Damage Tolerance of a Stiffened Composite Panel with an Access Cutout under Fatigue Loading and Validation Using FEM Analysis and Digital Image Correlation

Abstract

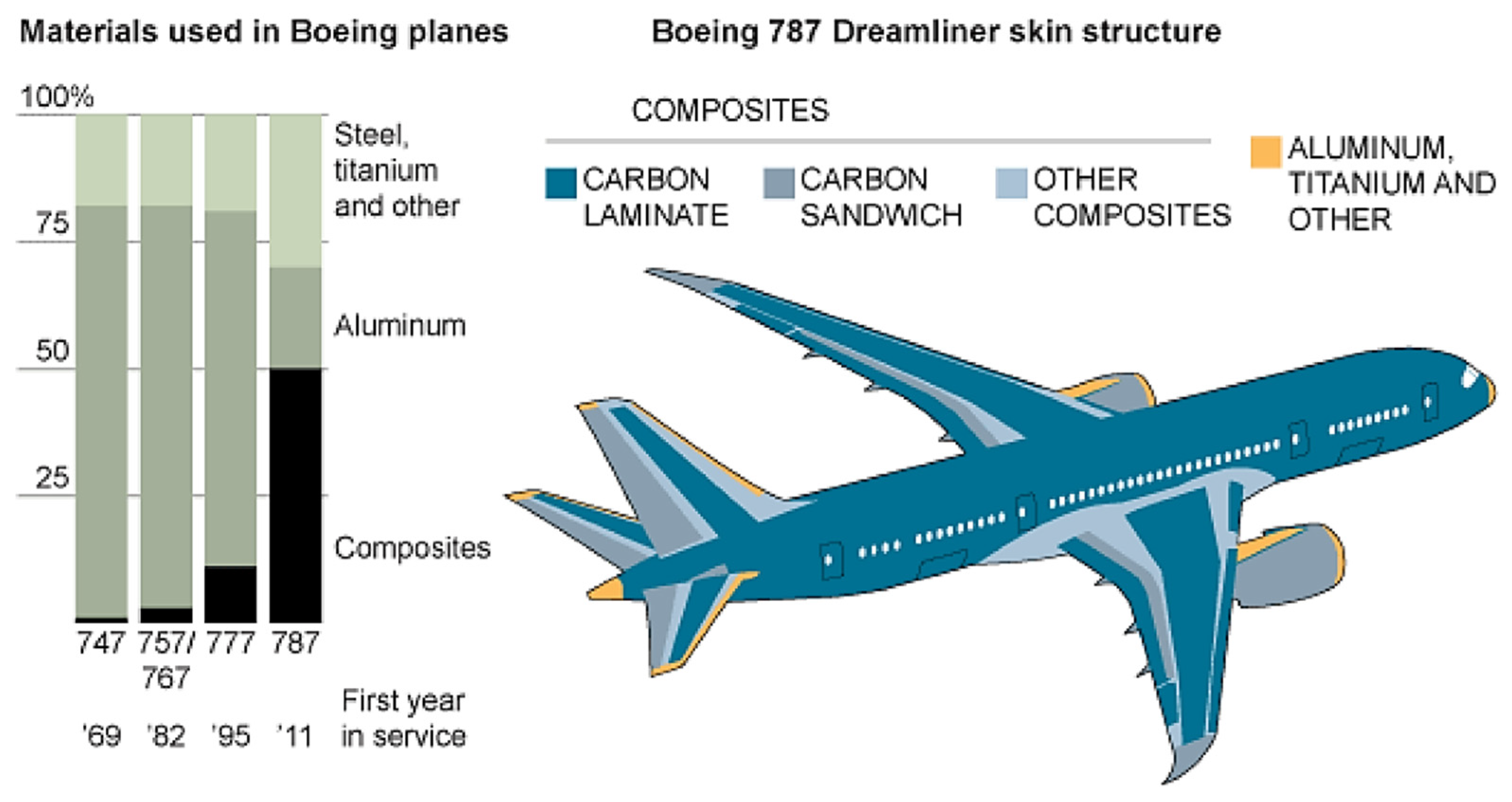

1. Introduction

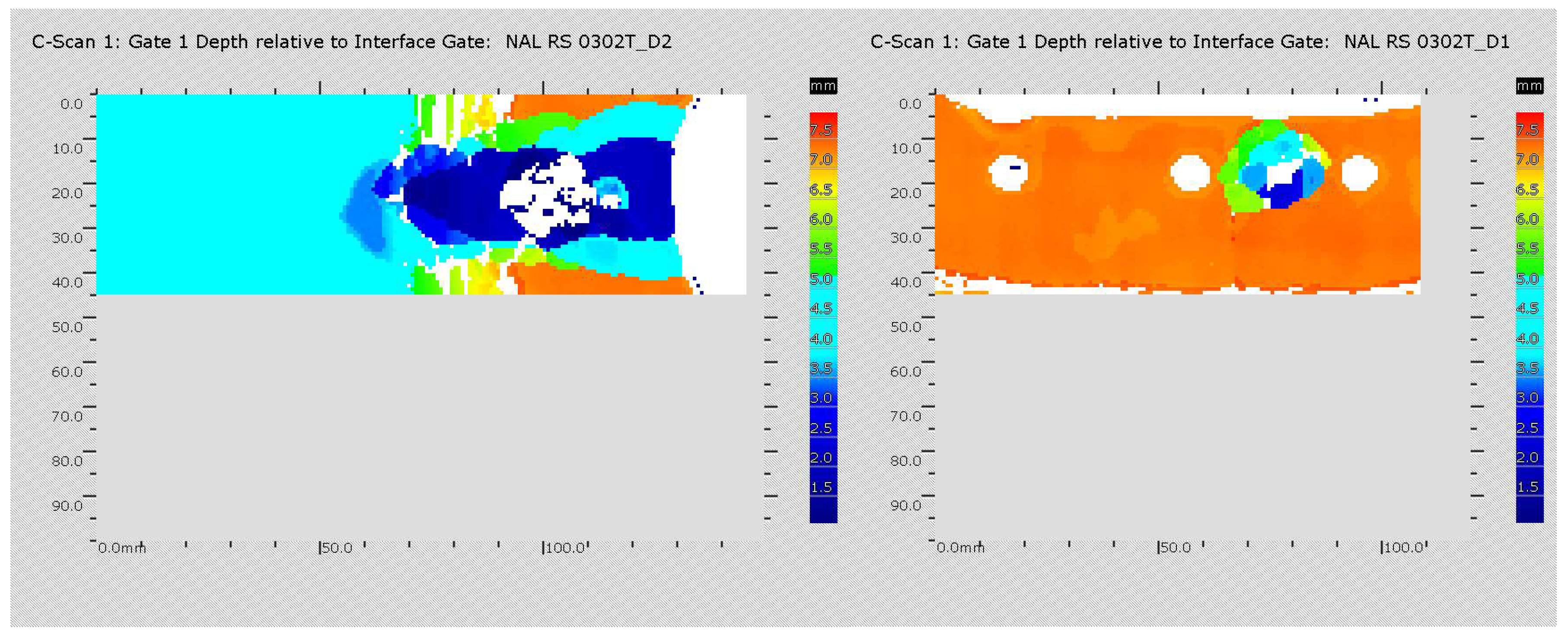

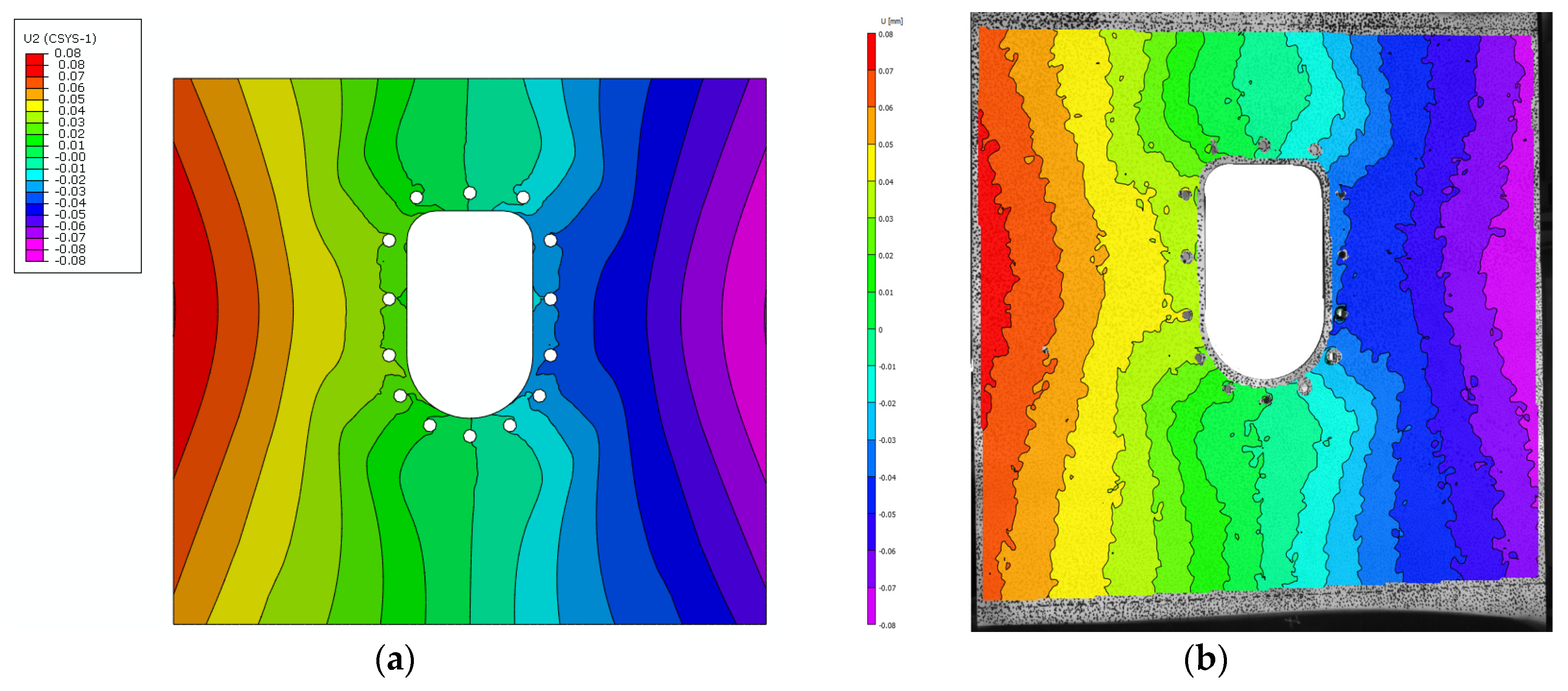

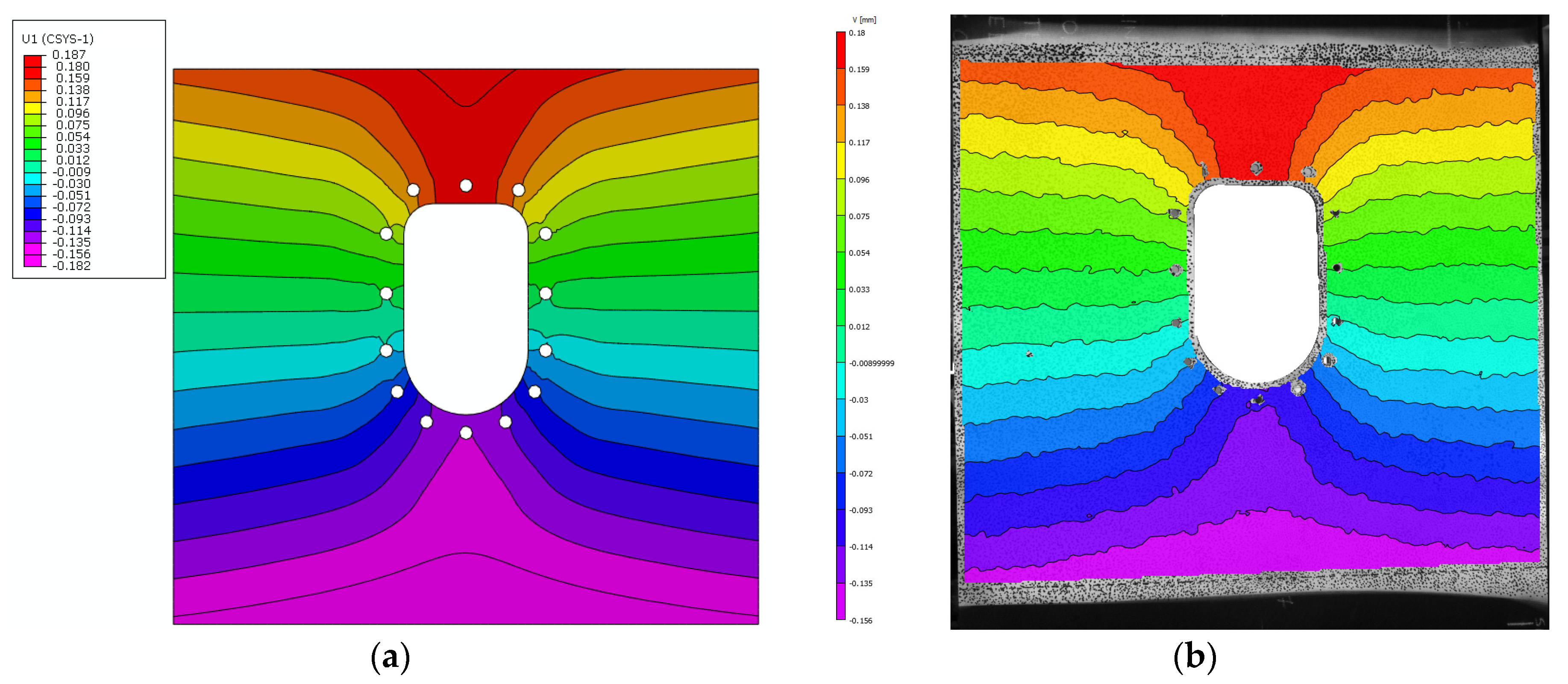

2. Materials and Methods

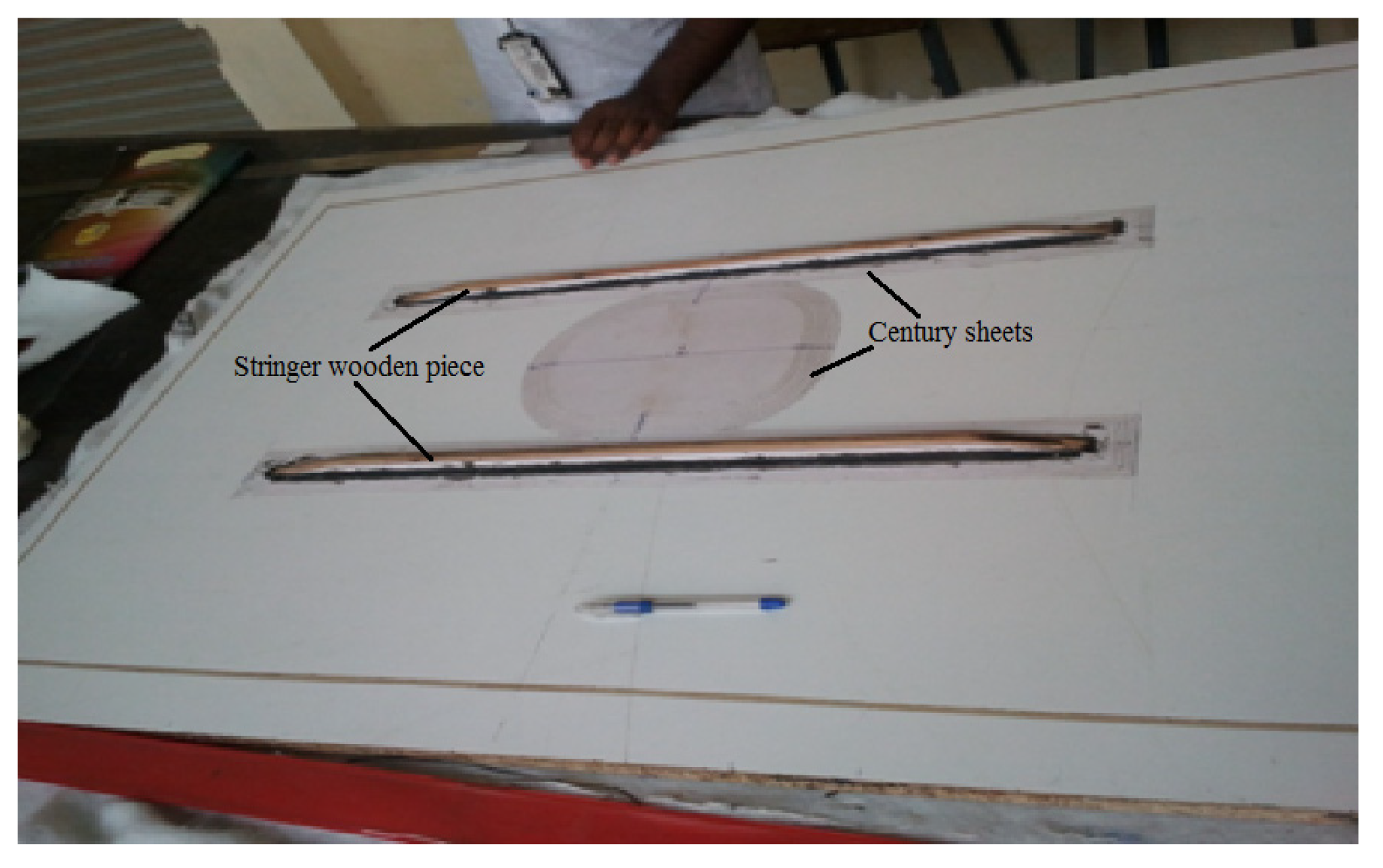

2.1. Tools and Caul Plate Fabrication

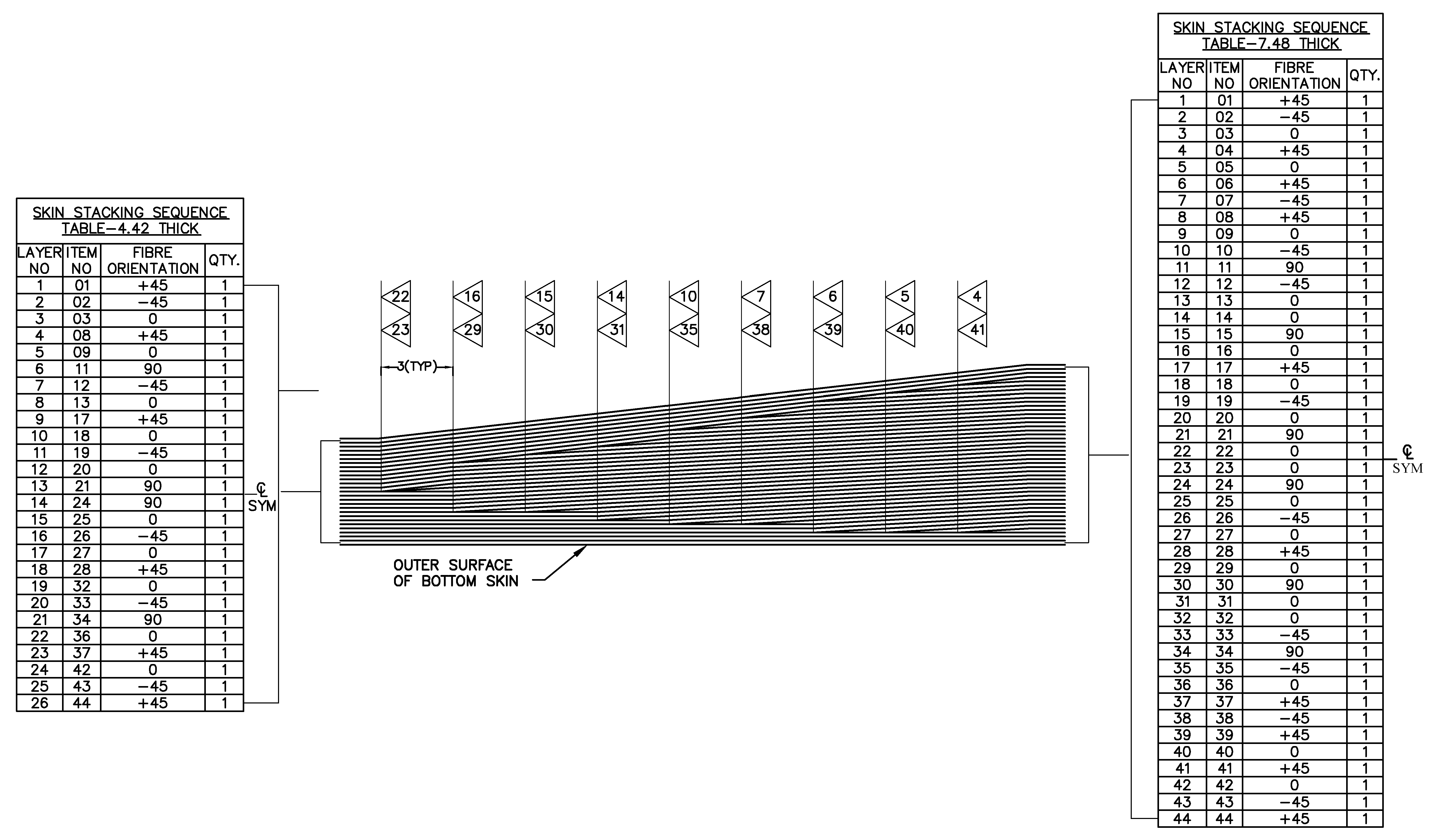

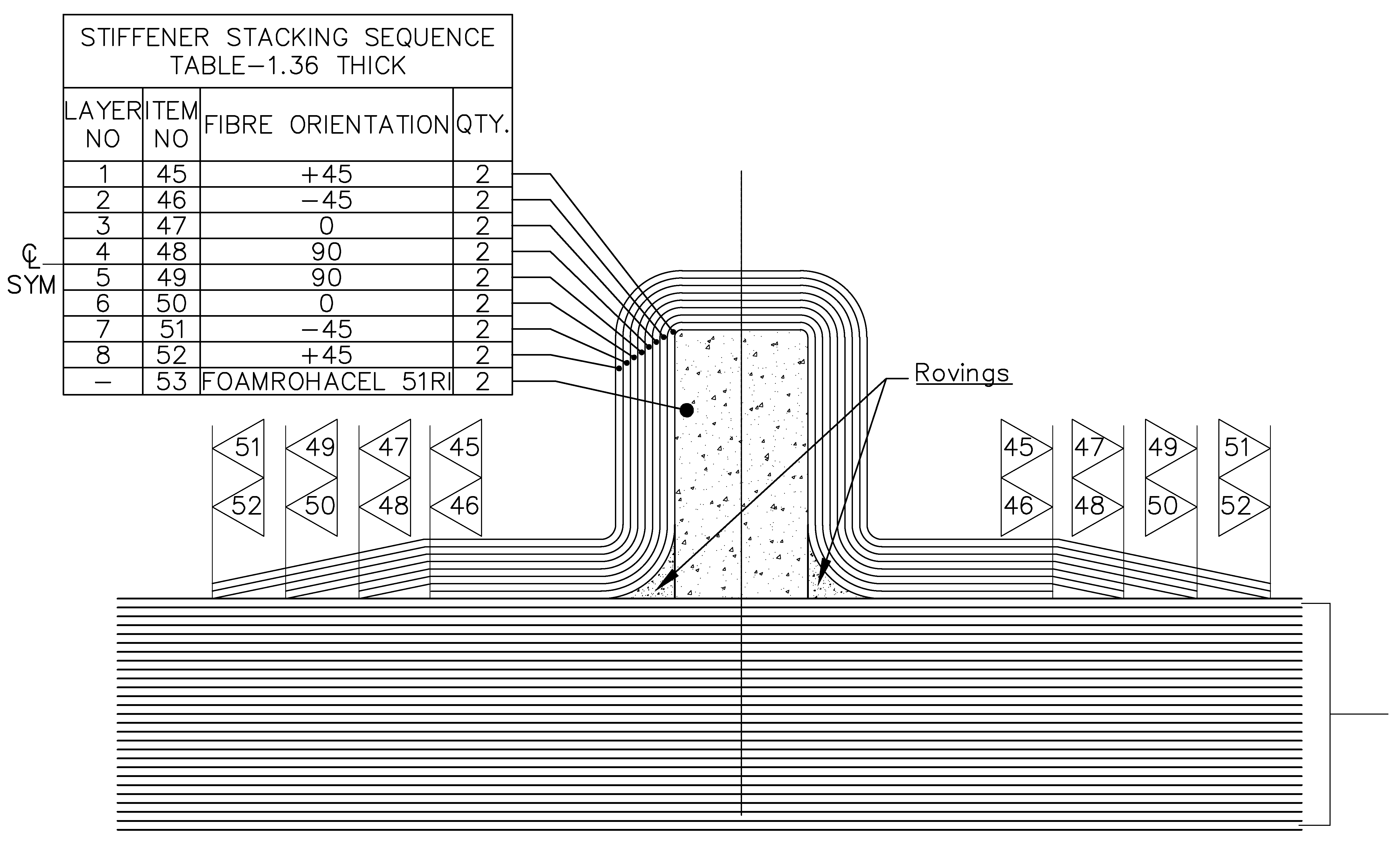

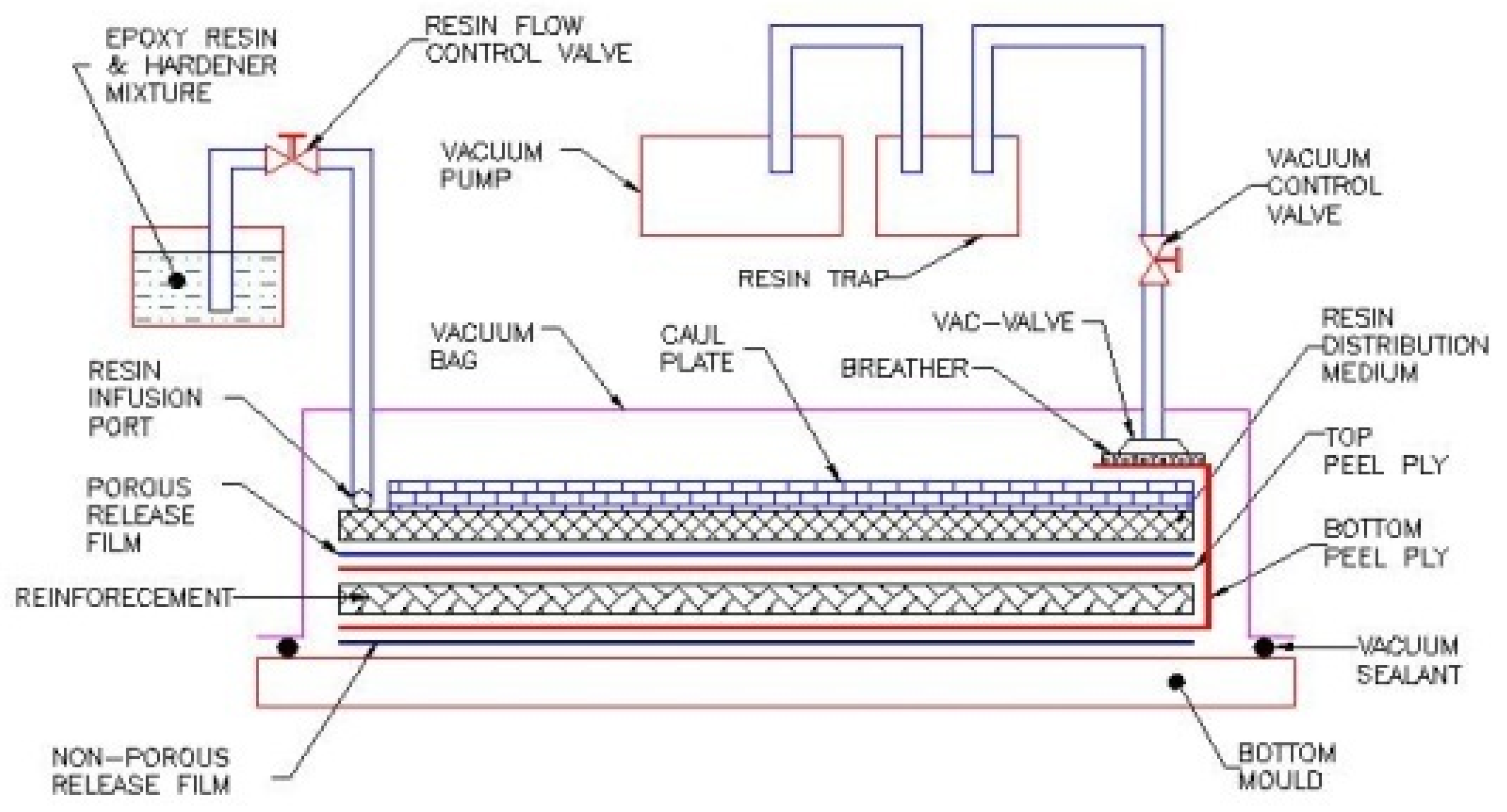

2.2. Fabrication of Composite Panel

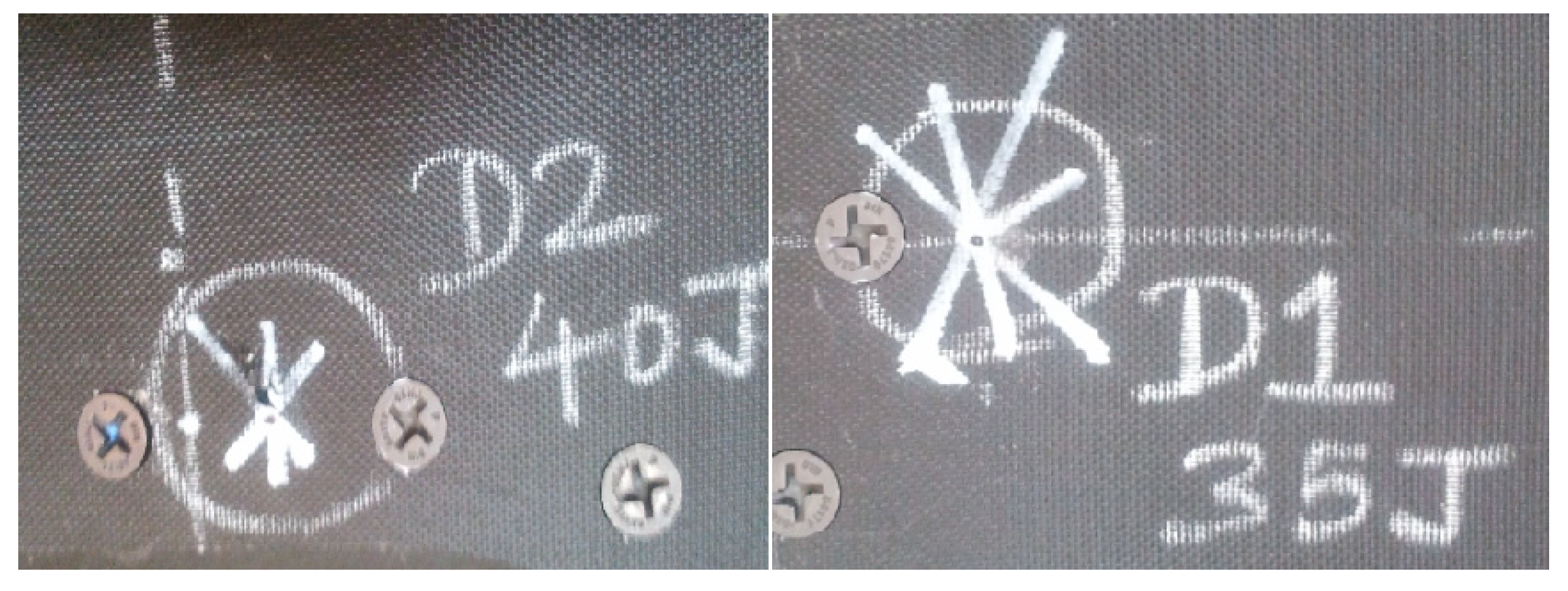

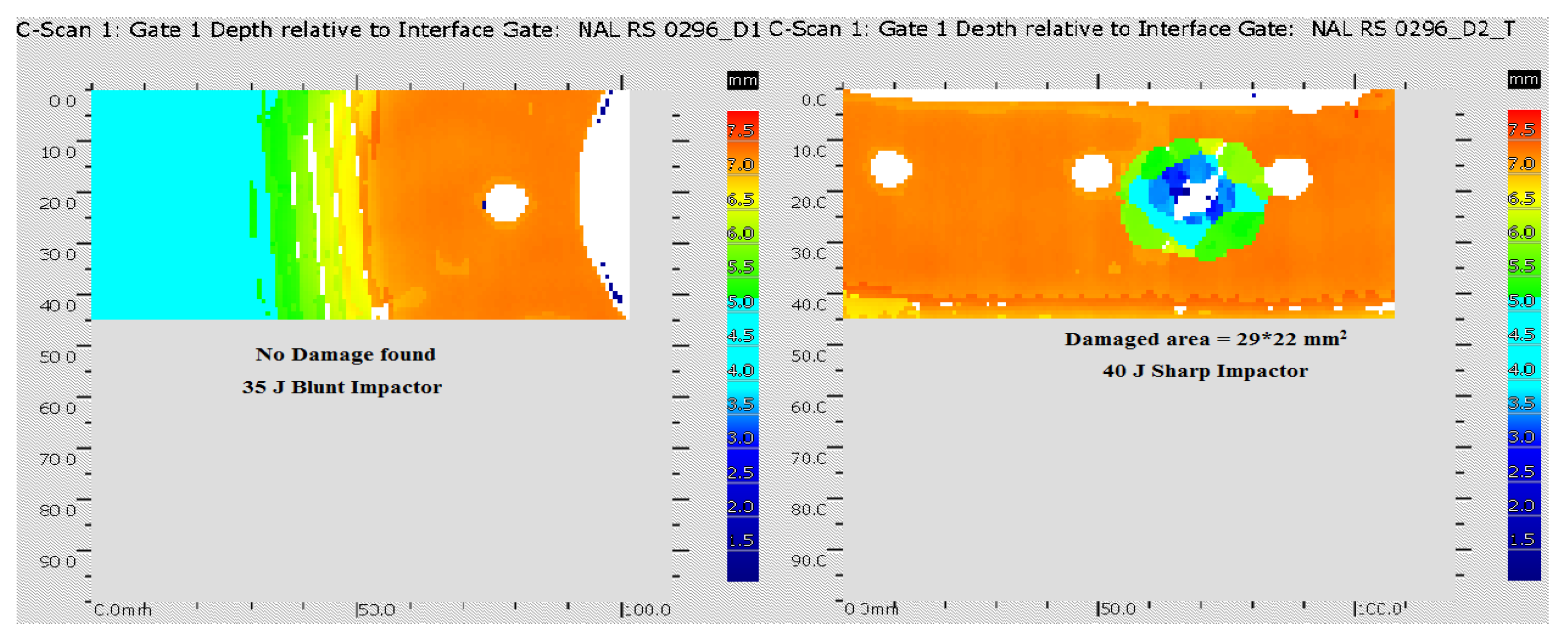

2.3. Impact Test

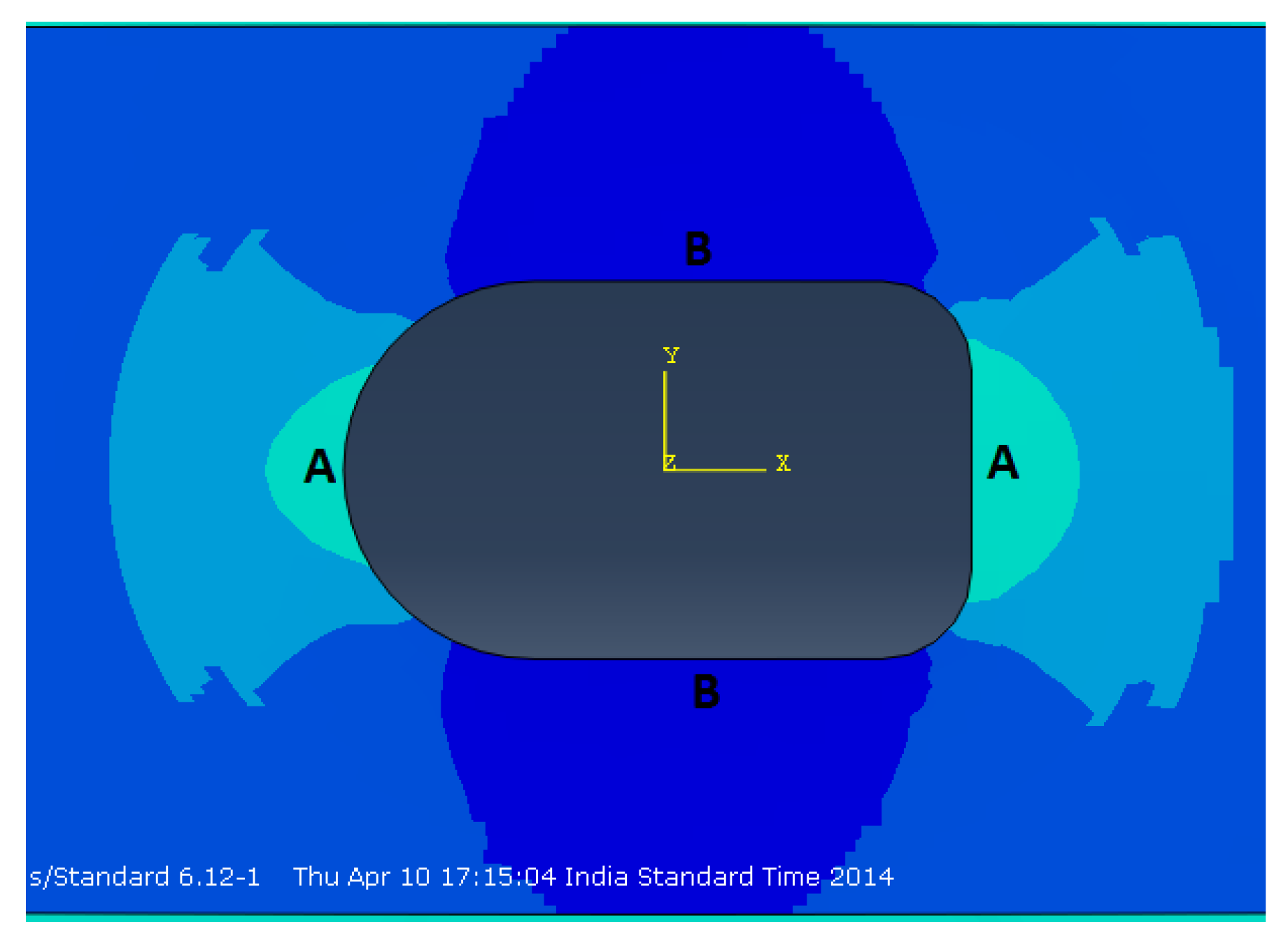

2.4. Panel Testing under Quasi-Static Load

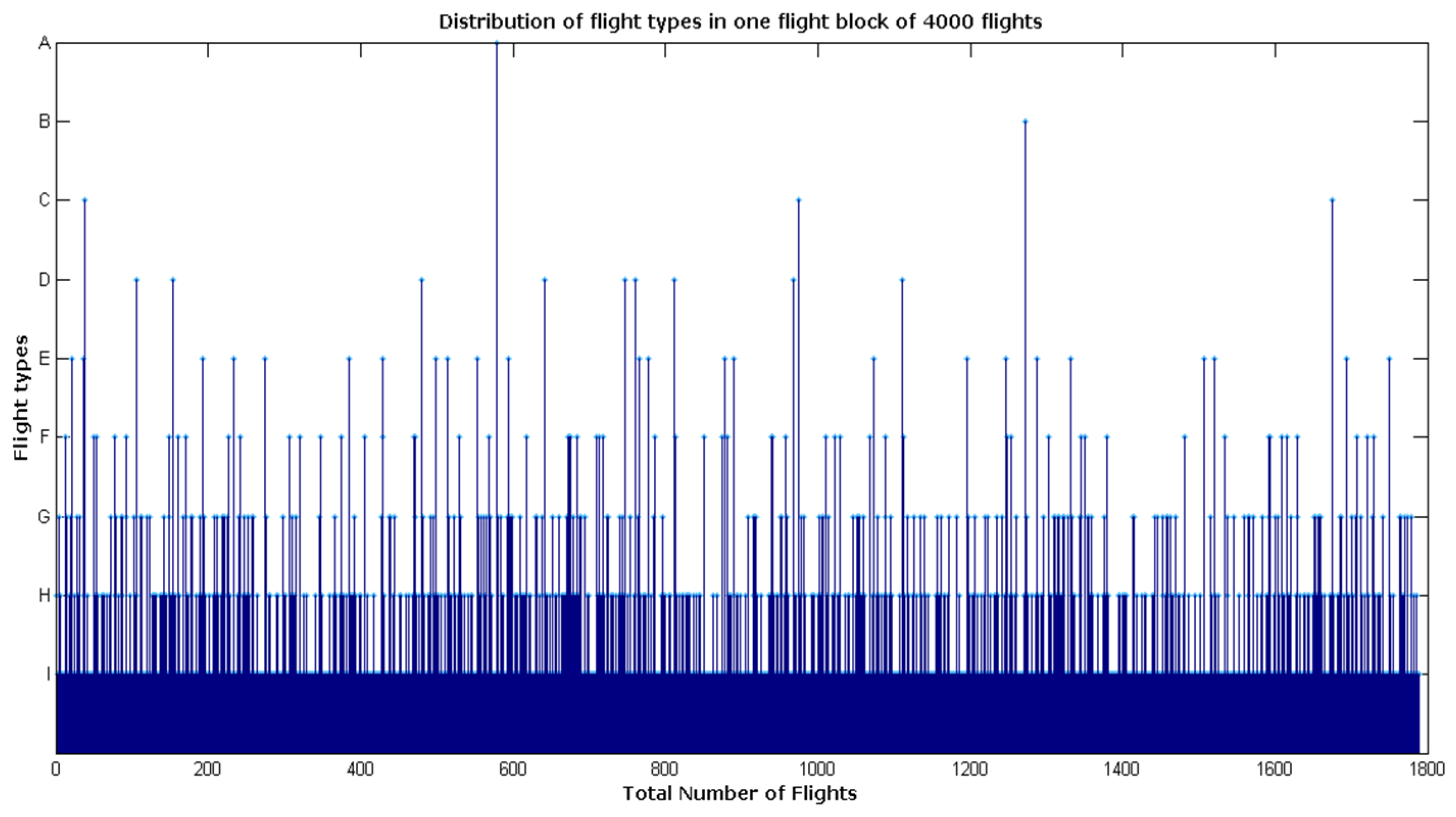

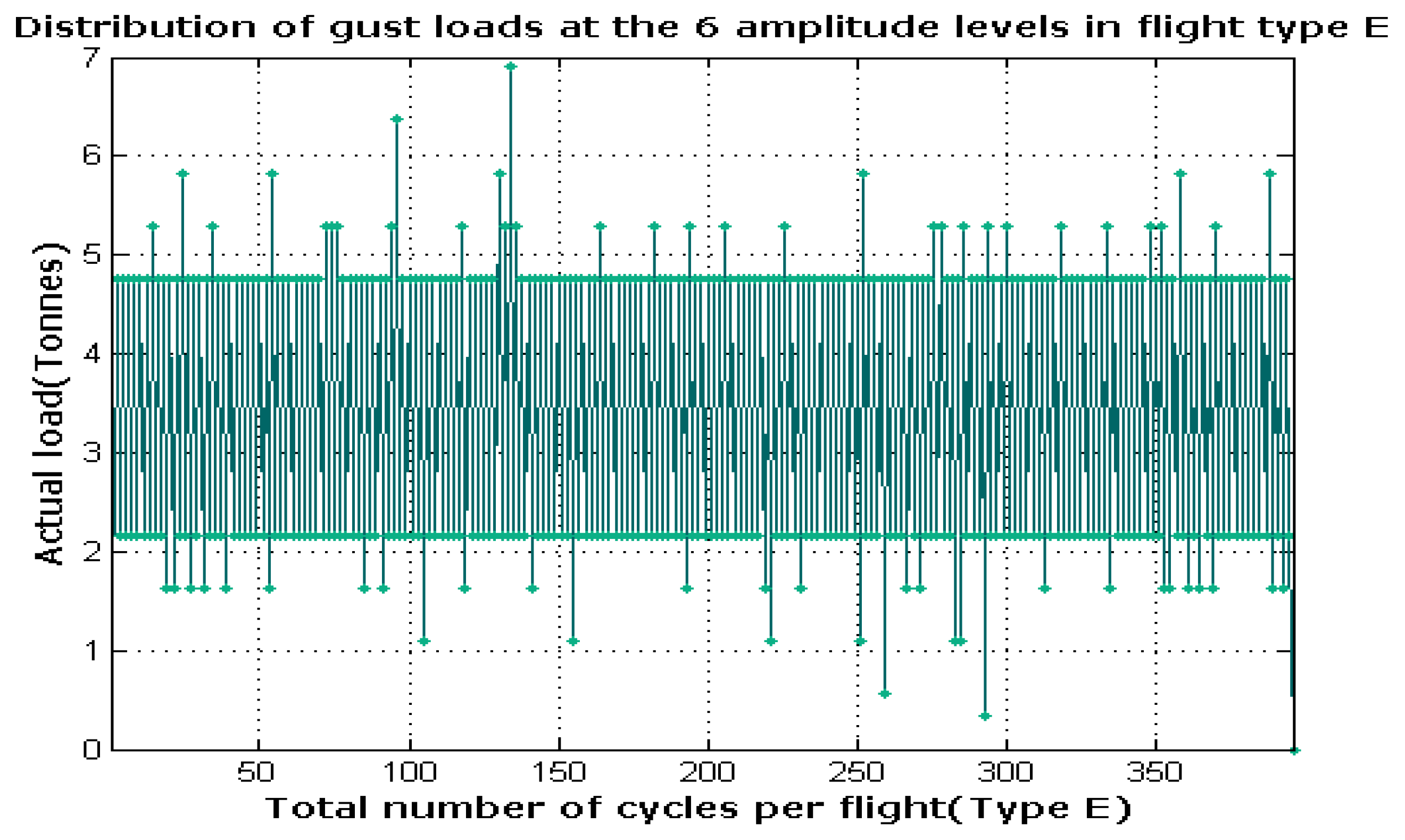

2.5. Derivation of Fatigue Spectrum Loads

- Type A: severe flight condition, high gust loads. Load level 1 occurs once in every block;

- Type B: the nest most severe flight condition. Level 2 occurs once in every block;

- Type C: load level 3 occurs only once;

- Type D: load level 4 occurs only once;

- Type E: load level 5 occurs only once;

- Type F: load level 6 occurs only once;

- Type G: load level 7 occurs only once;

- Type H: load level 8 occurs only once;

- Type I: load level 9 occurs only once;

- Type J: only gust loads with the smallest amplitude.

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bouvet, C.; Rivallant, S. Damage tolerance of composite structures under low-velocity impact. In Dynamic Deformation, Damage and Fracture in Composite Materials and Structures; Elsevier: Amsterdam, The Netherlands, 2016; pp. 7–33. [Google Scholar] [CrossRef]

- Talreja, R.; Phan, N. Assessment of damage tolerance approaches for composite aircraft with focus on barely visible impact damage. Compos. Struct. 2019, 219, 1–7. [Google Scholar] [CrossRef]

- Fernandes, P.; Pinto, R.; Correia, N. Design and optimization of self-deployable damage tolerant composite structures: A review. Compos. Part B Eng. 2021, 221, 109029. [Google Scholar] [CrossRef]

- Dubary, N.; Bouvet, C.; Rivallant, S.; Ratsifandrihana, L. Damage tolerance of an impacted composite laminate. Compos. Struct. 2018, 206, 261–271. [Google Scholar] [CrossRef]

- Shah, S.Z.H.; Karuppanan, S.; Megat-Yusoff, P.S.M.; Sajid, Z. Impact resistance and damage tolerance of fiber reinforced composites: A review. Compos. Struct. 2019, 217, 100–121. [Google Scholar] [CrossRef]

- Persico, L.; Giacalone, G.; Cristalli, B.; Tufano, C.; Saccorotti, E.; Casalone, P.; Mattiazzo, G. Recycling Process of a Basalt Fiber-Epoxy Laminate by Solvolysis: Mechanical and Optical Tests. Fibers 2022, 10, 55. [Google Scholar] [CrossRef]

- Manos, G.; Katakalos, K.; Soulis, V.; Melidis, L.; Bardakis, V. Experimental Investigation of the Structural Performance of Existing and RC or CFRP Jacket-Strengthened Prestressed Cylindrical Concrete Pipes (PCCP)—Part A. Fibers 2022, 10, 71. [Google Scholar] [CrossRef]

- Bayandor, J.; Thomson, R.S.; Scott, M.L.; Nguyen, M.Q.; Elder, D.J. Investigation of impact and damage tolerance in advanced aerospace composite structures. Int. J. Crashworthiness 2003, 8, 297–306. [Google Scholar] [CrossRef]

- Sebaey, T.A.; González, E.V.; Lopes, C.S.; Blanco, N.; Maimí, P.; Costa, J. Damage resistance and damage tolerance of dispersed CFRP laminates: Effect of the mismatch angle between plies. Compos. Struct. 2013, 101, 255–264. [Google Scholar] [CrossRef]

- Dávila, C.G.; Bisagni, C. Fatigue life and damage tolerance of postbuckled composite stiffened structures with initial delamination. Compos. Struct. 2017, 161, 73–84. [Google Scholar] [CrossRef]

- Goh, J.Y.; Georgiadis, S.; Orifici, A.C.; Wang, C.H. Effects of bondline flaws on the damage tolerance of composite scarf joints. Compos. Part A Appl. Sci. Manuf. 2013, 55, 110–119. [Google Scholar] [CrossRef]

- Sebaey, T.A.; González, E.V.; Lopes, C.S.; Blanco, N.; Costa, J. Damage resistance and damage tolerance of dispersed CFRP laminates: Effect of ply clustering. Compos. Struct. 2013, 106, 96–103. [Google Scholar] [CrossRef]

- Bogenfeld, R.; Freund, S.; Schuster, A. An analytical damage tolerance method accounting for delamination in compression-loaded composites. Eng. Fail Anal. 2020, 118, 104875. [Google Scholar] [CrossRef]

- Nash, N.H.; Young, T.M.; Stanley, W.F. An investigation of the damage tolerance of carbon/Benzoxazine composites with a thermoplastic toughening interlayer. Compos. Struct. 2016, 147, 25–32. [Google Scholar] [CrossRef]

- Dubinskii, S.; Feygenbaum, Y.; Senik, V.; Metelkin, E. A study of accidental impact scenarios for composite wing damage tolerance evaluation. Aeronaut. J. 2019, 123, 1724–1739. [Google Scholar] [CrossRef]

- Park, H. Investigation on repairable damage tolerance for structural design of aircraft composite structure. J. Compos. Mater. 2016, 002199831664357. [Google Scholar] [CrossRef]

- Tan, Y.; Wu, G.; Suh, S.S.; Yang, J.M.; Hahn, H.T. Damage tolerance and durability of selectively stitched stiffened composite structures. Int. J. Fatigue 2008, 30, 483–492. [Google Scholar] [CrossRef]

- Krzyzak, A.; Kosicka, E.; Borowiec, M.; Szczepaniak, R. Selected Tribological Properties and Vibrations in the Base Resonance Zone of the Polymer Composite Used in the Aviation Industry. Materials 2020, 13, 1364. [Google Scholar] [CrossRef]

- Richardson, M.O.W.; Wisheart, M.J. Review of low-velocity impact properties of composite materials. Compos. Part A Appl. Sci. Manuf. 1996, 27, 1123–1131. [Google Scholar] [CrossRef]

- Feng, D.; Aymerich, F. Finite element modelling of damage induced by low-velocity impact on composite laminates. Compos. Struct. 2014, 108, 161–171. [Google Scholar] [CrossRef]

- Maio, L.; Monaco, E.; Ricci, F.; Lecce, L. Simulation of low velocity impact on composite laminates with progressive failure analysis. Compos. Struct. 2013, 103, 75–85. [Google Scholar] [CrossRef]

- Johnson, A.F.; Holzapfel, M. Modelling soft body impact on composite structures. Compos. Struct. 2003, 61, 103–113. [Google Scholar] [CrossRef]

- May, M.; Arnold-Keifer, S.; Haase, T. Damage resistance of composite structures with unsymmetrical stacking sequence subjected to high velocity bird impact. Compos. Part C Open Access 2020, 1, 100002. [Google Scholar] [CrossRef]

- Liu, L.; Luo, G.; Chen, W.; Zhao, Z.; Huang, X. Dynamic Behavior and Damage Mechanism of 3D Braided Composite Fan Blade under Bird Impact. Int. J. Aerosp. Eng. 2018, 2018, 5906078. [Google Scholar] [CrossRef]

- Johnson, A.; Pickett, A.; Rozycki, P. Computational methods for predicting impact damage in composite structures. Compos. Sci. Technol. 2001, 61, 2183–2192. [Google Scholar] [CrossRef]

- Polimeno, U.; Meo, M. Detecting barely visible impact damage detection on aircraft composites structures. Compos. Struct. 2009, 91, 398–402. [Google Scholar] [CrossRef]

- Buonsanti, M.; Ceravolo, F.; Leonardi, G. Runway Debris Impact on Aircraft Composite Parts. Key Eng. Mater. 2017, 754, 283–286. [Google Scholar] [CrossRef]

- Palazotto, A.N.; Herup, E.J.; Gummadi, L.N.B. Finite element analysis of low-velocity impact on composite sandwich plates. Compos. Struct. 2000, 49, 209–227. [Google Scholar] [CrossRef]

- Wagih, A.; Maimí, P.; Blanco, N.; Costa, J. A quasi-static indentation test to elucidate the sequence of damage events in low velocity impacts on composite laminates. Compos. Part A Appl. Sci. Manuf. 2016, 82, 180–189. [Google Scholar] [CrossRef]

- Flores, M.; Mollenhauer, D.; Runatunga, V.; Beberniss, T.; Rapking, D.; Pankow, M. High-speed 3D digital image correlation of low-velocity impacts on composite plates. Compos. Part B Eng. 2017, 131, 153–164. [Google Scholar] [CrossRef]

- Pokkalla, D.K.; Poh, L.H.; Quek, S.T. Isogeometric shape optimization of missing rib auxetics with prescribed negative Poisson’s ratio over large strains using genetic algorithm. Int. J. Mech. Sci. 2021, 193, 106169. [Google Scholar] [CrossRef]

- Healey, R.; Wang, J.; Chiu, W.K.; Chowdhury, N.M.; Baker, A.; Wallbrink, C. A review on aircraft spectra simplification techniques for composite structures. Compos. Part C Open Access 2021, 5, 100131. [Google Scholar] [CrossRef]

- Nyman, T.; Ansell, H.; Blom, A. Effects of truncation and elimination on composite fatigue life. Compos. Struct. 2000, 48, 275–286. [Google Scholar] [CrossRef]

- Wan, A.-S.; Xu, Y.-G.; Xue, L.-H.; Xu, M.-R.; Xiong, J.-J. Finite element modeling and fatigue life prediction of helicopter composite tail structure under multipoint coordinated loading spectrum. Compos. Struct. 2021, 255, 112900. [Google Scholar] [CrossRef]

- Pokkalla, D.K.; Biswas, R.; Poh, L.H.; Wahab, M.A. Fretting fatigue stress analysis in heterogeneous material using direct numerical simulations in solid mechanics. Tribol. Int. 2017, 109, 124–132. [Google Scholar] [CrossRef]

| Flight Type | No. of Flights in One Block | Number of Gust Loads at Ten Amplitude Levels | Total Number of Cycles per Flight | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |||

| A | 1 | 1 | 1 | 1 | 4 | 8 | 18 | 64 | 112 | 391 | 900 | 1500 |

| B | 1 | 1 | 1 | 2 | 5 | 11 | 39 | 76 | 366 | 899 | 1400 | |

| C | 3 | 1 | 1 | 2 | 7 | 22 | 61 | 277 | 879 | 1250 | ||

| D | 9 | 1 | 1 | 2 | 14 | 44 | 208 | 680 | 950 | |||

| E | 24 | 1 | 1 | 6 | 24 | 165 | 603 | 800 | ||||

| F | 60 | 1 | 3 | 19 | 115 | 512 | 650 | |||||

| G | 181 | 1 | 7 | 70 | 412 | 490 | ||||||

| H | 420 | 1 | 16 | 233 | 250 | |||||||

| I | 1090 | 1 | 69 | 70 | ||||||||

| J | 2211 | 25 | 25 | |||||||||

| Total number of cycles per block | 1 | 2 | 5 | 18 | 52 | 152 | 800 | 4170 | 34,800 | 358,665 | ||

| Cumulative number of cycles per block | 1 | 3 | 8 | 26 | 78 | 230 | 1030 | 5200 | 40,000 | 398,665 | ||

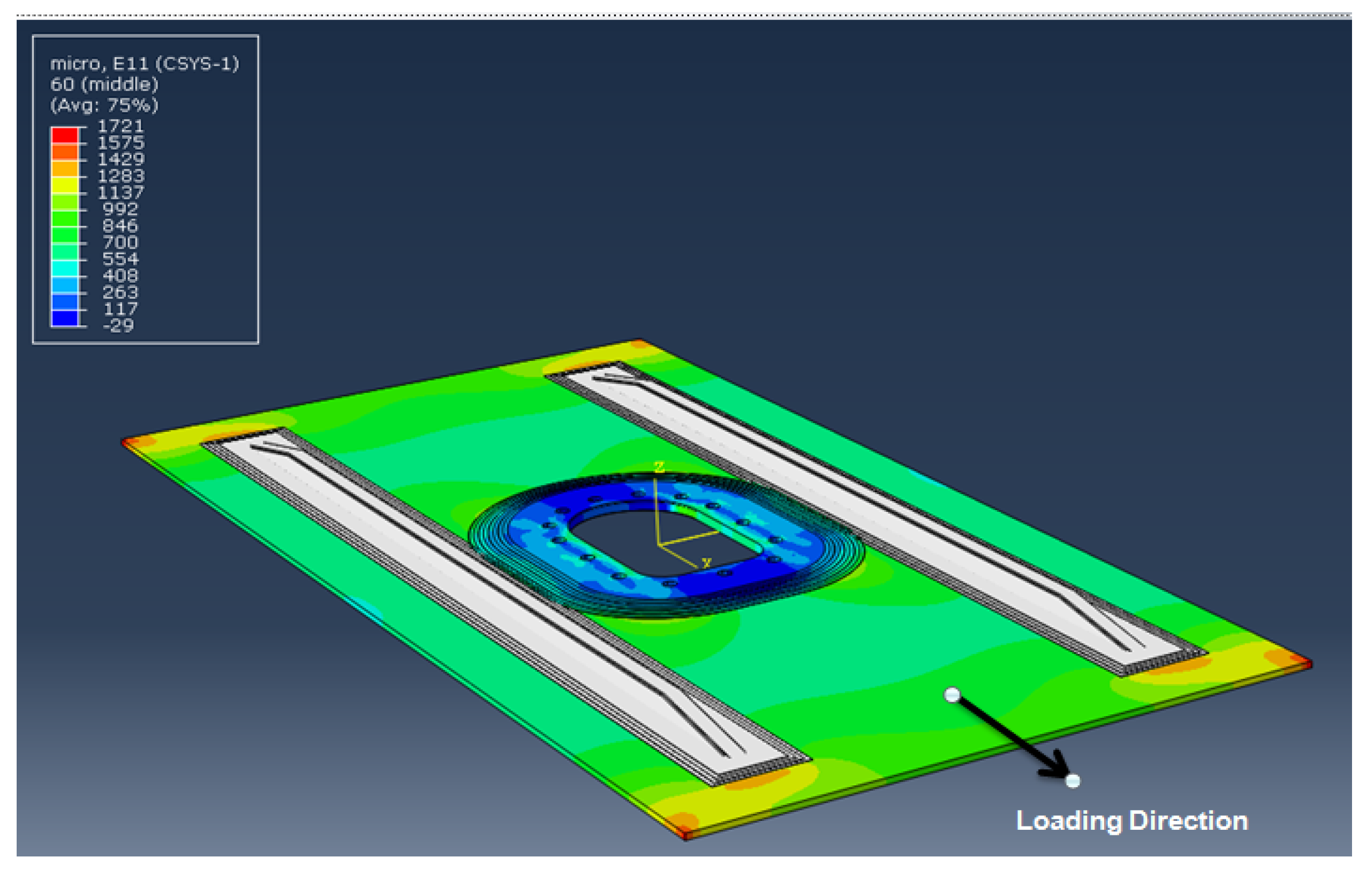

| Sl. No. | Strain Gauge Number | Element Id in FE Analysis | Far-Field Strain Data in Micro Strains | |

|---|---|---|---|---|

| FE Analysis | Reading from Strain Gauge at 9000 kgf | |||

| 1 | S17 | 1504 | 684 | 656 |

| 2 | S18 | 3120 | 679 | 757 |

| 3 | S8 | 11674 | 593 | 646 |

| 4 | S6 | 4537 | 597 | 699 |

| 5 | S16 | 2405 | 598 | 714 |

| 6 | S15 | 2037 | 613 | 738 |

| 7 | S20 | 6700 | 681 | 666 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hiremath, P.; Viswamurthy, S.R.; Shettar, M.; Naik, N.; Kowshik, S. Damage Tolerance of a Stiffened Composite Panel with an Access Cutout under Fatigue Loading and Validation Using FEM Analysis and Digital Image Correlation. Fibers 2022, 10, 105. https://doi.org/10.3390/fib10120105

Hiremath P, Viswamurthy SR, Shettar M, Naik N, Kowshik S. Damage Tolerance of a Stiffened Composite Panel with an Access Cutout under Fatigue Loading and Validation Using FEM Analysis and Digital Image Correlation. Fibers. 2022; 10(12):105. https://doi.org/10.3390/fib10120105

Chicago/Turabian StyleHiremath, Pavan, Sathyamangalam Ramanarayanan Viswamurthy, Manjunath Shettar, Nithesh Naik, and Suhas Kowshik. 2022. "Damage Tolerance of a Stiffened Composite Panel with an Access Cutout under Fatigue Loading and Validation Using FEM Analysis and Digital Image Correlation" Fibers 10, no. 12: 105. https://doi.org/10.3390/fib10120105

APA StyleHiremath, P., Viswamurthy, S. R., Shettar, M., Naik, N., & Kowshik, S. (2022). Damage Tolerance of a Stiffened Composite Panel with an Access Cutout under Fatigue Loading and Validation Using FEM Analysis and Digital Image Correlation. Fibers, 10(12), 105. https://doi.org/10.3390/fib10120105