Modern Insulation Materials for Sustainability Based on Natural Fibers: Experimental Characterization of Thermal Properties

Abstract

1. Introduction

1.1. Cold Storage Facilities and Construction

1.2. Organic Materials of Insulation

1.3. Three-Dimensional Printing and Biodegradable Materials

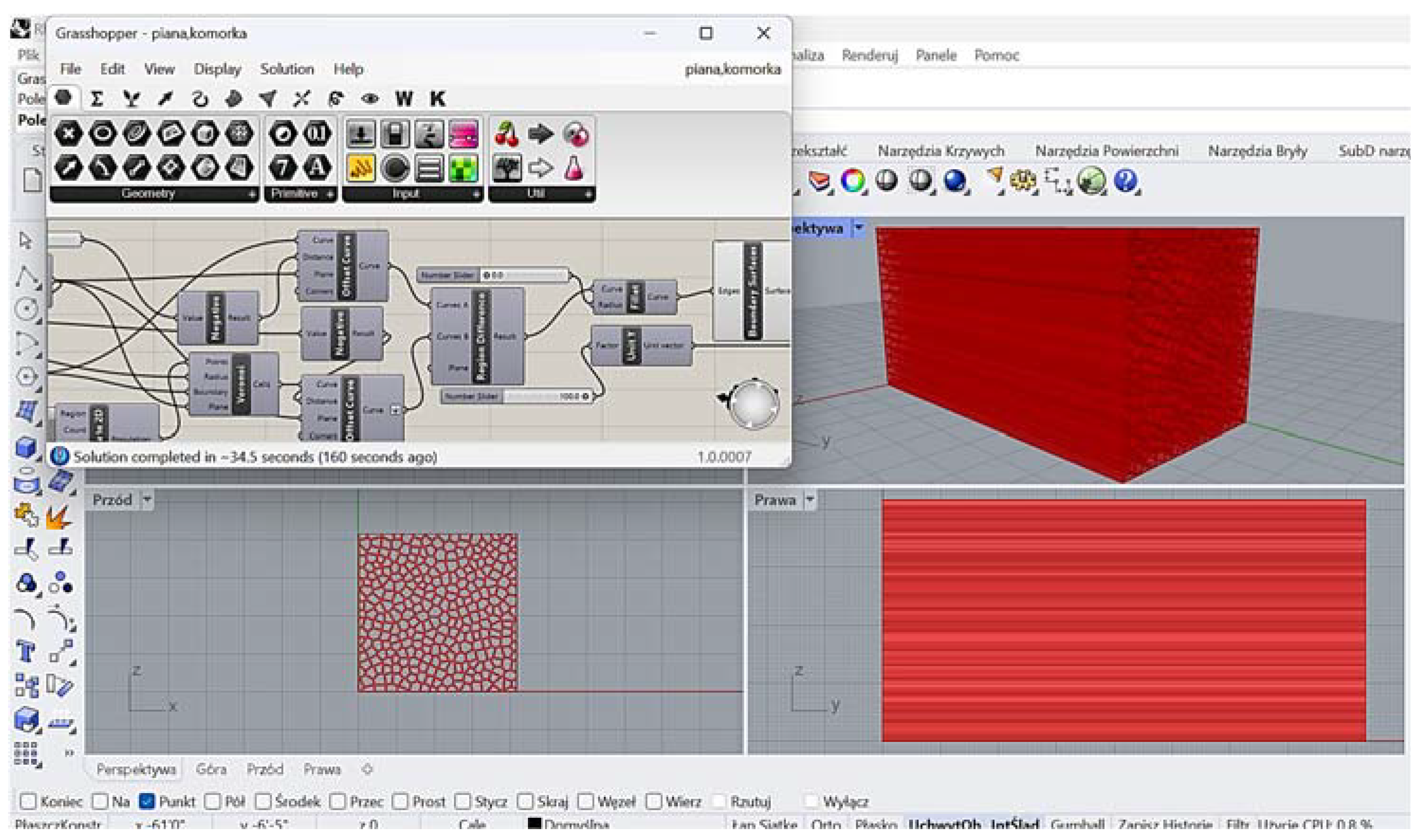

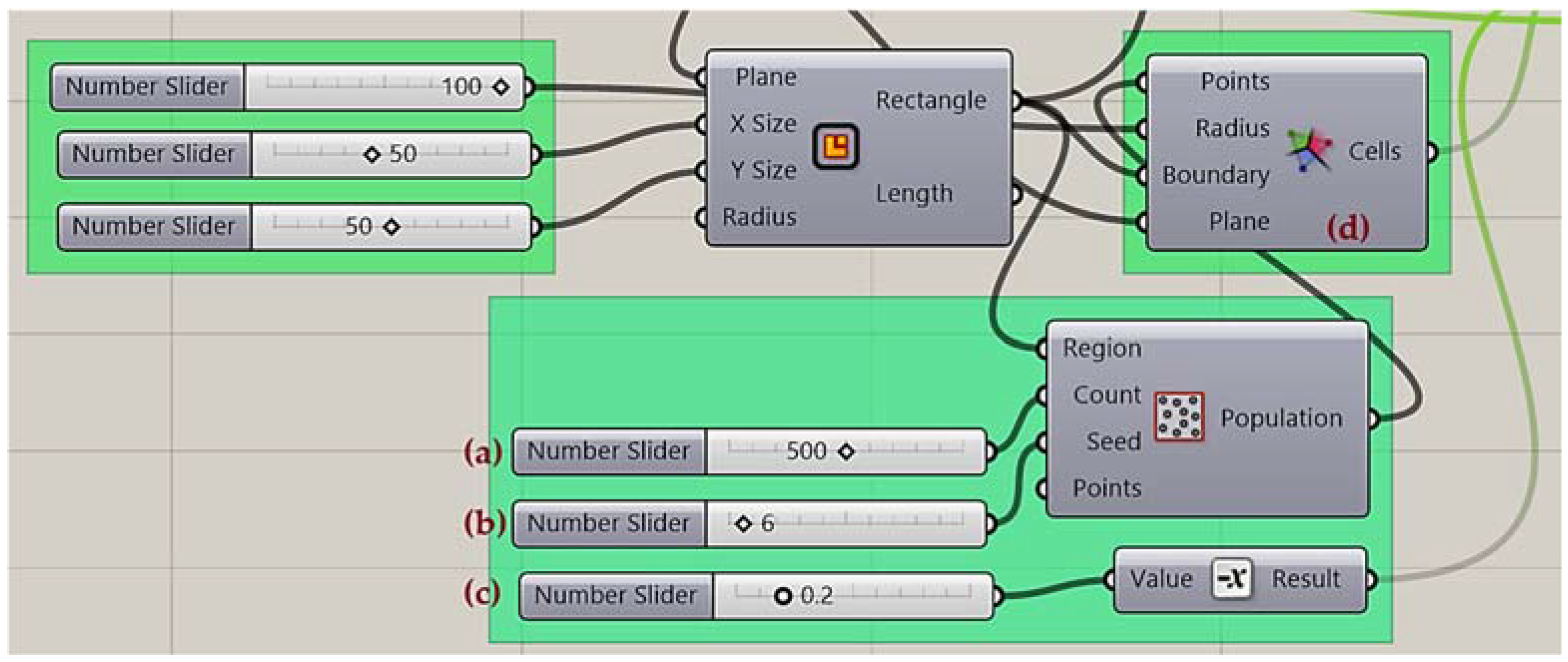

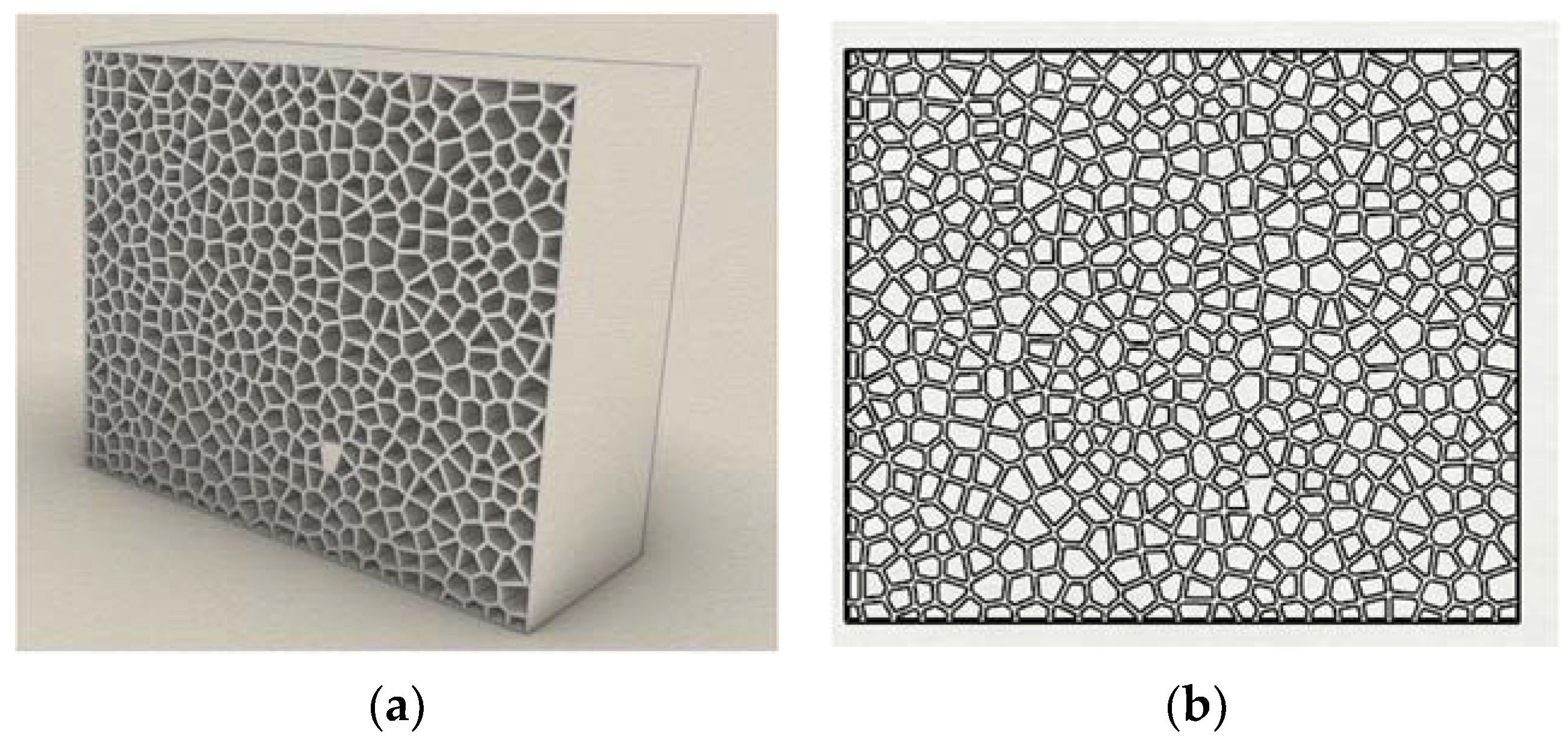

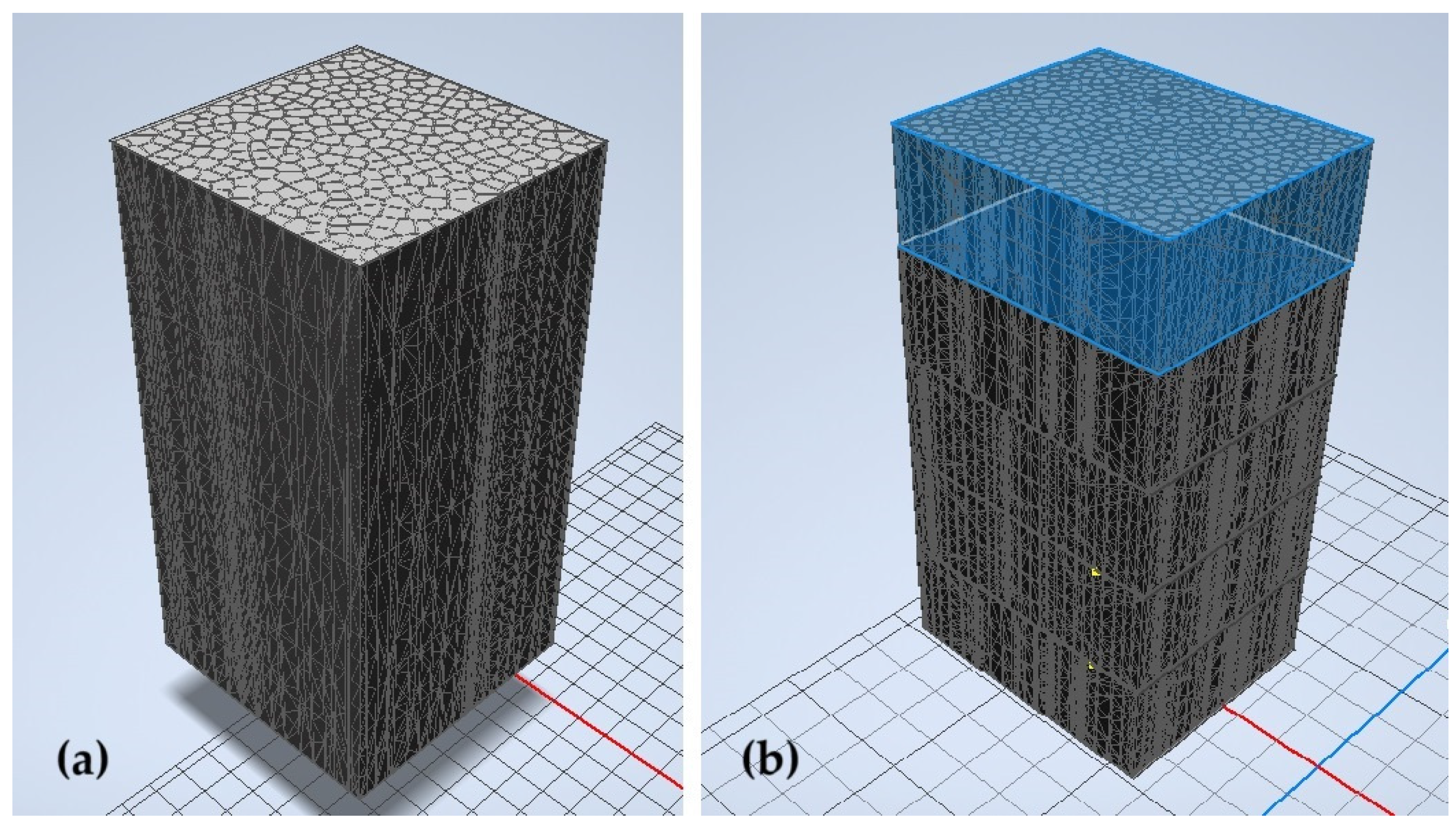

1.4. Three-Dimensional-Printed Cellular Composites for Thermal Insulation

Overview of 3D-Printed Cellular Composites’ Applications

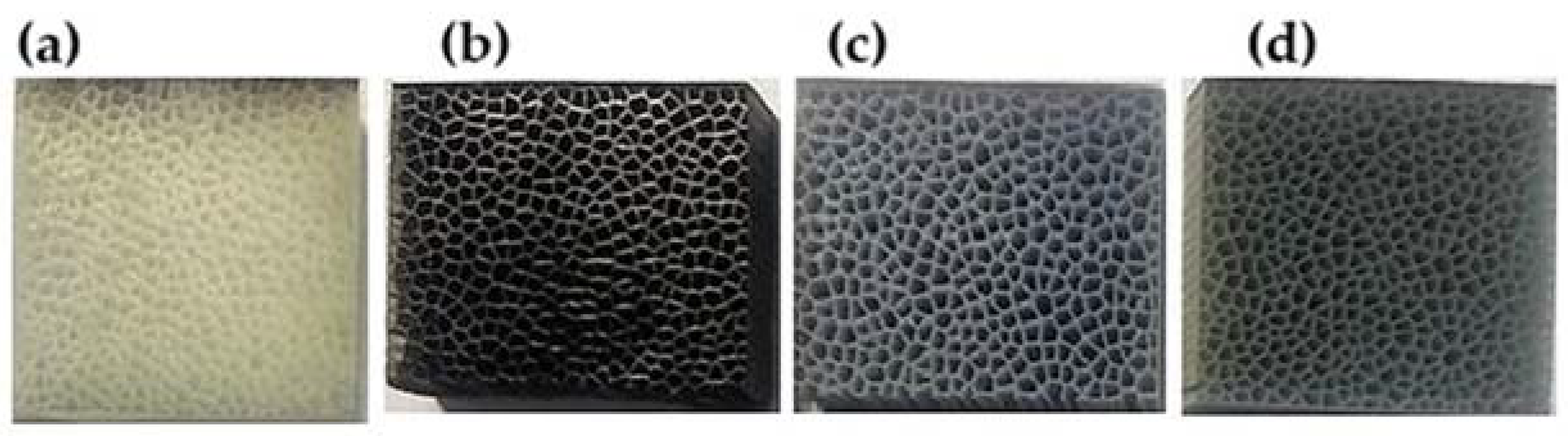

2. Materials and Methods

2.1. Research Material

2.2. Experimental Research

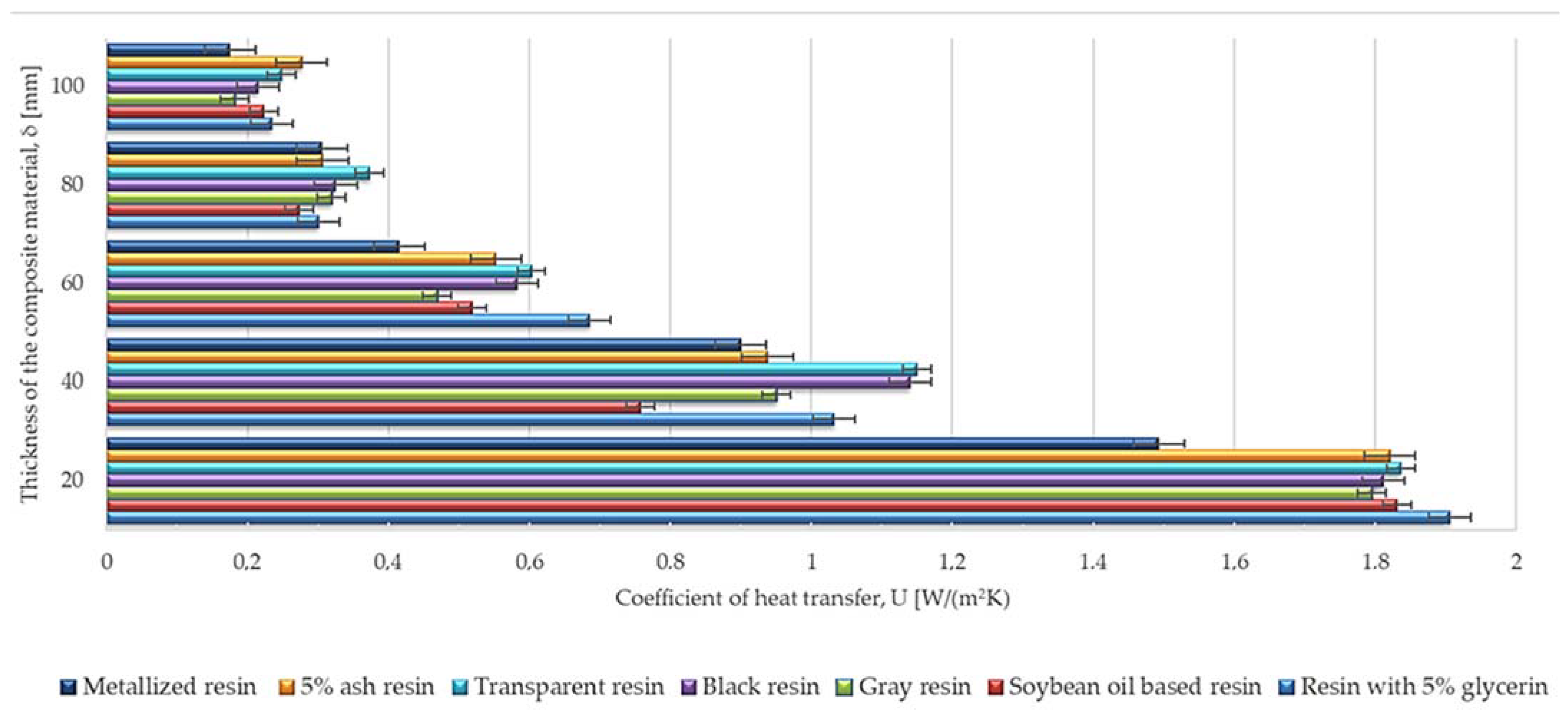

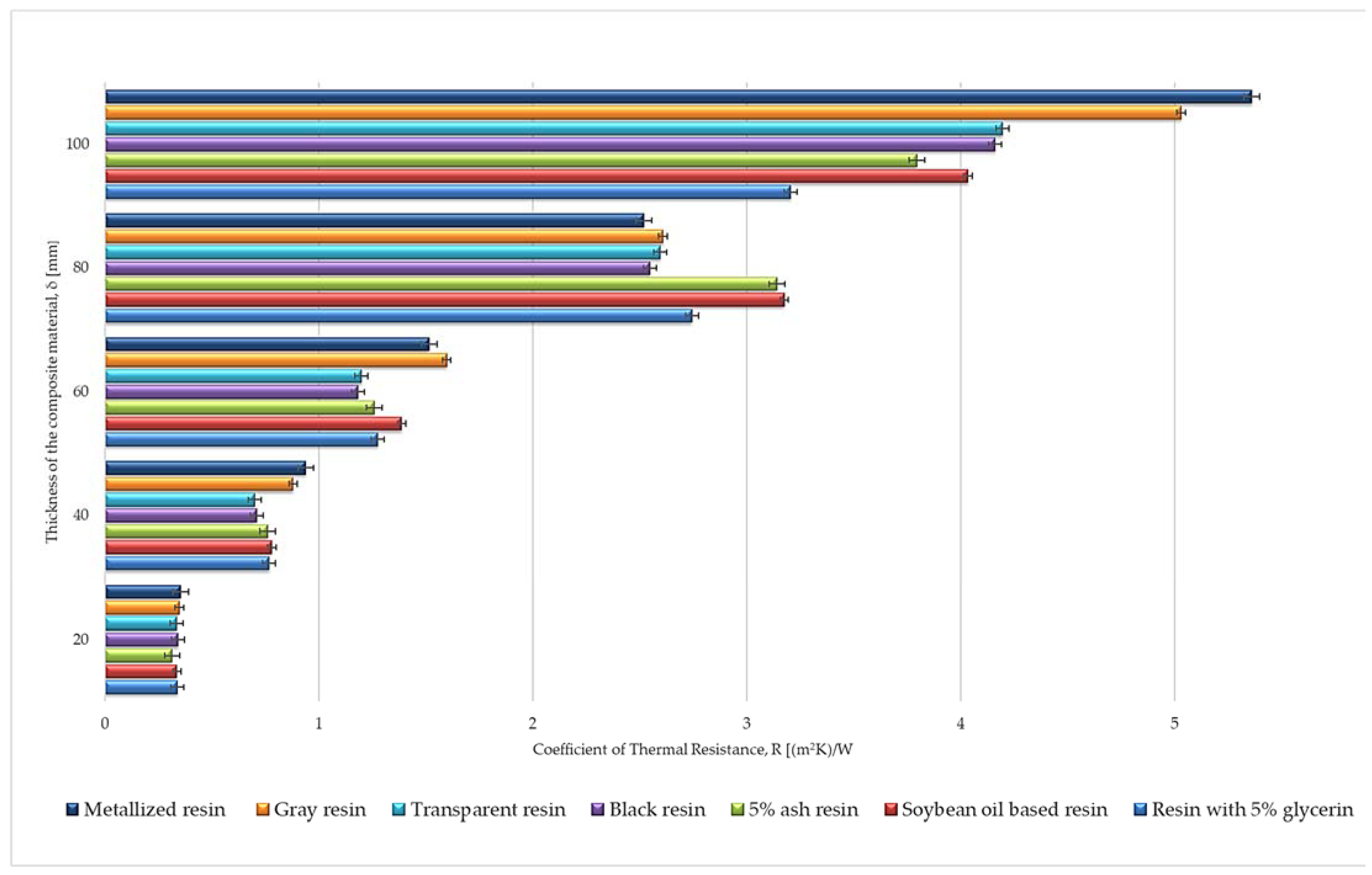

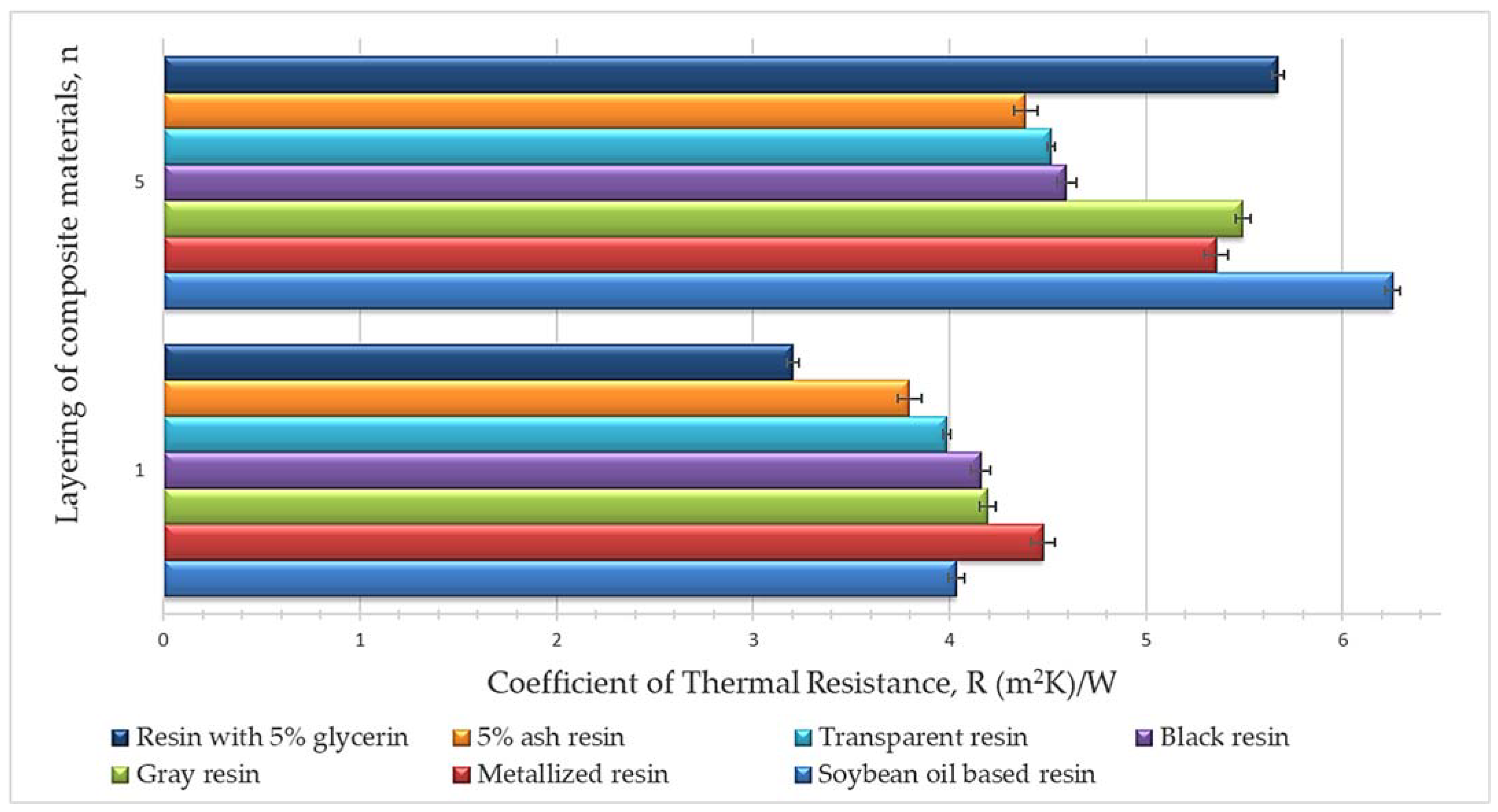

3. Results and Discussion

4. Conclusions

- Increasing the number of layers has a positive effect on the value of the heat transfer coefficient.

- For a sample with a thickness of only 40 mm, a decrease in its value of more than 40% was observed.

- The lowest value with a five-layer material is 0.16 W/m2·K, but all variants of resins of different colors meet the U-value standards for transparent partitions.

- The best choice in the selection of resin color is gray and metallized; these colors have the most stable and lowest values of heat transfer coefficient.

- The thickness of the sample also significantly improves the thermal properties. The thermal resistance, R, increased in the range of 2.962 to 6.273 (m2·K)/W. The heat transfer coefficient, U, decreased from 1.913 W/m2·K to 0.16 W/m2·K.

- Insulating materials with natural fibers have great potential. With only 5% ash and glycerin filler, the thermal transmittance values were similar or even lower than those of resin materials of different colors with the same thickness and layering. The 40 mm thick glycerin sample achieved a value of 0.94 W/m2·K, while only the metallized colored resin sample achieved a better result in this comparison, at 0.9 W/m2·K. In addition, each 100 mm thick composite is close to achieving a value of U = 0.2 W/m2·K, which is defined as the maximum value of the heat transfer coefficient for the building envelope according to ISO 9869-1:2014 [66].

- The soybean-oil-based resin sample has the best thermal properties of all the materials tested. The five-layer composite with a thickness of 100 mm obtained the highest effective thermal transmittance value of 0.16 W/m2·K among all tested samples.

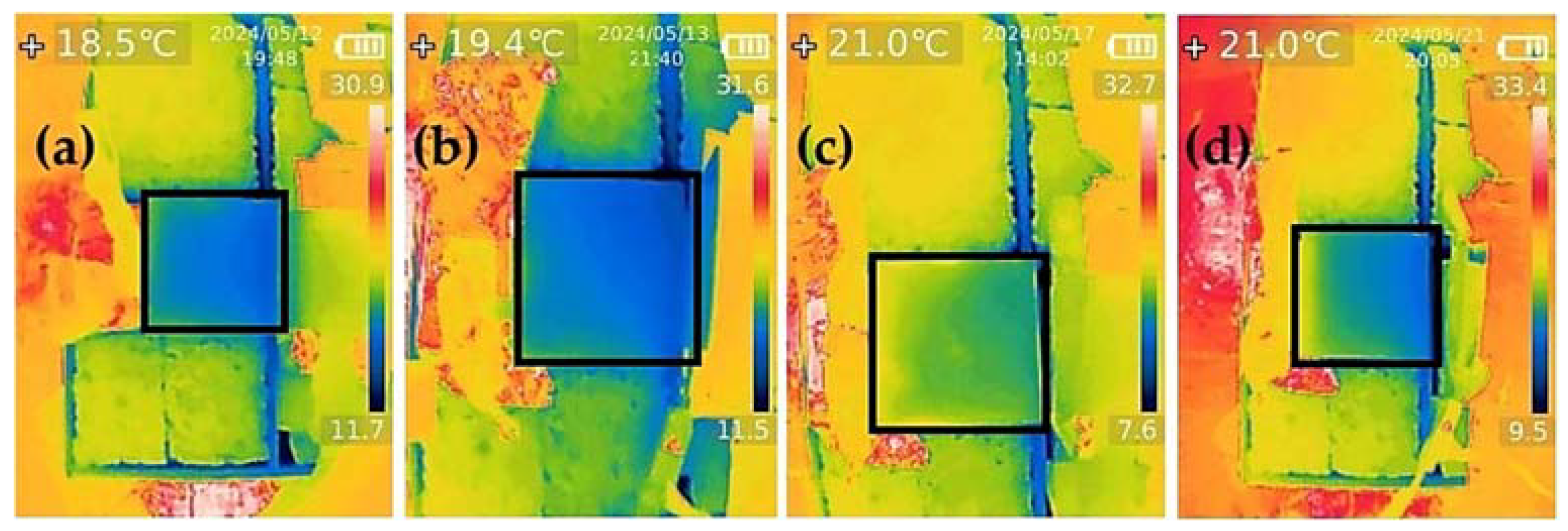

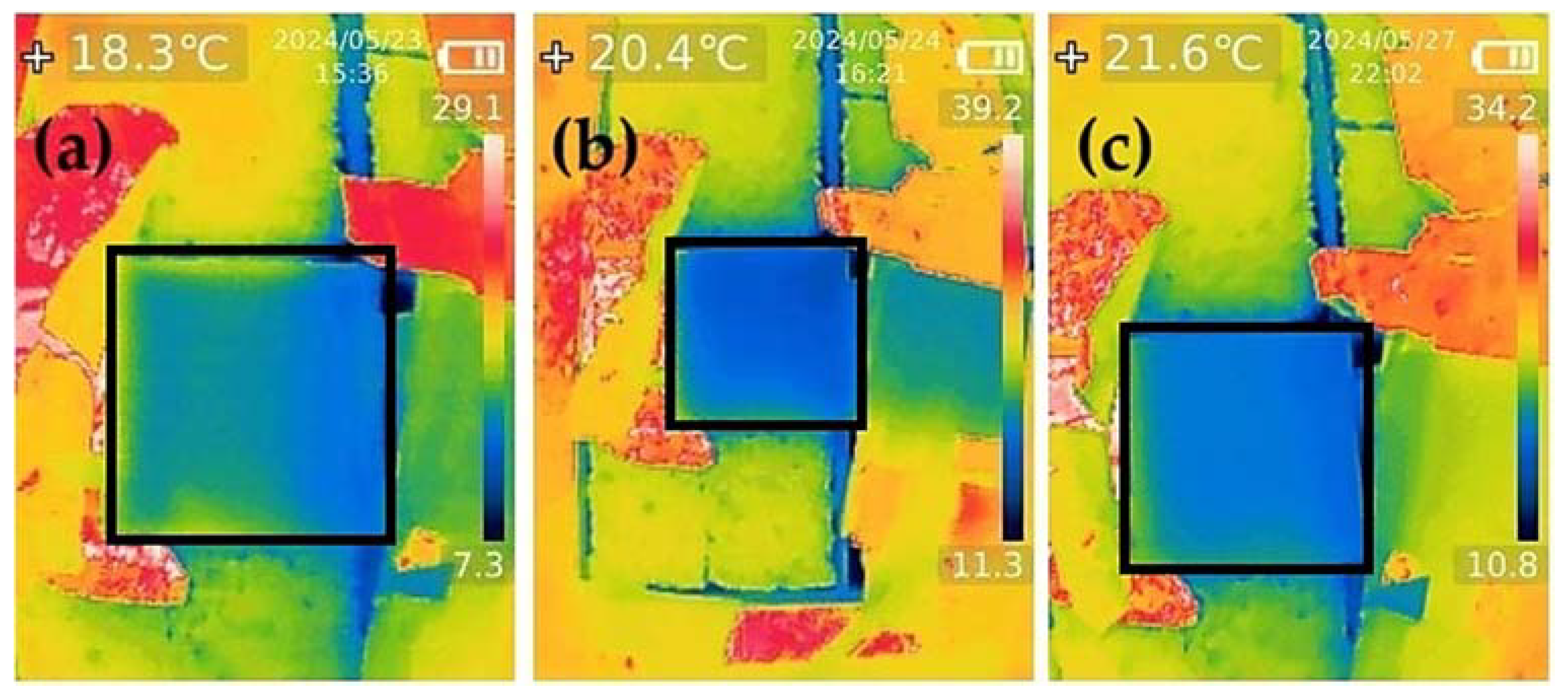

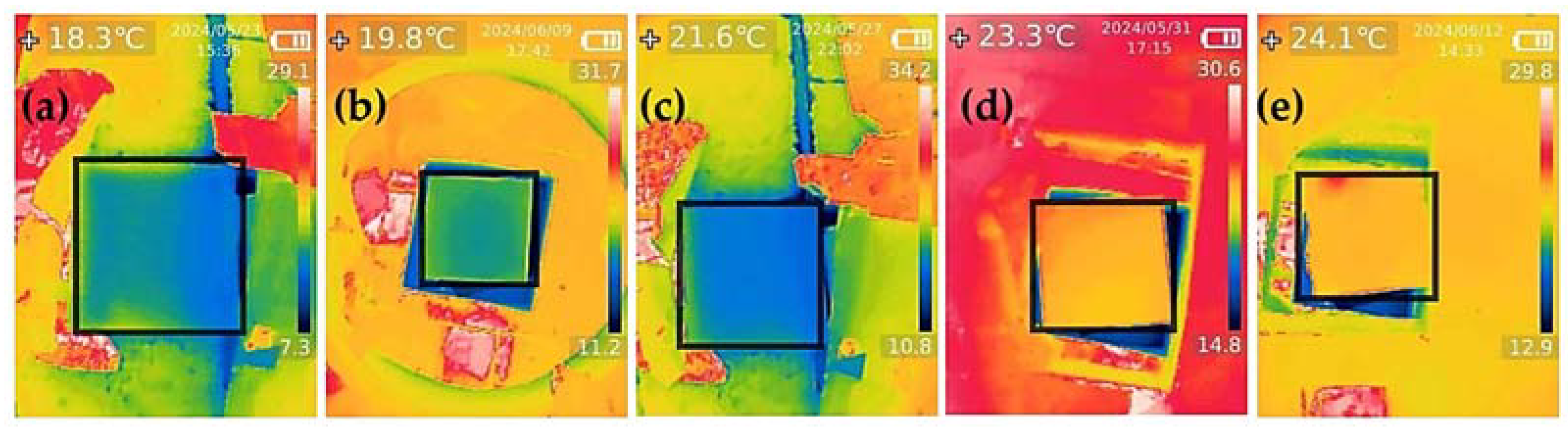

- From the analysis of images taken with a thermal imaging camera, it can be concluded that there are no thermal heat bridges in any of the tested samples and that increasing the thickness of the material reduces heat loss while increasing energy efficiency.

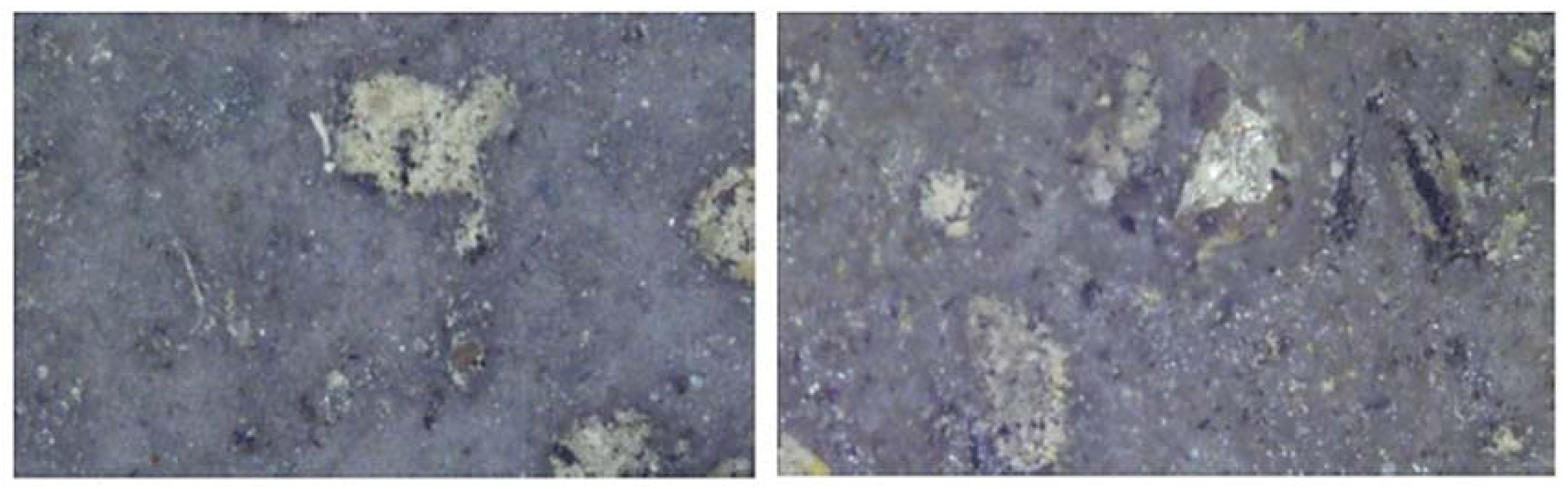

- Microscope images are a valuable tool for analyzing the structure of composite materials. They provide an opportunity to evaluate the quality of the material combination, particle distribution, and particle size. Such analyses create prospects for improving the technique of conducting experiments.

Funding

Data Availability Statement

Conflicts of Interest

References

- Barkhad, M.S.; Abu-Jdayil, B.; Iqbal, M.Z.; Mourad, A.-H.I. Thermal Insulation Using Biodegradable Poly(Lactic Acid)/Date Pit Composites. Constr. Build. Mater. 2020, 261, 120533. [Google Scholar] [CrossRef]

- Anwajler, B.; Zdybel, E.; Tomaszewska-Ciosk, E. Innovative Polymer Composites with Natural Fillers Produced by Additive Manufacturing (3D Printing)—A Literature Review. Polymers 2023, 15, 3534. [Google Scholar] [CrossRef] [PubMed]

- Veeman, D.; Sai, M.S.; Sureshkumar, P.; Jagadeesha, T.; Natrayan, L.; Ravichandran, M.; Mammo, W.D. Additive Manufacturing of Biopolymers for Tissue Engineering and Regenerative Medicine: An Overview, Potential Applications, Advancements, and Trends. Int. J. Polym. Sci. 2021, 2021, 4907027. [Google Scholar] [CrossRef]

- Arifin, N.; Sudin, I.; Ngadiman, N.H.A.; Ishak, M.S.A. A Comprehensive Review of Biopolymer Fabrication in Additive Manufacturing Processing for 3D-Tissue-Engineering Scaffolds. Polymers 2022, 14, 2119. [Google Scholar] [CrossRef] [PubMed]

- Sen, S.; Singh, A.; Bera, C.; Roy, S.; Kailasam, K. Recent Developments in Biomass Derived Cellulose Aerogel Materials for Thermal Insulation Application: A Review. Cellulose 2022, 29, 4805–4833. [Google Scholar] [CrossRef]

- Massoudinejad, M.; Amanidaz, N.; Santos, R.M.; Bakhshoodeh, R. Use of Municipal, Agricultural, Industrial, Construction and Demolition Waste in Thermal and Sound Building Insulation Materials: A Review Article. J. Environ. Health Sci. Eng. 2019, 17, 1227–1242. [Google Scholar] [CrossRef]

- Capêto, A.P.; Jesus, M.; Uribe, B.E.B.; Guimarães, A.S.; Oliveira, A.L.S. Building a Greener Future: Advancing Concrete Production Sustainability and the Thermal Properties of 3D-Printed Mortars. Buildings 2024, 14, 1323. [Google Scholar] [CrossRef]

- Özçelikci, E.; Oskay, A.; Bayer, İ.R.; Şahmaran, M. Eco-Hybrid Cement-Based Building Insulation Materials as a Circular Economy Solution to Construction and Demolition Waste. Cem. Concr. Compos. 2023, 141, 105149. [Google Scholar] [CrossRef]

- Lu, X.; Liu, B.; Zhang, Q.; Wen, Q.; Wang, S.; Xiao, K.; Zhang, S. Recycling of Coal Fly Ash in Building Materials: A Review. Minerals 2022, 13, 25. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.-H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, State-of-the-Art and Renewable Thermal Building Insulation Materials: An Overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Baino, F.; Ferraris, M. Production and Characterization of Ceramic Foams Derived from Vitrified Bottom Ashes. Mater. Lett. 2019, 236, 281–284. [Google Scholar] [CrossRef]

- Lee, S.W.; Lim, C.H.; Salleh, E.I. Bin Reflective Thermal Insulation Systems in Building: A Review on Radiant Barrier and Reflective Insulation. Renew. Sustain. Energy Rev. 2016, 65, 643–661. [Google Scholar] [CrossRef]

- Dhangar, M.; Chaturvedi, K.; Mili, M.; Patel, S.S.; Khan, M.A.; Bhargaw, H.N.; Srivastava, A.K.; Verma, S. Emerging 3D Printed Thermal Insulating Materials for Sustainable Approach: A Review and a Way Forward. Polym. Adv. Technol. 2023, 34, 1425–1434. [Google Scholar] [CrossRef]

- Al-Homoud, M.S. Performance Characteristics and Practical Applications of Common Building Thermal Insulation Materials. Build. Environ. 2005, 40, 353–366. [Google Scholar] [CrossRef]

- Kisilewicz, T.; Fedorczak-Cisak, M.; Barkanyi, T. Active Thermal Insulation as an Element Limiting Heat Loss through External Walls. Energy Build. 2019, 205, 109541. [Google Scholar] [CrossRef]

- Fang, Z.; Li, N.; Li, B.; Luo, G.; Huang, Y. The Effect of Building Envelope Insulation on Cooling Energy Consumption in Summer. Energy Build. 2014, 77, 197–205. [Google Scholar] [CrossRef]

- Cai, S.; Zhang, B.; Cremaschi, L. Review of Moisture Behavior and Thermal Performance of Polystyrene Insulation in Building Applications. Build. Environ. 2017, 123, 50–65. [Google Scholar] [CrossRef]

- Dylewski, R.; Adamczyk, J. Optimum Thickness of Thermal Insulation with Both Economic and Ecological Costs of Heating and Cooling. Energies 2021, 14, 3835. [Google Scholar] [CrossRef]

- Khalaf, Y.; El Hage, P.; Dimitrova Mihajlova, J.; Bergeret, A.; Lacroix, P.; El Hage, R. Influence of Agricultural Fibers Size on Mechanical and Insulating Properties of Innovative Chitosan-Based Insulators. Constr. Build. Mater. 2021, 287, 123071. [Google Scholar] [CrossRef]

- Mugahed Amran, Y.H.; El-Zeadani, M.; Huei Lee, Y.; Yong Lee, Y.; Murali, G.; Feduik, R. Design Innovation, Efficiency and Applications of Structural Insulated Panels: A Review. Structures 2020, 27, 1358–1379. [Google Scholar] [CrossRef]

- Li, C.; Yang, Y.; Xu, G.; Zhou, Y.; Jia, M.; Zhong, S.; Gao, Y.; Park, C.; Liu, Q.; Wang, Y.; et al. Insulating Materials for Realising Carbon Neutrality: Opportunities, Remaining Issues and Challenges. High Voltage 2022, 7, 610–632. [Google Scholar] [CrossRef]

- de Rubeis, T.; Ciccozzi, A.; Paoletti, D.; Ambrosini, D. 3D Printing for Energy Optimization of Building Envelope—Experimental Results. Heliyon 2024, 10, e31107. [Google Scholar] [CrossRef] [PubMed]

- Manohar, K.; Ramlakhan, D.; Kochhar, G.; Haldar, S. Biodegradable Fibrous Thermal Insulation. J. Braz. Soc. Mech. Sci. Eng. 2006, 28, 45–47. [Google Scholar] [CrossRef]

- Voet, V.S.D.; Guit, J.; Loos, K. Sustainable Photopolymers in 3D Printing: A Review on Biobased, Biodegradable, and Recyclable Alternatives. Macromol. Rapid Commun. 2021, 42, e2000475. [Google Scholar] [CrossRef] [PubMed]

- Guggenbiller, G.; Brooks, S.; King, O.; Constant, E.; Merckle, D.; Weems, A.C. 3D Printing of Green and Renewable Polymeric Materials: Toward Greener Additive Manufacturing. ACS Appl. Polym. Mater. 2023, 5, 3201–3229. [Google Scholar] [CrossRef]

- Macek, D.; Kosina, M. Analysis of the Structure of Heat Losses from Buildings and Benefits of Thermal Insulation Systems. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1165, 012004. [Google Scholar] [CrossRef]

- Ranjan, R.; Kumar, D.; Kundu, M.; Chandra Moi, S. A Critical Review on Classification of Materials Used in 3D Printing Process. Mater. Today Proc. 2022, 61, 43–49. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An Overview on 3D Printing Technology: Technological, Materials, and Applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Khan, N.; Riccio, A. A Systematic Review of Design for Additive Manufacturing of Aerospace Lattice Structures: Current Trends and Future Directions. Prog. Aerosp. Sci. 2024, 149, 101021. [Google Scholar] [CrossRef]

- Suntharalingam, T.; Upasiri, I.; Gatheeshgar, P.; Poologanathan, K.; Nagaratnam, B.; Santos, P.; Rajanayagam, H. Energy Performance of 3D-Printed Concrete Walls: A Numerical Study. Buildings 2021, 11, 432. [Google Scholar] [CrossRef]

- Kaszynka, M.; Olczyk, N.; Techman, M.; Skibicki, S.; Zielinski, A.; Filipowicz, K.; Wroblewski, T.; Hoffmann, M. Thermal-Humidity Parameters of 3D Printed Wall. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 082018. [Google Scholar] [CrossRef]

- Mihalache, A.; Hriţuc, A.; Boca, M.; Oroian, B.; Condrea, I.; Botezatu, C.; Slătineanu, L. Thermal Insulation Capacity of a 3D Printed Material. Macromol. Symp. 2021, 396, 2000286. [Google Scholar] [CrossRef]

- Alkhalidi, A.; Hatuqay, D. Energy Efficient 3D Printed Buildings: Material and Techniques Selection Worldwide Study. J. Build. Eng. 2020, 30, 101286. [Google Scholar] [CrossRef]

- Bi, X.; Huang, R. 3D Printing of Natural Fiber and Composites: A State-of-the-Art Review. Mater. Des. 2022, 222, 111065. [Google Scholar] [CrossRef]

- Feng, C.; Yu, S.-S. 3D Printing of Thermal Insulating Polyimide/Cellulose Nanocrystal Composite Aerogels with Low Dimensional Shrinkage. Polymers 2021, 13, 3614. [Google Scholar] [CrossRef]

- Anwajler, B.; Zielińska, S.; Witek-Krowiak, A. Innovative Cellular Insulation Barrier on the Basis of Voronoi Tessellation—Influence of Internal Structure Optimization on Thermal Performance. Materials 2024, 17, 1578. [Google Scholar] [CrossRef]

- Dey, D.; Panda, B. An Experimental Study of Thermal Performance of 3D Printed Concrete Slabs. Mater. Lett. 2023, 330, 133273. [Google Scholar] [CrossRef]

- Nemova, D.; Kotov, E.; Andreeva, D.; Khorobrov, S.; Olshevskiy, V.; Vasileva, I.; Zaborova, D.; Musorina, T. Experimental Study on the Thermal Performance of 3D-Printed Enclosing Structures. Energies 2022, 15, 4230. [Google Scholar] [CrossRef]

- Bedarf, P.; Dutto, A.; Zanini, M.; Dillenburger, B. Foam 3D Printing for Construction: A Review of Applications, Materials, and Processes. Autom. Constr. 2021, 130, 103861. [Google Scholar] [CrossRef]

- Lebedevaite, M.; Ostrauskaite, J.; Skliutas, E.; Malinauskas, M. Photoinitiator Free Resins Composed of Plant-Derived Monomers for the Optical µ-3D Printing of Thermosets. Polymers 2019, 11, 116. [Google Scholar] [CrossRef]

- Wu, Y.; Advincula, P.A.; Giraldo-Londoño, O.; Yu, Y.; Xie, Y.; Chen, Z.; Huang, G.; Tour, J.M.; Lin, J. Sustainable 3D Printing of Recyclable Biocomposite Empowered by Flash Graphene. ACS Nano 2022, 16, 17326–17335. [Google Scholar] [CrossRef] [PubMed]

- Lorente, S.; Petit, M.; Javelas, R. Simplified Analytical Model for Thermal Transfer in Vertical Hollow Brick. Energy Build. 1996, 24, 95–103. [Google Scholar] [CrossRef]

- Stefanizzi, P.; Lippolis, A.; Liuzzi, S. Experimental and numerical analysis of heat transfer in the cavities of hollow blocks. Int. J. Heat Technol. 2013, 31, 149–154. [Google Scholar] [CrossRef]

- Al-Tamimi, A.S.; Baghabra Al-Amoudi, O.S.; Al-Osta, M.A.; Ali, M.R.; Ahmad, A. Effect of Insulation Materials and Cavity Layout on Heat Transfer of Concrete Masonry Hollow Blocks. Constr. Build. Mater. 2020, 254, 119300. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, X.; Li, P.; Huang, G.; Feng, S.; Shen, C.; Han, B.; Zhang, X.; Jin, F.; Xu, F.; et al. Bioinspired Engineering of Honeycomb Structure—Using Nature to Inspire Human Innovation. Prog. Mater. Sci. 2015, 74, 332–400. [Google Scholar] [CrossRef]

- de Rubeis, T.; Ciccozzi, A.; Giusti, L.; Ambrosini, D. The 3D Printing Potential for Heat Flow Optimization: Influence of Block Geometries on Heat Transfer Processes. Sustainability 2022, 14, 15830. [Google Scholar] [CrossRef]

- de Rubeis, T. 3D-Printed Blocks: Thermal Performance Analysis and Opportunities for Insulating Materials. Sustainability 2022, 14, 1077. [Google Scholar] [CrossRef]

- de Rubeis, T.; Ciccozzi, A.; Pasqualoni, G.; Paoletti, D.; Ambrosini, D. On the Use of Waste Materials for Thermal Improvement of 3D-Printed Block—An Experimental Comparison. Buildings 2023, 13, 1136. [Google Scholar] [CrossRef]

- Grabowska, B.; Kasperski, J. The Thermal Conductivity of 3D Printed Plastic Insulation Materials—The Effect of Optimizing the Regular Structure of Closures. Materials 2020, 13, 4400. [Google Scholar] [CrossRef]

- Zhu, G.; Jing, H.; Wu, J.; Chen, S.; Gao, Y.; Yin, Q.; Yu, Z.; Qiao, Y.; Ren, J. Study on Heat Transfer Characteristics of Cement-Based Honeycomb Structures Based on Infrared Imaging. J. Build. Eng. 2023, 68, 106134. [Google Scholar] [CrossRef]

- Cuevas, K.; Strzałkowski, J.; Kim, J.-S.; Ehm, C.; Glotz, T.; Chougan, M.; Ghaffar, S.H.; Stephan, D.; Sikora, P. Towards Development of Sustainable Lightweight 3D Printed Wall Building Envelopes—Experimental and Numerical Studies. Case Stud. Constr. Mater. 2023, 18, e01945. [Google Scholar] [CrossRef]

- Witek-Krowiak, A.; Szopa, D.; Anwajler, B. Advanced Packaging Techniques—A Mini-Review of 3D Printing Potential. Materials 2024, 17, 2997. [Google Scholar] [CrossRef] [PubMed]

- Anwajler, B.; Szołomicki, J.; Noszczyk, P.; Baryś, M. The Potential of 3D Printing in Thermal Insulating Composite Materials—Experimental Determination of the Impact of the Geometry on Thermal Resistance. Materials 2024, 17, 1202. [Google Scholar] [CrossRef] [PubMed]

- Anwajler, B. The Thermal Properties of a Prototype Insulation with a Gyroid Structure—Optimization of the Structure of a Cellular Composite Made Using SLS Printing Technology. Materials 2022, 15, 1352. [Google Scholar] [CrossRef] [PubMed]

- Anwajler, B.; Witek-Krowiak, A. Three-Dimensional Printing of Multifunctional Composites: Fabrication, Applications, and Biodegradability Assessment. Materials 2023, 16, 7531. [Google Scholar] [CrossRef]

- Anwajler, B.; Szkudlarek, M. Właściwości Cieplne Materiałów o Strukturze TPMS Wykonanych w Technologii Druku Addytywnego SLS. Rynek Energii 2023, 1, 11–20. [Google Scholar]

- Anwajler, B.; Piwowar, A. Bioniczny Kompozyt Komórkowy o Właściwościach Izolacyjnych Wykonany w Technologii Addytywnej SLS. Izolacje 2023, 28, 116–123. [Google Scholar]

- Anwajler, B.; Spychaj, R.; Wójcik, P.; Piwowar, A. Doświadczalne Wyznaczenie Właściwości Cieplnych Prototypowych Materiałów Izolacyjnych Wykonanych Technologią Druku 3D. Rynek Energii 2021, 6, 44–51. [Google Scholar]

- Piwowar, A.; Anwajler, B.; Szulct, P. Właściwości Cieplne Materiałów Izolacyjnych Wykonanych w Technologii Druku 3D—Wpływ Optymalizacji Struktury Opartej Na Modelu Piany Kelvina. Rynek Energii 2024, 1, 60–68. [Google Scholar]

- Tang, L.; Shi, X.; Zhang, L.; Liu, Z.; Jiang, Z.; Liu, Y. Effects of Statistics of Cell’s Size and Shape Irregularity on Mechanical Properties of 2D and 3D Voronoi Foams. Acta Mech. 2014, 225, 1361–1372. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, J.; Wang, Z.; Song, Y.; Zhao, L. Study on the Thermal Properties of Closed-Cell Metal Foams Based on Voronoi Random Models. Numeri Heat. Transf. A Appl. 2013, 64, 1038–1049. [Google Scholar] [CrossRef]

- Chen, K.; Qin, H.; Ren, Z. Establishment of the Microstructure of Porous Materials and Its Relationship with Effective Mechanical Properties. Sci. Rep. 2023, 13, 18064. [Google Scholar] [CrossRef] [PubMed]

- Talischi, C.; Paulino, G.H.; Pereira, A.; Menezes, I.F.M. PolyMesher: A General-Purpose Mesh Generator for Polygonal Elements Written in Matlab. Struct. Multidiscip. Optim. 2012, 45, 309–328. [Google Scholar] [CrossRef]

- Wang, H.; Qin, Q.-H.; Xiao, Y. Special n -Sided Voronoi Fiber/Matrix Elements for Clustering Thermal Effect in Natural-Hemp-Fiber-Filled Cement Composites. Int. J. Heat. Mass. Transf. 2016, 92, 228–235. [Google Scholar] [CrossRef]

- Heim, D.; Mrowiec, A.; Prałat, K. Analysis and Interpretation of Results of Thermal Conductivity Obtained by the Hot Wire Method. Exp. Tech. 2016, 40, 513–519. [Google Scholar] [CrossRef]

- EN ISO 9869-1:2014; Thermal Insulation—Building Elements—In Situ Measurement of Thermal Resistance and Thermal Transmittance. Part 1: Heat Flow Meter Method. International Organization for Standardization: Geneva, Switzerland, 2014.

| M | Me | Min | Max | SD | Sk | K | |

|---|---|---|---|---|---|---|---|

| R, W/m2·K | 1.898 | 1.287 | 0.313 | 5.450 | 1.479 | 0.762 | −0.575 |

| U, (m2·K)/W | 0.778 | 0.554 | 0.171 | 1.913 | 0.593 | 0.867 | −0.726 |

| M | Me | Min | Max | SD | Sk | K | |

|---|---|---|---|---|---|---|---|

| R, W/m2·K | 4.581 | 4.434 | 2.962 | 6.273 | 0.819 | 0.428 | −0.257 |

| U, (m2·K)/W | 0.204 | 0.203 | 0.148 | 0.287 | 0.035 | 0.404 | −0.074 |

| Symbol That Identifies The Input Factors and Their Interactions | SS | df | MS | F | p |

|---|---|---|---|---|---|

| R, W/m2·K | |||||

| Absolute term | 378.563 | 1 | 378.563 | 38,558.69 | 0.000 |

| M | 2.599 | 6 | 0.433 | 44.13 | 0.000 |

| Δ | 215.4206 | 4 | 53.855 | 5485.44 | 0.000 |

| m*δ | 8.994 | 24 | 0.375 | 38.17 | |

| Absolute term | 0.6872 | 70 | 0.0098 | ||

| U, (m2·K)/W | |||||

| Absolute term | 63.5396 | 1 | 63.5396 | 77,929.07 | 0.000 |

| m | 0.2556 | 6 | 0.0426 | 52.26 | 0.000 |

| δ | 35.976 | 4 | 8.9941 | 11,030.88 | 0.000 |

| m*δ | 0.3076 | 24 | 0.0128 | 15.72 | |

| Absolute term | 0.0571 | 70 | 0.0008 | ||

| Symbol That Identifies The Input Factors and Their Interactions | SS | df | MS | F | p |

|---|---|---|---|---|---|

| R, W/m2·K | |||||

| Absolute term | 881.431 | 1 | 881.431 | 40,386.19 | 0.000 |

| m | 5.461 | 6 | 0.910 | 41.71 | 0.000 |

| n | 15.213 | 1 | 15.213 | 697.04 | 0.000 |

| m*n | 6.240 | 6 | 1.040 | 47.65 | |

| Absolute term | 0.611 | 28 | 0.022 | ||

| U, (m2·K)/W | |||||

| Absolute term | 1.7540 | 1 | 1.7540 | 30,854.14 | 0.000 |

| m | 0.0099 | 6 | 0.0017 | 29.14 | 0.000 |

| n | 0.0283 | 1 | 0.02826 | 497.03 | 0.000 |

| m*n | 0.01047 | 6 | 0.00174 | 30.68 | |

| Absolute term | 0.00159 | 28 | 0.00006 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anwajler, B. Modern Insulation Materials for Sustainability Based on Natural Fibers: Experimental Characterization of Thermal Properties. Fibers 2024, 12, 76. https://doi.org/10.3390/fib12090076

Anwajler B. Modern Insulation Materials for Sustainability Based on Natural Fibers: Experimental Characterization of Thermal Properties. Fibers. 2024; 12(9):76. https://doi.org/10.3390/fib12090076

Chicago/Turabian StyleAnwajler, Beata. 2024. "Modern Insulation Materials for Sustainability Based on Natural Fibers: Experimental Characterization of Thermal Properties" Fibers 12, no. 9: 76. https://doi.org/10.3390/fib12090076

APA StyleAnwajler, B. (2024). Modern Insulation Materials for Sustainability Based on Natural Fibers: Experimental Characterization of Thermal Properties. Fibers, 12(9), 76. https://doi.org/10.3390/fib12090076