Effect of the Sizing Removal Methods of Fiber Surface on the Mechanical Performance of Basalt Fiber-Reinforced Concrete

Abstract

1. Introduction

2. Material and Method

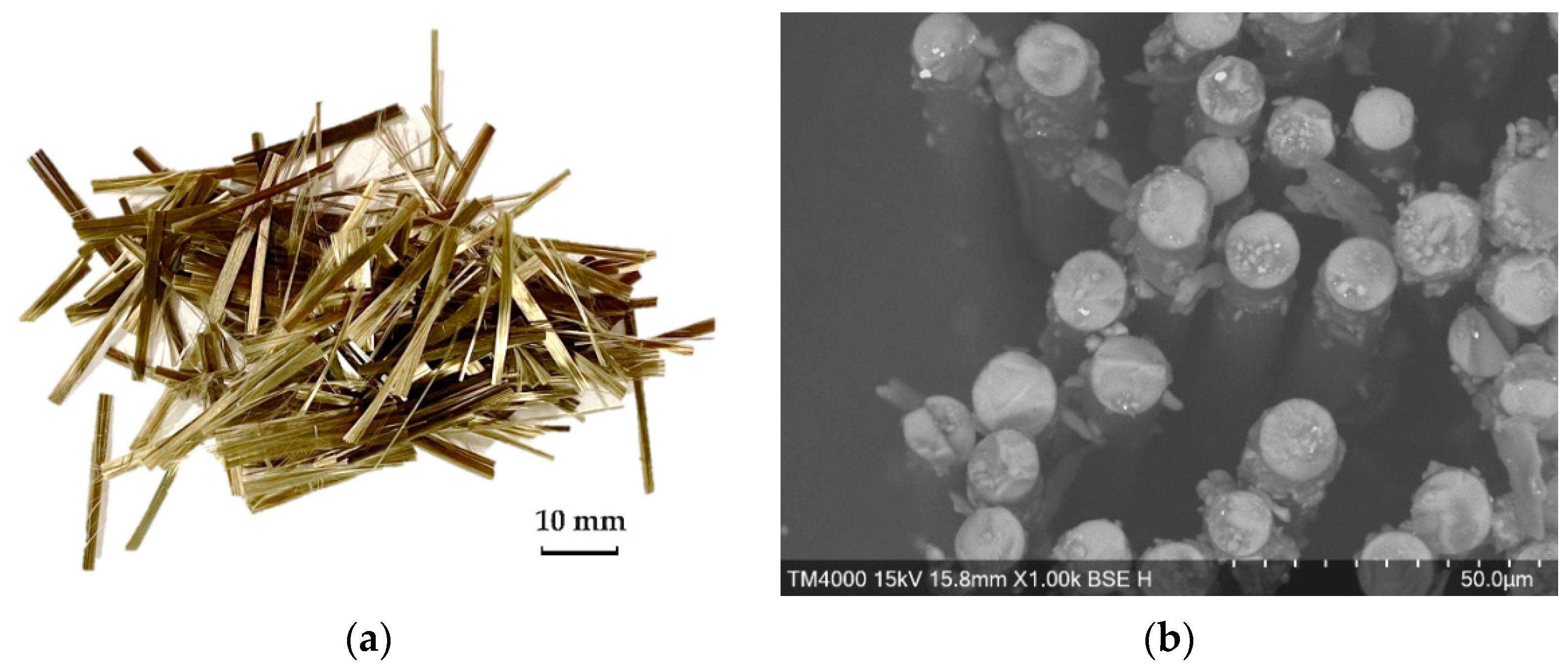

2.1. Surface Treatment of Basalt Fibers

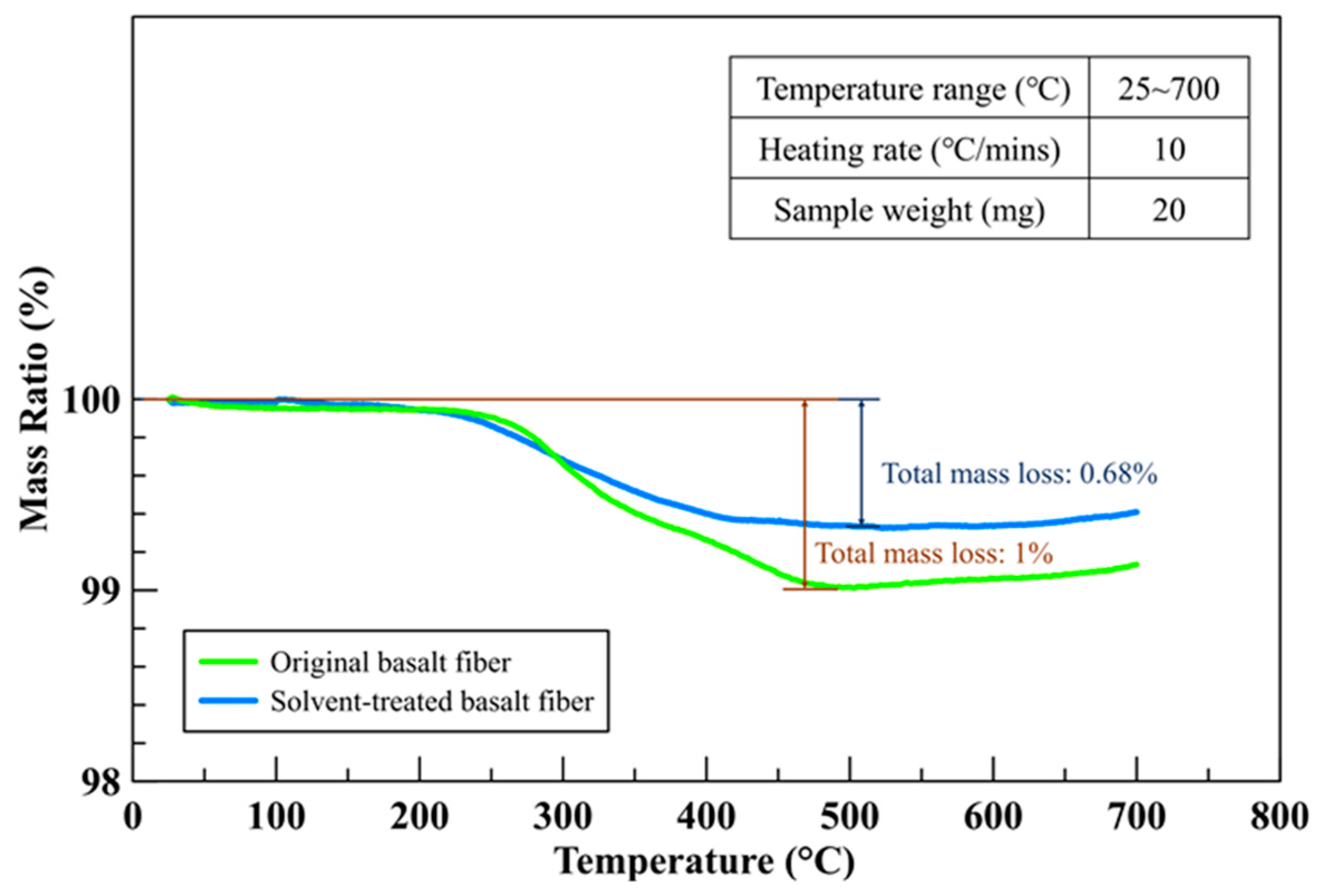

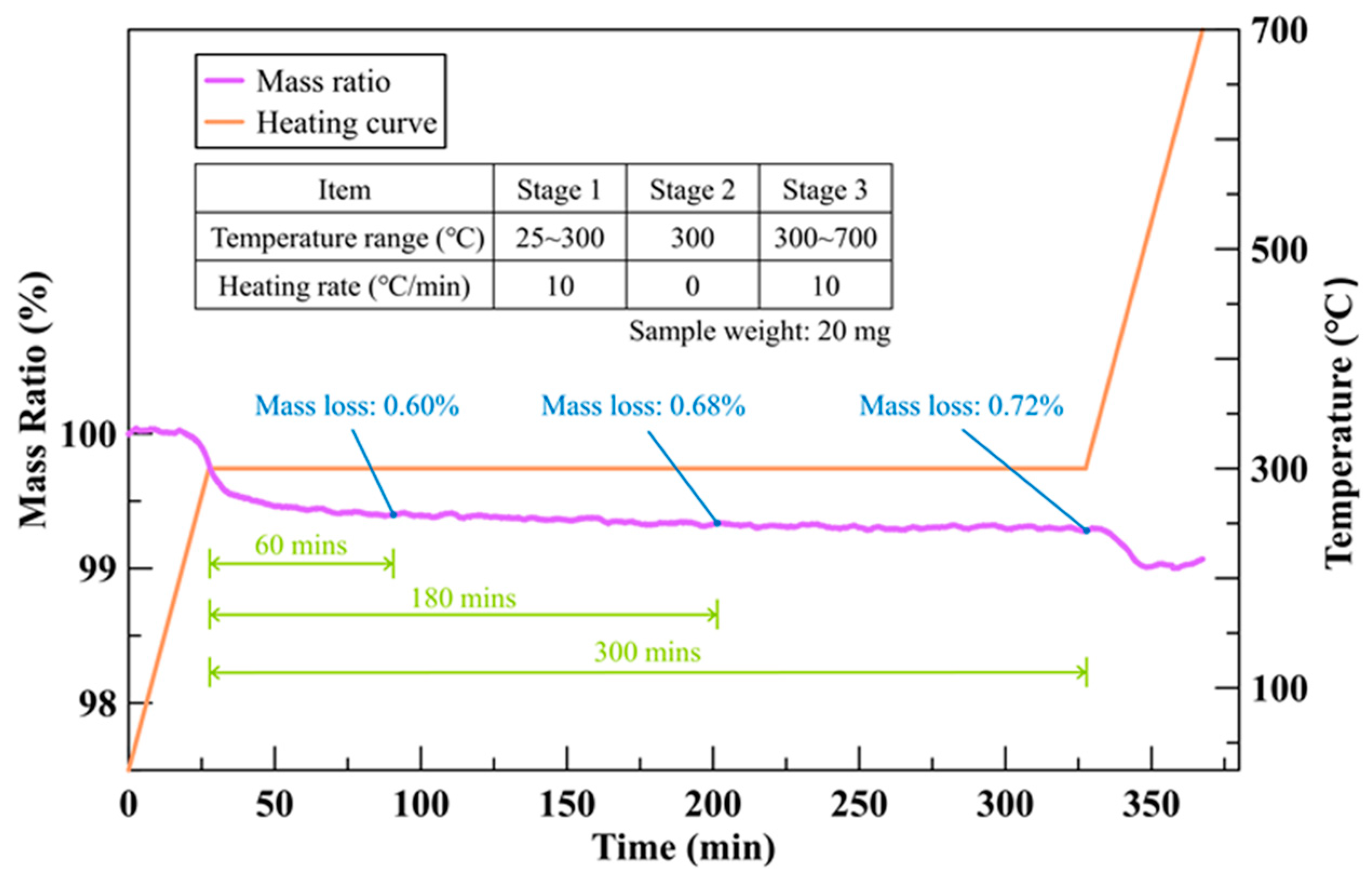

2.1.1. Heat Treatment

2.1.2. Solvent Treatment

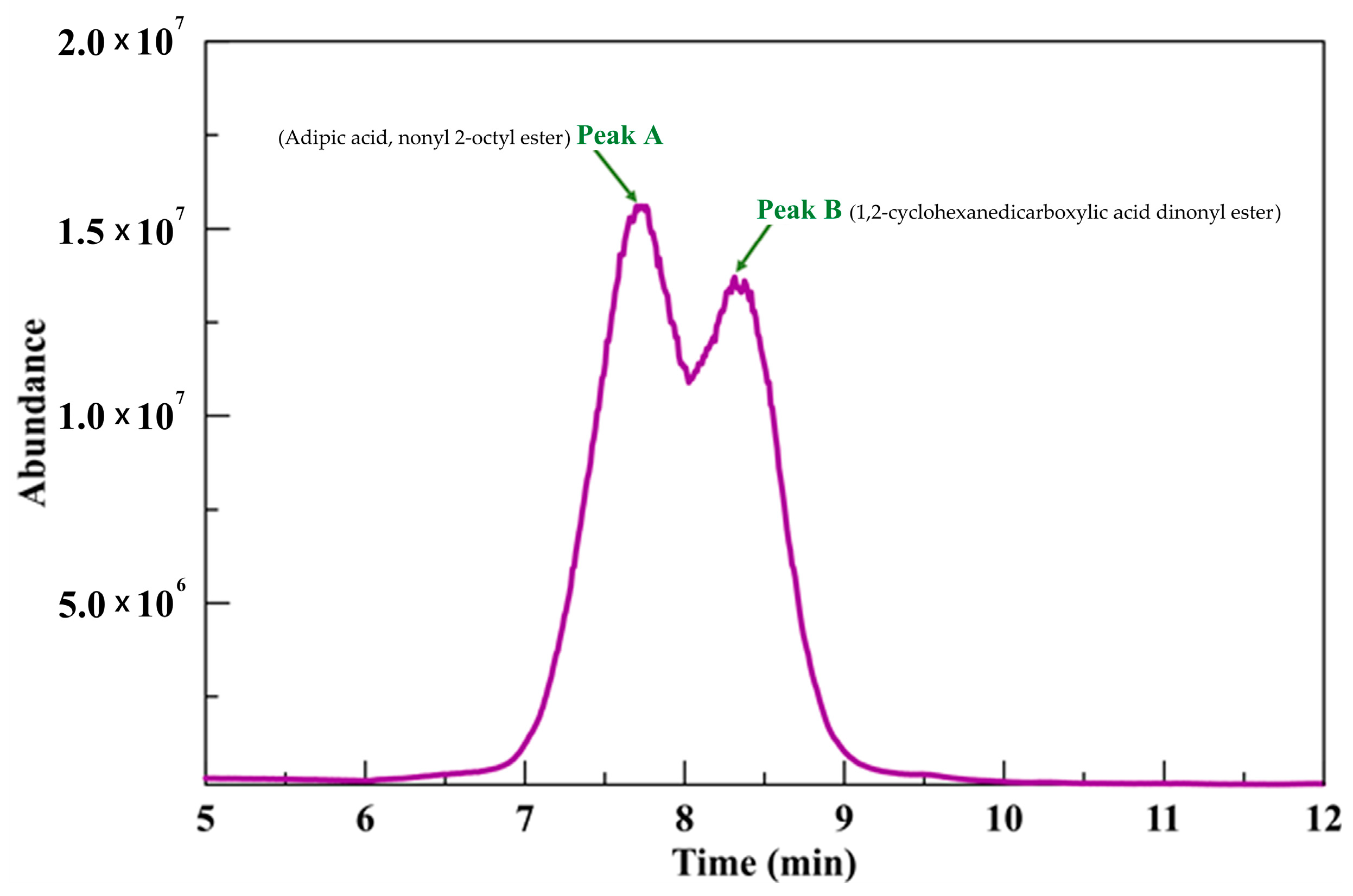

2.2. Sizing Composition Analysis of Basalt Fibers

2.3. Microscopic Observation and Analysis of Basalt Fibers

2.4. Tensile Force of Basalt Filament

2.5. BFRC Test Method

3. Physical–Chemical Property Results

3.1. Surface Treatment Results

3.1.1. Heat Treatment

3.1.2. Solvent Treatment

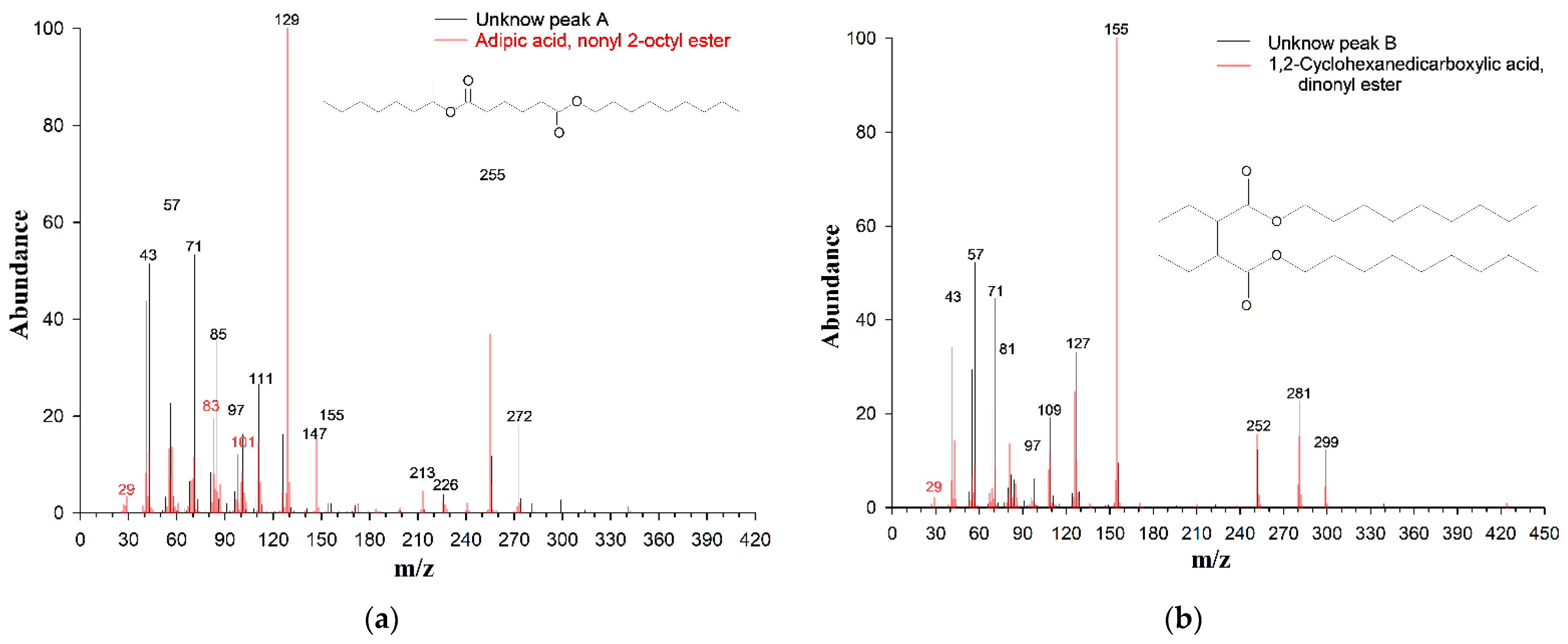

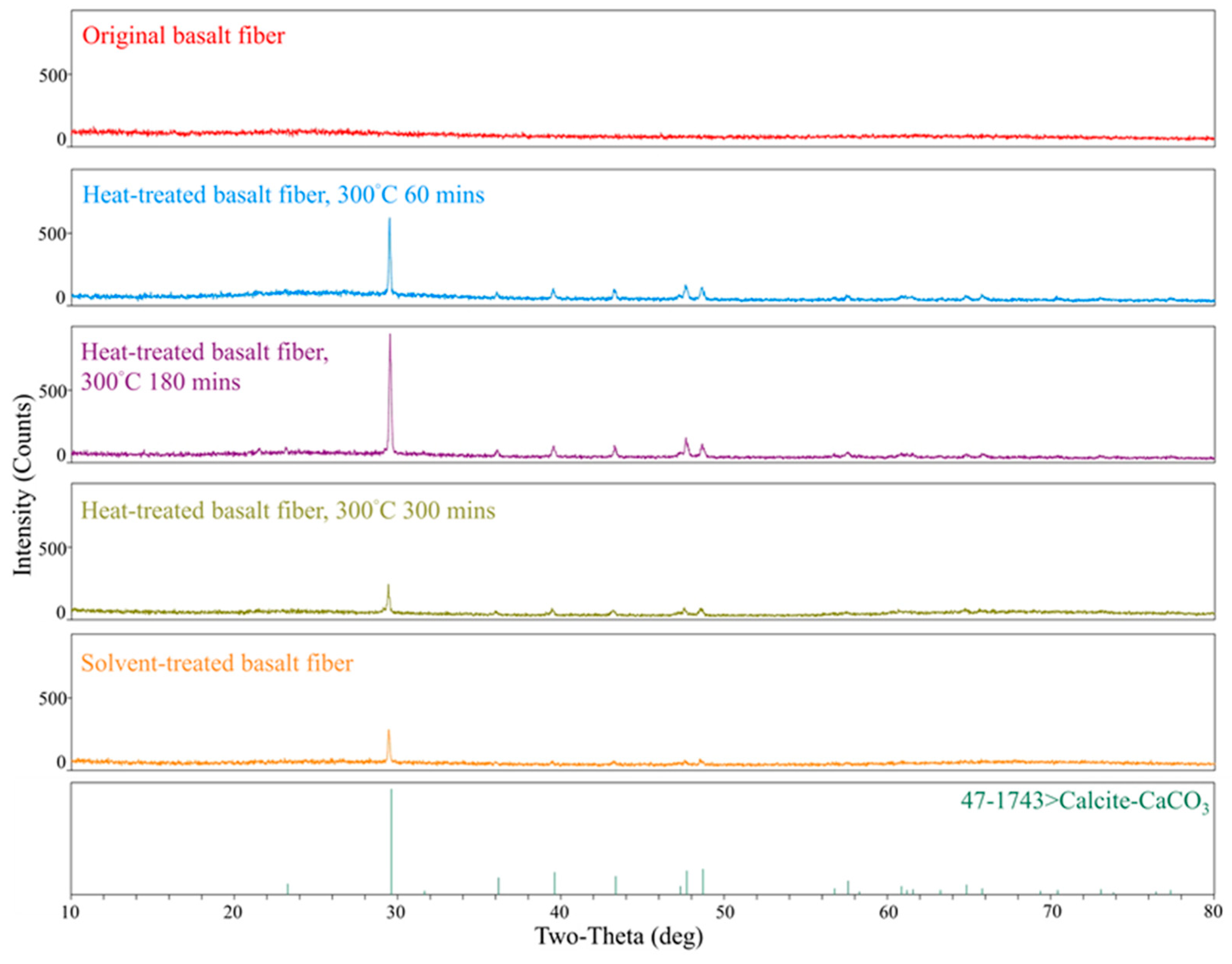

3.2. Sizing Composition Analysis

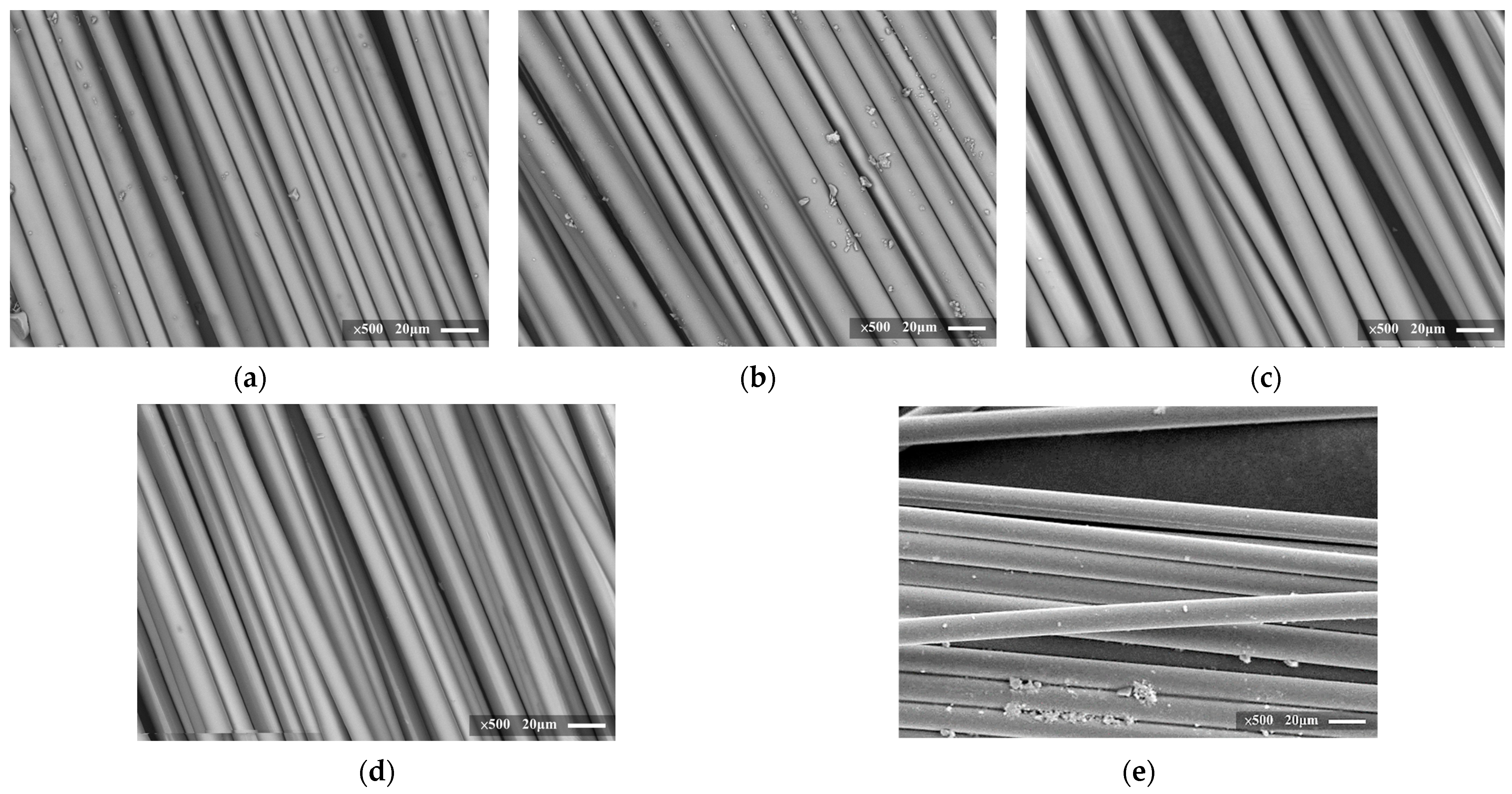

3.3. Microscopic Observation and Analysis

3.4. Peak Tensile Force of Basalt Filament

4. Mechanical Test of BFRC

4.1. Compressive Test Result

4.2. Flexural Test Result

4.3. Splitting Tensile Test Result

4.4. Discussion

5. Conclusions

- Based on a GC/MS analysis with the NIST database of extraction liquid of basalt fibers, the results showed that the two unknown substances might be “adipic acid, nonyl 2-octyl ester (C23H44O4)” and “1,2-cyclohexanedicarboxylic acid dinonyl ester (C26H48O4)”, respectively.

- The original basalt fibers were amorphous, with no crystals or diffraction peaks in the diffraction spectrum.

- The SEM images indicate that the heat treatment method was more effective in removing sizing from the basalt fibers compared to the solvent treatment method.

- Based on the TGA mass ratio–temperature and mass ratio–time relationships of the basalt fibers, the optimal conditions for removing sizing from the surfaces of the basalt fibers were a target temperature of 300 °C and a holding time of 180 min.

- The SEM image observation of the failed BFRC specimens indicated that the heat-treated basalt fibers were more uniformly dispersed in the concrete than the specimens with original and solvent-treated basalt fibers.

- The results indicated that the mechanical properties of specimens with sizing-removed basalt fibers (HBFRC and SBFRC) were better than the specimens with original basalt fibers (OBFRC) and the benchmark specimens (B).

- The compressive, flexural and split tensile test results show that BFRC specimens with heat-treated basalt fibers exhibited higher strengths compared to those with original and solvent-treated basalt fibers.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kim, J.J.; Park, G.J.; Kim, D.J.; Moon, J.H.; Lee, J.H. High-rate tensile behavior of steel fiber-reinforced concrete for nuclear power plants. Nucl. Eng. Des. 2014, 266, 43–54. [Google Scholar] [CrossRef]

- Banthia, N.; Majdzadeh, F.; Wu, J.; Bindiganavile, V. Fiber synergy in Hybrid Fiber Reinforced Concrete (HyFRC) in flexure and direct shear. Cem. Concr. Compos. 2014, 48, 91–97. [Google Scholar] [CrossRef]

- Mohammadi, Y.; Singh, S.P.; Kaushik, S.K. Properties of steel fibrous concrete containing mixed fibres in fresh and hardened state. Constr. Build. Mater. 2008, 22, 956–965. [Google Scholar] [CrossRef]

- Kang, S.T.; Choi, J.I.; Koh, K.T.; Lee, K.S.; Lee, B.Y. Hybrid effects of steel fiber and microfiber on the tensile behavior of ultra-high performance concrete. Compos. Struct. 2016, 145, 37–42. [Google Scholar] [CrossRef]

- Lou, K.; Kang, A.; Xiao, P.; Wu, Z.; Li, B.; Wang, X. Effects of basalt fiber coated with different sizing agents on performance and microstructures of asphalt mixture. Constr. Build. Mater. 2021, 266, 121155. [Google Scholar] [CrossRef]

- Wei, B.; Song, S.; Cao, H. Strengthening of basalt fibers with nano-SiO2–epoxy composite coating. Mater. Des. 2011, 32, 4180–4186. [Google Scholar] [CrossRef]

- Militký, J.; Kovačič, V.; Rubnerová, J. Influence of thermal treatment on tensile failure of basalt fibers. Eng. Fract. Mech. 2002, 69, 1025–1033. [Google Scholar] [CrossRef]

- Deák, T.; Czigány, T. Chemical composition and mechanical properties of basalt and glass fibers: A comparison. Text. Res. J. 2009, 79, 645–651. [Google Scholar] [CrossRef]

- Xiang, Y.; Xie, Y.; Long, G. Effect of basalt fiber surface silane coupling agent coating on fiber-reinforced asphalt: From macro-mechanical performance to micro-interfacial mechanism. Constr. Build. Mater. 2018, 179, 107–116. [Google Scholar] [CrossRef]

- Beppu, M.; Mori, K.; Ichino, H.; Muroga, Y. Local failure resistance of polypropylene fiber reinforced concrete plates subjected to projectile impact. Int. J. Prot. Struct. 2022, 13, 317–343. [Google Scholar] [CrossRef]

- Bheel, N.; Awoyera, P.; Aluko, O.; Mahro, S.; Viloria, A.; Sierra, C.A.S. Sustainable composite development: Novel use of human hair as fiber in concrete. Case Stud. Constr. Mater. 2020, 13, e00412. [Google Scholar] [CrossRef]

- Li, Y.F.; Lee, K.F.; Ramanathan, G.K.; Cheng, T.W.; Huang, C.H.; Tsai, Y.K. Static and dynamic performances of chopped carbon-fiber-reinforced mortar and concrete incorporated with disparate lengths. Materials 2021, 14, 972. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.F.; Wang, H.F.; Syu, J.Y.; Ramanathan, G.K.; Tsai, Y.K. Investigating the Mechanical Performance on Static and Shock Wave Loading of Aramid Fiber-Reinforced Concrete. Fibers 2022, 10, 82. [Google Scholar] [CrossRef]

- Li, Y.F.; Ramanathan, G.K.; Syu, J.Y.; Huang, C.H.; Tsai, Y.K. Mechanical behavior of different fiber lengths mix-proportions carbon fiber reinforced concrete subjected to static, impact, and blast loading. Int. J. Prot. Struct. 2022, 20414196221138596. [Google Scholar] [CrossRef]

- Abdellatef, M.; Heras Murcia, D.; Hogancamp, J.; Matteo, E.; Stormont, J.; Taha, M.M.R. The Significance of Multi-Size Carbon Fibers on the Mechanical and Fracture Characteristics of Fiber Reinforced Cement Composites. Fibers 2022, 10, 65. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A. The impact resistance and mechanical properties of the reinforced self-compacting concrete incorporating recycled CFRP fiber with different lengths and dosages. Compos. Part B Eng. 2017, 112, 74–92. [Google Scholar] [CrossRef]

- Fakharifar, M.; Dalvand, A.; Arezoumandi, M.; Sharbatdar, M.K.; Chen, G.; Kheyroddin, A. Mechanical properties of high performance fiber reinforced cementitious composites. Constr. Build. Mater. 2014, 71, 510–520. [Google Scholar] [CrossRef]

- Li, Y.F.; Wang, H.F.; Syu, J.Y.; Ramanathan, G.K.; Tsai, Y.K.; Lok, M.H. Mechanical properties of aramid/carbon hybrid fiber-reinforced concrete. Materials 2021, 14, 5881. [Google Scholar] [CrossRef]

- Li, Y.F.; Yang, K.H.; Hsu, P.Y.; Syu, J.Y.; Wang, S.J.; Kuo, W.S.; Tsai, Y.K. Comparing Mechanical Characterization of Carbon, Kevlar, and Hybrid-Fiber-Reinforced Concrete under Quasistatic and Dynamic Loadings. Buildings 2023, 13, 2044. [Google Scholar] [CrossRef]

- Palanisamy, E.; Ramasamy, M. Dependency of sisal and banana fiber on mechanical and durability properties of polypropylene hybrid fiber reinforced concrete. J. Nat. Fibers 2022, 19, 3147–3157. [Google Scholar] [CrossRef]

- Ganta, J.K.; Rao, M.S.; Mousavi, S.S.; Reddy, V.S.; Bhojaraju, C. Hybrid steel/glass fiber-reinforced self-consolidating concrete considering packing factor: Mechanical and durability characteristics. Structures 2020, 28, 956–972. [Google Scholar] [CrossRef]

- Teja Prathipati, S.R.R.; Rao, C.B.K. A study on the uniaxial behavior of hybrid graded fiber reinforced concrete with glass and steel fibers. Mater. Today Proc. 2020, 32, 764–770. [Google Scholar] [CrossRef]

- Thomason, J.L. Glass fibre sizing: A review. Compos. Part A Appl. Sci. Manuf. 2019, 127, 105619. [Google Scholar] [CrossRef]

- Ralph, C.; Lemoine, P.; Boyd, A.; Archer, E.; McIlhagger, A. The effect of fibre sizing on the modification of basalt fibre surface in preparation for bonding to polypropylene. Appl. Surf. Sci. 2019, 475, 435–445. [Google Scholar] [CrossRef]

- Gorowara, R.L.; Kosik, W.E.; McKnight, S.H.; McCullough, R.L. Molecular characterization of glass fiber surface coatings for thermosetting polymer matrix/glass fiber composites. Compos. Part A Appl. Sci. Manuf. 2001, 32, 323–329. [Google Scholar] [CrossRef]

- Iorio, M.; Santarelli, M.L.; González-Gaitano, G.; González-Benito, J. Surface modification and characterization of basalt fibers as potential reinforcement of concretes. Appl. Surf. Sci. 2018, 427, 1248–1256. [Google Scholar] [CrossRef]

- Thomason, J. A review of the analysis and characterisation of polymeric glass fibre sizings. Polym. Test. 2020, 85, 106421. [Google Scholar] [CrossRef]

- Li, Y.F.; Li, J.Y.; Ramanathan, G.K.; Chang, S.M.; Shen, M.Y.; Tsai, Y.K.; Huang, C.H. An experimental study on mechanical behaviors of carbon fiber and microwave-assisted pyrolysis recycled carbon fiber-reinforced concrete. Sustainability 2021, 13, 6829. [Google Scholar] [CrossRef]

- Li, Y.F.; Yang, T.H.; Kuo, C.Y.; Tsai, Y.K. A Study on improving the mechanical performance of carbon-fiber-reinforced cement. Materials 2019, 12, 2715. [Google Scholar] [CrossRef]

- Li, Y.F.; Li, J.Y.; Syu, J.Y.; Yang, T.H.; Chang, S.M.; Shen, M.Y. Mechanical Behaviors of Microwave-Assisted Pyrolysis Recycled Carbon Fiber-Reinforced Concrete with Early-Strength Cement. Materials 2023, 16, 1507. [Google Scholar] [CrossRef]

- Thomason, J.L.; Nagel, U.; Yang, L.; Bryce, D. A study of the thermal degradation of glass fibre sizings at composite processing temperatures. Compos. Part A Appl. Sci. Manuf. 2019, 121, 56–63. [Google Scholar] [CrossRef]

- Jenkins, P.G.; Yang, L.; Liggat, J.J.; Thomason, J.L. Investigation of the strength loss of glass fibre after thermal conditioning. J. Mater. Sci. 2015, 50, 1050–1057. [Google Scholar] [CrossRef]

- Wang, Z.T.; Luo, H.J.; Zhang, J.; Chen, H.W.; Zhang, L.; Wu, L.L.; Jiang, H. Water-soluble polysiloxane sizing for improved heat resistance of basalt fiber. Mater. Chem. Phys. 2021, 272, 125024. [Google Scholar] [CrossRef]

- Overkamp, T.; Mahltig, B.; Kyosev, Y. Strength of basalt fibers influenced by thermal and chemical treatments. J. Ind. Text. 2018, 47, 815–833. [Google Scholar] [CrossRef]

- Li, Y.F.; Hung, J.Y.; Syu, J.Y.; Chang, S.M.; Kuo, W.S. Influence of sizing of basalt fiber on the mechanical behavior of basalt fiber reinforced concrete. J. Mater. Res. Technol. 2022, 21, 295–307. [Google Scholar] [CrossRef]

- Frey, M.; Brunner, A.J. Assessing glass-fiber modification developments by comparison of glass-fiber epoxy composites with reference materials: Some thoughts on relevance. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2017, 231, 49–54. [Google Scholar] [CrossRef]

- Guo, X.; Lu, Y.; Sun, Y.; Wang, J.; Li, H.; Yang, C. Effect of sizing on interfacial adhesion property of glass fiber-reinforced polyurethane composites. J. Reinf. Plast. Compos. 2018, 37, 321–330. [Google Scholar] [CrossRef]

- Feih, S.; Wei, J.; Kingshott, P.; Sørensen, B.F. The influence of fibre sizing on the strength and fracture toughness of glass fibre composites. Compos. Part A Appl. Sci. Manuf. 2005, 36, 245–255. [Google Scholar] [CrossRef]

- Jiang, S.; Li, Q.; Zhao, Y.; Wang, J.; Kang, M. Effect of surface silanization of carbon fiber on mechanical properties of carbon fiber reinforced polyurethane composites. Compos. Sci. Technol. 2015, 110, 87–94. [Google Scholar] [CrossRef]

- Tanoglu, M.; Ziaee, S.; Mcknight, S.H.; Palmese, G.R.; Gillespie, J.W. Investigation of properties of fiber/matrix interphase formed due to the glass fiber sizings. J. Mater. Sci. 2001, 36, 3041–3053. [Google Scholar] [CrossRef]

- Thomason, J.L. The interface region in glass fibre-reinforced epoxy resin composites: 3. Characterization of fibre surface coatings and the interphase. Composites 1995, 26, 487–498. [Google Scholar] [CrossRef]

- Moosburger-Will, J.; Bauer, M.; Laukmanis, E.; Horny, R.; Wetjen, D.; Manske, T.; Schmidt-Stein, F.; Töpker, J.; Horn, S. Interaction between carbon fibers and polymer sizing: Influence of fiber surface chemistry and sizing reactivity. Appl. Surf. Sci. 2018, 439, 305–312. [Google Scholar] [CrossRef]

- ASTM D3822-07; Standard Test Method for Tensile Properties of Single Textile Fibers. ASTM: West Conshohocken, PA, USA, 2007.

- ASTM C33/C33M-18; Standard Specification for Concrete Aggregates. ASTM: West Conshohocken, PA, USA, 2018.

- ASTM C39/C39M-01; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 2001.

- ASTM C293/C293M-16; Standard Test Method for Flexural Strength of Concrete. ASTM: West Conshohocken, PA, USA, 2016.

- ASTM C496/C496M-17; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 2017.

- Ku-Herrera, J.J.; Avilés, F.; Nistal, A.; Cauich-Rodríguez, J.V.; Rubio, F.; Rubio, J.; Bartolo-Pérez, P. Interactions between the glass fiber coating and oxidized carbon nanotubes. Appl. Surf. Sci. 2015, 330, 383–392. [Google Scholar] [CrossRef]

- Britcher, L.G.; Kehoe, D.; Matisons, J.G. Direct spectroscopic measurements of adsorption of siloxane polymers onto glass fiber surfaces. In Silanes and Other Coupling Agents; Mittal, K.L., Ed.; CRC Press: London, UK, 2020; Volume 2, pp. 99–114. [Google Scholar]

- Chang, J.H.; Tsai, Y.S.; Yang, P.Y. A Review of Glass Fibre Recycling Technology Using Chemical and Mechanical Separation of Surface Sizing Agents. Recycling 2021, 6, 79. [Google Scholar] [CrossRef]

- Chakartnarodom, P.; Prakaypan, W.; Ineure, P.; Chuankrerkkul, N.; Laitila, E.A.; Kongkajun, N. Properties and performance of the basalt-fiber reinforced texture roof tiles. Case Stud. Constr. Mater. 2020, 13, e00444. [Google Scholar] [CrossRef]

- Bindiganavile, V.S. Dynamic Fracture Toughness of Fiber Reinforced Concrete. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2003. [Google Scholar]

- Demirboga, R.; Farhan, K.Z. Palm oil fuel ash (POFA). In Sustainable Concrete Made with Ashes and Dust from Different Sources; Rafat, S., Rafik, B., Eds.; Woodhead Publishing: Sawston/Cambridge, UK, 2022; Chapter 7; pp. 279–330. [Google Scholar]

| Item | Naming | Description |

|---|---|---|

| Specimen | B | Benchmark (without fiber) |

| OBFRC | BFRC with original basalt fibers | |

| HBFRC | BFRC with heat-treated basalt fibers | |

| SBFRC | BFRC with solvent-treated basalt fibers | |

| Mechanical test | C | Compressive test |

| F | Flexural test | |

| S | Splitting tensile test |

| Chemical Element | Original BF (wt%) | 300 °C, 60 min BF (wt%) | 300 °C, 180 min BF (wt%) | 300 °C, 300 min BF (wt%) | Solvent-Treated BF (wt%) |

|---|---|---|---|---|---|

| O | 45.3 | 44.2 | 44.1 | 43.2 | 46.6 |

| Si | 25.3 | 25.1 | 25.0 | 23.7 | 24.6 |

| Fe | 8.5 | 8.9 | 8.9 | 10.7 | 7.9 |

| Al | 8.2 | 8.2 | 8.3 | 8.1 | 7.3 |

| Ca | 5.3 | 5.1 | 5.2 | 5.9 | 5.3 |

| Mg | 3.2 | 3.3 | 3.3 | 3.2 | 2.8 |

| Na | 3.1 | 3.2 | 3.2 | 3.0 | 2.6 |

| K | 2.0 | 1.9 | 2.0 | 2.2 | 2.0 |

| No. | Original BF | 300 °C, 60 min BF | 300 °C, 180 min BF | 300 °C, 300 min BF | Solvent-Treated BF | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Force (gf) | Displ. (mm) | Force (gf) | Displ. (mm) | Force (gf) | Displ. (mm) | Force (gf) | Displ. (mm) | Force (gf) | Displ. (mm) | |

| 1 | 23.12 | 0.55 | 19.07 | 0.48 | 23.44 | 0.35 | 13.24 | 0.39 | 13.81 | 0.32 |

| 2 | 22.19 | 0.55 | 18.06 | 0.42 | 19.99 | 0.55 | 11.80 | 0.38 | 11.88 | 0.26 |

| 3 | 21.75 | 0.55 | 16.09 | 0.37 | 22.48 | 0.58 | 14.22 | 0.42 | 19.89 | 0.44 |

| 4 | 21.75 | 0.54 | 18.96 | 0.56 | 20.47 | 0.57 | 16.38 | 0.54 | 13.57 | 0.29 |

| 5 | 21.99 | 0.55 | 16.86 | 0.44 | 20.87 | 0.66 | 12.36 | 0.35 | 11.75 | 0.31 |

| 6 | 22.20 | 0.55 | 21.19 | 0.46 | 21.18 | 0.49 | 22.51 | 0.53 | 10.68 | 0.25 |

| 7 | 21.75 | 0.55 | 13.97 | 0.42 | 19.35 | 0.69 | 17.15 | 0.50 | 12.92 | 0.29 |

| 8 | 20.84 | 0.55 | 16.13 | 0.45 | 21.11 | 0.66 | 13.58 | 0.33 | 13.97 | 0.28 |

| 9 | 22.14 | 0.54 | 27.39 | 0.51 | 27.29 | 0.60 | 18.30 | 0.38 | 16.31 | 0.35 |

| 10 | 22.93 | 0.54 | 12.36 | 0.45 | 23.17 | 0.61 | 11.94 | 0.37 | 15.38 | 0.29 |

| 11 | 23.41 | 0.54 | 21.82 | 0.38 | 19.73 | 0.51 | 12.99 | 0.42 | 17.03 | 0.48 |

| 12 | 22.91 | 0.55 | 21.80 | 0.49 | 23.04 | 0.46 | 15.49 | 0.38 | 18.80 | 0.41 |

| 13 | 22.28 | 0.55 | 24.24 | 0.55 | 21.75 | 0.34 | 11.85 | 0.53 | 14.61 | 0.39 |

| 14 | 21.80 | 0.54 | 15.57 | 0.53 | 20.98 | 0.36 | 13.63 | 0.43 | 11.01 | 0.43 |

| 15 | 23.52 | 0.54 | 21.53 | 0.45 | 21.59 | 0.68 | 13.57 | 0.46 | 10.15 | 0.29 |

| Avg. | 22.31 | 0.55 | 19.00 | 0.46 | 21.76 | 0.54 | 14.60 | 0.43 | 14.12 | 0.34 |

| σ | 0.74 | 0.01 | 4.04 | 0.06 | 1.97 | 0.12 | 2.95 | 0.07 | 2.93 | 0.07 |

| F value | - | - | 0.033 | - | 0.139 | - | 0.062 | - | 0.063 | - |

| p value | - | - | 5.20 × 10−8 | - | 3.59 × 10−4 | - | 3.00 × 10−6 | - | 3.29 × 10−6 | - |

| t value | - | - | 3.12 | - | 1.00 | - | 9.81 | - | 10.50 | - |

| p value | - | - | 7.07 × 10−3 | - | 3.31 × 10−1 | - | 3.57 × 10−8 | - | 1.38 × 10−8 | - |

| Specimen | B-C | OBFRC-C | HBFRC-C | SBFRC-C |

|---|---|---|---|---|

| Compressive strength (MPa) | 23.58 | 23.91 | 25.56 | 24.39 |

| 22.98 | 24.71 | 24.08 | 24.87 | |

| 24.71 | 24.18 | 25.83 | 24.05 | |

| Avg. strength (MPa) | 23.76 | 24.27 | 25.16 | 24.44 |

| σ (MPa) | 0.9 | 0.4 | 0.9 | 0.4 |

| Specimen | B-F | OBFRC-F | HBFRC-F | SBFRC-F |

|---|---|---|---|---|

| Flexural strength (MPa) | 4.03 | 4.68 | 5.30 | 5.16 |

| 4.16 | 4.81 | 5.59 | 4.52 | |

| 4.36 | 4.34 | 5.78 | 4.77 | |

| Avg. strength (MPa) | 4.18 | 4.61 | 5.56 | 4.82 |

| σ (MPa) | 0.2 | 0.2 | 0.2 | 0.3 |

| Specimen | B-S | OBFRC-S | HBFRC-S | SBFRC-S |

|---|---|---|---|---|

| Splitting tensile strength (MPa) | 2.60 | 2.35 | 2.74 | 2.47 |

| 2.53 | 2.63 | 2.78 | 2.76 | |

| 2.20 | 2.89 | 2.74 | 2.78 | |

| Avg. strength (MPa) | 2.57 | 2.62 | 2.76 | 2.67 |

| σ (MPa) | 0.2 | 0.2 | 0.02 | 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.-F.; Hung, J.-Y.; Syu, J.-Y.; Chen, S.-H.; Huang, C.-H.; Chang, S.-M.; Kuo, W.-S. Effect of the Sizing Removal Methods of Fiber Surface on the Mechanical Performance of Basalt Fiber-Reinforced Concrete. Fibers 2024, 12, 10. https://doi.org/10.3390/fib12010010

Li Y-F, Hung J-Y, Syu J-Y, Chen S-H, Huang C-H, Chang S-M, Kuo W-S. Effect of the Sizing Removal Methods of Fiber Surface on the Mechanical Performance of Basalt Fiber-Reinforced Concrete. Fibers. 2024; 12(1):10. https://doi.org/10.3390/fib12010010

Chicago/Turabian StyleLi, Yeou-Fong, Jia-Yin Hung, Jin-Yuan Syu, Shih-Han Chen, Chih-Hong Huang, Shu-Mei Chang, and Wen-Shyong Kuo. 2024. "Effect of the Sizing Removal Methods of Fiber Surface on the Mechanical Performance of Basalt Fiber-Reinforced Concrete" Fibers 12, no. 1: 10. https://doi.org/10.3390/fib12010010

APA StyleLi, Y.-F., Hung, J.-Y., Syu, J.-Y., Chen, S.-H., Huang, C.-H., Chang, S.-M., & Kuo, W.-S. (2024). Effect of the Sizing Removal Methods of Fiber Surface on the Mechanical Performance of Basalt Fiber-Reinforced Concrete. Fibers, 12(1), 10. https://doi.org/10.3390/fib12010010