Application of Electrospun Nonwoven Fibers in Air Filters

Abstract

1. Introduction

2. Conventional Methods for the Fabrication of Nonwoven Fibrous Air Filters

2.1. Fabrication Techniques

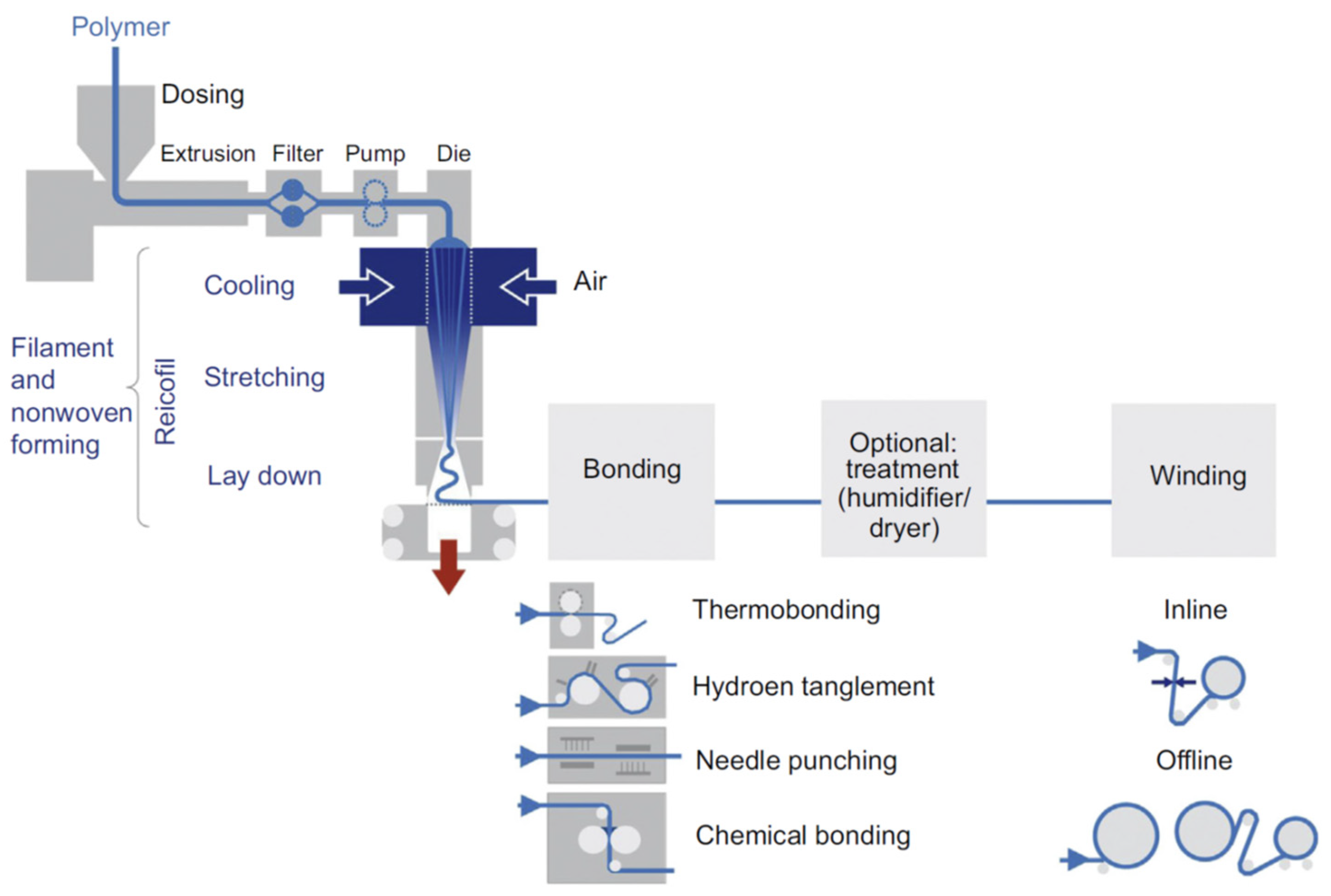

2.1.1. Spunbond

2.1.2. Melt-Blown

2.2. Applying a Fiber Charge

2.2.1. Corona Discharge

2.2.2. Triboelectrification

2.2.3. Liquid Contact

3. Electrospinning

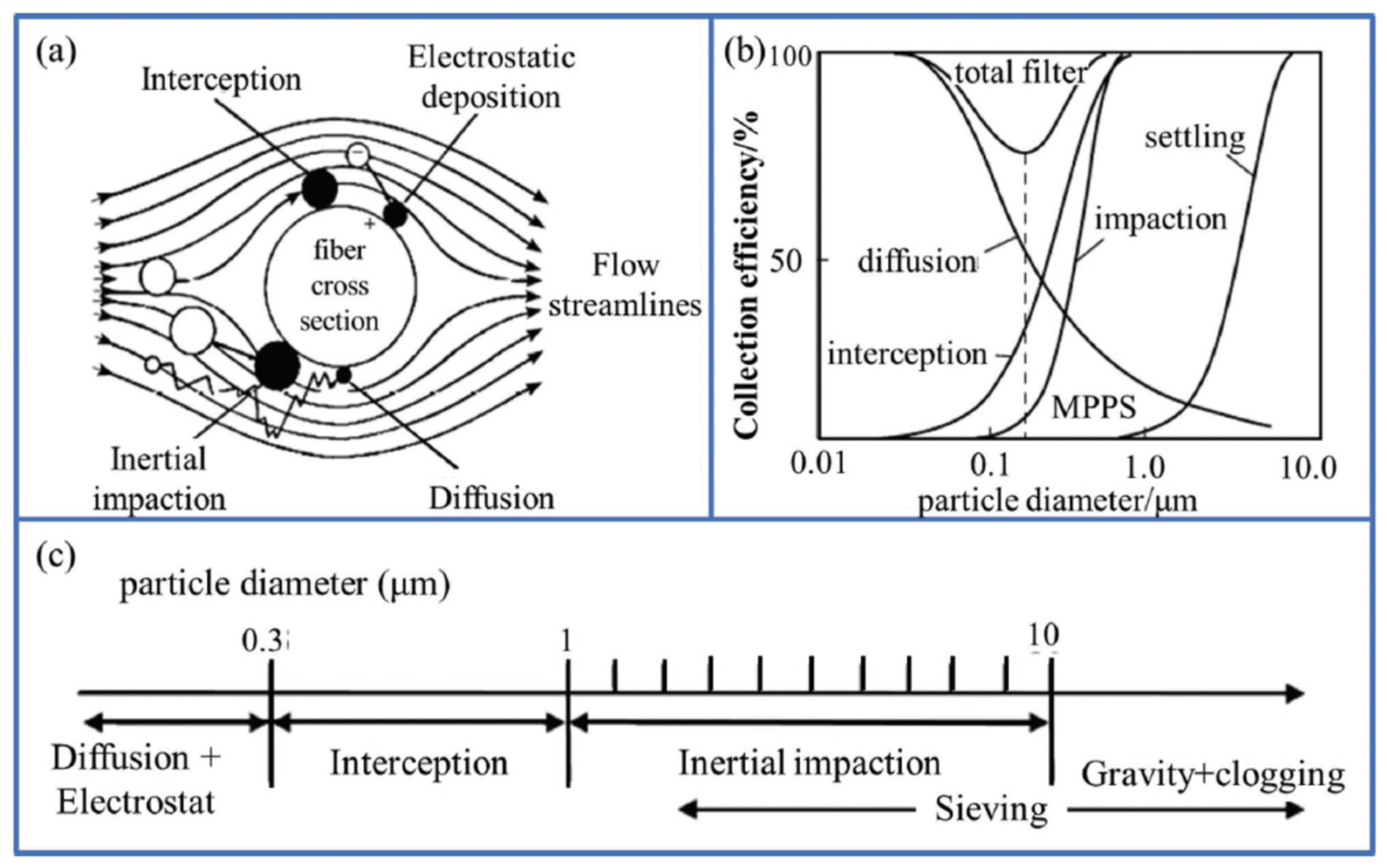

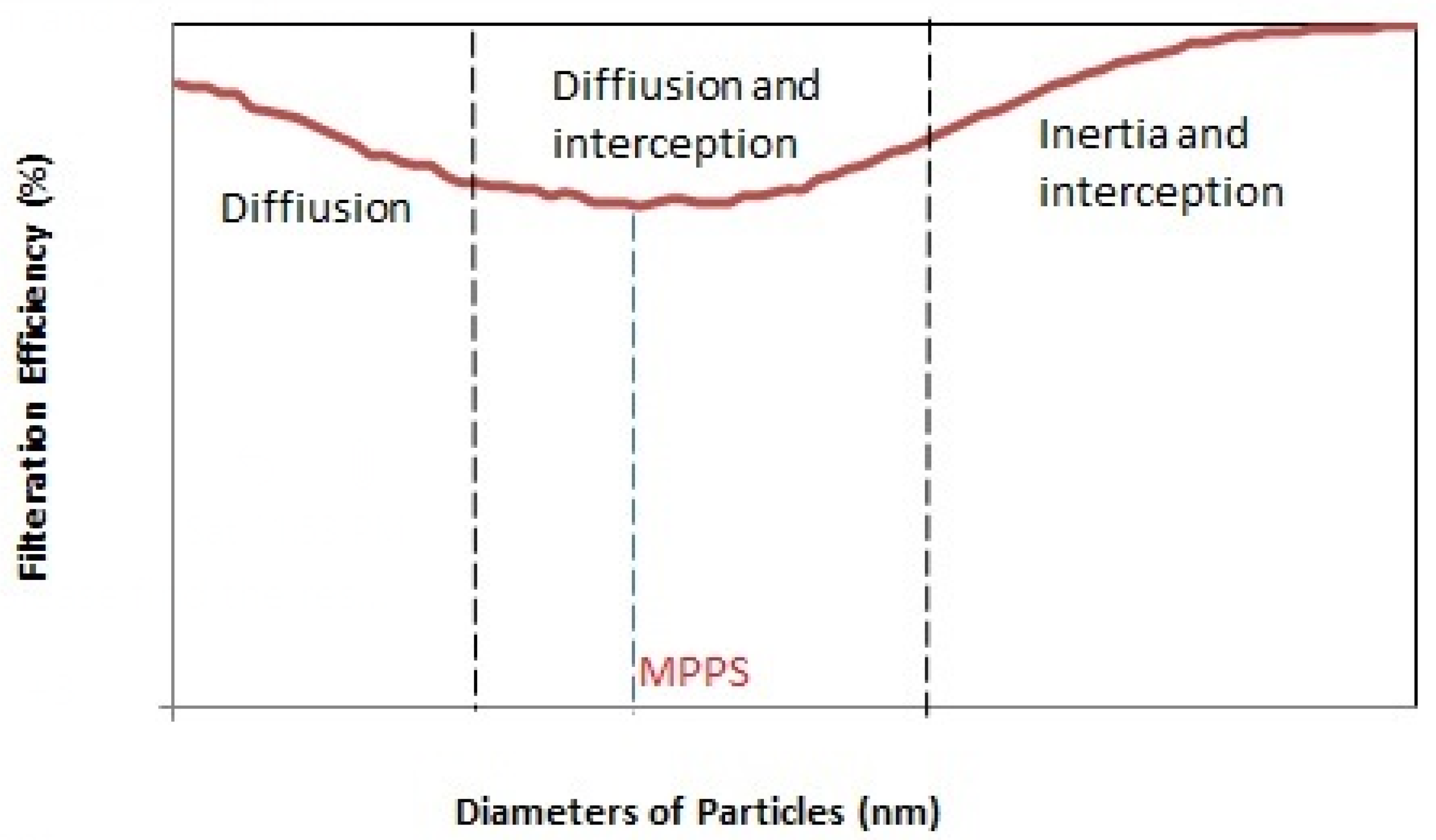

4. Mechanism of Filtering Process by a Nonwoven Fibrous Air Filter

4.1. Interception Mechanism

4.2. Inertial Impaction

4.3. Diffusion Mechanism

4.4. Electrostatic Effect Mechanism

4.5. Gravity Effect Mechanism

5. Parameters for Filter Performance Evaluation

6. The Effect of Morphological, Structural and Materials Parameters on the Performance of the Air Filters

6.1. Fiber Diameter

6.2. Fiber Roughness

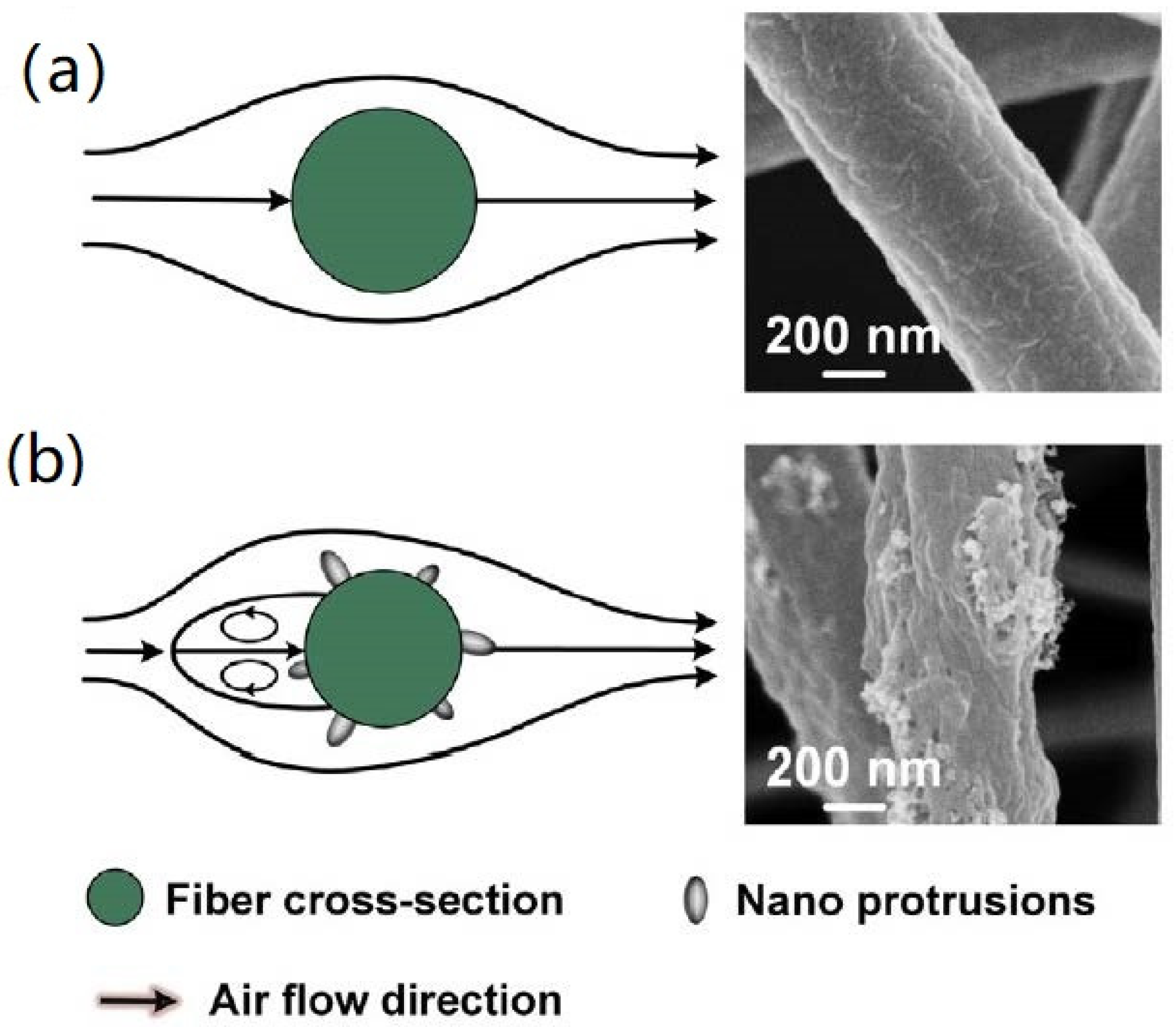

6.3. Presence of Beads

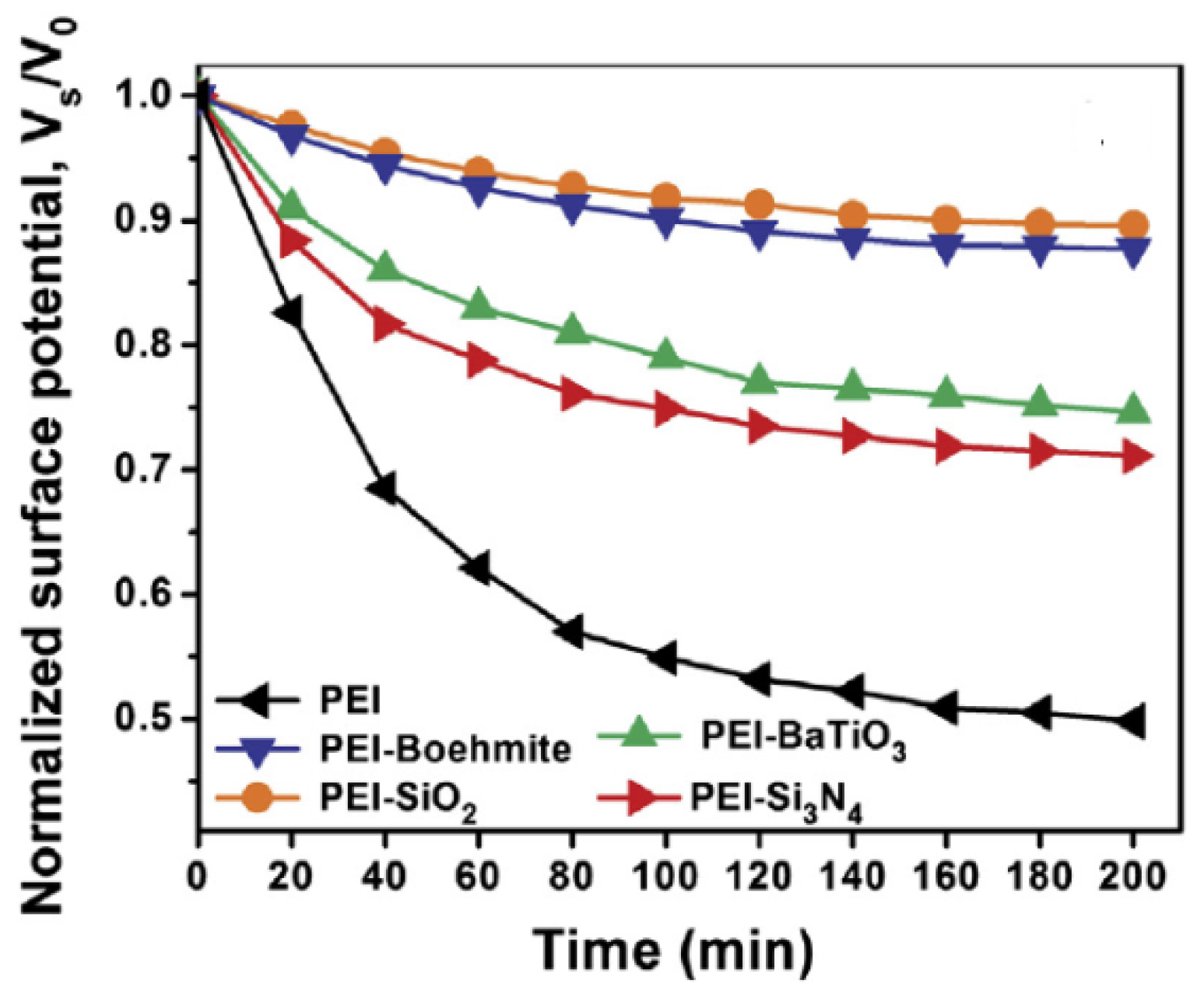

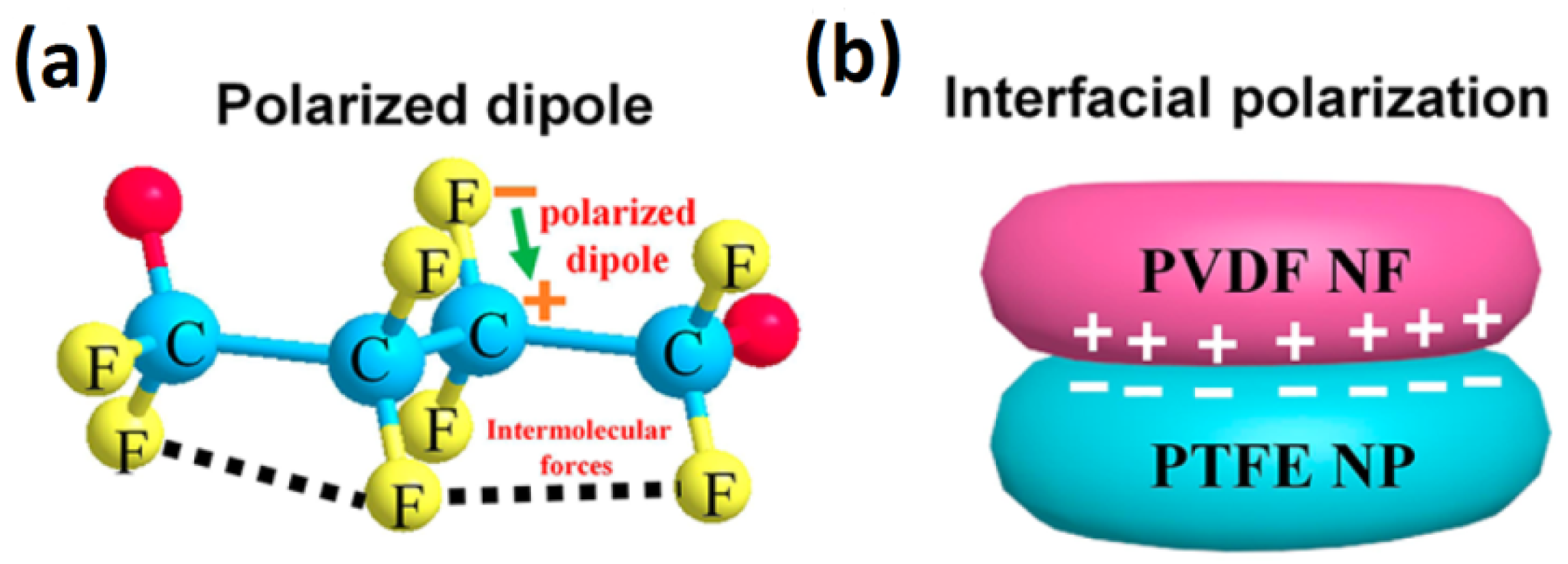

6.4. Charge Accumulation

6.5. Hydrophobicity

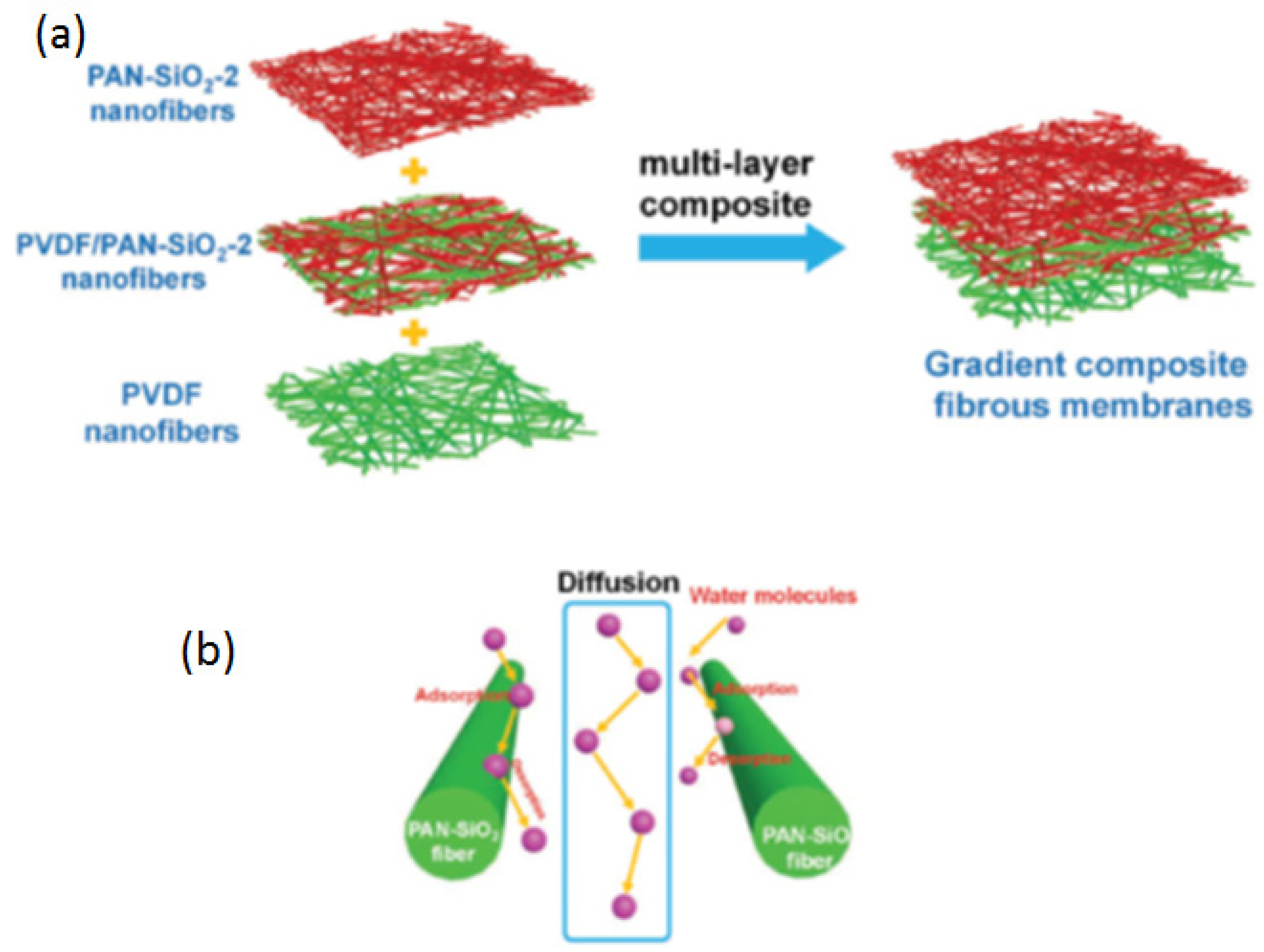

6.6. Stack Structure

7. Electrospinning Techniques for Making Air Filters

7.1. Single Component Polymer Air Filters

7.2. Multi-Component Air Filters

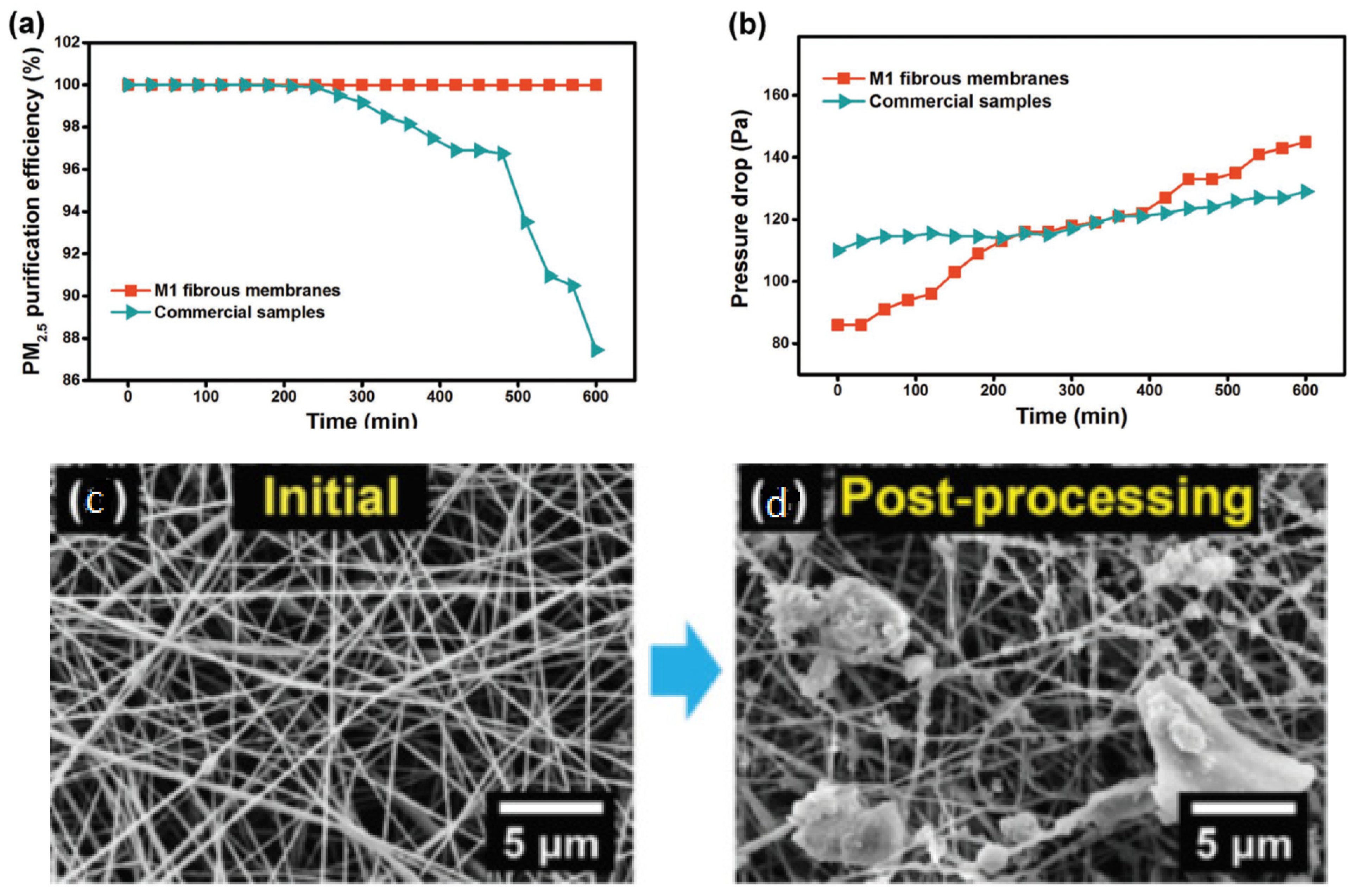

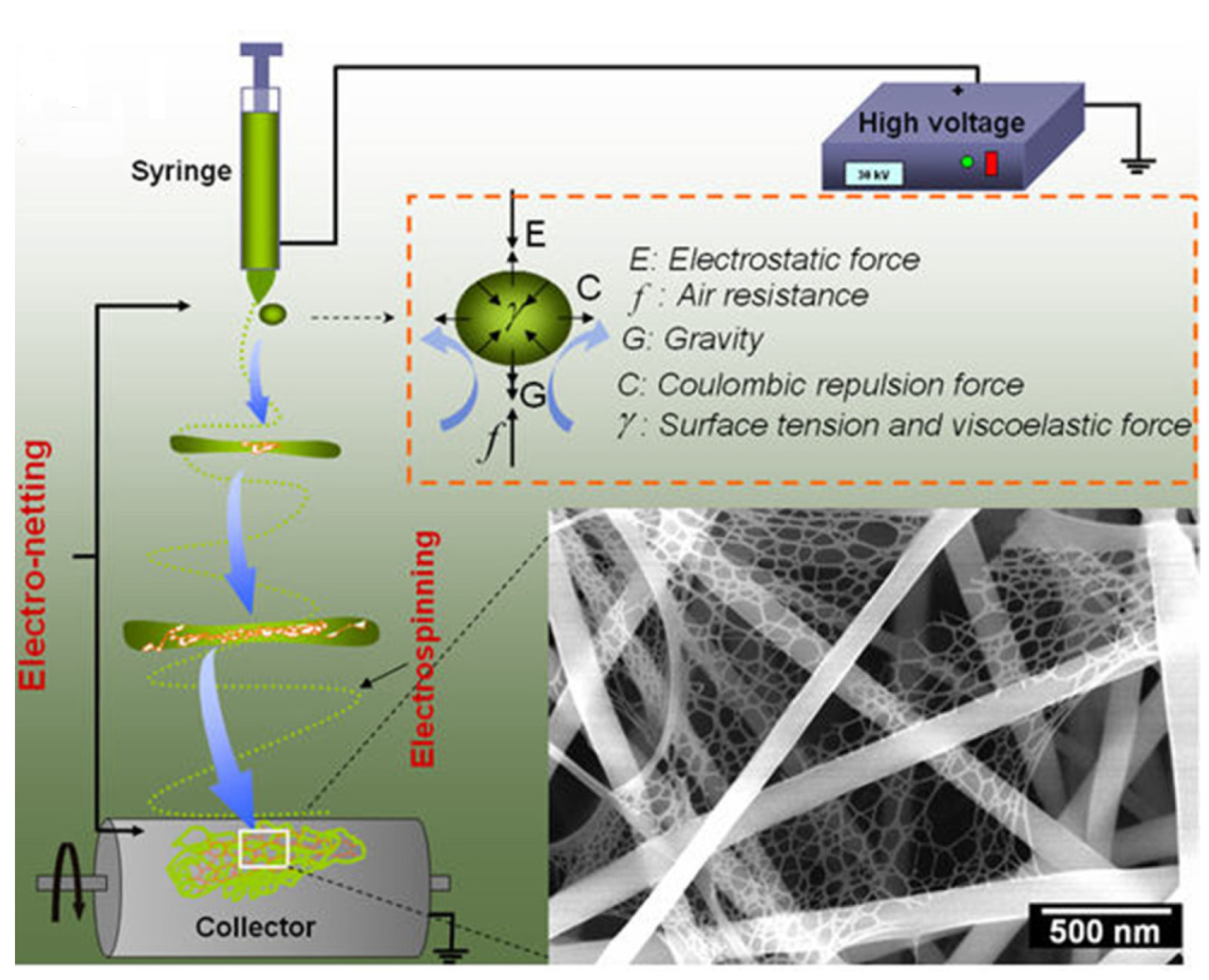

7.3. Nanonets

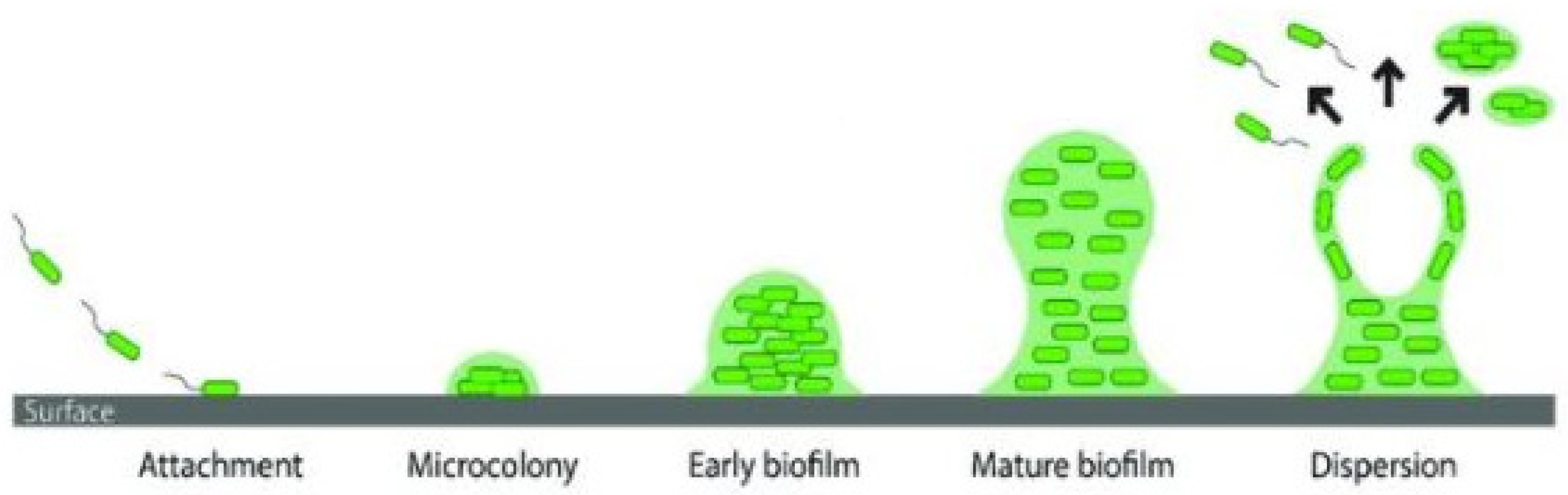

8. Antimicrobial Air Filter

8.1. Antimicrobial Polymers

8.2. Composting Antimicrobial Nanoparticles

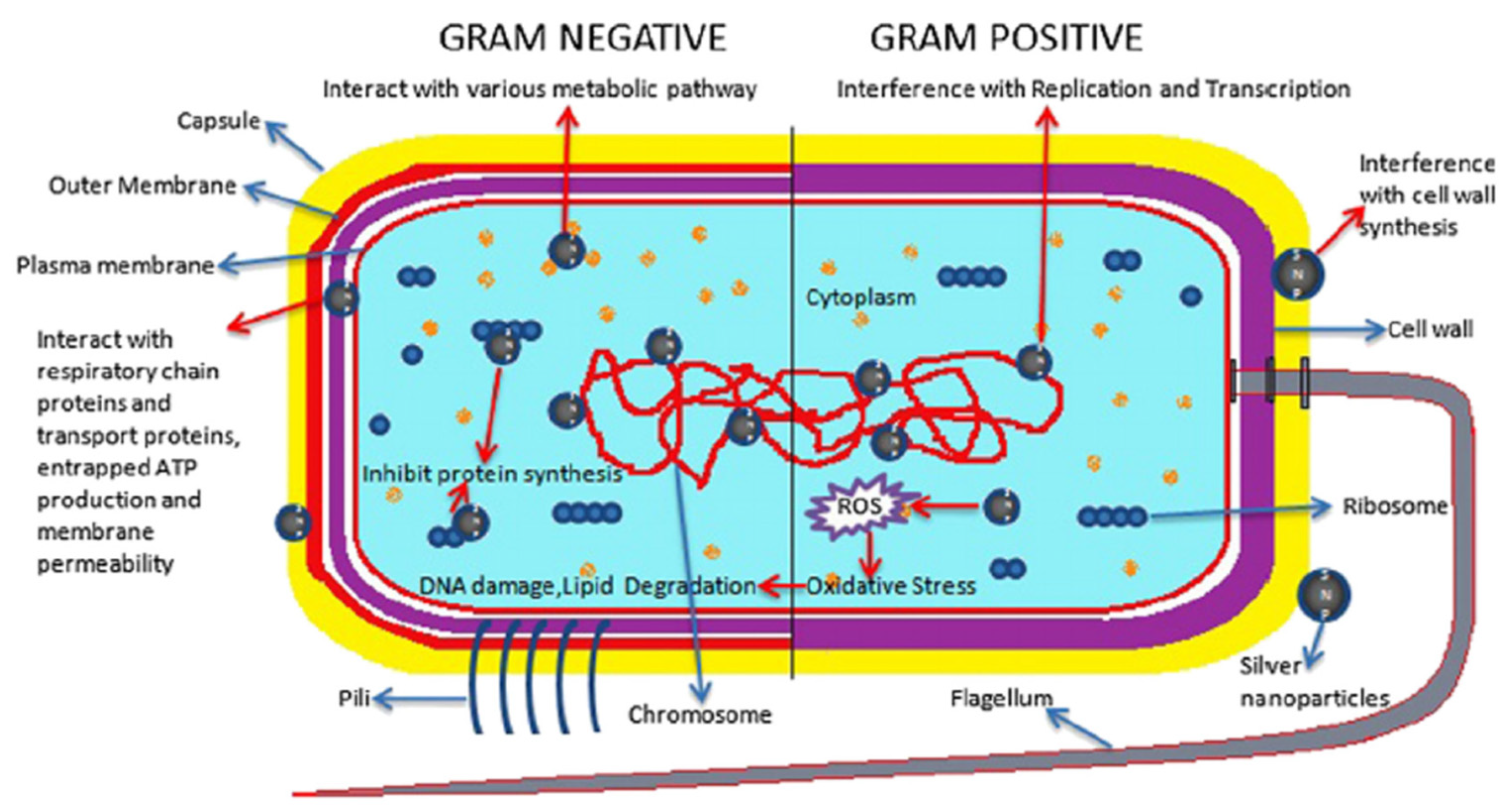

8.2.1. Metallic Nanoparticles

8.2.2. Metal Oxide Nanoparticles

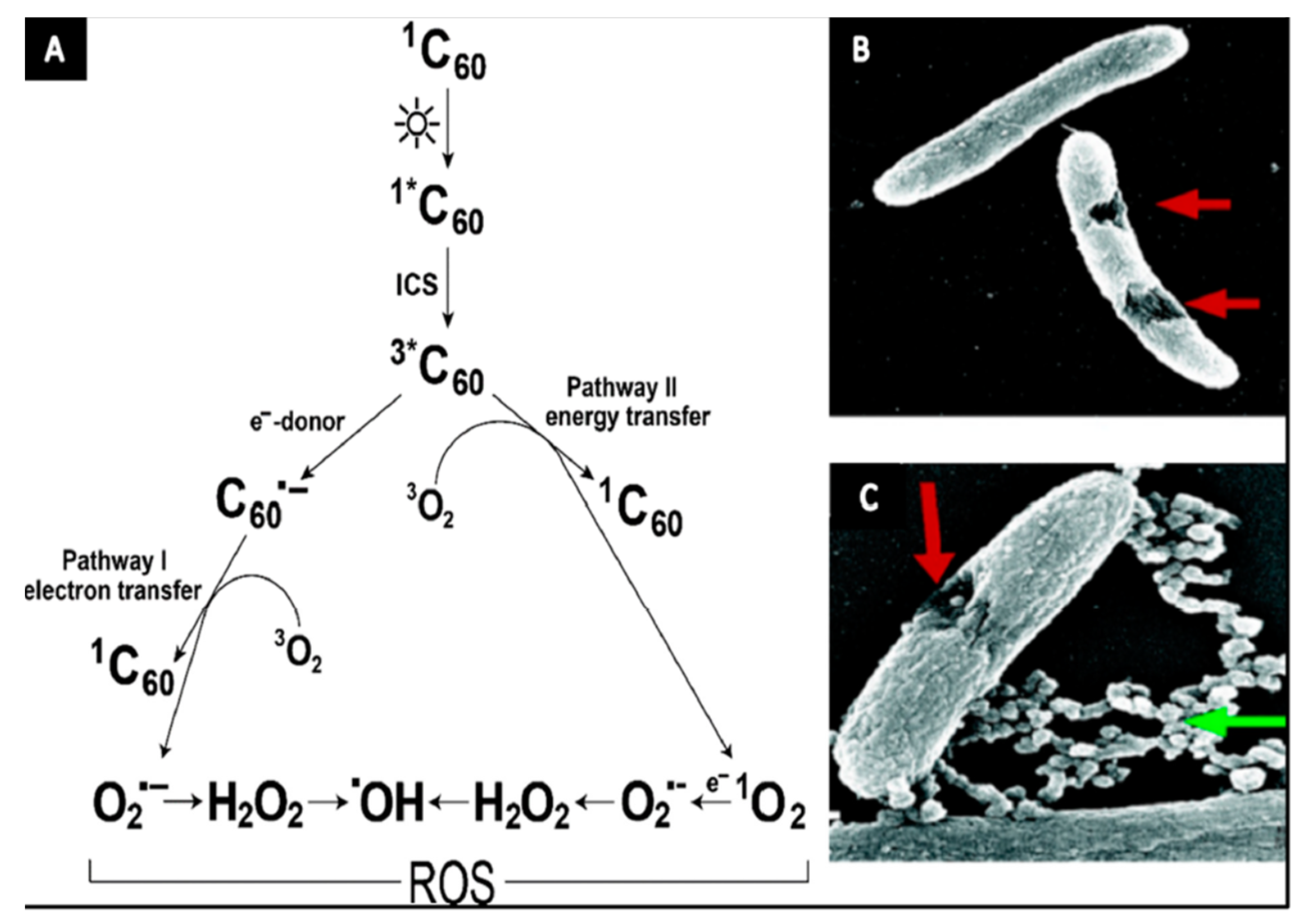

8.2.3. Carbon Nanostructure

8.3. Bio-Antimicrobial Molecules

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fortune Business Insights. Available online: https://www.fortunebusinessinsights.com/industry-reports/air-filters-market-101676 (accessed on 19 August 2021).

- Coccia, M. How do low wind speeds and high levels of air pollution support the spread of COVID-19. Atmos. Pollut. Res. 2021, 2, 437–445. [Google Scholar] [CrossRef]

- Bahri, M.; Haghighat, F.; Rohani, S.; Kazemian, H. Impact of design parameters on the performance of non-thermal plasma air purification system. Chem. Eng. J. 2016, 302, 204–212. [Google Scholar] [CrossRef]

- Schweinheim, C. Setting standards for HEPA filter efficiency. Filtr. Sep. 2015, 52, 13–15. [Google Scholar] [CrossRef]

- News Medical. Available online: https://www.news-medical.net/health/The-Size-of-SARS-CoV-2-Compared-to-Other-Things.aspx#:~:text=To%20date%2C%20research%20has%20%20shown,as%20large%20as%%2020500%20nm (accessed on 25 August 2021).

- Kothari, V.K.; Das, A.; Singh, S. Filtration behaviour of woven and nonwoven fabrics. Indian, J. Fibre Text Res. 2007, 32, 214–220. [Google Scholar]

- Yeom, B.Y.; Pourdeyhimi, B. Aerosol filtration properties of PA6/PE islands-in-the-sea bicomponent spunbond web fibrillated by high-pressure water jets. J. Mater. Sci. 2011, 46, 5761–5767. [Google Scholar] [CrossRef]

- Geus, H.G. Developments in manufacturing techniques for technical nonwovens. Adv. Tech. Nonwovens 2016, 133–153. [Google Scholar] [CrossRef]

- Hassan, M.A.; Yeom, B.Y.; Wilkie, A.; Pourdeyhimi, B.; Khan, S.A. Fabrication of nanofiber meltblown membranes and their filtration properties. J. Membr. Sci. 2013, 427, 336–344. [Google Scholar] [CrossRef]

- Demir, M.M.; Yilgor, I.; Yilgor, E.; Erman, B. Electrospinning of polyurethane fibers. Polymers 2002, 43, 3303–3309. [Google Scholar] [CrossRef]

- Buivydiene, D.; Krugly, E.; Ciuzas, D.; Tichonovas, M.; Kliucininkas, L.; Martuzevicius, D. Formation and characterisation of air filter material printed by melt electrospinning. J. Aerosol. Sci. 2019, 131, 48–63. [Google Scholar] [CrossRef]

- China-Supplie. Available online: http://www.china-supplie.com/difference-between-spunbond-and-meltblown/ (accessed on 13 July 2021).

- Hao, X.; Zeng, Y. A review on the studies of air flow field and fiber formation process during melt blowing. Ind. Eng. Chem. Res. 2019, 58, 11624–11637. [Google Scholar] [CrossRef]

- Nonwovens Industry. Available online: https://www.nonwovens-industry.com/contents/view_features/2005-08-17/spunbonded--melt-blown-nonwovens/ (accessed on 14 July 2021).

- Saleem, H.; Trabzon, L.; Kilic, A.; Zaidi, S.J. Recent advances in nanofibrous membranes: Production and applications in water treatment and desalination. Desalination 2020, 478, 114178. [Google Scholar] [CrossRef]

- Henry, J.J.; Goldbach, J.; Stabler, S.; Devisme, S.; Chauveau, J. Advancements in the production of meltblown fibres. Filtr. Sep. 2016, 53, 36–40. [Google Scholar] [CrossRef]

- Wu, W.; Sota, H.; Hirogaki, T.; Aoyama, E. Investigation of air filter properties of nanofiber nonwoven fabric manufactured by a modified melt-blowing method along with flash spinning method. Precis. Eng. 2021, 68, 187–196. [Google Scholar] [CrossRef]

- Sim, K.M.; Park, H.S.; Bae, G.N.; Jung, J.H. Antimicrobial nanoparticle-coated electrostatic air filter with high filtration efficiency and low pressure drop. Sci. Total Environ. 2015, 533, 266–274. [Google Scholar] [CrossRef]

- Liu, F.; Li, M.; Shao, W.; Yue, W.; Hu, B.; Weng, K.; Chen, Y.; Liao, X.; He, J. Preparation of a polyurethane electret nanofiber membrane and its air-filtration performance. J. Colloid Interface Sci. 2019, 557, 318–327. [Google Scholar] [CrossRef]

- Kilic, A.; Russell, S.; Shim, E.; Pourdeyhimi, B. The charging and stability of electret filters. In Fibrous Filter Media; Woodhead Publishing: Sawston, UK, 2017; pp. 95–121. [Google Scholar]

- Zhu, M.; Han, J.; Wang, F.; Shao, W.; Xiong, R.; Zhang, Q.; Pan, H.; Yang, Y.; Samal, S.K.; Zhang, F.; et al. Electrospun nanofibers membranes for effective air filtration. Macromol. Mater. Eng. 2017, 302, 1600353. [Google Scholar] [CrossRef]

- Xue, J.; Wu, T.; Dai, Y.; Xia, Y. Electrospinning and electrospun nanofibers: Methods, materials, and applications. Chem. Rev. 2019, 119, 5298–5415. [Google Scholar] [CrossRef]

- Haider, A.; Haider, S.; Kang, I.K. A comprehensive review summarizing the effect of electrospinning parameters and potential applications of nanofibers in biomedical and biotechnology. Arab. J. Chem. 2018, 11, 1165–1188. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A fascinating fiber fabrication technique. Biotech. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef]

- Reneker, D.H.; Yarin, A.L. Electrospinning jets and polymer nanofibers. Polymers 2008, 49, 2387–2425. [Google Scholar] [CrossRef]

- Zhang, S.; Rind, N.A.; Tang, N.; Liu, H.; Yin, X.; Yu, J.; Ding, B. Electrospun Nanofibers for Air Filtration. In Electrospinning: Nanofabrication and Applications; William Andrew Publishing: Norwich, NY, USA, 2019; pp. 365–389. [Google Scholar]

- Gao, H.; He, W.; Zhao, Y.B.; Opris, D.M.; Xu, G.; Wang, J. Electret mechanisms and kinetics of electrospun nanofiber membranes and lifetime in filtration applications in comparison with corona-charged membranes. J. Memb. Sci. 2020, 600, 117879. [Google Scholar] [CrossRef]

- Collins, G.; Federici, J.; Imura, Y.; Catalani, L.H. Charge generation, charge transport, and residual charge in the electrospinning of polymers: A review of issues and complications. J. Appl. Phys. 2012, 111, 44701. [Google Scholar] [CrossRef]

- Niu, Z.; Bian, Y.; Xia, T.; Zhang, L.; Chen, C. An optimization approach for fabricating electrospun nanofiber air filters with minimized pressure drop for indoor PM2.5 control. Build. Environ. 2021, 188, 107449. [Google Scholar] [CrossRef]

- Bian, Y.; Zhang, L.; Chen, C. Experimental and modeling study of pressure drop across electrospun nanofiber air filters. Build. Environ. 2018, 142, 244–251. [Google Scholar] [CrossRef]

- Xia, T.; Chen, C. Evolution of pressure drop across electrospun nanofiber filters clogged by solid particles and its influence on indoor particulate air pollution control. J. Hazard. Mater. 2021, 402, 123479. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Wang, Y.; Lu, T.; Liu, K.; Huang, C. High performance, environmentally friendly and sustainable nanofiber membrane filter for removal of particulate matter. J. Colloid Interface Sci. 2021, 597, 48–55. [Google Scholar] [CrossRef]

- Rashid, T.U.; Gorga, R.E.; Krause, W.E. Mechanical Properties of Electrospun Fibers—A Critical Review. Adv. Eng. Mater. 2019, 23, 153. [Google Scholar] [CrossRef]

- Nauman, S.; Lubineau, G.; Alharbi, H.F. Post Processing Strategies for the Enhancement of Mechanical Properties of ENMs (Electrospun Nanofibrous Membranes): A Review. Membranes 2021, 11, 39. [Google Scholar] [CrossRef]

- Li, B.; Liu, Y.; Wei, S.; Huang, Y.; Yang, S.; Xue, Y.; Xuan, H.; Yuan, H. A Solvent System Involved Fabricating Electrospun Polyurethane Nanofibers for Biomedical Applications. Polymers 2020, 12, 3038. [Google Scholar] [CrossRef]

- D’Amato, A.; Schaub, N.J.; Cardenas, J.M.; Franz, E.; Rende, D.; Ziemba, A.; Gilbert, R. Evaluation of procedures to quantify solvent retention in electrospun fibers and facilitate solvent removal. Fib. Polym. 2017, 18, 483–492. [Google Scholar] [CrossRef]

- Nayak, R.; Padhye, R.; Arnold, L. Melt-electrospinning of nanofibers. In Electrospun Nanofibers; Woodhead Publishing: Sawston, UK, 2017; pp. 11–40. [Google Scholar]

- Zhang, L.H.; Duan, X.P.; Yan, X.; Yu, M.; Ning, X.; Zhao, Y.; Long, Y.Z. Recent advances in melt electrospinning. RSC Adv. 2016, 6, 53400–53414. [Google Scholar] [CrossRef]

- De-Ling, L. Developments in Surface Contamination and Cleaning. In Particle Deposition onto Enclosure Surfaces; Kohli, R., Mittal, K.L., Eds.; William Andrew Publishing: Norwich, NY, USA, 2010; Chapter 1; pp. 1–56. [Google Scholar]

- Akbar-Khanzadeh, F.; Smigielski, K. Design and Set up of an Air Filter Testing Unit to Demonstrate Characteristics and Performance of Particulate Air Filters. Int. J. Occup. Hyg. 2006, 1, 1–8. [Google Scholar]

- Robert, B.; Nallathambi, G. A concise review on electrospun nanofibres/nanonets for filtration of gaseous and solid constituents (PM2. 5) from polluted air. Coll. Intface Sci. Comm. 2020, 37, 100275. [Google Scholar]

- Gardner, P.D.; Eshbaugh, J.P.; Harpest, S.D.; Richardson, A.W.; Hofacre, K.C. Viable viral efficiency of N95 and P100 respirator filters at constant and cyclic flow. J. Occup. Environ. Hyg. 2013, 10, 564–572. [Google Scholar] [CrossRef] [PubMed]

- Bian, Y.; Wang, S.; Zhang, L.; Chen, C. Influence of fiber diameter, filter thickness, and packing density on PM2.5 removal efficiency of electrospun nanofiber air filters for indoor applications. Build. Environ. 2020, 170, 106628. [Google Scholar] [CrossRef]

- Leung, W.W.; Hung, C.H.; Yuen, P.T. Effect of face velocity, nanofiber packing density and thickness on filtration performance of filters with nanofibers coated on a substrate. Sep. Pur. Tech. 2010, 71, 30–37. [Google Scholar] [CrossRef]

- Dharmanolla, S.; Chase, G.G. Computer program for filter media design optimization. J. Chin. Inst. Chem. Eng. 2008, 39, 161–167. [Google Scholar] [CrossRef][Green Version]

- Seok, J.; Chun, K.M.; Song, S.; Lee, S. Study on the filtration behavior of a metal fiber filter as a function of filter pore size and fiber diameter. J. Aerosol. Sci. 2015, 81, 47–61. [Google Scholar] [CrossRef]

- Gustafsson, S.; Mihranyan, A. Strategies for Tailoring the Pore-Size Distribution of Virus Retention Filter Papers. ACS Appl. Mater. Interfaces 2016, 8, 13759–13767. [Google Scholar] [CrossRef] [PubMed]

- Griffiths, I.M.; Mitevski, I.; Vujkovac, I.; Illingworth, M.R.; Stewart, P.S. The role of tortuosity in filtration efficiency: A general network model for filtration. J. Memb. Sci. 2020, 598, 117664. [Google Scholar] [CrossRef]

- Wang, N.; Si, Y.; Wang, N.; Sun, G.; El-Newehy, M.; Al-Deyab, S.S.; Ding, B. Multilevel structured polyacrylonitrile/silica nanofibrous membranes for high-performance air filtration. Sep. Purif. Tech. 2014, 126, 44–51. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, C.; Pan, Z. Porous bead-on-string poly (lactic acid) fibrous membranes for air filtration. J. Coll. Intrfc. Sci. 2015, 441, 121–129. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.J.; Tian, Y.; Wang, R.; Tian, M.; Liao, Y. Fabrication of bead-on-string polyacrylonitrile nanofibrous air filters with superior filtration efficiency and ultralow pressure drop. Sep. Purif. Tech. 2020, 237, 116377. [Google Scholar] [CrossRef]

- Rajak, A.; Hapidin, D.A.; Iskandar, F.; Munir, M.M.; Khairurrijal, K. Electrospun nanofiber from various source of expanded polystyrene (EPS) waste and their characterization as potential air filter media. WST Manag. 2020, 103, 76–86. [Google Scholar] [CrossRef] [PubMed]

- Yun, K.M.; Suryamas, A.B.; Iskandar, F.; Bao, L.; Niinuma, H.; Okuyama, K. Morphology optimization of polymer nanofiber for applications in aerosol particle filtration. Sep. Purif. Tech. 2010, 75, 340–345. [Google Scholar] [CrossRef]

- Jiang, P.; Zhao, X.; Li, Y.; Liao, Y.; Hua, T.; Yin, X.; Yu, J.; Ding, B. Moisture and oily molecules stable nanofibrous electret membranes for effectively capturing PM2. 5. Comp. Comm. 2017, 6, 34–40. [Google Scholar] [CrossRef]

- Leung, W.W.F.; Sun, Q. Electrostatic charged nanofiber filter for filtering airborne novel coronavirus (COVID-19) and nano-aerosols. Sep. Purif. Technol. 2020, 250, 116886. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Hsu, P.C.; Lee, H.W.; Ye, M.; Zheng, G.; Liu, N.; Li, W.; Cui, Y. Transparent air filter for high-efficiency PM 2.5 capture. Nat. Comm. 2015, 6, 1–9. [Google Scholar]

- Liu, L.; Lv, F.; Li, P.; Ding, L.; Tong, W.; Chu, P.K.; Zhang, Y. Preparation of ultra-low dielectric constant silica/polyimide nanofiber membranes by electrospinning. Comp. Part. A Appl. Sci. Manfctr. 2016, 84, 292–298. [Google Scholar] [CrossRef]

- Li, X.; Wang, N.; Fan, G.; Yu, J.; Gao, J.; Sun, G.; Ding, B. Electret polyetherimide–silica fibrous membranes for enhanced filtration of fine particles. J. Coll. Intrfc. Sci. 2015, 439, 12–20. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, X.; Yin, X.; Yu, J.; Ding, B. Electret polyvinylidene fluoride nanofibers hybridized by polytetrafluoroethylene nanoparticles for high-efficiency air filtration. ACS Appl. Mater Intrfcs. 2016, 8, 23985–23994. [Google Scholar] [CrossRef]

- Maddah, H.A. Polypropylene as a promising plastic: A review. Am. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar]

- Liu, H.; Huang, J.; Mao, J.; Chen, Z.; Chen, G.; Lai, Y. Transparent Antibacterial Nanofiber Air Filters with Highly Efficient Moisture Resistance for Sustainable Particulate Matter Capture. iScience 2019, 19, 214–223. [Google Scholar] [CrossRef] [PubMed]

- Srisitthiratkul, C.; Pongsorrarith, V.; Intasanta, N. The potential use of nanosilver-decorated titanium dioxide nanofibers for toxin decomposition with antimicrobial and self-cleaning properties. Appl. Surf. Sci. 2011, 257, 8850–8856. [Google Scholar] [CrossRef]

- de Man, P.; van Straten, B.; van den Dobbelsteen, J.; van der Eijk, A.; Horeman, T.; Koeleman, H. Sterilization of disposable face masks by means of standardized dry and steam sterilization processes; an alternative in the fight against mask shortages due to COVID-19. J. Hosp. Infect. 2020, 105, 356–357. [Google Scholar] [CrossRef]

- Leung, W.W.; Sun, Q. Charged PVDF multilayer nanofiber filter in filtering simulated airborne novel coronavirus (COVID-19) using ambient nano-aerosols. Sep. Purif. Technol. 2020, 245, 116887. [Google Scholar] [CrossRef]

- Buivydiene, D.; Todea, A.M.; Asbach, C.; Krugly, E.; Martuzevicius, D.; Kliucininkas, L. Composite micro/nano fibrous air filter by simultaneous melt and solution electrospinning. J. Aerosol Sci. 2021, 154, 105754. [Google Scholar] [CrossRef]

- Wang, X.; Xiang, H.; Song, C.; Zhu, D.; Sui, J.; Liu, Q.; Long, Y. Highly efficient transparent air filter prepared by collecting-electrode-free bipolar electrospinning apparatus. J. Hazard. Mater. 2020, 385, 121535. [Google Scholar] [CrossRef]

- Liu, J.; Dunne, F.O.; Fan, X.; Fu, X.; Zhong, W.H. A protein-functionalized microfiber/protein nanofiber Bi-layered air filter with synergistically enhanced filtration performance by a viable method. Sep. Purif. Technol. 2019, 229, 115837. [Google Scholar] [CrossRef]

- Zhao, X.; Li, Y.; Hua, T.; Jiang, P.; Yin, X.; Yu, J.; Ding, B. Cleanable air filter transferring moisture and effectively capturing PM2. 5. Small 2017, 13, 1603306. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Koo, H.Y.; Yu, C.; Choi, W.S. A novel approach to designing air filters: Ubiquitous material-based Janus air filter modules with hydrophilic and hydrophobic parts. Chem. Eng. J. 2021, 410, 128302. [Google Scholar] [CrossRef]

- Wang, X.; Ding, B.; Sun, G.; Wang, M.; Yu, J. Electro-spinning/netting: A strategy for the fabrication of three-dimensional polymer nano-fiber/nets. Prog. Mater. Sci. 2013, 58, 1173–1243. [Google Scholar] [CrossRef] [PubMed]

- Zargham, S.; Bazgir, S.; Tavakoli, A.; Rashidi, A.S.; Damerchely, R. The effect of flow rate on morphology and deposition area of electrospun nylon 6 nanofiber. J. Eng. Fib. Fabr. 2012, 7, 42–49. [Google Scholar] [CrossRef]

- Barakat, N.A.; Kanjwal, M.A.; Sheikh, F.A.; Kim, H.Y. Spider-net within the N6, PVA and PU electrospun nanofiber mats using salt addition: Novel strategy in the electrospinning process. Polymers 2009, 50, 4389–4396. [Google Scholar] [CrossRef]

- Pant, H.R.; Bajgai, M.P.; Nam, K.T.; Chu, K.H.; Park, S.J.; Kim, H.Y. Formation of electrospun nylon-6/methoxy poly (ethylene glycol) oligomer spider-wave nanofibers. Mater. Lett. 2010, 64, 2087–2090. [Google Scholar] [CrossRef]

- Liu, H.; Liu, L.; Yu, J.; Yin, X.; Ding, B. High-efficiency and super-breathable air filters based on biomimetic ultrathin nanofiber networks. Compos. Commun. 2020, 22, 100493. [Google Scholar] [CrossRef]

- Ma, H.; Yoon, K.; Rong, L.; Mao, Y.; Mo, Z.; Fang, D.; Hollander, Z.; Gaiteri, J.; Hsiao, B.S.; Chu, B. High-flux thin-film nanofibrous composite ultrafiltration membranes containing cellulose barrier layer. J. Mater. Chem. 2010, 20, 4692–4704. [Google Scholar] [CrossRef]

- Yoon, K.; Kim, K.; Wang, X.; Fang, D.; Hsiao, B.S.; Chu, B. High flux ultrafiltration membranes on electrospun nanofibrous PAN scaffolds and chitosan coating. Polymers 2006, 47, 2434–2441. [Google Scholar] [CrossRef]

- Gopal, R.; Kaur, S.; Ma, Z.; Chan, C.; Ramakrishna, S.; Matsuura, T. Electrospun nanofibrous filtration membrane. J. Memb. Sci. 2006, 281, 581–586. [Google Scholar] [CrossRef]

- Aryanti, P.T.; Sianipar, M.; Zunita, M.; Wenten, I.G. Modified membrane with antibacterial properties. Memb. Water Treat. 2017, 8, 463–481. [Google Scholar]

- Komaladewi, A.A.; Khoiruddin, K.; Surata, I.W.; Subagia, I.D.; Wenten, I.G. Recent advances in antimicrobial air filter. In Proceedings of the 3rd International Tropical Renewable Energy Conference “Sustainable Development of Tropical Renewable Energy” (i-TREC 2018), Kuta, Indonesia, 6–8 September 2018; p. 67. [Google Scholar]

- Lee, K.M.; Lee, B.H.; Park, C.J. A study on the Control of Bio-aerosol for Prevention of indoor aerial infection using Antimicrobial air filter. Appl. Mech. Mater. 2013, 284, 1601–1605. [Google Scholar] [CrossRef]

- Balagna, C.; Perero, S.; Bosco, F.; Mollea, C.; Irfan, M.; Ferraris, M. Antipathogen nanostructured coating for air filters. Appl. Surf. Sci. 2020, 508, 145283. [Google Scholar] [CrossRef]

- Passos da Silva, D.; Schofield, M.C.; Parsek, M.R.; Tseng, B.S. An update on the sociomicrobiology of quorum sensing in gram-negative biofilm development. Pathogens 2017, 6, 51. [Google Scholar] [CrossRef]

- Thurman, R.B.; Gerba, C.P.; Bitton, G. The molecular mechanisms of copper and silver ion disinfection of bacteria and viruses. Crit. Rev. Environ. Sci. Tech. 1989, 18, 295–315. [Google Scholar] [CrossRef]

- Deshmukh, S.P.; Patil, S.M.; Mullani, S.B.; Delekar, S.D. Silver nanoparticles as an effective disinfectant: A review. Mater. Sci. Eng. 2019, 97, 954–965. [Google Scholar] [CrossRef]

- Joe, Y.H.; Woo, K.; Hwang, J. Fabrication of an anti-viral air filter with SiO2-Ag nanoparticles and performance evaluation in a continuous airflow condition. J. Hazard. Mater. 2014, 280, 356–363. [Google Scholar] [CrossRef] [PubMed]

- Pan, W.; Wang, J.P.; Sun, X.B.; Wang, X.X.; Jiang, J.; Zhang, Z.G.; Li, P.; Qu, C.H.; Long, Y.Z.; Yu, G.F. Ultra uniform metal−organic framework-5 loading along electrospun chitosan/polyethylene oxide membrane fibers for efficient PM2.5 removal. J. Clean. Prod. 2021, 291, 125270. [Google Scholar] [CrossRef]

- Park, K.; Kang, S.; Park, J.; Hwang, J. Fabrication of silver nanowire coated fibrous air filter medium via a two-step process of electrospinning and electrospray for anti-bioaerosol treatment. J. Hazard. Mater. 2021, 411, 125043. [Google Scholar] [CrossRef]

- Balagna, C.; Francese, R.; Perero, S.; Lembo, D.; Ferraris, M. Nanostructured composite coating endowed with antiviral activity against human respiratory viruses deposited on fibre-based air filters. Surf. Coat. Technol. 2021, 409, 126873. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Yue, Y.; He, W.; Jiang, F.; Lin, C.H.; Pui, D.Y.H.; Liang, Y.; Wanf, J. The antibacterial performance of positively charged and chitosan dipped air filter media. Build. Environ. 2020, 180, 107020. [Google Scholar] [CrossRef]

- Dimassi, S.; Tabary, N.; Chai, F.; Blanchemain, N.; Martel, B. Sulfonated and sulfated chitosan derivatives for biomedical applications: A review. Carb. Polym. 2018, 202, 382–396. [Google Scholar] [CrossRef] [PubMed]

- Artan, M.; Karadeniz, F.; Karagozlu, M.Z.; Kim, M.M.; Kim, S.K. Anti-HIV-1 activity of low molecular weight sulfated chitooligosaccharides. Carb. Res. 2010, 345, 656–662. [Google Scholar] [CrossRef] [PubMed]

- Milewska, A.; Kaminski, K.; Ciejka, J.; Kosowicz, K.; Zeglen, S.; Wojarski, J.; Nowakowska, M.; Szczubiałka, K.; Pyrc, K. HTCC: Broad range inhibitor of coronavirus entry. PLoS ONE. 2016, 11, e0156552. [Google Scholar] [CrossRef] [PubMed]

- Milewska, A.; Chi, Y.; Szczepanski, A.; Barreto-Duran, E.; Dabrowska, A.; Botwina, P.; Obloza, M.; Liu, K.; Liu, D.; Guo, X.; et al. HTCC as a Polymeric Inhibitor of SARS-CoV-2 and MERS-CoV. J. Virol. 2021, 95, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Alipour, S.M.; Nouri, M.; Mokhtari, J.; Bahrami, S.H. Electrospinning of poly(vinyl alcohol)-water-soluble quaternized chitosan derivative blend. Carb. Res. 2009, 344, 2496–2501. [Google Scholar] [CrossRef]

- Mi, X.; Vijayaragavan, K.S.; Heldt, C.L. Virus adsorption of water-stable quaternized chitosan nanofibers. Carb. Res. 2014, 387, 24–29. [Google Scholar] [CrossRef]

- Mi, X. Electrospun Quaternized Chitosan Fibers for Virus Removal from Drinking Water. Ph.D. Thesis, Michigan Technological University, Houghton, MI, USA, 2013. [Google Scholar]

- Sakib, M.N.; Mallik, A.K.; Rahman, M.M. Update on chitosan-based electrospun nanofibers for wastewater treatment: A review. Carb. Polym Technol Appl. 2021, 2, 100064. [Google Scholar] [CrossRef]

- Cooper, A.; Oldinski, R.; Ma, H.; Bryers, J.D.; Zhang, M. Chitosan-based nanofibrous membranes for antibacterial filter applications. Carb. Polym. 2013, 92, 254–259. [Google Scholar] [CrossRef]

- Lekshmi Mohan, V.; Shiva Nagendra, S.M.; Maiya, M.P. Photocatalytic degradation of gaseous toluene using self-assembled air filter based on chitosan/activated carbon/TiO2. J. Environ. Chem. Eng. 2019, 7, 103455. [Google Scholar] [CrossRef]

- Nie, J.; Xie, H.; Zhang, M.; Liang, J.; Nie, S.; Han, W. Effective and facile fabrication of MOFs/cellulose composite paper for air hazards removal by virtue of in situ synthesis of MOFs/chitosan hydrogel. Carb. Polym. 2020, 250, 116955. [Google Scholar] [CrossRef]

- Shao, W.C.; Wu, H.; Shiue, A.; Tseng, C.H.; Wang, Y.W.; Hsu, C.F.; Leggett, G. Chitosan-dosed adsorptive filter media for removal of formaldehyde from indoor air—Performance and cancer risk assessment. Chem. Phys. Lett. 2021, 779, 138836. [Google Scholar] [CrossRef]

- Wang, J.; Yang, G.; Wang, L.; Wang, S.; Yan, W.; Ding, S. In-situ fabrication of transition-metal-doped TiO2 nanofiber/nanosheet structure for high-performance Li storage. J. Alloys Compd. 2019, 787, 1110–1119. [Google Scholar] [CrossRef]

- Park, D.H.; Joe, Y.H.; Piri, A.; An, S.; Hwang, J. Determination of Air Filter Anti-Viral Efficiency against an Airborne Infectious Virus. J. Hzrd Mater. 2020, 396, 122640. [Google Scholar] [CrossRef] [PubMed]

- Ju, Y.; Han, T.; Yin, J.; Li, Q.; Chen, Z.; Wei, Z.; Zhang, Y.; Dong, L. Bumpy structured nanofibrous membrane as a highly efficient air filter with antibacterial and antiviral property. Sci. Total Environ. 2021, 777, 145768. [Google Scholar] [CrossRef]

- Xiao, Y.; Wang, Y.; Zhu, W.; Yao, J.; Sun, C.; Militky, J.; Venkataraman, M.; Zhu, G. Development of tree-like nanofibrous air filter with durable antibacterial property. Sep. Purif. Technol. 2021, 259, 118135. [Google Scholar] [CrossRef]

- Sharma, A.; Kumar, S.R.; Katiyar, V.K.; Gopinath, P. Graphene oxide/silver nanoparticle (GO/AgNP) impregnated polyacrylonitrile nanofibers for potential application in air filtration. Nano Struct. Nano Obj. 2021, 26, 100708. [Google Scholar] [CrossRef]

- Gliga, A.R.; Skoglund, S.; Wallinder, I.O.; Fadeel, B.; Karlsson, H.L. Size-dependent cytotoxicity of silver nanoparticles in human lung cells: The role of cellular uptake, agglomeration and Ag release. Part. Fibre Toxicol. 2014, 11, 1–7. [Google Scholar] [CrossRef]

- Kim, M.W.; Kim, Y.I.; Park, C.; Aldalbahi, A.; Alanazi, H.S.; An, S.; Yarnim, A.L.; Yoon, S.S. Reusable and durable electrostatic air filter based on hybrid metallized microfibers decorated with metal–organic–framework nanocrystals. J. Mater. Sci. Technol. 2021, 85, 44–55. [Google Scholar] [CrossRef]

- Mihut, D.M.; Afshar, A. Electrically assisted silver and copper coated filter papers with enhanced bactericidal effects. Colloids Surf. A Physicochem. Eng. Asp. 2020, 606, 125428. [Google Scholar] [CrossRef]

- Longano, D.; Ditaranto, N.; Sabbatini, L.; Torsi, L.; Cioffi, N. Synthesis and antimicrobial activity of copper nanomaterials. In Nano-Antimicrobials; Springer: Berlin/Heidelberg, Germany, 2012; pp. 85–117. [Google Scholar]

- Van Doremalen, N.; Bushmaker, T.; Morris, D.H.; Holbrook, M.G.; Gamble, A.; Williamson, B.N.; Tamin, A.; Harcourt, J.L.; Thornburg, N.J.; Gerber, S.I.; et al. Aerosol and surface stability of SARS-CoV-2 as compared with SARS-CoV-1. N. Eng. J. Med. 2020, 382, 1564–1567. [Google Scholar] [CrossRef]

- Wang, X.; Ding, B.; Yu, J.; Yang, J. Large-scale fabrication of two-dimensional spider-web-like gelatin nanonets via electro-netting. Colloid Surf. Biointerfaces 2011, 86, 345–352. [Google Scholar] [CrossRef]

- Hashmi, M.; Ullah, S.; Kim, I.S. Copper oxide (CuO) loaded polyacrylonitrile (PAN) nanofiber membranes for antimicrobial breath mask applications. Curr. Res. Biotechnol. 2019, 1, 1–10. [Google Scholar] [CrossRef]

- Vincent, M.; Hartemann, P.; Engels-Deutsch, M. Antimicrobial applications of copper. Int. J. Hyg. Environ. Health 2016, 219, 585–591. [Google Scholar] [CrossRef]

- Hejazy, M.; Koohi, M.K.; Pour, A.B.M.; Najafi, D. Toxicity of manufactured copper nanoparticles—A review. Nanomed. Res. J. 2018, 3, 1–9. [Google Scholar]

- Pokhum, C.; Intasanta, V.; Yaipimai, W.; Subjalearndee, N.; Srisitthiratjul, C.; Pongsorrarith, V.; Phanomkate, N.; Chawengkijwanich, C. A facile and cost-effective method for removal of indoor airborne psychrotrophic bacterial and fungal flora based on silver and zinc oxide nanoparticles decorated on fibrous air filter. Atmos. Pollut. Res. 2018, 9, 172–177. [Google Scholar] [CrossRef]

- Cao, Y.; Naseri, M.; He, Y.; Xu, C.; Walsh, L.J.; Ziora, Z.M. Non-antibiotic antimicrobial agents to combat biofilm-forming bacteria. J. Glob. Antimic Resist. 2020, 21, 445–451. [Google Scholar] [CrossRef]

- Liu, C.; Guo, J.; Yan, X.; Tang, Y.; Mazumder, A.; Wu, S.; Liang, Y. Antimicrobial nanomaterials against biofilms: An alternative strategy. Environ. Rev. 2017, 25, 225–244. [Google Scholar] [CrossRef]

- El-Megharbel, S.M.; Alsawat, M.; Al-Salmi, F.A.; Hamza, R.Z. Utilizing of (Zinc Oxide Nano-Spray) for Disinfection against “SARS-CoV-2” and Testing Its Biological Effectiveness on Some Biochemical Parameters during (COVID-19 Pandemic)—”ZnO Nanoparticles Have Antiviral Activity against (SARS-CoV-2)”. Coatings 2021, 11, 388. [Google Scholar] [CrossRef]

- Ji, S.M.; Tiwari, A.P.; Oh, H.J.; Kim, H.Y. ZnO/Ag nanoparticles incorporated multifunctional parallel side by side nanofibers for air filtration with enhanced removing organic contaminants and antibacterial properties. Colloid Surf. A Physicochem. Eng. Asp. 2021, 621, 126564. [Google Scholar] [CrossRef]

- Matsunaga, T.; Tomoda, R.; Nakajima, T.; Wake, H. Photoelectrochemical sterilization of microbial cells by semiconductor powders. FEMS Microbiol. Lett. 1985, 29, 211–214. [Google Scholar] [CrossRef]

- Yadav, S.; Jaiswar, G. Review on undoped/doped TiO2 nanomaterial; synthesis and photocatalytic and antimicrobial activity. J. Chin. Chem. Soc. 2017, 64, 103–116. [Google Scholar] [CrossRef]

- Kubacka, A.; Fernández-García, M.; Cerrada, M.L.; Fernández-García, M. Titanium dioxide–polymer nanocomposites with advanced properties. In Nano-Antimicrobials; Springer: Berlin/Heidelberg, Germany, 2012; pp. 119–149. [Google Scholar]

- Zheng, X.; Shen, Z.P.; Cheng, C.; Shi, L.; Cheng, R.; Yuan, D.H. Photocatalytic disinfection performance in virus and virus/bacteria system by Cu-TiO2 nanofibers under visible light. Environ. Pollut. 2018, 237, 452–459. [Google Scholar] [CrossRef]

- Bono, N.; Ponti, F.; Punta, C.; Candiani, G. Effect of UV irradiation and TiO2-photocatalysis on airborne bacteria and viruses: An overview. Materials 2021, 14, 1075. [Google Scholar] [CrossRef]

- Matsuura, R.; Lo, C.W.; Wada, S.; Somei, J.; Ochiai, H.; Murakami, T.; Saito, N.; Ogawa, T.; Shinjo, A.; Benno, Y.; et al. Sars-cov-2 disinfection of air and surface contamination by TiO2 photocatalyst-mediated damage to viral morphology, rna, and protein. Viruses 2021, 13, 942. [Google Scholar] [CrossRef]

- Micochova, P.; Chadha, A.; Hesseloj, T.; Fraternali, F.; Ramsden, J.J.; Gupta, R.K. Rapid inactivation of SARS-CoV-2 by titanium dioxide surface coating. Welcome Open Res. 2021, 6, 56. [Google Scholar] [CrossRef]

- Al-Jumaili, A.; Alancherry, S.; Bazaka, K.; Jacob, M.V. Review on the antimicrobial properties of carbon nanostructures. Materials 2017, 10, 1066. [Google Scholar] [CrossRef]

- Dai, H.; Liu, X.; Zhang, C.; Ma, K.; Zhang, Y. Electrospinning Polyacrylonitrile/Graphene Oxide/Polyimide nanofibrous membranes for High-efficiency PM2.5 filtration. Sep. Purif Technol. 2021, 276, 119243. [Google Scholar] [CrossRef]

- Habibi Mohraz, M.; Je Yu, I.; Beitollahi, A.; Farhang Dehghan, S.; Hoon Shin, J.; Golbabaei, F. Assessment of the potential release of nanomaterials from electrospun nanofiber filter media. NanoImpact 2020, 19, 100223. [Google Scholar] [CrossRef]

- Rasmi, Y.; Saloua, K.S.; Nemati, M.; Choi, J.R. Recent progress in nanotechnology for covid-19 prevention, diagnostics and treatment. Nanomaterials 2021, 11, 1788. [Google Scholar] [CrossRef]

- Wang, L.; Gao, Y.; Xiong, J.; Shao, W.; Cui, C.; Sun, N.; Zhang, Y.; Chang, S.; Han, P.; Liu, F.; et al. Biodegradable and high-performance multiscale structured nanofiber membrane as mask filter media via poly(lactic acid) electrospinning. J. Colloid Intrfaces Sci. 2021, 606, 961–970. [Google Scholar] [CrossRef]

- Li, Y.; Xiang, Q.; Zhang, Q.; Huang, Y.; Su, Z. Overview on the recent study of antimicrobial peptides: Origins, functions, relative mechanisms and application. Peptides 2012, 37, 207–215. [Google Scholar] [CrossRef] [PubMed]

- Onaizi, S.A.; Leong, S.S. Tethering antimicrobial peptides: Current status and potential challenges. Biotech. Adv. 2011, 29, 67–74. [Google Scholar] [CrossRef]

- Felgueiras, H.P.; Amorim, M.T. Functionalization of electrospun polymeric wound dressings with antimicrobial peptides. Colloid Surf. Biointerfaces 2017, 156, 133–148. [Google Scholar] [CrossRef]

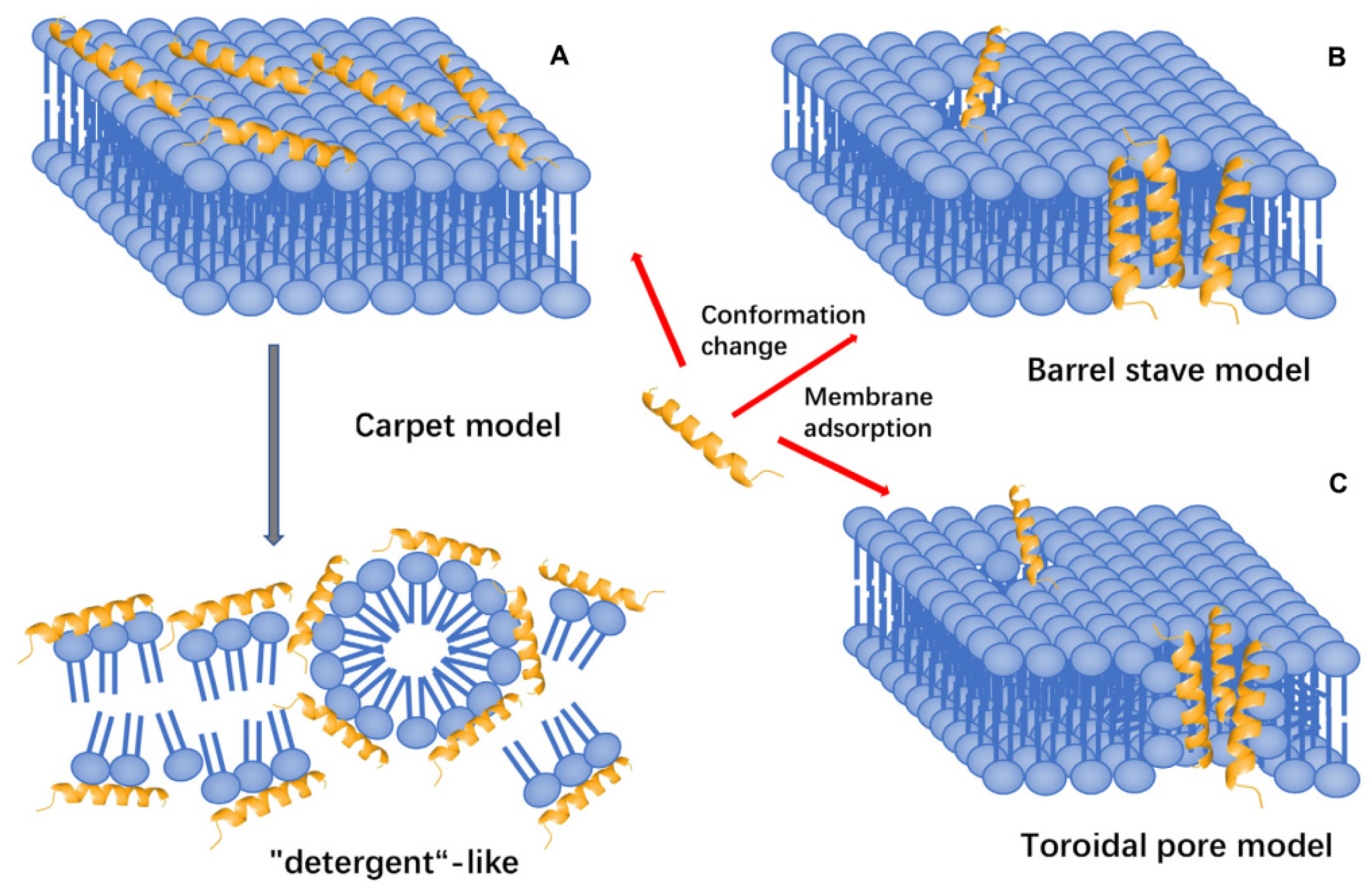

- Ciumac, D.; Gong, H.; Hu, X.; Lu, J.R. Membrane targeting cationic antimicrobial peptides. J. Colloid Interfaces Sci. 2019, 537, 163–185. [Google Scholar] [CrossRef] [PubMed]

- Corrêa, J.A.; Evangelista, A.G.; Nazareth, T.M.; Luciano, F.B. Fundamentals on the molecular mechanism of action of antimicrobial peptides. Matarials 2019, 8, 100494. [Google Scholar]

- Huan, Y.; Kong, Q.; Mou, H.; Yi, H. Antimicrobial peptides: Classification, design, application and research progress in multiple fields. Front. Microbiol. 2020, 11, 2559. [Google Scholar] [CrossRef]

- Yang, J.Q.; Wang, Z.; Wu, J.H.; Hao, L.M.; Tian, T.; Lin, S. Study on an air filter material immobilized with bio-antimicrobials. Adv. Mater. Res. 2011, 152, 1519–1524. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borojeni, I.A.; Gajewski, G.; Riahi, R.A. Application of Electrospun Nonwoven Fibers in Air Filters. Fibers 2022, 10, 15. https://doi.org/10.3390/fib10020015

Borojeni IA, Gajewski G, Riahi RA. Application of Electrospun Nonwoven Fibers in Air Filters. Fibers. 2022; 10(2):15. https://doi.org/10.3390/fib10020015

Chicago/Turabian StyleBorojeni, Iman Azarian, Grzegorz Gajewski, and Reza A. Riahi. 2022. "Application of Electrospun Nonwoven Fibers in Air Filters" Fibers 10, no. 2: 15. https://doi.org/10.3390/fib10020015

APA StyleBorojeni, I. A., Gajewski, G., & Riahi, R. A. (2022). Application of Electrospun Nonwoven Fibers in Air Filters. Fibers, 10(2), 15. https://doi.org/10.3390/fib10020015