Characterization of Tensile Properties of Cola lepidota Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.1.1. Plant Presentation

2.1.2. Extraction Process

2.2. Characterization Methods

2.2.1. Tensile Tests on Elementary CL Fibers

2.2.2. Impregnated Fiber Bundle Tests (IFBT) on CL Fibers Bundles

3. Results and Discussion

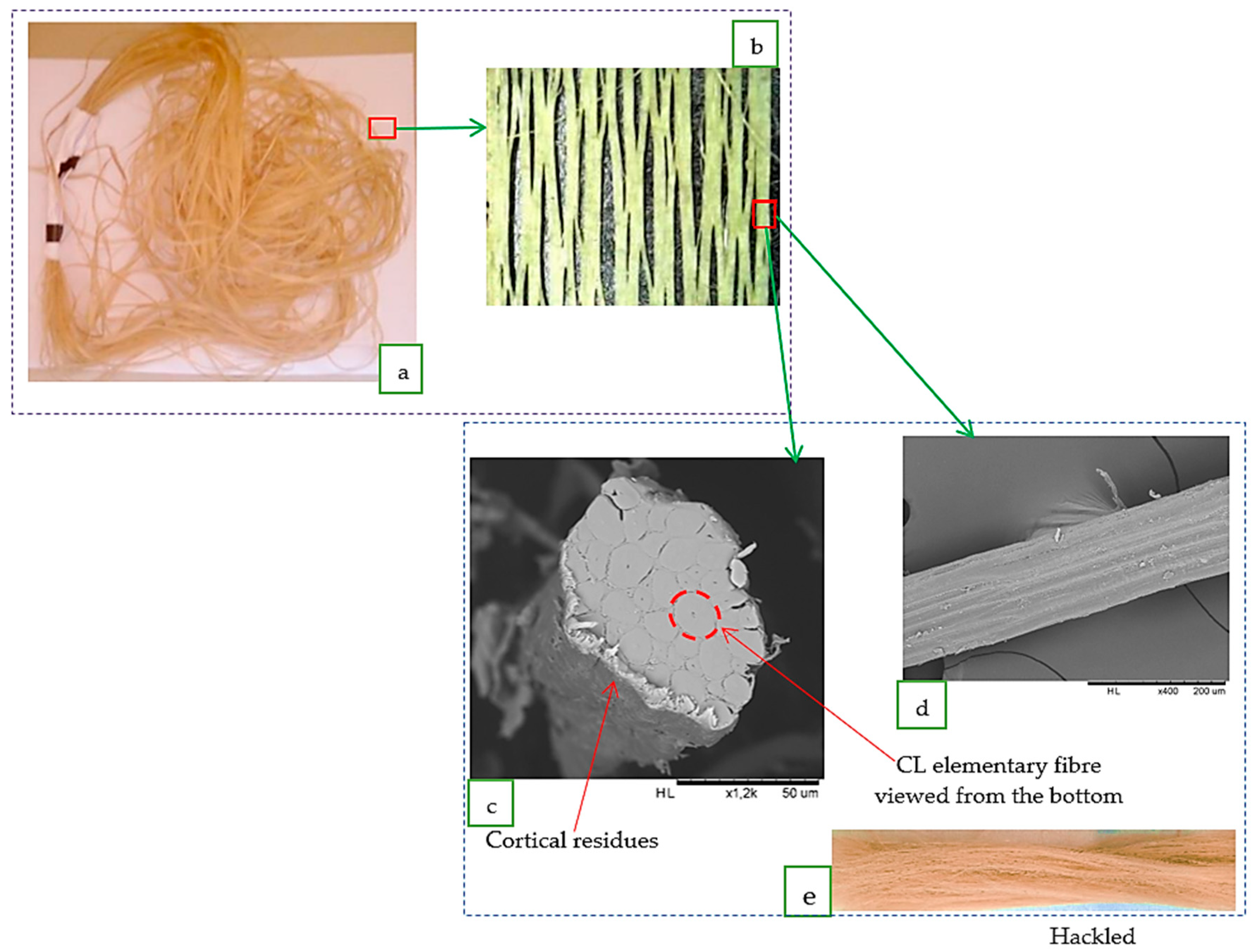

3.1. Physical Properties of CL Fiber

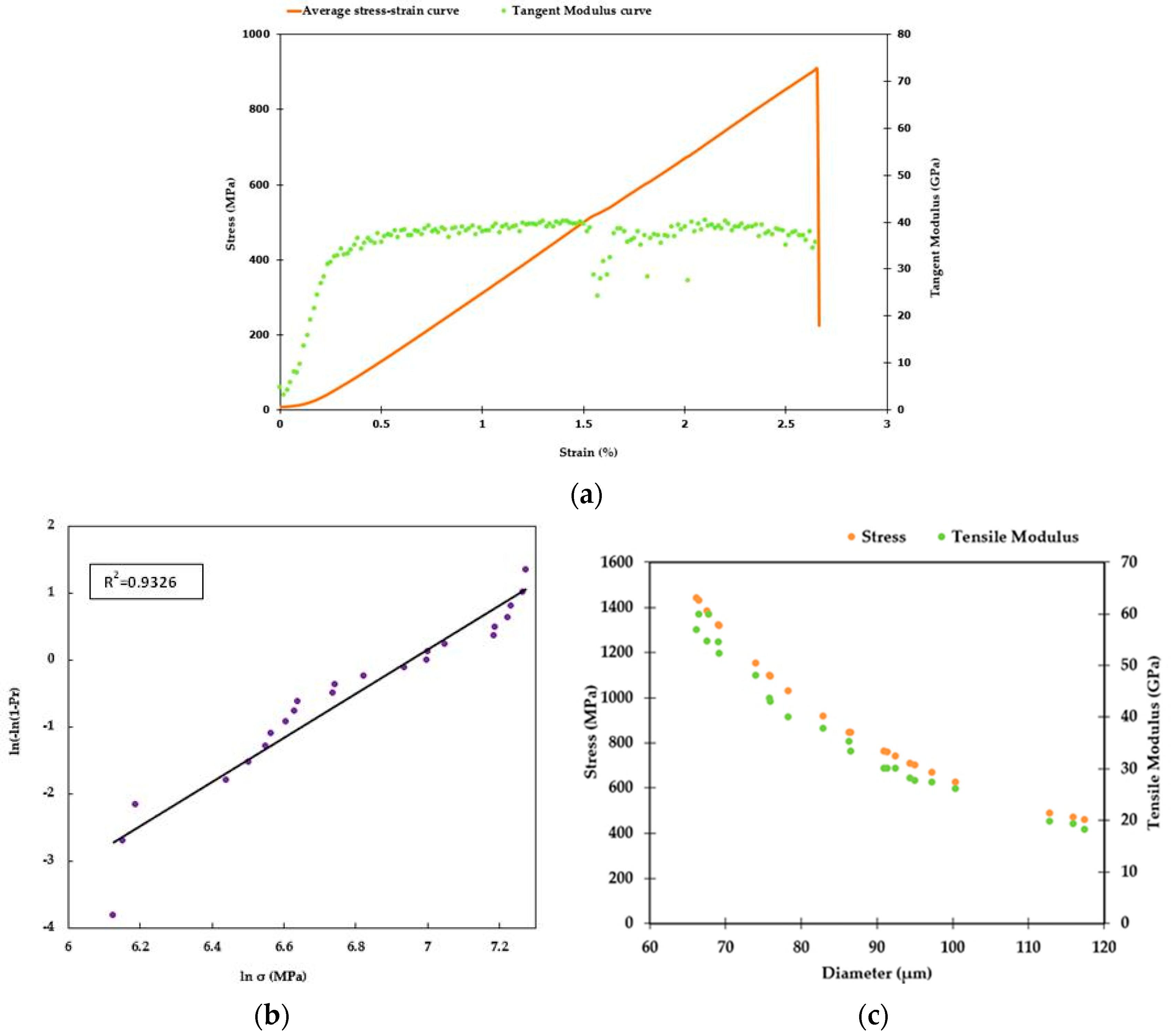

3.2. Tensile Properties of CL Fibers

3.3. Tensile Properties of CL Bundles by IFBT Method

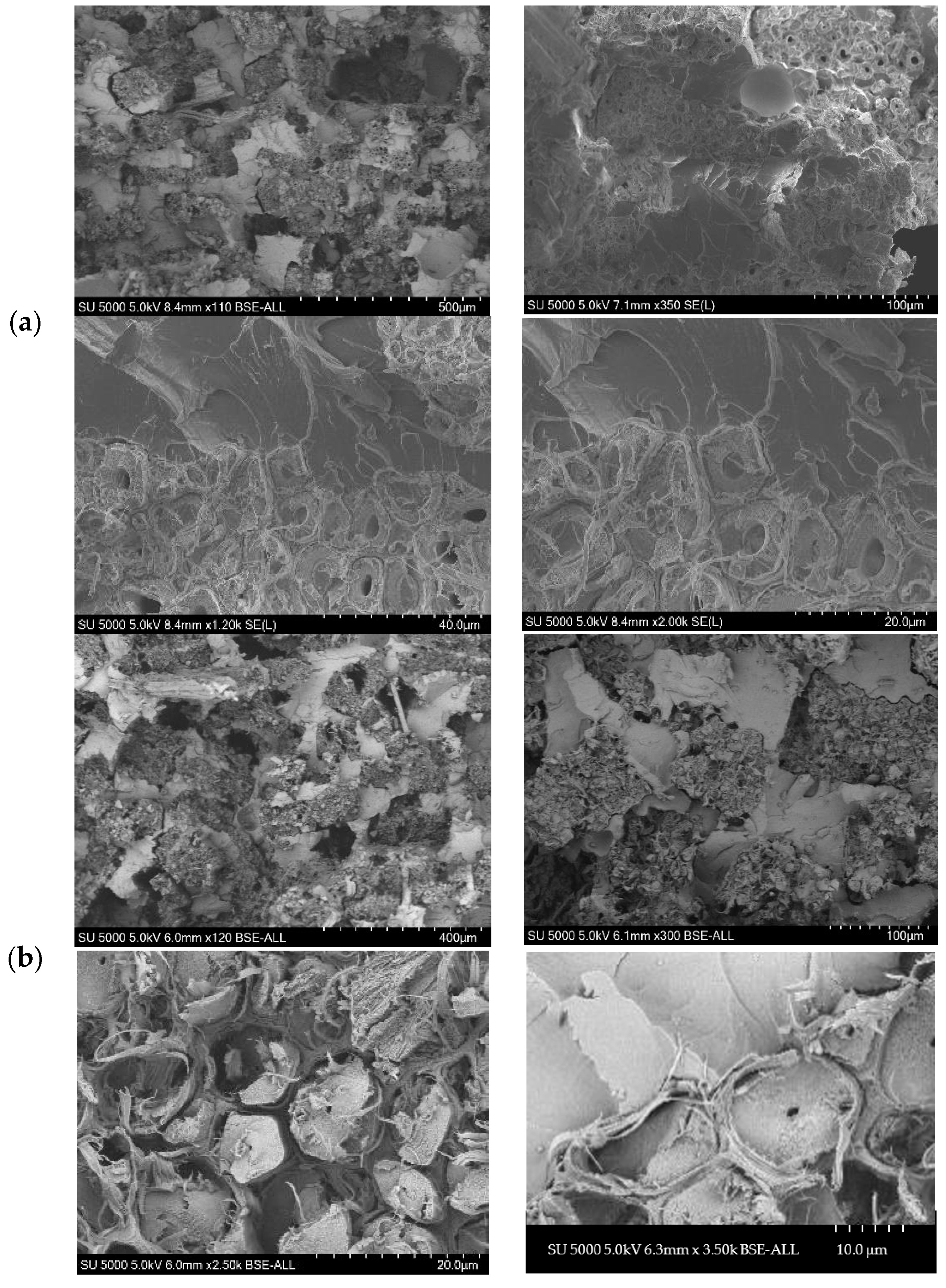

3.3.1. Properties of the IFBT Samples

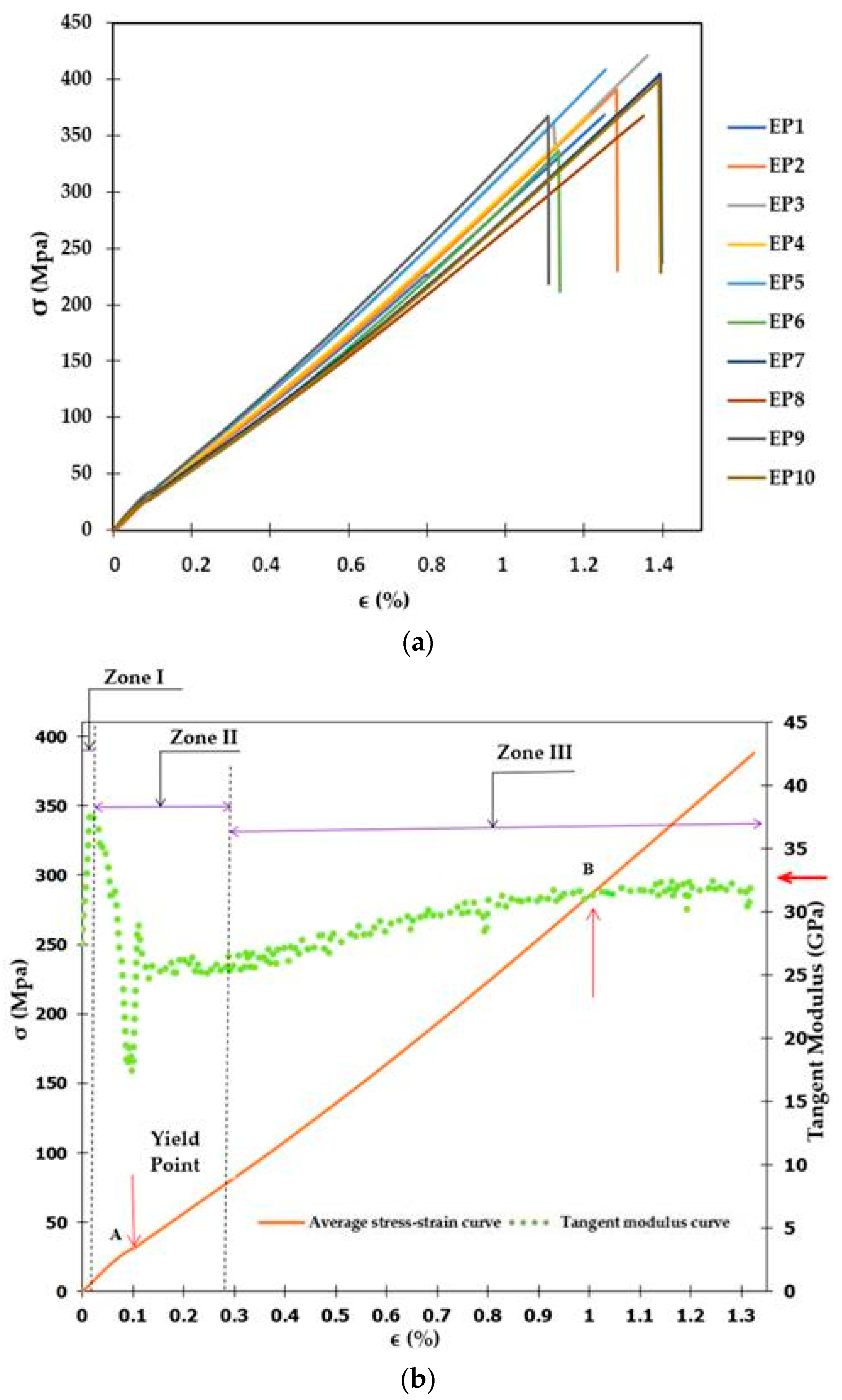

3.3.2. Tensile Properties of the IFBT Samples

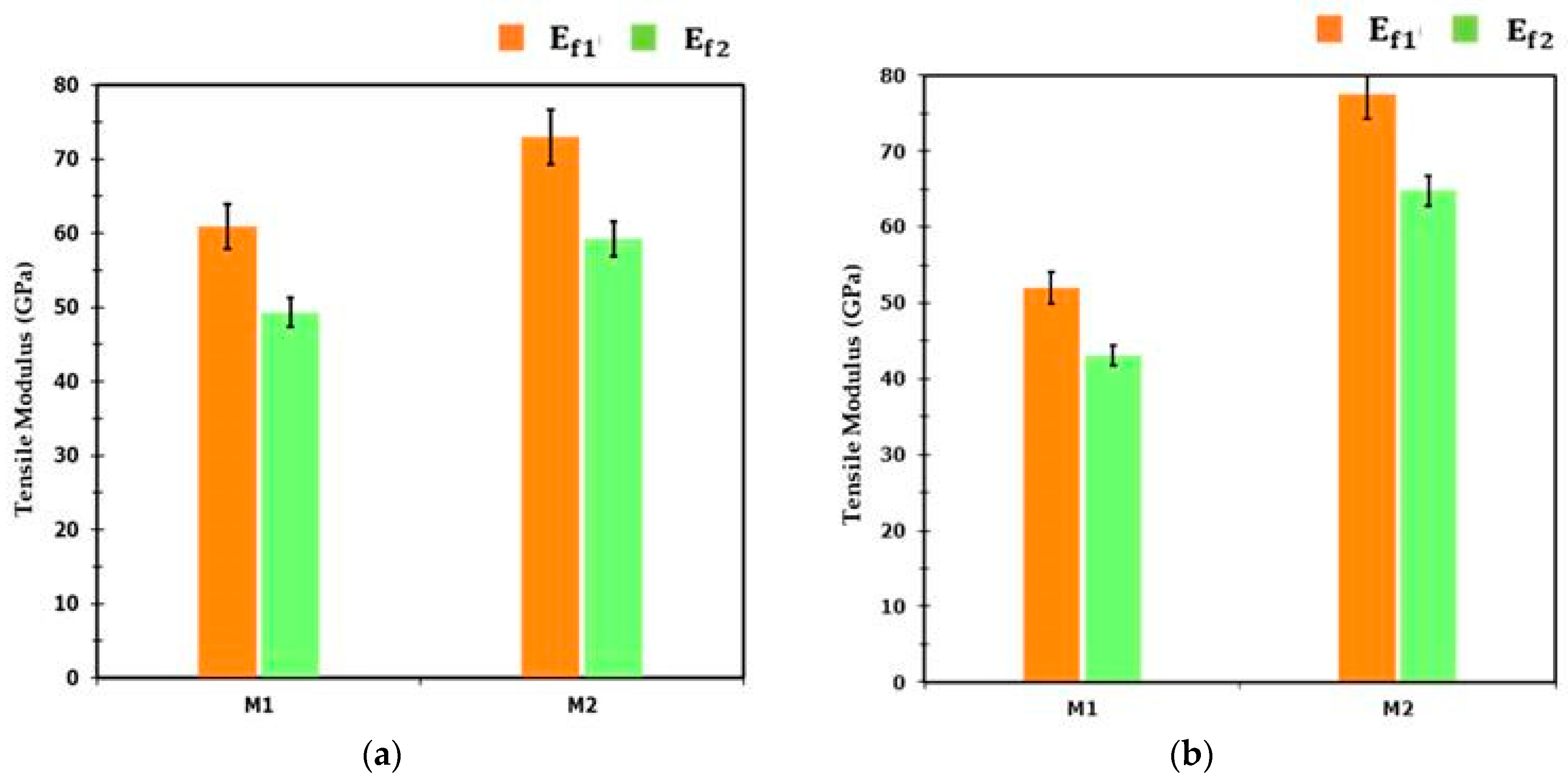

3.3.3. Tensile Properties of CL Fibers Back-Calculated

3.4. Comparison of Tensile Properties of Non-Hackled CL Fibers

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Müssig, J.; Amaducci, S.; Bourmaud, A.; Beaugrand, J.; Shah, D.U. Transdisciplinary top-down review of hemp fibre composites: From an advanced product design to crop variety selection. Compos. Part C Open Access 2020, 2, 100010. [Google Scholar] [CrossRef]

- Zhang, Z.; Cai, S.; Li, Y.; Wang, Z.; Long, Y.; Yu, T.; Shen, Y. High performances of plant fiber reinforced composites—A new insight from hierarchical microstructures. Compos. Sci. Technol. 2020, 194, 108151. [Google Scholar] [CrossRef]

- Richely, E.; Bourmaud, A.; Placet, V.; Guessasma, S.; Beaugrand, J. A critical review of the ultrastructure, mechanics and modelling of flax fibres and their defects. Prog. Mater. Sci. 2021, 124, 100851. [Google Scholar] [CrossRef]

- Chokshi, S.; Parmar, V.; Gohil, P.; Chaudhary, V. Chemical Composition and Mechanical Properties of Natural Fibers. Available online: https://www.tandfonline.com/doi/full/10.1080/15440478.2020.1848738 (accessed on 10 October 2021).

- Ramesh, M. Flax (Linum usitatissimum L.) fibre reinforced polymer composite materials: A review on preparation, properties and prospects. Prog. Mater. Sci. 2019, 102, 109–166. [Google Scholar] [CrossRef]

- Bourmaud, A.; Beaugrand, J.; Shah, D.U.; Placet, V.; Baley, C. Towards the design of high-performance plant fibre composites. Prog. Mater. Sci. 2018, 97, 347–408. [Google Scholar] [CrossRef]

- Sanivada, U.K.; Mármol, G.; Brito, F.P.; Fangueiro, R. PLA Composites Reinforced with Flax and Jute Fibers—A Review of Recent Trends, Processing Parameters and Mechanical Properties. Polymers 2020, 12, 2373. [Google Scholar] [CrossRef]

- Mazian, B.; Bergeret, A.; Benezet, J.C.; Malhautier, L. Influence of field retting duration on the biochemical, microstructural, thermal and mechanical properties of hemp fibres harvested at the beginning of flowering. Ind. Crop. Prod. 2018, 116, 170–181. [Google Scholar] [CrossRef]

- Müssig, J.; Haag, K.; Musio, S.; Bjelková, M.; Albrecht, K.; Uhrlaub, B.; Wang, S.; Wieland, H.J.; Amaducci, S. Biobased ‘Mid-performance’ composites using losses from the hackling process of long hemp—A feasibility study as part of the development of a biorefinery concept. Ind. Crop. Prod. 2020, 145, 111938. [Google Scholar] [CrossRef]

- Grégoire, M.; Bar, M.; de Luycker, E.; Musio, S.; Amaducci, S.; Gabrion, X.; Placet, V.; Ouagne, P. Comparing flax and hemp fibres yield and mechanical properties after scutching/hackling processing. Ind. Crop. Prod. 2021, 172, 114045. [Google Scholar] [CrossRef]

- Réquilé, S.; Mazian, B.; Grégoire, M.; Musio, S.; Gautreau, M.; Nuez, L.; Day, A.; Thiébeau, P.; Philippe, F.; Chabbert, B.; et al. Exploring the dew retting feasibility of hemp in very contrasting European environments: Influence on the tensile mechanical properties of fibres and composites. Ind. Crop. Prod. 2021, 164, 113337. [Google Scholar] [CrossRef]

- Garat, W.; Corn, S.; Le Moigne, N.; Beaugrand, J.; Bergeret, A. Analysis of the morphometric variations in natural fibres by automated laser scanning: Towards an efficient and reliable assessment of the cross-sectional area. Compos. Part A Appl. Sci. Manuf. 2018, 108, 114–123. [Google Scholar] [CrossRef]

- Summerscales, J.; Virk, A.S.; Hall, W. Fibre area correction factors (FACF) for the extended rules-of-mixtures for natural fibre reinforced composites. Mater. Today Proc. 2020, 31, S318–S320. [Google Scholar] [CrossRef]

- Baley, C.; Gomina, M.; Breard, J.; Bourmaud, A.; Davies, P. Variability of mechanical properties of flax fibres for composite reinforcement. A review. Ind. Crop. Prod. 2020, 145, 111984. [Google Scholar] [CrossRef]

- Bensadoun, F.; Verpoest, I.; Baets, J.; Müssig, J.; Graupner, N.; Davies, P.; Gomina, M.; Kervoelen, A.; Baley, C. Impregnated fibre bundle test for natural fibres used in composites. J. Reinf. Plast. Compos. 2017, 36, 942–957. [Google Scholar] [CrossRef]

- Lefeuvre, A.; Bourmaud, A.; Lebrun, L.; Morvan, C.; Baley, C. A study of the yearly reproducibility of flax fiber tensile properties. Ind. Crop. Prod. 2013, 50, 400–407. [Google Scholar] [CrossRef]

- Del Masto, A.; Trivaudey, F.; Guicheret-Retel, V.; Placet, V.; Boubakar, L. Investigation of the possible origins of the differences in mechanical properties of hemp and flax fibres: A numerical study based on sensitivity analysis. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105488. [Google Scholar] [CrossRef]

- Lefeuvre, A.; Bourmaud, A.; Morvan, C.; Baley, C. Elementary flax fibre tensile properties: Correlation between stress–strain behaviour and fibre composition. Ind. Crop. Prod. 2014, 52, 762–769. [Google Scholar] [CrossRef]

- Sarasini, F.; Fiore, V. A systematic literature review on less common natural fibres and their biocomposites. J. Clean. Prod. 2018, 195, 240–267. [Google Scholar] [CrossRef]

- Jawaid, M.; Asim, M.; Tahir, P.M.; Nasir, M. Pineapple Leaf Fibers. Processing, Properties and Applications; Springer Nature Singapore Private Ltd.: Singapore, 2020. [Google Scholar] [CrossRef]

- De Rosa, I.M.; Kenny, J.M.; Puglia, D.; Santulli, C.; Sarasini, F. Morphological, thermal and mechanical characterization of okra (Abelmoschus esculentus) fibres as potential reinforcement in polymer composites. Compos. Sci. Technol. 2010, 70, 116–122. [Google Scholar] [CrossRef]

- Manimaran, P.; Prithiviraj, M.; Saravanakumar, S.S.; Arthanarieswaran, V.P.; Senthamaraikannan, P. Physicochemical, tensile, and thermal characterization of new natural cellulosic fibers from the stems of Sida cordifolia. J. Nat. Fibers 2017, 15, 860–869. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Valenza, A. Characterization of a new natural fiber from Arundo donax L. as potential reinforcement of polymer composites. Carbohydr. Polym. 2014, 106, 77–83. [Google Scholar] [CrossRef]

- Belouadah, Z.; Ati, A.; Rokbi, M. Characterization of new natural cellulosic fiber from Lygeum spartum L. Carbohydr. Polym. 2015, 134, 429–437. [Google Scholar] [CrossRef]

- Jebadurai, S.G.; Raj, R.E.; Sreenivasan, V.S.; Binoj, J.S. Comprehensive characterization of natural cellulosic fiber from Coccinia grandis stem. Carbohydr. Polym. 2018, 207, 675–683. [Google Scholar] [CrossRef]

- Gopinath, R.; Billigraham, P.; Sathishkumar, T.P. Physicochemical and Thermal Properties of New Cellulosic Fiber Obtained from the Stem of Markhamia lutea. Available online: https://www.tandfonline.com/doi/abs/10.1080/15440478.2021.1964133 (accessed on 15 October 2021).

- Gopinath, R.; Billigraham, P.; Sathishkumar, T.P. Characterization Studies on New Natural Cellulosic Fiber Extracted from the Bark of Erythrina variegata. Available online: https://www.tandfonline.com/doi/abs/10.1080/15440478.2021.1961344 (accessed on 15 October 2021).

- Gopinath, R.; Billigraham, P.; Sathishkumar, T.P. Physicochemical and Thermal Properties of Cellulosic Fiber Extracted from the Bark of Albizia Saman. Available online: https://www.tandfonline.com/doi/abs/10.1080/15440478.2021.1929654 (accessed on 15 October 2021).

- Okonkwo, E.G.; Daniel-Mkpume, C.C.; Ude, S.N.; Onah, C.C.; Ijomah, A.I.; Omah, A.D. Chicken feather fiber—African star apple leaves bio-composite: Empirical study of mechanical and morphological properties. Mater. Res. Express 2019, 6, 105361. [Google Scholar] [CrossRef]

- Mewoli, A.E.; Segovia, C.; Ebanda, F.B.; Ateba, A.; Noah, P.M.A.; Ndiwe, B.; Njom, A.E. Physical-Chemical and Mechanical Characterization of the Bast Fibers of Triumfetta cordifolia A.Rich. from the Equatorial Region of Cameroon. J. Miner. Mater. Charact. Eng. 2020, 8, 163–176. [Google Scholar] [CrossRef]

- Béakou, A.; Ntenga, R.; Lepetit, J.; Atéba, J.A.; Ayina, L. Physico-chemical and microstructural characterization of “Rhectophyllum camerunense” plant fiber. Compos. Part A Appl. Sci. Manuf. 2008, 39, 67–74. [Google Scholar] [CrossRef]

- Noutegomo, B.; Ebanda, F.B.; Ateba, A. Study of the diffusion behavior of water vapor sorption in natural fiber composite: Plaster/Rhecktophyllum camerunense. MOJ Appl. Bionics Biomech. 2019, 3, 12–16. [Google Scholar] [CrossRef]

- Betene, A.D.O.; Betene, F.E.; Martoïa, F.; Dumont, P.J.; Atangana, A.; Noah, P.M.A. Physico-Chemical and Thermal Characterization of Some Lignocellulosic Fibres: Ananas comosus (AC), Neuropeltis acuminatas (NA) and Rhecktophyllum camerunense (RC). J. Miner. Mater. Charact. Eng. 2020, 8, 205–222. [Google Scholar] [CrossRef]

- FAO. Rapport sur les forêts 2011: La Situation des Forêts dans le Bassin Amazonien, le Bassin du Congo et l’Asie du Sud-Est; FAO: Brazzaville, Congo, 2011. [Google Scholar]

- Ndoumou, B.R.L.; Mevaa, L.; Ouagne, P.; Ebanda, F.B.; Noah, P.M.A.; Ateba, J.A. Physico-Chemical and Thermal Characterization of a Lignocellulosic Fiber, Extracted from the Bast of Cola lepidota Stem. J. Miner. Mater. Charact. Eng. 2020, 8, 377–392. [Google Scholar] [CrossRef]

- Vivien, J.; Faure, J.J. Fruitiers Sauvages d’Afrique—Espèces du Cameroun; Nguila-Kerou, Ed.; Editions Nguila-Kerou: Clohars-Carnoet, France, 1995; p. 416. [Google Scholar]

- Zafeiropoulos, N.E.; Baillie, C.A. A study of the effect of surface treatments on the tensile strength of flax fibres: Part II. Application of Weibull statistics. Compos. Part A Appl. Sci. Manuf. 2007, 38, 629–638. [Google Scholar] [CrossRef]

- European Linen & Hemp. Available online: www.mastersoflinen.com/ (accessed on 20 October 2021).

- Corbin, A.C.; Sala, B.; Soulat, D.; Ferreira, M.; Labanieh, A.R.; Placet, V. Development of quasi-unidirectional fabrics with hemp fiber: A competitive reinforcement for composite materials. J. Compos. Mater. 2020, 55, 551–564. [Google Scholar] [CrossRef]

- Virk, A.S.; Hall, W.; Summerscales, J. Modulus and strength prediction for natural fibre composites. Mater. Sci. Technol. 2012, 28, 864–871. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J.; Clifford, M.J. Modelling the effect of yarn twist on the tensile strength of unidirectional plant fibre yarn composites. J. Compos. Mater. 2013, 47, 425–436. [Google Scholar] [CrossRef]

- Madsen, B.; Thygesen, A.; Lilholt, H. Plant fibre composites—Porosity and stiffness. Compos. Sci. Technol. 2009, 69, 1057–1069. [Google Scholar] [CrossRef]

- Haag, K.; Padovani, J.; Fita, S.; Trouvé, J.-P.; Pineau, C.; Hawkins, S.; de Jong, H.; Deyholos, M.K.; Chabbert, B.; Müssig, J.; et al. Influence of flax fibre variety and year-to-year variability on composite properties. Ind. Crop. Prod. 2017, 98, 1–9. [Google Scholar] [CrossRef]

- Placet, V.; Cissé, O.; Boubakar, L. Nonlinear tensile behaviour of elementary hemp fibres. Part I: Investigation of the possible origins using repeated progressive loading with in situ microscopic observations. Compos. Part A Appl. Sci. Manuf. 2014, 56, 319–327. [Google Scholar] [CrossRef] [Green Version]

- Trujillo, E.; Moesen, M.; Osorio, L.; van Vuure, A.; Ivens, J.; Verpoest, I. Bamboo fibres for reinforcement in composite materials: Strength Weibull analysis. Compos. Part A Appl. Sci. Manuf. 2014, 61, 115–125. [Google Scholar] [CrossRef]

- Ntenga, R.; Saïdjo, S.; Beda, T.; Béakou, A. Beda Estimation of the Effects of the Cross-Head Speed and Temperature on the Mechanical Strength of Kenaf Bast Fibers Using Weibull and Monte-Carlo Statistics. Fibers 2019, 7, 89. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Bai, S.; Yue, X.; Long, B.; Choo-Smith, L.P. Relationship between chemical composition, crystallinity, orientation and tensile strength of kenaf fiber. Fibers Polym. 2016, 17, 1757–1764. [Google Scholar] [CrossRef]

- Nuez, L. Contribution to the Multi-Scale Study of Elementary Flax Fibres and Xylem for Composite material Reinforcement. Ph.D. Thesis, University of Southern Brittany, Lorient, France, 2021. [Google Scholar]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Samouh, Z.; Cherkaoui, O.; Soulat, D.; Labanieh, A.; Boussu, F.; Moznine, R. Identification of the Physical and Mechanical Properties of Moroccan Sisal Yarns Used as Reinforcements for Composite Materials. Fibers 2021, 9, 13. [Google Scholar] [CrossRef]

- Lansiaux, H.; Soulat, D.; Boussu, F.; Labanieh, A.R. Development and Multiscale Characterization of 3D Warp Interlock Flax Fabrics with Different Woven Architectures for Composite Applications. Fibers 2020, 8, 15. [Google Scholar] [CrossRef] [Green Version]

- Lecoublet, M.; Khennache, M.; Leblanc, N.; Ragoubi, M.; Poilâne, C. Physico-mechanical performances of flax fiber biobased composites: Retting and process effects. Ind. Crop. Prod. 2021, 173, 114110. [Google Scholar] [CrossRef]

- Sala, B.; Gabrion, X.; Trivaudey, F.; Guicheret-Retel, V.; Placet, V. Influence of the stress level and hygrothermal conditions on the creep/recovery behaviour of high-grade flax and hemp fibre reinforced GreenPoxy matrix composites. Compos. Part A Appl. Sci. Manuf. 2021, 141, 106204. [Google Scholar] [CrossRef]

- Charlet, K.; Jernot, J.P.; Gomina, M.; Bizet, L.; Bréard, J. Mechanical Properties of Flax Fibers and of the Derived Unidirectional Composites. J. Compos. Mater. 2010, 44, 2887–2896. [Google Scholar] [CrossRef]

- Shah, D.U.; Nag, R.K.; Clifford, M.J. Why do we observe significant differences between measured and ‘back-calculated’ properties of natural fibres? Cellulose 2016, 23, 1481–1490. [Google Scholar] [CrossRef] [Green Version]

| Fibers | Extraction Method | Loading Rate (mm/min) | Gauge Length (mm) | Weibull Parameters | References | |

|---|---|---|---|---|---|---|

| Shape Parameter (m) | Scale Parameter σ0 (MPa) | |||||

| Rhectophyllum Camerunense | Water retted manual extraction | 20 | 23 | 1.696 | 624.3 | [31] |

| Flax | Green | 1 | 10 | 3.3 | 1356 | [45] |

| Hemp | Water retted manual extraction | 0.5 | 10 | 4.2 | 745 | |

| Sisal | Decortication mechanical process | 0.1 | 10 | 4.6 | - | |

| 20 | 3.7 | - | ||||

| Bamboo | Manual | 1.3 | 80 | 2.9 | 228.2 | |

| Kenaf | Alkali 5% 90 mn/95 °C | 1 | 10 | 3.69 | 1010 | [46] |

| 20 | 3.74 | 786.32 | ||||

| CL | Water retted manual extraction | 2 | 20 | 3.29 | 1049 | this study |

| Fibers | d (µm) | E (GPa) | σr (MPa) | εr (%) | Specific Properties | References | |

|---|---|---|---|---|---|---|---|

(Gpa/g·cm−3) | |||||||

| Rhectophyllum Camerunense | 0.947 | 2.3–17 | 150–1738 | 10.9–53 | 588.3 | 6.1 | [31] |

| Kenaf | - | 41 | 745–930 | 1.6 | 620.8–775 | 34 | [46] |

| Banana | 10–30 | 12 | 12–30 | 1.5–9 | 8.8–22 | 8.8 | [48] |

| Bamboo | 25–40 | 11–32 | 140–800 | 2.5–3.7 | 127–727 | 10–29 | |

| Flax | 12–600 | 27.6–80 | 500–1500 | 1.2–3.3 | 333–1000 | 18.4–53.3 | |

| Palf | - | 71 | 1020–1600 | 0.8 | 680–1066 | 47.3 | |

| Sisal | 157–319.2 | 4.7–20.5 | 296.6–410.4 | 2.4–4 | 208.8–289 | 3.3–14.4 | [49] |

| Hemp | 13.7–25.8 | 31–65 | 182–1282 | 1.9–3.5 | 392.6–822.2 | 33.3 | [11] |

| CL1 | 66.2–117.4 | 18.2–60 | 457.6–1440 | 2.4–2.6 | 280–883 | 11.6–36.8 | This study |

| CL2 | 66.2–117.4 | 22.2–66.89 | 526–1655 | 2.4–2.6 | 322.7–1015 | 13.6–41 | |

| IFBT Samples | Vf (%) | Vp (%) |

|---|---|---|

| Hackled CL bundles | 52.8 ± 2.33 | 7.9 ± 1.95 |

| Non-hackled CL bundles | 51.6 ± 1.53 | 17.4 ± 4.2 |

| IFBT Specimen | E1 (GPa) | E2 (GPa) | σr (MPa) |

|---|---|---|---|

| Hackled CL fibers | 33.77 ± 3.11 | 27.61 ± 2.37 | 394 ± 21 |

| non-hackled CL fibers | 28.44 ± 3.68 | 23.86 ± 1.45 | 267 ± 47 |

| Ef (GPa) | σf (MPa) | |

|---|---|---|

| CL1 | 38.13 ±13.17 | 941 ± 318 |

| CL2 | 43.6 ± 14.85 | 1074 ± 364 |

| IFBT-M1 | 43.11 ± 4.15 | 708 ± 41 |

| IFBT-M2 | 64.78 ± 4.56 | 850 ± 32 |

| Fibers | Method | (GPa) | (MPa) | References |

|---|---|---|---|---|

| Flax | experimental | 44.5 ± 14 | 791 ± 319 | [15] |

| IFBT | 40.8 ± 3,5 | 527 ±138 | ||

| Sisal | experimental | 12.5 ± 7.8 | 340.02 ± 70.4 | [50] |

| IFBT | 17.02 ± 3.74 | - | ||

| Hemp (SANTHICA 27 R0) | experimental | 48 ± 17 | 732 ± 550 | [11] |

| IFBT | 50.3 ± 12 | 384 ± 225 | ||

| Hemp (FUTURA 75 R0) | experimental | 52 ± 34 | 795 ± 423 | [11] |

| IFBT | 47 ± 6 | 470 ± 98 | ||

| CL | experimental | 43.6 ± 14.85 | 1074 ± 364 | This study |

| IFBT | 43.11 ± 4.15 | 708 ± 41 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ndoumou, R.L.; Soulat, D.; Labanieh, A.R.; Ferreira, M.; Meva’a, L.; Atangana Ateba, J. Characterization of Tensile Properties of Cola lepidota Fibers. Fibers 2022, 10, 6. https://doi.org/10.3390/fib10010006

Ndoumou RL, Soulat D, Labanieh AR, Ferreira M, Meva’a L, Atangana Ateba J. Characterization of Tensile Properties of Cola lepidota Fibers. Fibers. 2022; 10(1):6. https://doi.org/10.3390/fib10010006

Chicago/Turabian StyleNdoumou, Rémy Legrand, Damien Soulat, Ahmad Rashed Labanieh, Manuela Ferreira, Lucien Meva’a, and Jean Atangana Ateba. 2022. "Characterization of Tensile Properties of Cola lepidota Fibers" Fibers 10, no. 1: 6. https://doi.org/10.3390/fib10010006

APA StyleNdoumou, R. L., Soulat, D., Labanieh, A. R., Ferreira, M., Meva’a, L., & Atangana Ateba, J. (2022). Characterization of Tensile Properties of Cola lepidota Fibers. Fibers, 10(1), 6. https://doi.org/10.3390/fib10010006