 | 93.5 | 6.6 | 0.3 |

| PLA80BF20CTSE 1 | 812.9 | 23.4 | 71.4 | 2.1 | 1537.6 | 142.4 | 7.1 | 0.3 |

| PLA80BF20CTSE 5 | 706.5 | 14.5 | 62.1 | 1.3 | 1553.9 | 61.4 | 6.0 | 0.5 |

| Sample ID | Shore D Hardness | Δ (n = 5) |

|---|---|---|

| PLA100 | 80.1 | ±0.8 |

| PLA100 PTSE 1 | 80.8 | ±0.6 |

| PLA100 PTSE 5 | 80.1 | ±1.6 |

| PLA100 CTSE 1 | 80.4 | ±0.4 |

| PLA100 CTSE 5 | 80.3 | ±0.8 |

| PLA80BF20 | 83.5 | ±0.9 |

| PLA80BF20PTSE 1 | 81.5 | ±0.6 |

| PLA80BF20PTSE 5 | 82.6 | ±0.9 |

| PLA80BF20CTSE 1 | 83.1 | ±1.0 |

| PLA80BF20CTSE 5 | 83.6 | ±1.2 |

| Sample ID | Tg (°C) | Tc (°C) | ∆Hc | Tm (°C) | ∆Hm | Xc (%) |

|---|---|---|---|---|---|---|

| PLA100 | 56.30 | - | - | 166.57 | 3.21 | 3.42 |

| PLA100 PTSE 1 | 56.98 | 106.50 | 27.53 | 169.05 | 36.01 | 38.43 |

| PLA100 PTSE 3 | 57.13 | 103.80 | 28.33 | 168.99 | 43.60 | 46.51 |

| PLA100 PTSE 5 | 55.28 | 96.13 | 20.08 | 168.16 | 48.30 | 51.52 |

| PLA100 CTSE 1 | 56.97 | 108.70 | 37.13 | 169.67 | 40.10 | 42.79 |

| PLA100 CTSE 3 | 54.84 | 101.36 | 32.95 | 168.37 | 40.44 | 43.16 |

| PLA100 CTSE 5 | 54.51 | 90.50 | 9.88 | 167.86 | 46.90 | 50.00 |

| PLA80BF20 | 56.47 | 107.99 | 24.41 | 169.70 | 28.14 | 30.03 |

| PLA80BF20 PTSE 1 | 59.64 | 111.17 | 31.93 | 169.56 | 32.73 | 34.93 |

| PLA80BF20 PTSE 3 | 54.85 | 102.15 | 24.15 | 168.34 | 31.73 | 33.87 |

| PLA80BF20 PTSE 5 | 55.40 | 97.81 | 20.84 | 167.99 | 39.17 | 41.80 |

| PLA80BF20 CTSE 1 | 56.48 | 106.82 | 28.83 | 169.36 | 31.45 | 33.56 |

| PLA80BF20 CTSE 3 | 54.47 | 95.18 | 12.66 | 167.74 | 32.59 | 34.79 |

| PLA80BF20 CTSE 5 | 56.56 | - | - | 167.52 | 34.40 | 36.71 |

| Sample ID | Mn (g/mol) | % Decrease | Mw (g/mol) | % Decrease |

|---|---|---|---|---|

| PLA100 | 49,271 | 0.00 | 132,954 | 0.00 |

| PLA100 PTSE 1 | 46,182 | 6.27 | 115,089 | 13.44 |

| PLA100 PTSE 3 | 35,985 | 26.97 | 97,031 | 27.02 |

| PLA100 PTSE 5 | 32,944 | 33.14 | 93,588 | 29.61 |

| PLA100 CTSE 1 | 46,316 | 6.00 | 119,851 | 9.86 |

| PLA100 CTSE 3 | 37,521 | 23.85 | 104,428 | 21.46 |

| PLA100 CTSE 5 | 28,307 | 42.55 | 74,116 | 44.25 |

| PLA80BF20 | 53,527 | 0.00 | 130,102 | 0.00 |

| PLA80BF20 PTSE 1 | 48,462 | 9.46 | 120,815 | 7.14 |

| PLA80BF20 PTSE 3 | 44,116 | 17.58 | 105,691 | 18.76 |

| PLA80BF20 PTSE 5 | 35,514 | 33.65 | 90,743 | 30.25 |

| PLA80BF20 CTSE 1 | 50,204 | 6.21 | 122,578 | 5.78 |

| PLA80BF20 CTSE 3 | 36,181 | 32.41 | 82,518 | 36.57 |

| PLA80BF20 CTSE 5 | 21,828 | 59.22 | 57,674 | 55.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chyzna, V.; Rowe, S.; Finnerty, J.; Howard, T.; Doran, C.; Connolly, S.; Gately, N.; Portela, A.; Murphy, A.; Devine, D.M.; et al. Effect of Screw Configuration on the Recyclability of Natural Fiber-Based Composites. Fibers 2025, 13, 98. https://doi.org/10.3390/fib13070098

Chyzna V, Rowe S, Finnerty J, Howard T, Doran C, Connolly S, Gately N, Portela A, Murphy A, Devine DM, et al. Effect of Screw Configuration on the Recyclability of Natural Fiber-Based Composites. Fibers. 2025; 13(7):98. https://doi.org/10.3390/fib13070098

Chicago/Turabian StyleChyzna, Vlasta, Steven Rowe, James Finnerty, Trevor Howard, Christopher Doran, Shane Connolly, Noel Gately, Alexandre Portela, Alan Murphy, Declan M. Devine, and et al. 2025. "Effect of Screw Configuration on the Recyclability of Natural Fiber-Based Composites" Fibers 13, no. 7: 98. https://doi.org/10.3390/fib13070098

APA StyleChyzna, V., Rowe, S., Finnerty, J., Howard, T., Doran, C., Connolly, S., Gately, N., Portela, A., Murphy, A., Devine, D. M., & Colbert, D. M. (2025). Effect of Screw Configuration on the Recyclability of Natural Fiber-Based Composites. Fibers, 13(7), 98. https://doi.org/10.3390/fib13070098