Experimental Analysis of Low-Energy Impact Damage in Composite Material Airfoils

Highlights

- Low-energy impacts caused matrix cracking and delamination in all specimens, while fiber–matrix debonding and matrix tearing were only observed in flat laminates, not in curved airfoil profiles.

- Airfoil geometry influenced damage propagation; GOE777-IL showed higher impact resistance while SC(2)-0714 presented larger damage areas.

- Conventional visual inspection may underestimate internal damage, highlighting the importance of advanced non-destructive techniques.

- Results support the development of geometry-specific impact tolerance criteria for composite structures.

Abstract

1. Introduction

2. Materials and Methods

2.1. Composite Material and Airfoil Profiles

2.2. Mechanical Testing

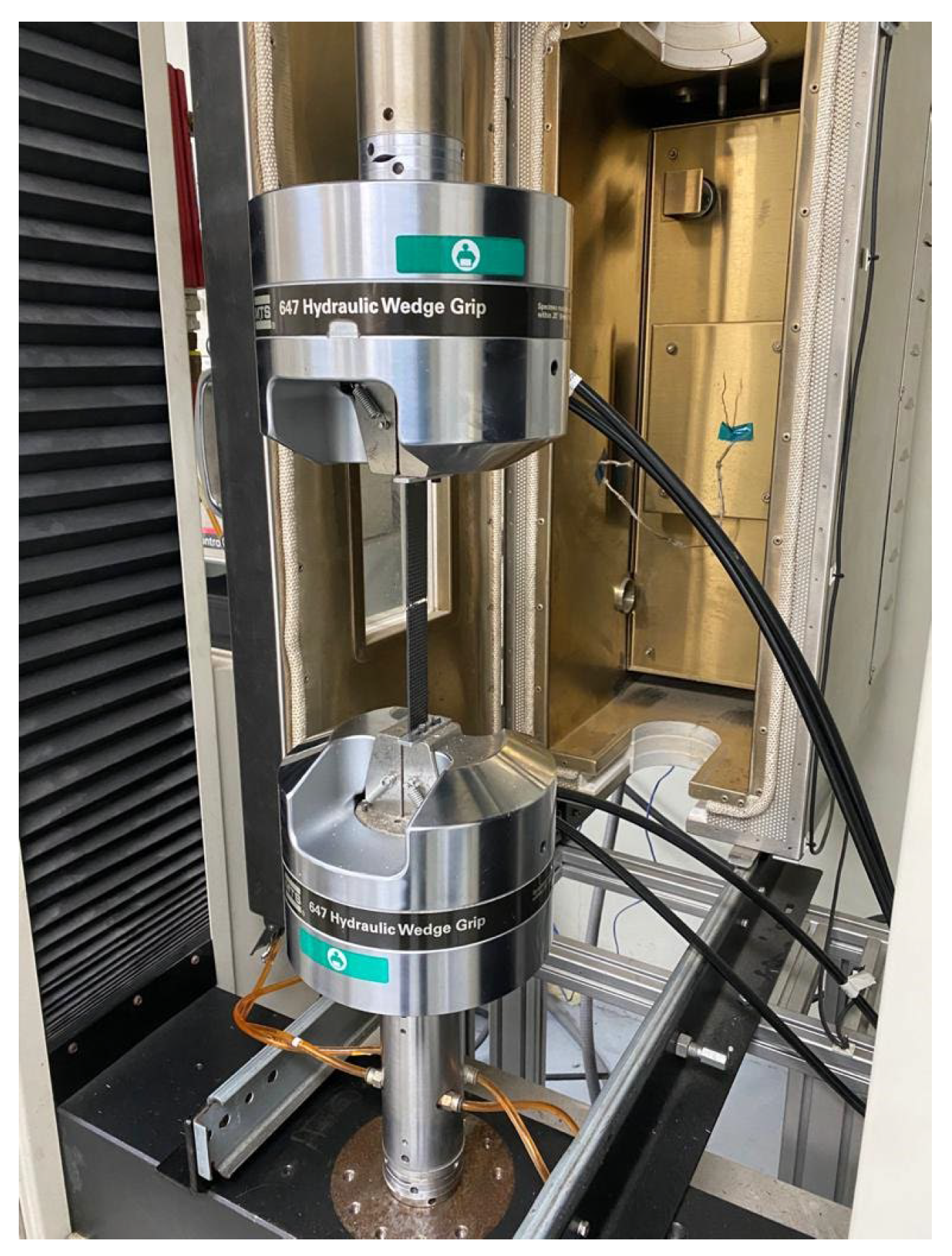

2.2.1. Tensile Testing

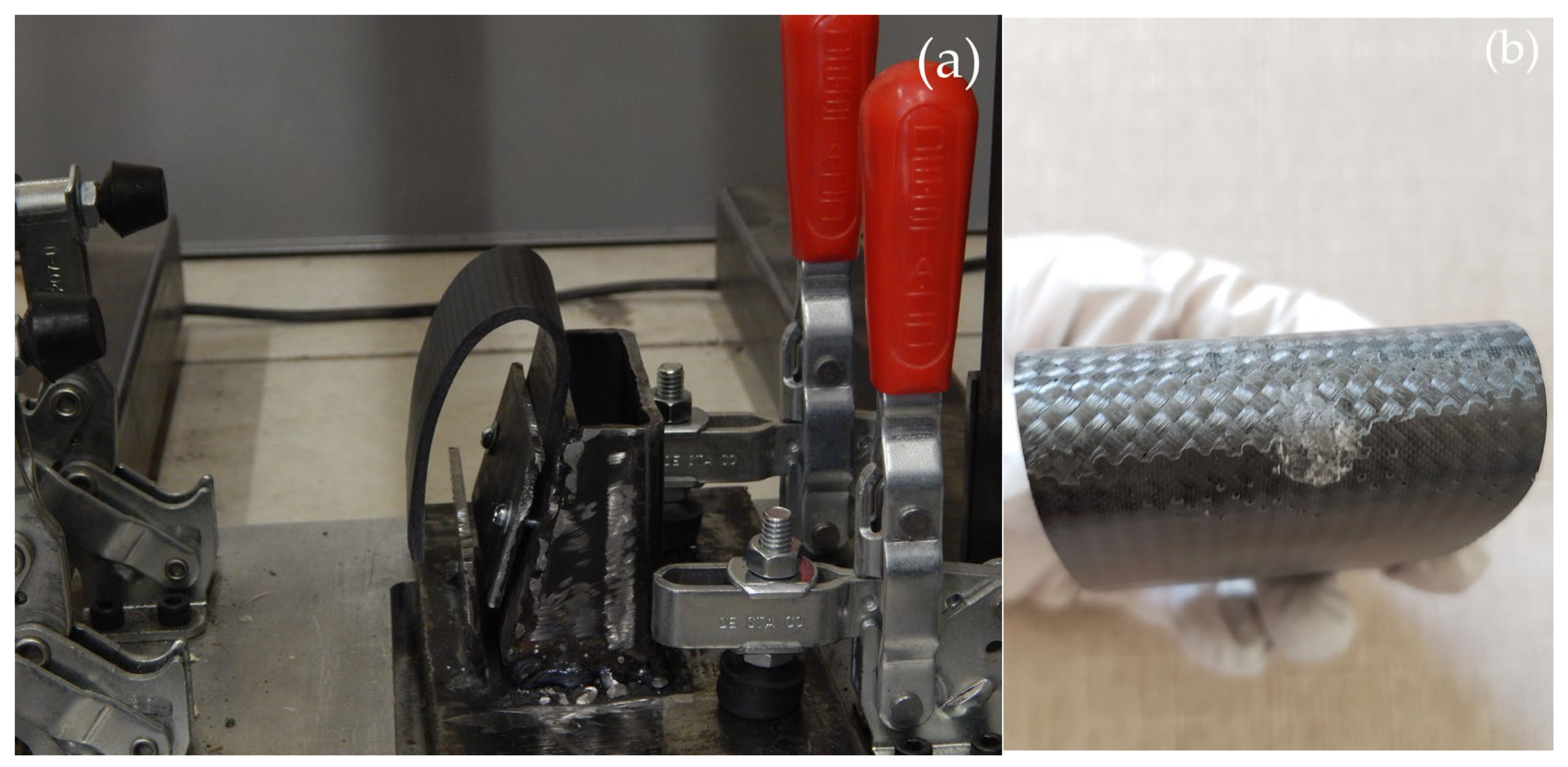

2.2.2. Low-Energy Impact Testing

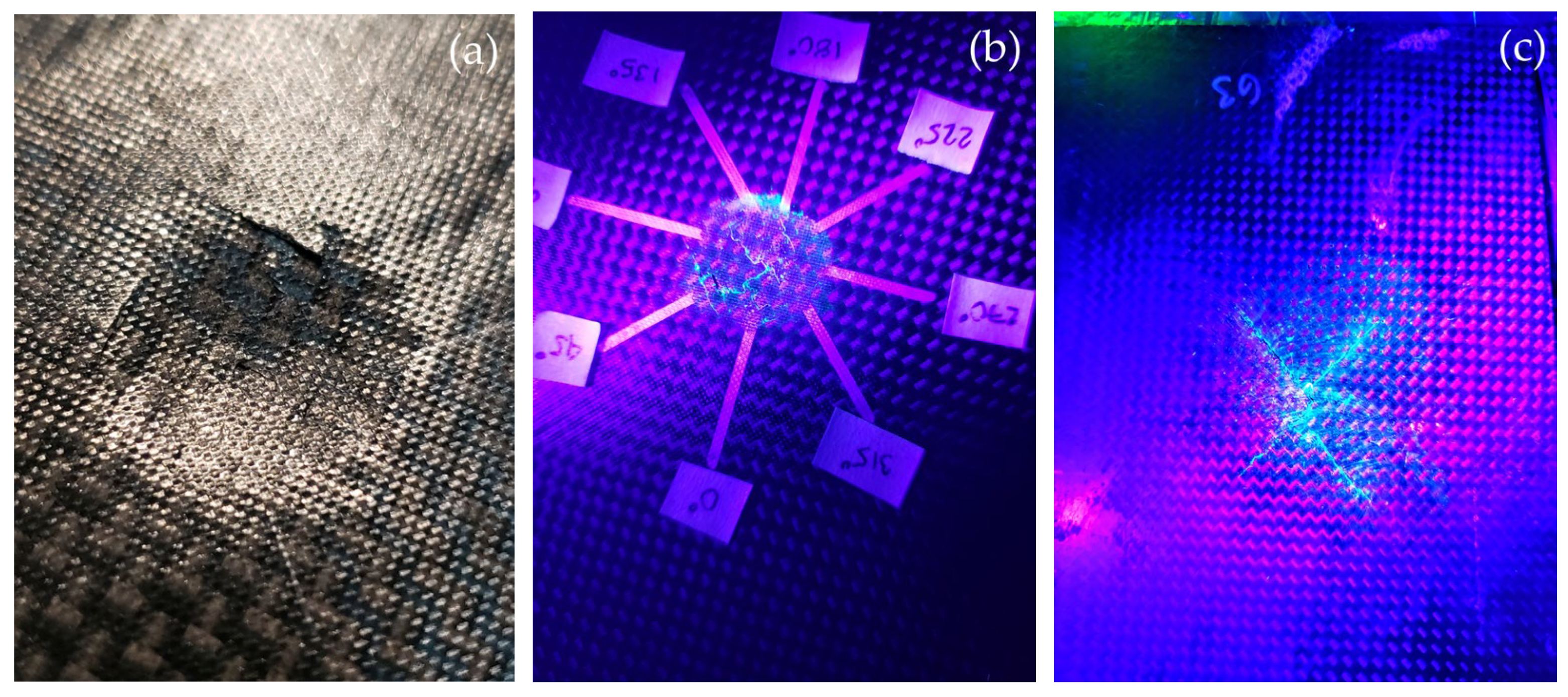

2.3. Damage Characterization and Analysis

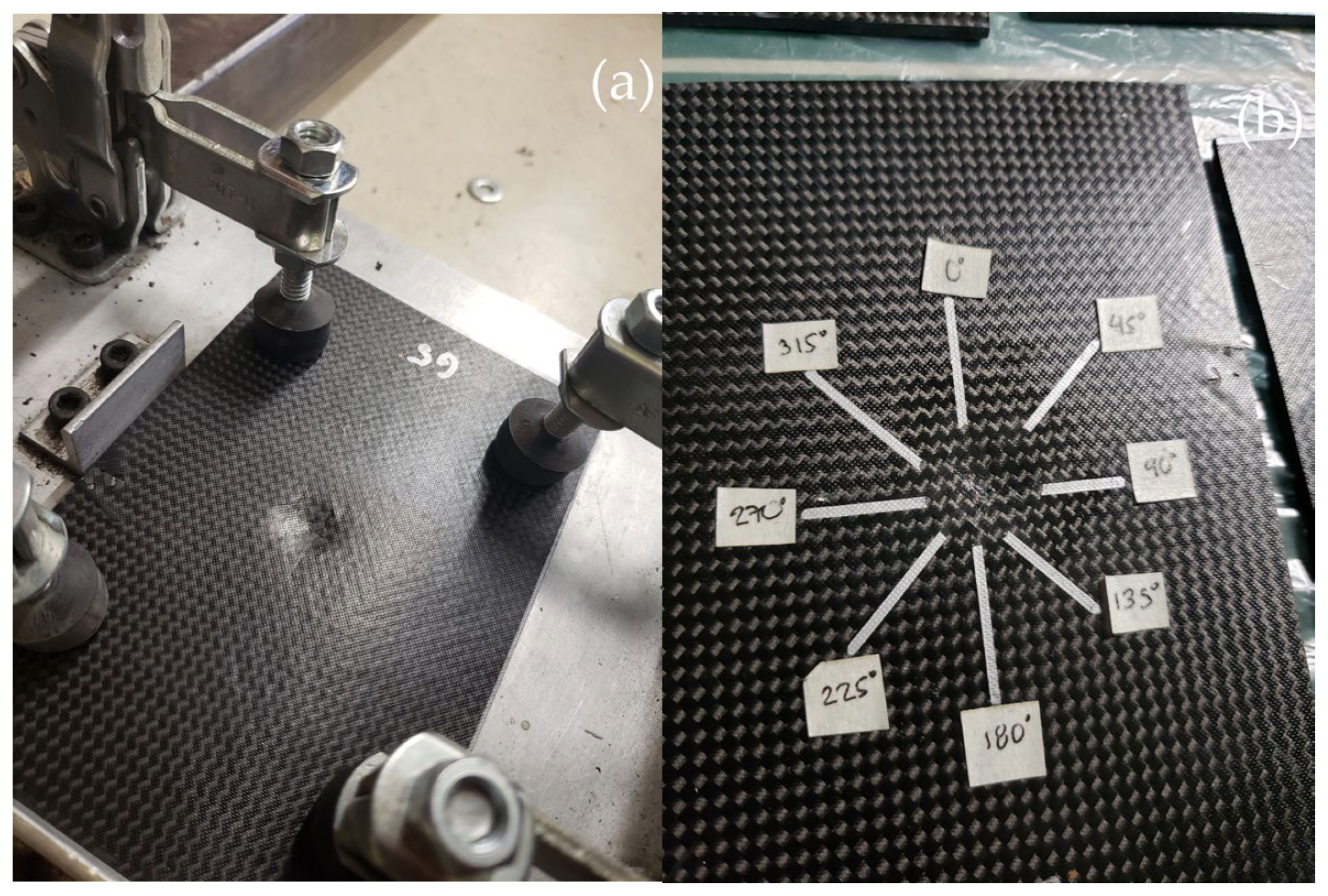

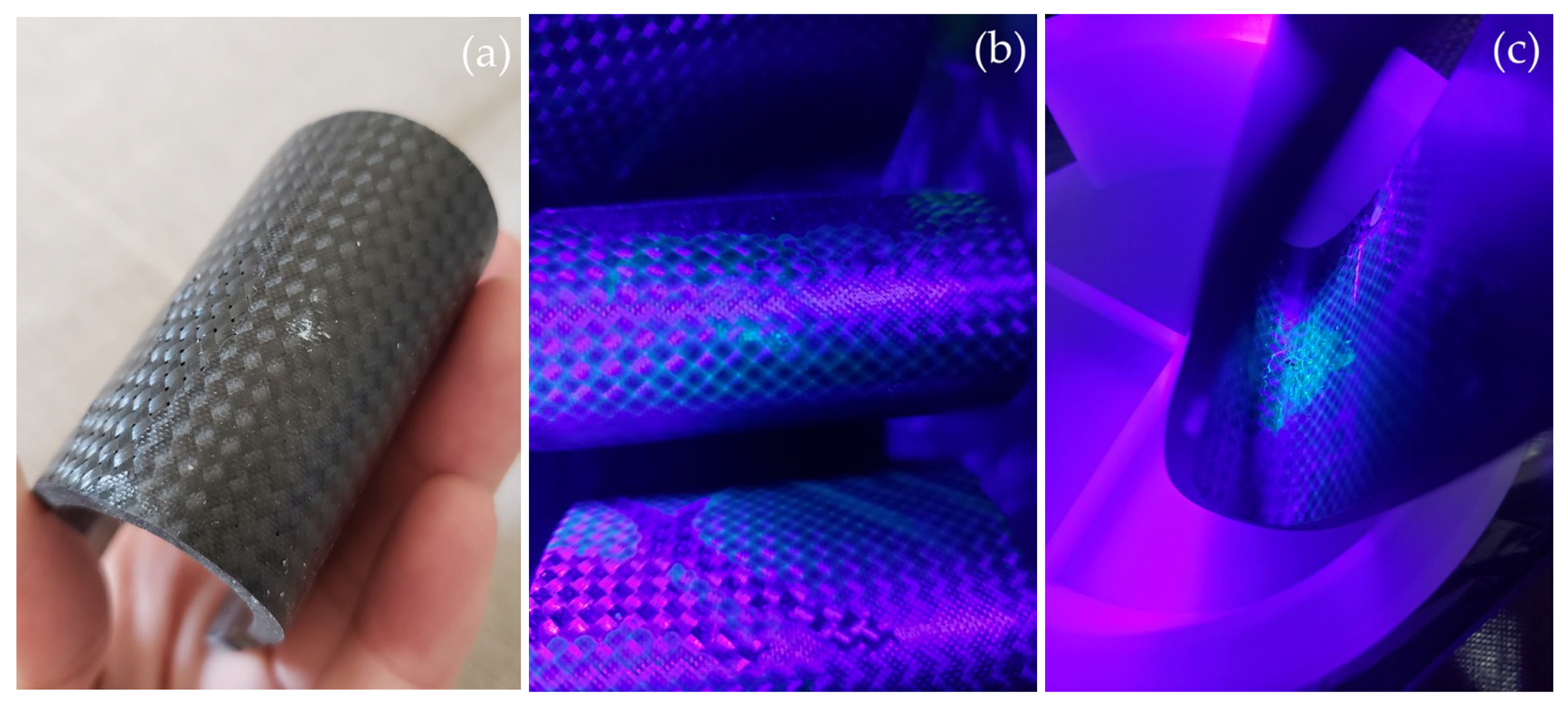

2.3.1. Non-Destructive Inspection

2.3.2. Microscopy Analysis

3. Manufacturing and Specimen Preparation

Fabrication of Flat and Curved Specimens

- Gross trimming was performed using a Dremel 3000 rotary tool (Dremel, Mount Prospect, IL, USA) fitted with a thin abrasive cutting disk to remove flash and excess resin around the perimeter.

- Precision sectioning along the chord and span was performed using the Dremel rotary tool guided by manually delineated cutting lines based on CAD templates.

4. Results

4.1. Tensile and Impact Results

4.1.1. Tensile Testing Results

4.1.2. Impact Testing Results

4.2. Damage Analysis

4.2.1. NDT Results

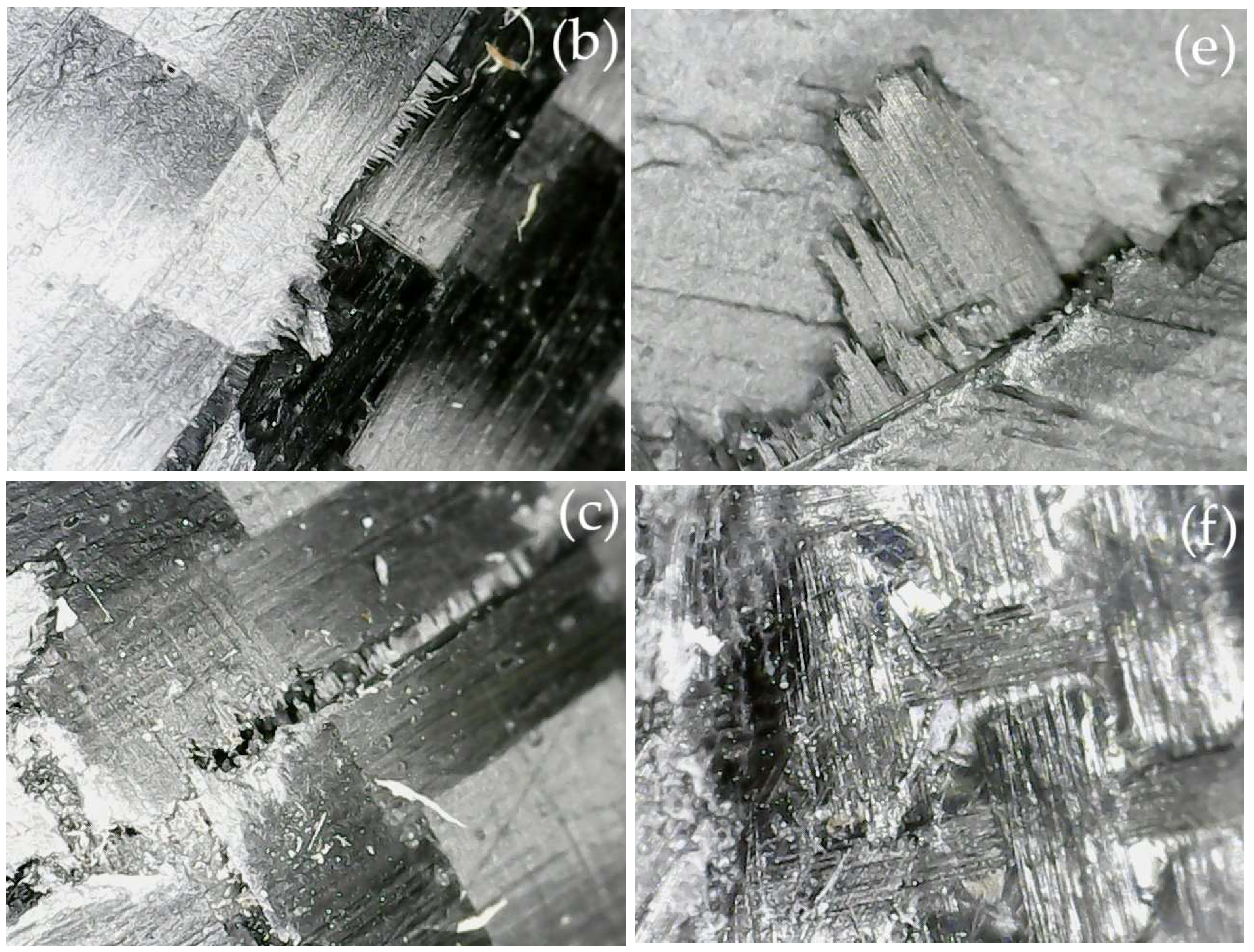

4.2.2. Microscopy Analysis and Damage Patterns

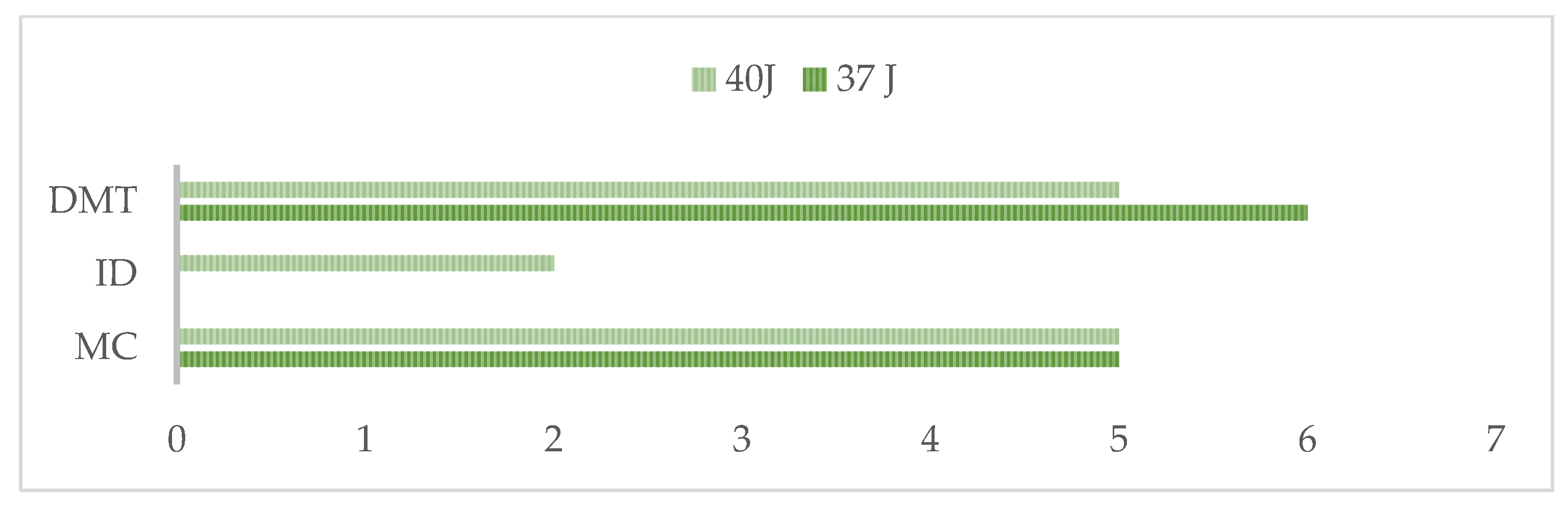

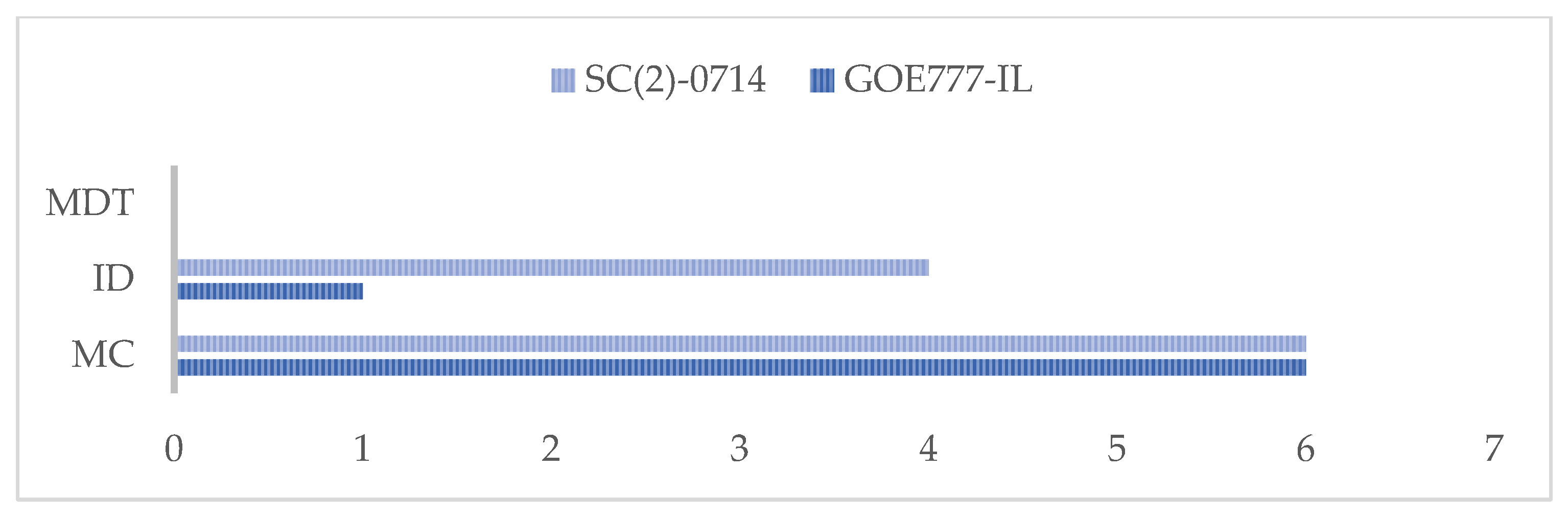

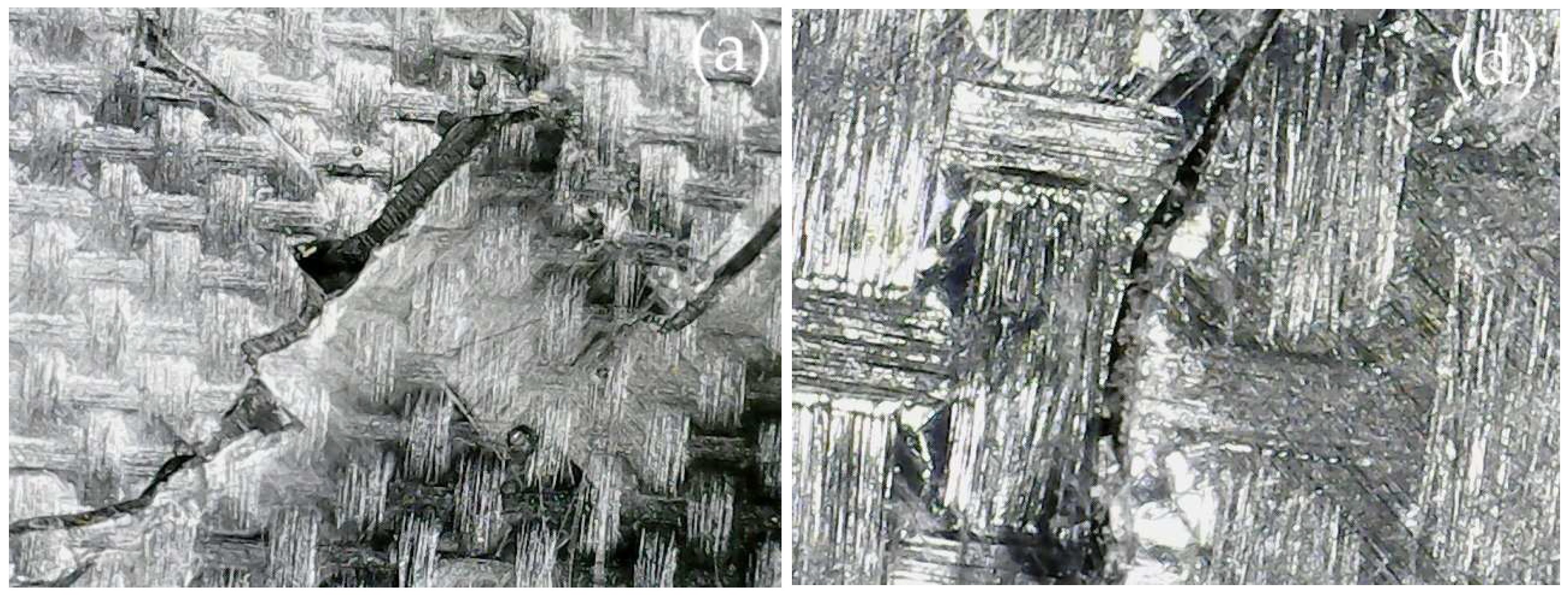

- Matrix Cracking (MC): These cracks appeared in regions subjected to high tensile stresses, primarily near the impact site. Crack propagation was observed perpendicular to fiber orientation, indicating matrix-dominated failure in tensile-loaded areas.

- Interlaminar Delamination (ID): Delaminations were concentrated along the mid-thickness plane, particularly in areas where interlaminar shear stresses were highest. The separation of fiber layers confirmed interlaminar failure, a common damage mechanism in laminated composite structures.

- Debonding and Matrix Tearing (DMT): Microscopy analysis revealed fiber-matrix debonding and matrix cracking, particularly in off-axis plies laminates. These cracks were more pronounced in specimens subjected to higher impact energy (40 J), demonstrating that increased impact loads exacerbate fiber-matrix separation.

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- He, D.; Kim, H.C.; Sommacal, S.; Stojcevski, F.; Soo, V.K.; Lipiński, W.; Morozov, E.; Henderson, L.C.; Compston, P.; Doolan, M. Improving mechanical and life cycle environmental performances of recycled CFRP automotive component by fibre architecture preservation. Compos. Part A Appl. Sci. Manuf. 2023, 175, 107749. [Google Scholar] [CrossRef]

- Guo, R.; Li, C.; Niu, Y.; Xian, G. The fatigue performances of carbon fiber reinforced polymer composites—A review. J. Mater. Res. Technol. 2022, 21, 4773–4789. [Google Scholar] [CrossRef]

- Frhaan, W.K.M.; Abu Bakar, B.H.; Hilal, N.; Al-Hadithi, A.I. CFRP for strengthening and repairing reinforced concrete: A review. Innov. Infrastruct. Solut. 2021, 6, 49. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, L.; Ren, S.; Wang, K.; Li, J. In-situ experimental characterization and numerical investigation of the crack initiation of SMC composite under uniaxial tension. Compos. Part A Appl. Sci. Manuf. 2025, 188, 108543. [Google Scholar] [CrossRef]

- Liu, Z.; Li, P. Effect of fiber orientation of adjacent plies on the mode I delamination fracture of carbon fiber reinforced polymer multidirectional laminates. Polym. Compos. 2025, 46, 2560–2572. [Google Scholar] [CrossRef]

- Duan, L.; Zhang, Y.; Yan, L.; Bao, S.; Liu, H.; Lu, J. Investigation on the crack development behaviour of CFRP strengthened RC beams under static and impact loading. Eng. Fail. Anal. 2025, 171, 109369. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, Y.; Yu, C.; Chen, H.; Chen, Y.; Liu, Y. Mechanical property and fracture characteristics of carbon fiber reinforced aluminum matrix composites prepared by friction stir welding. J. Mater. Res. Technol. 2025, 34, 1080–1089. [Google Scholar] [CrossRef]

- Jiang, L.; He, X.; Zhao, Y.; Li, P.; Zhao, Y.; Wang, Z.; Guo, D.; Gu, Q. Experimental study on the strengthening mechanism of carbon fiber-reinforced sand powder 3D-printed rock-like materials. Case Stud. Constr. Mater. 2025, 22, e04275. [Google Scholar] [CrossRef]

- Li, C.X.; Kalfon-Cohen, E.; Lee, J.; Furtado, C.; Patel, P.; Kopp, R.; Hank, T.J.; Magato, J.; Kinsella, M.; Kessler, S.S.; et al. Interlaminar reinforcement of carbon fiber reinforced polyimide composites using vertically aligned carbon nanotubes. Compos. Part B Eng. 2024, 292, 112098. [Google Scholar] [CrossRef]

- Hou, N.; Guo, Q.; Zaïri, F.; Ding, N. Mode I crack propagation in polydimethylsiloxane-short carbon fiber composites. Compos. Struct. 2025, 352, 118682. [Google Scholar] [CrossRef]

- Sanchez, J.F.R.; Waas, A.M. Experimental results for fatigue damage growth in laminated fiber reinforced cross-ply laminates. Compos. Struct. 2025, 352, 118702. [Google Scholar] [CrossRef]

- Aşkan, A.; Aydın, M. The role of impact energy and silica concentration on dynamic impact and quasi-static puncture resistance of fabrics treated with shear-thickening fluids. Compos. Struct. 2025, 352, 118689. [Google Scholar] [CrossRef]

- Balaga, U.K.; Gargitter, V.; Yarlagadda, S.; Heider, D.; Crane, R.; Tierney, J.; Advani, S.G. Influence of ply thickness on transverse cracking onset, damage progression in thin ply composites and impact on mechanical performance. Compos. Struct. 2025, 354, 118827. [Google Scholar] [CrossRef]

- Feki, I.; Shirinbayan, M.; Nouira, S.; Bi, R.T.; Maeso, J.-B.; Thomas, C.; Fitoussi, J. Multi-scale fatigue damage analysis in filament-wound carbon fiber reinforced epoxy composites for hydrogen storage tanks. Compos. Part C Open Access 2024, 15, 100537. [Google Scholar] [CrossRef]

- Raza, H.; Rodera, O.; Carpenter, K.; Pärnänen, T.; Jokinen, J.; Kanerva, M.; Bayandor, J. Predictive methods for initiation of delamination and intra-laminar damage in carbon fibre reinforced polymer laminates subject to impact. Aeronaut. J. 2024, 128, 846–874. [Google Scholar] [CrossRef]

- Yan, K.; Cao, X.; Xie, X.; Mei, H.; Tang, J.; Sun, X.; Ren, F. Loading rate effect on the shear behavior of the carbon fiber/epoxy interface. Compos. Sci. Technol. 2024, 257, 110785. [Google Scholar] [CrossRef]

- Zhang, Y.; Gui, Z.; Ma, S.; Nan, B.; Xiong, S. Tensile impact behaviors and damage mechanism of woven carbon fiber-reinforced-polymer laminates considering adiabatic shear band. Eng. Fail. Anal. 2024, 158, 107995. [Google Scholar] [CrossRef]

- Dong, T.; Zhao, Z.; Zheng, B.; Chen, C.; Ma, P. Response and damage mechanism of carbon/aramid intra-ply hybrid weft-knitted reinforced composites under low-velocity impact. Thin-Walled Struct. 2023, 196, 111495. [Google Scholar] [CrossRef]

- Abdullah, S.S.; Bokti, S.; Wong, K.; Johar, M.; Chong, W.; Dong, Y. Mode II and mode III delamination of carbon fiber/epoxy composite laminates subjected to a four-point bending mechanism. Compos. Part B Eng. 2024, 270, 111110. [Google Scholar] [CrossRef]

- Sulaiman, B.H.; Abdo, A.R.; Erkliğ, A.; Bozkurt, Ö.Y.; Bulut, M. Effectiveness of multi-walled carbon nanotube on the improvement of tensile, flexural, and low-velocity impact properties of hybrid Kevlar/carbon fiber reinforced epoxy-based composites. Polym. Compos. 2024, 45, 7647–7660. [Google Scholar] [CrossRef]

- Ayyagari, S.; Al-Haik, M. Mitigating Crack Propagation in Hybrid Composites: An Experimental and Computational Study. J. Compos. Sci. 2024, 8, 122. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Z.; Liu, Z.; Ren, Y.; Jiang, H. Hybrid effects and failure mechanisms of carbon/Kevlar fiber composite laminates under the bending-after-impact loading. Eng. Struct. 2024, 299, 117101. [Google Scholar] [CrossRef]

- Ali, H.Q.; Aydin, M.S.; Khan, R.M.A.; Yildiz, M. The role of “thickness effect” on the damage progression and crack growth inside the plain-woven carbon fiber composites. Compos. Sci. Technol. 2023, 241, 110108. [Google Scholar] [CrossRef]

- Li, J.; Yang, L.; Xie, H.; Wei, P.; Li, D.; Xu, Y.; Zhang, F. Research on impact toughness and crack propagation of basalt fiber reinforced concrete under SHPB splitting test. J. Build. Eng. 2023, 77, 107445. [Google Scholar] [CrossRef]

- Deng, Y.; Tu, H.; Hu, Z. In-situ analysis of mode I delamination behaviour of carbon fibre/epoxy composites with chopped aramid/flax fiber reinforcement by X-ray micro-computed tomography. Compos. Part B Eng. 2025, 297, 112247. [Google Scholar] [CrossRef]

- Peng, J.; Cai, D.; Qian, Y.; Liu, C. Low-velocity impact and compression after impact behavior of 3D integrated woven spacer composites. Thin-Walled Struct. 2022, 177, 109450. [Google Scholar] [CrossRef]

- Shi, W.; Guo, Y.; Liu, Y.; Wang, W.; Duan, P.; Bian, H.; Chen, J. Impact of basalt fiber on the fracture properties of recycled aggregate concrete. Constr. Build. Mater. 2024, 418, 135363. [Google Scholar] [CrossRef]

- Lei, Z.; Ma, J.; Sun, W.; Yin, B.; Liew, K. Low-velocity impact and compression-after-impact behaviors of twill woven carbon fiber/glass fiber hybrid composite laminates with flame retardant epoxy resin. Compos. Struct. 2023, 321, 117253. [Google Scholar] [CrossRef]

- Reiner, J.; Fu, Y.-F. Data-driven parameter identification to simulate progressive damage in fiber reinforced laminates under low velocity impact. Int. J. Impact Eng. 2023, 180, 104711. [Google Scholar] [CrossRef]

- Al-Areqi, A.M.; Aloyaydi, B.; Subbarayan, S.; Al-Mufadi, F.A. Low-velocity impact performance of 3D-printed PLA/Epoxy/Glass fibers of composite structures and latches. Mater. Today Commun. 2024, 39, 109264. [Google Scholar] [CrossRef]

- Goraj, Z.J.; Kustron, K. Review of current research trends in bird strike and hail impact simulations on wing leading edge. Aircr. Eng. Aerosp. Technol. 2018, 90, 602–612. [Google Scholar] [CrossRef]

- Civera, M.; Surace, C. Non-Destructive Techniques for the Condition and Structural Health Monitoring of Wind Turbines: A Literature Review of the Last 20 Years. Sensors 2022, 22, 1627. [Google Scholar] [CrossRef]

- Zhang, C.; Rao, Y.; Li, W. Low-velocity impact behavior of intralayer hybrid composites based on carbon and glass non-crimp fabric. Compos. Struct. 2020, 234, 111713. [Google Scholar] [CrossRef]

- ASTM D3039; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D7136; Standard Test Method for Measuring the Damage Resistance of a Fiber-Reinforced Polymer Matrix Composite to a Drop-Weight Impact Event. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM E1417; Standard Practice for Liquid Penetrant Testing. ASTM International: West Conshohocken, PA, USA, 2021.

- Papa, I.; Lopresto, V.; Langella, A. Ultrasonic inspection of composites materials: Application to detect impact damage. Int. J. Light. Mater. Manuf. 2021, 4, 37–42. [Google Scholar] [CrossRef]

- Sacco, C.; Radwan, A.B.; Anderson, A.; Harik, R.; Gregory, E. Machine learning in composites manufacturing: A case study of Automated Fiber Placement inspection. Compos. Struct. 2020, 250, 112514. [Google Scholar] [CrossRef]

- Raspall, F.; Velu, R.; Vaheed, N.M. Fabrication of complex 3D composites by fusing automated fiber placement (AFP) and additive manufacturing (AM) technologies. Adv. Manuf. Polym. Compos. Sci. 2019, 5, 6–16. [Google Scholar] [CrossRef]

- Rajan, S.; Sutton, M.A.; Wehbe, R.; Tatting, B.; Gürdal, Z.; Kidane, A.; Harik, R. Experimental investigation of prepreg slit tape wrinkling during automated fiber placement process using StereoDIC. Compos. Part B Eng. 2019, 160, 546–557. [Google Scholar] [CrossRef]

- Gordon, T.; Xu, X.; Wisnom, M.R.; Kim, B.C. Novel tape termination method for automated fibre placement: Cutting characteristics and delamination suppression. Compos. Part A Appl. Sci. Manuf. 2020, 137, 546–557. [Google Scholar] [CrossRef]

- Oromiehie, E.; Prusty, B.G.; Compston, P.; Rajan, G. Automated fibre placement based composite structures: Review on the defects, impacts and inspections techniques. Compos. Struct. 2019, 224, 110987. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2019, 53, 1579–1669. [Google Scholar] [CrossRef]

- Dhimole, V.K.; Serrao, P.; Cho, C. Review and Suggestion of Failure Theories in Voids Scenario for VARTM Processed Composite Materials. Polymers 2021, 13, 969. [Google Scholar] [CrossRef] [PubMed]

- Ricotta, M.; Quaresimin, M.; Talreja, R. Mode I strain energy release rate in composite laminates in the presence of voids. Compos. Sci. Technol. 2008, 68, 2616–2623. [Google Scholar] [CrossRef]

- Sharma, S.; Chavan, V.M.; Agrawal, R.G.; Patel, R.J.; Kapoor, R.; Chakravartty, J.K. Split-Hopkinson Pressure Bar: An Experimental Technique for High Strain Rate Tests; BARC Technical Report 2011, BARC/2011/E/013:1–47; Bhabha Atomic Research Centre: Mumbai, India, 2011. [Google Scholar]

- Salvi, A.G.; Chung, J.; Waas, A.M.; Caliskan, A. Strain-rate effects on unidirectional carbon-fiber composites. AIAA J. 2003, 41, 2020–2028. [Google Scholar] [CrossRef]

- Zhao, Y.; Huang, W.; Liu, L.; Zhang, J. Effect of strain rate on the mechanical properties and failure mechanisms of epoxy resin. Polym. Test. 2021, 93, 106878. [Google Scholar] [CrossRef]

- Amirkhosravi, M.; Liu, D.; Othman, R.; Vaidya, U.K. Dynamic characterization and strain rate sensitivity of epoxy resins and carbon fiber/epoxy composites. J. Compos. Mater. 2019, 53, 347–361. [Google Scholar]

- Pasquali, M.; Gaudenzi, P. Effects of curvature on high-velocity impact resistance of thin woven fabric composite targets. Compos. Struct. 2017, 160, 349–365. [Google Scholar] [CrossRef]

- Usta, F.; Mullaoglu, F.; Türkmen, H.S.; Balkan, D.; Mecitoglu, Z.; Kurtaran, H.; Akay, E. Effects of thickness and curvature on impact behaviour of composite panels. Procedia Eng. 2016, 167, 216–222. [Google Scholar] [CrossRef]

- Gökçe, T.; Tüfekçi, E. The effect of curvature on the mechanical behavior of CFRP laminates under impact load. Adv. Compos. Mater. 2022, 31, 391–407. [Google Scholar]

- Riccio, A.; Saputo, S.; Sellitto, A.; Di Caprio, F.; Di Palma, L. Effect of constraint conditions and specimen curvature on impact behaviour of composites. Compos. Struct. 2020, 250, 112519. [Google Scholar] [CrossRef]

- Langella, A.; Lopresto, V.; Papa, I.; Leone, M. Experimental and numerical investigation on curved composite panels under compressive preload and impact damage. Compos. Struct. 2019, 229, 111447. [Google Scholar]

- Fernandes, O.; Dutta, J.; Pai, Y. Effect of various factors and hygrothermal ageing environment on the low velocity impact response of fibre reinforced polymer composites—A comprehensive review. Cogent Eng. 2023, 10, 2247228. [Google Scholar] [CrossRef]

- Karasek, M.L. The Effect of Temperature and Moisture on the Impact Response of Polymer Matrix Composites. Ph.D. Thesis, The Pennsylvania State University, University Park, PA, USA, 1992. [Google Scholar]

| Specimen | Width mm [in] | Length mm [in] | Thickness mm [in] |

|---|---|---|---|

| G1 | 101.6 [4] | 152.73 [6.013] | 2.94 [0.116] |

| G2 | 102.08 [4.019] | 152.73 [6.013] | 2.92 [0.115] |

| G3 | 101.95 [4.014] | 152.67 [6.011] | 2.92 [0.115] |

| G4 | 101.82 [4.009] | 152.73 [6.013] | 2.87 [0.113] |

| G5 | 102.13 [4.021] | 152.78 [6.015] | 2.89 [0.114] |

| G6 | 101.93 [4.013] | 152.88 [6.019] | 2.87 [0.113] |

| Mean | 101.90 [4.012] | 152.75 [6.014] | 2.89 [0.114] |

| Standard deviation | 0.17 [0.007] | 0.05 [0.002] | 0.02 [0.001] |

| Specimen | Width mm [in] | Length mm [in] | Thickness mm [in] |

|---|---|---|---|

| D1 | 102.03 [4.017] | 152.52 [6.005] | 3.048 [0.120] |

| D2 | 101.65 [4.002] | 152.83 [6.017] | 3.07 [0.121] |

| D3 | 101.16 [3.983] | 152.65 [6.01] | 3.12 [0.123] |

| D4 | 101.95 [4.014] | 152.65 [6.01] | 3.09 [0.122] |

| D5 | 101.67 [4.003] | 152.57 [6.007] | 3.09 [0.122] |

| D6 | 101.54 [3.998] | 152.01 [5.985] | 3.09 [0.122] |

| Mean | 101.65 [4.002] | 152.52 [6.005] | 3.07 [0.121] |

| Standard deviation | 0.30 [0.012] | 0.254 [0.010] | 0.025 [0.001] |

| Condition | Ultimate Tensile Strength (MPa) | Elastic Modulus (GPa) | Strain-to-Failure (%) |

|---|---|---|---|

| Non-Impacted | 920.4 ± 15.3 | 56.2 ± 2.1 | 1.83 ± 0.05 |

| Impacted (37 J) | 745.8 ± 20.1 | 52.6 ± 3.4 | 1.57 ± 0.07 |

| Impacted (40 J) | 690.2 ± 18.7 | 50.9 ± 2.9 | 1.42 ± 0.06 |

| Impact Energy (J) | Maximum Force (kN) | Absorbed Energy (J) | Damage Area (mm2) |

|---|---|---|---|

| 37 | 4.75 ± 0.12 | 22.5 ± 1.3 | 8.28 ± 0.33 |

| 40 | 5.02 ± 0.15 | 25.1 ± 1.5 | 8.42 ± 0.33 |

| Airfoil Profile | Impact Energy (J) | Maximum Force (kN) | Absorbed Energy (J) | Damage Area (mm2) |

|---|---|---|---|---|

| SC(2)-0714 | 40 | 3.2 ± 0.15 | 36.8 ± 1.5 | 100 ± 53 |

| GOE777-IL | 40 | 3.5 ± 0.17 | 38.5 ± 1.4 | 60 ± 48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jauregui Bogarin, I.; Angel, V.G.; Hernández, M.S.; Durazo Romero, E.S.; Magaña-Almaguer, H.D.; Vargas Osuna, L.E.; González Vizcarra, B. Experimental Analysis of Low-Energy Impact Damage in Composite Material Airfoils. Fibers 2025, 13, 67. https://doi.org/10.3390/fib13050067

Jauregui Bogarin I, Angel VG, Hernández MS, Durazo Romero ES, Magaña-Almaguer HD, Vargas Osuna LE, González Vizcarra B. Experimental Analysis of Low-Energy Impact Damage in Composite Material Airfoils. Fibers. 2025; 13(5):67. https://doi.org/10.3390/fib13050067

Chicago/Turabian StyleJauregui Bogarin, Ilse, Virginia G. Angel, Miriam Siqueiros Hernández, Emmanuel Santiago Durazo Romero, Hernán D. Magaña-Almaguer, Lidia Esther Vargas Osuna, and Benjamín González Vizcarra. 2025. "Experimental Analysis of Low-Energy Impact Damage in Composite Material Airfoils" Fibers 13, no. 5: 67. https://doi.org/10.3390/fib13050067

APA StyleJauregui Bogarin, I., Angel, V. G., Hernández, M. S., Durazo Romero, E. S., Magaña-Almaguer, H. D., Vargas Osuna, L. E., & González Vizcarra, B. (2025). Experimental Analysis of Low-Energy Impact Damage in Composite Material Airfoils. Fibers, 13(5), 67. https://doi.org/10.3390/fib13050067