1. Introduction

Steel-Reinforced Grout (SRG) composite systems, which comprise unidirectional textiles of ultra-high tensile strength steel cords embedded in an inorganic matrix, developed in the last few years, represents an effective solution for strengthening existing reinforced concrete or masonry structures.

SRG systems were used in many practical applications for flexural and shear strengthening of reinforced concrete beams, the strengthening of masonry elements, and the confinement of both reinforced concrete and masonry columns. Several studies were conducted to investigate the performances of reinforced concrete structures strengthened in flexure with SRG; the obtained results available in the technical literature evidenced significant improvements in both strength and ductility of the strengthened elements [

1,

2,

3,

4,

5,

6]. The available results of research, both experimental and theoretical, devoted to the analysis of the bond of SRG to concrete and SRG to masonry joints are also numerous [

7,

8]. On the contrary, the results related to the analysis of the performances of reinforced concrete beams strengthened in shear with SRG strips are still limited. The few contributions available in the technical literature [

9,

10,

11,

12] are recent and mainly experimental.

Gonzalez-Libreros et al. [

4,

9] investigated the behavior of reinforced concrete beams strengthened in shear with U-shaped SRG strips. The varied parameters were the internal steel stirrups configuration and the textile installation (with and without anchors). The obtained results provide evidence of a significant increase (30% on average) in the shear capacity of the strengthened beams with respect to the un-strengthened ones, independently of the textile anchorage and a change in the failure modes in beams strengthened with anchored strips.

Thermou et al. [

10] analyzed the influence of the steel fabric density (1.57 cords/cm and 4.72 cords/cm) and the number of fabric layers within the SRG strips on the shear capacity of SRG-strengthened reinforced concrete beams. The results of the investigation evidenced that the failure mode changed with the different strengthening configurations of the beams. In particular, a brittle failure in shear occurred in beams strengthened with U-shaped strips while a flexural failure occurred in fully wrapped strengthened beams. Moreover, the shear capacity increased in both U-shaped SRG (104%) and fully wrapped SRG (118% and 168% for strips with one and two textile layers, respectively) strengthened beams with respect to the unreinforced one. Through experimental results, a simple formulation for evaluating the effective strain of the SRG strips was also proposed.

A large experimental investigation was also conducted by Wakjira and Ubead [

11,

12] on SRG shear-strengthened reinforced concrete beams. Tests were conducted varying the steel fabric density (1.57 cords/cm and 3.14 cords/cm), the strengthening configuration (U-shaped and side-bonded SRG strips), the internal shear reinforcement ratio in the shear span, and the span-to-effective depth (

a/

d) ratio. Test results evidenced that (

i) the failure modes that occurred in all strengthened beams were shear failure associated with SRG-to-concrete debonding; (

ii) the shear capacity in strengthened beams increased up to 71% with respect to the un-strengthened ones; (

iii) upon increasing the shear capacity of beams, the effectiveness of the U-shaped strengthening configuration was greater than that of the side-bonded one; (

iv) the number of internal steel stirrups reduced the SRG strength gain; and (

v) the

a/

d influenced the shear capacity of the SRG-strengthened beams, which increased for deep beams (

a/

d < 2) while it decreased for slender beams (

a/

d > 2). An analytical model found based on the simplified modified compression field theory was also developed to estimate the shear capacity of SRG-strengthened reinforced concrete beams.

The results of the above-described research, even if evidencing the improvement of shear capacity and deformability performances of SRG shear-strengthened reinforced concrete beams, are not yet sufficient for a complete and exhaustive understanding of all aspects of the mechanical behavior of the SRG-strengthened elements. Further experimental numerical and analytical studies are needed for an improvement of the technical knowledge, also aimed at wider use of the SRG as a strengthening system of existing reinforced concrete structures.

In this scenario, the authors, in a previous paper [

1], reported the first results of an extensive experimental study conducted on SRG shear-strengthened reinforced concrete beams. The study focused on both the experimental performances of strengthened beams and the effectiveness of two proposed models, one analytical and the other numerical, to predict the structural behavior of beams. The results of the study evidenced that the strengthening configuration, the number of SRG layers, and the use of anchors significantly influenced the shear capacity of beams. In addition, the comparison with experimental results provides evidence that the proposed models are able to aptly predict the structural response of strengthened beams.

To complete the study, in this paper, further results of tests on SRG shear-strengthened beams (Series II) are described. A detailed and accurate analysis of all experimental results is reported, focusing on the influence of the strengthening configuration on the structural performances of strengthened beams. With this aim, the considered parameters were the sf/wf ratio, with sf being the distance between two consecutive SRG strips and wf being the width of a single strip and the number of steel fabric layers.

An analytical model to calculate the shear capacity of strengthened beams is provided. The model found based on the Mörsch truss computes the contribution of the SRG composites by values of the effective strain, i.e., the average tensile strain in the composite bridging a shear crack at the debonding.

To evaluate the “effective strain” of the SRG strips, two methods were proposed: The first based on a statistical analysis of results obtained by tests on FRCM shear-strengthened reinforced concrete beams, and the second one developed through the results analysis of single-lap direct shear tests performed on SRG-to-concrete joints. The effectiveness of the two proposed methods was evaluated by a comparison of their predictions and the available experimental results.

2. Materials and Methods

2.1. Experimental Investigation

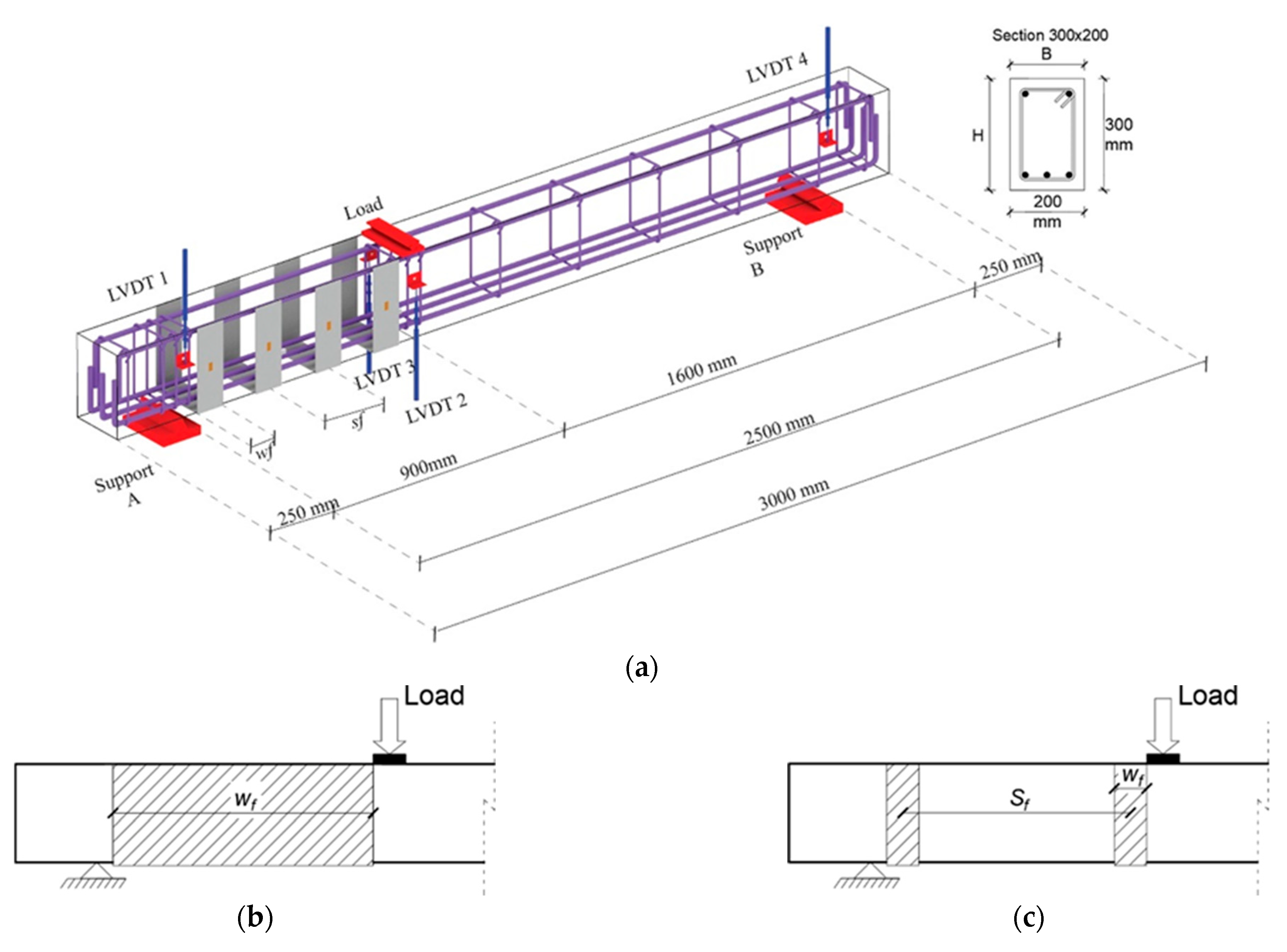

A total of eleven simply supported reinforced concrete beams were tested in a non-symmetric three-point bending scheme. One of the beams was un-strengthened and considered as a reference, while the remaining ones were shear strengthened with U-shaped strips. All beams were 3000 mm long and had a rectangular cross-section 200 mm wide and 300 mm high. The shear span of the beams was 900 mm long; the shear span-to-height, a/h, was set to 3 for all the beams. Three 18-mm diameter steel bars on the tension side and two 18-mm diameter steel bars on the compression side were used as internal longitudinal reinforcements. The shear span of beams was designed without internal steel stirrups, while 8-mm diameter steel stirrups spaced at 310 mm were positioned in the remaining length. The clear cover of the steel reinforcing bars was 20 mm on all sides of the beams.

The SRG strengthening configuration is illustrated in

Figure 1;

Table 1 reports the adopted geometrical parameters.

Beams were designated as follows:

B-Control identifies the control beam while the strengthened beams were identified with the notation

B-nL-mS, where

B indicates the beam specimen,

nL is the number of fabric layers, and

mS is the number of U-shaped SRG strips externally bonded to the beams in the shear span. The tested beams are subdivided into two Series: Series II groups the beams designed as B-1L-2S, B-2L-2S, B-1L-5S, and B-2L-5S while Series I groups the remaining ones [

1].

2.2. The SRG Strengthening System

The SRG strengthening system consisted of steel fibers and an inorganic matrix (mineral geo-mortar). The steel fibers were in the form of a unidirectional sheet made of high-strength, galvanized, twisted steel micro-cords held together by a micro-mesh of glass fiber (

Figure 2).

The system has a density of 670 g/m2 (low density); the cross-sectional area of each chord was 0.538 mm2, and the distance between two consecutive cords was equal to 0.6 mm with an equivalent thickness of tf = 0.084 mm.

2.3. Mechanical Properties of Materials

Cylindrical concrete specimens were manufactured during the casting of the beams, cured under the same environmental conditions, and tested at 28 days after the casting. Standard tests were conducted on cylinders; the average values of compressive, fcm, and tensile ftm, strength were 14.40 MPa (COV = 0.01) and 2.42 MPa (COV = 0.02), respectively.

The mechanical properties of steel bars were determined by tension tests on three samples of each bar size. The yield strength fy, the yield strain εy, and the ultimate strength fu of the 18-mm diameter bars were 617 MPa (CoV = 0.01), 0.003 mm/mm, and 751 MPa (CoV = 0.02), respectively, while they were 565 MPa (CoV = 0.02), 0.00276 mm/mm, and 644 MPa (CoV = 0.02), for the 8-mm diameter bars.

Steel fibers were characterized by tensile tests performed on five dry textile coupons according to provisions of the guidelines [

13]. The obtained values of the elastic modulus, tensile stress, and ultimate strain were

197 GPa (

CoV = 0.006),

3.07 GPa (

CoV = 0.014), and

0.020 mm/mm (

CoV = 0.08), respectively.

According to the EN 1015-11 provisions [

14], flexural and compressive tests were performed to determine the mechanical properties of the matrix; the average values were

10.90 MPa (

CoV = 0.07) and

55.54 MPa (

CoV = 0.02), respectively.

Direct tensile tests were carried out on five SRG specimens with a nominal size of

500 × 50 × 10 mm. Two thin steel plates were glued with epoxy for a length of

100 mm to the ends of the coupon to improve the grip of the textile during testing. The tests were conducted on stroke control.

Figure 3a reports a photo of the adopted test setup, while

Figure 3b illustrates the stress–strain curves obtained by tests.

The stress–strain curve can be modeled by tri-linear branches, which refer to the un-cracked condition (Stage I), the crack development condition (Stage II), and the cracked condition up to failure (Stage III). Each branch of the curve is characterized by the values of the strain, ε (mm/mm), stress, σ (MPa), and tensile modulus (GPa) reported in the following: Stage I, εI = 0.2 mm/mm (C.o.V. = 0.37), σI =281 MPa (C.o.V. = 0.28), and EI = 1450 GPa (C.o.V.= 0.10); Stage II, εII = 2.0 mm/mm (C.o. V. = 0.21), σII = 533 MPa (C.o.V. = 0.17), and EII = 126 GPa (C.o.V. = 0.27); Stage III, εIII = 20.8 mm/mm (C.o. V. = 0.07), σIII =2768 MPa (C.o.V. = 0.03), and EIII = 54 GPa (C.o.V. = 0.06).

2.4. Bond Tests

Single-lap direct shear tests were performed on

9 SRG-to-concrete joints;

6 specimens were manufactured with

1 layer of steel textile while the remaining

3 were manufactured with

2 layers of textile. SRG strips

50 mm wide were bonded for a length of

260 mm on the sides of concrete prisms, which have a

150 × 200 mm rectangular cross-section as shown in

Figure 4. Prior to bonding the SRG strips, the faces of concrete prisms were sandblasted and wetted. The SRG strips were bonded starting at a distance of

40 mm from the prism edge at the loaded end; the fibers were bare outside the bonded area. According to the manufacturer’s recommendations [

15], the SRG strips were manufactured with two or three layers of mortar

3 mm thick when one layer or two layers of textile, respectively, were used. The SRG -to-concrete joints were manufactured with the same materials (steel fabrics, mortar, and concrete) used to build the strengthened reinforced concrete beams. The notations

DS-nL-Z, where

DS indicates the classic push–pull configuration,

nL is the number of steel fabric, and

Z is the specimen number, were used to identify the tested specimens.

The tests were executed with the setup illustrated in

Figure 4; to grip the textile, two thin aluminum plates were glued with epoxy resin for a length of

100 mm to the end of the SRG strips. Concrete prisms were restrained by a steel frame bolted to the testing machine base. As illustrated in

Figure 4, the load was uniformly distributed through a steel plate inserted between the steel frame and the top face of concrete prisms. Vertical displacements were measured by four LVDTs; two of them (LVDTa and LVDT b in

Figure 4), measured the slip of the fibers at the beginning of the bonded area. Further details about the test setup are reported in [

1]. Loads were applied to all specimens under displacement control with a rate of

0.00084 mm/s.

2.5. Specimen Preparation

The strengthening of the beams was performed in accordance with the composite manufacturer’s recommendations. To guarantee good bonding, the bottom concrete surface was wetted before applying the composite. After the application of the first matrix layer (3 mm thick) on the concrete surface, the first layer of steel fabric was applied and pressed into the matrix to assure proper impregnation. The next 3 mm mortar layer covered the steel fabric completely; the operation was repeated until all steel layers were applied and covered by mortar.

2.6. Test Setup and Procedure

After the strengthening, beams were cured at room conditions for at least

30 days before testing.

Figure 1 shows the arrangement and the test setup.

A hydraulic jack was used to gradually apply the load, which was measured with a load cell. All beams were loaded until failure at a load rate of approximately

40 N/s. Four LVDTs were used to record vertical displacements during tests; they were located along the beam length. In particular, two LVDTs were located at the point load (one on each side of the beam), while the others were on each support.

Figure 1 also illustrates the position of the strain gauges bonded on the concrete surface, steel bars (both longitudinal and transversal), and steel textiles. Deflections, strains, and applied loads were recorded by a data acquisition system.

3. Results

The main results of the tests are described and discussed in the following section.

3.1. Bond Tests

All tested specimens failed by the SRG debonding occurring at the internal matrix–fiber interface as a result of the matrix fracture between the fibers. In all specimens, the interfacial crack formed along the fibers (

Figure 5b).

Transversal hairline cracks (

Figure 5d) formed in the matrix near the loaded end of the SRG strip and are related to the slippage of the fibers at the internal matrix layer interface [

16].

Figure 6 reports the experimental load–global slip curves of all specimens. The analysis of the graphs evidences an initial linear branch, which describes the elastic behavior of the fiber-to-matrix bond. Due to the occurrence of micro-damages, a slight reduction in stiffness was also observed. Once the maximum load

Pmax is reached, the response of one-steel-fabric-layer-reinforced specimens was different from that provided by two-layer-reinforced specimens. In the former, the increase in global slips took place in an almost constant applied load until sudden and rapid degradation without softening response occurred; in the latter, the load degradation took place immediately.

This phenomenon was due to a different failure mode observed in specimens reinf orced with two layers of steel fabric. The interfacial crack was observed only in the most internal steel fabric (close to the substrate) due to a rapid load degradation (

Figure 5c).

Table 2 summarizes the test results in terms of maximum load and stress; the stress was evaluated as

σ = P/nAsy with

P being the applied load,

n being the number of cords of steel strips (

24 in these tests), and

Asy being the area of a single steel cord (

0.538 mm2).

The average stress values reported in

Table 2 were

20% and

15% of the tensile strength of fibers (

σfu = 3070 MPa), for one- and two-layer-reinforced specimens, respectively. The average values of debonding strains were

0.31% and

0.235% for one- and two-layer-reinforced specimens, respectively; they are much lower than the fiber rupture strain

εfu = 2%.

3.2. Beam Tests

All tested beams exhibited the typical behavior of shear-deficient reinforced concrete beams, with the gradual appearance of diagonal cracks in the shear span region. The un-strengthened beam,

B control, failed after the formation of a main diagonal crack in the shear zone, inclined

45° to the beam axis (

Figure 7). Shear failures were also observed in all strengthened beams. The failure configurations were different upon varying the

sf/

wf ratio (i.e., varying the number of U-shaped strips in the shear span). As illustrated in

Figure 7, the main diagonal crack in the

B-1L-2S beams developed similarly to that of the

B Control; it was inclined almost

45° to the beam axis and crossed the U-shaped strip located under the loading point at its end.

The failure of the beam was a typical shear failure with concrete crushing at the loading point: The rupture of the steel fibers was observed in the SRG strip at the level of the diagonal crack. In the B-1L-3S beam (sf/wf = 3.50), the diagonal crack crossed the central U-shaped SRG strip; the failure occurred immediately after the sudden and simultaneous detachment of the central SRG strip from both sides of the beam.

In the B-1L-4S beam (sf/wf = 2.34), the main diagonal crack crossed all the U-shaped strips located in the shear zone; some other diagonal cracks formed and developed between the consecutive strips. At failure, debonding of the two SRG strips located in the shear zone occurred. The main crack in the B-1L-5S beam (sf/wf = 1.70) developed horizontally at the top of the beam near the point load, then it developed a strong inclination (higher than 45°) between two subsequent strips and horizontally at the bottom of the beam. All SRG strips crossed from the diagonal crack were damaged; the failure occurred due to the fiber-to-matrix debonding of the intermediate U-shaped strip. Moreover, in the B-1L-1S beam (sf/wf = 1.00) where a continuous strengthening configuration was adopted, the main diagonal crack formed at an incline of almost 40° to the beam axis. The failure occurred due to the concrete crushing without detachment of the SRG reinforcement. Upon increasing the steel fabric layers (i.e., increasing the rigidity of the SRG strips), the failure configurations of the strengthened beams changed even if shear failure occurred with the formation of the main diagonal crack.

In the

B-2L-2S beam, the diagonal crack developed between the two strips; its inclination to the beam axis was almost

30°. The crack crossed the two SRG strips but was not visible; at failure, no detachment of the strips was observed. Two main diagonal cracks formed in the

B-2L-3S beam; they crossed all SRG strips; at failure, the intermediate strip detached from the beam (

Figure 8). A similar cracking configuration was observed in the

B-2L-4S strips where shear failure occurred after the sudden and simultaneous detachment of the intermediate strips from both sides of the beam. A main diagonal crack also formed in the

B-2L-5S beam; it developed only between the two U-shaped strips near the loading point.

At failure, the mid-length strip detached from the beam at the matrix-to-substrate interface together with a thin layer of the substrate (

Figure 9). A similar failure mode was observed in the

B-2L-1S beam in which the U-shaped strip detached completely from the beam.

3.3. Load–Deflection Responses

Figure 10 and

Figure 11 report the load-deflection diagrams recorded for all beams; the former reports the curves of beams strengthened with one-layer SRG strips while those of beams strengthened with two-layer SRG strips are reported in the latter. Deflection values are determined as the average of the values measured by LVDTs at the loading point.

An almost tri-linear curve was obtained for all tested beams. The first linear branch represents the elastic behavior of the un-cracked beam. The second almost linear branch describes the behavior of the cracked beam; it ends when the maximum applied load is reached. In the majority of tested beams, the maximum load resulted lower than that corresponding to the first yielding of the steel rebars. After the peak load, the brittle behavior of the beams is described through a descending branch.

The analysis of the curves shows a slight change in stiffness in all shear-strengthened beams when compared to the control. In addition, the response of the one-layer SRG strip strengthened beams was not excessively influenced by the

sf/

wf ratio: The curves obtained for

B-1L-2S and

B-1L-3S are, in fact, coincident and similar to

B-Control, while the curves of the

B-1L-4S,

B-1L-5S, and

B-1L-1L beams present a similar trend with a slight variation in the peak load values. The response of the two-layer SRG strips was strongly influenced by the

sf/

wf ratio; as illustrated in

Figure 10, the curves are different from each other with a wide variation in the peak loads.

Table 3 reports the load values corresponding to the attainment of the concrete cracking,

Pcr, and those at the failure of the beams,

Pu, together with the corresponding deflection values

δcr and

δu.

The data collected in

Table 3 highlight the influence of both the

sf/

wf ratio and the rigidity,

Eftf, of the SRG strips on the ultimate load of the tested beams.

Figure 12 shows the experimental non-dimensional shear strength values

v =

Vu/

Vucontrol against the

sf/

wf ratio varying the rigidity of the SRG U-shaped strips.

Vu and

Vucontrol are the shear values at failure of strengthened and control beams, respectively; they are evaluated as

Vu = (

l −

a)/

l Pu, with

a being the shear span,

l being the beam length, and

Pu being the ultimate load. In the same Figure, the regression lines for both beams strengthened with one- and two-layer SRG strips are also reported; as previously mentioned, the R

2 values indicate that the results obtained for single-layer SRG strips strengthened beams are more regular than those corresponding to two-layer SRG strips strengthened beams.

As expected, the shear capacity of strengthened beams is higher than that of the control beam; it decreased with the increase in the sf/wf values while it increased with the rigidity of the SRG strips. In particular, for beams strengthened with one-layer SRG U-shaped strips, the increase in the non-dimensional shear capacity is between 1.04 (B-1L-2S beam, sf/wf = 7.0) and 1.2 (B-1L-1S beam, sf/wf = 1.0) while it varied between 1.04 (B-2L-4S beam, sf/wf = 2.34) and 1.80 (B-2L-1S beam, sf/wf = 1.0) for beams strengthened with two-layer SRG strips.

The same value,

v = 1.04, was obtained for the

B-2L-4S and

B-1L-3S beams, as reported in

Table 3; this unforeseen result is due to the premature failures that occurred in both beams (complete detachment of the most stressed U-shaped strips).

In

Table 3, for all tested beams, the load point deflection values at the cracking load,

δcr, and at the ultimate load,

δu, are also reported together with the ratio

δu/δcr. They provide evidence of the favorable effect of the SRG shear strengthening on the deformability of beams. The

δu/δcr ratio evaluated for strengthened beams was, in fact, higher than that of the un-strengthened beam; it increased both when the rigidity of the SRG strips increased and when the

sf/

wf ratio decreased.

3.4. Strain Analysis

Strains of steel bars and SRG strips were measured by gauges. Two electrical strain gauges were applied to the internal steel bars in tension at the mid-length of the shear zone and at the loading point, while, as illustrated in

Figure 1, one strain gauge was applied to the steel fabric of each SRG U-shaped strip.

The applied load–steel bar strain curves obtained by values measured at loading points are reported in

Figure 13 and

Figure 14; in the same figures, the line corresponding to the yield strain of the steel bars is shown.

By analyzing strain values, it is evident that, except for the

B-1L-5S and

B-2L-5S beams, the failure of shear-strengthened beams occurred before the yielding of the steel bars. In addition, as shown in

Figure 13 and

Figure 14, failures of the strengthened beams occurred for strain values in steel bars almost equal to

50% of the yield strain value.

The variation of the steel fabric strain with the applied load is shown in

Figure 15 and

Figure 16 for all the tested beams. Strains were measured by electrical gauges applied to the steel fabric using an epoxy resin (as recommended by the manufacturer); after connecting the cables, a protective coating was applied to protect the gauges during casting and testing.

The curves refer to the strain measured in the most stressed SRG strips for each tested beam.

By analyzing the curves drawn in both Figures, the highest strain value was measured in the SRG strips bonded to the

B-1L-4S and

B-2L-1S beams. The maximum values of the measured strain in the SRG strips,

εfmax, are also listed in

Table 4 for each tested beam. In the table, the exploitation ratio values,

εfmax/

εfu, with

εfu = 0.020 mm/mm, are also reported.

These values provide evidence that the steel textiles strains were very low in comparison to the ultimate strain value of dry textile at failure.

4. Analytical Modeling

The shear capacity of SRG-strengthened reinforced concrete beams can be predicted analytically through a relationship derived from the Ritter–Mörsch criteria failure. The shear capacity,

VR, is expressed by Equation (1)

where

Vunstr is the shear strength of the un-strengthened beam and

Vf is the contribution provided by the external SRG reinforcement.

Vf is analytically expressed as [

13]:

where

εfe and

Ef are the effective strain and the elastic modulus of the SRG, respectively,

nf is the number of SRG layers bonded on each side of the beam,

tf is the equivalent thickness of a single layer of fibers,

b and

d are the width and the effective depth of the beam’s cross-section, respectively,

θ is the angle of the diagonal crack (usually

θ = 45°), and

α is the inclination angle of the fibers with respect to the beam axis. Equation (3) is founded on the hypothesis that failure is due to the main diagonal crack, inclined as the compressed concrete strut, and the SRG on both sides of the beam furnishes the same contribution to the shear capacity of the beam.

The effective strain, εfe, is the average strain in the fibers crossing the shear crack at failure; its value depends on the bond between the concrete and the strengthening material.

The effective strain is the key parameter to evaluate the shear contribution Vf; its value depends on numerous parameters related to the stress transfer mechanism at the fabric-to-mortar interface and strengthening system-to-concrete substrate. As is well-known in FRCM systems, the stress transfer mechanisms are too complex and governed by many parameters both geometrical and mechanical; as a consequence, it is difficult to define analytical models able to provide a reliable prediction of the effective strain. At the same time, experimental measurements of the strain in the strengthening system are influenced by many variables and, generally, they are not reliable.

In this scenario, the procedures to determine the effective strain of the SRG strengthening systems, available in the technical literature, are based on semi-empirical models generally performed through statistical analyses of experimental results. Two methods for the evaluation of the effective strain were described in the following, and the analytical relationships of εfe were adopted in Equation (2) to calculate the shear contribution provided by the SRG U-shaped strips.

4.1. Method I-Tests on FRCM Shear-Strengthened Reinforced Concrete Beams

This method is founded on the analysis of test results of FRCM shear-strengthened reinforced concrete beams. The experimental values of the FRCM strain are calculated by Equation (3)

where

Vfexp is the difference between the experimental shear capacity of strengthened beams,

VRexp, and that of the un-strengthened ones,

VRunstr, were collected in a database. The analysis of the data allows one to define an analytical relationship for the effective strain of FRCM shear-strengthened reinforced concrete beams. The reduced number of test results, however, makes it difficult to define a general analytical relationship to estimate the effective strain (or the effective stress) of the composite system in shear-strengthened reinforced concrete beams.

The Database of Beam Tests Results

The database refers to the results obtained on

64 reinforced concrete beams strengthened in shear with FRCM U-shaped strips. The experimental results were available in the literature; details are reported in [

17].

Table 4 reports the range of variability for the main mechanical and geometrical parameters of the collected data (

Asw and

isw are the area and the spacing of internal steel stirrups, respectively, and

fcm is the compressive strength of concrete).

The following analytical relationship was determined through a best-fit analysis of the data

where

ρf =

2 tf/

b (

sf/

wf) is the reinforcement ratio, and

Ef (

GPa) and

εfu are the elastic modulus and the ultimate strain of the steel fibers, respectively.

4.2. Method II-Bond Tests

The stress transfer mechanisms at the composite system-to-concrete substrate interface or, for FRCM systems, at the fiber-to-matrix interface, are generally analyzed by the results of bond tests such as single- or double-lap direct shear tests.

The experimental observations of bond tests evidenced that the failure of FRCM composites may occur as debonding at different interfaces, that is, at the matrix–fiber interface with slippage of the fibers (mode A), at the matrix–fiber interface with damage of the matrix (mode B), at the matrix–substrate interface without damage to the substrate (mode C), and at the matrix–substrate interface with the detachment of a thin layer of the substrate (mode D).

As observed in this experimental investigation, the failure (mode D) of some of the SRG shear-strengthened beams (B-1L-4S, B-1L-5S, B-2L-1S, B-2L-3S, and B-2L-5S beams) occurred due to the debonding of the SRG strips following the above-described failure modes.

It is then reasonable to connect the SRG strain values achieved by direct shear tests to the effective strain in the SRG of strengthened reinforced concrete beams. Direct shear tests are commonly performed to determine the mechanical properties of the strengthening system as indicated by certain Codes and Guidelines [

13]. Thus, a great number of experimental observations are available and can be adapted to estimate the effective strain of the strengthening systems. With this aim, many direct shear test results obtained on SRG-concrete joints were collected in a database. A regression analysis of the data allowed us to determine the analytical relationship of the SRG effective strain.

The Database of Direct Shear Test Results

The results of 113 direct shear tests performed on SRG-to-concrete joints were collected and analyzed. The experimental results were available in the literature [

18,

19,

20,

21]; the range of variability for the parameters characterizing the collected data are listed in

Table 5 where γ (g/m

2) is the density of the steel fabrics,

lb (mm) is the bonded length,

bf (mm) is the width of the SRG,

fcm (MPa) is the compressive concrete strength, and

tf and

Af the equivalent thickness and the area of the steel fabric, respectively.

The analysis of the data allowed us to define the analytical relationship to predict the effective strain of the SRG system

4.3. Validation of the Proposed Methods

The two considered methods were validated by the comparison between their predictions and experimental results. The comparison was performed considering only beams shear strengthened with SRG U-shaped strips, which failed via the debonding of strips. The experimental effective strain values, determined by Equation (3), refer to both the results of tests reported in the present investigation and those obtained by Wakjira and Ebead [

11,

12], Gonzalez et al. [

9], and Thermou et al. [

10].

Figure 17 illustrates the results of the comparison.

The analysis of the obtained results highlights how Method I provides more accurate predictions than Method II. In fact, the last one overestimates the experimental values for high values of the Efρf/fcm2/3 ratio while it offers better predictions for low values of the Efρf/fcm2/3 ratio.

Further experimental results are, however, needed to better define the numerical coefficients of both methods that, also in this form, could still be adopted to predict the shear capacity of SRG-strengthened reinforced concrete beams.