A Study on the Effect of an Oxidizing Atmosphere During the Recycling of CFRP by Pyrolysis

Abstract

1. Introduction

2. Experimental Method

2.1. Materials

2.2. Methodology

2.2.1. Reclamation Procedure

2.2.2. r-CF Plate Manufacturing Using VARI

2.2.3. Characterization

3. Results and Discussion

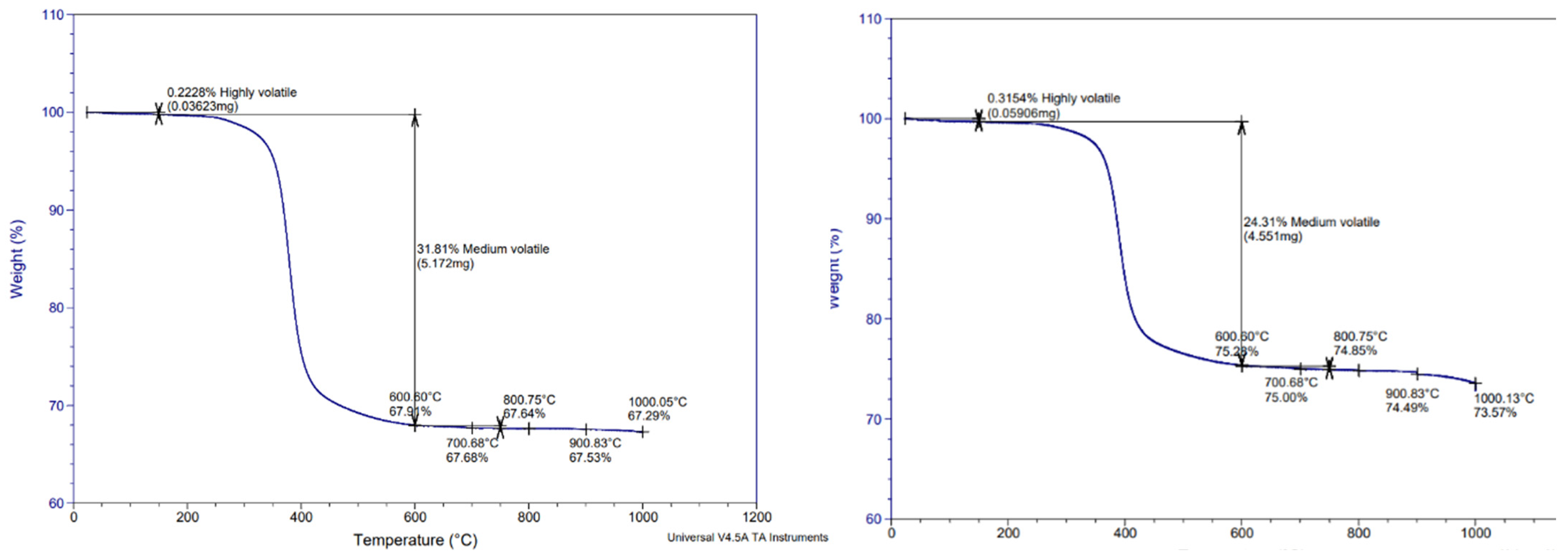

3.1. Initial Characterization of CFRP Samples: Experimental Fiber Content by Weight Percentage Using TGA and Chemical Digestion

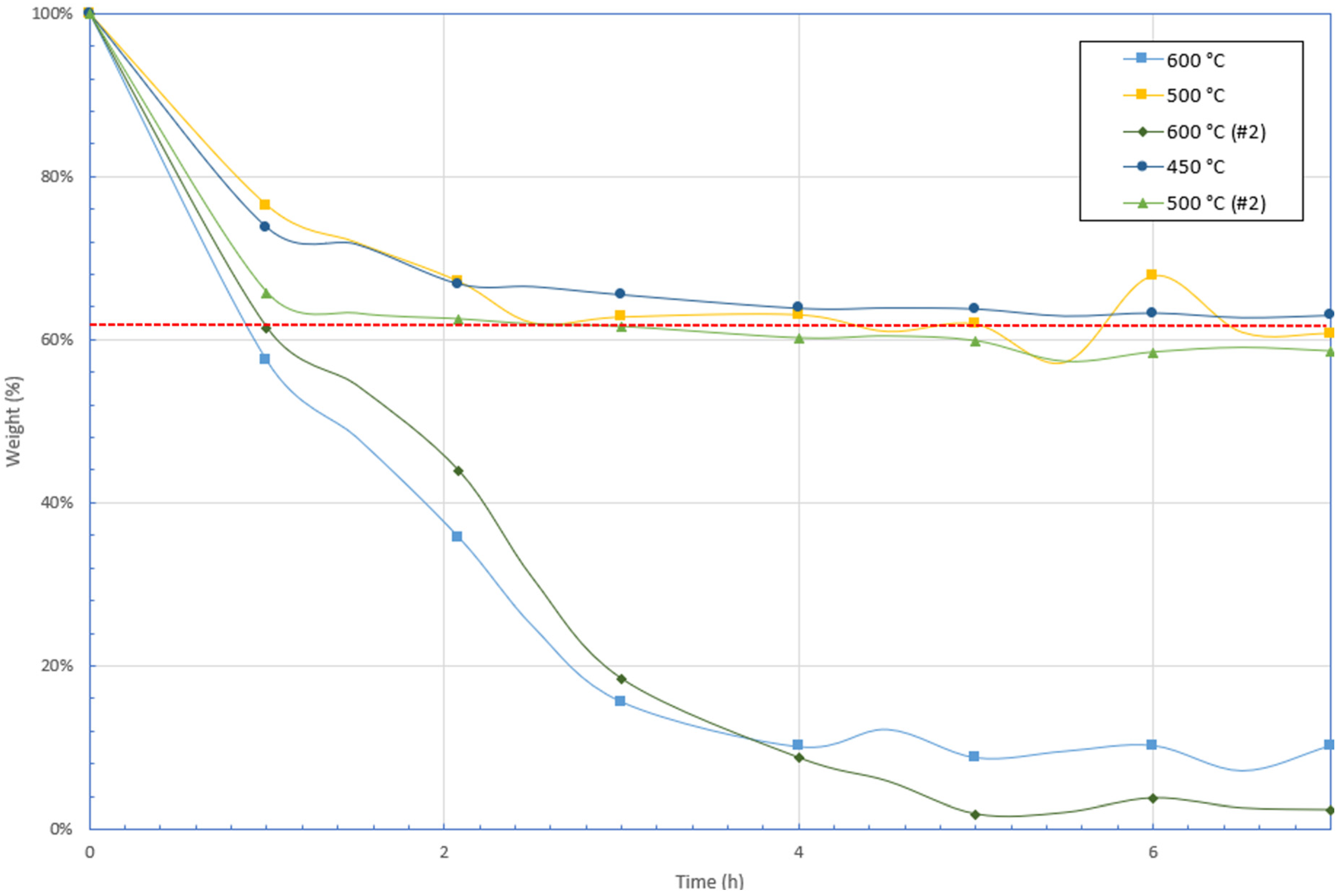

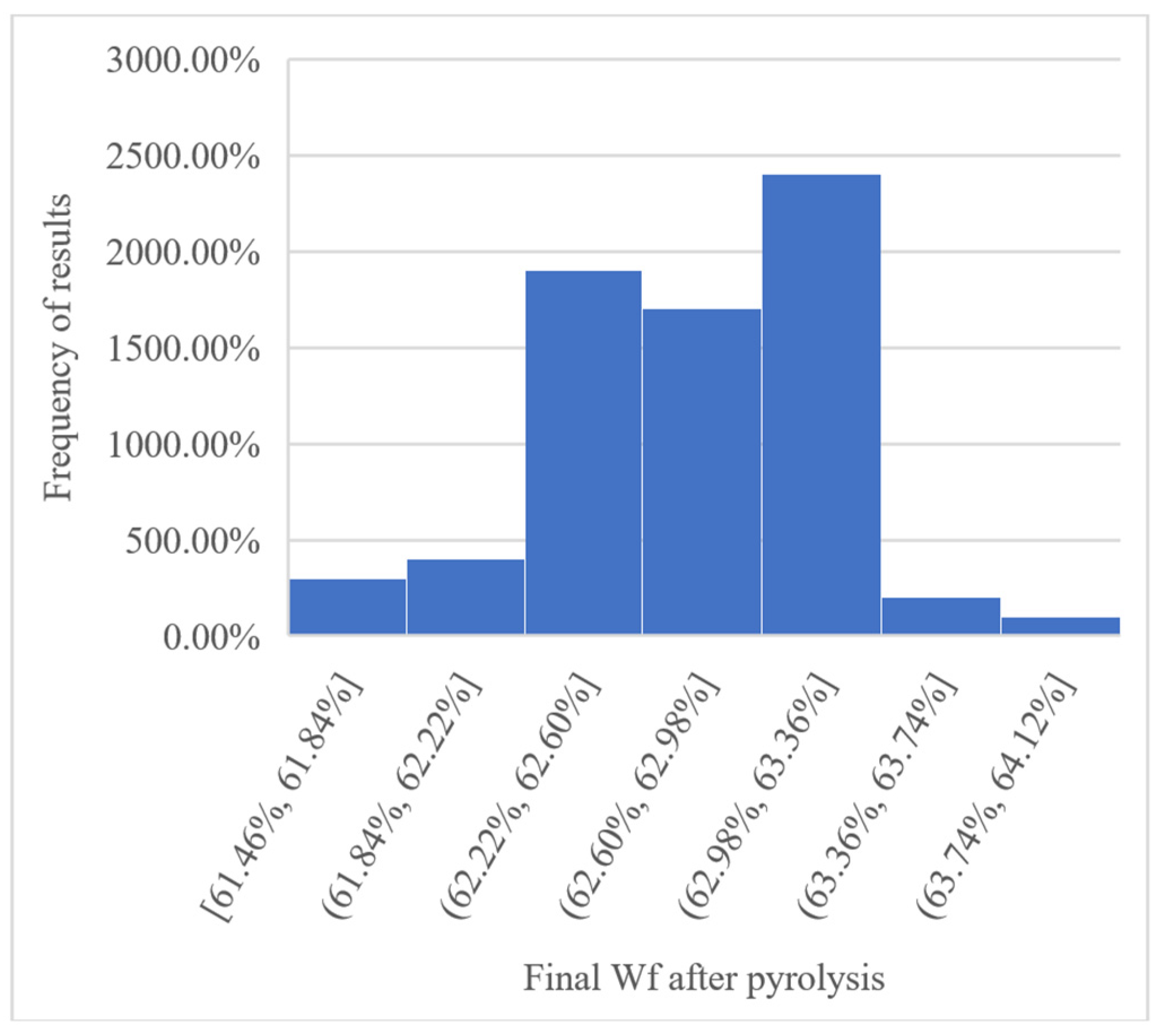

3.2. Pyrolysis of CFRP Sample Under Ambient Air

3.3. Properties of Recycled Fibers

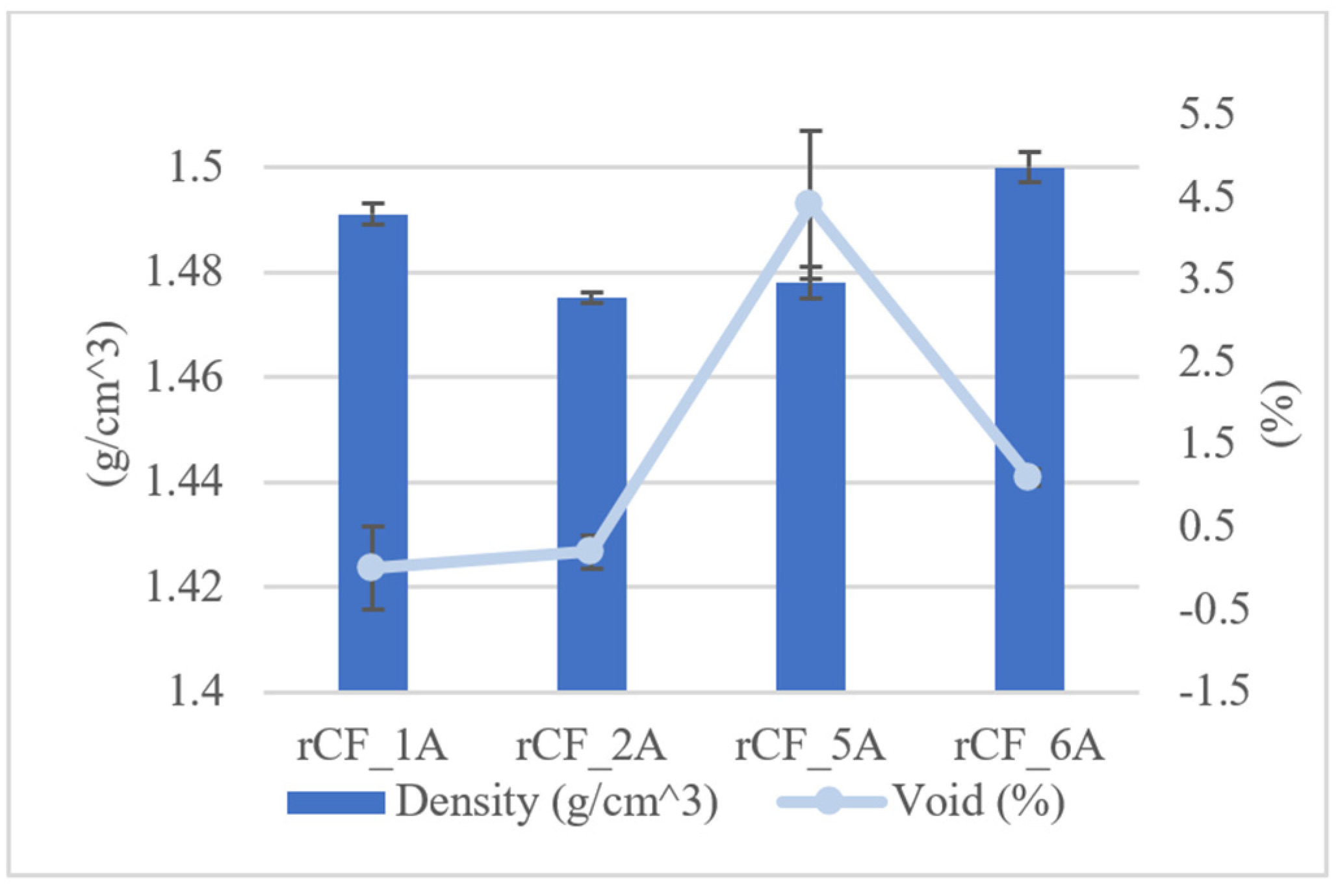

3.3.1. Density per ASTM D792 Procedure B and Void Content per ASTM D3171 B

3.3.2. Glass Transition Temperature per ASTM D7028

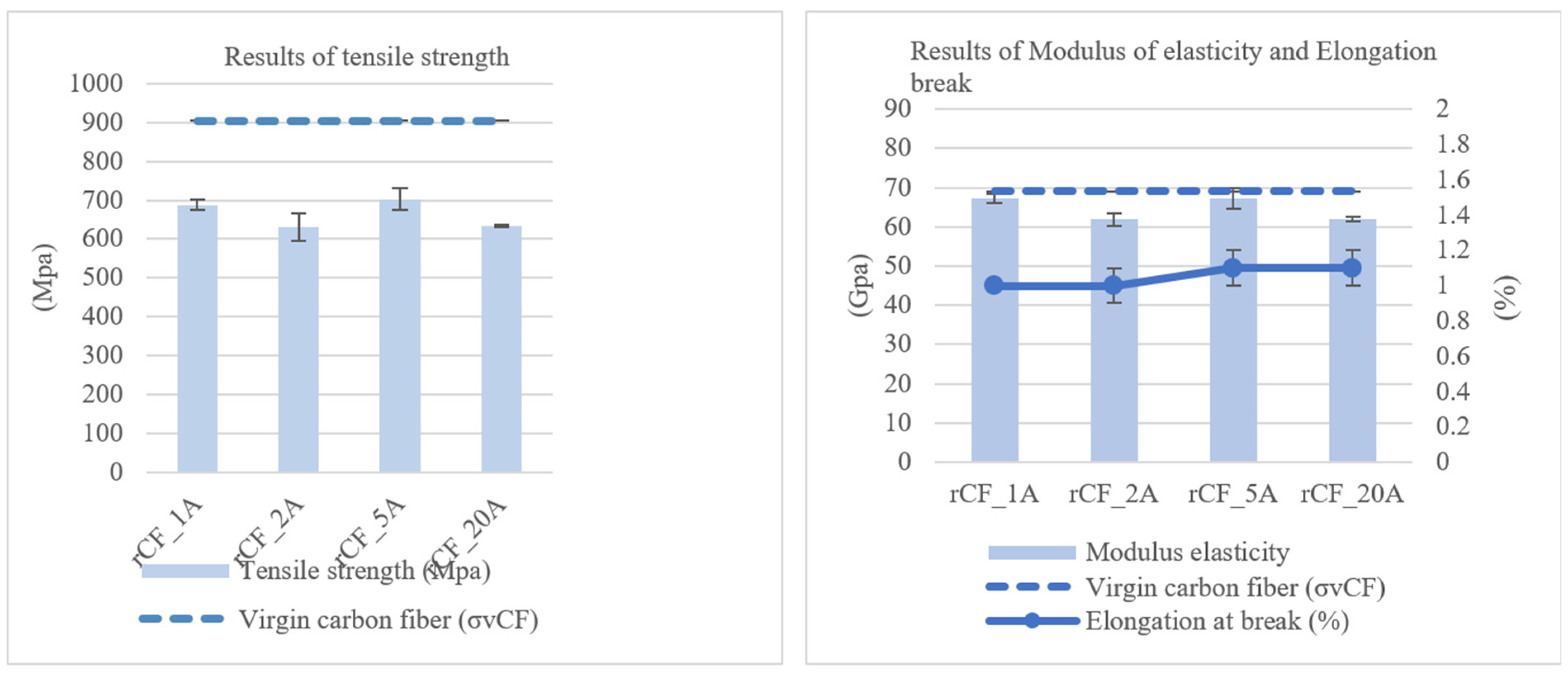

3.3.3. Mechanical Properties of rCF Composite Plates

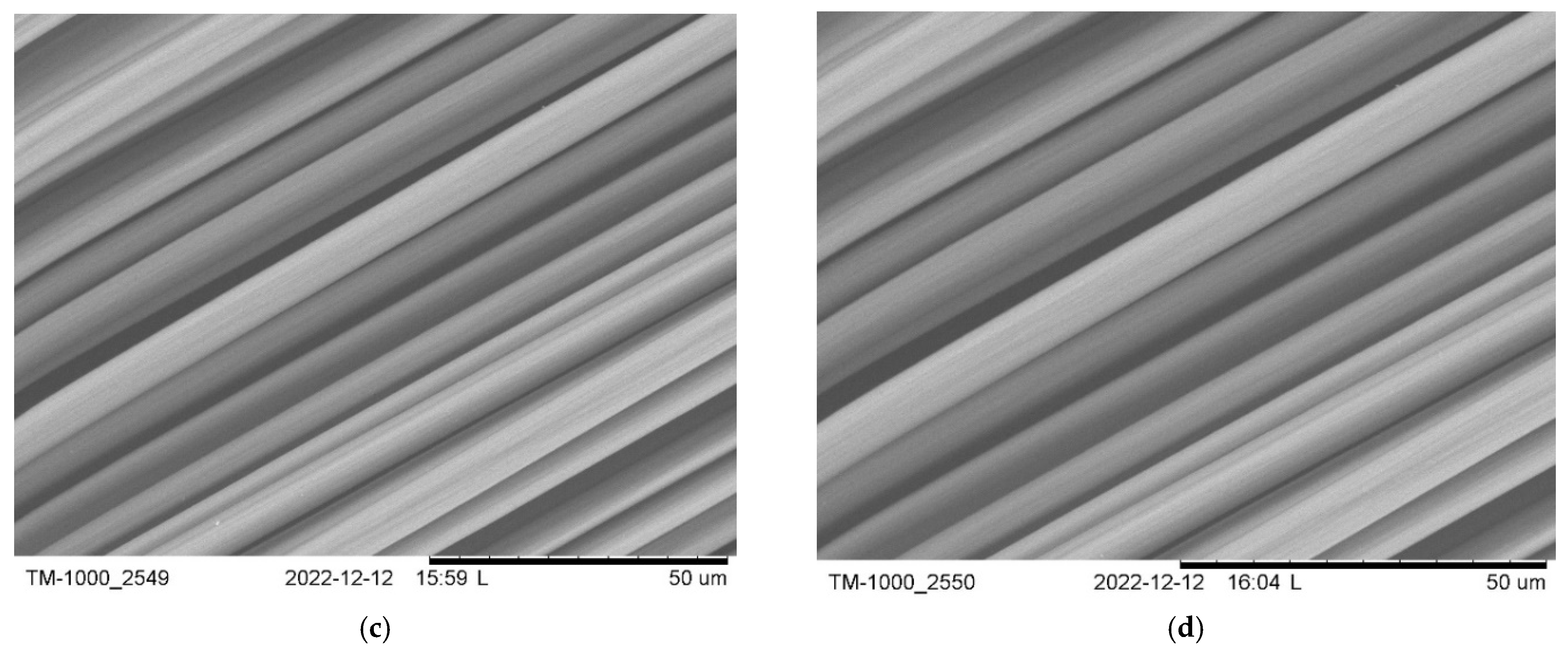

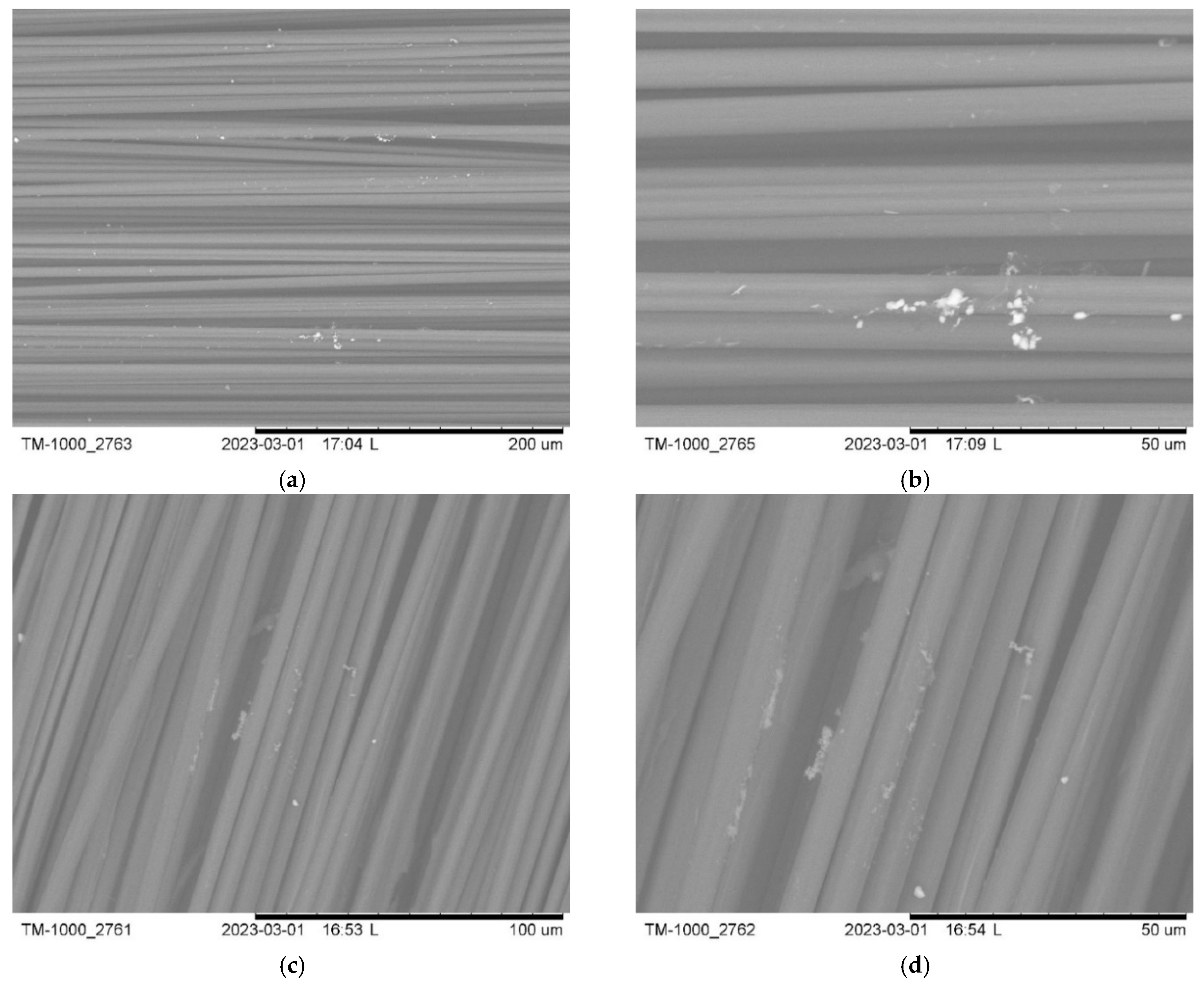

3.4. Morphology of Recycled Carbon Fibers

3.5. Summary of rCFRP Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. A review on recycling and reuse methods for carbon fiber/glass fiber composites waste from wind turbine blades. Compos. B Eng. 2021, 215, 108768. [Google Scholar] [CrossRef]

- He, Y.; Yang, S.; Liu, H.; Shao, Q.; Chen, Q.; Lu, C.; Jiang, Y.; Liu, C.; Guo, Z. Reinforced carbon fiber laminates with oriented carbon nanotube epoxy nanocomposites: Magnetic field assisted alignment and cryogenic temperature mechanical properties. J. Colloid. Interface Sci. 2018, 517, 40–51. [Google Scholar] [CrossRef]

- Xing, M.; Li, Z.; Zheng, G.; Du, Y.; Chen, C.; Wang, Y. Recycling of carbon fiber-reinforced epoxy resin composite via a novel acetic acid swelling technology. Compos. B Eng. 2021, 224, 109230. [Google Scholar] [CrossRef]

- Utekar, V.K.S.; More, S.N.; Rao, A. Comprehensive study of recycling of thermosetting polymer composites—Driving force, challenges and methods. Compos. B Eng. 2021, 207, 108596. [Google Scholar] [CrossRef]

- Anguita, J.V.; Smith, C.T.G.; Stute, T.; Funke, M.; Delkowski, M.; Silva, S.R.P. Dimensionally and environmentally ultra-stable polymer composites reinforced with carbon fibres. Nat. Mater. 2020, 19, 317–322. [Google Scholar] [CrossRef] [PubMed]

- Pramanik, A.; Basak, A.K.; Dong, Y.; Sarker, P.K.; Uddin, M.S.; Littlefair, G.; Dixit, A.; Chattopadhyaya, S. Joining of carbon fibre reinforced polymer (CFRP) composites and aluminium alloys—A review. Compos. Part A Appl. Sci. Manuf. 2017, 101, 1–29. [Google Scholar] [CrossRef]

- Knappich, F.; Klotz, M.; Schlummer, M.; Wolling, J.; Maurer, A. Recycling process for carbon fiber reinforced plastics with polyamide 6, polyurethane and epoxy matrix by gentle solvent treatment. Waste Manag. 2019, 85, 73–81. [Google Scholar] [CrossRef] [PubMed]

- Vieira, D.R.; Vieira, R.K.; Chain, M.C. Strategy and management for the recycling of carbon fiber-reinforced polymers (CFRPs) in the aircraft industry: A critical review. Int. J. Sustain. Dev. World Ecol. 2016, 24, 214–223. [Google Scholar] [CrossRef]

- Spini, F.; Bettini, P. End-of-Life wind turbine blades: Review on recycling strategies. Compos. B Eng. 2024, 275, 111290. [Google Scholar] [CrossRef]

- Zhao, Q.; Jiang, J.; Li, C.; Li, Y. Efficient recycling of carbon fibers from amine-cured CFRP composites under facile condition. Polym. Degrad. Stab. 2020, 179, 109268. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, G.; Vaidya, U.; Wang, H. Past, present and future prospective of global carbon fibre composite developments and applications. Compos. B Eng. 2023, 250, 110463. [Google Scholar] [CrossRef]

- Wu, J.; Gao, X.; Wu, Y.; Wang, Y.; Nguyen, T.; Guo, M. Recycling Carbon Fiber from Carbon Fiber-Reinforced Polymer and Its Reuse in Photocatalysis: A Review. Polymers 2023, 15, 170. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Cui, X.; Ge, H.; Yang, Y.; Wang, Y.; Zhang, C.; Li, J.; Deng, T.; Qin, Z.; Hou, X. Chemical recycling of carbon fiber reinforced epoxy resin composites via selective cleavage of the carbon–nitrogen bond. ACS Sustain. Chem. Eng. 2015, 3, 3332–3337. [Google Scholar] [CrossRef]

- Pietroluongo, M.; Padovano, E.; Frache, A.; Badini, C. Mechanical recycling of an end-of-life automotive composite component. Sustain. Mater. Technol. 2020, 23, e00143. [Google Scholar] [CrossRef]

- Vincent, G.A.; de Bruijn, T.A.; Wijskamp, S.; Rasheed, M.I.A.; Van Drongelen, V.; Akkerman, R. Shredding and sieving thermoplastic composite scrap: Method development and analyses of the fibre length distributions. Compos. B Eng. 2019, 176, 107197. [Google Scholar] [CrossRef]

- Mazzocchetti, L.; Benelli, T.; D’Angelo, E.; Leonardi, C.; Zattini, G.; Giorgini, L. Validation of carbon fibers recycling by pyro-gasification: The influence of oxidation conditions to obtain clean fibers and promote fiber/matrix adhesion in epoxy composites. Compos. Part A Appl. Sci. Manuf. 2018, 112, 504–514. [Google Scholar] [CrossRef]

- Kim, K.W.; Lee, H.M.; Jan, J.H.; Chung, D.C.; An, K.H.; Kim, B.J. Recycling and characterization of carbon fibers from carbon fiber reinforced epoxy matrix composites by a novel super-heated-steam method. J. Environ. Manag. 2017, 203, 872–879. [Google Scholar] [CrossRef]

- Kim, D.H.; Lee, M.; Goh, M. Enhanced and eco-friendly recycling of carbon-fiber-reinforced plastics using water at ambient pressure. ACS Sustain. Chem. Eng. 2020, 8, 2433–2440. [Google Scholar] [CrossRef]

- He, D.; Soo, V.K.; Kim, H.C.; Compston, P.; Doolan, M. Comparative life cycle energy analysis of carbon fibre pre-processing, processing and post-processing recycling methods. Resour. Conserv. Recycl. 2020, 158, 104794. [Google Scholar] [CrossRef]

- Stróżyk, M.A.; Muddasar, M.; Conroy, T.J.; Hermansson, F.; Janssen, M.; Svantrom, M.; Frank, E.; Culebras, M.; Collins, M.N. Decreasing the environmental impact of carbon fibre production via microwave carbonisation enabled by self-assembled nanostructured coatings. Adv. Compos. Hybrid. Mater. 2024, 7, 39. [Google Scholar] [CrossRef]

- Mainka, H.; Tager, O.; Korner, E.; Hilfert, L.; Busse, S.; Edelmann, F.T.; Herrmann, A.S. Lignin—An alternative precursor for sustainable and cost-effective automotive carbon fiber. J. Mark. Res. 2015, 4, 283–296. [Google Scholar] [CrossRef]

- Zhang, J.; Chevali, V.; Wang, H.; Wang, C. Current status of carbon fibre and carbon fibre composites recycling. Compos. B Eng. 2020, 193, 108053. [Google Scholar] [CrossRef]

- Meyer, L.O.; Schulte, K.; Grove-Nielsen, E. CFRP-Recycling Following a Pyrolysis Route: Process Optimization and Potentials. J. Compos. Mater. 2009, 43, 1121–1132. [Google Scholar] [CrossRef]

- Colucci, G.; Ostrovskaya, O.; Frache, A.; Martorana, B.; Badini, C. The effect of mechanical recycling on the microstructure and properties of PA66 composites reinforced with carbon fibers. J. Appl. Polym. Sci. 2015, 132, 42275. [Google Scholar] [CrossRef]

- Abdou, T.R.; Junior, A.B.; Espinosa, D.; Tenório, J. Recycling of polymeric composites from industrial waste by pyrolysis: Deep evaluation for carbon fibers reuse. Waste Manag. 2021, 120, 1–9. [Google Scholar] [CrossRef]

- Naqvi, S.R.; Mysore Prabhakara, H.; Bramer, E.A.; Dierkes, W.; Akkerman, R.; Brem, G. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef]

- Meng, F.; Olivetti, E.A.; Zhao, Y.; Chang, J.C.; Pickering Stephen, J.; Mckechnie, J. Comparing Life Cycle Energy and Global Warming Potential of Carbon Fiber Composite Recycling Technologies and Waste Management Options. ACS Sustain. Chem. Eng. 2018, 6, 9854–9865. [Google Scholar] [CrossRef]

- Dong, P.A.V.; Azzaro-Pantel, C.; Cadene, A.-L. Economic and environmental assessment of recovery and disposal pathways for CFRP waste management. Resour. Conserv. Recycl. 2018, 133, 63–75. [Google Scholar] [CrossRef]

- Hadigheh, S.A.; Wei, Y.; Kashi, S. Optimisation of CFRP composite recycling process based on energy consumption, kinetic behaviour and thermal degradation mechanism of recycled carbon fibre. J. Clean. Prod. 2021, 292, 125994. [Google Scholar] [CrossRef]

- Chen, P.-Y.; Feng, R.; Xu, Y.; Zhu, J.-H. Recycling and Reutilization of Waste Carbon Fiber Reinforced Plastics: Current Status and Prospects. Polymers 2023, 15, 3508. [Google Scholar] [CrossRef]

- Kim, H.-H.; Kim, B.-J. Recovery of carbon fibers from carbon fiber-reinforced epoxy-isophorone diamine composites via step thermolysis. Compos. B Eng. 2023, 260, 110757. [Google Scholar] [CrossRef]

- Bard, S.; Demleitner, M.; Weber, R.; Zeiler, R.; Altstadt, V. Effect of curing agent on the compressive behavior at elevated test temperature of carbon fiber-reinforced epoxy composites. Polymers 2019, 11, 943. [Google Scholar] [CrossRef] [PubMed]

- Behniafar, H.; Nazemi, M.K. Effect of amine-functionalized silica nanoparticles on thermal and mechanical behaviors of DGEBA/IPD epoxy networks. Polym. Bull. 2017, 74, 3739–3749. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, D. Vacuum assisted resin transfer Moulding process review and variability analysis using Taguchi optimization technique. Mater. Today Proc. 2022, 50, 1472–1479. [Google Scholar] [CrossRef]

- Kuentzer, N.; Simacek, P.; Advani, S.G.; Walsh, S. Correlation of void distribution to VARTM manufacturing techniques. Compos. Part A Appl. Sci. Manuf. 2007, 38, 802–813. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, B.-M.; Wang, D.-F.; Wu, Z.-J. Effects of cure cycles on void content and mechanical properties of composite laminates. Compos. Struct. 2006, 73, 303–309. [Google Scholar] [CrossRef]

- Hernández, S.; Sket, F.; Molina-Aldareguı’a, J.M.; González, C.; Llorca, J. Effect of curing cycle on void distribution and interlaminar shear strength in polymermatrix composites. Compos. Sci. Technol. 2011, 71, 1331–1341. [Google Scholar] [CrossRef]

- Hao, W.; Huang, Z.; Xu, Y.; Zhao, G.; Chen, H.; Fang, D. Acoustic emission characterization of tensile damage in 3D braiding composite shafts. Polym. Test. 2020, 81, 106176. [Google Scholar] [CrossRef]

- Agius, S.L.; Magniez, K.J.V.; Fox, B.L. Cure behaviour and void development within rapidly cured out-of-autoclave composites. Compos. Part B Eng. 2013, 47, 230–237. [Google Scholar] [CrossRef]

- Saenz-Castillo, D.; Martín, M.I.; Calvo, S.; Rodriguez-Lence, F.; Güemes, A. Effect of processing parameters and void content on mechanical properties and NDI of thermoplastic composites. Compos. Part A Appl. Sci. Manuf. 2019, 121, 308–320. [Google Scholar] [CrossRef]

- Agius, S.L.; Fox, B.L. Rapidly cured out-of-autoclave laminates: Understanding and controlling the effect of voids on laminate fracture toughness. Compos. Part A Appl. Sci. Manuf. 2015, 73, 186–194. [Google Scholar] [CrossRef]

- Swarup, S. A comparative study of bisphenol-A, hydantoin and cyanuric acid based epoxy resins using XRD. Mater. Sci. Appl. 2011, 2, 1516–1519. [Google Scholar] [CrossRef][Green Version]

- Bennett, S.C.; Johnson, D.J.; Johnson, W. Strength-structure relationships in PAN-based carbon fibres. J. Mater. Sci. 1983, 18, 3337–3347. [Google Scholar] [CrossRef]

- Sui, X.; Xu, Z.; Hu, C.; Chen, L.; Liu, L.; Kuang, L. Microstructure evolution in γ-irradiated carbon fibers revealed by a hierarchical model and Raman spectra from fiber section. Compos. Sci. Technol. 2016, 130, 46–52. [Google Scholar] [CrossRef]

- Zhou, G.; Byun, J.H.; Lee, S.B.; Yi, J.W.; Lee, W.; Lee, S.K. Nano structural analysis on stiffening phenomena of PAN-based carbon fibers during tensile deformation. Carbon N. Y. 2014, 76, 232–239. [Google Scholar] [CrossRef]

- Liu, X.; Zhu, C.; Guo, J.; Liu, Q.; Dong, H.; Gu, Y. Nanoscale dynamic mechanical imaging of the skin-core difference: From PAN precursors to carbon fibers. Mater. Lett. 2014, 128, 417–420. [Google Scholar] [CrossRef]

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing, and Design, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2007; 638p. [Google Scholar]

| Plate ID | Number of Plies | Average Thickness (mm) | ASTM D792 | ASTM D3171 | ASTM D7028 | ASTM D3039 | ASTM D6641 | ASTM D5379 | ASTM D2344 | ASTM D790 |

|---|---|---|---|---|---|---|---|---|---|---|

| rCF_1A | 8 | 2.99 | X | X | X | X | X | |||

| rCF_2A * | 8 | 3.14 | X | X | X | X | X | |||

| rCF_5A | 4 | 1.41 | X | X | X | X | X | |||

| rCF_6A | 4 | 1.41 | X | X | ||||||

| rCF_20A | 4 | 1.48 | X | |||||||

| rCF_21A | 4 | 4.12 | X | |||||||

| rCF_27A | 8 | 3.74 | X |

| ID | Average Value of rCFRP (Mpa) | Average Value of rCFRP (ksi) | Average Value of vCF (ksi) | Average Value of vCF (Mpa) | Recovery Rate in % |

|---|---|---|---|---|---|

| Tensile strength | 663.23 | 96.19 | 131.3 | 905.28 | 73.26% |

| Tensile modulus | 64.56 × 103 | 9.36 × 103 | 10.02 × 103 | 69.09 × 103 | 93.45% |

| Compressive strength | 378.00 | 54.82 | 108.8 | 750.15 | 50.39% |

| Compressive modulus | 45.40 × 103 | 6.58 × 103 | 9.18 × 103 | 63.29 × 103 | 71.73% |

| Shear strength | 45.00 | 6.53 | 8.29 | 57.16 | 78.73% |

| Shear modulus | 2.58 × 103 | 0.37 × 103 | 0.81 × 103 | 5.58 × 103 | 46.20% |

| Short beam strength | 34.40 | 4.99 | 11.93 | 82.25 | 41.82% |

| Material | SAE 1010 Steel | 6061-T6 Aluminum Alloy | CFRP (Quasi-Isotropic) | Sheet Molding Compound (Isotropic) | rCFRP |

|---|---|---|---|---|---|

| Tensile strength (MPa) | 365 * | 310 * | 579 * | 164 * | 663 |

| Material | SAE 1010 Steel | 6061-T6 Aluminum Alloy | CFRP (Quasi-Isotropic) | SMC Composite (Isotropic) | rCFRP |

|---|---|---|---|---|---|

| Tensile strength-to-weight ratio (103 m) | 4.72 * | 11.7 * | 38 * | 8.9 * | 42.4 |

| Material | 6061-T6 Aluminum Alloy | E-Glass Fiber-Epoxy Matrix (UD) | CFRP (Quasi-Isotropic) | SMC Composite (Isotropic) | rCFRP |

|---|---|---|---|---|---|

| Modulus (GPa) | 68.9 * | 39.3 * | 45.5 * | 15.8 * | 64.55 |

| Properties | Unit | Value |

|---|---|---|

| Density | g/cm3 | 1.486 |

| Void content | % | 1.55 |

| Glass transition temperature | °C | 59.6 |

| Tensile strength | MPa | 663.23 |

| Tensile modulus | GPa | 64.56 |

| Tensile elongation at break | % | 1.06 |

| Compressive strength | MPa | 378 |

| Compressive modulus | GPa | 45.4 |

| Flexural strength | MPa | 692.9 |

| Flexural modulus | GPa | 38.26 |

| Maximum flexural deformation | % | 1.6 |

| Shear strength | MPa | 45 |

| Maximum shear deformation | % | 5 |

| Shear modulus | MPa | 2580 |

| Short-beam strength | MPa | 34.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dega, C.; Jadidinia, A.; Boukhili, R. A Study on the Effect of an Oxidizing Atmosphere During the Recycling of CFRP by Pyrolysis. Fibers 2025, 13, 58. https://doi.org/10.3390/fib13050058

Dega C, Jadidinia A, Boukhili R. A Study on the Effect of an Oxidizing Atmosphere During the Recycling of CFRP by Pyrolysis. Fibers. 2025; 13(5):58. https://doi.org/10.3390/fib13050058

Chicago/Turabian StyleDega, Cynthie, Ali Jadidinia, and Rachid Boukhili. 2025. "A Study on the Effect of an Oxidizing Atmosphere During the Recycling of CFRP by Pyrolysis" Fibers 13, no. 5: 58. https://doi.org/10.3390/fib13050058

APA StyleDega, C., Jadidinia, A., & Boukhili, R. (2025). A Study on the Effect of an Oxidizing Atmosphere During the Recycling of CFRP by Pyrolysis. Fibers, 13(5), 58. https://doi.org/10.3390/fib13050058