Acid Resistance of Metakaolin-Based Geopolymers and Geopolymeric Mortars Reinforced with Coconut Fibers

Abstract

1. Introduction

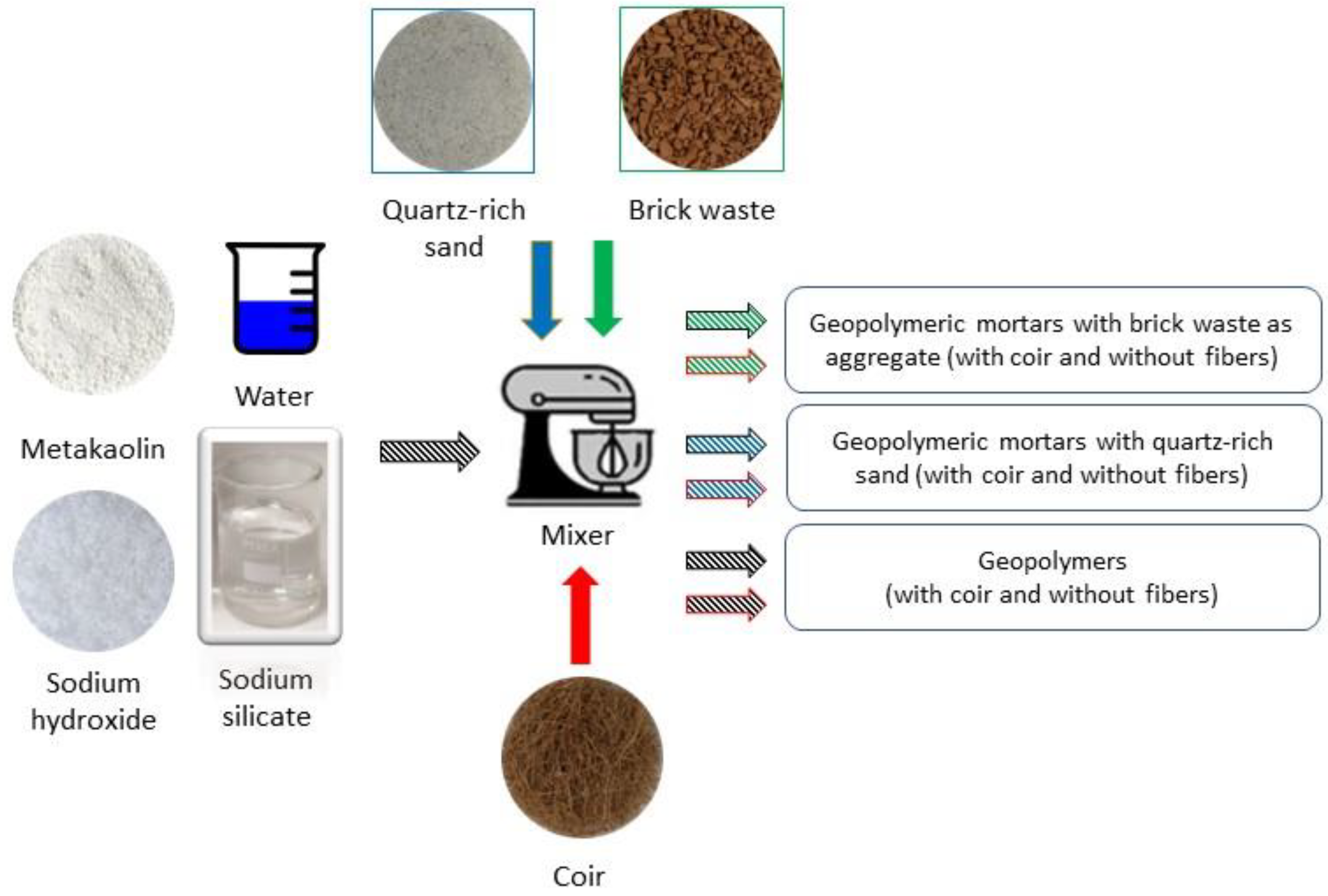

2. Materials and Methods

2.1. The Raw Materials

2.2. Specimen Preparation

2.3. Testing and Characterization

2.4. Acid Attack Tests

3. Results and Discussion

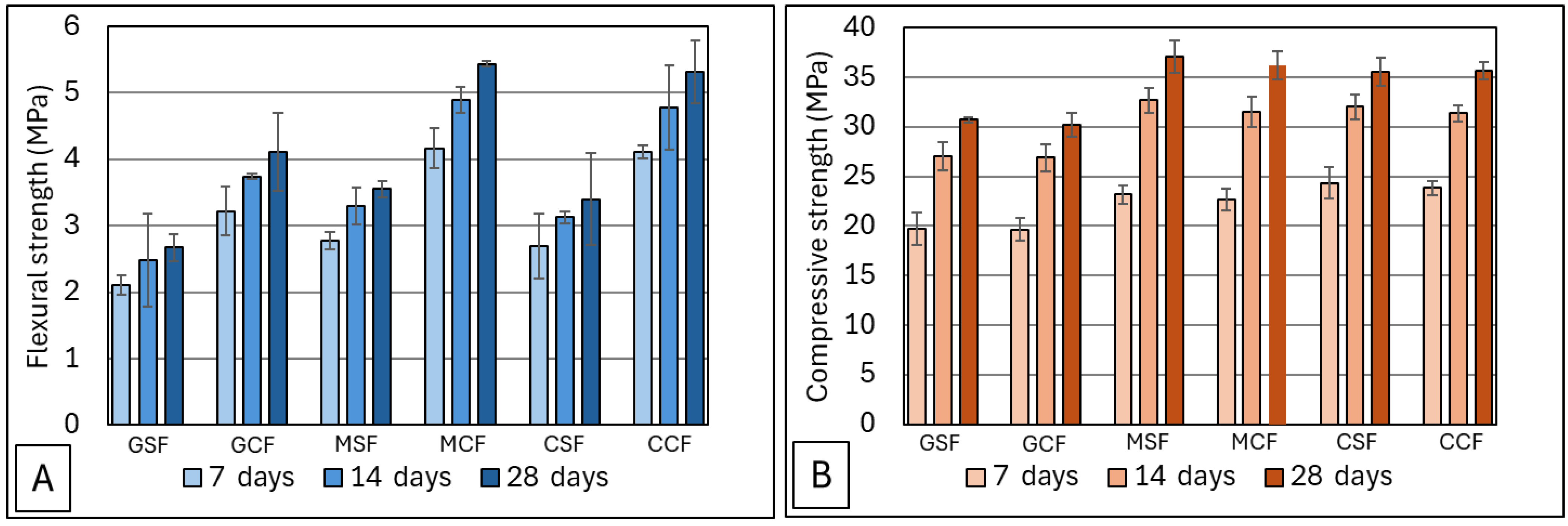

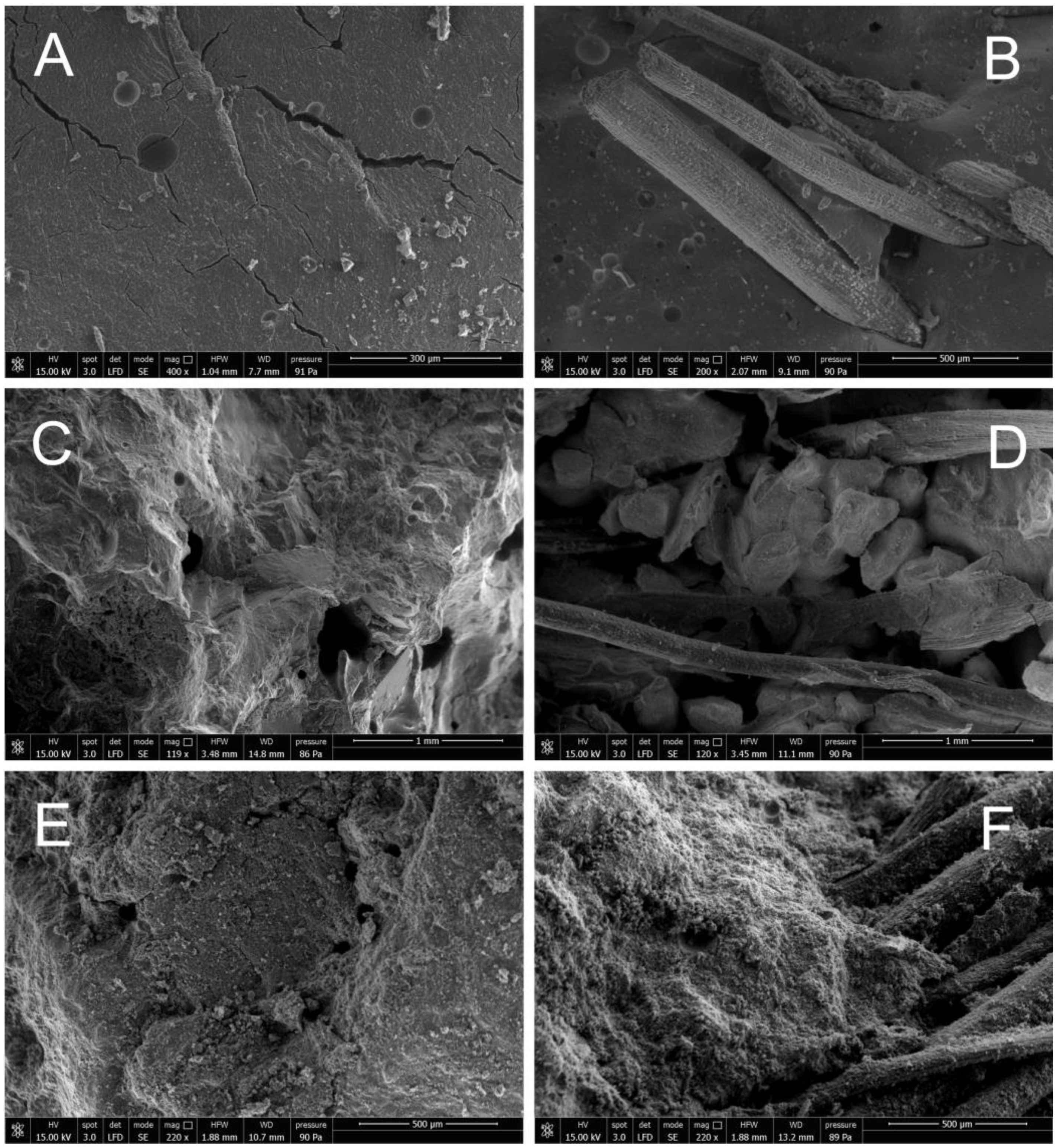

3.1. Influence of Coir Addition on the Physical and Mechanical Properties of Geopolymers and Geopolymeric Mortars

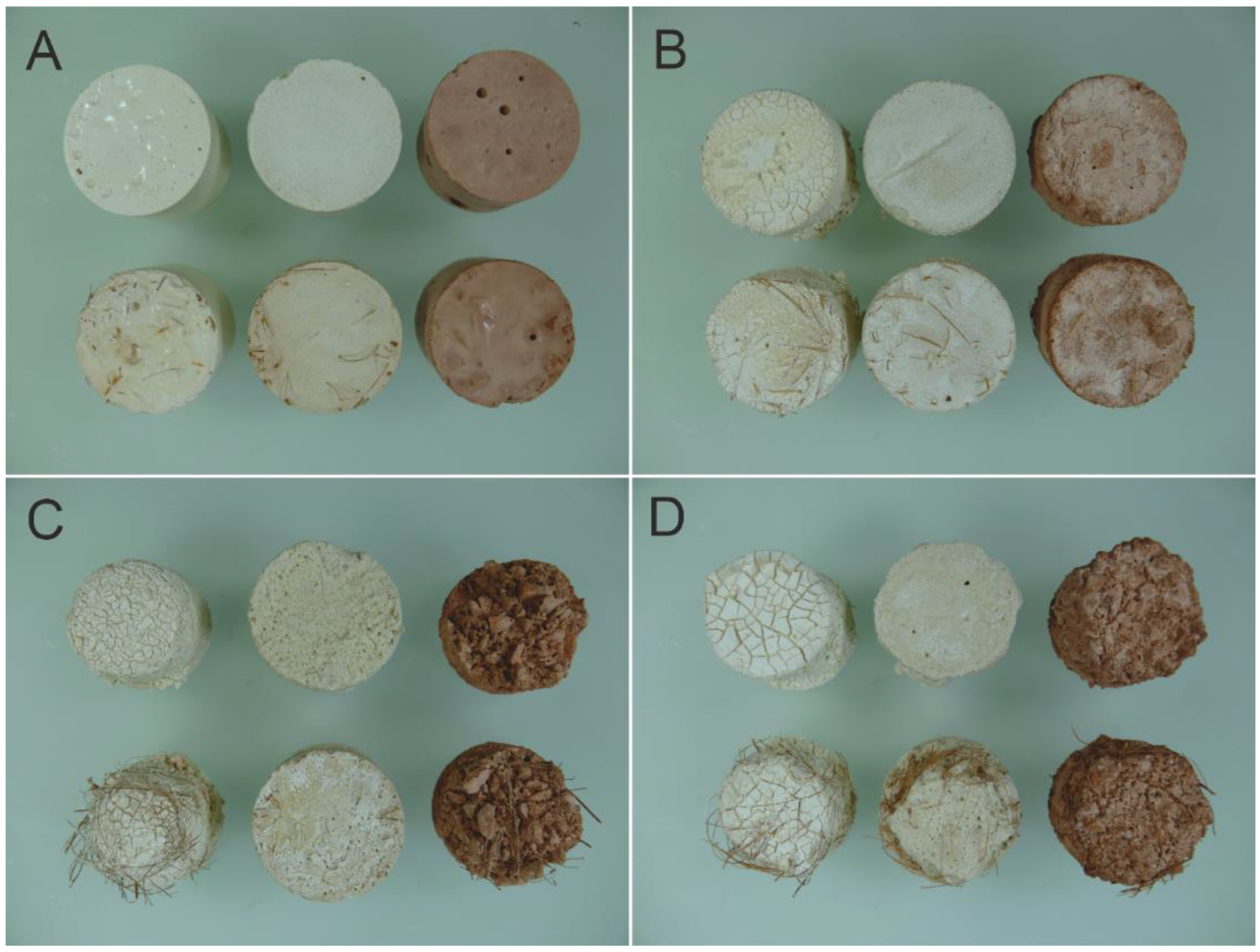

3.2. Visual Inspection after Acid Attack

3.3. Loss in Mass after Acid Attack

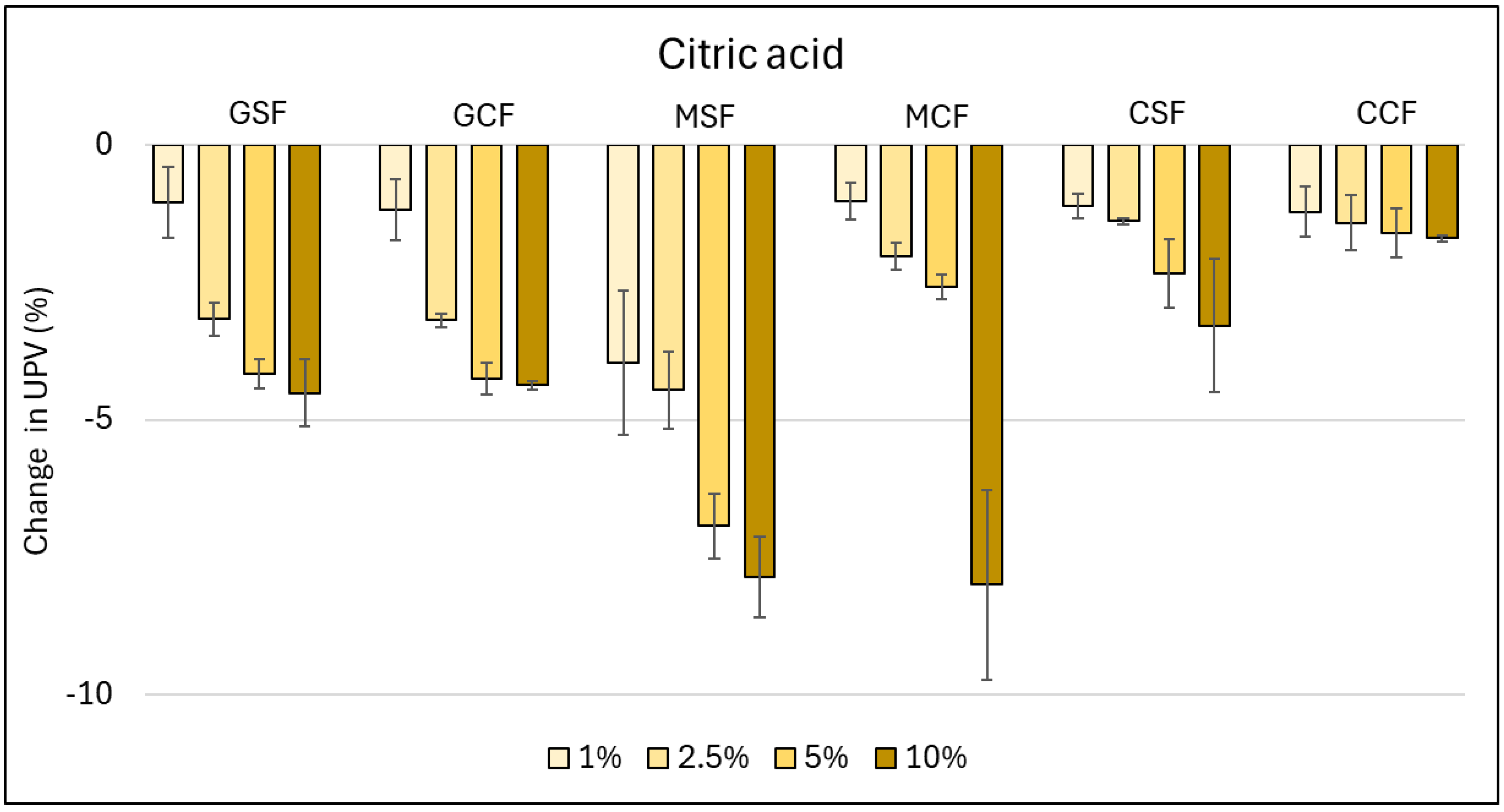

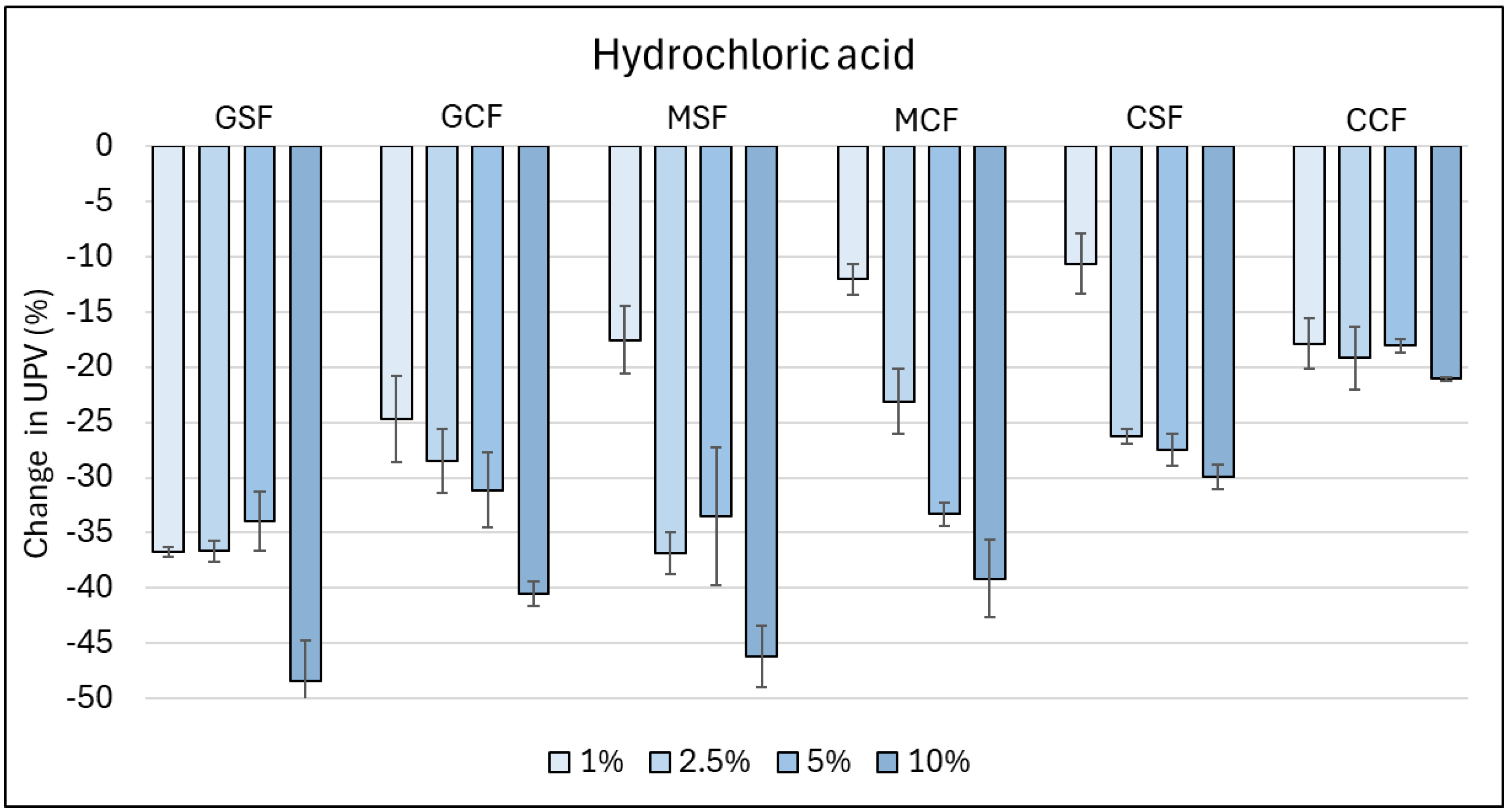

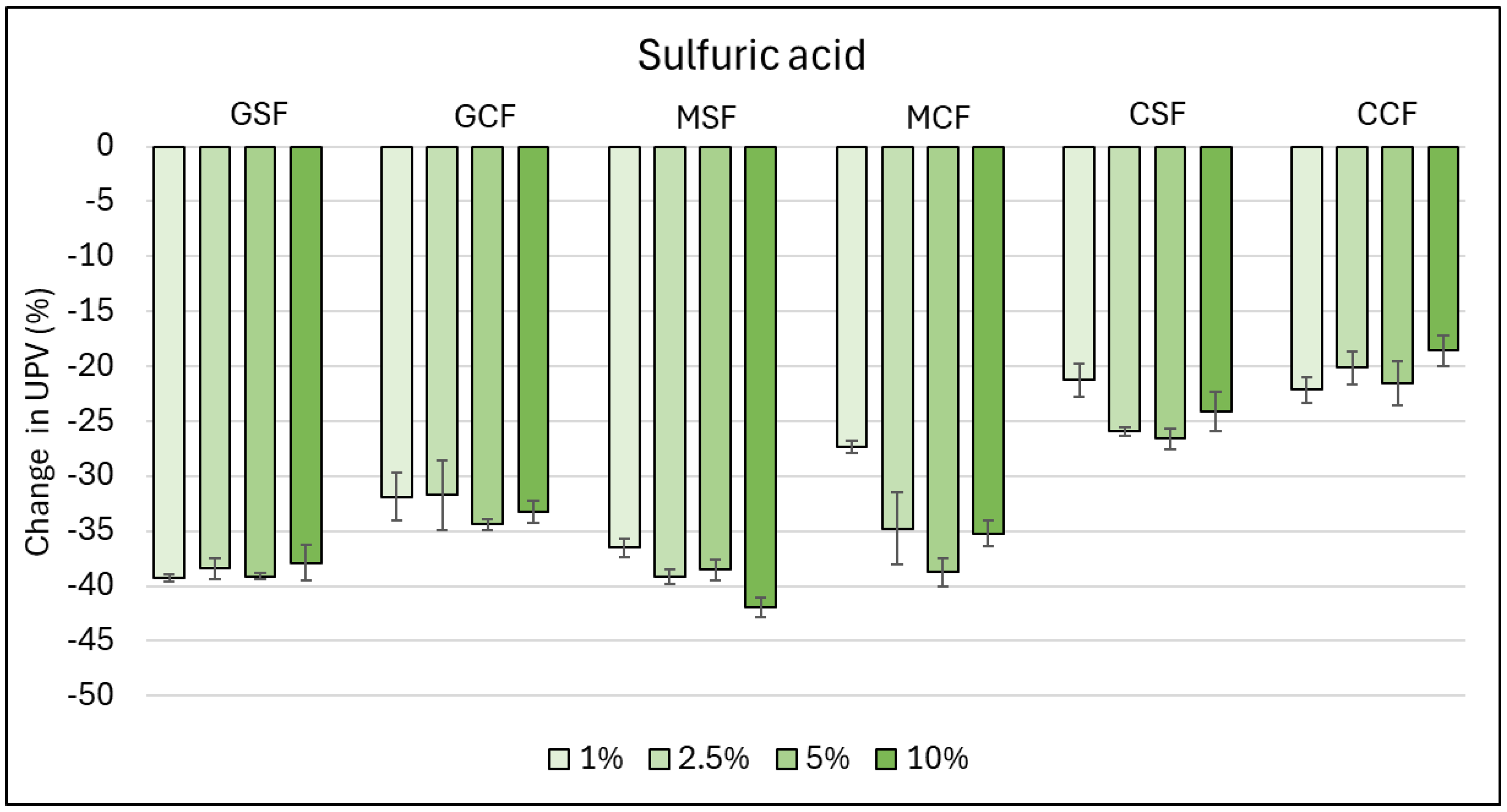

3.4. Ultrasound Pulse Velocity after Acid Attack

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Davidovits, J. Geopolymer Chemistry and Applications; Geopolymer Institute: Saint-Quentin, France, 2008. [Google Scholar]

- Aleem, M.I.A.; Arumairaj, P.D. Geopolymer concrete—A review. Int. J. Eng. Sci. Emerg. Technol. 2012, 1, 118–122. [Google Scholar] [CrossRef]

- Cong, P.; Cheng, Y. Advances in geopolymer materials: A comprehensive review. J. Traffic Transp. Eng. (Engl. Ed.) 2021, 8, 283–314. [Google Scholar] [CrossRef]

- Ricciotti, L.; Molino, A.J.; Roviello, V.; Chianese, E.; Cennamo, P.; Roviello, G. Geopolymer composites for potential applications in cultural heritage. Environments 2017, 4, 91. [Google Scholar] [CrossRef]

- Pagnotta, S.; Tenorio, A.L.; Tinè, M.R.; Lezzerini, M. Geopolymer mortar: Metakaolin-based recipe for cultural heritage application. In Proceedings of the 2020 IMEKO TC-4 International Conference on Metrology for Archaeology and Cultural Heritage, Trento, Italy, 22–24 October 2020; pp. 55–59. [Google Scholar]

- Pagnotta, S.; Lluveras Tenorio, A.; Tinè, M.R.; Aquino, A.; Lezzerini, M. Geopolymers as a potential material for preservation and restoration of Urban Build Heritage: An overview. IOP Conf. Ser. Earth Environ. Sci. 2020, 609, 12057. [Google Scholar] [CrossRef]

- Si, R.; Dai, Q.; Guo, S.; Wang, J. Mechanical property, nanopore structure and drying shrinkage of metakaolin-based geopolymer with waste glass powder. J. Clean. Prod. 2020, 242, 118502. [Google Scholar] [CrossRef]

- Bakharev, T. Resistance of geopolymer materials to acid attack. Cem. Concr. Res. 2005, 35, 658–670. [Google Scholar] [CrossRef]

- Kong, D.L.Y.; Sanjayan, J.G. Damage behavior of geopolymer composites exposed to elevated temperatures. Cem. Concr. Compos. 2008, 30, 986–991. [Google Scholar] [CrossRef]

- Nurruddin, M.F.; Sani, H.; Mohammed, B.S.; Shaaban, I. Methods of curing geopolymer concrete: A review. Int. J. Adv. Appl. Sci. 2018, 5, 31–36. [Google Scholar] [CrossRef]

- Hawa, A.; Tonnayopas, D.; Prachasaree, W.; Taneerananon, P. Development and performance evaluation of very high early strength geopolymer for rapid road repair. Adv. Mater. Sci. Eng. 2013, 2013, 764180. [Google Scholar] [CrossRef]

- Wallah, S.E. Creep behaviour of fly ash-based geopolymer concrete. Civ. Eng. Dimens. 2010, 12, 73–78. [Google Scholar]

- Sagoe-Crentsil, K.; Brown, T.; Taylor, A. Drying shrinkage and creep performance of geopolymer concrete. J. Sustain. Cem. Mater. 2013, 2, 35–42. [Google Scholar] [CrossRef]

- Chen, K.; Wu, D.; Xia, L.; Cai, Q.; Zhang, Z. Geopolymer concrete durability subjected to aggressive environments—A review of influence factors and comparison with ordinary Portland cement. Constr. Build. Mater. 2021, 279, 122496. [Google Scholar] [CrossRef]

- Niveditha, M.; Koniki, S. Effect of Durability properties on Geopolymer concrete—A Review. E3S Web Conf. 2020, 184, 1092. [Google Scholar] [CrossRef]

- Amran, M.; Al-Fakih, A.; Chu, S.H.; Fediuk, R.; Haruna, S.; Azevedo, A.; Vatin, N. Long-term durability properties of geopolymer concrete: An in-depth review. Case Stud. Constr. Mater. 2021, 15, e00661. [Google Scholar] [CrossRef]

- Siddique, R.; Klaus, J. Influence of metakaolin on the properties of mortar and concrete: A review. Appl. Clay Sci. 2009, 43, 392–400. [Google Scholar] [CrossRef]

- Jindal, B.B.; Alomayri, T.; Hasan, A.; Kaze, C.R. Geopolymer concrete with metakaolin for sustainability: A comprehensive review on raw material’s properties, synthesis, performance, and potential application. Environ. Sci. Pollut. Res. 2022, 1–26. [Google Scholar] [CrossRef] [PubMed]

- Kim, B.; Lee, S. Review on characteristics of metakaolin-based geopolymer and fast setting. J. Korean Ceram. Soc. 2020, 57, 368–377. [Google Scholar] [CrossRef]

- Lahoti, M.; Wong, K.K.; Yang, E.-H.; Tan, K.H. Effects of Si/Al molar ratio on strength endurance and volume stability of metakaolin geopolymers subject to elevated temperature. Ceram. Int. 2018, 44, 5726–5734. [Google Scholar] [CrossRef]

- Pagnotta, S.; Lezzerini, M. Comparison Between LEEB And Knoop Hardness On Metakaolin-Based Geopolymer. Atti Soc. Tosc. Sci. Nat. Mem. Ser. A 2020, 127, 67–73. [Google Scholar] [CrossRef]

- Junaid, M.T.; Kayali, O.; Khennane, A.; Black, J. A mix design procedure for low calcium alkali activated fly ash-based concretes. Constr. Build. Mater. 2015, 79, 301–310. [Google Scholar] [CrossRef]

- Pan, Z.; Tao, Z.; Cao, Y.F.; Wuhrer, R.; Murphy, T. Compressive strength and microstructure of alkali-activated fly ash/slag binders at high temperature. Cem. Concr. Compos. 2018, 86, 9–18. [Google Scholar] [CrossRef]

- Gailitis, R.; Sprince, A.; Kozlovskis, T.; Radina, L.; Pakrastins, L.; Vatin, N. Long-term properties of different fiber reinforcement effect on fly ash-based geopolymer composite. Crystals 2021, 11, 760. [Google Scholar] [CrossRef]

- Fan, F.; Liu, Z.; Xu, G.; Peng, H.; Cai, C.S. Mechanical and thermal properties of fly ash based geopolymers. Constr. Build. Mater. 2018, 160, 66–81. [Google Scholar] [CrossRef]

- Zhang, G.; He, J.; Gambrell, R.P. Synthesis, characterization, and mechanical properties of red mud–based geopolymers. Transp. Res. Rec. 2010, 2167, 1–9. [Google Scholar] [CrossRef]

- Qaidi, S.M.A.; Tayeh, B.A.; Ahmed, H.U.; Emad, W. A review of the sustainable utilisation of red mud and fly ash for the production of geopolymer composites. Constr. Build. Mater. 2022, 350, 128892. [Google Scholar] [CrossRef]

- Kumar, A.; Saravanan, T.J.; Bisht, K.; Kabeer, K.I.S.A. A review on the utilization of red mud for the production of geopolymer and alkali activated concrete. Constr. Build. Mater. 2021, 302, 124170. [Google Scholar] [CrossRef]

- Cheng, T.-W.; Chiu, J.P. Fire-resistant geopolymer produced by granulated blast furnace slag. Miner. Eng. 2003, 16, 205–210. [Google Scholar] [CrossRef]

- Qaidi, S.M.A.; Tayeh, B.A.; Isleem, H.F.; de Azevedo, A.R.G.; Ahmed, H.U.; Emad, W. Sustainable utilization of red mud waste (bauxite residue) and slag for the production of geopolymer composites: A review. Case Stud. Constr. Mater. 2022, 16, e00994. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, Z.; Wang, J.; Guo, J.; Hu, S.; Ling, Y. Properties of fresh and hardened fly ash/slag based geopolymer concrete: A review. J. Clean. Prod. 2020, 270, 122389. [Google Scholar] [CrossRef]

- Djobo, J.N.Y.; Elimbi, A.; Tchakouté, H.K.; Kumar, S. Mechanical properties and durability of volcanic ash based geopolymer mortars. Constr. Build. Mater. 2016, 124, 606–614. [Google Scholar] [CrossRef]

- Pulidori, E.; Lluveras-Tenorio, A.; Carosi, R.; Bernazzani, L.; Duce, C.; Pagnotta, S.; Lezzerini, M.; Barone, G.; Mazzoleni, P.; Tiné, M.R. Building geopolymers for CuHe part I: Thermal properties of raw materials as precursors for geopolymers. J. Therm. Anal. Calorim. 2022, 147, 5323–5335. [Google Scholar] [CrossRef]

- Pelosi, C.; Occhipinti, R.; Finocchiaro, C.; Lanzafame, G.; Pulidori, E.; Lezzerini, M.; Barone, G.; Mazzoleni, P.; Tiné, M.R. Thermal and morphological investigations of alkali activated materials based on Sicilian volcanic precursors (Italy). Mater. Lett. 2023, 335, 133773. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Magbool, H.M.; Tayeh, B.A.; de Azevedo, A.R.G.; Abutaleb, A.; Hussain, Q. Production of geopolymer concrete by utilizing volcanic pumice dust. Case Stud. Constr. Mater. 2022, 16, e00802. [Google Scholar] [CrossRef]

- Çelik, A.İ.; Tunç, U.; Bahrami, A.; Karalar, M.; Mydin, M.A.O.; Alomayri, T.; Özkılıç, Y.O. Use of waste glass powder toward more sustainable geopolymer concrete. J. Mater. Res. Technol. 2023, 24, 8533–8546. [Google Scholar] [CrossRef]

- Xiao, R.; Huang, B.; Zhou, H.; Ma, Y.; Jiang, X. A state-of-the-art review of crushed urban waste glass used in OPC and AAMs (geopolymer): Progress and challenges. Clean. Mater. 2022, 4, 100083. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Heniegal, A.M.; Abdellatief, M.; Tayeh, B.A.; Abd Elrahman, M. Properties of ultra-high performance geopolymer concrete incorporating recycled waste glass. Case Stud. Constr. Mater. 2022, 17, e01393. [Google Scholar] [CrossRef]

- He, X.; Yuhua, Z.; Qaidi, S.; Isleem, H.F.; Zaid, O.; Althoey, F.; Ahmad, J. Mine tailings-based geopolymers: A comprehensive review. Ceram. Int. 2022, 48, 24192–24212. [Google Scholar] [CrossRef]

- Zhang, N.; Hedayat, A.; Figueroa, L.; Steirer, K.X.; Li, L.; Sosa, H.G.B. Physical, mechanical, cracking, and damage properties of mine tailings-based geopolymer: Experimental and numerical investigations. J. Build. Eng. 2023, 75, 107075. [Google Scholar] [CrossRef]

- Qaidi, S.M.A.; Tayeh, B.A.; Zeyad, A.M.; de Azevedo, A.R.G.; Ahmed, H.U.; Emad, W. Recycling of mine tailings for the geopolymers production: A systematic review. Case Stud. Constr. Mater. 2022, 16, e00933. [Google Scholar] [CrossRef]

- Gu, F.; Xie, J.; Vuye, C.; Wu, Y.; Zhang, J. Synthesis of geopolymer using alkaline activation of building-related construction and demolition wastes. J. Clean. Prod. 2023, 420, 138335. [Google Scholar] [CrossRef]

- Ozcelikci, E.; Kul, A.; Gunal, M.F.; Ozel, B.F.; Yildirim, G.; Ashour, A.; Sahmaran, M. A comprehensive study on the compressive strength, durability-related parameters and microstructure of geopolymer mortars based on mixed construction and demolition waste. J. Clean. Prod. 2023, 396, 136522. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber-reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Camargo, M.M.; Adefrs Taye, E.; Roether, J.A.; Tilahun Redda, D.; Boccaccini, A.R. A review on natural fiber-reinforced geopolymer and cement-based composites. Materials 2020, 13, 4603. [Google Scholar] [CrossRef] [PubMed]

- Samal, S.; Blanco, I. An Application Review of Fiber-Reinforced Geopolymer Composite. Fibers 2021, 9, 23. [Google Scholar] [CrossRef]

- Korniejenko, K.; Łach, M.; Mikuła, J. The influence of short coir, glass and carbon fibers on the properties of composites with geopolymer matrix. Materials 2021, 14, 4599. [Google Scholar] [CrossRef] [PubMed]

- Silva, G.; Kim, S.; Aguilar, R.; Nakamatsu, J. Natural fibers as reinforcement additives for geopolymers—A review of potential eco-friendly applications to the construction industry. Sustain. Mater. Technol. 2020, 23, e00132. [Google Scholar] [CrossRef]

- Furtos, G.; Molnar, L.; Silaghi-Dumitrescu, L.; Pascuta, P.; Korniejenko, K. Mechanical and thermal properties of wood fiber reinforced geopolymer composites. J. Nat. Fibers 2022, 19, 6676–6691. [Google Scholar] [CrossRef]

- Sá Ribeiro, M.G.; Sá Ribeiro, M.G.; Keane, P.F.; Sardela, M.R.; Kriven, W.M.; Sá Ribeiro, R.A. Acid resistance of metakaolin-based, bamboo fiber geopolymer composites. Constr. Build. Mater. 2021, 302, 124194. [Google Scholar] [CrossRef]

- Natali Murri, A.; Medri, V.; Landi, E. Production and thermomechanical characterization of wool–geopolymer composites. J. Am. Ceram. Soc. 2017, 100, 2822–2831. [Google Scholar] [CrossRef]

- Zhong, H.; Zhang, M. Engineered geopolymer composites: A state-of-the-art review. Cem. Concr. Compos. 2023, 135, 104850. [Google Scholar] [CrossRef]

- Zhang, X.; Bai, C.; Qiao, Y.; Wang, X.; Jia, D.; Li, H.; Colombo, P. Porous geopolymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2021, 150, 106629. [Google Scholar] [CrossRef]

- Shaikh, F.U.A. Review of mechanical properties of short fibre reinforced geopolymer composites. Constr. Build. Mater. 2013, 43, 37–49. [Google Scholar] [CrossRef]

- Farhan, K.Z.; Johari, M.A.M.; Demirboğa, R. Impact of fiber reinforcements on properties of geopolymer composites: A review. J. Build. Eng. 2021, 44, 102628. [Google Scholar] [CrossRef]

- Ali, B.; Hawreen, A.; Ben Kahla, N.; Talha Amir, M.; Azab, M.; Raza, A. A critical review on the utilization of coir (coconut fiber) in cementitious materials. Constr. Build. Mater. 2022, 351, 128957. [Google Scholar] [CrossRef]

- Amalia, F.; Akifah, N. Development of coconut trunk fiber geopolymer hybrid composite for structural engineering materials. IOP Conf. Ser. Mater. Sci. Eng. 2017, 180, 12014. [Google Scholar] [CrossRef]

- Zakaria, M.; Ahmed, M.; Hoque, M.M.; Islam, S. Scope of using jute fiber for the reinforcement of concrete material. Text. Cloth. Sustain. 2017, 2, 123. [Google Scholar] [CrossRef]

- Driouich, A.; Chajri, F.; El Hassani, S.E.A.; Britel, O.; Belouafa, S.; Khabbazi, A.; Chaair, H. Optimization synthesis geopolymer based mixture metakaolin and fly ash activated by alkaline solution. J. Non. Cryst. Solids 2020, 544, 120197. [Google Scholar] [CrossRef]

- Liu, J.; Doh, J.-H.; Dinh, H.L.; Ong, D.E.L.; Zi, G.; You, I. Effect of Si/Al molar ratio on the strength behavior of geopolymer derived from various industrial waste: A current state of the art review. Constr. Build. Mater. 2022, 329, 127134. [Google Scholar] [CrossRef]

- Li, N.; Shi, C.; Zhang, Z.; Wang, H.; Liu, Y. A review on mixture design methods for geopolymer concrete. Compos. Part B Eng. 2019, 178, 107490. [Google Scholar] [CrossRef]

- Bouguermouh, K.; Bouzidi, N.; Mahtout, L.; Pérez-Villarejo, L.; Martínez-Cartas, M.L. Effect of acid attack on microstructure and composition of metakaolin-based geopolymers: The role of alkaline activator. J. Non. Cryst. Solids 2017, 463, 128–137. [Google Scholar] [CrossRef]

- Lezzerini, M.; Tamponi, M.; Bertoli, M. Reproducibility, precision and trueness of X-ray fluorescence data for mineralogical and/or petrographic purposes. Atti Soc. Tosc. Sci. Nat. Mem. Ser. A 2013, 120, 67–73. [Google Scholar] [CrossRef]

- Lezzerini, M.; Tamponi, M.; Bertoli, M. Calibration of XRF data on silicate rocks using chemicals as in-house standards. Atti Soc. Tosc. Sci. Nat. Mem. Ser. A 2014, 121, 65–70. [Google Scholar]

- EN 1925; Natural Stone Test Methods—Determination of Water Absorption Coefficient by Capillary. European Committee for Standardization (CEN): Brussels, Belgium, 1999.

- EN 1936; Natural Stone Test Methods—Determination of Real Density and Apparent Density, and of Total and Open Porosity. European Committee for Standardization (CEN): Brussels, Belgium, 2006.

- Franzini, M.; Lezzerini, M. A mercury-displacement method for stone bulk-density determinations. Eur. J. Mineral. 2003, 15, 225–229. [Google Scholar] [CrossRef]

- Trincal, V.; Benavent, V.; Lahalle, H.; Balsamo, B.; Samson, G.; Patapy, C.; Jainin, Y.; Cyr, M. Effect of drying temperature on the properties of alkali-activated binders-Recommendations for sample preconditioning. Cem. Concr. Res. 2022, 151, 106617. [Google Scholar] [CrossRef]

- EN 1015-11; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. European Committee for Standardization (CEN): Brussels, Belgium, 2019; pp. 1–15.

- EN 12504-4; Testing Concrete—Part 4: Determination of Ultrasonic Pulse Velocity. European Committee for Standardization (CEN): Brussels, Belgium, 2004.

- Ayeni, O.; Mahamat, A.A.; Bih, N.L.; Stanislas, T.T.; Isah, I.; Savastano Junior, H.; Boakye, E.; Onwualu, A.P. Effect of Coir Fiber Reinforcement on Properties of Metakaolin-Based Geopolymer Composite. Appl. Sci. 2022, 12, 5478. [Google Scholar] [CrossRef]

- Korniejenko, K.; Frączek, E.; Pytlak, E.; Adamski, M. Mechanical properties of geopolymer composites reinforced with natural fibers. Procedia Eng. 2016, 151, 388–393. [Google Scholar] [CrossRef]

- Papa, E.; Medri, V.; Landi, E.; Ballarin, B.; Miccio, F. Production and characterization of geopolymers based on mixed compositions of metakaolin and coal ashes. Mater. Des. 2014, 56, 409–415. [Google Scholar] [CrossRef]

- Qu, F.; Li, W.; Wang, K.; Zhang, S.; Sheng, D. Performance deterioration of fly ash/slag-based geopolymer composites subjected to coupled cyclic preloading and sulfuric acid attack. J. Clean. Prod. 2021, 321, 128942. [Google Scholar] [CrossRef]

- Duan, P.; Yan, C.; Zhou, W.; Luo, W.; Shen, C. An investigation of the microstructure and durability of a fluidized bed fly ash-metakaolin geopolymer after heat and acid exposure. Mater. Des. 2015, 74, 125–137. [Google Scholar] [CrossRef]

- Vasanelli, E.; Colangiuli, D.; Calia, A.; Sileo, M.; Aiello, M.A. Ultrasonic pulse velocity for the evaluation of physical and mechanical properties of a highly porous building limestone. Ultrasonics 2015, 60, 33–40. [Google Scholar] [CrossRef]

| Sample | Materials |

|---|---|

| GSF | Geopolymer without fiber |

| GCF | Geopolymer with coconut fiber |

| MSF | Sand mortar without fiber |

| MCF | Sand mortar with coconut fiber |

| CSF | Brick waste mortar without fiber |

| CCF | Brick waste mortar with coconut fiber |

| Sample | LOI | Na2O | MgO | Al2O3 | SiO2 | P2O5 | SO3 | K2O | CaO | TiO2 | MnO | Fe2O3 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MK | 0.68 | 0.24 | 0.10 | 43.64 | 52.84 | 0.06 | 0.10 | 0.16 | 0.03 | 1.72 | <0.01 | 0.43 |

| WB | 0.71 | 0.47 | 0.96 | 19.47 | 65.05 | 0.16 | 0.71 | 2.88 | 1.13 | 0.87 | 0.11 | 7.48 |

| QS | 0.33 | 0.10 | 0.22 | 3.16 | 94.57 | 0.03 | 0.01 | 1.34 | 0.06 | 0.05 | 0.01 | 0.12 |

| Sample | γd | AbW | Abv | P | SI |

|---|---|---|---|---|---|

| g/cm3 | wt. % | vol. % | vol. % | ||

| GSF | 1.335 | 29.26 | 39.15 | 41.82 | 94 |

| 0.005 | 0.06 | 0.08 | 0.23 | 1 | |

| GCF | 1.314 | 29.57 | 38.67 | 43.14 | 90 |

| 0.004 | 0.22 | 0.20 | 0.18 | 1 | |

| MSF | 1.789 | 11.71 | 21.06 | 28.35 | 74 |

| 0.007 | 0.18 | 0.16 | 0.74 | 2 | |

| MCF | 1.790 | 12.27 | 22.12 | 28.17 | 79 |

| 0.006 | 0.07 | 0.47 | 0.54 | 3 | |

| CSF | 1.618 | 17.7 | 28.72 | 35.36 | 81 |

| 0.004 | 0.72 | 1.07 | 0.21 | 3 | |

| CCF | 1.617 | 18.84 | 30.41 | 35.68 | 85 |

| 0.003 | 0.17 | 0.34 | 0.19 | 1 |

| Sample | Citric Acid | Hydrochloric Acid | Sulfuric Acid | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1% | 2.5% | 5% | 10% | 1% | 2.5% | 5% | 10% | 1% | 2.5% | 5% | 10% | |

| (wt. %) | (wt. %) | (wt. %) | (wt. %) | (wt. %) | (wt. %) | (wt. %) | (wt. %) | (wt. %) | (wt. %) | (wt. %) | (wt. %) | |

| GSF | −1.16 | −1.35 | −1.87 | −2.62 | −2.74 | −5.96 | 14.13 | 22.24 | −4.41 | −8.72 | 18.20 | 26.09 |

| 0.16 | 0.08 | 0.07 | 0.28 | 0.62 | 0.23 | 0.89 | 0.31 | 0.29 | 0.37 | 0.23 | 1.08 | |

| GCF | −0.93 | −1.23 | −1.84 | −2.65 | −4.89 | −7.61 | 15.40 | 23.02 | −4.87 | −9.40 | 19.37 | 30.08 |

| 0.23 | 0.17 | 0.08 | 0.45 | 0.28 | 0.22 | 0.84 | 0.36 | 0.40 | 0.62 | 0.31 | 0.85 | |

| MSF | −0.40 | −0.53 | −1.08 | −1.98 | −0.62 | −2.67 | −4.74 | −6.57 | −4.30 | −5.02 | −6.19 | −7.52 |

| 0.14 | 0.12 | 0.17 | 0.28 | 0.13 | 0.12 | 0.49 | 0.43 | 0.35 | 0.22 | 0.31 | 0.37 | |

| MCF | −0.72 | −0.84 | −1.06 | −1.51 | −2.10 | −3.85 | −4.57 | −5.00 | −4.79 | −5.07 | −5.95 | −6.21 |

| 0.04 | 0.05 | 0.17 | 0.02 | 0.29 | 0.16 | 0.25 | 0.25 | 0.12 | 0.09 | 0.19 | 0.29 | |

| CSF | −1.25 | −1.40 | −1.68 | −2.12 | −0.56 | −1.86 | −3.86 | −6.02 | −2.76 | −3.36 | −4.83 | −6.32 |

| 0.13 | 0.14 | 0.04 | 0.16 | 0.03 | 0.17 | 0.12 | 0.26 | 0.19 | 0.08 | 0.07 | 0.13 | |

| CCF | −0.77 | −0.93 | −0.99 | −1.26 | −1.99 | −2.87 | −3.36 | −3.76 | −2.66 | −2.99 | −3.78 | −4.66 |

| 0.15 | 0.12 | 0.30 | 0.11 | 0.12 | 0.10 | 0.30 | 0.17 | 0.04 | 0.30 | 0.15 | 0.30 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lezzerini, M.; Aquino, A.; Pagnotta, S. Acid Resistance of Metakaolin-Based Geopolymers and Geopolymeric Mortars Reinforced with Coconut Fibers. Fibers 2024, 12, 40. https://doi.org/10.3390/fib12050040

Lezzerini M, Aquino A, Pagnotta S. Acid Resistance of Metakaolin-Based Geopolymers and Geopolymeric Mortars Reinforced with Coconut Fibers. Fibers. 2024; 12(5):40. https://doi.org/10.3390/fib12050040

Chicago/Turabian StyleLezzerini, Marco, Andrea Aquino, and Stefano Pagnotta. 2024. "Acid Resistance of Metakaolin-Based Geopolymers and Geopolymeric Mortars Reinforced with Coconut Fibers" Fibers 12, no. 5: 40. https://doi.org/10.3390/fib12050040

APA StyleLezzerini, M., Aquino, A., & Pagnotta, S. (2024). Acid Resistance of Metakaolin-Based Geopolymers and Geopolymeric Mortars Reinforced with Coconut Fibers. Fibers, 12(5), 40. https://doi.org/10.3390/fib12050040