Moisture and Surface Properties of Radically Photo-Grafted Poly-(Ethylene Terephthalate) Woven Fabric

Highlights

- The surface of a polyethylene terephthalate (PET) fabric was modified by using a fast photoinduced grafting process without affecting the aspect of the textile and the yarn size.

- The water wettability of the PET fabric was significantly improved; the water contact angle value diminished from 110° to 0°.

- The PET fabrics after the photografting treatment showed a good improvement in the dynamic moisture management. According to the AATCC Test Method 195-2011, wetting and absorption indices were improved.

- The surface treatment was durable and the modification was maintained after laundering, dry cleaning, and rubbing depending on the type of monomer used and its concentration.

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

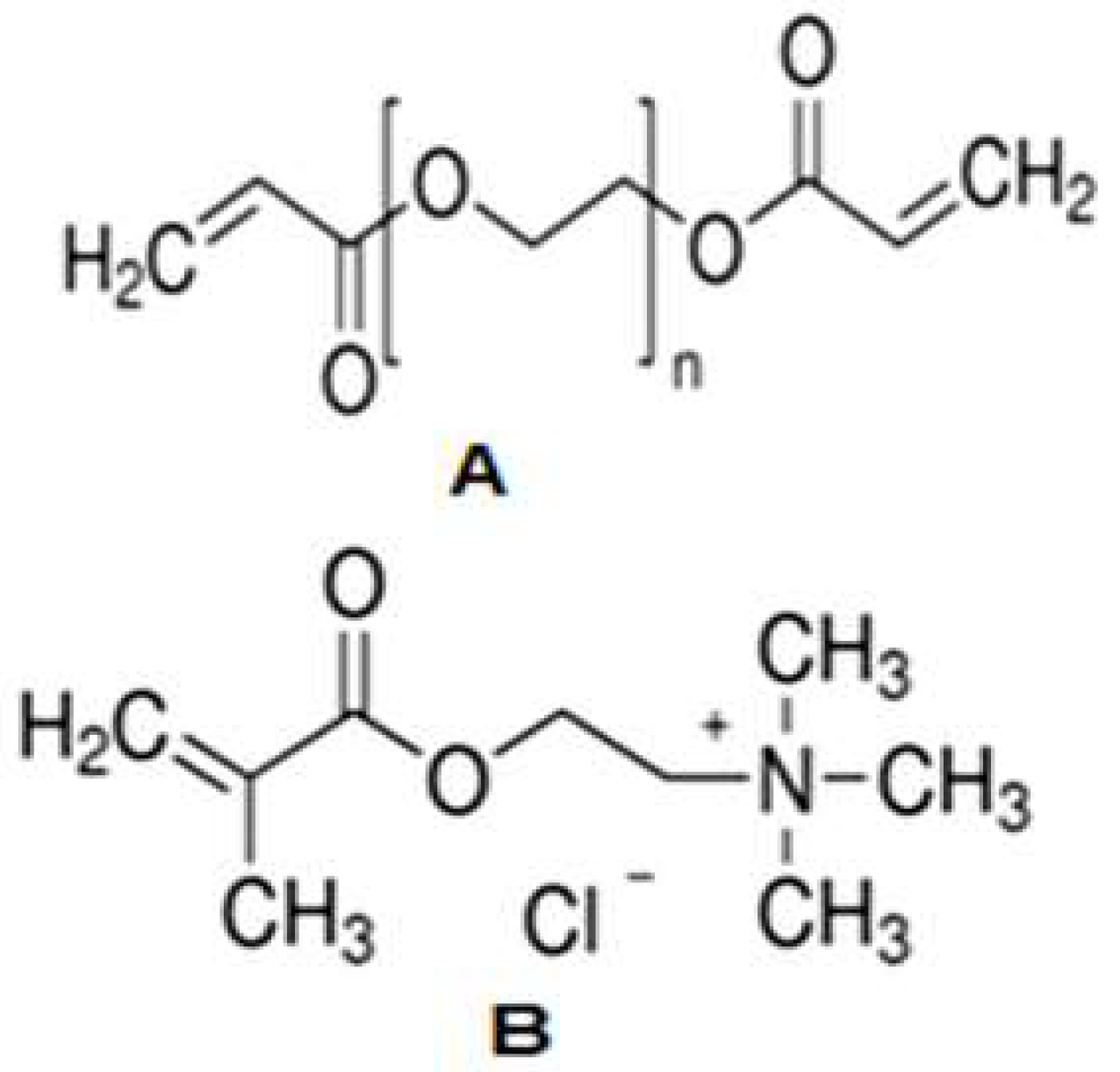

2.1.1. Fabrics and Grafting Reagents

2.1.2. Dyeing Materials for PET

2.2. Methods

2.2.1. Fabric Preparation

2.2.2. UV-Radical Grafting

2.2.3. Dyeing

2.2.4. Fabric Characterization

3. Results

3.1. PET Wettability and Moisture Management by Photografting

3.2. Durability of UV-Grafting Treatment and Compatibility with Dying

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Fabric | L* | a* | b* | C* | h |

|---|---|---|---|---|---|

| PET | 40.52 | 51.53 | 8.53 | 53.22 | 9.22 |

| PEGDA-g-PET 0.2% | 38.46 | 51.97 | 8.27 | 53.66 | 8.79 |

| PEGDA-g-PET 1% | 37.64 | 52.21 | 7.77 | 53.79 | 8.46 |

| METAC-g-PET 1% | 38.61 | 52.60 | 7.71 | 53.47 | 8.34 |

| METAC-g-PET 5% | 37.77 | 52.32 | 6.64 | 54.76 | 7.35 |

| Fabric | Hand/Appearance after Laundering | Hand/Appearance after Drycleaning | Color Fastness Dry/Wet Rubbing | Color Fastness Washing/Washing Staining |

|---|---|---|---|---|

| PET | B5/A5 | B5/A5 | 4/3.5 | 4/4 |

| PEGDA-g-PET 0.2% | B5/A5 | B4/A4 | 4/3.5 | 4.5/4.5 |

| PEGDA-g-PET 1% | B5/A5 | B5/A5 | 4.5/4 | 4.5/4.5 |

| METAC-g-PET 1% | B5/A5 | B5/A5 | 4.5/4 | 4.5/4 |

| METAC-g-PET 5% | B5/A5 | B5/A5 | 5/4.5 | 5/4.5 |

References

- The Fiber Year 2024. A World Survey on Textile and Nonwovens Industry. 2024. Available online: https://thefiberyear.com/ (accessed on 20 July 2024).

- Pastore, C.; Kiekens, P. (Eds.) Surface Characteristics of Polyester Fibers. In Surface Characteristics of Fibers and Textiles; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Li, Y.; Zhu, Q. Simultaneous Heat and Moisture Transfer with Moisture Sorption, Condensation, and Capillary Liquid Diffusion in Porous Textiles. Text. Res. J. 2003, 73, 515–524. [Google Scholar] [CrossRef]

- Kamalha, E.; Zeng, Y.; Mwasiagi, J.I.; Kyatuheire, S. The Comfort Dimension; a Review of Perception in Clothing. J. Sens. Stud. 2013, 28, 423–444. [Google Scholar] [CrossRef]

- Ullah, H.M.K.; Lejeune, J.; Cayla, A.; Monceaux, M.; Campagne, C.; Devaux, É. A review of noteworthy/major innovations in wearable clothing for thermal and moisture management from material to fabric structure. Text. Res. J. 2022, 92, 3351–3386. [Google Scholar] [CrossRef]

- Aoyama, M.; Tanaka, Y. History of Polyester Resin Development for Synthetic Fibers and Its Forefront. In High-Performance and Specialty Fibers: Concepts, Technology and Modern Applications of Man-Made Fibers for the Future; Springer: Tokyo, Japan, 2016; pp. 67–80. [Google Scholar]

- Sun, L.; Zhu, R.; Hu, H.; Yu, J.; Wang, X.; Huang, L.; Liu, X. Effect of the Sequence Distribution and Internal Structure on the Hydrophilicity of Poly(ethylene terephthalate-co-aliphatic amide) Copolymers. ACS Appl. Polym. Mater. 2022, 4, 6179–6191. [Google Scholar] [CrossRef]

- Yan, Y.; Gooneie, A.; Ye, H.; Deng, L.; Qiu, Z.; Reifler, F.A.; Hufenus, R. Morphology and Crystallization of Biobased Polyamide 56 Blended with Polyethylene Terephthalate. Macromol. Mater. Eng. 2018, 303, 1800214. [Google Scholar] [CrossRef]

- Zeronian, S.H.; Collins, M.J. Surface Modification of Polyester by Alkaline Treatments. Text. Prog. 1989, 20, 1–26. [Google Scholar] [CrossRef]

- Čorak, I.; Tarbuk, A.; Đorđević, D.; Višić, K.; Botteri, L. Sustainable Alkaline Hydrolysis of Polyester Fabric at Low Temperature. Materials 2022, 15, 1530. [Google Scholar] [CrossRef] [PubMed]

- Gupta, D.; Chaudhary, H.; Gupta, C. Topographical changes in polyester after chemical, physical and enzymatic hydrolysis. J. Text. Inst. 2015, 106, 690–698. [Google Scholar] [CrossRef]

- Elsaeed, S.M.; Farag, R.K. Synthesis and characterization of unsaturated polyesters based on the aminolysis of poly(ethylene terephthalate). J. Appl. Polym. Sci. 2009, 112, 3327–3336. [Google Scholar] [CrossRef]

- Fávaro, S.L.; Rubira, A.F.; Muniz, E.C.; Radovanovic, E. Surface modification of HDPE, PP, and PET films with KMnO4/HCl solutions. Polym. Degrad. Stab. 2007, 92, 1219–1226. [Google Scholar] [CrossRef]

- Tegegne, W.; Haile, A. Improving hydrophilicity and comfort characteristics of polyester/cotton blend fabric through lipase enzyme treatment. Clean Technol. Env. Policy 2024, 1–14. [Google Scholar] [CrossRef]

- Karaca, B.; Demir, A.; Özdoğan, E.; İşmal, Ö.E. Environmentally benign alternatives: Plasma and enzymes to improve moisture management properties of knitted PET fabrics. Fibers Polym. 2010, 11, 1003–1009. [Google Scholar] [CrossRef]

- Mowafi, S.; El-Sayed, H. A benign synergism of O2 plasma and protein biopolymer for improving some properties of polyester fabrics. J. Text. Inst. 2024, 1–13. [Google Scholar] [CrossRef]

- Owad, T.T.; Siddig, E.A.; Salih, R.E.; Zhang, Y.; Wang, C.; Xu, Y.; Zhang, J. Durable and recoverable hydrophilicity of polyethylene terephthalate fabric prepared with plasma selective etching. Surf. Interfaces 2022, 32, 102081. [Google Scholar] [CrossRef]

- Gabardo, R.S.; de Carvalho Cotre, D.S.; Lis Arias, M.J.; Moisés, M.P.; Martins Ferreira, B.T.; Samulewski, R.B.; Hinestroza, J.P.; Bezerra, F.M. Surface Modification of Polyester Fabrics by Ozone and Its Effect on Coloration Using Disperse Dyes. Materials 2021, 14, 3492. [Google Scholar] [CrossRef]

- Miyata, T.; Takeno, A.; Mishima, Y.; Takahashi, S. Surface Modification of Polyester Fiber Using Ozone Microbubbles. Kobunshi Ronbunshu 2016, 73, 341–346. [Google Scholar] [CrossRef]

- Zhou, Y.; Zheng, F.; Zuo, J.; Xu, Y.; Li, Y.; Zhang, K. Toward a Sustainable Approach for Durably Hydrophilic and UV Protective PET Fabric through Surface Activation and Immobilization Integrating Epigallocatechin Gallate and Citric Acid. ACS Appl. Mater. Interfaces 2024, 16, 38576–38585. [Google Scholar] [CrossRef]

- Sadeghi, S.; Montazer, M.; Dadashian, F. Insights into the hexamine-assisted ZnO based-MOFs formation on PET fabric for improved self-cleaning, flame retardant, and hydrophilic properties. Prog. Org. Coat. 2024, 192, 108458. [Google Scholar] [CrossRef]

- Agarwal, R.; Jassal, M.; Agrawal, A.K. Nano surface modification of poly(ethylene terephthalate) fabrics for enhanced comfort properties for activewear. J. Ind. Eng. Chem. 2021, 98, 217–230. [Google Scholar] [CrossRef]

- Le, Y.; Yang, L.; Zhu, Y.; Yang, D.Q. Robust and repairable PET superwicking surfaces: A simple two-step fabrication approach for enhanced liquid transport. Surf. Interfaces 2024, 52, 104862. [Google Scholar] [CrossRef]

- Zhao, K.; Wang, Y.; Wang, W.; Yu, D. Moisture absorption, perspiration and thermal conductive polyester fabric prepared by thiol–ene click chemistry with reduced graphene oxide finishing agent. J. Mater. Sci. 2018, 53, 14262–14273. [Google Scholar] [CrossRef]

- Zhang, S.; Ding, F.; Wang, Y.; Ren, X.; Huang, T.S. Antibacterial and Hydrophilic Modification of PET Fabrics by Electron Beam Irradiation Process. Fibers Polym. 2020, 21, 1023–1031. [Google Scholar] [CrossRef]

- Bongiovanni, R.; Vacche, S.D.; Vitale, A. Photoinduced Processes as a Way to Sustainable Polymers and Innovation in Polymeric Materials. Polymers 2021, 13, 2293. [Google Scholar] [CrossRef]

- Rånby, B. Photochemical modification of polymers—Photocrosslinking, surface photografting, and lamination. Polym. Eng. Sci. 1998, 38, 1229–1243. [Google Scholar] [CrossRef]

- Deng, J.; Wang, L.; Liu, L.; Yang, W. Developments and new applications of UV-induced surface graft polymerizations. Prog. Polym. Sci. 2009, 34, 156–193. [Google Scholar] [CrossRef]

- Ghamarpoor, R.; Jamshidi, M.; Sayyadian, M.; Razavizadeh, M. Chemical/photochemical functionalization of polyethylene terephthalate fabric: Effects on mechanical properties and bonding to nitrile rubber. Sci. Rep. 2023, 13, 14533. [Google Scholar] [CrossRef]

- Golshaei, P.; Güven, O. Chemical modification of PET surface and subsequent graft copolymerization with poly(N-isopropylacrylamide). React. Funct. Polym. 2017, 118, 26–34. [Google Scholar] [CrossRef]

- Liu, X.D.; Sheng, D.K.; Gao, X.M.; Li, T.B.; Yang, Y.M. UV-assisted surface modification of PET fiber for adhesion improvement. Appl. Surf. Sci. 2013, 264, 61–69. [Google Scholar] [CrossRef]

- Dai, X.; Yu, X.; Zheng, J.; Yang, X.; Pan, J.; Zhang, X.; Min, J. A kelp-inspired polyester fabric surface of UV grafted hydrogel for drag reduction. J. Appl. Polym. Sci. 2022, 139, 51634. [Google Scholar] [CrossRef]

- Xin-Cheng, X.; Xiao-Jing, Y.; Wen, H.; Zuo-Shen, L.; Xin-Long, L. Study on polyester fabric grafted with acrylic acid initiated by ultraviolet light. J. Phys. Conf. Ser. 2021, 2009, 012019. [Google Scholar] [CrossRef]

- Rui, W.; Wenqing, W.; Fanghe, W.; Anying, Z.; Xiuqin, Z.; Deyi, W. Construction of nano-multilayer coatings on copolyester fabrics using UV-grafting mediated layer-by-layer self-assembly for improved anti-droplet and flame retardent performance. Polym. Degrad. Stab. 2021, 183, 109405. [Google Scholar] [CrossRef]

- Khamala, E. Towards Replacement of Cotton Fiber with Polyester. Doctoral Thesis, Politecnico di Torino, Turin, Italy, 2018. [Google Scholar]

- Schanda, J. CIE Colorimetry. In Colorimetry: Understanding the CIE System; John Wiley & Sons: New York, NY, USA, 2007; pp. 25–78. [Google Scholar]

- Marmur, A. Soft contact: Measurement and interpretation of contact angles. Soft Matter. 2006, 2, 12–17. [Google Scholar] [CrossRef] [PubMed]

- Hasan, M.M.B.; Calvimontes, A.; Synytska, A.; Dutschk, V. Effects of Topographic Structure on Wettability of Differently Woven Fabrics. Text. Res. J. 2008, 78, 996–1003. [Google Scholar] [CrossRef]

- Huhtamäki, T.; Tian, X.; Korhonen, J.T.; Ras, R.H.A. Surface-wetting characterization using contact-angle measurements. Nat. Protoc. 2018, 13, 1521–1538. [Google Scholar] [CrossRef]

- Lee, M.; Lee, M.S.; Wakida, T.; Tokuyama, T.; Inoue, G.; Ishida, S.; Itazu, T.; Miyaji, Y. Chemical modification of nylon 6 and polyester fabrics by ozone-gas treatment. J. Appl. Polym. Sci. 2006, 100, 1344–1348. [Google Scholar] [CrossRef]

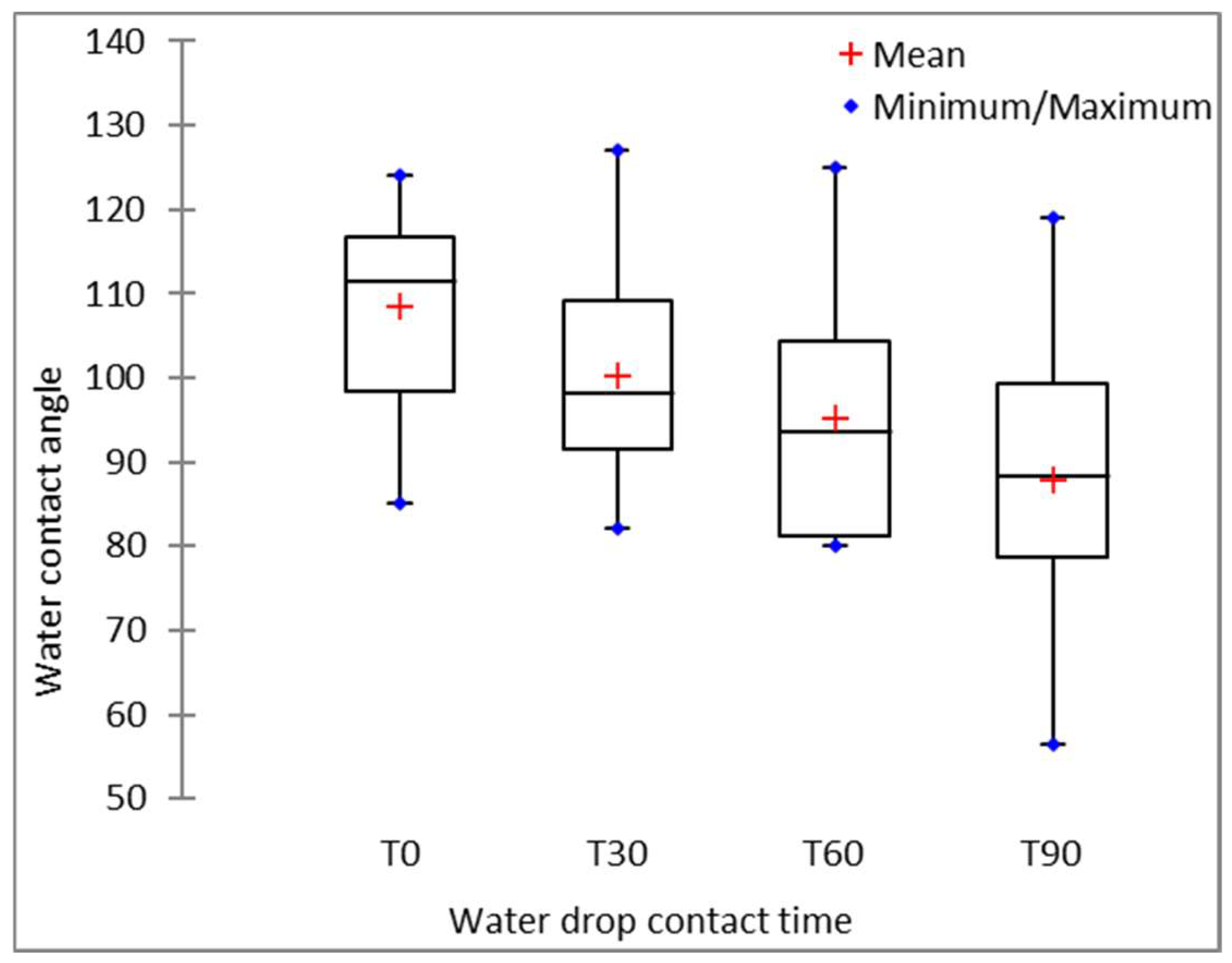

| Water Drop Contact Time (s) | UV Irradiation Time (min) and WCA ± Standard Deviation | |||||

|---|---|---|---|---|---|---|

| 0 | 5 | 10 | 15 | 20 | 25 | |

| T0 | 110 ± 5 | 100 ± 3 | 100 ± 9 | 98 ± 4 | 90 ± 8 | 86 ± 6 |

| T30 | 100 ± 8 | 97 ± 7 | 95 ± 7 | 89 ± 9 | 82 ± 9 | 84 ± 5 |

| T60 | 95 ± 4 | 90 ± 5 | 89 ± 4 | 87 ± 8 | 71 ± 6 | 73 ± 9 |

| T90 | 88 ± 5 | 89 ± 6 | 87 ± 7 | 86 ± 8 | 70 ± 8 | 70 ± 7 |

| PEGDA Conc. (% v/v) | Add-on (%) | WCA at T0 | |

|---|---|---|---|

| 5 | 2.7 | 0 | |

| 3 | 2.4 | 0 | |

| 2 | 1.6 | 0 | |

| 1 | 0.9 | 0 | |

| 0.5 | 0.9 | 0 | |

| 0.2 | 0.3 | 0 | |

| 0.1 | 0.2 | 0 | |

| METAC conc. (% v/v) | Add-on (%) | WCA at T0 | WCA at T30 |

| 5 | 2.1 | 0 | 0 |

| 3 | 0.89 | 5 | 0 |

| 2 | 0.62 | 7 | 0 |

| 1 | 0.45 | 10 | 0 |

| 0.5 | 0.15 | 36 | 0 |

| 0.2 | 0.08 | 34 | 10 |

| 0.1 | 0.05 | 45 | 15 |

| Fabric | TW (s) | BW (s) | TA (%/s) | BA (%/s) | TM (mm) | BM (mm) | TS (mm/s) | BS (mm/s) | AOT |

|---|---|---|---|---|---|---|---|---|---|

| PET | 3.5 | 120 | 29.2 | 0.0 | 5.0 | 0.0 | 1.4 | 0.0 | −834 |

| PET irradiated 5 min | 2.5 | 120 | 40.9 | 0.0 | 5.0 | 0.0 | 1.8 | 0.0 | −893 |

| PET irradiated 10 min | 2.9 | 120 | 41.3 | 0.0 | 5.0 | 0.0 | 1.6 | 0.0 | −828 |

| PEGDA-g-PET 0.2% | 3.0 | 5.8 | 39.5 | 25.0 | 13.8 | 22.5 | 3.0 | 3.6 | −43.9 |

| PEGDA-g-PET 1% | 2.6 | 2.3 | 46.5 | 37.3 | 17.5 | 27.5 | 4.5 | 6.5 | 214 |

| METAC-g-PET 1% | 3.5 | 5.6 | 32.2 | 19.7 | 10.0 | 15.0 | 1.9 | 2.0 | −242 |

| METAC-g-PET 5% | 3.0 | 4.5 | 36.7 | 23.8 | 15.0 | 17.0 | 2.3 | 2.1 | −136 |

| PEGDA Conc. (% v/v) | After Washing | After Soxhlet Extraction | ||||

|---|---|---|---|---|---|---|

| WCA T0 | WCA T30 | WCA T0 | WCA T30 | WCA T60 | ||

| 5 | 0 | 0 | 31 | 0 | 0 | |

| 3 | 0 | 0 | 12 | 0 | 0 | |

| 2 | 0 | 0 | 19 | 0 | 0 | |

| 1 | 0 | 0 | 32 | 0 | 0 | |

| 0.5 | 5 | 0 | 28 | 0 | 0 | |

| 0.2 | 33 | 5 | 25 | 5 | 0 | |

| 0.1 | 43 | 0 | 64 | 21 | 0 | |

| METAC conc. (% v/v) | after washing | after Soxhlet extraction | ||||

| WCA T0 | WCA T30 | WCA T60 | WCA T0 | WCA T30 | WCA T60 | |

| 5 | 103 | 42 | 0 | 27 | 15 | 0 |

| 3 | 103 | 61 | 0 | 18 | 0 | 0 |

| 2 | 100 | 55 | 0 | 22 | 5 | 0 |

| 1 | 83 | 30 | 0 | 55 | 37 | 0 |

| 0.5 | 101 | 20 | 0 | 85 | 35 | 30 |

| 0.2 | 98 | 51 | 22 | 89 | 56 | 27 |

| 0.1 | 88 | 50 | 28 | 80 | 30 | 25 |

| PEGDA Conc. (% v/v) | After Dry Rubbing | After Wet Rubbing | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| WCA T0 | WCA T30 | WCA T0 | WCA T30 | |||||||

| 5 | 0 | 0 | 0 | 0 | ||||||

| 3 | 0 | 0 | 0 | 0 | ||||||

| 2 | 0 | 0 | 5 | 0 | ||||||

| 1 | 7 | 0 | 0 | 0 | ||||||

| 0.5 | 0 | 0 | 0 | 0 | ||||||

| 0.2 | 10 | 0 | 15 | 5 | ||||||

| 0.1 | 0 | 0 | 10 | 0 | ||||||

| METAC conc. (% v/v) | after dry rubbing | after wet rubbing | ||||||||

| WCA T0 | WCA T30 | WCA T60 | WCA T0 | WCA T30 | WCA T60 | |||||

| 5 | 0 | 0 | 0 | 5 | 0 | 0 | ||||

| 3 | 5 | 5 | 0 | 5 | 0 | 0 | ||||

| 2 | 7 | 0 | 0 | 11 | 0 | 0 | ||||

| 1 | 16 | 0 | 0 | 13 | 0 | 0 | ||||

| 0.5 | 41 | 20 | 0 | 31 | 5 | 0 | ||||

| 0.2 | 26 | 11 | 0 | 39 | 15 | 0 | ||||

| 0.1 | 30 | 15 | 0 | 45 | 25 | 10 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bongiovanni, R.; Guan, J.; Ferri, A.; Vitale, A. Moisture and Surface Properties of Radically Photo-Grafted Poly-(Ethylene Terephthalate) Woven Fabric. Fibers 2024, 12, 90. https://doi.org/10.3390/fib12100090

Bongiovanni R, Guan J, Ferri A, Vitale A. Moisture and Surface Properties of Radically Photo-Grafted Poly-(Ethylene Terephthalate) Woven Fabric. Fibers. 2024; 12(10):90. https://doi.org/10.3390/fib12100090

Chicago/Turabian StyleBongiovanni, Roberta, Jinping Guan, Ada Ferri, and Alessandra Vitale. 2024. "Moisture and Surface Properties of Radically Photo-Grafted Poly-(Ethylene Terephthalate) Woven Fabric" Fibers 12, no. 10: 90. https://doi.org/10.3390/fib12100090

APA StyleBongiovanni, R., Guan, J., Ferri, A., & Vitale, A. (2024). Moisture and Surface Properties of Radically Photo-Grafted Poly-(Ethylene Terephthalate) Woven Fabric. Fibers, 12(10), 90. https://doi.org/10.3390/fib12100090