Sensitivity of Offline and Inline Indicators for Fiber Stretching in Continuous Polyacrylonitrile Stabilization

Abstract

1. Introduction

2. Materials and Methods

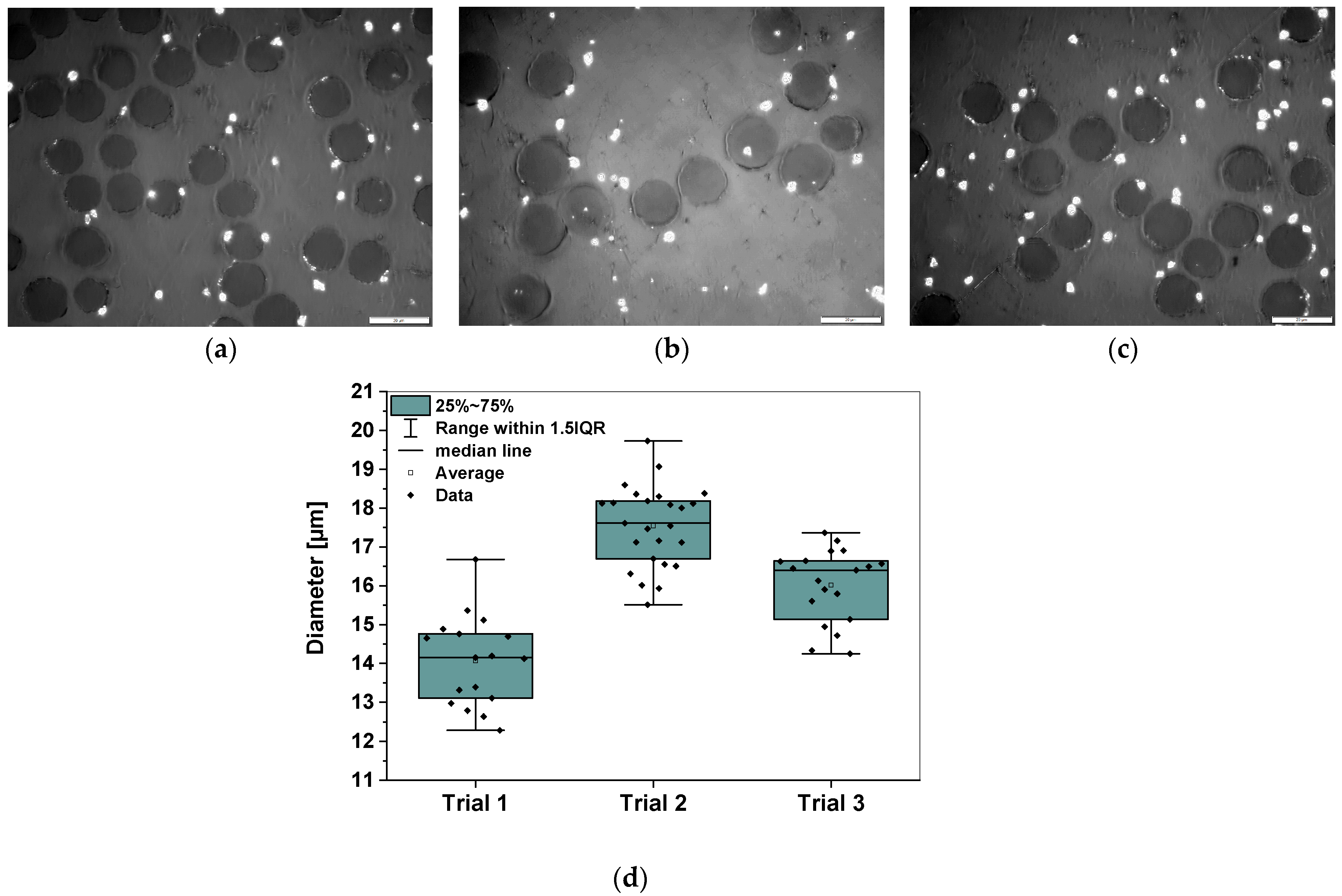

2.1. Materials

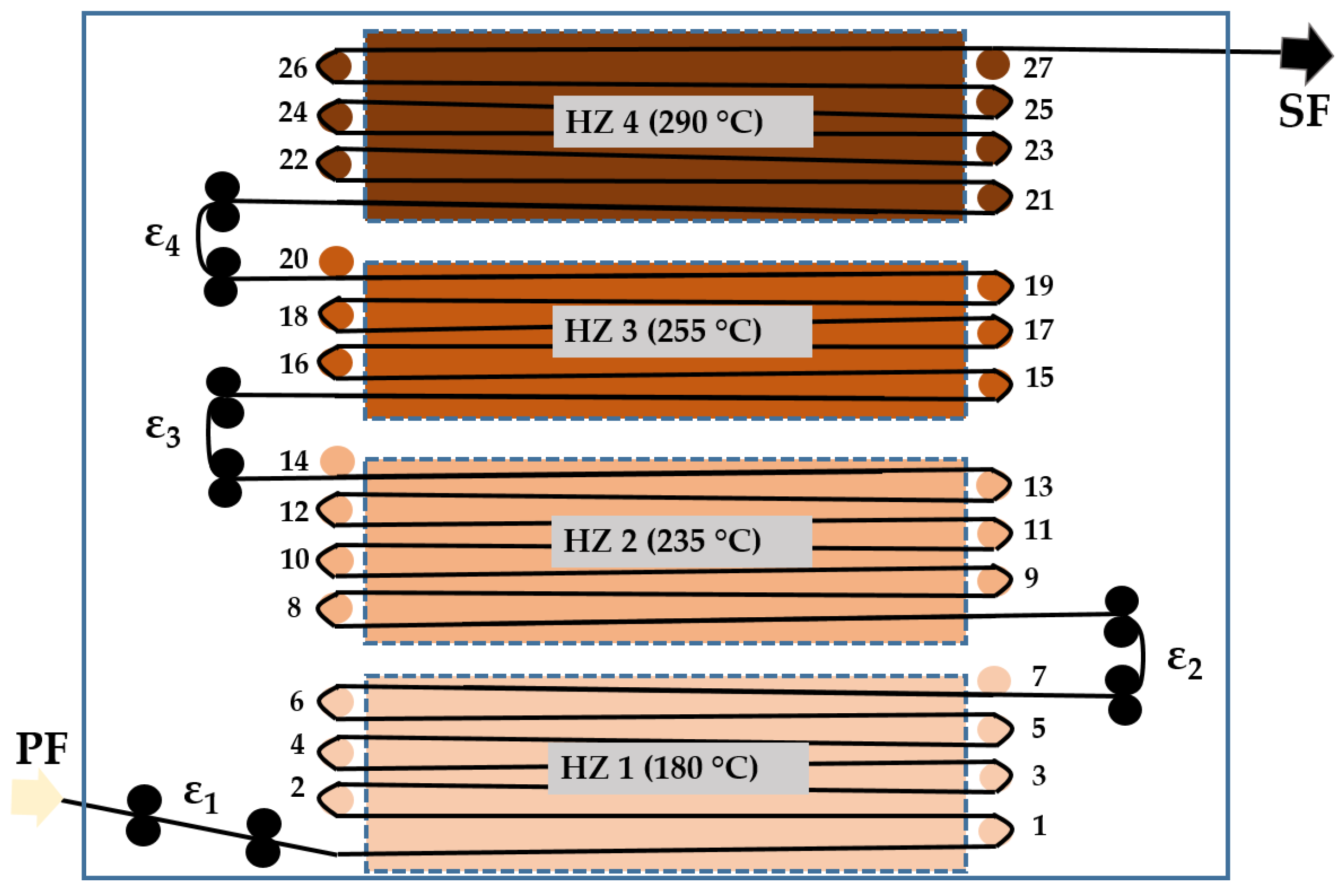

2.2. Thermal Treatment—Stabilization

2.3. Characterization

3. Results and Discussion

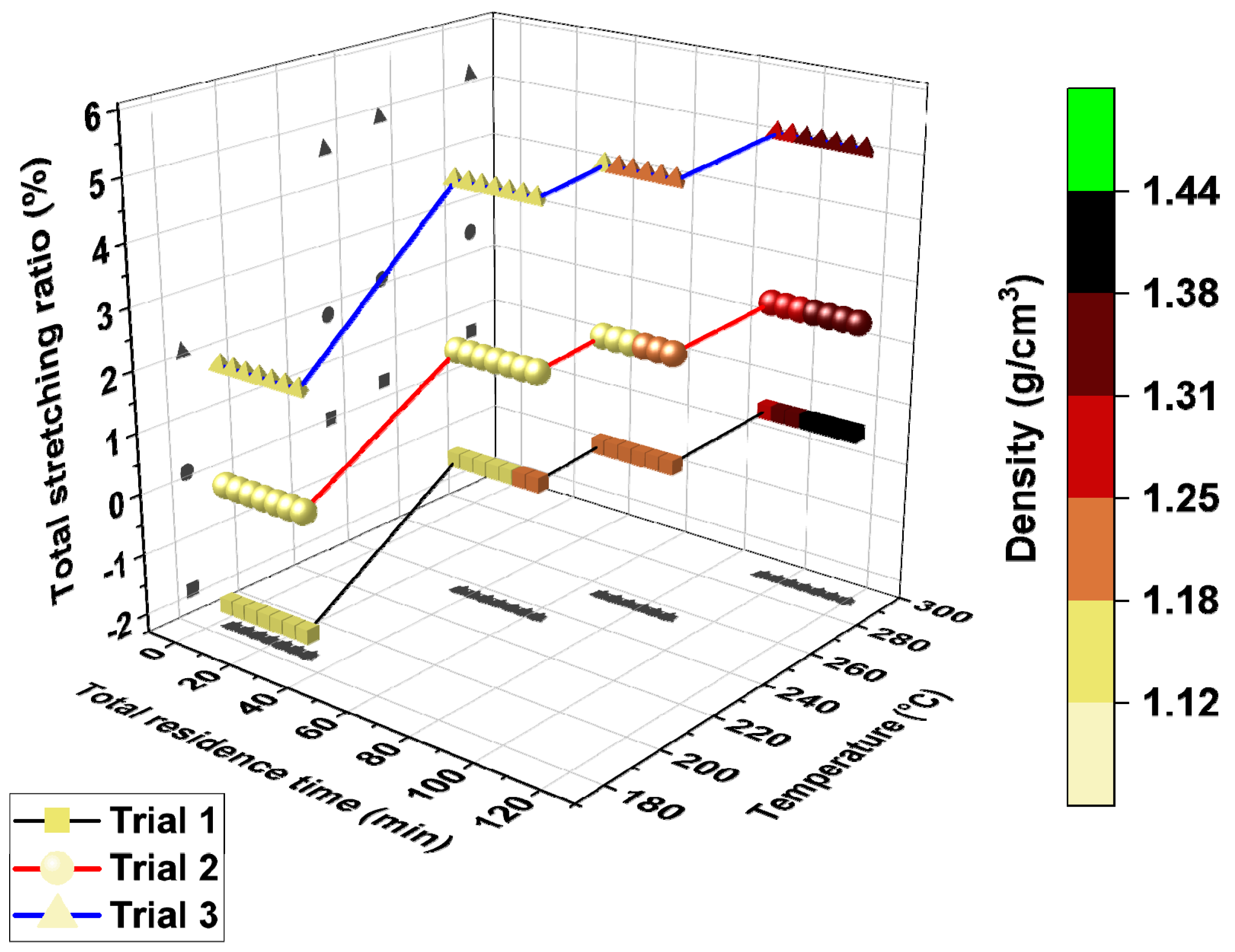

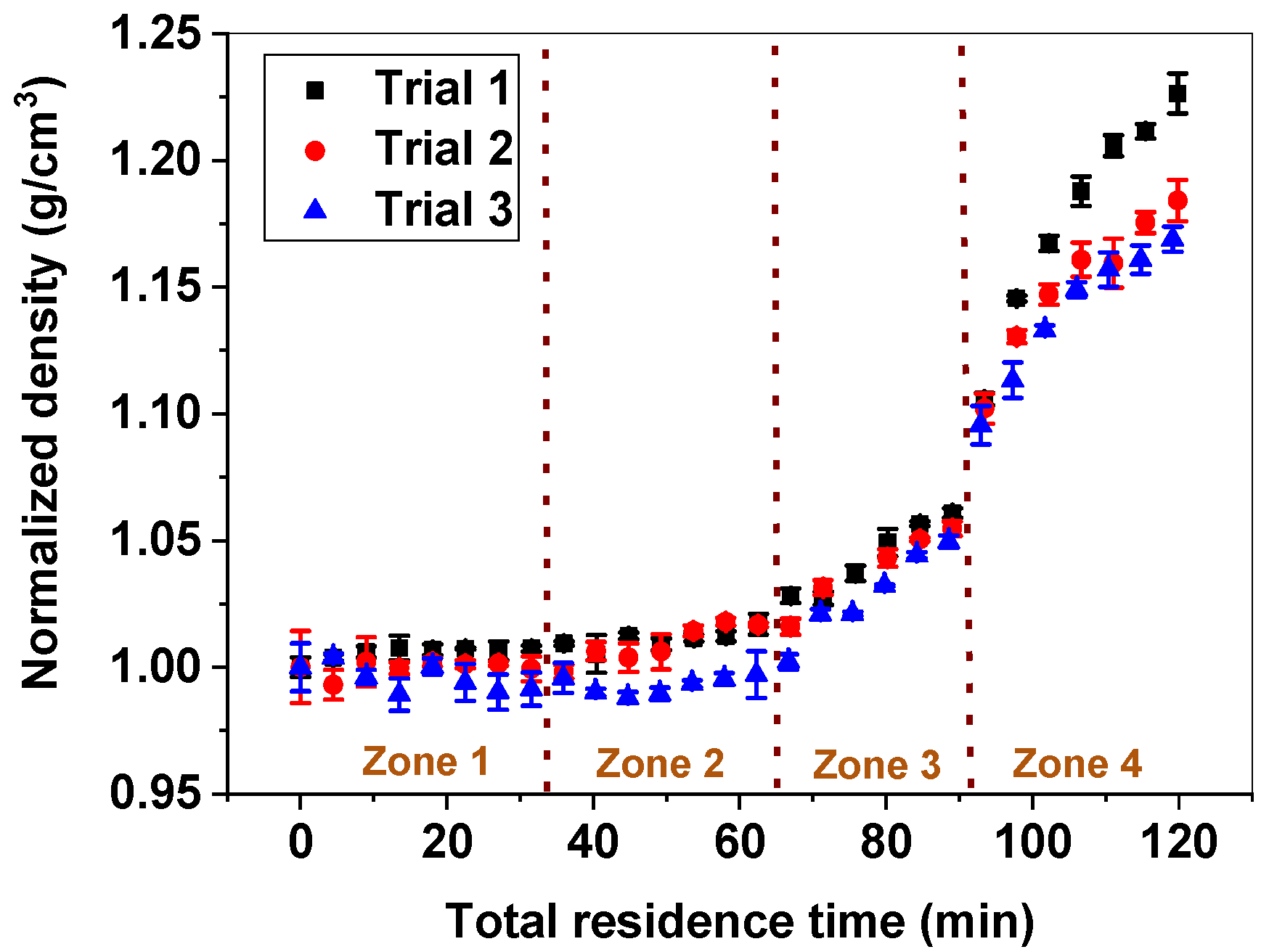

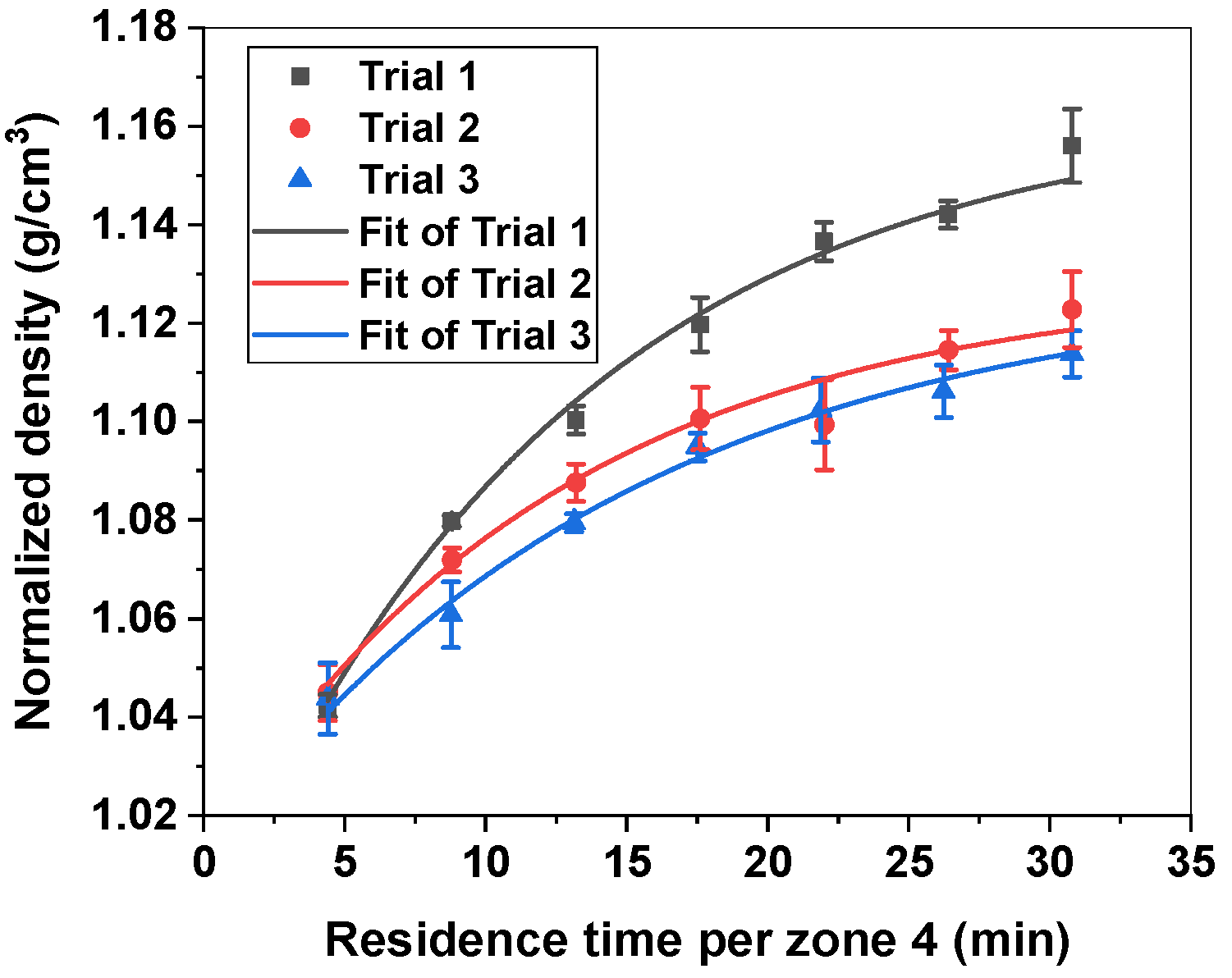

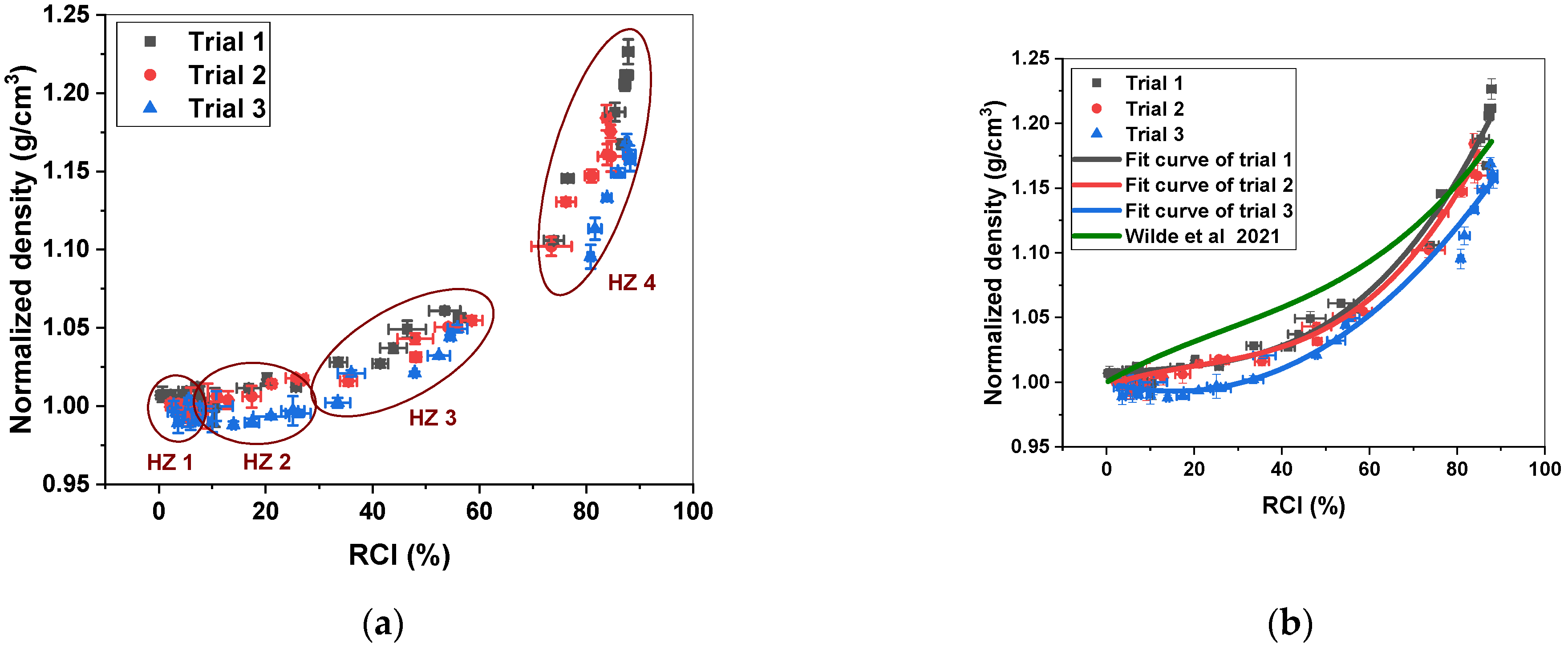

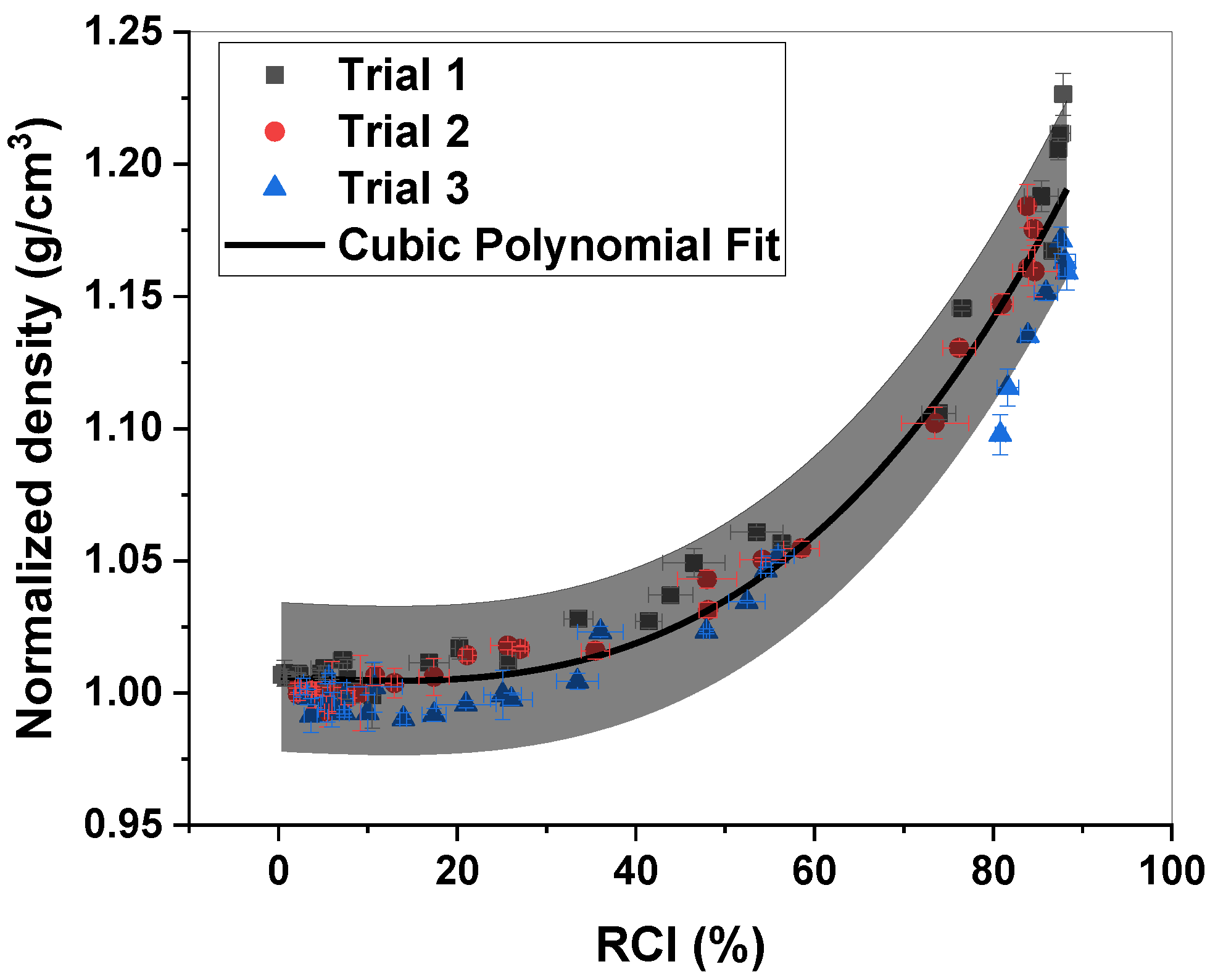

3.1. Effect of Stretching on Stabilized Fiber Density (Offline Indicator)

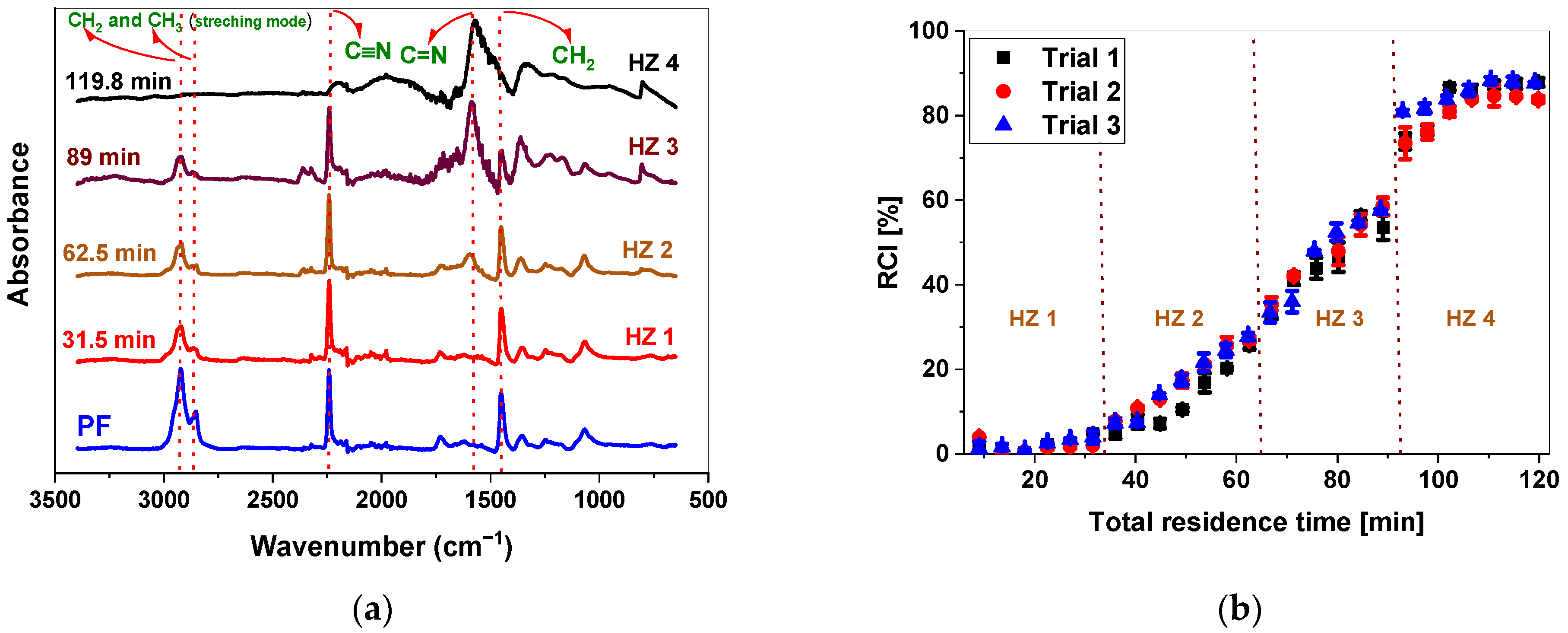

3.2. FTIR Results and Corresponding Relative Cyclization Index (Inline Soft Sensor)

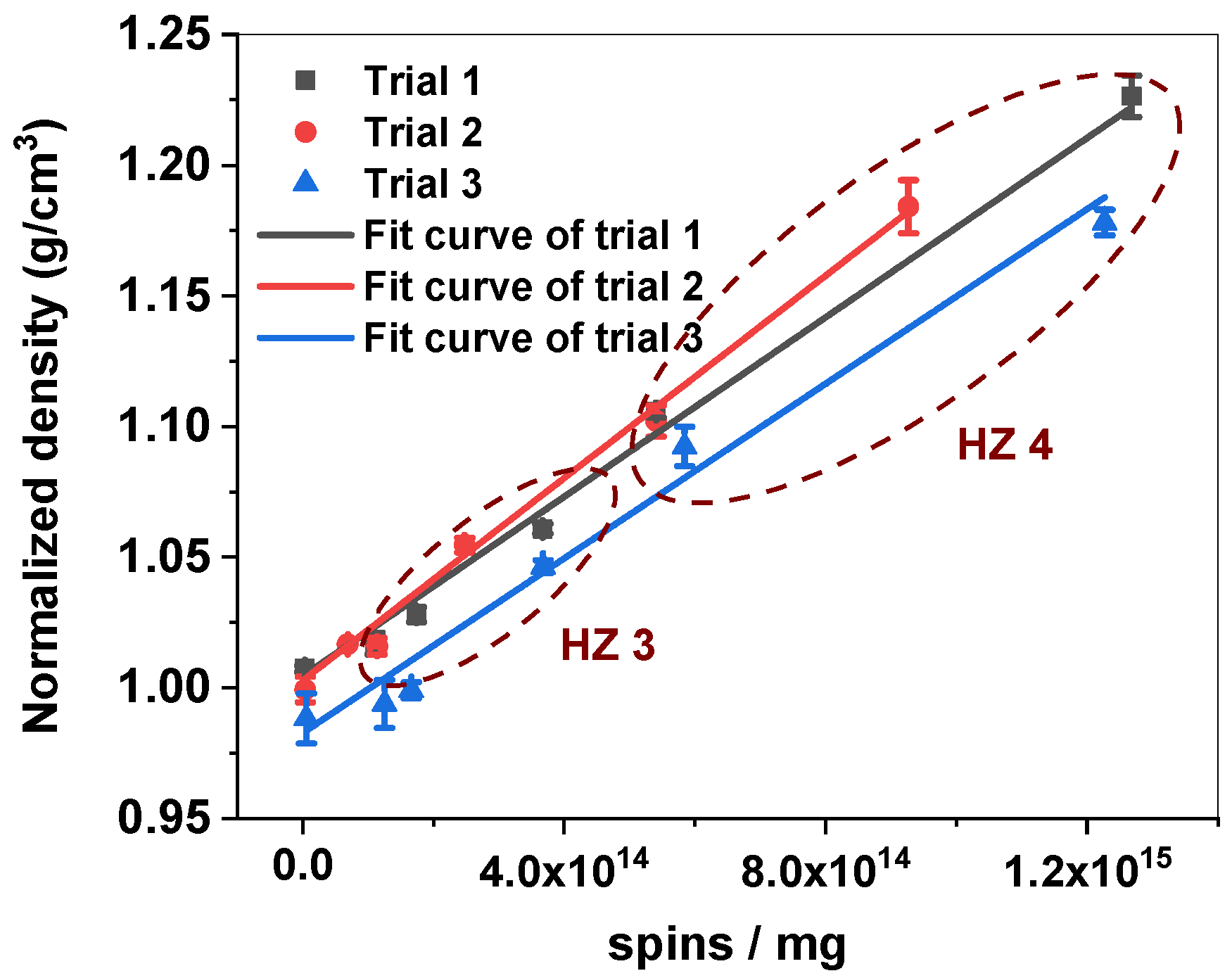

3.3. EPR Results and Corresponding Free Radical Concentration Index (Inline Soft Sensor)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Measured Point Number | Residence Time Per Zone (mins) | Total Residence Time (mins) | Stretching Ratio Per Zone (%) | Total Stretching Ratio (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| HZ 1 (180 °C) | HZ 2 (235 °C) | HZ 3 (255 °C) | HZ 4 (290 °C) | HZ 1 (180 °C) | HZ 2 (235 °C) | HZ 3 (255 °C) | HZ 4 (290 °C) | |||

| 1 | 4.5 | - | - | - | 4.5 | −1.92 | - | - | - | −1.92 |

| 2 | 9.0 | - | - | - | 9.0 | −1.92 | - | - | - | −1.92 |

| 3 | 13.5 | - | - | - | 13.5 | −1.92 | - | - | - | −1.92 |

| 4 | 18.0 | - | - | - | 18.0 | −1.92 | - | - | - | −1.92 |

| 5 | 22.5 | - | - | - | 22.5 | −1.92 | - | - | - | −1.92 |

| 6 | 27.0 | - | - | - | 27.0 | −1.92 | - | - | - | −1.92 |

| 7 | 31.5 | - | - | - | 31.5 | −1.92 | - | - | - | −1.92 |

| 8 | 31.5 | 4.4 | - | - | 36.0 | −1.92 | 1.92 | - | - | 0.00 |

| 9 | 31.5 | 8.8 | - | - | 40.4 | −1.92 | 1.92 | - | - | 0.00 |

| 10 | 31.5 | 13.3 | - | - | 44.8 | −1.92 | 1.92 | - | - | 0.00 |

| 11 | 31.5 | 17.7 | - | - | 49.3 | −1.92 | 1.92 | - | - | 0.00 |

| 12 | 31.5 | 22.1 | - | - | 53.7 | −1.92 | 1.92 | - | - | 0.00 |

| 13 | 31.5 | 26.5 | - | - | 58.1 | −1.92 | 1.92 | - | - | 0.00 |

| 14 | 31.5 | 31.0 | - | - | 62.5 | −1.92 | 1.92 | - | - | 0.00 |

| 15 | 31.5 | 31.0 | 4.4 | - | 67.0 | −1.92 | 1.92 | 0.29 | - | 0.29 |

| 16 | 31.5 | 31.0 | 8.8 | - | 71.4 | −1.92 | 1.92 | 0.29 | - | 0.29 |

| 17 | 31.5 | 31.0 | 13.3 | - | 75.8 | −1.92 | 1.92 | 0.29 | - | 0.29 |

| 18 | 31.5 | 31.0 | 17.7 | - | 80.2 | −1.92 | 1.92 | 0.29 | - | 0.29 |

| 19 | 31.5 | 31.0 | 22.1 | - | 84.6 | −1.92 | 1.92 | 0.29 | - | 0.29 |

| 20 | 31.5 | 31.0 | 26.5 | - | 89.0 | −1.92 | 1.92 | 0.29 | - | 0.29 |

| 21 | 31.5 | 31.0 | 26.5 | 4.4 | 93.4 | −1.92 | 1.92 | 0.29 | 0.29 | 0.58 |

| 22 | 31.5 | 31.0 | 26.5 | 8.8 | 97.8 | −1.92 | 1.92 | 0.29 | 0.29 | 0.58 |

| 23 | 31.5 | 31.0 | 26.5 | 13.3 | 102.2 | −1.92 | 1.92 | 0.29 | 0.29 | 0.58 |

| 24 | 31.5 | 31.0 | 26.5 | 17.7 | 106.6 | −1.92 | 1.92 | 0.29 | 0.29 | 0.58 |

| 25 | 31.5 | 31.0 | 26.5 | 22.1 | 111.0 | −1.92 | 1.92 | 0.29 | 0.29 | 0.58 |

| 26 | 31.5 | 31.0 | 26.5 | 26.5 | 115.4 | −1.92 | 1.92 | 0.29 | 0.29 | 0.58 |

| 27 | 31.5 | 31.0 | 26.5 | 31.0 | 119.8 | −1.92 | 1.92 | 029 | 0.29 | 0.58 |

| Measured Point Number | Residence Time Per Zone (mins) | Total Residence Time (mins) | Stretching Ratio Per Zone (%) | Total Stretching Ratio (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| HZ 1 (180 °C) | HZ 2 (235 °C) | HZ 3 (255 °C) | HZ 4 (290 °C) | HZ 1 (180 °C) | HZ 2 (235 °C) | HZ 3 (255 °C) | HZ 4 (290 °C) | |||

| 1 | 4.5 | - | - | - | 4.5 | 0.07 | - | - | - | 0.07 |

| 2 | 9.0 | - | - | - | 9.0 | 0.07 | - | - | - | 0.07 |

| 3 | 13.5 | - | - | - | 13.5 | 0.07 | - | - | - | 0.07 |

| 4 | 18.0 | - | - | - | 18.0 | 0.07 | - | - | - | 0.07 |

| 5 | 22.5 | - | - | - | 22.5 | 0.07 | - | - | - | 0.07 |

| 6 | 27.0 | - | - | - | 27.0 | 0.07 | - | - | - | 0.07 |

| 7 | 31.5 | - | - | - | 31.5 | 0.07 | - | - | - | 0.07 |

| 8 | 31.5 | 4.4 | - | - | 36.0 | 0.07 | 1.73 | - | - | 1.80 |

| 9 | 31.5 | 8.8 | - | - | 40.4 | 0.07 | 1.73 | - | - | 1.80 |

| 10 | 31.5 | 13.3 | - | - | 44.8 | 0.07 | 1.73 | - | - | 1.80 |

| 11 | 31.5 | 17.7 | - | - | 49.3 | 0.07 | 1.73 | - | - | 1.80 |

| 12 | 31.5 | 22.1 | - | - | 53.7 | 0.07 | 1.73 | - | - | 1.80 |

| 13 | 31.5 | 26.5 | - | - | 58.1 | 0.07 | 1.73 | - | - | 1.80 |

| 14 | 31.5 | 31.0 | - | - | 62.5 | 0.07 | 1.73 | - | - | 1.80 |

| 15 | 31.5 | 31.0 | 4.4 | - | 67.0 | 0.07 | 1.73 | 0.29 | - | 2.09 |

| 16 | 31.5 | 31.0 | 8.8 | - | 71.4 | 0.07 | 1.73 | 0.29 | - | 2.09 |

| 17 | 31.5 | 31.0 | 13.3 | - | 75.8 | 0.07 | 1.73 | 0.29 | - | 2.09 |

| 18 | 31.5 | 31.0 | 17.7 | - | 80.2 | 0.07 | 1.73 | 0.29 | - | 2.09 |

| 19 | 31.5 | 31.0 | 22.1 | - | 84.6 | 0.07 | 1.73 | 0.29 | - | 2.09 |

| 20 | 31.5 | 31.0 | 26.5 | - | 89.0 | 0.07 | 1.73 | 0.29 | - | 2.09 |

| 21 | 31.5 | 31.0 | 26.5 | 4.4 | 93.4 | 0.07 | 1.73 | 0.29 | 0.29 | 2.38 |

| 22 | 31.5 | 31.0 | 26.5 | 8.8 | 97.8 | 0.07 | 1.73 | 0.29 | 0.29 | 2.38 |

| 23 | 31.5 | 31.0 | 26.5 | 13.3 | 102.2 | 0.07 | 1.73 | 0.29 | 0.29 | 2.38 |

| 24 | 31.5 | 31.0 | 26.5 | 17.7 | 106.6 | 0.07 | 1.73 | 0.29 | 0.29 | 2.38 |

| 25 | 31.5 | 31.0 | 26.5 | 22.1 | 111.0 | 0.07 | 1.73 | 0.29 | 0.29 | 2.38 |

| 26 | 31.5 | 31.0 | 26.5 | 26.5 | 115.4 | 0.07 | 1.73 | 0.29 | 0.29 | 2.38 |

| 27 | 31.5 | 31.0 | 26.5 | 31.0 | 119.8 | 0.07 | 1.73 | 029 | 0.29 | 2.38 |

| Measured Point Number | Residence Time Per Zone (mins) | Total Residence Time (mins) | Stretching Ratio Per Zone (%) | Total Stretching Ratio (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| HZ 1 (180 °C) | HZ 2 (235 °C) | HZ 3 (255 °C) | HZ 4 (290 °C) | HZ 1 (180 °C) | HZ 2 (235 °C) | HZ 3 (255 °C) | HZ 4 (290 °C) | |||

| 1 | - | - | - | - | 0.0 | - | - | - | - | 0.00 |

| 1 | 4.5 | - | - | - | 4.5 | 2.01 | - | - | - | 2.01 |

| 2 | 9.0 | - | - | - | 9.0 | 2.01 | - | - | - | 2.01 |

| 3 | 13.5 | - | - | - | 13.5 | 2.01 | - | - | - | 2.01 |

| 4 | 18.0 | - | - | - | 18.0 | 2.01 | - | - | - | 2.01 |

| 5 | 22.5 | - | - | - | 22.5 | 2.01 | - | - | - | 2.01 |

| 6 | 27.0 | - | - | - | 27.0 | 2.01 | - | - | - | 2.01 |

| 7 | 31.5 | - | - | - | 31.5 | 2.01 | - | - | - | 2.01 |

| 8 | 31.5 | 4.4 | - | - | 36.0 | 2.01 | 2.52 | - | - | 4.53 |

| 9 | 31.5 | 8.8 | - | - | 40.4 | 2.01 | 2.52 | - | - | 4.53 |

| 10 | 31.5 | 13.3 | - | - | 44.8 | 2.01 | 2.52 | - | - | 4.53 |

| 11 | 31.5 | 17.7 | - | - | 49.3 | 2.01 | 2.52 | - | - | 4.53 |

| 12 | 31.5 | 22.1 | - | - | 53.7 | 2.01 | 2.52 | - | - | 4.53 |

| 13 | 31.5 | 26.5 | - | - | 58.1 | 2.01 | 2.52 | - | - | 4.53 |

| 14 | 31.5 | 31.0 | - | - | 62.5 | 2.01 | 2.52 | - | - | 4.53 |

| 15 | 31.5 | 31.0 | 4.4 | - | 67.0 | 2.01 | 2.52 | 0.29 | - | 4.82 |

| 16 | 31.5 | 31.0 | 8.8 | - | 71.4 | 2.01 | 2.52 | 0.29 | - | 4.82 |

| 17 | 31.5 | 31.0 | 13.3 | - | 75.8 | 2.01 | 2.52 | 0.29 | - | 4.82 |

| 18 | 31.5 | 31.0 | 17.7 | - | 80.2 | 2.01 | 2.52 | 0.29 | - | 4.82 |

| 19 | 31.5 | 31.0 | 22.1 | - | 84.6 | 2.01 | 2.52 | 0.29 | - | 4.82 |

| 20 | 31.5 | 31.0 | 26.5 | - | 89.0 | 2.01 | 2.52 | 0.29 | - | 4.82 |

| 21 | 31.5 | 31.0 | 26.5 | 4.4 | 93.4 | 2.01 | 2.52 | 0.29 | 0.29 | 5.11 |

| 22 | 31.5 | 31.0 | 26.5 | 8.8 | 97.8 | 2.01 | 2.52 | 0.29 | 0.29 | 5.11 |

| 23 | 31.5 | 31.0 | 26.5 | 13.3 | 102.2 | 2.01 | 2.52 | 0.29 | 0.29 | 5.11 |

| 24 | 31.5 | 31.0 | 26.5 | 17.7 | 106.6 | 2.01 | 2.52 | 0.29 | 0.29 | 5.11 |

| 25 | 31.5 | 31.0 | 26.5 | 22.1 | 111.0 | 2.01 | 2.52 | 0.29 | 0.29 | 5.11 |

| 26 | 31.5 | 31.0 | 26.5 | 26.5 | 115.4 | 2.01 | 2.52 | 0.29 | 0.29 | 5.11 |

| 27 | 31.5 | 31.0 | 26.5 | 31.0 | 119.8 | 2.01 | 2.52 | 029 | 0.29 | 5.11 |

References

- Chua, C.Y.X.; Liu, H.C.; Trani, N.D.; Susnjar, A.; Ho, J.; Scorrano, G.; Rhudy, J.; Sizovs, A.; Lolli, G.; Hernandez, N.; et al. Carbon fiber reinforced polymers for implantable medical devices. Biomaterials 2021, 271, 120719. [Google Scholar] [CrossRef] [PubMed]

- Fitzer, E. Pan-based carbon fibers—Present state and trend of the technology from the viewpoint of possibilities and limits to influence and to control the fiber properties by the process parameters. Carbon 1989, 27, 621–645. [Google Scholar] [CrossRef]

- Liu, C.; Li, Q.; Kang, W.; Lei, W.; Wang, X.; Lu, C.; Naebe, M. Structural design and mechanism analysis of hierarchical porous carbon fibers for advanced energy and environmental applications. J. Mater. Chem. A 2021, 10, 10–49. [Google Scholar] [CrossRef]

- Wang, G.; Lu, C.; Sun, T.; Li, Y. Accelerating the stabilization of polyacrylonitrile fibers by nitrogen pretreatment. J. Appl. Polym. Sci 2022, 139, 52129. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, G.; Vaidya, U.; Wang, H. Past, present and future prospective of global carbon fibre composite developments and applications. Compos. Part B Eng. 2023, 250, 110463. [Google Scholar] [CrossRef]

- Böhm, R.; Thieme, M.; Wohlfahrt, D.; Wolz, D.S.; Richter, B.; Jäger, H. Reinforcement Systems for Carbon Concrete Composites Based on Low-Cost Carbon Fibers. Fibers 2018, 6, 56. [Google Scholar] [CrossRef]

- Kraft, R.; Kahnt, A.; Grauer, O.; Thieme, M.; Wolz, D.S.; Schlüter, D.; Tietze, M.; Curbach, M.; Holschemacher, K.; Jäger, H.; et al. Advanced Carbon Reinforced Concrete Technologies for Façade Elements of Nearly Zero-Energy Buildings. Materials 2022, 15, 1619. [Google Scholar] [CrossRef]

- Khayyam, H.; Jazar, R.N.; Nunna, S.; Golkarnarenji, G.; Badii, K.H.; Fakhrhoseini, S.M.; Kumar, S.; Naebe, M. PAN precursor fabrication, applications and thermal stabilization process in carbon fiber production: Experimental and mathematical modelling. Prog. Mater. Sci. 2020, 107, 100575. [Google Scholar] [CrossRef]

- Khayyam, H.; Naebe, M.; Milani, A.S.; Fakhrhoseini, S.M.; Date, A.; Shabani, B.; Atkiss, S.; Ramakrishna, S.; Fox, B.; Jazar, R.N. Improving energy efficiency of carbon fiber manufacturing through waste heat recovery: A circular economy approach with machine learning. Energy 2021, 225, 120113. [Google Scholar] [CrossRef]

- Bajaj, P.; Roopanwal, A.K. Thermal Stabilization of Acrylic Precursors for the Production of Carbon Fibers: An Overview. J. Macromol. Sci. Part C Polym. Rev. 1997, 37, 97–147. [Google Scholar] [CrossRef]

- Dunham, M.G.; Edie, D.D. Model of stabilization for pan-based carbon fiber precursor bundles. Carbon 1992, 30, 435–450. [Google Scholar] [CrossRef]

- Wilde, A.L.; Alexander, D.L.J.; Pierlot, A.P.; Denning, R.; Miao, M. Predicting the Cyclization Index and Density of Stabilized Polyacrylonitrile Tow from Processing Conditions. Fibers Polym. 2021, 22, 3241–3250. [Google Scholar] [CrossRef]

- Simitzis, J.; Soulis, S. Correlation of chemical shrinkage of polyacrylonitrile fibres with kinetics of cyclization. Polym. Int. 2008, 57, 99–105. [Google Scholar] [CrossRef]

- Shin, H.K.; Park, M.; Kim, H.-Y.; Park, S.-J. An overview of new oxidation methods for polyacrylonitrile-based carbon fibers. Carbon Lett. 2015, 16, 11–18. [Google Scholar] [CrossRef]

- Badii, K.; Church, J.S.; Golkarnarenji, G.; Naebe, M.; Khayyam, H. Chemical structure based prediction of PAN and oxidized PAN fiber density through a non-linear mathematical model. Polym. Degrad. Stab. 2016, 131, 53–61. [Google Scholar] [CrossRef]

- Mädler, J.; Richter, B.; Wolz, D.S.J.; Behnisch, T.; Böhm, R.; Jäger, H.; Gude, M.; Urbas, L. Hybride semi-parametrische Modellierung der thermooxidativen Stabilisierung von PAN-Precursorfasern. Chem. Ing. Tech. 2022, 94, 889–896. [Google Scholar] [CrossRef]

- Choi, J.; Kim, S.-S.; Chung, Y.-S.; Lee, S. Evolution of structural inhomogeneity in polyacrylonitrile fibers by oxidative stabilization. Carbon 2020, 165, 225–237. [Google Scholar] [CrossRef]

- Yang, J.; Liu, Y.; Liu, J.; Shen, Z.; Liang, J.; Wang, X. Rapid and Continuous Preparation of Polyacrylonitrile-Based Carbon Fibers with Electron-sBeam Irradiation Pretreatment. Materials 2018, 11, 1270. [Google Scholar] [CrossRef]

- Takaku, A.; Hashimoto, T.; Miyoshi, T. Tensile properties of carbon fibers from acrylic fibers stabilized under isothermal conditions. J. Appl. Polym. Sci. 1985, 30, 1565–1571. [Google Scholar] [CrossRef]

- Yu, M.; Wang, C.; Bai, Y.; Wang, Y.; Zhu, B. Evolution of tension during the thermal stabilization of polyacrylonitrile fibers under different parameters. J. Appl. Polym. Sci. 2006, 102, 5500–5506. [Google Scholar] [CrossRef]

- Nunna, S.; Maghe, M.; Rana, R.; Varley, R.J.; Knorr, D.B.; Sands, J.M.; Creighton, C.; Henderson, L.C.; Naebe, M. Time Dependent Structure and Property Evolution in Fibres during Continuous Carbon Fibre Manufacturing. Materials 2019, 12, 1069. [Google Scholar] [CrossRef] [PubMed]

- Heine, M. Optimisation of the Reaction Conditions of Thermoplastic Polymer Fibers Like Polyacrylonitrile for Carbon Fiber Production. Ph.D. Dissertation, Technical University of Karlsruhe, Karlsruhe, Germany, 1989. [Google Scholar] [CrossRef]

- Jing, M.; Wang, C.; Bai, Y.; Zhu, B.; Wang, Y. Effect of temperatures in the rearmost stabilization zone on structure and properties of PAN-based oxidized fibers. Polym. Bull. 2007, 58, 541–551. [Google Scholar] [CrossRef]

- Leopold, A.-K.; Müller, M.T.; Zimmerer, C.; Bogar, M.S.; Richter, M.; Wolz, D.S.; Stommel, M. Influence of Temperature and Dose Rate of E-Beam Modification on Electron-Induced Changes in Polyacrylonitrile Fibers. Macro Chem. Phys. 2023, 224, 2200265. [Google Scholar] [CrossRef]

- Qin, X.; Lu, Y.; Xiao, H.; Zhao, W. Effect of heating and stretching polyacrylonitrile precursor fibers in steam on the properties of stabilized fibers and carbon fibers. Polym. Eng. Sci. 2013, 53, 827–832. [Google Scholar] [CrossRef]

- Yu, M.; Wang, C.; Bai, Y.; Wang, Y.; Wang, Q.; Liu, H. Combined Effect of Processing Parameters on Thermal Stabilization of PAN Fibers. Polym. Bull. 2006, 57, 525–533. [Google Scholar] [CrossRef]

- Liu, J.; Lian, F.; Ma, Z.; Liang, J. Effects of deformation-induced orientation on cyclization and oxidation of polyacrylonitrile fibers during stabilization process. Chin. J. Polym. Sci. 2012, 30, 786–795. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, C.; Gao, Q.; Wang, Y.; Zhao, S.; Cui, B.; Yue, Y. Study on the relationship between chemical structure transformation and morphological change of polyacrylonitrile based preoxidized fibers. Eur. Polym. J. 2021, 159, 110742. [Google Scholar] [CrossRef]

- Wang, B.; Li, C.; Cao, W. Effect of stretching on the orientation structure and reaction behavior of PAN fiber during the thermal stabilization. Mater. Res. Express 2021, 8, 85603. [Google Scholar] [CrossRef]

- Wang, B.; Xiao, S.; Cao, W.; Shi, X.; Xu, L. Evolution of aggregation structure of polyacrylonitrile fibers in the cyclization reaction. J. Appl. Polym. Sci. 2012, 124, 3413–3418. [Google Scholar] [CrossRef]

- Wang, B.; Li, C.; Cao, W. Effect of Polyacrylonitrile Precursor Orientation on the Structures and Properties of Thermally Stabilized Carbon Fiber. Materials 2021, 14, 3237. [Google Scholar] [CrossRef]

- Gupta, A.; Harrison, I.R. New aspects in the oxidative stabilization of PAN-based carbon fibers: II. Carbon 1997, 35, 809–818. [Google Scholar] [CrossRef]

- Tsai, J.-S. Tension effects on the properties of oxidized polyacrylonitrile and carbon fibers during continuous oxidation. Polym. Eng. Sci. 1995, 35, 1313–1316. [Google Scholar] [CrossRef]

- Liu, W.; Wang, M.; Xing, Z.; Wu, G. The free radical species in polyacrylonitrile fibers induced by γ-radiation and their decay behaviors. Radiat. Phys. Chem. 2012, 81, 835–839. [Google Scholar] [CrossRef]

- Gohs, U.; Böhm, R.; Brünig, H.; Fischer, D.; Leopold, A.-K.; Malanin, M.; Müller, M.-T.; Cherif, C.; Richter, M.; Wolz, D.S.J.; et al. Influence of gas atmosphere on electron-induced reactions of polyacrylonitrile homopolymer powder at elevated temperature. Radiat. Phys. Chem. 2019, 158, 94–102. [Google Scholar] [CrossRef]

- Liu, W.; Shen, R.; Liu, S.; Tian, F.; Zhang, X.; Li, X.; Wang, M.; Tang, Z. Free radical evolution and decay of PAN nano-fibers formed by irradiation and thermal stabilization. Polym. Degrad. Stab. 2021, 188, 109570. [Google Scholar] [CrossRef]

- Park, S.; Yoo, S.H.; Kang, H.R.; Jo, S.M.; Joh, H.-I.; Lee, S. Comprehensive stabilization mechanism of electron-beam irradiated polyacrylonitrile fibers to shorten the conventional thermal treatment. Sci. Rep. 2016, 6, 27330. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, M.; Zhang, W.; Liu, W.; Yang, C.; Shen, R.; Wu, G. Significantly reduced pre-oxidation period of PAN fibers by continuous electron beam irradiation: Optimization by monitoring radical variation. Polym. Degrad. Stab. 2018, 158, 72–82. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, M.; Liu, W.; Yang, C.; Wu, G. Higher dose rate effect of 500-keV EB irradiation favoring free radical annealing and pre-oxidation of polyacrylonitrile fibers. Polym. Degrad. Stab. 2019, 167, 201–209. [Google Scholar] [CrossRef]

- Kirsten, M.; Meinl, J.; Schönfeld, K.; Michaelis, A.; Cherif, C. Characteristics of wet-spun and thermally treated poly acrylonitrile fibers. J. Appl. Polym. Sci. 2016, 133, 43698. [Google Scholar] [CrossRef]

- Nunna, S.; Blanchard, P.; Buckmaster, D.; Davis, S.; Naebe, M. Development of a cost model for the production of carbon fibres. Heliyon 2019, 5, e02698. [Google Scholar] [CrossRef]

- Kirsten, M.; Freudenberg, C.; Cherif, C. Carbonfasern, der Werkstoff des 21. Jahrhunderts. Beton-Und Stahlbetonbau 2015, 110, 8–15. [Google Scholar] [CrossRef]

- Collins, G.L.; Thomas, N.W.; Williams, G.E. Kinetic relationships between heat generation and nitrile consumption in the reaction of poly(acrylonitrile) in air at 265 °C. Carbon 1988, 26, 671–679. [Google Scholar] [CrossRef]

- Ge, Y.; Fu, Z.; Zhang, M.; Zhang, H. The role of structural evolution of polyacrylonitrile fibers during thermal oxidative stabilization on mechanical properties. J. Appl. Polym. Sci. 2021, 138, 49603. [Google Scholar] [CrossRef]

- Maghe, M.; Creighton, C.; Henderson, L.C.; Huson, M.G.; Nunna, S.; Atkiss, S.; Byrne, N.; Fox, B.L. Using ionic liquids to reduce energy consumption for carbon fibre production. J. Mater. Chem. A 2016, 4, 16619–16626. [Google Scholar] [CrossRef]

- Li, X.; Ji, X.; He, C. Evolution of the morphological and structural properties of plasticized spinning polyacrylonitrile fibers during the stabilization process. RSC Adv. 2015, 5, 81399–81406. [Google Scholar] [CrossRef]

- Fitzer, E.; Frohs, W.; Heine, M. Optimization of stabilization and carbonization treatment of PAN fibres and structural characterization of the resulting carbon fibres. Carbon 1986, 24, 387–395. [Google Scholar] [CrossRef]

- Barua, B.; Saha, M.C. Studies of reaction mechanisms during stabilization of electrospun polyacrylonitrile carbon nanofibers. Polym. Eng. Sci. 2018, 58, 1315–1321. [Google Scholar] [CrossRef]

| Precursor Fiber (PAN Fiber) | Glass Transition Temperature (°C) | Diameter (µm) | Density (g/cm3) |

|---|---|---|---|

| Trial 1 | 100.4 | 14.06 ± 1.16 | 1.17 ± 0.01 |

| Trial 2 | 100.5 | 17.55 ± 0.99 | 1.14 ± 0.02 |

| Trial 3 | 100.5 | 15.93 ± 1.01 | 1.17 ± 0.01 |

| Stretching Ratio (%) | |||||

|---|---|---|---|---|---|

| ε1 | ε2 | ε3 | ε4 | εtotal * | |

| Trial 1 | −1.92 | 1.92 | 0.29 | 0.29 | 0.58 |

| Trial 2 | 0.07 | 1.73 | 0.29 | 0.29 | 2.38 |

| Trial 3 | 2.01 | 2.52 | 0.29 | 0.29 | 5.11 |

| Model | Non-Linear Fit | ||

|---|---|---|---|

| Equation | y = a(1 − exp(−b(t − tonset))) | ||

| Experiments | Trial 1 | Trial 2 | Trial 3 |

| a | 1.16387 ± 0.00648 | 1.12834 ± 0.00643 | 1.12856 ± 0.00692 |

| tR | −23.97247 ± 2.77552 | −28.0991 ± 5.55655 | −33.29719 ± 5.89252 |

| b | 0.07994 ± 0.00888 | 0.0808 ± 0.01496 | 0.06781 ± 0.01148 |

| R-Squared (R2) | 0.99652 | 0.99086 | 0.98934 |

| Model | Cubic Polynomial Function | ||

|---|---|---|---|

| Equation | ND = A + B1 RCI + B2 RCI2 + B3 RCI3 | ||

| Experiments | Trial 1 | Trial 2 | Trial 3 |

| Y-intercept (A) | 1.007 ± 0.002 | 0.997 ± 0.001 | 1.000 ± 0.005 |

| B1 | 3.464 × 10−4 ± 4.143 × 10−4 | 0.001 ± 1.726 × 10−4 | −8.450 × 10−4 ± 5.253 × 10−4 |

| B2 | −9.445 × 10−6 ± 1.237 × 10−5 | −2.870 × 10−5 ± 5.338 × 10−6 | 2.633 × 10−5 ± 1.374 × 10−5 |

| B3 | 3.564 × 10−7 ± 9.556 × 10−8 | 4.705 × 10−7 ± 4.462 × 10−8 | 3.775 × 10−8 ± 9.760 × 10−8 |

| R-squared (R2) | 0.989 | 0.994 | 0.981 |

| Model | Cubic Polynomial Fnction |

|---|---|

| Equation | ND = A + B1 RCI + B2 RCI2 + B3 RCI3 |

| Y-intercept (A) | 1.006 ± 0.002 |

| B1 | −1.688 × 10−4 ± 3.759 × 10−4 |

| B2 | 1.039 × 10−6 ± 1.114 × 10−5 |

| B3 | 2.784 × 10−7 ± 8.609 × 10−8 |

| R-Squared (R2) | 0.946 |

| Model | Linear Function | ||

|---|---|---|---|

| Equation | ND = d + f FRC | ||

| Experiments | Trial 1 | Trial 2 | Trial 3 |

| Y-intercept (d) | 1.004 ± 0.003 | 1.003 ± 0.002 | 0.983 ± 0.006 |

| Slope (f) | 1.72 × 10−16 ± 1.12 × 10−17 | 1.94 × 10−16 ± 1.33 × 10−17 | 1.67 × 10−16 ± 1.14 × 10−17 |

| R-Squared (R2) | 0.983 | 0.981 | 0.981 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadeghi Bogar, M.; Wolf, J.; Wolz, D.S.J.; Seidel-Greiff, R.; Dmitrieva, E.; Israel, N.; Rosenkranz, M.; Behnisch, T.; Müller, M.T.; Gude, M. Sensitivity of Offline and Inline Indicators for Fiber Stretching in Continuous Polyacrylonitrile Stabilization. Fibers 2023, 11, 68. https://doi.org/10.3390/fib11080068

Sadeghi Bogar M, Wolf J, Wolz DSJ, Seidel-Greiff R, Dmitrieva E, Israel N, Rosenkranz M, Behnisch T, Müller MT, Gude M. Sensitivity of Offline and Inline Indicators for Fiber Stretching in Continuous Polyacrylonitrile Stabilization. Fibers. 2023; 11(8):68. https://doi.org/10.3390/fib11080068

Chicago/Turabian StyleSadeghi Bogar, Mohsen, Jan Wolf, Daniel Sebastian Jens Wolz, Robert Seidel-Greiff, Evgenia Dmitrieva, Noel Israel, Marco Rosenkranz, Thomas Behnisch, Michael Thomas Müller, and Maik Gude. 2023. "Sensitivity of Offline and Inline Indicators for Fiber Stretching in Continuous Polyacrylonitrile Stabilization" Fibers 11, no. 8: 68. https://doi.org/10.3390/fib11080068

APA StyleSadeghi Bogar, M., Wolf, J., Wolz, D. S. J., Seidel-Greiff, R., Dmitrieva, E., Israel, N., Rosenkranz, M., Behnisch, T., Müller, M. T., & Gude, M. (2023). Sensitivity of Offline and Inline Indicators for Fiber Stretching in Continuous Polyacrylonitrile Stabilization. Fibers, 11(8), 68. https://doi.org/10.3390/fib11080068