A Comparative Analysis of Denim Fabric Performances from Cotton/Polyester Blended Rigid and Stretched Yarns

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

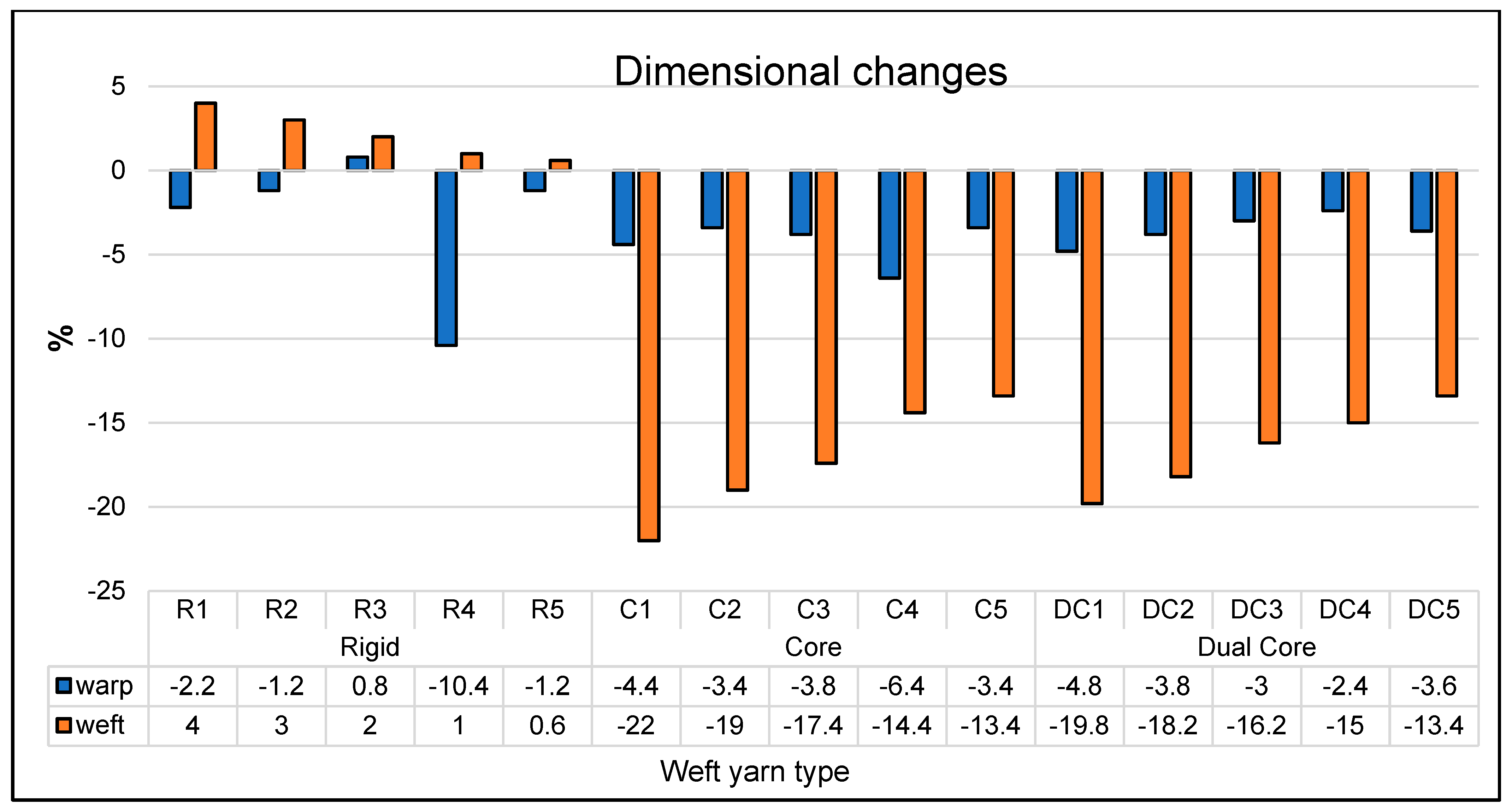

3.1. Weight and Dimensional Changes of the Fabric

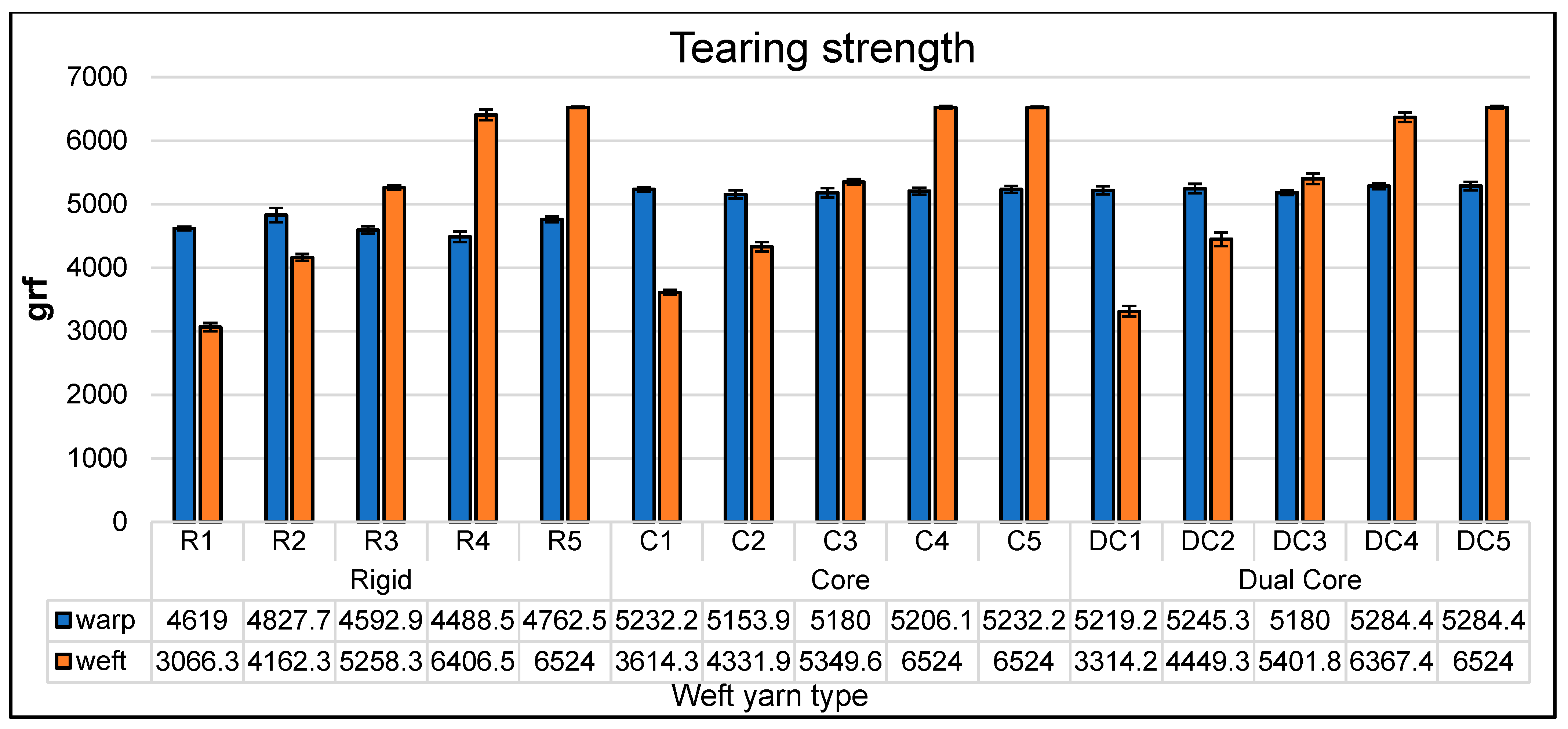

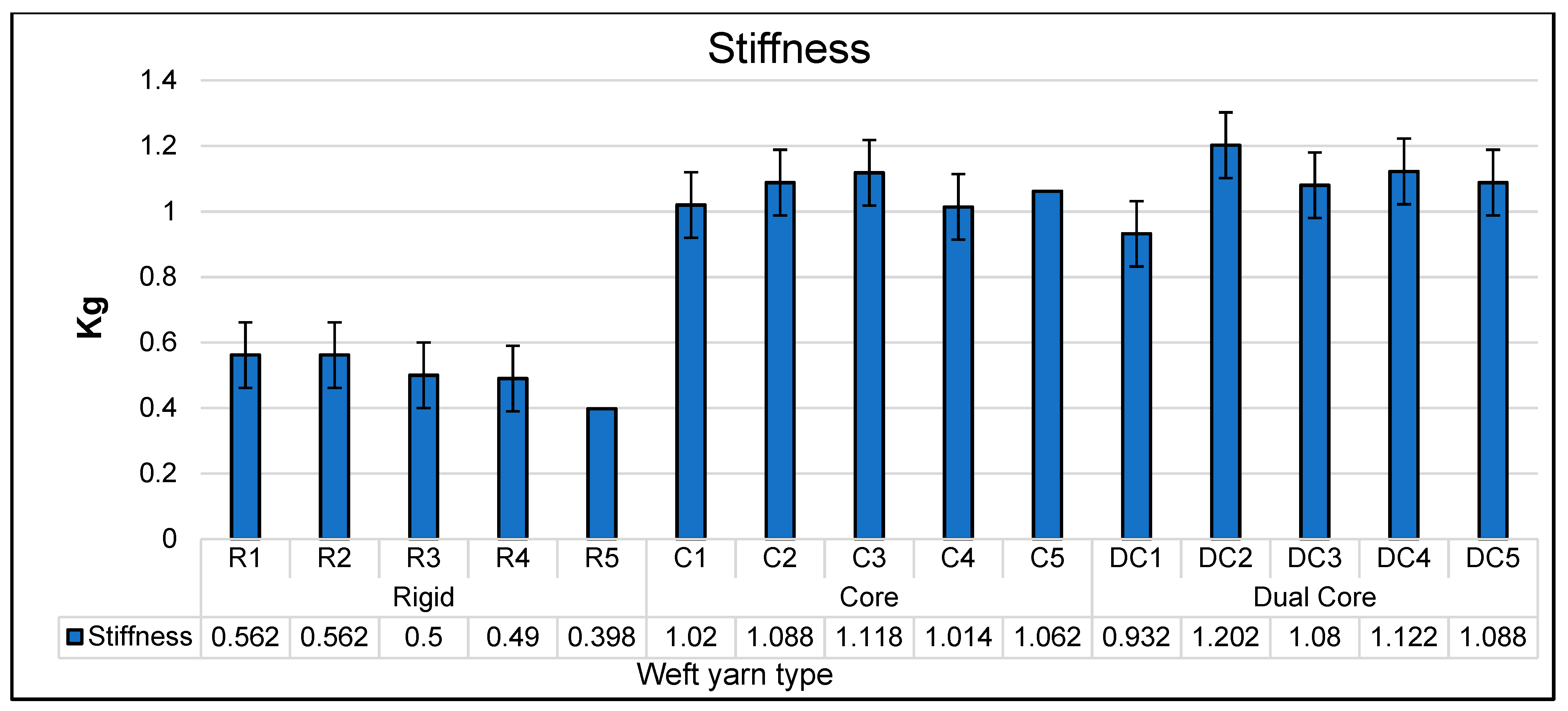

3.2. Strength and Stiffness

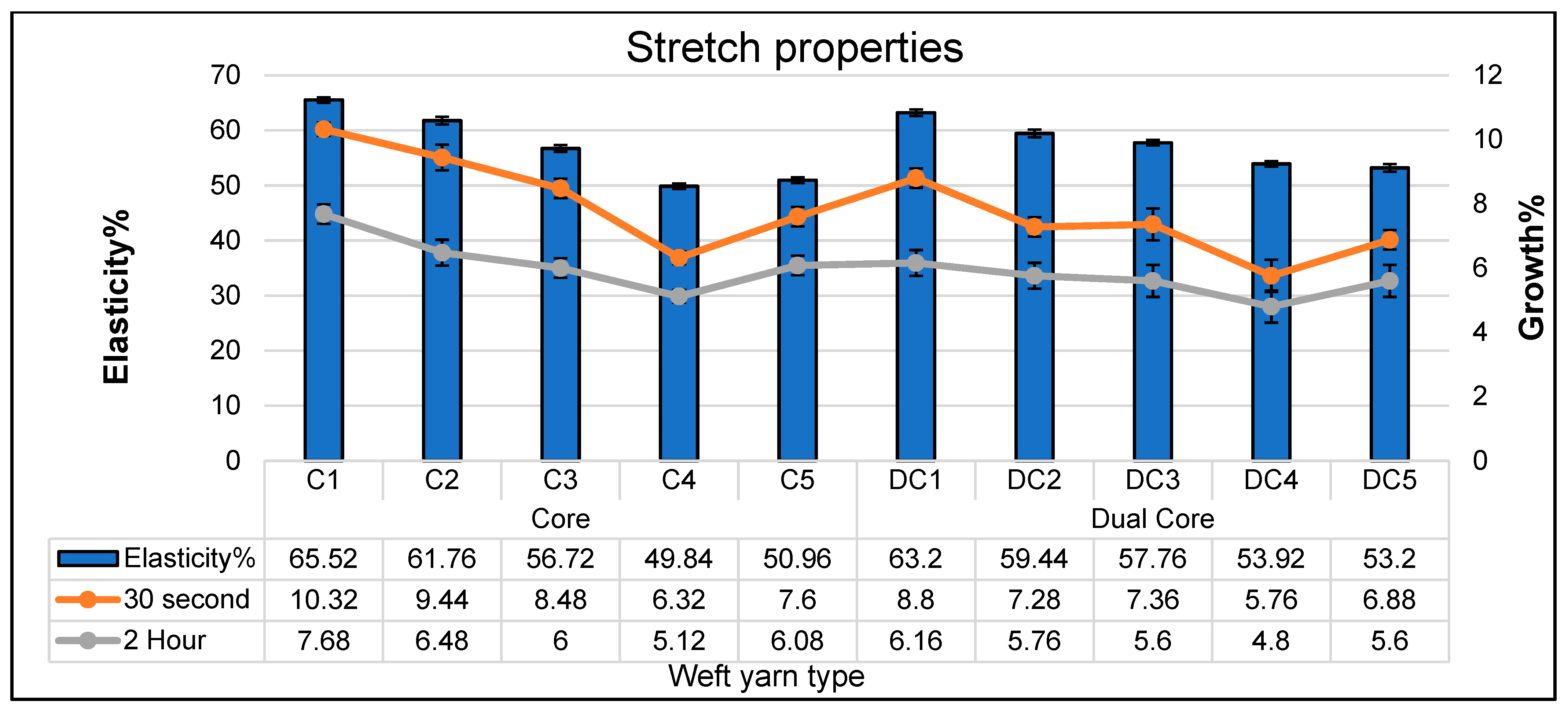

3.3. Stretch Properties

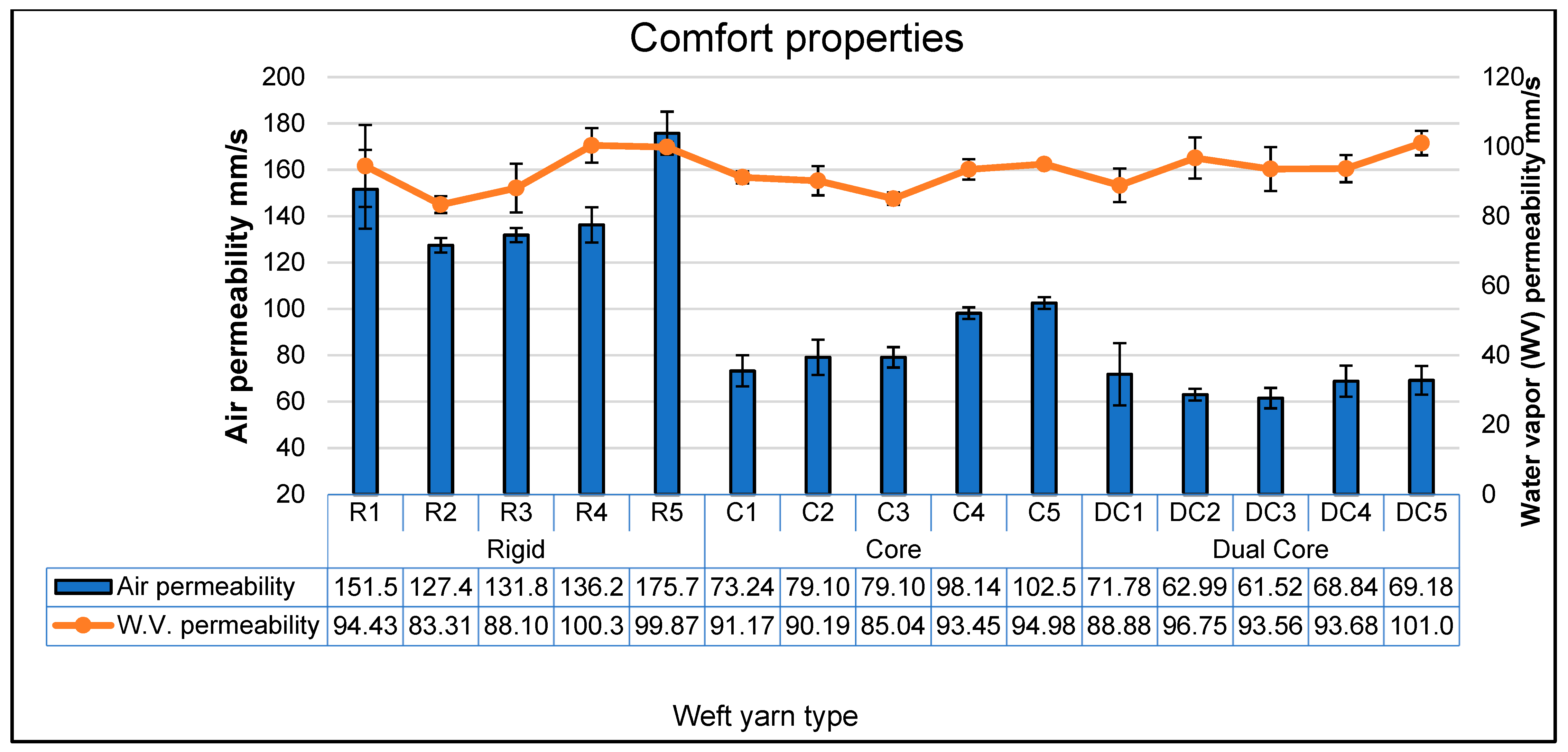

3.4. Comfort Properties

3.5. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Choudhury, A.K.R. Environmental Impacts of Denim Washing; Elsevier Ltd.: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Paul, R. Denim and Jeans: An Overview; Elsevier Ltd.: Amsterdam, The Netherlands, 2015. [Google Scholar] [CrossRef]

- Sowmya, R.; Vasugi Raaja, N.; Prakash, C. Investigation of Relationship between Blend Ratio and Yarn Twist on Yarn Properties of Bamboo, Cotton, Polyester, and its Blends. J. Nat. Fibers 2017, 14, 228–238. [Google Scholar] [CrossRef]

- Babaarslan, O.; Shahid, A.; Dilek, S. Evaluation of Denim Fabric Performances from Sustainable Yarn. Mater. Sci. Forum 2022, 1063, 15–23. [Google Scholar] [CrossRef]

- Yoon, H.N.; Sawyer, L.C.; Buckley, A. Improved Comfort Polyester: Part II: Mechanical and Surface Properties. Text. Res. J. 1984, 54, 357–365. [Google Scholar] [CrossRef]

- Ruppenicker, G.F.; Harper, R.J.; Sawhney, A.P.; Robert, K.Q. Comparison of Cotton/Polyester Core and Staple Blend Yarns and Fabrics. Text. Res. J. 1989, 59, 12–17. [Google Scholar] [CrossRef]

- Çelik, P.; Kadoǧlu, H. A research on yarn liveliness tendency of staple yarns. Tekst. Konfeksiyon 2009, 19, 189–196. [Google Scholar]

- Canoglu, S.; Tanir, S.K. Studies on Yarn Hairiness of Polyester/Cotton Blended Ring-Spun Yarns Made from Different Blend Ratios. Text. Res. J. 2009, 79, 235–242. [Google Scholar] [CrossRef]

- Temel, E.; Celik, P. A Reaserch on spinnability of 100% polyester and polyester-cotton blend sirospun yarns. Tekst. Konfeksiyon 2010, 20, 23–29. [Google Scholar]

- Scheirs, J.; Long, T.E. Modern Polyesters: Chemistry and Technology of Polyesters and Copolyesters; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2003; pp. 1–784. [Google Scholar]

- Chen, Q.; Zhao, T. The thermal decomposition and heat release properties of the nylon/cotton, polyester/cotton and Nomex/cotton blend fabrics. Text. Res. J. 2016, 86, 1859–1868. [Google Scholar] [CrossRef]

- Militky, J. The chemistry, manufacture and tensile behaviour of polyester fibers. In Handbook of Tensile Properties of Textile and Technical Fibres; Woodhead Publishing: Cambridge, UK, 2009; pp. 223–314. [Google Scholar]

- Grand View Research. Synthetic Fiber, Market Analysis, 2017–2028. 2021. Available online: https://www.grandviewresearch.com/industry-analysis/synthetic-fibers-market (accessed on 20 July 2024).

- Textile Exchanges. Preferred Fiber & Materials Market Report 2020 Welcome to the 2020 Preferred Fiber & Materials Market Report. 2020. Available online: https://textileexchange.org/knowledge-center/reports/preferred-fiber-materials-market-report-2020/ (accessed on 20 July 2024).

- Jaffe, M.; Easts, A.J.; Feng, X. 8—Polyester Fibers. In Thermal Analysis of Textiles and Fibers; Woodhead Publishing: Cambridge, UK, 2020. [Google Scholar] [CrossRef]

- Kumar, D.V.; Raja, D. Study of Thermal Comfort Properties on Socks made from Recycled Polyester/Virgin Cotton and its Blends. Fibers Polym. 2021, 22, 841–846. [Google Scholar] [CrossRef]

- Tyagi, G.K.; Sharma, D. Thermal comfort characteristics of polyester-cotton MVS yarn fabrics. Indian J. Fibre Text. Res. 2005, 30, 363–370. [Google Scholar]

- Fiseha, K.; Das, D.; Palaniswamy, N.K. Effect of Blend Ratio of Deep-Grooved Polyester/Cotton Fibers on Mechanical and Comfort Properties of Woven Fabrics. Fibers Polym. 2019, 20, 2215–2221. [Google Scholar] [CrossRef]

- Özdemir, H. Thermal Comfort Properties of Clothing Fabrics Woven with Polyester/Cotton Blend Yarns. Autex Res. J. 2017, 17, 135–141. [Google Scholar] [CrossRef]

- Islam, T. A Study on Thermal Comfort Feeling Properties of 60%/40% and 80%/20% Cotton/Polyester and 100% Cotton Fleece. J. Text. Sci. Fash. Technol. 2019, 4, 1–5. [Google Scholar] [CrossRef]

- Xiao, Q.; Wang, R.; Zhang, S.; Li, D.; Sun, H.; Wang, L. Prediction of pilling of polyester—Cotton blended woven fabric using artificial neural network models. J. Eng. Fibers Fabr. 2020, 15, 1558925019900152. [Google Scholar] [CrossRef]

- Chandrasekaran, R.; Periyasamy, S.; Shabaridharan, K. Statistical analysis of the pilling behaviour of polyester/cotton and polyester/viscose blended woven fabrics. Fibres Text. East. Eur. 2018, 26, 66–70. [Google Scholar] [CrossRef]

- Kara, G.; Akgun, M. Effect of weft yarn fiber contents on the moisture management performance of denim fabrics woven with different constructional parameters. Tekst. Konfeksiyon 2018, 28, 151–161. [Google Scholar]

- Akhtar, K.S.; Ahmad, S.; Afzal, A.; Anam, W.; Ali, Z.; Hussain, T. Influence and comparison of emerging techniques of yarn manufacturing on physical–mechanical properties of polyester-/cotton-blended yarns and their woven fabrics. J. Text. Inst. 2020, 111, 555–564. [Google Scholar] [CrossRef]

- Anam, W.; Ashraf, M.; Qadir, M.B.; Akhtar, K.S.; Ahmad, S.; Afzal, A.; Ullah, T. Influence of Yarn Manufacturing Techniques on Dyeing Behavior of Polyester/Cotton Blended Woven Fabrics. Fibers Polym. 2019, 20, 2550–2555. [Google Scholar] [CrossRef]

- Sarıoğlu, E.; Babaarslan, O. Porosity and air permeability relationship of denim fabrics produced using core-spun yarns with different filament finenesses for filling. J. Eng. Fibers Fabr. 2019, 14, 1558925019837810. [Google Scholar] [CrossRef]

- Bedez Ute, T. Analysis of mechanical and dimensional properties of the denim fabrics produced with double-core and core-spun weft yarns with different weft densities. J. Text. Inst. 2019, 110, 179–185. [Google Scholar] [CrossRef]

- Aydoǧdu, S.H.Ç.; Yilmaz, D. Analyzing some of the dual-core yarn spinning parameters on yarn and various fabric properties. Tekst. Konfeksiyon 2020, 29, 197–207. [Google Scholar]

- Türksoy, H.G.; Kılıç, G.; Üstüntağ, S.; Yılmaz, D. A comparative study on properties of dual-core yarns. J. Text. Inst. 2019, 110, 980–988. [Google Scholar] [CrossRef]

- Özdil, N. Stretch and bagging properties of denim fabrics containing different rates of elastane. Fibres Text. East. Eur. 2008, 16, 63–67. [Google Scholar]

- Shahid, M.A.; Dip, T.M.; Tanni, T.R.; Babaarslan, O. Natural fiber: Twistless and core spun yarn. In Multiscale Textile Preforms and Structures for Natural Fiber Composites; Woodhead Publishing: Cambridge, UK, 2023; pp. 87–118. [Google Scholar]

- Babaarslan, O.; Shahid, M.A.; Doğan, F.B. Comparative analysis of cotton covered elastomeric hybrid yarns and denim fabric properties. J. Eng. Fibers 2021, 16, 155892502110591. [Google Scholar] [CrossRef]

- Su, X.; Su, X.; Liu, X. Research on performance of twin-core spun yarn and fabric. Int. J. Cloth. Sci. Technol. 2019, 32, 338–355. [Google Scholar] [CrossRef]

- Babaarslan, O.; Balcı, H.; Guler, O. Elastan (SpandexIlavesininPoliester/Viskon Karişimli Dokuma KumaÖzellikleriÜzerindekiEtkisi Effect of Elastane on the Properties of Pes/Vis Blend. Tekst. Konfeksiyon 2007, 2, 110–114. [Google Scholar]

- Almetwally; Mmmmheaa. Physical and Stretch Properties of Woven Cotton Fabrics Containing Different Rates of Spandex. J. Am. Sci. 2012, 8, 567–572. [Google Scholar]

- Babaarslan, O.; Shahid, M.A.; Doǧan, F.B. Design of Hybrid Yarn with the Combination of Fiber and Filaments and Its Effect on the Denim Fabric Performance. Fibres Text. East. Eur. 2023, 31, 25–37. [Google Scholar] [CrossRef]

- Akter, N.; Repon, M.R.; Mikučionienė, D.; Jalil, M.A.; Islam, T.; Karim, M.R. Fabrication and characterization of stretchable denim fabric using core spun yarn. Heliyon 2021, 7, e08532. [Google Scholar] [CrossRef]

- Babaarslan, O.; Sarıoğlu, E.; Ertek Avcı, M. A comparative study on performance characteristics of multicomponent core-spun yarns containing cotton/PET/elastane. J. Text. Inst. 2020, 111, 775–784. [Google Scholar] [CrossRef]

- Babaarslan, O.; Shahid, M.A.; Okyay, N. Investigation of the Performance of Cotton/Polyester Blend in Different Yarn Structures. Autex Res. J. 2022, 23, 370–380. [Google Scholar] [CrossRef]

- TS EN ISO 139; Textiles-Standard Atmospheres for Conditioning and Testing. Türk Standardları Enstitüsü: Ankara, Turkey, 2008.

- TS EN 12127; Textiles-Fabrics-Determination of Mass per Unit Area Using Small Samples. Türk Standardları Enstitüsü: Ankara, Turkey, 1999.

- TS EN ISO 5077; Textiles-Determination of Dimensional Change in Washing and Drying. Türk Standardları Enstitüsü: Ankara, Turkey, 2012.

- TS EN ISO 13934-1; Textiles-Tensile Properties of Fabrics—Part 1: Determination of Maximum Force and Elongation at Maximum Force Using the Strip Method. Türk Standardları Enstitüsü: Ankara, Turkey, 2013.

- TS EN ISO 13934-2; Textiles-Tensile Properties of Fabrics—Part 2: Determination of Maximum Force Using the Grab Method. Türk Standardları Enstitüsü: Ankara, Turkey, 2014.

- TS 1409; Stiffness Determination of Woven Textiles. Türk Standardları Enstitüsü: Ankara, Turkey, 1973.

- ASTM D3107; Standard Test Methods for Stretch Properties of Fabrics Woven from Stretch Yarns. ASTM: West Conshohocken, PA, USA, 2019.

- TS 391 EN ISO 9237; Textiles-Determination of Permeability of Fabrics to Air. Türk Standardları Enstitüsü: Ankara, Turkey, 1999.

- TS 257 EN 20811; Textiles Fabrics-Determination of Resistance to Water Penetration-Hydrostatic Pressure Test. Türk Standardları Enstitüsü: Ankara, Turkey, 1996.

| Fineness (mic) | Length (mm) | Uniformity Index | Strength (g/tex) | Elongation (%) | Brightness (Rd) | Spinnability Index | Short Fiber Index |

|---|---|---|---|---|---|---|---|

| 4–4.5 | 28–31 | 83–85 | 29–34 | 5–6.5 | 69–72 | 110–140 | 9–12 |

| Fineness (dtex) | Length (mm) | Tenacity (cN/tex) | Elongation% | Dry Heat Shrinkage% (196 °C, 30 min) | Crimp/cm | Luster |

|---|---|---|---|---|---|---|

| 1.33 | 32 | 63.6 | 15 | 6 | 4.3 | semi-dull |

| Sample Code and Yarn Type | Sheath | Core | Yarn Composition | |

|---|---|---|---|---|

| R1 | Rigid Yarn | 100% CO | -- | 100% CO |

| R2 | 75/25% (CO/PES) | -- | 75/25% (CO/PES) | |

| R3 | 50/50% (CO/PES) | -- | 50/50% (CO/PES) | |

| R4 | 25/75% (CO/PES) | -- | 25/75% (CO/PES) | |

| R5 | 100% PES | -- | 100% PES | |

| C1 | Core-spun Yarn | 100% CO | 78 dtex El | 93.4% CO + 6.6% El |

| C2 | 75/25% (CO/PES) | 78 dtex El | 70% CO + 23.4% PES + 6.6% El | |

| C3 | 50/50% (CO/PES) | 78 dtex El | 46.7% CO + 46.7% PES + 6.6% El | |

| C4 | 25/75% (CO/PES) | 78 dtex El | 23.4% CO + 70% PES + 6.6% El | |

| C5 | 100% PES | 78 dtex El | 93.4% PES + 6.6% El | |

| DC1 | Dual-core-spun Yarn | 100% CO | 50 dtex PBT 78 dtex El | 76.7% CO + 16.7% PBT + 6.6% El |

| DC2 | 75/25% (CO/PES) | 50 dtex PBT 78 dtex El | 57.5% CO + 19.2% PES + 16.7% PBT + 6.6% El | |

| DC3 | 50/50% (CO/PES) | 50 dtex PBT 78 dtex El | 38.3% CO + 38.3% PES + 16.7% PBT + 6.6% El | |

| DC4 | 25/75% (CO/PES) | 50 dtex PBT 78 dtex El | 19.2% CO + 57.5% PES + 16.7% PBT + 6.6% El | |

| DC5 | 100% PES | 50 dtex PBT 78 dtex El | 76.7% PES + 16.7% PBT + 6.6% El | |

| Rigid Yarn | Core-Spun Yarn | Dual-Core-Spun Yarn | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R1 | R2 | R3 | R4 | R5 | C1 | C2 | C3 | C4 | C5 | DC1 | DC2 | DC3 | DC4 | DC5 | |

| Strength | 15.2 | 15.7 | 18.5 | 26.2 | 31.9 | 12.9 | 15.3 | 18.8 | 23.1 | 30.8 | 13.3 | 14.2 | 18.4 | 22.1 | 27.9 |

| Elongation | 6.2 | 7.1 | 9.2 | 11.9 | 12.6 | 8.8 | 9.9 | 12.5 | 14.2 | 15.2 | 11.1 | 12.4 | 16.5 | 16.4 | 18.2 |

| Unevenness | 11.2 | 10.1 | 9.6 | 8.4 | 7.3 | 11.2 | 10.3 | 9.0 | 8.4 | 7.1 | 10.7 | 9.9 | 9.1 | 7.6 | 6.6 |

| Hairiness | 7.6 | 6.9 | 6.4 | 6.6 | 6.4 | 7.2 | 7.0 | 6.7 | 7.1 | 7.4 | 7.5 | 7.0 | 7.4 | 7.2 | 7.2 |

| Dependent Variable | Source | F | Sig. |

|---|---|---|---|

| Fabric dry gsm | Weft yarn type | 11,669.107 | 0.000 |

| Blending ratio | 10.143 | 0.000 | |

| Weft yarn type*Blending ratio | 14.053 | 0.000 | |

| Fabric washed gsm | Weft yarn type | 32,817.425 | 0.000 |

| Blending ratio | 139.722 | 0.000 | |

| Weft yarn type*Blending ratio | 53.865 | 0.000 | |

| Warp side dimensional changes | Weft yarn type | 135.497 | 0.000 |

| Blending ratio | 53.943 | 0.000 | |

| Weft yarn type*Blending ratio | 21.849 | 0.000 | |

| Weft side dimensional changes | Weft Yarn type | 41,503.390 | 0.000 |

| Blending ratio | 484.768 | 0.000 | |

| Weft yarn type*Blending ratio | 464.833 | 0.000 | |

| Stiffness | Weft yarn type | 508.125 | 0.000 |

| Blending ratio | 5.962 | 0.000 | |

| Weft yarn type*Blending ratio | 4.031 | 0.001 | |

| Warp side tensile strength | Weft yarn type | 1589.340 | 0.000 |

| Blending ratio | 15.567 | 0.000 | |

| Weft yarn type*Blending ratio | 9.550 | 0.000 | |

| Weft side tensile strength | Weft yarn type | 25.587 | 0.000 |

| Blending ratio | 1948.672 | 0.000 | |

| Weft yarn type*Blending ratio | 13.523 | 0.000 | |

| Warp side tear strength | Weft yarn type | 659.777 | 0.000 |

| Blending ratio | 8.824 | 0.000 | |

| Weft yarn type*Blending ratio | 9.056 | 0.000 | |

| Weft side tear strength | Weft yarn type | 60.035 | 0.000 |

| Blending ratio | 7573.129 | 0.000 | |

| Weft yarn type*Blending ratio | 21.046 | 0.000 | |

| Elasticity% | Weft yarn type | 121,287.166 | 0.000 |

| Blending ratio | 868.919 | 0.000 | |

| Weft yarn type*Blending ratio | 261.704 | 0.000 | |

| Growth% at 30 s | Weft yarn type | 7056.609 | 0.000 |

| Blending ratio | 154.754 | 0.000 | |

| Weft yarn type*Blending ratio | 45.775 | 0.000 | |

| Growth% at 2 h | Weft yarn type | 4622.385 | 0.000 |

| Blending ratio | 80.744 | 0.000 | |

| Weft yarn type*Blending ratio | 21.455 | 0.000 | |

| Air permeability | Weft yarn type | 304.783 | 0.000 |

| Blending ratio | 11.691 | 0.000 | |

| Weft yarn type*Blending ratio | 4.621 | 0.000 | |

| Water vapor permeability | Weft yarn type | 5.298 | 0.008 |

| Blending ratio | 14.577 | 0.000 | |

| Weft yarn type*Blending ratio | 5.708 | 0.000 |

| Fabric Properties | p-Value | R Squared | Regression Equation | Equation No. |

|---|---|---|---|---|

| Fabric dry gsm | 0.000 | 0.839 | 220.287 + 35.10 A + 0.3 B | 1 |

| Fabric washed gsm | 0.000 | 0.774 | 200.340 + 72.06 A − 4.20 B | 2 |

| Warp side dimensional changes | 0.030 | 0.093 | −1.567 − 0.760 A + 0.153 B | 3 |

| Weft side dimensional changes | 0.000 | 0.696 | 5.192 − 9.316 A + 0.965 B | 4 |

| Stiffness | 0.000 | 0.697 | 0.322 + 0.290 A − 0.005 B | 5 |

| Warp side tensile strength | 0.000 | 0.747 | 49.947 + 13.260 A + 0.373 B | 6 |

| Weft side tensile strength | 0.000 | 0.962 | 18.580 − 1.50 A + 10.82 B | 7 |

| Warp side tear strength | 0.000 | 0.713 | 4432.389 + 292.272 A + 5.651 B | 8 |

| Weft side tear strength | 0.000 | 0.947 | 2509.099 + 63.932 A + 850.299 B | 9 |

| Elasticity% | 0.000 | 0.753 | −12.693 + 28.752 A − 2.219 B | 10 |

| Growth% at 30 s | 0.000 | 0.612 | −0.608 + 3.608 A − 0.464 B | 11 |

| Growth% at 2 h | 0.000 | 0.818 | −1.728 + 3.608 A − 3.31 B | 12 |

| Air permeability | 0.000 | 0.774 | 163.681 − 38.854 A + 4.397 B | 13 |

| Water vapor permeability | 0.000 | 0.209 | 85.437 + 0.776 A + 2.001 B | 14 |

| T1 | T2 | A | B | C | D | E | F | G | H | I | J | K | L | M | N | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T1 | 1 | 0.000 | 0.916 ** | 0.875 ** | 0.834 ** | 0.863 ** | −0.078 | 0.844 ** | 0.042 | 0.860 ** | 0.764 ** | 0.893 ** | −0.287 * | −0.821 ** | −0.863 ** | 0.100 |

| T2 | 1 | 0.014 | −0.089 | −0.023 | 0.042 | 0.977 ** | 0.028 | 0.972 ** | −0.115 | −0.170 | −0.142 | 0.100 | 0.147 | 0.169 | 0.446 ** | |

| A | 1 | 0.980 ** | 0.946 ** | 0.958 ** | −0.058 | 0.929 ** | 0.073 | 0.972 ** | 0.921 ** | 0.959 ** | −0.471 ** | −0.942 ** | −0.894 ** | −0.014 | ||

| B | 1 | 0.934 ** | 0.971 ** | −0.140 | 0.930 ** | −0.024 | 0.997 ** | 0.969 ** | 0.980 ** | −0.519 ** | −0.986 ** | −0.889 ** | −0.053 | |||

| C | 1 | 0.899 ** | −0.102 | 0.881 ** | 0.039 | 0.932 ** | 0.890 ** | 0.893 ** | −0.455 ** | −0.899 ** | −0.864 ** | −0.049 | ||||

| D | 1 | −0.005 | 0.918 ** | 0.100 | 0.964 ** | 0.930 ** | 0.948 ** | −0.498 ** | −0.952 ** | −0.842 ** | 0.013 | |||||

| E | 1 | −0.032 | 0.951 ** | −0.169 | −0.215 | −0.195 | 0.050 | 0.188 | 0.262 * | 0.481 ** | ||||||

| F | 1 | 0.057 | 0.924 ** | 0.883 ** | 0.908 ** | −0.504 ** | −0.896 ** | −0.809 ** | −0.052 | |||||||

| G | 1 | −0.054 | −0.122 | −0.099 | 0.080 | 0.076 | 0.089 | 0.413 ** | ||||||||

| H | 1 | 0.981 ** | 0.983 ** | −0.507 ** | −0.990 ** | −0.887 ** | −0.060 | |||||||||

| I | 1 | 0.963 ** | −0.521 ** | −0.982 ** | −0.839 ** | −0.113 | ||||||||||

| J | 1 | −0.463 ** | −0.971 ** | −0.887 ** | −0.036 | |||||||||||

| K | 1 | 0.520 ** | 0.319 ** | −0.036 | ||||||||||||

| L | 1 | 0.863 ** | 0.072 | |||||||||||||

| M | 1 | 0.168 | ||||||||||||||

| N | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahid, M.A.; Okyay, N.; Babaarslan, O. A Comparative Analysis of Denim Fabric Performances from Cotton/Polyester Blended Rigid and Stretched Yarns. Fibers 2024, 12, 86. https://doi.org/10.3390/fib12100086

Shahid MA, Okyay N, Babaarslan O. A Comparative Analysis of Denim Fabric Performances from Cotton/Polyester Blended Rigid and Stretched Yarns. Fibers. 2024; 12(10):86. https://doi.org/10.3390/fib12100086

Chicago/Turabian StyleShahid, Md Abul, Neslihan Okyay, and Osman Babaarslan. 2024. "A Comparative Analysis of Denim Fabric Performances from Cotton/Polyester Blended Rigid and Stretched Yarns" Fibers 12, no. 10: 86. https://doi.org/10.3390/fib12100086

APA StyleShahid, M. A., Okyay, N., & Babaarslan, O. (2024). A Comparative Analysis of Denim Fabric Performances from Cotton/Polyester Blended Rigid and Stretched Yarns. Fibers, 12(10), 86. https://doi.org/10.3390/fib12100086