1. Introduction

With the rapid development of economic construction, the environments in which various engineering projects are situated have become increasingly complex, and the demand for diverse properties of concrete has been escalating. Particularly for projects in frigid regions—whose definition varies by region but is uniformly tied to cold-induced durability challenges—there are stringent requirements for concrete’s resistance to freeze–thaw (F-T) cycle-induced damage. Specifically, European studies characterize frigid regions based on the combined indicators of average annual air temperature and frost index (FI) [

1]. In contrast, Chinese research defines frigid regions using the annual average number of F-T cycles, with typical values of 84 cycles/year in North China, 120 cycles/year in Northeast China, and 118 cycles/year in Northwest China—all reflecting environments where F-T damage poses a critical threat to concrete structures [

2]. How to enhance the mechanical properties of concrete under F-T cycles is thus a topic worthy of urgent investigation. Scholars worldwide have conducted extensive research on improving the frost resistance of concrete and found that the incorporation of fibers can effectively enhance such resistance [

3]. Studies have demonstrated that various fibers, including basalt fiber, steel fiber, polypropylene fiber, carbon fiber, and glass fiber, exhibit favorable effects in enhancing concrete’s frost resistance [

4,

5,

6,

7,

8,

9,

10], though their mechanisms of action differ. Among various fibers, BF is a new type of environmentally friendly inorganic fiber derived from basalt. Owing to its environmental benignity, excellent comprehensive performance, and relatively reasonable cost [

11], it has emerged as a high-performance inorganic fiber with substantial development potential for engineering applications. Notably, recent studies on fiber-reinforced concrete (FRC) durability in harsh environments have confirmed that the interfacial bonding between fibers and the concrete matrix is a core factor affecting long-term performance—especially under multi-factor coupling conditions (e.g., freeze–thaw cycles, chemical erosion) [

12]. Specifically, this study systematically analyzed the correlation between fiber surface properties, incorporation methods, and FRC’s environmental adaptability, pointing out that inorganic fibers exhibit better interfacial stability than organic fibers in freeze–thaw environments due to their low water absorption and high compatibility with cement hydration products. This conclusion further supports the rationality of selecting BF as the additive to improve concrete frost resistance in this study.

Huang et al. [

13] investigated the effect of BF with varying lengths (3 mm, 6 mm, 9 mm, 12 mm) on concrete properties at a fixed dosage. The results indicated that the incorporation of BF can effectively enhance concrete’s mechanical properties and frost resistance, with 6 mm-long BF exhibiting the most significant enhancement effect. Shao et al. [

14] examined the reliability of engineering applications of BF fly ash concrete and found that BF incorporation refines pores, reduces the maximum pore size and porosity; the fiber bridging effect inhibits the development of radial pore cracks; fly ash improves the pore structure via delayed hydration and micro-filling. Guo et al. [

15] explored the effect and mechanism of BF on concrete frost resistance under three curing conditions: standard, short-term, and seawater curing. The results demonstrated that 0.15% BF can increase the residual compressive strength of concrete after F-T cycles by 5.4%, 28.1%, and 30.9%, respectively, compared to ordinary concrete. Ma et al. [

16] investigated the enhancement effect of BF on concrete frost resistance. The results indicated that adding an appropriate amount of BF can significantly enhance concrete frost resistance and mitigate F-T damage: after 150 F-T cycles, the relative dynamic elastic modulus (RDEM, a key indicator reflecting the integrity of concrete’s internal structure, A detailed description of RDEM can be found in

Section 2.2) can be maintained at 98% with a 0.1% dosage, while the mass loss rate can be controlled at 0.87% with a 0.3% dosage. Considering both frost resistance efficacy and economic factors, it is recommended that the BF dosage in frost-resistant concrete be 0.1%. Yuan et al. [

17] investigated the effect of fly ash and BF on the frost resistance of recycled permeable concrete. The results demonstrated that fly ash can reduce cement dosage and improve the mechanical properties and frost resistance of recycled permeable concrete. At the same time, BF can enhance its integrity after F-T cycles.

BF can not only improve the frost resistance of concrete, but also optimize its internal structure, thereby enhancing the mechanical properties and toughness of concrete. Qin et al. [

18] found that there exists an optimal dosage and length of BF for improving the mechanical properties of concrete. When the dosage of BF is 2 kg/m

3, and the length is 24 mm, the mechanical properties of BFRC reach their best. Compared with the reference concrete, its compressive strength, splitting tensile strength, flexural strength, axial compressive strength, and elastic modulus are increased by 12.6%, 16.1%, 6.3%, 10.3%, and 13.7%, respectively. The reason is that basalt forms a bridging effect inside the concrete, which improves the pore structure, reduces the number of microcracks, inhibits the propagation of microcracks, and thus enhances the compactness of concrete. However, it will reduce the workability of concrete, such as slump, and with the increase in the dosage and length of BF, the slump and slump flow of concrete gradually decrease. Julita Krassowska [

19] studied the effect of BF on the flexural toughness and tensile strength of concrete. The results showed that BF significantly improved the flexural toughness and tensile strength of concrete, and the linear segment of its load-crack opening displacement curve was also extended. Li et al. [

20] studied the variation law of mechanical properties of BFRC with the number of loading cycles, fiber dosage, and stress level through staged fatigue loading tests. The results showed that BF can reduce the strength attenuation of concrete under fatigue load, which is helpful to optimize the pore structure during service. In addition, under fatigue load, the porosity and total pore volume of BF concrete have a high correlation with flexural strength. Xu et al. [

21] compared and analyzed the effects of steel fiber and basalt fiber on the mechanical properties of concrete, respectively. The results showed that both steel fiber and basalt fiber can improve the tensile and flexural strength of concrete, and the improvement effect of steel fiber is slightly higher than that of basalt fiber. However, the production cost and CO

2 emission of SFRC are 2.46 times and 1.21 times that of BFRC, respectively. BFRC has more economic and environmental advantages, so adding BF is a better choice.

However, despite the confirmed benefits of BF, a direct and systematic comparison of the frost resistance efficacy between single-length and hybrid-length fibers remains insufficiently explored. Furthermore, there is a scarcity of studies that integrate experimental data with probabilistic models to quantify the service life of BFRC for specific engineering applications in cold regions. To address these gaps, this study systematically investigates the effects of both BF volume content and incorporation method on the frost resistance of C30 concrete (designed without mineral admixtures to isolate the fiber’s contribution), analyzing the damage mechanism through the evolution of mass loss rate and relative dynamic elastic modulus over 225 freeze–thaw cycles. The primary novelty of this work lies in establishing a freeze–thaw damage evolution model based on the two-parameter Weibull distribution, which is then employed to predict the theoretical service life of BFRC under the specific environmental conditions of a high-altitude cold region (e.g., Songpan County, Sichuan Province, 85 annual F-T cycles, annual temperatures below 6 °C). This approach provides a quantitative theoretical basis and practical technical reference for the durability design of BFRC structures in frigid environments.

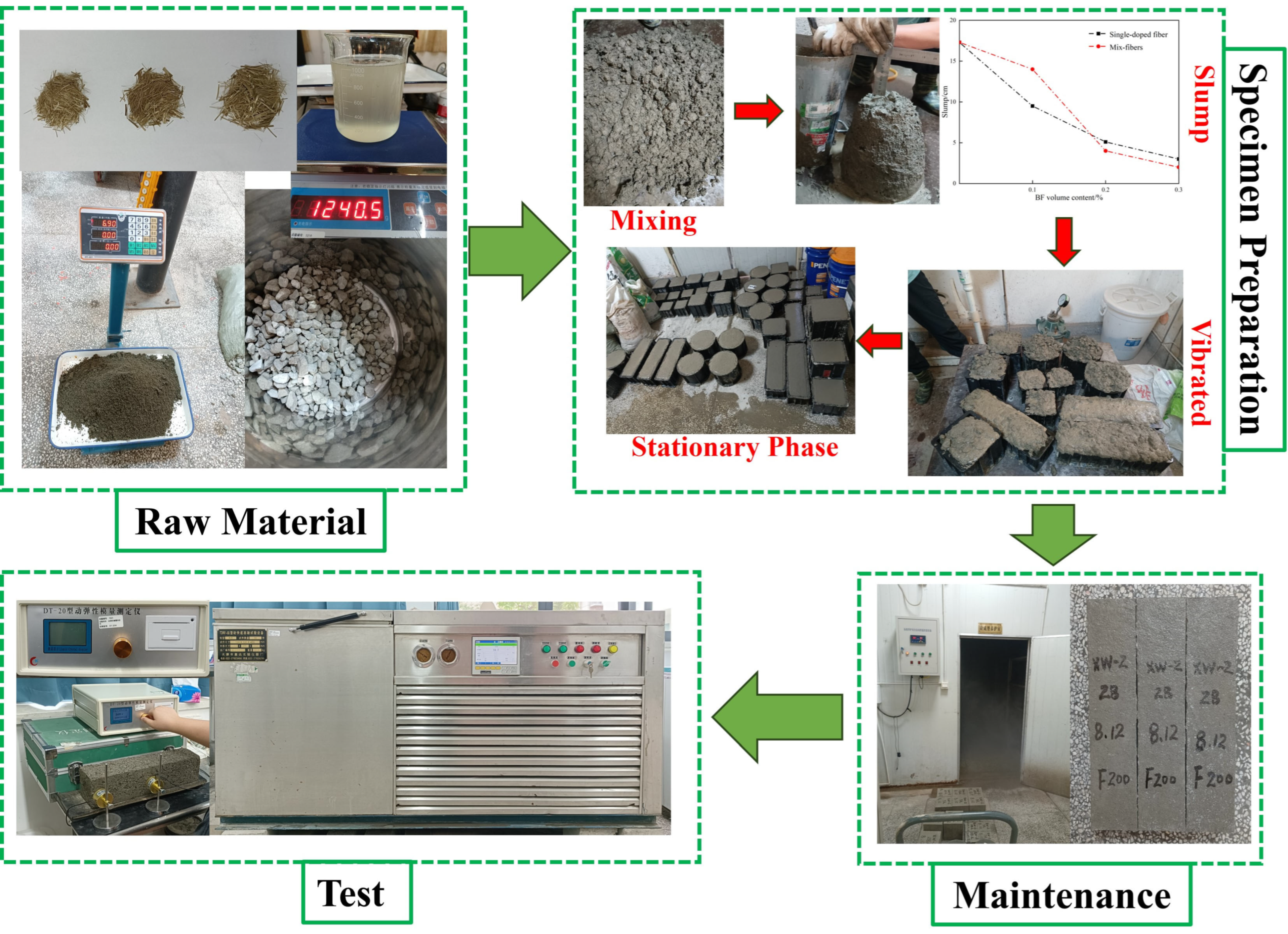

3. Results and Discussion

The surface changes in BFRC with different volume contents of mixed fibers (6 mm, 12 mm, 18 mm) and single-doped fiber (18 mm) from 0 to 225 F-T cycles are presented in

Figure 2.

The surface changes in BF concrete in

Figure 2 were observed and analyzed. With increasing F-T cycles, the F-T damage stages (surface mortar pulverization → mortar shedding → aggregate exposure) gradually emerged in BFRC with different mix proportions. When the number of F-T cycles reached

n = 125, aggregate leakage was observed in the 0.1% and 0.2% BFRC specimens; when

n = 225, most surface aggregates were exposed in these specimens, whereas the 0.3% BFRC specimens only exhibited slight pulverization and spalling with no obvious aggregate leakage.

Next, the frost resistance of BFRC was quantitatively evaluated using the mass loss rate and RDEM of the specimens after F-T cycles.

3.1. Effect of BF on Frost Resistance of Concrete

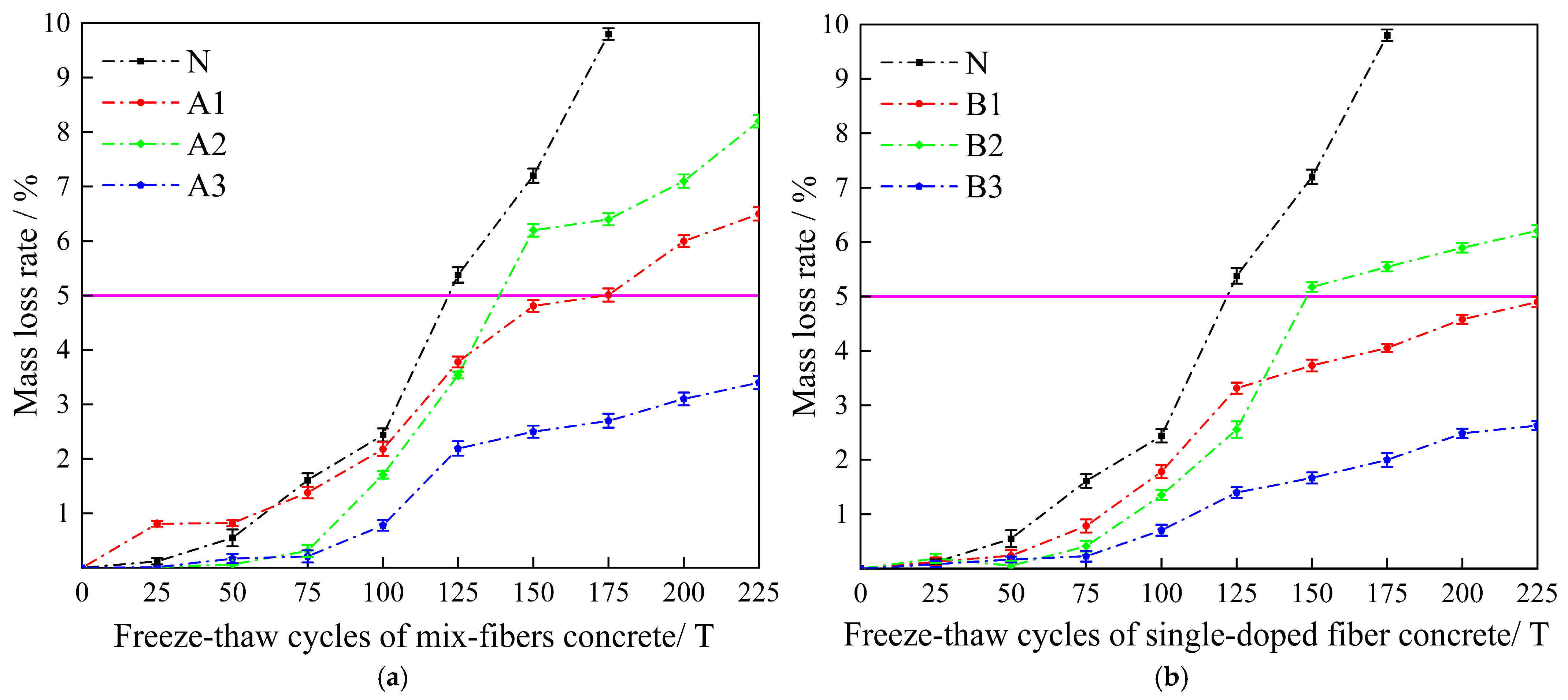

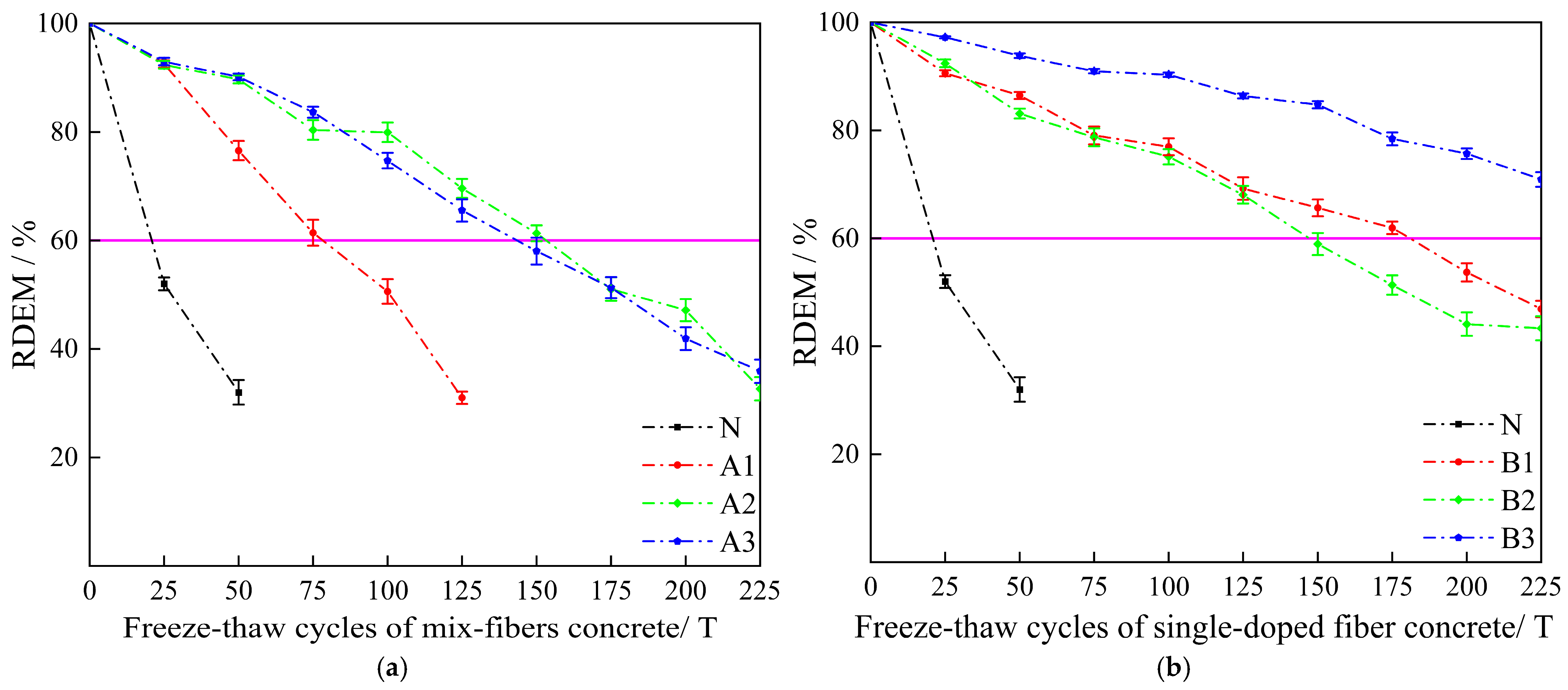

The mass loss rate and RDEM of BFRC with increasing F-T cycles are presented in

Figure 3 and

Figure 4.

Analysis of the data in

Figure 3 and

Figure 4 reveals that, within the scope of this study, both the volume content and incorporation method of BF significantly affect the frost resistance of concrete. When using the mass loss rate of concrete specimens as the evaluation criterion for frost resistance, the mass loss rate of specimens without fiber incorporation (V

BF = 0) reaches 5.4% after 125 F-T cycles, failing to meet the specification requirements. When using the RDEM of concrete specimens as the evaluation criterion, the RDEM of non-fiber-incorporated specimens (V

BF = 0) drops below 60% after 25 F-T cycles, similarly failing to meet the specification requirements. However, the incorporation of BF can effectively increase the number of F-T cycles required for the mass loss rate and RDEM of concrete to reach the failure thresholds. In terms of BF incorporation methods, the frost resistance of concrete with single-doped BF is significantly superior to that with mixed-doped BF. For concrete with mixed-doped fibers, there is a significant discrepancy in the number of F-T cycles corresponding to the failure thresholds when evaluated by the mass loss rate and RDEM, respectively. In contrast, for concrete with single-doped fibers, the number of F-T cycles corresponding to the failure thresholds under the two evaluation criteria is relatively close.

The reasons for the above conclusions are analyzed as follows:

- (1)

The key to frost resistance lies in inhibiting the propagation of microcracks and the spalling of surface mortar during F-T cycles. The incorporation of BF enhances the compactness of concrete and inhibits the development of microcracks and mortar spalling through the bridging effect. Therefore, the frost resistance of BFRC is significantly higher than that of the reference concrete without fiber incorporation.

- (2)

The 18 mm-long fibers used in single doping have an aspect ratio of 900, enabling them to more effectively form a “spatial skeleton” within the concrete. Through mechanical anchoring and interfacial bonding, they achieve cross-crack bridging. For surface mortar, long fibers can enhance the bond between mortar and aggregate, thereby reducing surface spalling induced by F-T cycles. In contrast, the 6 mm (aspect ratio 300) and 12 mm (aspect ratio 600) short fibers in mixed doping exhibit a weaker effect on enhancing the bond of surface mortar, and their inhibitory effect on surface mortar spalling is inferior to that of 18 mm fibers, resulting in a higher mass loss rate. That is, when evaluated by the mass loss rate, the frost resistance of concrete with mixed-doped fibers is inferior to that with single-doped 18 mm fibers.

- (3)

Within the concrete, at the same fiber content, a shorter fiber length results in a larger number of fibers, which are more prone to local agglomeration—potentially forming tiny “voids” in the matrix. This phenomenon may reduce local compactness and create weak points for water intrusion during F-T cycles, which could help explain why the RDEM of concrete with 0.3% volume content of mixed-doped BF decreases so rapidly. Given the absence of direct supporting data to confirm the existence of such agglomeration-induced “voids,” this explanation is proposed as a hypothesis based on the observed RDEM variation trend and the well-documented mechanism of fiber dispersion in fiber-reinforced concrete.

- (4)

Short fibers cannot inhibit the propagation of medium-sized cracks. During F-T cycles, the freezing and expansion of free water within concrete generate stress, leading to the continuous propagation of microcracks. The 18 mm-long fibers can disperse stress through the bridging effect, preventing crack propagation. However, the short fibers in mixed doping can only inhibit extremely fine cracks. When cracks propagate to a certain width, short fibers lose their restraining capacity, and cracks rapidly develop into macroscopic cracks, resulting in a decrease in the integrity of the internal structure and a sharp reduction in RDEM.

- (5)

The synergy at the fiber-mortar interface is inadequate. In mixed doping, the interfacial bonding properties of fibers with different lengths vary: short fibers have a small bonding area and low bonding strength with mortar, and are prone to detachment from mortar during F-T cycles, forming “interface cracks”—a phenomenon consistent with the reason for the higher mass loss rate of concrete with mixed-doped BF. Moreover, the proportion of long fibers is only 30%, which cannot compensate for the failure of the short fiber interface, leading to faster stiffness loss of the overall structure, manifested as a significant decrease in RDEM.

In summary, the frost resistance of concrete with single-doped BF is superior to that with mixed-doped BF, with the core reason being the limitations of short fibers in mixed doping and the insufficient proportion of long fibers. The RDEM reflects the integrity of the internal structure of concrete. The above analysis also explains why, when concrete is evaluated by the two methods of reaching the failure thresholds of mass loss rate and RDEM, the number of F-T cycles corresponding to failure is roughly the same for concrete with single-doped BF, but there is a significant discrepancy for concrete with mixed-doped BF.

Therefore, within the scope of this study, fiber concrete with 0.3% volume content of single-doped 18 mm BF exhibits the optimal frost resistance.

3.2. Frost Resistance Strength Grade Presumption

Combined with the two evaluation criteria for concrete frost resistance, namely the concrete mass loss rate and RDEM, the smaller number of F-T cycles is selected as the frost resistance strength index of concrete. Based on the curve trends in

Figure 3 and

Figure 4, the frost resistance strength indexes of the specimens corresponding to the seven test schemes were inferred, as presented in

Table 3.

A comprehensive comparison of BF volume contents reveals that the frost resistance of BFRC increases with increasing volume content, while its slump decreases significantly. The reason is analyzed as follows: BF has a large specific surface area, enabling it to bind a portion of free water to form a water film on the fiber surface. Therefore, the higher the BF volume content, the lower the slump. Similarly, a higher slump indicates a greater amount of relative free water in the concrete mixture. During curing, more tiny free water migration channels are formed in the specimens, which indirectly affects the compactness of concrete. During the F-T cycle test, water can more easily penetrate into the interior of the specimens through these migration channels. After multiple F-T cycles, fatigue damage occurs around the migration channels, gradually increasing their length and width and eventually leading to more frequent F-T damage in concrete specimens. After F-T damage occurs, the bridging effect of BF inhibits the spalling of surface mortar and the development of internal microcracks. Under the combined effect, the frost resistance of BFRC increases with increasing BF volume content.

Although BF can significantly improve the frost resistance of concrete, a critical constraint emerges for both single-doped and mixed-doped BF systems. When the BF volume content reaches 0.3%, the workability of concrete is severely impaired. Common technical approaches to alleviate this workability inhibition—such as increasing water dosage, adding high-efficiency water reducers, incorporating fiber dispersion aids, or conducting fiber surface modification—all have inherent limitations: increasing water dosage directly reduces the strength of hardened concrete, while adding high-efficiency water reducers, fiber dispersion aids, or modifying fiber surfaces substantially raises construction costs. Notably, this study has already incorporated a high-efficiency water reducer at the recommended dosage (0.9% of cement mass), yet the workability of concrete with 0.3% BF volume content still remains significantly compromised. From the perspective of practical engineering application, therefore, a BF volume content exceeding 0.2% is not recommended for general projects, unless the structure is subjected to extreme freeze–thaw environments or has exceptionally stringent frost resistance requirements.

4. Freeze–Thaw Damage Model and Service Life Prediction

Commonly used probability models for concrete freeze–thaw damage service life prediction include the two-parameter Weibull prediction model, gray prediction model, log-normal distribution model, and extreme gradient boosting (XGBoost) prediction model [

31,

32,

33,

34]. Specifically, each model’s prediction focus aligns with concrete freeze–thaw-related performance. The two-parameter Weibull model and log-normal distribution model are used to predict the statistical distribution of concrete freeze–thaw damage service life and durability degradation indicators, such as the relative dynamic elastic modulus loss rate after freeze–thaw cycles. The gray prediction model is applied for short-term prediction of freeze–thaw damage development trends, including the strength attenuation rate with increasing freeze–thaw cycles. The XGBoost model integrates multi-factor inputs—such as mix proportion, fiber content, and environmental freeze–thaw cycles—to predict comprehensive indicators related to freeze–thaw service life, including the critical freeze–thaw cycle number before failure and the freeze–thaw damage degree at target service time.

Among these models, the two-parameter Weibull model is particularly suitable for this study’s focus on freeze–thaw damage service life prediction due to its unique advantages. It can flexibly describe the statistical distribution of concrete’s freeze–thaw failure process—from initial microcrack initiation to macroscopic structural damage—with only two parameters. One is the shape parameter, which reflects the concentration degree of freeze–thaw failure time; the other is the scale parameter, which represents the characteristic service life corresponding to 63.2% failure probability. This parameter setting enables concise yet accurate characterization of freeze–thaw damage evolution, a key requirement for simplifying the prediction process while ensuring reliability [

7,

31,

33,

35,

36]. Therefore, in this study, a concrete F-T damage evolution model based on the two-parameter Weibull distribution is established, and the maximum expected service life of each BFRC group is predicted using the Weibull probability distribution.

4.1. Freeze–Thaw Damage Model Based on Weibull Distribution

In this study, the two-parameter Weibull distribution model is employed to predict the durable service life of concrete. It is assumed that the durable service life N of concrete follows this distribution, and the reliability function of concrete is thereby established. The distribution function and reliability function are expressed in Equations (3) and (4):

where

b is the shape parameter,

b ≥ 0;

is the scale parameter,

≥ 0;

n is the actual test value of the concrete F-T cycle life

N;

is the damage degree of the concrete.

In selecting damage variables, considering that the internal damage of concrete is irreversible and difficult to repair, and RDEM is a test parameter reflecting the integrity of the internal structure of concrete, RDEM is used for evaluation. The damage variable

can be expressed as follows:

where

is the damage degree of concrete;

is the RDEM of initial concrete, taken as 1;

is the measured value of RDEM of concrete after

n F-T cycles.

Therefore, Equation (5) can be rewritten as follows:

By combining Equations (3)–(6), the following is obtained

By taking the natural logarithm twice on both sides of Equation (7), the following is derived:

Since b and ε are constants, let

,

,

. Then, the above equation can be transformed into a simple linear equation:

It should be noted that this formula predicts the RDEM of concrete after F-T damage. When there is no F-T damage, , n = 0, which satisfies the solution of Equation (7) but does not meet the parameter requirements of Equations (8) and (9).

According to the regression fitting of the test data, the regression values of b and a under different BF volume content and mixing method are obtained. When deriving from Equation (8) to (9), we used substitution to define

. Once the regression values of a and b are obtained, ε is calculated via

, with results in

Table 4.

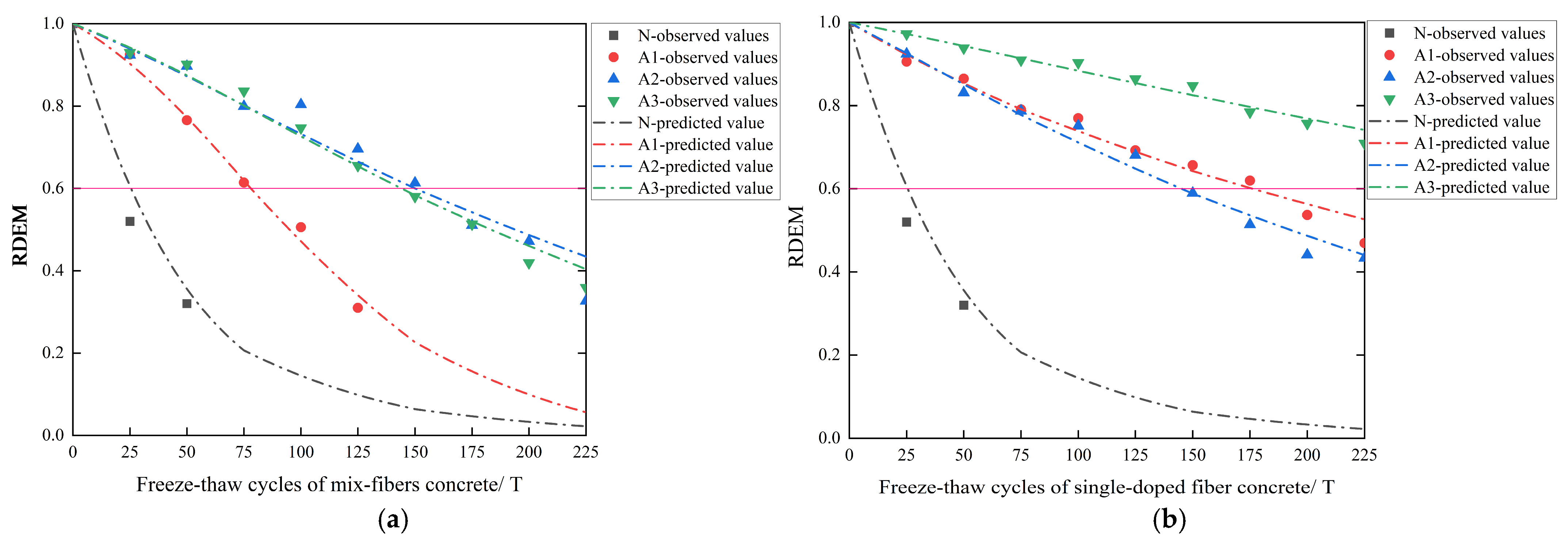

Substituting the data in

Table 4 into Equation (7) yields the prediction results for different F-T cycles under each mix proportion, with a comparison to the actual test results presented in

Figure 5.

According to the comparison results, the predicted values of the fitting function are generally consistent with the experimental data. The model can accurately describe the relationship between the number of F-T cycles and the degree of damage. Therefore, based on the prediction model, the frost resistance of BF concrete is evaluated, and the frost resistance strength index is presumed as the number of F-T cycles corresponding to

Pn = 0.6. The presumed values are presented in

Table 5.

4.2. Service Life Prediction of BFRC

According to the specification, the durable service life of concrete expires when its RDEM drops to 60% or below. Based on the frost resistance strength derived from the previous prediction model, the durable service life of concrete in alpine environments can be determined.

Based on the investigation by Li Jinyu et al. [

2,

37] on the relationship between the number of indoor concrete F-T cycles and outdoor natural F-T cycles in different regions of China, the service life prediction formula for concrete in cold-region engineering structures is derived as follows:

where

T is the service life of the concrete structure (years);

k is the proportional coefficient of F-T test, with a value of 11.3 for concrete without an air-entraining agent;

n is the number of indoor F-T cycles of concrete when the RDEM is 0.6;

N is the number of F-T cycles experienced by concrete structures in the natural environment per year.

The number of indoor F-T cycle failures based on the two-parameter Weibull prediction model is presented in

Table 5. In the southwest region, taking the flood control project in Songpan County, Aba Tibetan and Qiang Autonomous Prefecture, Sichuan Province as an example, its altitude ranges from 3000 m to 3200 m, with an average of 85 annual F-T cycles (N = 85). Substituting the above two values into Equation (10) yields the maximum theoretical service life of BFRC structures. The specific values are presented in

Table 6. To avoid false accuracy (a concern raised in peer review), the service life values in

Table 6 are rounded to whole numbers—this aligns with practical engineering needs, as structural service life decisions do not depend on decimal-level precision.

To address the limitation of single-region analysis and quantify the impact of varying freeze–thaw conditions on service life, a sensitivity analysis was supplemented in

Table 7. Three typical annual F-T cycle scenarios were selected based on actual meteorological data of cold regions in China, covering low-altitude (e.g., northern Jiangsu, China, N = 50), medium-altitude (e.g., Songpan County, Sichuan, China, N = 85), and high-altitude (e.g., Yushu, Qinghai, China, N = 120) environments.

The sensitivity coefficient (S = −1.0) in

Table 7 confirms that service life is inversely proportional to annual F-T cycles: for example, the optimal mix proportion B3 has a service life of ~85 years in regions with N = 50, but this decreases to ~35 years when N increases to 120 (a 140% increase in N leads to a 58.8% decrease in T). This quantification provides clear guidance for engineers to select appropriate BFRC mix proportions based on the specific freeze–thaw intensity of their project locations.

As can be seen from

Table 6 and

Table 7, the incorporation of fibers significantly prolongs the overall service life of concrete. Compared with ordinary concrete, BFRC exhibits significantly enhanced frost resistance. Combined with the two-parameter Weibull prediction model and sensitivity analysis, the service life of BFRC can be predicted and adapted to different cold-region scenarios.

Although the model and sensitivity analysis can provide scenario-specific service life predictions, the southwest region has numerous mountains with large elevation differences, resulting in significant variations in the annual average number of natural F-T cycles. Therefore, for regions at different altitudes, corresponding meteorological data are still required to refine service life predictions.

5. Conclusions

Cold regions worldwide face severe challenges of concrete structure damage caused by freeze–thaw (F-T) cycles, which threatens engineering safety and service life. Basalt fiber (BF) has emerged as a promising additive to improve concrete frost resistance, but existing studies lack systematic comparisons of single-doped vs. mixed-doped BF efficacy and targeted life prediction for high-altitude cold regions. To fill these gaps, this study aimed to: (1) investigate how BF volume content (0.1%, 0.2%, 0.3%) and incorporation method (single-doped 18 mm, mixed-doped 6 mm/12 mm/18 mm) affect the frost resistance of C30 concrete; (2) establish a quantitative service life prediction model using the two-parameter Weibull distribution. The methodology included 225 quick F-T cycle tests, monitoring of mass loss rate and RDEM, and theoretical analysis via Weibull damage modeling.

In this study, the frost resistance characteristics of BFRC were investigated through rigorous F-T cycle tests and systematic theoretical analysis tools—specifically, the two-parameter Weibull distribution model and quantitative damage evaluation based on mass loss rate/RDEM, and its service life was predicted. The main conclusions are as follows:

- (1)

BF significantly enhances the frost resistance of concrete with quantifiable efficacy: Within the volume content range of 0.1–0.3%, the reference group (no BF) had an RDEM drop below 60% after only 25 F-T cycles, while the group with 0.3% single-doped 18 mm BF retained good integrity (RDEM > 60%) after 225 F-T cycles, with a frost resistance grade exceeding F225. Compared to the reference group, the 0.3% single-doped BF group delayed the onset of F-T failure by ~9 times. This validates the critical reinforcing effect of fibers on concrete frost resistance.

- (2)

The fiber incorporation method and length dominate the differences in frost resistance efficacy, with measurable superiority of single-doped long fibers: At the same volume content, the frost resistance of single-doped 18 mm BF was significantly better than that of mixed-doped 6 mm/12 mm/18 mm BF. For example, after 225 F-T cycles, the RDEM of the 0.3% single-doped group (B3) was 38% higher than that of the 0.3% mixed-doped group (A3), and the mass loss rate of B3 was 1.2% lower than that of A3. Long fibers form a “spatial skeleton” and achieve cross-crack bridging through mechanical anchoring and interfacial bonding, effectively inhibiting surface mortar spalling and internal crack propagation. In contrast, the short fibers (6 mm and 12 mm) in the mixed-doped system, due to their smaller aspect ratios and proneness to agglomeration, form weak points, resulting in a less effective enhancement of frost resistance.

- (3)

There exists a quantifiable trade-off relationship between fiber content and workability: As BF volume content increased from 0.1% to 0.3%, the frost resistance of BFRC continuously improved, such as the frost resistance grade of single-doped BF groups increased from F175 (B1, 0.1%) to >F225 (B3, 0.3%), while slump decreased significantly from 9.5 cm (B1) to 3 cm (B3). This is attributed to the high specific surface area of BF binding free water. In practical applications, it is necessary to optimize the content based on engineering requirements to balance frost resistance and constructability.

- (4)

Life prediction confirms the engineering application value. Based on the two-parameter Weibull model and the conversion relationship of F-T cycles in cold regions, under an environment with 85 F-T cycles per year, the theoretical service life of concrete with 0.3% single-doped BF reaches 48.91 years, 25 times that of the reference group. Practice in the test section of the Songpan County Flood Control Project also demonstrates that after 2 winter F-T cycles, the strength of concrete with this proportion is 44% higher than that of the reference group, with a 35% lower discreteness, confirming its engineering applicability in frigid and high-altitude areas.

This study can provide a targeted theoretical basis and technical support for the design and durability evaluation of BFRC structures in frigid regions. However, the limitations of this study must be acknowledged to avoid overgeneralization of the results and guide future research. The specific limitations are outlined as follows:

- (1)

Limitation in concrete strength grade: This study only focused on C30 concrete (without mineral admixtures or air-entraining agents) to control variables and clarify the independent effect of BF. However, practical engineering involves various concrete strength grades. The optimal BF content, length, and incorporation method may vary with concrete strength—for instance, high-strength concrete with a lower water-cement ratio may have different fiber-matrix interfacial bonding properties, which could affect frost resistance enhancement. Thus, the conclusions cannot be directly extended to non-C30 concrete.

- (2)

Constraints in service life prediction scenarios: Although a sensitivity analysis of annual F-T cycles (50, 85, 120 cycles/year) was added to cover typical cold regions in China, the life prediction model does not account for the synergistic effect of other environmental factors (e.g., salt freezing, dry–wet cycles) that are common in practical cold regions (e.g., coastal cold areas with chloride ion erosion, semi-arid cold areas with alternating freeze–thaw and drying). Additionally, the model assumes a constant annual F-T cycle number, while natural environments may have interannual variations in temperature and precipitation, which could lead to deviations between predicted and actual service life.

- (3)

Limitation in parameter range for BF: The study only tested BF with lengths of 6 mm, 12 mm, and 18 mm, and volume contents of 0.1–0.3%. It did not involve other BF lengths (e.g., 3 mm, 24 mm), nor did it explore the synergy between BF and other admixtures (e.g., fly ash, air-entraining agents). This narrow parameter range restricts the generalization of the findings to more diverse engineering scenarios.