The Influence of Silica Fume on the Properties of Mortars Containing Date Palm Fibers

Abstract

:1. Introduction

2. Experimental Program

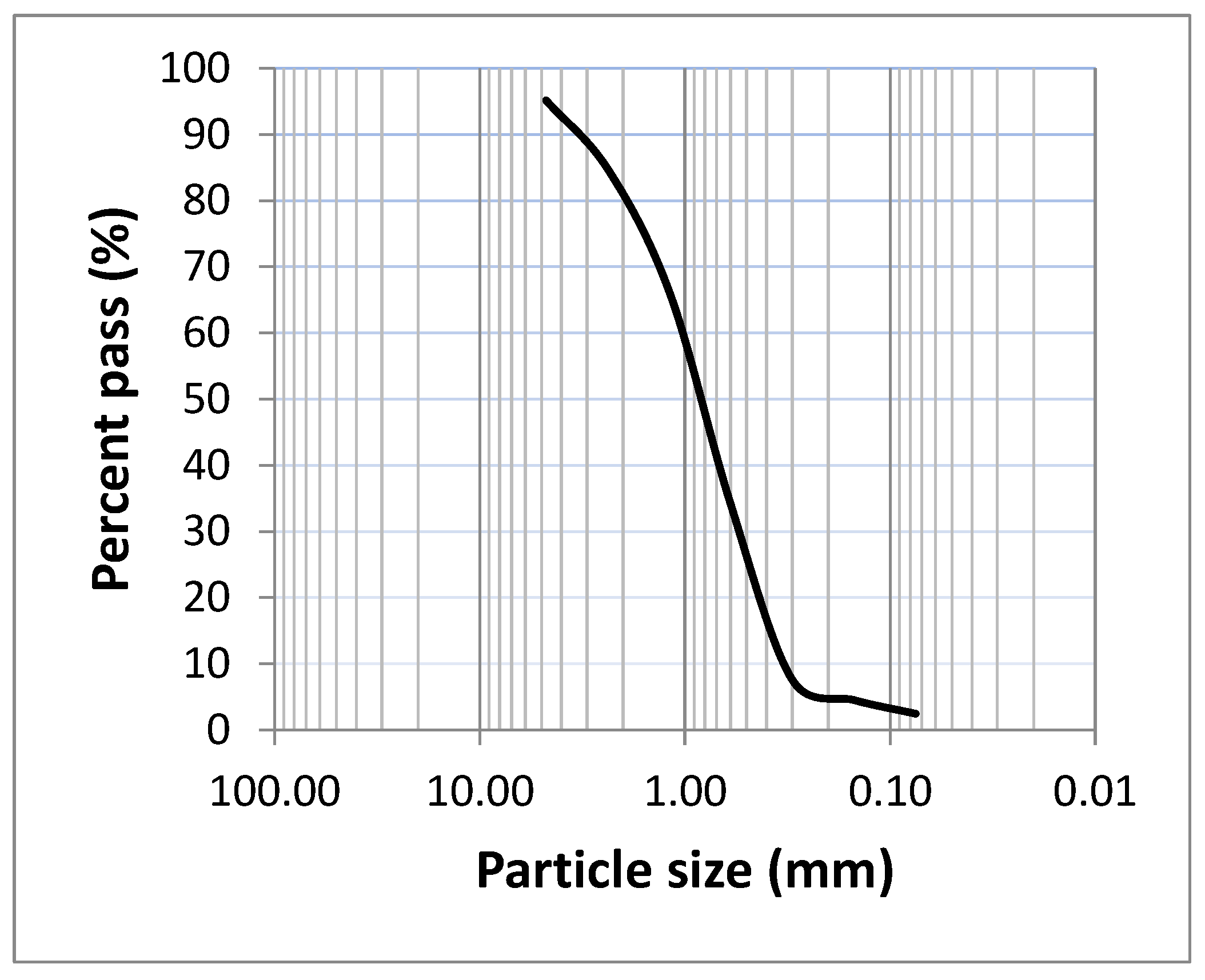

2.1. Materials

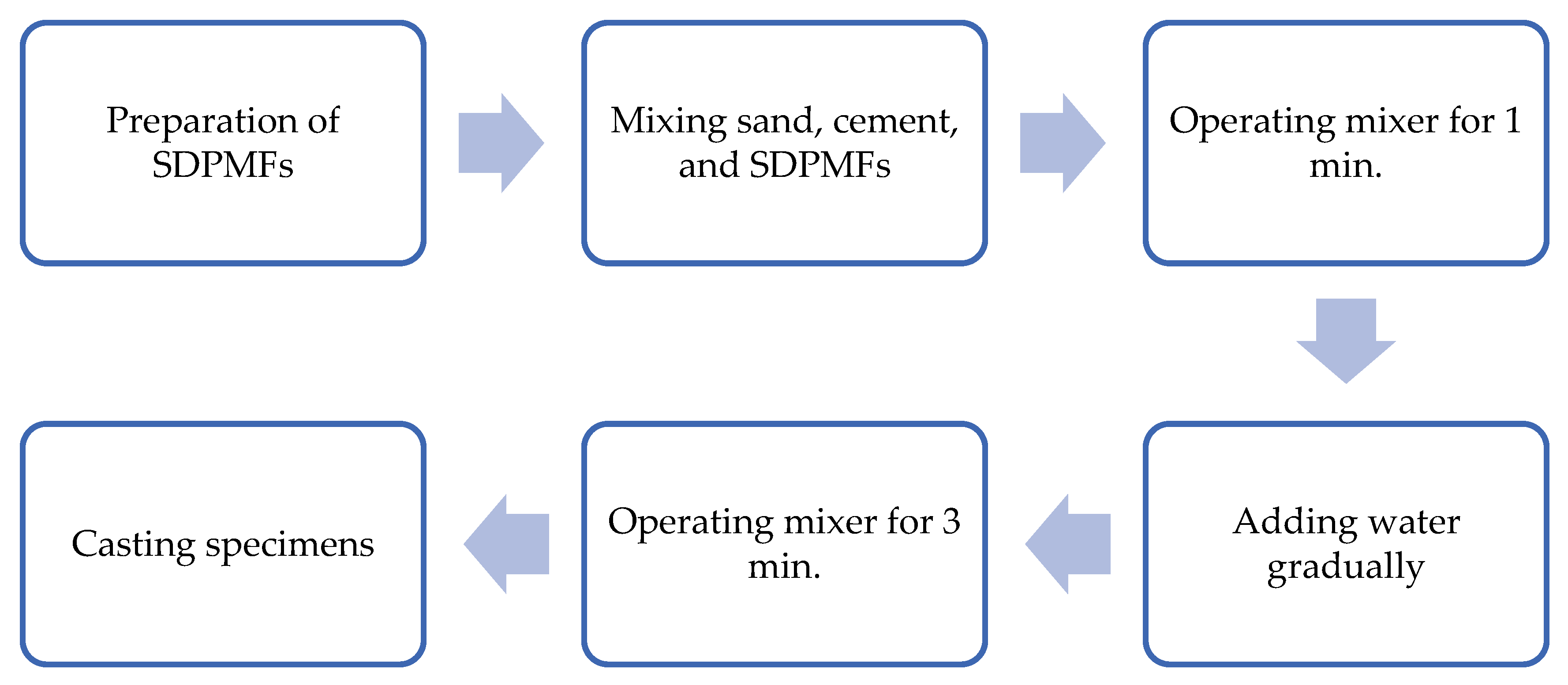

2.2. Mix Proportion

2.3. Tests

2.3.1. SDPMF Properties

2.3.2. Mortar Properties

3. Results and Discussion

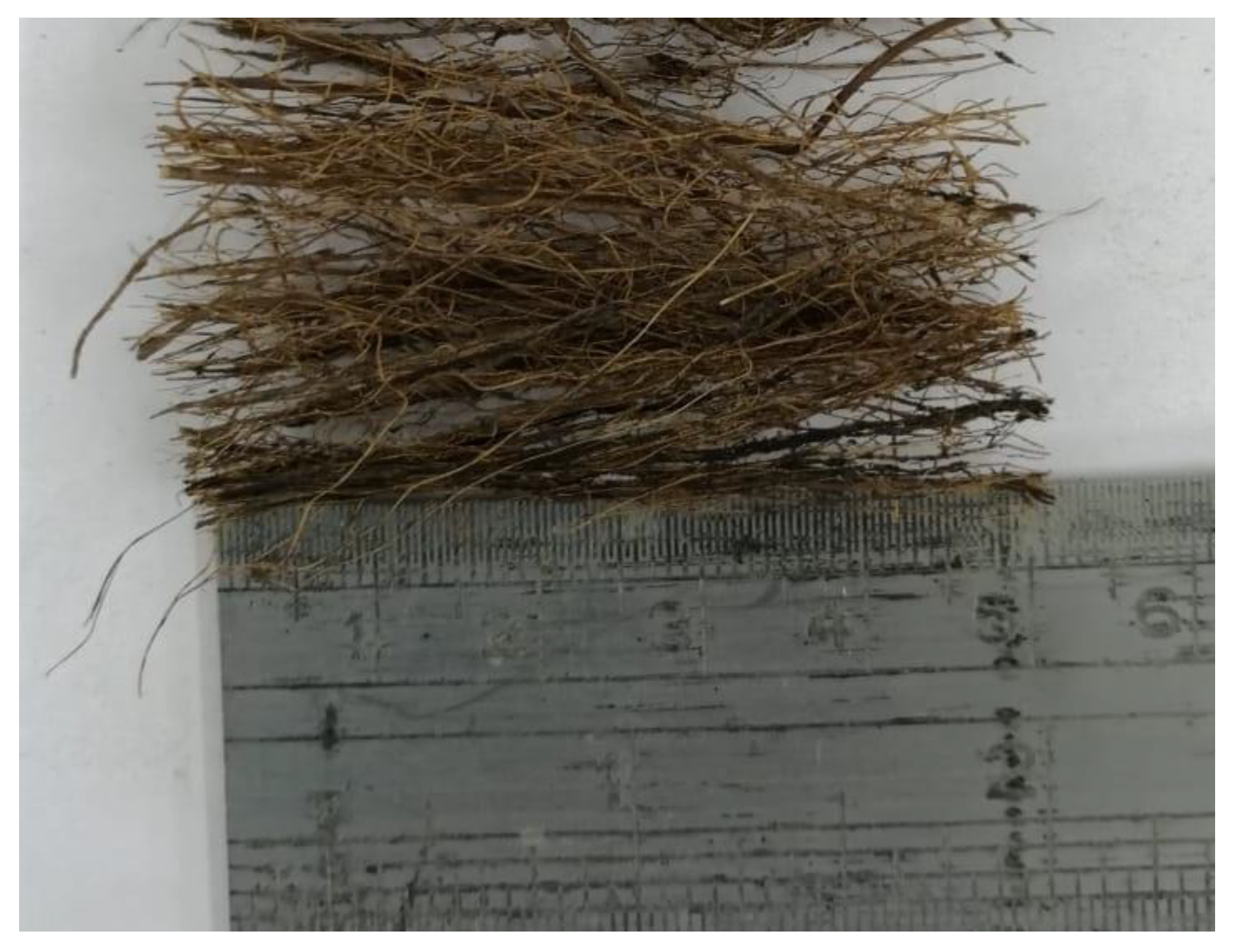

3.1. Physical Properties of SDPMFs

3.2. Workability of Mortars

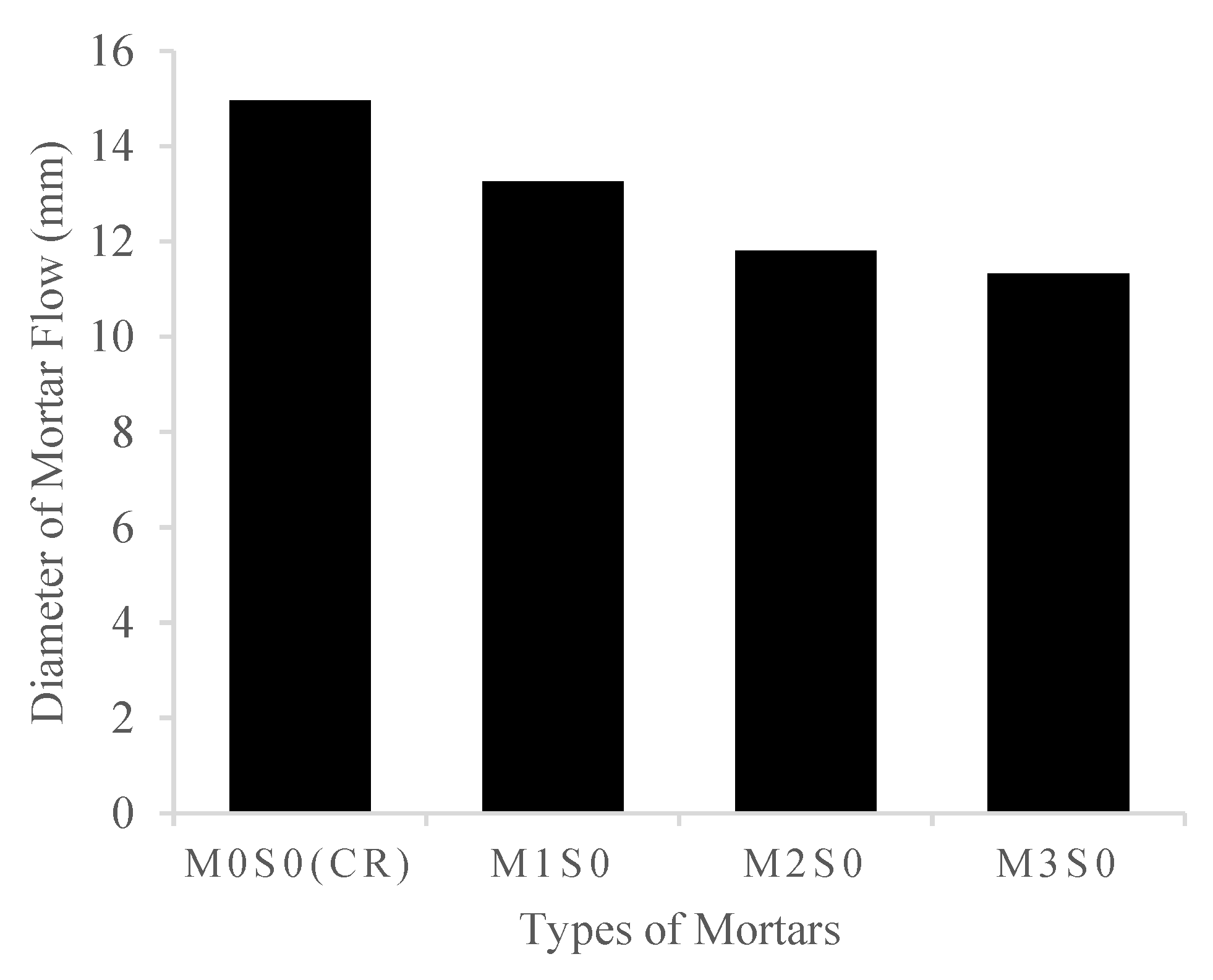

3.2.1. Effects of SDPMF Content

3.2.2. Effects of SDPMF Content and 10% SF

3.2.3. Effects of SF Content

3.3. Water Absorption and Open Porosity

3.4. Density

3.5. Compressive Strength

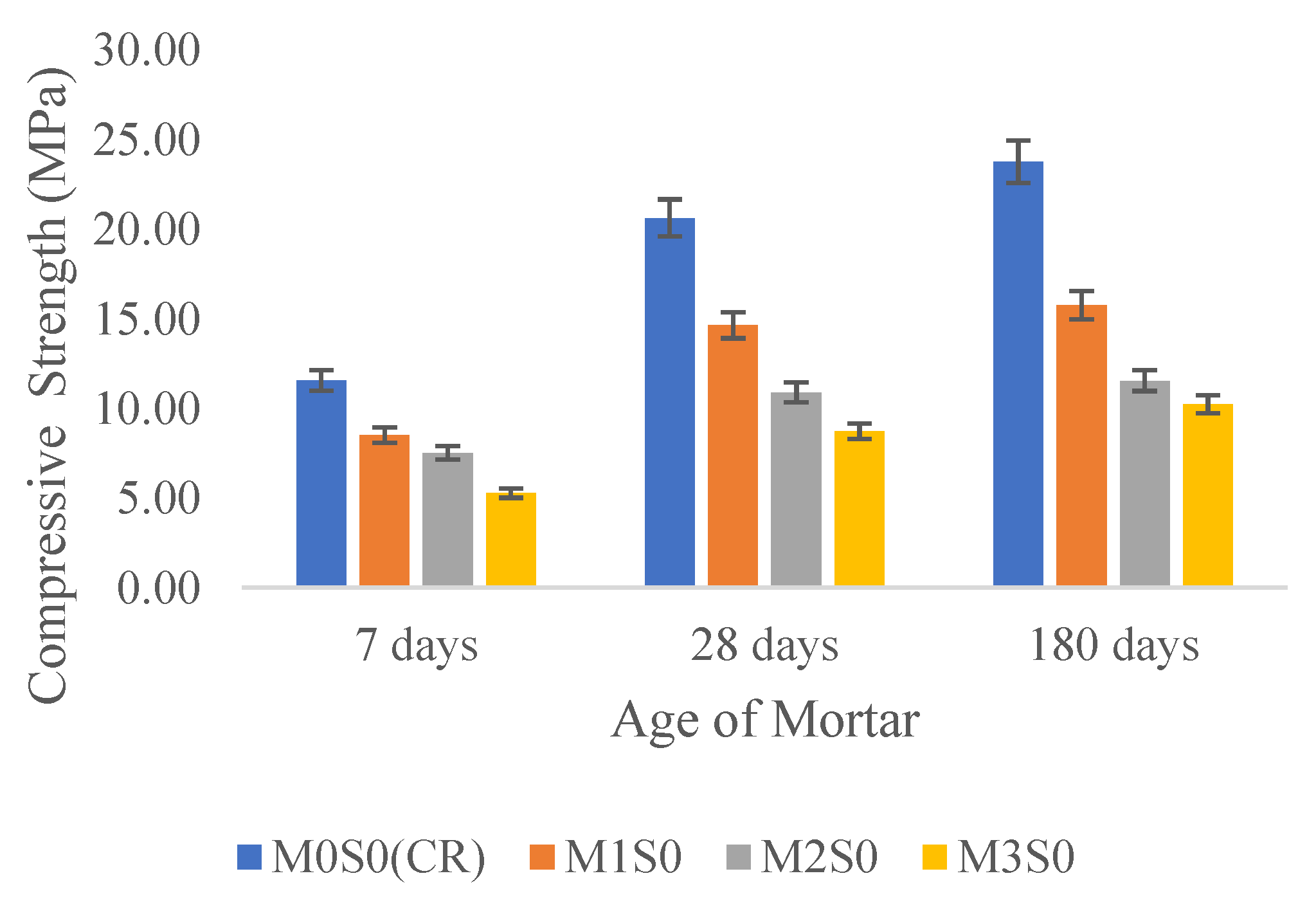

3.5.1. Effects of SDPMF Content

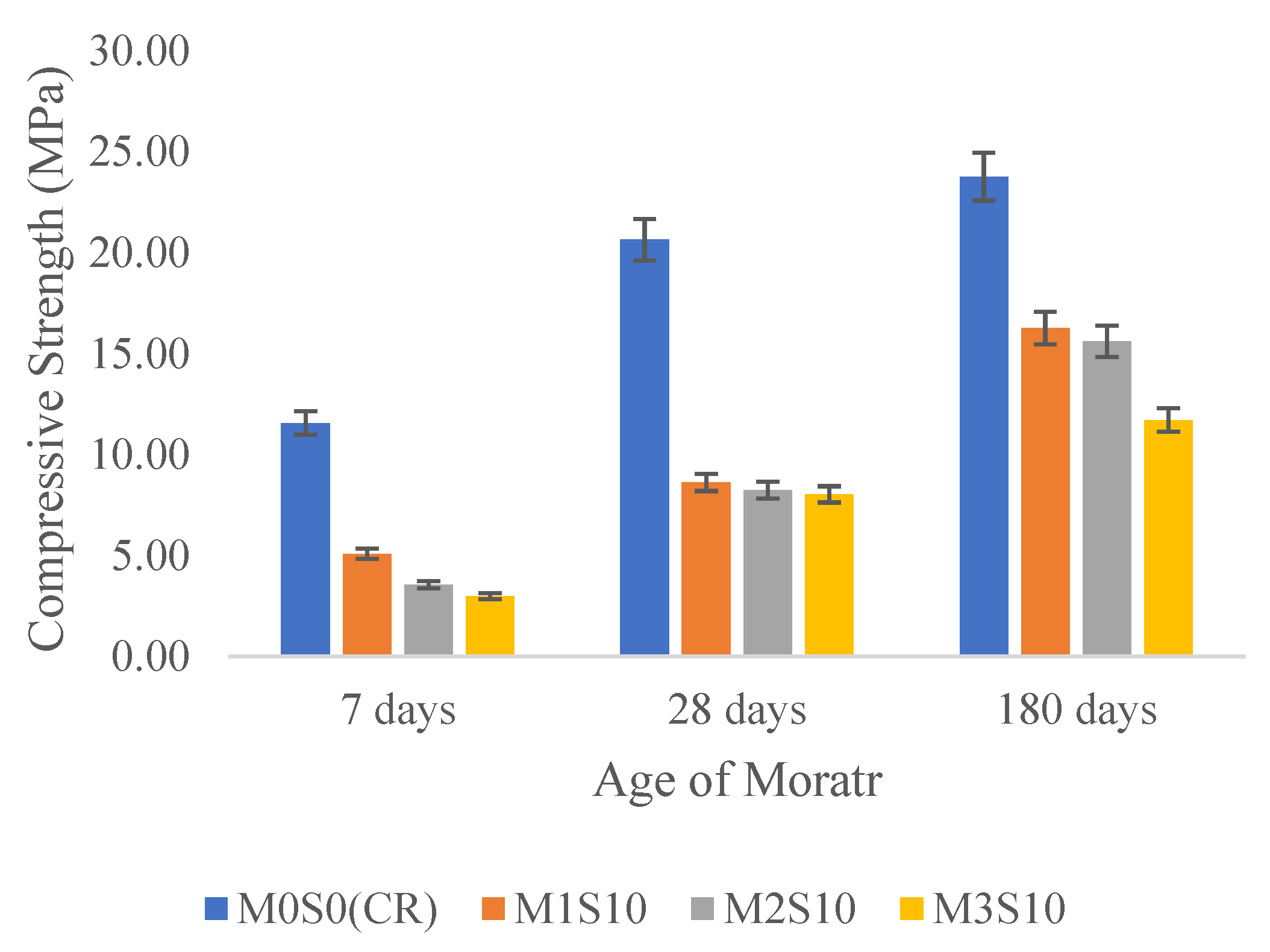

3.5.2. Effects of SDPMF Content and 10% SF

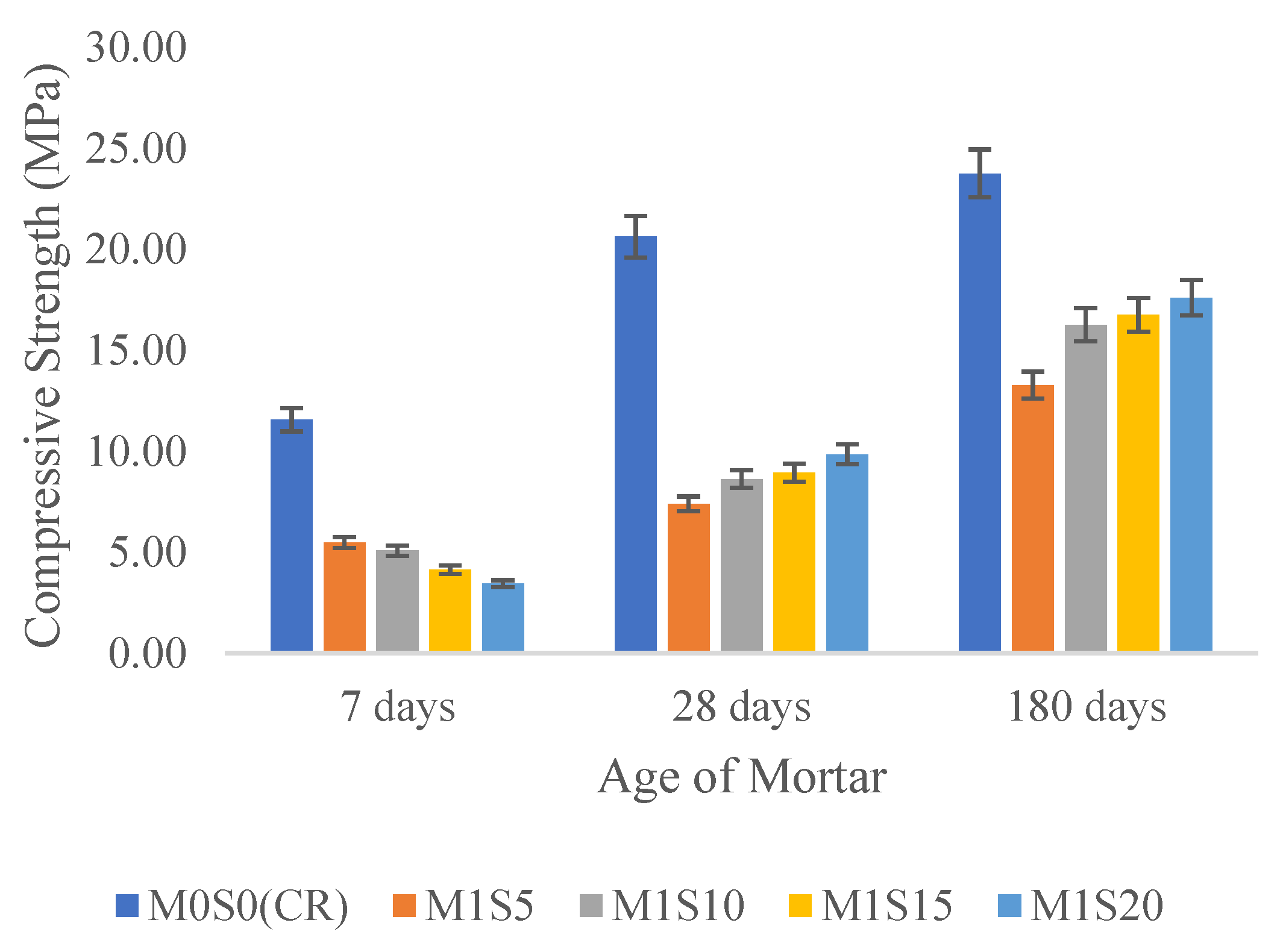

3.5.3. Effects of SF Content

4. SDPMF Mortar’s Applications

5. Conclusions

- The low density (951.78 kg/m3) and high absorption capacity (122.53%) of SDPMFs classify them as lightweight fibers, which might produce light mortars towards green construction materials.

- The workability of mortars was affected and reduced due to the inclusion of SDPMFs and reduced more as SF partially replaced the cement. With changing the content of SDPMFs and SF, the workability was reduced up to 24.25% and 33.11%, respectively, as compared to the control mortar.

- The density of mortars was insignificantly affected by the presence of SDPMFs and SF, with improvements up to 1.13% as compared to the control mortar. However, some mortars showed insignificant reduction up to 2.21%.

- All mortars showed higher water absorption and higher open porosity as compared to the control mortar. With changing the content of SDPMFs and SF, the water absorption and open porosity were increased up to 86.18% and 68.11%, respectively.

- The mortars containing SDPMFs showed a loss in compressive strength up to 57.66% at 28 days for 3% SDPMF inclusion. The loss in compressive strength at early ages becomes higher when SF is introduced to the mortars.

- The loss in compressive strength due to the inclusion of SDPMFs could be compensated by incorporating SF. A substantial improvement in compressive strength up to 63.10% at age of 180 days could be observed when 20% SF is incorporated to a mortar containing 1% SDPMFs.

- Mortars containing SDPMFs could be produced with acceptable strength for use in structural applications.

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Paik, I.; Na, S. Evaluation of Carbon Dioxide Emissions amongst Alternative Slab Systems during the Construction Phase in a Building Project. Appl. Sci. 2019, 9, 4333. [Google Scholar] [CrossRef] [Green Version]

- Ali, K.A.; Ahmad, M.I.; Yusup, Y. Issues, Impacts, and Mitigations of Carbon Dioxide Emissions in the Building Sector. Sustainability 2020, 12, 7427. [Google Scholar] [CrossRef]

- Sandanayake, M.; Bouras, Y.; Haigh, R.; Vrcelj, Z. Current Sustainable Trends of Using Waste Materials in Concrete—A decade Review. Sustainability 2020, 12, 9622. [Google Scholar] [CrossRef]

- Ali, M.B.; Saidur, R.; Hossain, M.S. A review on emission analysis in cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2252–2261. [Google Scholar] [CrossRef]

- Anand, S.; Vrat, P.; Dahiya, R.P. Application of a system dynamics approach for assessment and mitigation of CO2 emissions from the cement industry. J. Environ. Manag. 2006, 79, 383–398. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef] [Green Version]

- Kesikidou, F.; Stefanidou, M. Natural fiber-reinforced mortars. J. Build. Eng. 2019, 25, 100786. [Google Scholar] [CrossRef]

- Song, H.; Liu, J.; He, K.; Ahmad, W. A comprehensive overview of jute fiber reinforced cementitious composites. Case Stud. Constr. Mater. 2021, 15, e00724. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. A review of the mechanical and durability performance of kraft-fibre reinforced mortar and concrete. Constr. Build. Mater. 2021, 297, 123759. [Google Scholar] [CrossRef]

- Quiñones-Bolaños, E.; Gómez-Oviedo, M.; Mouthon-Bello, J.; Sierra-Vitola, L.; Berardi, U.; Bustillo-Lecompte, C. Potential use of coconut fibre modified mortars to enhance thermal comfort in low-income housing. J. Environ. Manag. 2021, 277, 111503. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Richardson, M. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Kumarasamy, K.; Shyamala, G.; Gebreyowhanse, H. Strength Properties of Bamboo Fiber Reinforced Concrete. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Chennai, India, 16–17 September 2020; Volume 981. [Google Scholar] [CrossRef]

- Marrero, R.E.; Soto, H.L.; Benitez, F.R.; Medina, C.; Suarez, O.M. Study of high-strength concrete reinforced with bamboo fibers. Adv. Mater.-TechConnect Briefs 2017, 2, 301–304. [Google Scholar]

- Thomas, B.C.; Jose, Y.S. Impact of sisal fiber reinforced concrete and its performance analysis: A review. Evol. Intell. 2019, 1–11. [Google Scholar] [CrossRef]

- Arshad, S.; Sharif, M.B.; Irfan-Ul-Hassan, M.; Khan, M.; Zhang, J.L. Efficiency of Supplementary Cementitious Materials and Natural Fiber on Mechanical Performance of Concrete. Arab. J. Sci. Eng. 2020, 45, 8577–8589. [Google Scholar] [CrossRef]

- Khan, M.; Ali, M. Improvement in concrete behavior with fly ash, silica-fume and coconut fibres. Constr. Build. Mater. 2019, 203, 174–187. [Google Scholar] [CrossRef]

- Khan, M.; Rehman, A.; Ali, M. Efficiency of silica-fume content in plain and natural fiber reinforced concrete for concrete road. Constr. Build. Mater. 2020, 244, 118382. [Google Scholar] [CrossRef]

- Food and Agriculture Organization. Global Forest Resources Assessment 2020; Food and Agriculture Organization: Rome, Italy, 2020. [Google Scholar] [CrossRef]

- Ministry of Environment W and A. Available online: https://www.mewa.gov.sa/ar/InformationCenter/Researchs/StaticticsData/Pages/default.aspx (accessed on 20 January 2022).

- El-Juhany, L.I. Surveying of lignocellulosic agricultural residues in some major cities of Saudi Arabia. Res. Bull. 2001, 1, 5–23. [Google Scholar]

- Vantadori, S.; Carpinteri, A.; Zanichelli, A. Lightweight construction materials: Mortar reinforced with date-palm mesh fibres. Theor. Appl. Fract. Mech. 2019, 100, 39–45. [Google Scholar] [CrossRef]

- Bamaga, S. Physical and mechanical properties of mortars containing date palm fibers. Mater. Res. Express 2022, 9, 015102. [Google Scholar] [CrossRef]

- Benmansour, N.; Agoudjil, B.; Gherabli, A.; Kareche, A.; Boudenne, A. Thermal and mechanical performance of natural mortar reinforced with date palm fibers for use as insulating materials in building. Energy Build. 2014, 81, 98–104. [Google Scholar] [CrossRef]

- Belakroum, R.; Gherfi, A.; Kadja, M.; Maalouf, C.; Lachi, M.; El Wakil, N.; Mai, T. Design and properties of a new sustainable construction material based on date palm fibers and lime. Constr. Build. Mater. 2018, 184, 330–343. [Google Scholar] [CrossRef]

- Boukhattem, L.; Boumhaout, M.; Hamdi, H.; Benhamou, B.; Nouh, F.A. Moisture content influence on the thermal conductivity of insulating building materials made from date palm fibers mesh. Constr. Build. Mater. 2017, 148, 811–823. [Google Scholar] [CrossRef]

- Kareche, A.; Agoudjil, B.; Haba, B.; Boudenne, A. Study on the Durability of New Construction Materials Based on Mortar Reinforced with Date Palm Fibers Wastes. Waste Biomass-Valorization 2019, 11, 3801–3809. [Google Scholar] [CrossRef]

- Ozerkan, N.G.; Ahsan, B.; Mansour, S.; Iyengar, S.R. Mechanical performance and durability of treated palm fiber reinforced mortars. Int. J. Sustain. Built Environ. 2013, 2, 131–142. [Google Scholar] [CrossRef] [Green Version]

- Chikhi, M. Young’s modulus and thermophysical performances of bio-sourced materials based on date palm fibers. Energy Build. 2016, 129, 589–597. [Google Scholar] [CrossRef]

- Boumhaout, M.; Boukhattem, L.; Hamdi, H.; Benhamou, B.; Nouh, F.A. Thermomechanical characterization of a bio-composite building material: Mortar reinforced with date palm fibers mesh. Constr. Build. Mater. 2017, 135, 241–250. [Google Scholar] [CrossRef]

- Braiek, A.; Karkri, M.; Adili, A.; Ibos, L.; ben Nasrallah, S. Estimation of the thermophysical properties of date palm fibers/gypsum composite for use as insulating materials in building. Energy Build. 2017, 140, 268–279. [Google Scholar] [CrossRef]

- Chennouf, N.; Agoudjil, B.; Alioua, T.; Boudenne, A.; Benzarti, K. Experimental investigation on hygrothermal performance of a bio-based wall made of cement mortar filled with date palm fibers. Energy Build. 2019, 202, 109413. [Google Scholar] [CrossRef]

- Kriker, A.; Bali, A.; Debicki, G.; Bouziane, M.; Chabannet, M. Durability of date palm fibres and their use as reinforcement in hot dry climates. Cem. Concr. Compos. 2008, 30, 639–648. [Google Scholar] [CrossRef]

- Kriker, A.; Debicki, G.; Bali, A.; Khenfer, M.M.; Chabannet, M. Mechanical properties of date palm fibres and concrete reinforced with date palm fibres in hot-dry climate. Cem. Concr. Compos. 2005, 27, 554–564. [Google Scholar] [CrossRef]

- Benaimeche, O.; Carpinteri, A.; Mellas, M.; Ronchei, C.; Scorza, D.; Vantadori, S. The influence of date palm mesh fibre reinforcement on flexural and fracture behaviour of a cement-based mortar. Compos. Part B Eng. 2018, 152, 292–299. [Google Scholar] [CrossRef] [Green Version]

- Ali-Boucetta, T.; Ayat, A.; Laifa, W.; Behim, M. Treatment of date palm fibres mesh: Influence on the rheological and mechanical properties of fibre-cement composites. Constr. Build. Mater. 2021, 273, 121056. [Google Scholar] [CrossRef]

- Lahouioui, M.; ben Arfi, R.; Fois, M.; Ibos, L.; Ghorbal, A. Investigation of Fiber Surface Treatment Effect on Thermal, Mechanical and Acoustical Properties of Date Palm Fiber-Reinforced Cementitious Composites. Waste Biomass-Valorization 2020, 11, 4441–4455. [Google Scholar] [CrossRef]

- Bogoeva-Gaceva, G.; Avella, M.; Malinconico, M.; Buzarovska, A.; Grozdanov, A.; Gentile, G.; Errico, M. Natural fiber eco-composites. Polym. Compos. 2007, 28, 98–107. [Google Scholar] [CrossRef]

- Vellaichamy, P.; Priyadharshini, S.; R, S.; Selvan, S. Studies on Effect of Silica Fume on Workability and Strength of Concrete. Int. Res. J. Multidiscip. Technovation 2019, 1, 165–171. [Google Scholar] [CrossRef]

- Prakash, S.; Kumar, S.; Biswas, R.; Rai, B. Influence of silica fume and ground granulated blast furnace slag on the engineering properties of ultra-high-performance concrete. Innov. Infrastruct. Solut. 2022, 7, 117. [Google Scholar] [CrossRef]

- Machado, P.J.C.; dos Reis Ferreira, R.A.; de Castro Motta, L.A. Study of the effect of silica fume and latex dosages in cementitious composites reinforced with cellulose fibers. J. Build. Eng. 2020, 31, 101442. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, B.; Yan, P. Comparative study of effect of raw and densified silica fume in the paste, mortar and concrete. Constr. Build. Mater. 2016, 105, 82–93. [Google Scholar] [CrossRef]

- Lei, D.Y.; Guo, L.P.; Sun, W.; Liu, J.; Shu, X.; Guo, X.L. A new dispersing method on silica fume and its influence on the performance of cement-based materials. Constr. Build. Mater. 2016, 115, 716–726. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Evaluation of high-performance concrete with recycled aggregates: Use of densified silica fume as cement replacement. Constr. Build. Mater. 2017, 147, 803–814. [Google Scholar] [CrossRef]

- Ismail, M.A. Compressive and Tensile Strength of Natural Fibre-reinforced Cement base Composites. Al-Rafidain Eng. J. AREJ 2007, 15, 42–51. [Google Scholar] [CrossRef]

- Gencel, O.; Nodehi, M.; Yavuz Bayraktar, O.; Kaplan, G.; Benli, A.; Gholampour, A.; Ozbakkaloglu, T. Basalt fiber-reinforced foam concrete containing silica fume: An experimental study. Constr. Build. Mater. 2022, 326, 126861. [Google Scholar] [CrossRef]

- Fallah, S.; Nematzadeh, M. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr. Build. Mater. 2017, 132, 170–187. [Google Scholar] [CrossRef]

- Muralitharan, R.S.; Ramasamy, V. Development of Lightweight concrete for structural applications. J. Struct. Eng. 2017, 44, 1–9. [Google Scholar]

| Compound Composition | Content (%) |

|---|---|

| SiO2 | 91.6 |

| Al2O3 | 1.65 |

| Fe2O3 | 0.99 |

| CaO | 0.22 |

| MgO | 0.30 |

| SO3 | 0.07 |

| Cl | 0.01 |

| Na2O | 0.25 |

| K2O | 0.17 |

| LOI | 3.75 |

| Relative density | 2.27 |

| Color | Grey dark |

| Mixture | SDPMF (%) | SF (%) | w/c | Binder:Sand |

|---|---|---|---|---|

| M0S0(CR) | 0 | 0 | 0.5 | 1:2 |

| M1S0 | 1 | 0 | 0.5 | 1:2 |

| M2S0 | 2 | 0 | 0.5 | 1:2 |

| M3S0 | 3 | 0 | 0.5 | 1:2 |

| M1S10 | 1 | 10 | 0.5 | 1:2 |

| M2S10 | 2 | 10 | 0.5 | 1:2 |

| M3S10 | 3 | 10 | 0.5 | 1:2 |

| M1S5 | 1 | 5 | 0.5 | 1:2 |

| M1S15 | 1 | 15 | 0.5 | 1:2 |

| M1S20 | 1 | 20 | 0.5 | 1:2 |

| SDPMF Property | Value Range |

|---|---|

| Density (OD) | 951.78 ± 20.78 kg/m3 |

| Absorption | 122.53 ± 8.24% |

| Mixture | Apparent Density (kg/m3) | Absorption (%) | Open Porosity (%) | |||

|---|---|---|---|---|---|---|

| Value | Dev. | Value | Dev. | Value | Dev. | |

| M0S0 | 2331.00 | 8.00 | 5.86 | 0.37 | 12.01 | 0.70 |

| M1S0 | 2354.05 | 63.55 | 8.12 | 0.07 | 14.99 | 2.18 |

| M2S0 | 2342.80 | 25.16 | 8.13 | 0.57 | 16.00 | 1.07 |

| M3S0 | 2357.41 | 9.32 | 8.15 | 0.35 | 16.11 | 0.63 |

| M1S10 | 2347.31 | 20.60 | 9.03 | 0.96 | 18.14 | 1.70 |

| M2S10 | 2352.84 | 2.99 | 9.34 | 0.86 | 17.53 | 1.28 |

| M3S10 | 2322.99 | 6.39 | 10.91 | 1.35 | 20.19 | 2.06 |

| M1S5 | 2279.33 | 46.00 | 8.74 | 0.31 | 14.77 | 3.48 |

| M1S15 | 2331.34 | 42.03 | 9.21 | 0.32 | 17.11 | 1.32 |

| Mixture | 7 Days | 28 Days | 180 Days |

|---|---|---|---|

| M0S0(CR) | 11.56 | 20.63 | 23.76 |

| M1S0 | 8.51 | 14.65 | 15.76 |

| M2S0 | 7.52 | 10.90 | 11.55 |

| M3S0 | 5.29 | 8.74 | 10.24 |

| M1S10 | 5.08 | 8.62 | 16.26 |

| M2S10 | 3.55 | 8.24 | 15.61 |

| M3S10 | 2.97 | 8.03 | 11.71 |

| M1S5 | 5.47 | 7.39 | 13.27 |

| M1S15 | 4.13 | 8.93 | 16.75 |

| M1S20 | 3.44 | 9.84 | 17.60 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bamaga, S.O. The Influence of Silica Fume on the Properties of Mortars Containing Date Palm Fibers. Fibers 2022, 10, 41. https://doi.org/10.3390/fib10050041

Bamaga SO. The Influence of Silica Fume on the Properties of Mortars Containing Date Palm Fibers. Fibers. 2022; 10(5):41. https://doi.org/10.3390/fib10050041

Chicago/Turabian StyleBamaga, S. O. 2022. "The Influence of Silica Fume on the Properties of Mortars Containing Date Palm Fibers" Fibers 10, no. 5: 41. https://doi.org/10.3390/fib10050041

APA StyleBamaga, S. O. (2022). The Influence of Silica Fume on the Properties of Mortars Containing Date Palm Fibers. Fibers, 10(5), 41. https://doi.org/10.3390/fib10050041